RURAL TOWNS completely cut off with no or limited electricity, water, food and telecommunications, blocked roads, flooded and wrecked homes and buildings, paddocks and orchards turned into lakes.

And even worse, the tragic loss of life in both urban and rural areas.

And the Ministry for Primary Industries (MPI) last week said it would take a week before the full impact of Cyclone Gabrielle is known.

The storm left a path of destruction severely testing the true resilience of rural communities in the upper, central and East Coast of

the North Island. The rural town of Wairoa on the East Coast has been among worst hit.

Cyclone Gabrielle is already being described as one of the worst natural disasters to hit NZ.

As Dairy News went to press it was impossible to make contact with some of the worst affected areas because cell phone communications were down. At the same time various local and central government agencies along with industry organisations were scrambling to get a handle on the extent and scale of the damage. Some of the scenes coming out of rural areas were harrowing to say the least and vividly shown on national television and newspapers.

Nick Story, MPI’s director – rural

communities and farming support told Dairy News that the full impact of it may take a week or more to get clarity on.

He says the dairy regions have been badly hit and up to 150 farmers in Northland either couldn’t milk their cows due to power outages or had to dump milk because it could not be collected due to multiple road closures.

Story says it’s still too early to get an accurate figure on stock losses, but says there are clearly many. He says efforts are being made to get generators to farmers because getting the power back on in isolated areas may take quite a while.

“We are working with the NZ Veterinary Association to produce guidance for farmers to help them with

whatever animal welfare issues may come up. A key issue is to ensure that animals are fed and have clean water as soon as possible,” he says.

Story says there are major problems for commercial growers and orchardist who have seen floodwater rising above their trees and vines and inundating vegetable crops. He says some meat processing plants have been flooded and that’s added to the woes of farmers who were trying to destock.

He says the while this storm is bad, it’s the compounding effect of this and other storms, including cyclone Hale, that have hit the same regions in the past six months. Tairawhiti in particular has been hammered and damage from previous storms has not been repaired.

LOSS OF power supply remains the biggest issue facing many Northland farmers.

Federated Farmers Northland President, Colin Hannah, told Dairy News that it may take weeks to fix.

He says trees have taken down the feeder power lines and he knows of one case where six power poles which carry power lines are lying flat by the side of the road. He says the power companies are doing a splendid job, but the problem is massive.

When Hannah spoke to Dairy News last week, there was no power at his drystock farm just out of Whangarei.

Hannah says the impact of the storm has

been compounded by the heavy rainfall for the past six months, which have left the ground sodden. He says there are potential animal welfare issues such as cow lameness in the making due to the wet.

“We are probably looking at a disaster in the making which could happen around June, July and August because we

haven’t had the opportunity to conserve the feed we had.

“[On] the east coast of the province a lot of the maize crops have failed; some have been planted three times and have gone again.

“A young farmer told me the other day that with the two floods he had in quick succession this year it’s going to cost

him about $300,000. It’s incredible,” he says.

Hannah says the nearby Hikurangi swamp which drains into the Kaipara harbour is now a lake and will take some time to drain.

Stock have been moved from the area. He says many farmers are looking for grazing because their farms have been inundated with

floodwaters. He’s aware of one farmer looking for grazing for 600 cows.

Hannah adds that the kumara crop in Dargaville is devastated.

“Dargaville is a major problem and Ruawai will be without power for some time,” he says.

According to Hannah, cyclone Gabrielle is the worst storm he’s seen in Northland, worse than

THE GOVERNMENT has announced an initial $4 million to help farmers, growers, whenua Maori owners and rural communities mobilise and co-ordinate recovery efforts from cyclone Gabrielle.

Agriculture Minister Damien O’Connor says the breadth of this storm’s impact is unprecedented with milk collection disrupted, orchards inundated and livestock losses across much of the North Island.

“This is a dynamic situation and we are responding accordingly to help the rural sector. I expect we will provide more support once a full and thorough assessment of the damage caused by Gabrielle is complete. That destruction includes flooded farms and orchards, damage to vital roading and electricity infrastructure, and isolated communities. Conditions continue to make it difficult to assess the full extent of crop damage, livestock losses, and disruption,” he says.

Bola, and the only other event he thinks may be like it dates back to the 1950s when he was a kid.

He is optimistic about moving on, saying farmers

DAIRYNZ SAYS region-specific support is being offered to cycloneaffected farmers, who are responding to a range of different issues on farms across the North Island.

DairyNZ’s farm performance general manager Sarah Speight says dairy farmers in Northland, Bay of Plenty, Coromandel, Waikato, Hawke’s Bay and the Lower North Island appear to be the most impacted.

“We won’t know the full extent of

damage across the regions until flood waters recede, but we will continue working closely with those directly impacted to understand the support required,” says Speight.

“Recovery will take some time, but DairyNZ and other sector partners are providing regionally relevant support where possible, including feed budgeting assistance, as many cycloneaffected farmers had damage to crops and feed supplies.”

Here at Alleva Animal Health, we’re constantly evolving and innovating so NZ farmers have reliable products that outperform in the field. We’re proudly NZ owned, operated and offer world-leading parasite control solutions exclusively through vet clinics nationwide.

TURBO® Pour On is designed for NZ’s unruly weather conditions. Its world-first formula can help to achieve cattle weight gains ahead of winter and improve overall condition. Rain or shine, enjoy the ultimate parasite coverage.

Speight says recovering from these events takes a toll on families, farm staff and their families, and farm businesses, and the support agencies are here to work with farmers through the recovery period.

DairyNZ is working closely with Fonterra, MPI, Rural Support Trust, Federated Farmers, and other rural professionals to ensure a cohesive response and provide farmers with the support they need across the

regions.

“Many dairy farmers have experienced extensive flooding and wind damage, which has impacted farm paddocks, crops and infrastructure, including broken fences and damaged herd homes.

“Some farms are still without power, which is causing real concern, as it impacts farmers’ ability to milk their cows and provide fresh water,” says Speight.

are used to these events and will get through it, but months, potentially years, of work lies ahead before normal life is resumed in the province.

“The focus for farmers right now is to ensure that their animals are fed, watered and comfortable.

“We know that if milking is an issue, cows can tolerate delays of a few days and can return to production with careful handling.

“Recovery of pastures and cropped areas should be discussed once the situation is clearer, either with your DairyNZ extension partner or relevant rural professionals.”

PROUDLY NZ OWNED

second largest milk processor is not rushing to lift its milk price forecast despite a rise in global dairy prices.

Instead the Talleysowned company will keep an eye on dairy prices in the coming weeks before adjusting its forecast milk price.

Open Country Dairy chief executive Steve Koekemoer welcomed the 3.2% jump in whole milk powder prices.

While still way off the US$4757/MT mark reached one year ago, a rebounding demand in China for dairy products is a good omen for the coming months.

Koekemoer says it was great to see the WMP prices lift at the recent Global Dairy Trade auction.

However, it’s a little early to call it an upward trend, he says.

“But it certainly indicates a positive step forward.

“We did expect the market to recover from the extended low point that we have experienced over the past few months and this seems to be the

start of it. Demand for our ingredients has certainly gained more traction recently, which aligns with the market outlook.

“We welcome the incremental WMP price increases and will monitor market developments over the coming weeks carefully.

“Our preference is to proceed with caution as opposed to rash changes. Our milk price forecast remains unchanged at this stage as we had factored the recovery into our future periods.

“Clearly, if the recovery is stronger than we anticipated we would adjust for further upside.”

Koekemoer told OCD suppliers that its cheese product portfolio, which now includes the new lactose plant, is delivering the best return for their milk solids and has been for a while now.

“Maximising this product mix ensures we stay very competitive on milk price. The factories are running well as we look to minimise costs and keep our efficiencies up with milk declining towards the tail end of the season.”

BNZ senior economist Dug Steel agrees that there have been some recent signs of stabili-

sation. “This follows as global economic sentiment has improved a bit, China has reopened, and, not so positively, adverse weather sees downside risk to late season NZ milk production.”

Steel notes that GDT prices rose 3.2% in early February but are still down 27% on a year ago.

Fonterra’s current forecast milk price range for 22/23 has a $9 midpoint and he sees some downside risk to that.

“We recently trimmed

our own 22/23 milk price forecast to $8.60.”

ANZ has also slashed its forecast milk price for the season by 25c to $8.50/kgMS; the lower end of Fonterra’s latest price guidance of $8.50 to $9.50/kgMS.

The bank’s agriculture economist Susan Kilsby notes that dairy prices have been quite weak this summer, compared to recent years.

But she also expects prices will steadily improve from here.

The last GDT result “will help to instil some confidence in the market.”

“We are forecasting a modest improvement in dairy prices across the remainder of the 2022-23 season,” she says. While demand from China may be improving, a big domestic WMP stockpile may stand in the way of global price rises.

“WMP prices are highly dependent on demand from China. While demand from the Chinese market appears

to be improving, it does not appear that this market is short of stock at present.

“Additional domestic production of WMP is also expected to bolster stocks, but many Chinese companies still prefer to use imported milk powders due to the consistent quality of the product.”

The strengthening New Zealand dollar will also have a say on future dairy prices.

Kilsby also notes that exchange rate have been

largely unfavourable for farmgate prices.

“While we expect dairy commodity prices to gradually recover, we also expect the NZD to appreciate further.”

“The NZD has been relatively weak over the past year, which has helped offset a period of lower dairy commodity prices. The NZD is now trending higher, but dairy farmers will still benefit both this season and next season from processors’ FX hedging positions.”

The rockstar hybrid now upgraded to NEA12, giving 8% more yield for greater animal performance.

could save more than a billion dollars over a decade by incorporating plantain into their pastures.

This was revealed at special field day at Massey University in Palmerston North this month to highlight the benefits of dairy farmers using plantain as part of their pasture sward to reduce nitrogen leaching.

Presently, only Ecotain plantain produced by PGG Wrightson has been proved to do this following four years of trials at one of the university’s farmlets.

The $22 million project, known as Plantain Potency Practice (PPP) programme, is funded by DairyNZ , MPI through the SFFF, PGG Wrightson Seeds and Fonterra, but work on the programme has been done by a number of other science institutes, including AgResearch, Lincoln University, Plant and Food Research, Manaaki Whenua, Fonterra, DairyNZ and Agricom.

The trials at Massey have involved running 80 cows over pasture which incorporates ecotain plantain.

DairyNZ chief exec-

utive Tim Mackle, who fronted a media event at Massey, says the results are exciting and show that by feeding cows plantain, nitrogen leaching on a dairy farm can be reduced by between 20-60%. But to achieve this there is one proviso – it requires somewhere between 24-45% of the farm to have plantain in the pasture. He says there is now robust scientific evidence that Ecotain plantain is an effective solution to help dairy farmers further reduce their environmental footprint and continue playing their part in

improving water quality.

“We all want healthy freshwater to swim and play in, and dairy farmers can confidently use Ecotain plantain on-farm to support that,” he says.

Mackle says, of the contaminants that dairy farmers have to deal with, nitrogen is by far the biggest. He says the project is an integrated one and it’s important that local regional councils are involved and recognise the significance of the technology.

“You have to look at it in the context of the whole value chain to make

sure all the issues have been solved, such as plantain not affecting production or milk quality, which it doesn’t.

“The great thing is the cost benefit side which only requires plantain to be added to the seed mix,” he says.

Mackle says more science is still needed to get clarity around persistence right across the dairying regions. He says the project excites him – especially seeing some of the best minds in agriculture, including farmers, working together to solve big issues.

Emeritus

Peter Kemp and a team of 30 people there have been researching the effects of plantain over several years and the experimental plots were established at the university in 2019.

He says this includes designing an innovative drainage system that uses the soil structure on the farm to enable measurement of all the nitrogen leaching from each paddock.

Kemp says the great thing is that the trial site allows the results to be directly transferable to current farming systems in NZ.

“Importantly for farmers, transition to plantain pastures results in no loss of production, while simultaneously reducing nitrogen leaching significantly from farms into freshwater,” he says.

Kemp says farmers have the choice of planting a number of paddocks in plantain or incorporating in with their clover and ryegrass, but he says mixing it in with other grass species ensures that farmers have it available all the time across their farm.

Plantain is essentially a diuretic, meaning it dilutes the urine coming out of the cow.

Peter Kemp says the nutritive composition of plantain means that more of the N in the cow ends up in dung, which is a benefit to reducing N leaching.

He says there is still more scientific research needed to better understand just how plantain works, especially around its persistence in the range of pastures around the country.

“A dairy farm is quite a complex system and so when you make a change to it there is a lot of science in understanding all the ramifications of that,” he says.

Glenn Judson is an animal nutritionist at Agricom which has developed Ecotain Plantain. He says research into plantain began back in the 1980s when it was still seen as a weed and was eventually developed into a quality pasture species. He says this took time as initially seed yields were poor and it took agronomists time to sort this out.

“What we did notice in a lot of our work was some really strange things, such as when we had pure strands of plantain, we could never find a urine patch near it. Also when we brought the animals into the yards, animals who had been grazing plantain seemed to be urinating a lot more than others. So it actually took us quite a long time to catch on to the fact that this plant had been doing something to the nitrogen cycle,” he says.

He says Agricom now realises they have a very powerful tool in the form of Ecotain. He says it brings resilience to pas-

DANNEVIRKE DAIRY farmer Thomas Read is a strong advocate for plantain.

He runs 1,300 cows on a 500ha block and has been using it for the last eight years. He says he started looking at plantain after going through two droughts and was looking for slightly diverse pasture that would fit in with his system, was cost effective and was more drought tolerant.

He says as a result of this he incorporated plantain into his system and, as word got out about the environmental benefits, he joined the plantain working group and has been working with DairyNZ.

“I would recommend it to other farmers. The simplicity behind it, the fact that it integrates into your businesses, the cost effectiveness is great too – then there is the environmental benefit,” he says.

tures when it gets dry, it’s very good at passing on trace elements to animals and it has some effect in terms of animal parasites. But Judson says the most exciting factor is the environmental aspect which

is that plantain promotes diuresis, the increased production of urine.

But what is longevity and why is it so important? It goes beyond high production - a cow that lasts has a full purpose in life and has a significant impact on the staff and farmer alike. We asked Robbie why having better cows leads to a better life with CRV.

To watch the video follow the link below.

Better cows, better life.

‘With CRV we’re building a herd with longevity.’

Robbie Sherriff, Huirimu Farms, Arohena

USE OF cow monitoring collars is on the rise, with about 700,000 of New Zealand’s 4.9 million cows in milk now thought to be fitted with them – about 14% of the national milking herd.

That number is likely to keep climbing, according to MSD Animal Health Intelligence.

At a technical symposium for veterinarians hosted by MSD Animal Health late last year, Austin Heffernan, national commercial manager, monitoring and automation, told vets the company had supplied 200,000 of the Allflex cow collars in 2022 alone.

In some areas the uptake is higher. Rico Nortje, Rangiora Vet Centre, reported that about 40% of the dairy cows serviced by the practice were wearing some type of collar device.

“It’s past the tipping point for us now,” he said.

Ryan Luckman of Oamaru Vets said about 27% of the dairy farms within their practice, accounting for about 60,000 cows, had collars fitted.

Heffernan said that initially some farmers had felt overwhelmed

sage about how to start using the data was boiled down to simply helping identify sick cows so you can quickly do something about it, then the new technology seemed less intimidating, and more farmers started getting on board.

Steph Voice, training specialist lead with Allflex Livestock Intelligence, said dairy farmers were given intensive aftersales training and support

A team of seven training specialists were on hand to help farmers create their own data sets, with training started once the herd was loaded into the system.

Voice said farmers were reassured early on that they could confidently have a play with their data to learn the system without fear that they will accidentally “break” something.

“There’s nothing that you

RUMINATION DATA from the collars can provide useful insights.

for heat detection. “It just confuses the issue.”

cations targeted by new users. Voice said there was a lot of data potentially available, but clients could dial back the amount used until they gained more confidence and discovered other useful applications.

She said the system software generates a warning if a collar has fallen off, or if a collar has gone AWOL for more than 24 hours.

Some farms had readers for the collars only in the shed while others also had readers at different points around the farm, generating more “realtime” data and alerts for at-risk cows.

Ryan Luckman said cow monitoring collars had thrown light on the crucial transition period. He said rumination data for the period leading up to calving had exposed underfeeding in some herds, meaning it took longer for cows to bounce back after calving. His practice had created an energy balance calculator to help clients use the rumination data to target 90–100% of energy requirements pre-calving, rather than the 60 percent seen on a lot of farms. He said it was important to note when a cow had calved on the day it happens so they could be drafted out of a tight springer paddock promptly.

He said that when a collar generates a lot of health alerts for a herd, the cause can often be traced back to a feeding issue.

Steph Voice said heat detection via the collars came through a combination of activity and rumination data. She noted that the system doesn’t detect pregnancy – PD data as well as AI records, calving and culling needed to be entered – but it can detect anoestrous cows. The monitoring collars can also detect “silent heats”. She said tail painting is discouraged if the collars are used

Voice emphasised that the collars shouldn’t be used as a proxy for good stockmanship in watching out for issues like mastitis or lameness, but they can help detect issues that otherwise might go unnoticed for a time.

This might be through abnormally low rumination rates (“any cow ruminating less than 200 minutes a day is in trouble”) or it might highlight a problem such as a twisted stomach, metritis or ketosis, which might not otherwise show up for several days. Issues like heat stress can also be flagged.

Amanda Kilsby, MSD Animal Health Intelligence technical veterinarian, said the technology provides some peace of mind and acts as “another set of eyes” watching the cows alongside skilled farm workers. She said the technology is accurate and consistent at heat detection.

“For farms that struggle with heat detection, the collars can help the move away from bulls, shorten the mating period, improve submission rates and 3-week in-calf rates, and pick up weak heats and returns late in the mating season when human fatigue usually kicks in.”

“When you get to the sixth or seventh week of mating, you’re starting to get a little over it, which I’m sure contributes to the empty rate. CowManager doesn’t allow you to do that. It just keeps telling you the cows.”

MARK DANIEL markd@ruralnews co

MARK DANIEL markd@ruralnews co

THE RECENT presentation of a cheque for $4,500 to the Rural Support Trust, was the result of the Fieldays’ inaugural Tractor Racing Experience that replaced the usual tractor pulling competition.

The event, supported by training professionals’ Ag Drive, allowed visitors to get behind the wheel of one of two identical 200hp Case IH tractors for a high-speed dash down the track against the clock and their mates, under the guidance of a team of skilled

instructors.

New Zealand National Fieldays Society chief executive Peter Nation was thrilled to have raised a healthy sum towards the Trust’s critical work.

“Mental health is a big area of concern in rural communities and people often don’t know where or who to turn when things get tough.

“The work that the Rural Support Trust does is vital. And of course, it’s not hard to have fun when you’re behind the wheel of a 200hp Case IH tractor racing your mates,” says Nation.

Rural Support Trust is a not-forprofit network of regional trusts that

WAIKATO MILKING Systems (WMS) says its range of rotary milking systems and smart technologies are now available to Dutch farmers.

The company has appointed Driehoeven Melktechniek as its distributor in the Netherlands.

“This partnership is a great convergence of our mutual business values,” says Jamie Mikkelson, executive chairman of WM. Like us, Driehoeven Melktechniek is focused on providing total solutions for sustainable and profitable dairy farming.

“We share the same philosophy: first listen to dairy farmers so we understand their requirements and only then do we develop customised

solutions to maximise a farm’s performance, productivity and profitability.”

Pieter Copal,

managing director of Driehoeven Melktechniek, says the challenges facing dairy farmers in the

Netherlands are great.

“It is our strength to offer solutions for these. To do so, we work with global and local suppliers

where the price/quality is right and the service is high.

“We are therefore pleased with Waikato’s

provide free and confidential assistance to rural people facing challenges in everyday rural life.

The Trust is made up of farmers and those with a good understanding of rural life, acknowledging that there are often ups and downs, and the farming community faces many stressors around health and wellbeing, financial pressures, animal welfare, employment matters and adverse events.

Fieldays organisers also provided the Rural Support Trust a site in the Hauora Taiwhenua Health and Wellbeing Hub, giving visitors the opportunity to stop by and chat with the trusts’ coordinators.

exclusive partnership for the Benelux. Waikato has distinctive products and invests a lot in new technologies that help farmers in their operations.”

WMS designs and manufactures a wide range of milking parlours, milking automation, milk management, milk cooling and milk hygiene, that is now available to the Netherlands.

The deal also allows Driehoeven Melktechniek to offer dairy farmers full system solutions, advice, 24/7 service, spare parts and maintenance.

Mikkelson says WMS was founded more than

50 years ago in New Zealand and now has an international reputation for reliability, product innovation, animal welfare, food production and environmental sustainability.

“We are constantly innovating and refining our smart milking technology so that farmers around the world can increase the value of their dairy cattle,” he says.

“We are proud to partner with Driehoeven Melktechniek to help farmers in the Netherlands farm more productively, cost-efficiently and profitably.”

“This partnership is a great convergence of our mutual business values,”

Strong women step into the light

DIANNA MALCOLM

A DREAM came true for 25-year-old Joanna Fowlie when she won Supreme Champion of All Breeds at the New Zealand Dairy Event (NZDE) in Feilding month.

It’s always hard for Intermediate Champions to first beat the Senior Champions of their breed to earn the chance for a crack at the All Breeds title, especially when the Senior Breed Champion –a former Supreme Champion of the show – is considered a breed legend herself.

However, Fowlie’s second-calved three-year-old Raetea Rubicom Debbie took that first step when she beat the 2021 NZDE Supreme Champion, Pukekaraka Elle Delila (exhibited by the Gilbert family, from Ashburton) in the Ayrshire ring.

Delila, aged eight, was in great form and she had had the longest trip from Canterbury. However, South African judge (and World Ayrshire Federation president) Edmund Els

The line-up for the 7 years and over Ayrshire class.

created Debbie’s chance when he chose her.

By capturing the Grand Champion Ayrshire title, Debbie moved forward to the All Breeds competition – another significant hurdle – given that she was up against the Holstein, Jersey and Combined Breeds Champions – who were all senior cows.

History now shows that the All Breeds judges, which included Els, Daniel Bacon (Jersey judge, Australia) Ben Govett (Combined judge, Australia), Mark Nutsford (Holstein Friesian judge, UK) and Gordon Fullerton (Youth Show judge, Waikato) would crown Debbie the Queen of the show.

It is the first time

an Intermediate Ayrshire Champion has won Supreme Champion at the NZDE and only the second time an Intermediate of any breed has won Supreme – and it happened just one week after a similar feat was tabled in Australia at International Dairy Week.

Fowlie joined two other women who enjoyed a great show.

Letitia Horn was at the helm of Horn Genetics’ campaign, that included broad ribbons in three breeds. While it’s undoubtedly a team effort, the 24-year-old manager of her family’s 200-cow operation in Feilding, put in a lot of the grunt work in the lead-up to the show. Leti-

tia and her father, Peter, made the decision to break in eight-year-old Kuku Tbone Leila after she calved in with her seventh calf last spring.

Sired by Richies Jace Tbone, Letitia said Leila had been close to getting a NZDE start for a number of years, but she had always been trumped by her herdmates. This year, there was no denying her form and in her first show she gave her owners their first NZDE Grand Champion Jersey title.

Nicknamed “Nana” by Letitia’s brother, Letham, because she is so quiet and likes to follow everyone around licking them, Leila’s previous lactation was 6,870 litres and 628kg

www.cosio.co.nz 8000m

Authorised

of milk solids.

“Out in the ring she just looked like the proudest old cow, and I was so proud of how well she did, given she’d just been broken in a few months before. It was a very emotional moment to watch her win, because we saw something special in her.”

Letitia said Leila took to the show programme like a duck to water.

“She’s one of those cows we didn’t even worry about when we

bagged them. Going into the show there was never a time she didn’t eat, never a time she didn’t drink, and she was just so content. That’s what she’s like at home. She’s always eating, always going out there and doing what she needs to do to keep that milk on her.”

The family also ticked a box in the Holstein ring, winning Reserve Senior Holstein Champion with Okawa Mogul Lexa.

It involved 14 hours of trucking one way –which included crossing the Cook Strait. The four-year-old impressed the Combined Breeds judge Ben Govett (Australia), validating Rachel’s faith in the young cow when she was sashed Senior Champion, Best Senior Udder and Grand Champion of the Combined Breeds. Rachel said when she competed at Christchurch Show enough people were impressed with Bella to give her the momentum to push on and expose her to more competition.

“She did what I hoped she was capable of,” Rachel said. “I wasn’t expecting to win, but I really wanted to see where she fitted nationally. It was definitely worth the trip, the expense, and the stress of it all.

“Without the help and support of family and close friends I couldn’t have done this.”

Rachel said she and her brother, Bernard, used to show Brown Swiss together and she loved their temperament.

She and the rest of the Canterbury cattle were just ahead of ferocious weather following the show, which included one of the Interislander ferries breaking down in three-metre swells with 40-knot winds.

There wasn’t an exhibitor who had landed their cows safely at Picton ahead of the storm who wouldn’t have breathed a deep sigh of relief.

AS WE know from research done here in New Zealand and overseas, pasture management and quality have a strong correlation with profitability.

Farmers that manage to utilise a high percentage of the pasture they grow on farm, and maintain pasture quality to the best possible level over the whole season, will make more profit than those farmers that lose pasture quality during parts of the season, especially over the summer.

The initial loss of pasture quality in New Zealand occurs just before summer when grass species want to change to the reproductive stage. Even the best pasture managers cannot avoid this from happening due to the physiological result of increasing soil temperatures and hot weather that trigger different pasture species to go from the vegetative stage to the reproductive stage.

Research shows that metabolisable energy (ME) in pasture can drop from 11.5 - 12.5 ME/kgDM in spring to 9.5 - 10.5 ME/ kgDM over the summer period and even lower if it is under severe dry conditions.

It is not just the ME value that changes: neutral detergent fibre (NDF) in the same pasture can increase from 35-45 %DM in spring to 42-55 %DM in summer, reducing the total DM intake of pasture in dairy cows.

Another pasture component that drops significantly during summer is the crude protein (CP).

Universal values in spring for pasture in New Zealand are 20-30 %CP/ kgDM, but in summer this can drop to 9-14 %CP/ kgDM in dry conditions which we are experiencing more and more often each season.

This decrease in quality and volume of pasture consumption can reduce milk production significantly if left unattended.

As farmers, we need to estimate when this change in the pasture will happen to adapt our herds’ diet

accordingly. Some of the indicators we can use to know when the plants are starting to have this change in quality are the presence of seed head and the drop in milk production when the cows are fully feed.

Although there are seasonal changes every year, farmers should know when this is about to happen on their farm and make the decision early enough to avoid the drop in milk production by adding high energy (ME), high protein (rumen degradable protein) and low NDF feeds. Or alternatively, replacing the current feed for a more suitable one with the above qualities.

Another misunderstanding is that by doing these changes early enough, milk production will go up. This is not the case at all. By implementing these changes, we expect milk production to maintain and not drop or increase. According to Dairy NZ data a crossbred cow needs 80 MJ ME to produce 1kg of milksolids. So, if we do not compensate for the loss in quality and total intake milk production will drop by 0.71 kgMS/cow/day. At a $7.50-dollar pay out that will represent a loss in income of $5.32/cow/day if we do not balance the cows’ diet. If the process of adjusting the diet takes us one week, we will lose $37.24/cow.

Let’s assume that one cow is doing 1.90 MS/ day just before the drop in quality happens. If she loses only half of what is expected, then each cow will lose 0.35 MS/day in milk production. At $7.50 dollars payout, what will happen when we compare not doing anything, or feeding 1.5 kg/day of feed costing $800/tonne landed on farm?

As a result of not balancing the diet and letting the cows’ milk production drop, you will lose $1.43 dollars per cow per day after discounting the landed price of the imported feed. If you do the same numbers with a payout of $9.00 dollars as we are experiencing now, the profit lost is even higher at $1.95 per

cow per day.

As a farm consultant, I focus on profitability and enjoy doing these kinds of analysis for farmers that are experiencing the same outcomes year after year and want better results.

In my opinion, it makes a lot more sense to

make a profit while maintaining milk production, rather than letting cows drop production over the summer. When deciding what strategies to follow, don’t just consider costs, think about profit as well.

“YOU CAN’T have it both ways” was sage advice my father would give me when I was trying to discuss options with him about something I wanted to do. “You have to choose one or the other.”

A QUESTION I often get asked around this time of year is, “I am trying to reduce my cost of feed. Is it really worth applying inoculant to my maize silage?” And like any good politician my answer is always the same. It depends.

At the recent Australasian Dairy Science Symposium, Dr Pierre Beukes from DairyNZ presented a paper which I, alongside Tai Chikazhe (a modeller with DairyNZ), helped co-author. It investigated the profitability and sustainability of feeding

Before I go any further, it is important for me to declare my position. I work for Pioneer. We sell silage inoculants. I will not be talking about any other company’s products on the market but will restrict my comments to principles around inoculants and their use.

Make sure the inoculant you use comes from a reputable company.

Inoculants are sold by a wide range of companies. Some have a long history of providing good, science-based products into the market. Others don’t. A person selling inoculant should be able to show you evidence from several trials that the actual product you are buying is proven to work. If they can’t give you any data, or they provide general inoculant trial data that did not test their actual product, then don’t buy their inoculant.

Make sure the inoculant does what it says it does.

GEOGARD Lining for life™

Look for a label claim. A product that can be trusted will say what type of bacteria are present in the inoculant and provide bacterial numbers.

maize silage which was grown on a dedicated cropping block within a dairy farm.

Pierre showed a great cartoon where a married couple in bed were

There should be some kind of quality certification system that ensures every bottle meets the minimum standards. Some products on the market leave bacterial numbers off the label and therefore they can’t be held accountable for product quality because their inoculant has no minimum standards. There have been situations in the past where inoculants bought off the shelf didn’t provide the number of live bacteria they claimed.

Make sure the inoculant you buy is backed by good after sales service.

fighting over a duvet that was obviously too small to cover both of them. He made the point that, at a systems level, there will always be compromise as we seek to maximise profit and milk production while at the same time minimising nitrogen loss. The paper showed that using a dedicated cropping block to grow maize silage in summer and grass silage in winter, dairy farmers could potentially meet their nitrogen loss goals without too much reduction in profit.

The study simulated three different scenarios over five consecutive seasons (2013/14 to 2017/18), using DairyNZ’s Whole Farm Model (WFM), Agricultural Production Systems sIMulator (APSIM) and the Urine Patch Framework (UPF). The scenarios were:

Farm (FF) (2.6 cows/ ha, applying 85kg N/ha fertiliser, high genetic merit cows, imported maize grain as low-N feed, with a standoff pad.

3) The maize silageblock farm (Future Farm Plus (FFP) 3.2 cows/ha, high genetic merit cows, 85kg N/ha to pasture, feed pad, maize silage

was opened after 60 days, the aerobic stability of the 11C33RR inoculated maize silage increased to 135 hours and the losses were only 25% of the untreated silage. Simply put, 11C33RR works. By doing the trial, Shaun was able to clearly show that 11C33RR did exactly what it claimed to do under New Zealand conditions.

Return on Investment

I have used the trial results (above) to calculate the return on the investment from using 11C33RR.

low protein crop.

■ Effluent captured from the milking shed and feed pad is an excellent fertiliser source to grow maize.

■ Annual ryegrass is an effective winter catch crop.

For both early opening and later opening of the stack, the inoculant proved to be an excellent investment. For the early opening every dollar invested, returned $2.53 with the later opening giving a $3.79 return for every dollar invested.

8000m 7400m3

It is important that the person selling you an inoculant is able to provide the after sales service you deserve. This includes things like advice on stack

management and best feed out practices. If you encounter a silage quality or feeding issue you need to be sure that the person who sold you the inoculant will be there when you call them.

proves it works.

My colleague Shaun

Body ran four local trials comparing uninoculated maize silage with maize silage treated Pioneer® brand 11C33 Rapid React (11C33RR). A new product on the New Zealand market, but sold extensively overseas, 11C33RR

1) A typical Waikato dairy farm (P21 Base farm (CF) - 3.2 cows/ha, 125kg N/ha fertiliser on pasture 25% replacement, harvesting grass silage for use during periods of feed deficits, no standoff pad.

claims to improve front end fermentation and then reduce feed out losses by keeping the silage cool.

heating (aerobic stability) and drymatter losses were measured for both opening times (Table 1).

■ The extra feed grown on the cropping block meant the farm didn’t need to reduce the stocking rate and the farm produced more milksolids per cow and per hectare.

Make sure the inoculant you buy is supported by good science that

• Rolls up to 15m wide, therefore fewer joins which means less risk, faster installation and shorter good weather window required.

Many regional councils are requiring farmers to make significant reductions in the N loss from their farms.

In the trials, maize silage that was uninoculated or inoculated with 11C33RR was exposed to air after 9-11 days or 60 days. The time before

2) The P21 Future

Applying 11C33RR inoculant to maize silage doubled the aerobic stability and halved the aerobic losses when the silage was exposed to air after 9-11 days. If the silage

In conclusion, some inoculants are a great investment and its worthwhile spending your money on them. If someone is trying to sell you an unproven product or one that lacks bacterial numbers or quality control standards, leave your money in your back pocket.

• Ian Williams is a Pioneer forage specialist. Contact him at iwilliams@genetic. co.nz

Any change in farm system nearly always requires compromise of one metric compared to another. I started this article with the statement, “You can’t have it both ways”. This modelling exercise hints that maybe you can.

• Nationwide Firestone trained and accredited installation contractors. • Future proof - dependable performance, 50 year Authorised importer and distributor Email: vaughan@cosio.co.nz www.cosio.co.nz

grown on a dedicated block occupying 15% of the effective farm area followed by annual ryegrass).

• Design assistance and volume calculations available.

PPP have local Installers in Westport & Hokitika

Each scenario considered the production, profit and N leached implications, with profit calculations also including depreciation on the feed pad.

While the FF had the largest reduction in N leaching per hectare, it also had the largest reduction in profit when compared to the CF. The FFP farm still had a very significant drop in N loss, but the profit was close to breaking even when compared to the CF.

THE NEW BLUE DISPENSER WITH STAINLESS STEEL DROPPERS INNOVATIVE AGRICULTURE EQUIPMENT Serving NZ farmers since 1962

• New installations • Upgrades • Nationwide installs –great back up support LK0107792©

The results of the modelling exercise are shown in Table 1.

The results show that by adding a dedicated cropping block to a dairy farm and using a range of mitigation strategies, farmers can reduce N leaching by 26% with a relatively small (4%) reduction in profit. The reasons why this system worked were numerous:

■ Maize silage is a high N demand, high yielding,

www.pppindustries.co.nz sales@pppindustries.co.nz 0800 901 902

Many regional councils are requiring farmers to make significant reductions in the N loss from their farms. The FFP farm gives the industry some hope that, by including a dedicated cropping block on the farm, farmers may be able to meet these targets with very little reduction in profitability.

Maize silage is a high N demand, high yielding, low protein crop. Are you hitting your target market? Contact your local sales representative for more information Auckland Stephen Pollard Ph 021-963 166 Waikato Lisa Wise Ph 027-369 9218 Wellington Ron Mackay Ph 021-453 914 Christchurch Kaye Sutherland Ph 021-221 1994 www.dairynews.co.nz

• Ian Williams is a Pioneer forage specialist. Contact him at iwilliams@genetic.co.nz.

■ BREAKING NEWS ■ MACHINERY REVIEWS ■ MANAGEMENT STORIES ■ AND MUCH MORE...

DAIRYNZ’S NEW strategy and investment leader, Alyce Butler, is excited to be working on solutions to key dairy sector issues, with a particular focus on staff shortages and dairy careers.

She is returning to her farming roots and getting the opportunity to support farmers, helping them feel more confident about the sector’s direction.

“Farmers are facing some difficult times, with a more volatile climate, changing consumer demands and government requirements, both on a national and international scale,” she says.

“My work will help

support farmers through some of these key challenges, while also opening new opportunities. I want to help build a resilient and successful dairy sector, where dairy farming is a career people are proud of.”

Her background in providing strategic advice to many of the largest food and agriculture players in New Zealand and internationally, including driving strategic partnerships to solve complex sector-wide challenges, should be a great asset to help deliver a better future for dairy farmers.

Butler also graduated with a Bachelor of Law and Bachelor of Commerce and Admin-

istration, from Victoria University of Wellington, and is a chartered accountant. She joins DairyNZ from her most recent position as director for Future of Food at Monitor Deloitte in Amsterdam.

DairyNZ chief executive Tim Mackle says Butler was raised and worked on a dairy farm in Taranaki, bringing handson experience of the responsibilities, opportunities and challenges facing the sector.

“We are lucky to have someone with a global perspective and wealth of knowledge join our leadership team, as DairyNZ continues to work with farmers to deliver our vision of a better future

EDGETM granular technology provides unmatched stability with 3 mechanisms of action: • LACTIC ACID PRODUCING BACTERIA (Competitive inoculants are typically either bacteria or preservatives, EDGETM puts both in the bag.)

EDGE TM is proudly made in New Zealand. This means that EDGE TM supports the Kiwi economy rather than padding pockets of offshore multinationals.

for New Zealand dairy farmers.”

Butler will be focused on delivering solutions for on-farm capability and consider how DairyNZ can engage and partner better with farmers.

“One focus for Alyce will be on closing the labour and skills shortage gap, which continues to be a key concern for farmers,” says Mackle.

“She will be helping our team to deliver solutions that attract and retain people in dairy farming. This includes our Great Futures in Dairying plan, to shape dairy as a competitive career option through a range of workplace and technological advances.”

CRV SAYS sales of its sexed semen and dairy beef jumped by more than 40% last year as New Zealand dairy farmers change their genetics buying behaviour to help mitigate increasing regulatory and

age of total sexed semen and dairy beef sales increased by 44% and 41% respectively.

On average, each farmer who bought sexed semen this made up 18% of their order. Those buying dairy beef it made up 14% of their order and conventional semen made up 68%. CRV manag-

ing director James Smallwood says the shift is no surprise as dairy farmers continue to look for ways to remain profitable while dealing with rapid change.

“Breeding a feed efficient herd is now more crucial than ever. Feed and fertiliser costs and feed quality levels have become an ongoing chal-

lenge for dairy farmers. In addition, they must comply with more regulations and market requirements to reduce greenhouse gas emissions, improve water quality, such as limits on the application of synthetic nitrogen, and reduce the number of bobby calves.

“We are seeing a real shift in buying behaviours as farmers seek to minimise waste through good management and ensuring their animals are healthy, last longer and turn as much grass as possible into milk.

“Sexed and dairy beef semen can both play a key part in minimising waste and maximising profit, with farmers able to breed better replacements to boost their rate of genetic gain and ensure they get more value from nonreplacements.”

Meanwhile, the company says the number of dairy farmers using CRV’s myDNA service has doubled over the last year.

Smallwood says farmers are looking to use the service to make better use of the genetics they are ordering and identify superior animals to breed to sexed semen.

“Data is increasingly being used by dairy farmers to ensure the right

genetics are being used at the right time over the right cows.

“Farmers are not only ordering more sexed and dairy beef semen, but also ensuring that the effectiveness of those products is maximised by using data provided through DNA testing and milk test information.

“They are also using their herd recording software more effectively to select better replacement animals, allocate sexed semen to genetically superior cows, and fast track the genetic gain in their herds.”

CRV is hosting a series of Better Herd Events from February until April to help farmers understand their options and explore what might work for their business.

They can learn more about the latest genetics CRV has on offer, its sexed semen technology, and options to capture, interpret and link data for better decision making.

Local farmers from each area will also be on hand to share what they have done to achieve their breeding goals, while tackling increasing regulatory and financial challenges.

For more information visit www.crv4all.co.nz

Maintaining herd health needs proactive management and responsible antibiotic use. Combining animal health checks with your regular herd tests is a simple way to monitor health while looking for variations in herd performance.

Using samples from your herd test, LIC’s animal health testing can identify diseases such as BVD, Johne’s and Staph aureus mastitis before they cost you a fortune. It can also confirm pregnancy and identify animals that produce A2 beta casein milk.

Adding any of these easy and convenient tests is one of the smart moves you can make today to get more insight into your herd’s health and status, all from a drop of milk.*

Talk to your LIC Agri Manager today about setting up regular herd testing with animal health checks.

*Minimum sample volume and sample numbers apply.

There's always room for improvement

JOHN AND Donna McCarty no longer use intermammary antibiotics for mastitis or dry cow treatment, which has saved them money and improved herd health.

The couple farm 142 hectares (350 acres) at Riverlea near Kaponga, in South Taranaki (near Mt Egmont) milking 320head through a 44-bale rotary. They are progressing towards a F8/J8 herd with a production average of 500-550 MS per cow.

Their production is sitting at 1,250 kgMS per ha, and they recently recorded their highest production on-farm at 159,970 kgMS. Their average BMCC [Bulk Milk Cell Count] runs at 120,000. Their local vet practice acknowledges all of its cli-

ents’ level of antibiotic use on-farm with a ranking between one and 10 –with 10 being the highest.

The area average is seven. McCarty’s is 1.5 – one of the lowest within this practice.

Their secret? In part, a chance conversation during a maize overload crisis. John said they

were smashed by Cyclone Gita four years ago, and his maize crop, which was poised to yield 23T/

ha was torn down to 15T/ ha. He decided the fallen crop left in the paddock was too valuable to waste,

recorded

so after discussing it with his vets, he made the call to carefully feed the paddock off in small breaks.

If your chiller can cool your milk within two hours of completion of milking but your blend temperature is marginal then all you may need is a CSL Chillboost

Although it had never been done, and the vets warned against it, it was working…until the cows broke out.

“I’d got through 30 days, and they were cleaning up the cobs like they were turnips,” said John.

“They were loving them. And, then the morning after they broke out I got the call, ‘There’s four cows down in the paddock, two down in the shed, and one on the race.’ I got to the shed and by that time there were cows down all over the place with acidosis. We got two vets out, and started treating them as fast as we could.”

John estimates the cows lost an estimated 0.5 – 0.75 in body condition score and he was dreading what lay in front of them at calving because of the metabolic trauma and his herd’s rapid weight loss.

Probiotic Revolution’s Chris Collier recommended adding BioRumen DFM, a direct fed microbial, which has been fortified with uprecedented amounts of probiotic bacteria, probiotics, enzymes and yeasts.

Importantly, 70-80% of a mammal’s immune function is driven by the bacteria in their body –most of which is in the lower gastrointestinal (GI) tract.

So getting the right concentrations of microencapsulated probiotics to the sweet spot – to outcompete pathogenic bacteria – allows cows to fight infection on their own.

The yeasts also stabilise the rumen at a healthy pH of 6-7. John said he couldn’t believe how well it worked.

“We had no acidosis, no retrained cleaning, our SCC was 110,000. And, that was the year we achieved a production record by 7,000 kgMS – even though the cows started from the worst position possible.”

Waste not, want not John and Donna have a feed pad, because they believe that maize is an expensive feed to have trampled into a paddock. They don’t feed meal in the bale. They add BioRumen DFM to their maize silage, and the cows

have access to it before the afternoon milking. John said he already used organic fertilisers, and the probiotic path had always interested him.

“I’m not organic and I probably never will be, but I’ve been interested in not using antibiotics to treat mastitis.”

Changing their approach, they have now completed two seasons using no antibiotics for mastitis.

This season the 25 clinical cases of mastitis in total have been instead treated with a potent oral probiotic drench for four to seven days. It cost $11.50/treatment, with nil milk withhold. Twentyfour have recovered. One was culled.

“You know, I had some cows that I thought would never come right. One had a rock-hard quarter, and when I’ve treated those cows in the past with antibiotics I’d get maybe a 30 percent cure rate,” John said.

“With the ImmunoMax drench [a treatment product which includes 190 billion Colony Forming Units/dose], five days after I started, the quarter was still rock hard, and I remembered that Chris [Collier] said it might take six or seven days. I drenched her again on the sixth morning, and I noticed the quarter was starting to soften.

“On the seventh morning I missed her completely because the swelling had gone, so I never even saw her come into the shed. I deliberately made sure I caught her on the next milking, and I stripped her, and she didn’t have a trace of mastitis anywhere.”

Before drying off last season, they didn’t use any traditional intermammary antibiotics on the herd.

However, they did draft and dose 77 SCCproblem cows with ImmunoMax through the water trough. The qualifying criteria included:

1. They either had one clinical case of mastitis during the season.

2. One herd test over 300,000 SCC.

3. Or two herd tests over 150,000 SCC. It cost John and Donna just over

$17/cow (with the added benefit of nil withholding), compared to approximately $28/cow for antibiotic dry cow treatment (without teat seal).

The rest of the herd were fed the herd’s probiotic, BioRumen DFM –albeit in higher dose rates – during the last three

weeks of their dry period.

“Of those 77 problem cows, four came in with clinical mastitis and the overall herd SCC is similar to last year at around 120,000,” John said.

“It could have been luck, but I’m happy to promote this as an alternative to antibiotics.”

Get

Dairy Cooling Solutions have the cooling equipment to help you comply with the milk cooling regulations.

European design and quality

Packo have over 50 years experience in developing milk cooling tanks and are one of Europe’s leading dairy cooling systems producers for the needs of farmers around the world. DCS offer nationwide coverage and After-Sales support.

Energy Saving with Packo Ice Builders (PIB’s)

Thanks to the ice energy store build-up during night time hours, a smaller refrigeration unit can be installed, plus the potential savings of off-peak power rates.

Water Saving with PIB’s

Bore water pre-cooling is not necessary with the correctly sized PIB. This is ideal for drought prone regions or where water supplies are restricted.

Improved Milk quality through Snap Chilling = potentially a higher return adding PROFITS to the farm.

See what Dairy Farmers have to say about how this technology has changed their milk processing.

www.dairycoolingsolutions.nz/testimonials

PAINTWORK ON a fertiliser spreader is exposed to heavy wear and tear due to the potentially corrosive nature of the products being spread, particularly if they are exposed to any moisture.

Of course, a high-quality paint finish helps prevent rust perforation, but German manufacturer Amazone has now taken the painting process a stage further. The characteristic of this multi-layer painting process is effectively the best of both worlds, via the combination of cathodic dip painting and powder coating.

A new premium painting process for the ZA-V and ZA-TS mounted fertiliser spreaders, alongside the ZG-TS bulk fertiliser spreader, was implemented for the 2022 model year. The process involves a cathodic dip painting process (known as KTL) for priming to give the best possible protection, particularly on the internal surfaces of tubes.

Subsequently, a powder coating provides an extra-thick coat of paint for increased protection against mechanical knocks and bangs as well as giving the fertiliser spreader a high-quality visual

appearance, with the added assurance of a seven-year anti-rust perforation guarantee.

The premium painting is carried out in four main steps, initially with the carrier material being prepared for painting in 14 processing stages, including multiple etching and degreasing operations.

The second stage sees components subjected to zinc phosphating in order to prevent the formation of rust as effectively as possible.

The third step includes the thicklayer KTL cathodic dip-paint process, before the spreaders receive their powder coating. The application of a particularly thick powder coating layer gives the spreader even better protection against bumps and knocks, alongside the double corrosion protection provided by the stove-baking process.

The 7-year rust perforation guarantee can be easily applied for free of charge in the myAMAZONE digital customer portal at www.amazone. net/myAMAZONE, which also lists the terms and conditions.

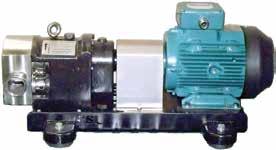

BELIEVED TO be two of the largest effluent tankers built in Ireland, Conor Engineering of County Clare has recently shipped a duo of 30 cubic metre units, destined for the large paddocks of Mid Canterbury.

With capacities of

6,000 gallons or 25,000 litres, most of the statistics on the pair are plus-sized, as will be the contractor’s prime movers that will be tasked with hauling these heavy loads. With liquid effluent typically 1,000kg per cubic metre, the 30 tonne load will be added to the tanker’s tare weight of around 7 tonnes, plus the prime movers weight, meaning

they will only be destined for off-road applications when fully loaded. Alongside their impressive physical statistics, the standard equipment hits some big numbers too, with a fast turnaround assured by a vacuum pump capable of 18,000l/ min. This is augmented by an additional centrifugal pump mounted on top of the filler arm.

The company notes that high capacity pumps of this type, used in rapidfill situations over short bursts, are prone to overheating, so the configuration includes an air/ water cooling system with a radiator bank mounted next to the vacuum pump.

Up at the front end, the drawbar is fitted with a spring-damped hydraulic system, ball and spoon coupling, air brakes and complemented by a hand operated parking jack or easy attachment and removal.

Loading on one unit is via a direct-fill system, featuring an 8-inch pipe dropped directly into a holding, with a hydraulic bleed valve incorporated to drain the pipe when it is raised.

The second tanker is filled via a loading pipe that couples to a groundbased loading hopper, carried under the tanker body when not in use or during transit between jobs.

Equipped with a triaxle system, using forced steering on the front and rear assemblies, the configuration is said to allow tight turns in confined spaces.

The tankers also incorporate a clever tank balance system, meaning the operator can empty from the rear of the tanker during downhill sections and return to front end emptying on level ground.

At the business end of the tankers, a four-section, the 12-metre boom and dribble bar assembly is carried on a three-point linkage system that allows the contractor to attach a separate shallow disc cultivator if the effluent needs to be incorporated. A clever boom unfold system works sequentially from the transport position, out into the full 12m working width.

The tankers are also pre-equipped with variable application technology, which the owner is considering for the future.

Taking around 3 months to build, followed by an estimated 10-week journey time to New Zealand, the purchaser is obviously keen to exploit the fertiliser value of effluent, having invested €360,000 ($615,000) in the machines – of course with an all-black colour scheme.

ANYONE WHO has spent time in a milking shed will know the chore of climbing out of the pit to bring lethargic cows forwards is a pain in the proverbial.

Of course, mechanised backing gates can be installed, but they still need operator interven-

closely, a recent trial over two weeks saw three sheds being closely scrutinised. Shed 1 milked 1,200 cows through a 60-point rotary, Shed 2 milked 1,250 cows through the same set up and Shed 3, the control system, milked 1,100 cows, again through a 60-point rotary. Sheds1 and 2 were fitted with the Gatekeeper system, while Shed 3 was fitted with an operator-

tion and when used incorrectly can put undue stress on animals.

Gatekeeper from Moover Ltd takes things a stage further by using camera-driven artificial intelligence (AI) to look at cow density in the holding yard and autonomously move animals towards the dairy shed.

Offering several benefits, not least an overall reduction in milking times, the system also ensures that cows are not kept standing on concrete for too long, an issue said to be a major contributor to white line disease of the hoof.

Founder and chief executive of Moover, Richard Appleby, says alongside reducing operating costs, the system keeps cows calm and happy and eliminates over-zealous backing gate pressure. Over a relatively short time, the cows learn the system and move forwards with very little prompting.

Retrofittable to any current systems, without any installation disruptions, the system also features a safety stop function in case the backing gate hits an obstruction, while also offering automated yard washing and pre-milking backing gate positioning.

Looking at the cost saving benefits more

activated traditional backing gate.

Averaging 2.75, 2.79 and 2.77-hour milking times respectively, at a time of peak supply, the automated backing system in Sheds 1 and 2, led to a reduction in milking time of 30 and 38 minutes respectively.

With two operators working in each of the sheds, this equated to a man-hour saving of 60 and 76 minutes, or a cumulative saving of 13.68 and 17.62 man-hours over the two-week trial.

As the trial took place during peak milking, Richard suggests that it was a little difficult to extrapolate the results over the whole season, but commented, “even being very conservative, our calculations show time saving of 9 to 11%, so looking at the whole season it would be very achievable to save 270 man hours and 342 man hours in Sheds 1 and 2 respectively, meaning that after purchase and installation costs, the system would pay for itself in about 12 months”.

In addition, those savings in milking times and reduced man-hours would also lead to reduced energy consumption and free up staff for more non-milking tasks and improved animal husbandry.

Retrofittable to any current systems, without any installation disruptions, the system also features a safety stop function in case the backing gate hits an obstruction.Gatekeeper is said to keeps cows calm and happy and eliminates over-zealous backing gate pressure.