Maintaining herd health needs proactive management and responsible antibiotic use. Combining animal health checks with your regular herd tests is a simple way to monitor health while looking for variations in herd performance.

Using samples from your herd test, LIC’s animal health testing can identify diseases such as BVD, Johne’s and Staph aureus mastitis before they cost you a fortune. It can also confirm pregnancy and identify animals that produce A2 beta casein milk.

Adding any of these easy and convenient tests is one of the smart moves you can make today to get more insight into your herd’s health and status, all from a drop of milk.*

Talk to your LIC Agri Manager today about setting up regular herd testing with animal health checks.

*Minimum sample volume and sample numbers apply. There's always room for improvement

its new multi-national customer,” says Allbon.

CANTERBURY MILK processor Synlait’s recovery has hit a roadblock with a major profit downgrade and signs of a strained relationship with a key customer and stakeholder.

A month after announcing a net profit after tax (NPAT) guidance of between $15 and $25 million for 2023 financial year, the listed company last week issued a new NPAT guidance of a net loss of $5m to a net profit of $5m.

The shock turnaround spooked investors and Synlait’s share price fell 27% to an all-time low of $1.56/ share last Thursday.

Synlait attributes its change in fortunes to further demand reduction from one of its infant formula customers, claiming it wipes off $16.5m from its NPAT. The remainder of the NPAT impact of $3.5m is attributed to higher financing and supply chain costs.

But Synlait’s key infant formula customer and cornerstone shareholder, a2 Milk Company, says it was surprised at the extent of the reduction in Synlait’s guidance range.

In an NZX release, a2MC claims its production volume reductions equates to less than 5% of Synlait’s reported advanced nutritional sales volumes over the 12 months ending 31 January 2023.

Jarden director equity research Adrian Allbon believes there are dif-

ferences emerging between Synlait and a2MC.

“The relationship appears to be problematic again in terms of demand/supply planning and execution,” Allbon told Dairy News

Allbon expressed surprise at Synlait’s profit downgrade, given the guidance provided by the company at its half-year results on March 27 and no downgrade from a2MC.

He believes there could be an issue with Synlait’s new multinational customer or further issues with its new SAP IT system which

the company blamed for its poor half-year results.

But from Synlait’s statement, the main source appears to demand downgrade from a2MC.

Allbon says the latest financial setback will impact Synlait’s recovery, by slowing it and elevating high debt loading further.

He says it’s also hard to know if Synlait will be forced to issue further profit downgrades.

“Synlait is a volatile business and has high concentration of profits to key customers like a2MC and

In its statement to NZX last week, Synlait said it remains highly focused on diversifying its customers, mitigating risk, and reducing its cost base and inventory to strengthen its balance sheet.

But it left the door open for further profit downgrades.

“In addition to the demand reductions and financing and supply chain costs cited above, as previously communicated, Synlait continues to manage several material risks which could impact its yearend performance, including, but not limited to, the SAMR re-registration timeline and supporting activities, the onboarding timeline for Synlait Pokeno’s new multinational customer, UHT volume ramp up, a tight labour market, and high inflationary cost pressures.

“These factors could impact Synlait’s current guidance.”

Synlait’s woes began in December 2020 when a2 Milk suddenly reduced its demand for infant formula. This led to a $28.5 million loss for FY2021, its first loss after nine years of profitability.

Founder director John Penno then took charge and announced a plan to return to “robust profitability”. Last year the company posted a net profit of $38.5m.

Chinese dairy giant Bright Dairy owns 39% of Synlait. Penno holds 2.3% stake in the company while a2MC holds 19%.

SOME GOOD news on the horizon for dairy farmers.

Westpac says the annual rural inflation rate has peaked and will drop from the 15.3% as at last December to a low of 4% at the end of 2023. It says it will drop another 2% during 2024.

The report by senior agri economist Nathan Penny says the reason for the drop will be lower feed, fertiliser, and fuel prices.

However, there are quite a few ‘buts’ in the report. One of these is

the news that farm and orchard cost structures are likely to remain high. A big one, and not good news for farmers, is that wage inflation will buck the positive trends and remain high. This is due to high employment and a very tight labour market and the fact that workers still have negotiating power.

Penny says in the report that while cost inflation may cool, he doesn’t believe that costs will fall back to previous levels and that farm and orchard cost structures are likely to remain permanently higher.

The report notes that dairy farms experienced

AS COSTS of production soar and cow numbers decline, more dairy farmers need to take advantage of the technologies available to identify the best animals to rear and mate, ensuring they use their investment in livestock wisely.

This is the message from CRV managing director James Smallwood following the release this month of 2021/22 New Zealand Dairy Statistics report.

The report shows an increasing number of farmers are tapping into technology and information to help them breed healthier and more efficient cows.

The season saw an increased uptake of herd improvement services, with record herd testing levels of 3.79 million cows.

While more New Zealand farmers are using data and insights to support on-farm decisions, Smallwood believes there are still many

the biggest spike in farm costs with prices up 17% - well ahead of sheep and beef farms and orchards. But against that, the Westpac reports that feed costs will fall steeply from now due to pastures which have been supercharged by the rains of Cyclone Gabrielle and the mild summer and autumn weather. Farmers they say have ample feed for winter, putting downward pressure on feed prices.

So it’s a mixed bag in some respects, but the promise of lower rural inflation will be a sweetener in the light of a testy and sour year.

Fed Farmers president

Andrew Hoggard says, if the predictions translate into reality, it will be helpful for farmers who are spending less on the

farm with commodity prices coming back a bit. But he says there will still be pain out there on dairy farms.

“One would hope that the Reserve Bank is listening to this and stops ramping up interest rates. They should have a breather and wait to see what impact the rate rises have had and hopefully will look to soften things up as inflation starts to come under control, because those interest rates are still high,” he says.

In the light of the squeeze, Andrew Hoggard says he’s made some important decisions on his own farm to hold off doing some things until the situation settles down. He says, like many, he’s concerned at the geopolitical situation with

the war in Ukraine which he says has impacted grain and energy prices in Europe.

Hoggard says we then have to look at the US/ China issue, which paints a challenging picture for us because China, one of our major export markets, is locking horns with one of our traditional allies.

“That is a massive challenge for the NZ Government to balance all that up and it would be easier if the US would offer us an FTA. They expect us to be friends but don’t want to trade with us,” he says.

@dairy_news

facebook.com/dairynews

genetic gains faster.”

Smallwood says knowing which cows are in the bottom 20% can also be profitable.

“The worst performers can be culled or bred for dairy beef, while animals with genetic potential can be inseminated with sexed semen or targeted with specific traits to boost the productivity potential of their progeny.”

genetics they order, not just the sexed bull available on the day. This means they get the right bull for their herd to achieve more rapid genetic gain.

“By helping farmers select the right mix of sexed semen, conventional semen and dairy beef sires they can breed better replacements, higher value dairy beef calves and reduce the number of bobby calves.”

who have not yet realised the value of tools like herd testing and DNA and genomic testing.

“While this trend is encouraging, there are still many farmers who are not using the tools already available to help them future proof their business,” he says.

“Our herd testing and myHERD data shows the average production of the top 20% of a herd gives 160kg more milk solids per lactation when

compared to the average production of the bottom 20% of that same herd.

“They all eat the same and cost the same to get into the herd. Imagine if every dairy farmer in New Zealand knew who their top performers were early and then mated accordingly.

“It makes financial sense to know which cows are in the top 20%. You breed from these animals to increase the productivity of your herd and get

CRV says it has seen demand for sexed semen continue to grow year on year as farmers look to accelerate their herds’ genetic gain and reduce bobby calf numbers – increasingly important as they consider animal welfare and make sure every calf enters the value chain.

“For herds with good fertility management, using sexed semen from the very best bulls on your best cows is the most effective and fastest way to get ahead,” says Smallwood.

“Our farmer customers get the

Last year, CRV collaborated with Genus IntelliGen® Technologies to bring proven innovative sexed semen technology to New Zealand, giving dairy farmers access to high quality sexed semen to accelerate the genetic gains of their herd.

“As margins continue to be squeezed, it is more crucial than ever for New Zealand dairy farmers to leverage these types of technologies to make sure the investment they are making in their herds is delivering the best returns.”

TWO YEARS ago, sharemilking brothers Sumit Kamboj and Manoj Kumar created history by becoming the first siblings to win the Share Farmers of the Year title in the New Zealand Dairy Industry Awards.

At that time, they were sharemilking at a 780-cow property at Eketahuna.

Last year, the brothers, originally from India, took up a new sharemilking role on a 530ha farm near Ashburton, mid-Canterbury, where they milk 2000 cows and employ 13 staff.

Winning the national title has opened many doors for Kamboj and Kumar. Not only have they progressed as sharemilkers, they have also hosted delegations from Indian state governments and dairy companies and have been invited to travel to Uttarakhand state in northern India to talk about their success in the NZ dairy industry.

Kamboj says it’s been a great journey since they won the award.

“We entered the awards to benchmark ourselves with other great farmers in the country,” he told Dairy News.

“It has given us a great platform to progress. As migrants we did not have many contacts and a big network in the dairy industry but after winning the award, it has opened many doors to network within the dairy industry.”

Kamboj says the award has been “a very powerful source of motivation for them”.

“It has been a very important part of our journey as it has given us lots of great opportunities/options to grow our dairy business.

“Networking with NZ farmers and rural professionals has also been invaluable.”

The brothers’ win has also been noticed in their home country, which is the largest producer of milk in the world.

In December last year, Uttarakhand State Minister of Animal Husbandry and Fisheries Saurabh Bahuguna and senior government official Dr Avinash Anand visited their farm.

Kamboj says the delegation from their home state was keen to learn about NZ dairying and the practices and technology they employed on farm.

“During their visit, we took them for a farm tour and showed our dairy farming systems and practices.”

Last month, the brothers hosted a high-level delegation from Amul, India’s largest dairy brand. The Amul delegation was led interim chief executive Jayan Mehta and included board members of the farmer-owned co-operative. Agriculture Minister Damien O’Connor and parliamentary under-secretary for agriculture Jo Luxton also joined the farm tour.

Kamboj says they shared their story of dairy farming in NZ and took them on a tour of the farm.

He says their progress through the NZ dairy industry is being noticed in India and is attracting more young Indian dairy farmers to the country.

“Both of the visits have been very positive, and we shared a lot of information about dairy farming,” says Kamboj.

“The Minister from Uttarakhand has planned to invite us for an interactive conclave with farmers of Uttarakhand to showcase our best practices and technology in the sector.”

Kamboj says a few years ago, there weren’t too many Indian dairy farmers in NZ.

“Nowadays, a lot of young Indians are in dairy farming in NZ and definitely hearing our success story gives them motivation to do well in the industry.”

Kamboj says like other dairy farmers, they are facing challenges around rising input costs and

weather.

But they are determined to carry on and hope for things to improve.

“It has been a chal-

lenging season so far with all the costs going up. Hopefully going forward these costs will ease up and we hope for a strong payout.”

• New Zealand’s trusted and most popular monitoring solution.1

• Accurate heat detection, including insemination timing.

• Integrations available including, seamless automatic drafting with Allflex® Intelligate or Protrack® Draft Gate.

• Health and rumination data customisable to NZ pastoral farming. Subscription and finance options available. World-class training and technical support from a local team.

• Backed by global research and development that is heavily invested in what’s coming next.

for the second time in the Outstanding NZ Food Producer Awards.

OAMARU-BASED ARTISAN cheesemaker Whitestone Cheese has been named Dairy Champion

At this year’s tasting judges struggled to set aside Whitestone Oamaru Blue, describing it as “delicious, great blue

cheese”. “True flavour, well balanced with buttery unctuous texture… we could not stop eating this,” they said.

Whitestone Cheese was awarded Dairy Champion in the inau-

gural 2017 Outstanding NZ Food Producer Awards and has amassed 27 medals during the past seven years.

Whitestone Cheese managing director Simon Berry told Dairy News

ADVERTORIAL

VETERINARIAN Kelly Andrews from Te Awamutu recommends Tracesure capsules following “amazing results” after treating a mob of calves whose prognosis looked grim.

“190 calves were moved to grazing whereby 3 died and 19 were identified with ill-thrift losing 0.3kg/c/d. With half of these on a fatal path due to a confirmed diagnosis of Yersiniosis and Theileriosis the calves were mob separated with ill-thrift calves being offered meal supplementation, antibiotic and anti-inflammatory treatment and a Tracesure capsule”.

30 days later Kelly says the calves were unrecognisable and gaining 1kg/c/d vs gains of 0.45kg/c/d for the mob not given the bolus. The farmer requested the other mob also get Tracesure after seeing the results.

Tracesure is a controlled-release capsule that provides 6 months supply of Iodine, Selenium and Cobalt in an accurate and reliable daily amount.

Think of it as like putting a dosing pump system inside the calf. Tracesure can be used in combination with Copasure capsules to provide copper at the same time. It appeals to many farmers because the capsule takes the guesswork out of bodyweight/dose rate calculations. Trace mineral supplementation can be done once, accurately and forgotten about for 6 months.

Says Andrews “We get continual great feedback from our graziers on how well weaned calves transition when Tracesure is used in newly weaned calves off to grazing. Calves and young stock transition to their new environments with less risk of Yersinia, less ill-thrift, recover faster from illness and provide some incredible mating results to name a few of the benefits seen. We routinely use the capsules at the end of the zinc treatment period, enabling young stock to replenish vital trace element stores as they head into winter when such elements become generally less available from pasture, as soil temperatures drop”. Results speak for themselves and Andrews sees Tracesure/Copasure as an indispensable tool to optimise health, growth and fertility of weaned young stock leading up to mating.

Tracesure and Copasure are available from your local veterinarian.

that it was a fantastic result for all the team involved in achieving this.

“Two titles in seven years cements our position as a quality focused dairy producer,” says Berry.

“There’s no secret behind our success, just an ongoing focus on quality and remaining true to our handmade craft.”

The Whitestone Oamaru Blue was developed after domestic market analysis identifying no high moisture blue cheese with complex flavours blue being produced in NZ, says Berry.

“We combined multiple blue mould strains, including our 45 South Blue that was discovered in a Fairlie hay bale, to develop a new flavour.

“We then utilised a combination of natural maturation techniques to enable blue mould growth in such a high moisture cheese.

“The result is a cheese that can only be produced on a small scale and with peak spring and summer

milk only, therefore this is a new seasonal cheese addition to our Black Label cheese range.”

Berry says the key to their success is its key raw ingredient – pasturefed whole milk.

“North Otago’s limestone milk is world class and our milk tests have proven it has very high calcium mineral properties, essential in producing full flavoured cheese.”

Whitestone Cheese sources milk from local farmers.

“Local farm supply is critical and key to our quality levels; fresh raw milk is delivered to us daily from local farms’ morning milking,” says Berry.

For the 2023 Outstanding NZ Food Producer Awards, judges tasted and assessed more than 290 locally harvested, grown and made food and drink products. Of the food 206 were recognised with medals of which 98 were gold, 60 were silver and a further 48 were bronze.

LOCAL CHEESEMAKERS are facing competition from subsidised frozen EU imports flooding the NZ market, tariff-free, says Whitestone Cheese managing director Simon Berry.

Berry says NZ’s open door trade policy provides zero protection to New Zealand domestic producers.

“Inferior industrially bulk manufactured EU cheeses are becoming more and more prevalent in our market as a result.”

Another challenge facing local cheesemakers is accessing naming rights already used in Europe.

Cheese produced in New Zealand branded as ‘feta’ will have to find another name under the free trade agreement (FTA) the Government recently secured with the European Union.

The deal includes what are referred to as geographic indications (GI), which are names of products unique to a certain area that a country or market wants to protect.

“The naming rights of feta is an opportunity for NZ producers to stamp our quality mark on our own NZ fetas, separating them from the inferior EU bulk industrial shipments. It will be interesting to see if Danish feta cheese, where the majority is produced in Europe, is able to use the Greek certified name,” says Berry.

4 essential trace elements and 6 months of peace of mind for young to adult cattleand deer. Te Awamutu veterinarian Kelly Andrews

PETER BURKE peterb@ruralnews.co.nz

PETER BURKE peterb@ruralnews.co.nz

THE BATTLE lines are being drawn on National Party’s recently announced agricultural policy.

While ‘Getting Back to Farming’ has a strong focus on reducing regulations and replacing them with ‘more practical ones’, National’s plans to reinstate live animal exports is winning a mixture of strong support and some unease. News that National would lift the ban on live exports came on the same day as the last shipment of

Aotearoa (VAWA) is unhappy about National’s proposal to reinstate live animal exports if it became the government.

The collective, while it calls itself ‘veterinarians’, includes other non-vets such as animal welfare advocates, animal welfare scientists, and other non-veterinary and body corporate members. Founding members include Bryce Johnson, former head of Fish and Game, and ecologist Mike Joy. It was established in 2022 to provide a science-based animal welfare advocacy voice.

Group spokesperson and veterinarian Dr Helen Beattie says animal welfare is not political, it is scientific and as such should not be used as a vote-chasing, political football. She says it’s disappointing to hear that National would consider reinstating livestock exports.

Beattie says it’s especially disappointing given that several National Party MPs sat in on the select committee hearing where a harrowing description was given of animals’ experiences during livestock export.

“Irrespective of vessels being purpose built, animals would still be subjected to sea journeys of up to three weeks and a journey across the equator. Managing cattle welfare in these circumstances while maintaining an economically viable model would be extremely difficult and for that reason could never be classed as ‘gold standard’,” she says.

Beattie says she’s also concerned about some of National’s plans around winter grazing rules. She says there is also a significant and historically unacceptable animal welfare aspect to winter grazing.

live animals for the foreseeable future left NZ’s shores due to Labour banning such exports.

Federated Farmers president Andrew Hoggard is one of those to support National’s policy. He personally thinks it’s a good thing – especially if there is an excellent standard of care on the journey. He says, from what he’s heard, this is usually the case and he points out the last disaster when a ship sank was, by all accounts, due to mechanical and human error.

Hoggard says even with live exports, it’s still hard and frustrating for farmers to dispose of their bobby calves

AS THE last shipment of live animals by sea left New Plymouth on April 20, 2023, Agriculture Minister Damien O’Connor was hailing the move as one that puts NZ in step with like-minded partners on the importance of animal welfare.

He says Australia has moved to phase-out live exports of sheep, and animal welfare standards are bedded into our FTAs with the UK and the EU.

“Recent talk of restarting live exports by sea simply ignores the reality that our consumers overseas take issues of sustainability, climate, and animal welfare seriously, which is why they’re reflected in our recent FTAs. This decision is part of a number of moves by our Government to protect future export growth and protect our reputation as world-leading food producers, “he says.

O’Connor says the decision to ban live exports was supported by the National Animal Welfare Advisory Committee. He says the two-year transition period allowed affected farmers the time to adjust their supply chains and move to different business models.

– especially in relation to getting killing space at freezing works.

“I haven’t done bobbies for years, nor exported calves. I have always managed to get people to buy our surplus beef calves. But in the last few years the market has just crashed. Suddenly, if we are going to push through 200,000 extra calves without live exports, it could mean even lower prices for farmers,” he says.

Hoggard says he’s worried about the flowon effect of not having live exports. He questions claims that live animal exports threaten NZ’s export credentials

“In a market where consumers are becoming more and more discerning about ethical and environmental credentials, this Government has moved to ensure that New Zealand’s reputation for ethical trade is not at risk,” he says.

Damien O’Connor says NZ farmers are world leaders and must be supported to stay ahead of the curve.

and says, if there were any problems, that would be a reason for putting a ban in place. Hoggard says, based on that logic, you could make an argument that the same risk applies moving animals anywhere and he believes there needs to be a realistic approach applied.

“I haven’t heard anything from overseas with people saying they are not going to buy anything from NZ because it has sent surplus heif-

ers to China. It’s possible the Chinese may not be that interested in buying our milk powder because we are not willing to help them with their dairy industry,” he days.

Hoggard says sometimes he thinks that NZ makes up justifications for other countries to put trade barriers against us. He says we should be championing what we do, not coming up with excuses for other countries to put us down.

Some farmers think a telehandler is for the big farms or best suited to European or North American operations. But you’ll be surprised to know that telehandlers are the fastest growing on-farm utility category in the New Zealand market. You’ll also be surprised by what you can do with a LOADALL and how much it improves productivity on all types of farms. You won’t however be surprised to know that the JCB SERIES III is the world’s No.1 LOADALL.

YOU CAN IMAGINE IT, A JCB

CAN LIFT IT.

FONTERRA SAYS its will convert coal boilers at its Hautapu site to wood pellets as part of its decarbonisation work.

The co-operative says it will also install a heat pump at its Palmerston North milk processing site that supplies the local market.

Both projects have received support from the Government Investment in Decarbonising Industry (GIDI) Process Heat Contestable Fund.

Fonterra chief operating officer Fraser Whineray says the co-operative is commercially focused on reducing emissions.

“There are a number of solutions we’re using to decarbonise our operations and these two projects are a good example

of different technologies available.”

Once complete in early 2024 the Hautapu site will reduce our carbon emissions by a forecast 15,785 tonnes per annum – the equivalent of taking about 6500 cars off New Zealand’s roads.

The heat pump at the Palmerston North site will convert wasted heat from the refrigeration system into a heat source. This will reduce the amount of natural gas needed for process heat. The site will also generate additional heat via a solar thermal plant.

“This GIDI co-funding will help the co-operative progress two emission reduction projects ahead of time. It will help us continue to make prog-

ress towards our target of reducing emissions by 30% across all our manufacturing operations by 2030 (from a 2018 baseline), on the way to net

zero by 2050, and transition out of coal by 2037,” says Whineray.

Fonterra is receiving up to $2.5million in co-funding to complete

The Stirling wood biomass boiler will fire up for the first time today, marking the next step on the site’s transition to be totally reliant on renewable energy for its process heat.

Changing to this boiler will reduce the annual carbon emissions by 18,500 tonnes –the equivalent of taking approximately 7700 cars off New Zealand’s roads.

the work at Hautapu and $425,000 for the Palmerston North site project. These projects are just two of many underway to decarbonise the Fonterra

business, such as the Waitoa and Stirling sites that are in the process of installing wood biomass boilers to transition out of coal.

The new Waitoa wood biomass boiler, due to be operational in November 2023, will reduce the site’s annual carbon emissions by approximately 48,000 tonnes, the equivalent of taking approximately 20,000 cars off New Zealand’s roads.

@dairy_news

facebook.com/dairynews

DAIRY WOMEN’S Net-

work (DWN) chief executive Jules Benton says it’s always exciting to see the women nominated for the Regional Leader of the Year award.

The award, sponsored by FMG, celebrates members of DWN’s Regional Leader programme.

“Our Regional Leaders across New Zealand are women who believe in helping their communities, connecting their rural networks, and in supporting individuals,” says Benton.

“They often juggle running a farm, families, are heavily involved in their communities – and then are our volunteer Regional Leaders as well; organising, attending and often inspiring events in their communities,” she

says.

“I’m thrilled to see these three amazing women become finalists.”

The award will be presented later this year at the Gala dinner of the DWN 2023 Conference, which is themed “Brighter, Braver, Bolder”. Here are the three finalists:

EMILY WILLIAMS

Farming near Oxford, North Canterbury, Emily Williams is described as someone who is always

willing to help and support others.

She aims to become a better leader and has created a positive impact in a short time in the Regional Leader role.

Last year, Williams was involved in a series of social nights and book swaps, designed to get women reading and taking time for themselves off-farm.

She has also arranged a Pink Ribbon Breakfast for Selwyn and North

Canterbury DWN members who will learn from a stage 3 breast cancer survivor and local fudge maker for the first week in May.

RACHEL USMAR

Based in Matamata, Rachel Usmar is a fulltime AB technician for LIC.

She has found a passion in teaching others and is mentoring and inspiring young women, working alongside Primary ITO to attract

women into the dairy sector.

Usmar has also set up a native plant nursery, donating plants to local schools while teaching them about the different varieties and how to plant them onto a nearby dairy farm.

This year, as well as working as a Regional Leader, Usmar has been on the organising committee for the 2023 Brighter Braver Bolder DWN conference as well

as her work as a member of the DWN Te Awamutu Business Group.

ROSEANNE MEGAW

Roseanne Megaw has had a varied career over the years.

As well as farming in Canterbury, Megaw has been a teacher at her local preschool, and a wellness coach.

She posts about her life on-farm and life as a mum on Instagram under the username @living.life. with.rosie.

Megaw is described as someone who is passionate about encouraging women in the dairy sector and wants to inspire other women to reach their potential.

Fully

Central Plateau mid Winter Christmas 13-16 June 2023

Now $1,899 per person

A 4 day Central Plateau winter stunner!

RAKAIA CALF-REARER Lisa- Between August 2020 and was in charge of eventually died.” so the inspector issued a Notice

Zealong Tea Estate, Ohinemutu Village, Waimungu Thermal Valley-Lake Rotomahana Cruise, Honey Hive, Huka Falls, Lava Glass, Lake Taupo, Waiouru Army Museum, Christmas Dinner, Northern Explorer Rail Journey.

0800 11 60 60

FONTERRA HAS established its fifth application centre in China but unlike the other four, the newest one is focused on beverage applications.

The facility opened last week and is based

in the country’s southern city of Shenzhen. It is equipped to design innovative solutions for the co-op’s China customers.

“It’s a huge milestone for Fonterra and Shenzhen is the perfect loca-

tion for it,” says Fonterra Greater China chief executive officer Teh-han Chow.

“Many of China’s leading beverage customers are headquartered in Shenzhen where new

ideas flourish due to the city’s young population and innovative environment.

“We see great potential in combining Fonterra’s high-quality dairy products with the rich

flavours of Chinese beverages. This fusion is sure to create some exciting new products that will delight both consumers and industry players alike.”

Consumer preferences in China are constantly changing. Health awareness has grown since Covid-19 which has increased dairy consumption. The government is also pushing for people to aim for a daily

the diverse use of Fonterra products in beverages and provide innovative application solutions to meet the local needs of Chinese consumers,” says Chow.

The new application centre is also an important part of the co-op’s global R&D system.

Food technicians and chefs experienced in beverage production will be based at the application centre.

Their job will be to create an interactive and diverse experiential space for customers through product development seminars, demonstrations as well as live online tutorials.

Fonterra’s application centres are part of its strategy to bring the goodness of New Zealand milk to Chinese customers in innovative ways and continuing to partner with local Chinese companies to do so.

Fonterra recently completed digital upgrades of its two application centres located in Beijing and Shanghai.

While the Shenzhen application centre will be focused on beverage applications, it will also have bakery capacity. Likewise, the four other application centres have beverage application capacity.

READING THE PAPER ONLINE HAS NEVER BEEN EASIER. BREAKING NEWS MANAGEMENT STORIES MARKETS & TRENDS MACHINERY REVIEWS COMPETITIONS AND MUCH MORE...Fonterra Greater China chief executive officer Teh-Han Chow at the launch. Chinese beverages using Fonterra products on display at the new application centre.

CHINESE-OWNED MILK processor Westland Milk Products is building a new $70 million lactoferrin plant at its Hokitika site.

The new plant will secure Westland Milk as one of the world’s leading producers of highly prized bioactive ingredients, the company says.

The investment was announced last week by Westland’s resident director, Zhiqiang Li, and chief executive Richard Wyeth.

Westland is owned by the Yili Group, the fifth largest dairy company in the world.

The investment will more than treble production capacity of the multifunctional protein at

Hokitika.

The plant upgrade follows a $40m investment which doubled consumer butter production at Hokitika, increasing global sales of the prize-winning product upon completion in 2021, including ranging of Westgold butter in US retail giant Walmart.

Lactoferrin is a minor protein in milk with growing international demand across a variety of nutritional categories because of its reported health benefits.

Li says the investment signalled Westland’s commitment to take the lead in the high-value bioactive dairy ingredients sector.

“Westland is the only

New Zealand commercial manufacturer of bovine colostrum powder and this move will place us in the top three leading global companies in the lactoferrin category, with a market share of approx-

imately 10%,” Li says.

“We were one of the first to market with this highly specialised protein ingredient, and over the past 20 years have established a reputation as a manufacturer of a prod-

uct of exceptional quality.”

Wyeth says the investment extends Westland’s focus on high-value consumer goods and specialised ingredients to leverage its growing

international reputation as a producer of premium dairy products and ingredients.

“We cannot improve on the incredible quality of the natural product our farmers produce day after day, but we can ensure that we extract maximum value for that product, and our lactoferrin strategy is a critical part of that,” Wyeth says.

“Our bioactive ingredients innovation pipeline is well advanced, and we’re excited to be a step closer to bringing these concepts to commercialisation.”

Global demand for lactoferrin in the last five years has far outstripped Westland’s production

capacity with demand expected to continue to increase.

Construction of the new plant, which significantly increases production capacity at Hokitika from a current 20 metric tonne per annum, is expected to take 16 months. Construction is currently forecast for the first half of 2024.

With the addition of spray-dried lactoferrin to complement Westland’s freeze-dried lactoferrin range, Westland will be one of the only lactoferrin manufacturers in the world capable of producing both formats on the one site, a unique advantage for Westland’s customers.

Hooroo!

YOU CAN’T blame young Kiwis for jumping the ditch for a better life, and they should get the same rights as Aussies when there. But coming changes in the rules create a conundrum for employers, like dairy farmers, who are already struggling to find good staff. New Zealanders living in Aus will soon have access to Australian citizenship and its benefits, after four years - a major change to immigration rules that adds to the long list of benefits of moving to Aus.

In the last five or so years, the median wage gap has gone from Australians earning $17,400 more to $23,400 more. The cost of living in Australia is lower. Interest rates are 1.5-2% lower. Housing is cheaper. They can’t play rugby, but a young emigrant could probably overlook that.

Westpac predicts that, while inflation in NZ will come down later this year, wage inflation will buck the positive trend and remain high due to high employment and a tight labour market. Best of luck to those youngsters who jump the ditch. The rest of us need to think about how we make NZ a place with better prospects for them to stay.

THE LATE Queen Elizabeth II was the proud owner of 200 or so well-bred Jersey cows, some from Don Ferguson’s Ferdon stud in Otorohanga.

With young Charlie about to ascend to the throne, will the known tree-hugger keep the Queen’s beloved farm animals, which as well as the Jerseys, include a Sussex beef herd, 140 breeding sows and 1500 Lohmann Brown hens?

Charles recently gifted seven heifers, given to the Queen to celebrate the Platinum Jubilee, to a Jersey farmer who lost 100 cows to botulism. A nice gesture. Milking It just hopes King Charles III will resist pressure from anti-cow ramblers and badger enablers for him to join the fad of blaming cows for every gram of greenhouse gas. His published opinions on livestock farming don’t seem to indicate a problem: he promotes regenerative farming, advocates for small-scale farmers, and is patron of the Rare Breeds Survival Trust.

We can but hope Charles keeps calm and carries on the Queen’s farming legacy and earns the plaudit “a champion of farming” – bestowed on him recently at Darlington Farmers Auction, UK.

A RECENT visit to New Zealand by a delegation of senior Indian dairy industry officials has left a bad taste in the mouth of one dairy industry worker.

Media reports in India suggest that a trade visit by India’s largest dairy brand Amul has been marred by allegations of sexual harassment.

A woman working at the farm in Waimakariri on South Island alleged she was “grabbed” and had “unwanted photographs taken” by two men who were part of a cooperative linked to dairy giant Amul.

The incident is said to have occurred on 17 April during a trade event that was attended by a New Zealand government minister and delegates. The media reports quote NZ Police as saying they have received a report and are investigating.

Amul, owned by Gujarat Cooperative Milk Marketing Federation (GCMMF), claims the incident is “fabricated”.

FONTERRA’S impending departure from Hamilton’s central business district is causing anxiety among business houses.

For over 60 years, dairy co-operatives have been one of the biggest employers in central Hamilton. Locals may remember ‘gumboot castle’ for instance – the old NZ Dairy Group building in the CBD.

Fonterra said it was committed to retaining an office in the Waikato, but it was looking all over – not just in Hamilton.

The Hamilton Business Association desperately hopes the co-op and its 400 staff stay in town; after all, the city was built on agri-businesses like Fonterra and it’s predecessors.

But Fonterra is seeing an increase in employees opting to ‘work from home’. This means that a large site like the eight-storey building on London St is no longer fit for purpose.

AS THE Galloway Express left Port Taranaki last month with cattle for China, it marked the end of livestock export. A nationwide ban is now in place, imposed by the Labour Government to “protect New Zealand’s reputation as an ethical food producer”.

Sadly, the ban takes no account of how the loss of live exporting will be felt throughout the country.

Federated Farmers president Andrew Hoggard is worried about the flow-on effect of not having live exports.

Even with live exports, it was hard and frustrating for farmers to dispose of their bobby calves – especially in relation to getting killing space at freezing works.

Hoggard has neither done bobbies nor exported calves. He always managed to get people to buy his beef calves. But in the last few years the market has crashed. Suddenly, if we are going to push through 200,000 extra calves without live exports, it could mean even lower prices for farmers, he warns.

He questions claims that live animal exports threaten NZ’s export credentials and says, if there were any problems, that would be a reason for putting a ban in place.

The livestock export ban will also hit farmers and sharemilkers who raise a few extras, maybe a dozen or even 20 surplus animals, for export sales each year.

This provided an excellent boost for their income, particularly sharemilkers, if they were trying to build up a bit of capital, because their main asset is livestock.

So that good avenue would now be taken off the table and for farmers that’s one of the big frustrations with losing that trade.

But not all is lost. The decision to ban live exports from April 30th could be short-lived, however, after National leader Christopher Luxon announced they will resume, albeit with stricter rules, under his party’s agricultural policy if it is elected in October.

Hoggard supports National’s policy, adding that it’s a good thing – especially if there is an excellent standard of care on the journey.

“I haven’t heard anything from overseas with people saying they are not going to buy anything from NZ because it has sent surplus heifers to China. It’s possible the Chinese may not be that interested in buying our milk powder because we are not willing to help them with their dairy industry,” he says.

Hoggard says sometimes he thinks that NZ makes up justifications for other countries to put trade barriers against us. He says we should be championing what we do, not coming up with excuses for other countries to put us down.

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226

Editor: Sudesh Kissun Ph 021-963 177

Machinery Editor: Mark Daniel Ph 021-906 723 markd@ruralnews.co.nz

AUCKLAND SALES REPRESENTATIVE: Stephen Pollard Ph 021-963 166 stephenp@ruralnews.co.nz

WAIKATO SALES REPRESENTATIVE: Lisa Wise Ph 027-369 9218 lisaw@ruralnews.co.nz

Postal Address: PO Box 331100,

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Dave Ferguson Ph 027-272 5372

Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

WELLINGTON SALES REPRESENTATIVE: Ron Mackay Ph 021-453 914 ronm@ruralnews.co.nz

SOUTH ISLAND SALES REPRESENTATIVE: Kaye Sutherland Ph 021-221 1994 kayes@ruralnews.co.nz

ACT primary industries spokesman Mark Cameron gives National a 6/10 for its recently released ‘Getting Back to Farming’ package. He explains why…

NATIONAL’S AGRICULTURE policy says the right things but has too much compromise and a glaring omission of policy on He Waka Eke Noa (HWEN) and protecting property rights from Significant Natural Areas (SNAs). ACT has the policy that will bring about real change for farmers.

cap is nice as well, but ACT believes the sensible policy change would be to remove the cap on the number of RSEs completely, like Australia’s scheme.

It seems like National doesn’t want to talk about He Waka Eke Noa, that’s probably because they back it.

The good news for farmers is that ACT will be campaigning to make the next government’s agriculture policy a 10/10, by getting rid of the RSE cap completely, putting an end to virtue-signalling climate policy like HWEN, retaining property rights by repealing SNAs, and going further to ensure regional government has full control over freshwater limits.

It seems like National doesn’t want to talk about He Waka Eke Noa, that’s probably because they back it. The document claims there will be announcements to come on emissions pricing, but farmers deserve to know what their position is now. It is one of the most significant issues affecting farmers today.

ACT was the only party to vote against the Zero Carbon Act because we knew that it would lead to costly virtue-signalling interventions on sectors like agriculture, without lowering global emissions. We’re clear that emissions pricing is not the answer; the fairest and most simple answer is to match our agricultural emission reduction goals with our five closest trading partners. This means there is no risk of reducing production so other countries can pick up the slack.

Doubling the RSE

It’s good they have adopted ACT’s position on live animal exports. It is a $500m industry that the country needs, and I have a Member’s Bill ready to go.

Getting rid of some of the central planning around freshwater policies is good. ACT has been campaigning to allow regional councils and communities to set their own freshwater management limits right from the start and if National is truly committed to getting Wellington out of farming, they should do the same.

ACT agrees farmers are overregulated, but we don’t need more bureaucracy in the form of a panel to work that out. HWEN, intensive winter grazing regs, SNAs would all go under ACT. No serious reformer proposes the two regulations for one rule. It’s a great sound bite, but it doesn’t solve any problem. If you’re not serious about regulatory discipline, you just end up with the average regulation being twice as long.

The next Government can’t just water down Labour and the Greens’ anti-farming policies. They need to be scrapped entirely.

ACT has committed to getting rid of HWEN in favour of a marketconsistent climate policy that works, and scrapping Significant Natural Areas entirely, instead of National’s proposal to ‘focus the definition’.

Change is possible for

Read is one of more than 100 Kiwi farmers trialling a unique plant on their farms to help improve water quality.

Plantain is a nutritious leafy herb cows like to eat – and it has a superpower. Recent Massey University research has found Ecotain plantain can reduce nitrogen loss from dairy farms by 20 to 60%.

That’s a win for the environment, as less nitrogen going through groundwater into waterways helps improve water quality.

Read is a partner farmer in the DairyNZ-led Tararua Plantain Project, which supports farmers to incorporate plantain in their pastures as part of their cows’ regular diet.

The project sees farmers, scientists, councils, DairyNZ specialists and community members working together with a common goal of reducing environmental footprint.

Working with partners, DairyNZ carries out research with farmers on their properties, and shares results and advice with other farmers on how to best manage plantain.

The project has achieved great results, with 88 of the catchment’s 263 dairy farms so far planting plantain on their properties and improving water quality in streams on their farms. Water quality moni-

toring helps the farmers understand where to focus their environmental efforts.

Read says he finds plantain an exciting option. Since he’s started using it, nitrogen loss from his farm has reduced by 10 percent. He’s gradually increasing the proportion of plantain in his pasture to achieve even better results.

He and his wife Jennifer have planted 12,000 trees across their farm including alongside waterways, which helps improve water quality. They’re also fencing wetlands that make up 10 percent of their farm to protect them. Wetlands can improve water quality, boost biodiversity and provide habitat for birds and fish.

The partners in the five-year Tararua Plantain Project are DairyNZ, Agricom, MPI, Fonterra and Nestlé. Read is now part of a farmer advisory group of the national DairyNZ-led Plantain Potency and Practice research and develop-

ment programme.

This $22 million programme brings partners, farmers, industry, and government together to research plantain and develop strategies to support farmers to successfully adopt it on their farms.

The goal is for plantain to be widely adopted throughout New Zealand.

The programme works closely with 22 partner farmers in Waikato, Bay of Plenty, Tararua, Canterbury and Southland, and will share lessons with all dairy farmers.

A key objective of the programme is to tailor advice for local areas, including looking at the effects of different soil and climate conditions.

It’s important farmers know how to best manage plantain in their local area.

The programme has two large-scale farm trials underway, quantifying Ecotain plantain as an effective solution to help dairy farmers continue playing their part in improving water quality.

At the Massey Univer-

sity farm trial, scientists are measuring nitrogen leaching from paddocks grazed by 80 dairy cows. After two years, results show reduced nitrogen leaching by 20 to 60 percent in perennial ryegrass and clover pastures containing 30 to 50% Ecotain plantain.

Initial results from the programme’s Lincoln University study in Canterbury, on lighter soils under irrigation, show similar trends to the Massey University trial. More data are being collected.

The programme uses Ecotain environmental plantain from Agricom because it has proven effectiveness. An evaluation system is available to assess the environmental benefits of all plantain cultivars sold by a range of providers.

The seven-year Plantain Potency and Practice programme is funded by DairyNZ, Ministry for Primary Industries’ Sustainable Food and Fibre Futures Fund, PGG Wrightson Seeds and Fonterra.

CUST DAIRY grazers Gary and Penny Robinson have advanced their subsurface drip irrigation (SDI) trial with positive feedback from farmers following field days at trial blocks in North Canterbury and Central Otago.

The system is also being installed at Linwood Park in Christchurch.

Gary and Penny are participating in Next Generation Farming; a project that aims to help farmers meet tough nitrate caps while maintaining their viability. As part of this project, farmers like the Robinsons are using innovation and demonstrating its productivity and environmental benefits to their neighbours in the region and beyond.

Waimakariri Landcare Trust (WLT) and Waimakariri Irrigation Limited (WIL) have partnered with the Ministry for Primary Industries (MPI) for the project, with support from MPI’s Sustainable Food and Fibre Futures fund along with Environment Canterbury, Ballance, and DairyNZ.

SDI’s low-pressure system saves water and power and improves crop yields by eliminating surface water evaporation and reducing the incidence of weeds and disease. Water is applied directly to the root zone of the crop and not to the soil surface.

Gary and Penny recently held two field days at trial blocks in Cust, North Canterbury and in Maniototo, Cen-

tral Otago which were well received by farmers and industry partners. Despite heavy rain during the Cust field day, Penny says farmers were keen to learn about subsurface irrigation and seeing the system in the ground and being able to ask practical questions built a stronger understanding of how the system works.

“The weather wasn’t in our favour, but we still had a good turnout, and everyone was very engaged and interested. From the questions asked and discussion we had, SDI does seem to be accepted as a viable solution and option for irrigation in New Zealand.”

Over 50 farmers turned out for the Maniototo field day where the difference between the 18-hectare test block using subsurface irrigation and the adjacent block using traditional irrigation was evident, says Gary.

“It was a stinking hot day, and it was perfect because they have had a hot and dry summer down there so you could really see the difference with lush green grass growing on the block where we have installed the SDI.

“The farmer, Luke Jeffries, is really impressed with the system and after the field day we had quite a few local farmers approach us to learn more.”

Gary and Penny are now focused on gathering data to prove the benefits of the subsurface drip irrigation system.

OVER THE past few weeks, farmers have begun to receive herd mating results from their vets.

Many are reporting higher than usual empty rates and are asking themselves what went wrong during mating?

While it is important to acknowledge that every farm is unique and there is no single answer to the question, a couple of factors seem to stand out. These are cow condition at calving and lower feed intakes over last season’s mating period.

Cow condition at calving

The summer and autumn of the 2021-22 season was particularly hard on cows.

A prolonged summer dry coupled with the promise of a great payout meant that a significant number of farmers milked on longer than they would have in a normal season. Cows had an insufficient time to reach body condition score (BCS) targets and there was less feed on hand for the 2022-23 milking season.

As a result of these factors, cows cycled later and there was a shorter period to get cows in calf.

Malcolm Ellis, LIC, General Manager markets, reported in the last Dairy News that national submission rates were down 1.3%. There is strong scientific evidence which says that cows in BCS 5 at calving will cycle 8-10 days earlier than cows in BCS 4, so achieving target condition scores makes very good sense if cows are to get in calf easily.

Spring feeding

The other factor farmers and vets have attributed lower in-calf rates to, was the cold, wet, sunless spring. While many farmers reported having enough grass, it would appear from spring milk production figures and mating results that many cows were underfed leading up to, during and immediately after the mating period. While it may have appeared there was enough grass, I suspect that the wet conditions

resulted in poorer pasture utilisation and this combined with lower drymatter and energy concentration of the pasture, meant less energy was consumed.

On some farms, especially those with a short AB period, the sheer volume of late cycling cows, including those which had returned to service, was too high for the number of bulls on hand.

Maize silage – a great tool

For those farms who have had disappointing mating results, it is important that this isn’t repeated in the coming season. Maize silage is an incredibly valuable tool in a farmer’s toolbox to help achieve target BCS. Work done at DairyNZ’s Lye farm showed that it was one of the most efficient feeds at putting condition on cows.

Depending on breed, cows require between 110 kgDM (small Jersey) and 180 kgDM (large Friesian) of maize silage to put on 1 BCS. To achieve the same BCS increase from autumn saved pasture requires 145 kgDM and 225 kgDM for Jerseys and Friesians respectively.

Feeding maize silage to put BCS on cows simply makes sense.

I wouldn’t normally recommend feeding

“While many farmers reported having enough grass, it would appear from spring milk production figures and mating results that many cows were underfed leading up to, during and immediately after the mating period.”

vent them going anoestrous.

maize silage in spring when there appears to be enough pasture. However, in cold wet springs like the last one, it is important to take into account the fact that pasture utilisation and energy intake can be lower and as a result cows may be underfed. In these conditions, maize silage is a valuable tool to make sure that cows receive enough energy to keep them cycling and to pre-

If you need any more information or would like someone to help you understand what may have gone wrong with the mating performance on your farm, get in touch with your consultant, vet, animal breeding representative or one of our Forage Specialists (visit pioneer.nz).

• Ian Williams is a Pioneer forage specialist. Contact him at iwilliams@genetic. co.nz

MOVING DAY is the busiest time of the year for livestock movements.

DairyNZ, Ospri and Ministry for Primary Industries stress that good biosecurity practices, including NAIT compliance, are critical over this period.

When NAIT compliance is compromised, the country’s traceability system is threatened, and we run the risk of having a system that will not

perform in the event of another disease outbreak.

Ospri’s message is clear: all movements of cattle and deer between NAIT locations must be recorded in NAIT within 48 hours of them leaving one property and arriving at a new property.

The Person in Charge of Animals (PICA) sending the animals is responsible for recording a sending movement in NAIT. The PICA receiving

the animals is responsible for recording a receiving movement.

All animal movements between NAIT locations must be recorded, even if there has been no change of ownership — for example, moving them for grazing or mating and even if the animals are exempt from tagging.

Ospri says it’s important to record movements because up-to-date information in NAIT

means the time it takes to control disease outbreaks, the number of affected farms and the risk to livelihood can all be reduced.

Farmers are advised that to record a movement, they need their NAIT location number, the NAIT location number of the other property, the date the animals left, or arrived at your property and the individual NAIT RFID

or visual ID tag numbers of the animals that have moved. Farmers are also required to complete an Animal Status Declaration (ASD) while moving animals to another property, a saleyard or meat processor, although there are exceptions.

ASDs transfer important information about animals being sold or moved to the next PICA or meat processor. This includes information

about animal health and treatments, farming practices, and TB incidence and testing.

As well as passing on information to a new PICA, ASD information is important when deciding if animal products are suitable for overseas markets. They support the issuing of export certificates by the Government — vital to New Zealand’s trade-dependent economy. Meat processors use

the information to guide examinations of the animals before and after slaughter.

Ospri says if you are the PICA for any animals that must have an ASD before they move off farm, it is your responsibility to complete it.

“If you buy animals from a saleyard, they pass on the ASD, which they will adjust if the number of animals on the vendor’s ASD has changed.”

DAIRYNZ SAYS all cattle, regardless of their purpose, must be treated with care and respect as they are being prepared for transport and then physically transported.

A comfortable and safe journey for cattle reduces effluent on public roads and ensures animals arrive at their destination fit and healthy.

DairyNZ recommends a checklist for transporting cows – for farmers and transporters. This checklist covers: transport planning, days of transport, checking to see if the animals good to go and how to take care of sick animals.

It says farmers must ensure body condition score (BCS) targets will be met as per contract on takeover date.

“If BCS, pasture cover targets or supplements on hand are not going to be met, have a proactive conversation with the other party as to what arrangement can be made to compensate,” it says.

Planning for the movement of cattle must commence in the weeks and months prior to transport.

DairyNZ recommends completing Body Condition Scoring (BCS) of

all animals for transport and making plans to ensure all stock will reach target BCS by moving day.

“Do a final check over for any cull cows that have been missed – arrange for removal from farm. Where possible, ensure they will go to the nearest processing plant. If processing plants are full then make a Plan B.

“Dry off as many animals as possible and do this with sufficient time to ensure that they are properly dried off on the day of transport and con-

firm the exact number of cattle you need to transport.

“Ensure all animals that are going to be transported are NAIT compliant (i.e. have NAIT tags in their ear and are registered with NAIT).”

Day prior to transporting

• Confirm stock are all ‘good to go’ with BCS of 3 or higher, fit and healthy and not likely to give birth during the journey

• Stand stock off green feed for at least four hours, but continue feeding

silage, hay or straw during stand-off

• Ensure all stock have access to water prior to loading. Many farmers have plumbed in a basic water trough at the yards that can be filled while the yards are in use.

• Give extra calcium and magnesium to any lactating cows and consider any other minerals or trace elements (e.g. extra Phosphorus for cows being fed Fodder beet). Make arrangements to ensure that these cows are milked immediately prior

to loading.

• Confirm with the transporter times and address details and your expectations for the move.

• Make sure you have enough people to help with the loading and unloading for a smooth and efficient process.

• Confirm that agreed food and water will be available to animals along the journey if necessary, and upon arrival.

Day of transporting

• Inspect each animal prior to loading to ensure they are fit and healthy for transport.

• Milk any lactating cows.

• Confirm with transport operator that effluent tanks are empty on trucks prior to loading stock.

• Complete ASD and NAIT documentation.

• Move to appropriate feed and water access as soon as possible after arrival.

• Two hours following unloading cattle must be checked for signs of injury or illness.

With Moving Day on the way, we are encouraging Farmers to do their bit to maintain the integrity of our biosecurity system.

1 Create a new NAIT location number.

2 Create a movement within 48 hours of moving.

3 Deactivate the old NAIT location number. Register any new grazing blocks you are in charge of and record movements in NAIT for any animals sold or sent away to grazing.

If you have followed all of the instructions to update your NAIT details and are still struggling, our Support Centre is geared up to assist you. Call 0800 482 463

Complete and sign a PICA change form at your current NAIT location and make sure you become the registered PICA if you are moving to another farm.

For more Moving Day information see OSPRI.co.nz

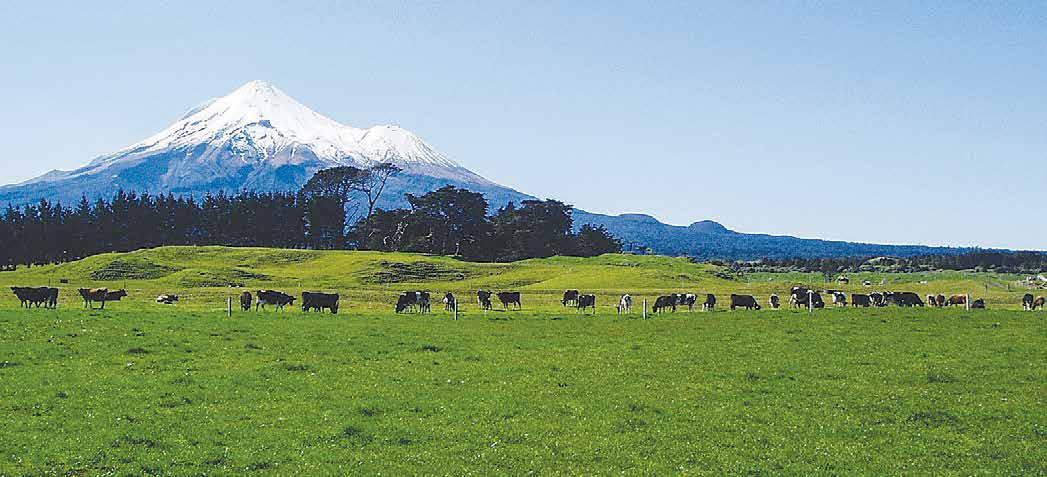

TARANAKI AND Whanganui farmers encouraged to use their technology to capitalise on a record autumn.

An unseasonal wet summer has set the Taranaki and Whanganui rural regions up for one of the best autumns on record. However, farmers are still feeling the pinch from rising inflation and on farm costs – an issue their on-farm technology could help tackle.

“While the temptation is to sit back and make the most of the flush feed situation, using the technology they have already invested in to drive efficiencies can help farmers make the most of the good autumn and keep costs down as much as possible,” says Gallagher territory manager Martin Weir.

“Dairy farmers in Taranaki were still

at this time of year, they would usually be at oncea-day or once every 16 hours.

“We have also seen record growth rates for young stock. But while the wet wash out of summer has delivered unexpected benefits going into autumn, there are still challenges to navigate. Using technology to drive efficiency on farm has never been more important.”

Weir joined the Gallagher Animal Management team covering Taranaki and Whanganui about six months ago after working for NZ Farm Source

in the Taranaki region. Based on what he’s seen on his travels, he estimates only around 20% of farmers in the region are using or getting the most out of their technology to both manage their stock and drive day-today efficiencies on farm.

“It’s about identifying the areas where farmers can save time and use that time to be more productive in other areas of their business,” says Weir.

“There are some valuable tools out there that can provide a better picture of how animals are tracking. This information can help guide farm-

ers’ decisions about the best time to get animals off farm, identify potential health issues, or find out how they’re placed for seasonal transitions like breeding.”

Technology has come a long way and farmers no longer waste precious time tripping back and forth to turn energisers on or off or spend hours trying to find where a fence is shorting out, he says.

“Energisers can now be controlled by an app on your phone that will tell you when amps drop

below the acceptable level,” says Weir. “You can even split your farm into zones that can be individually controlled. You can power on or off certain areas of the farm, depending on what you’re working on, all with the touch of a button on your phone.”

Weighing and EID technology now allows farmers to track each animal’s performance across each weighing session, automatically loading weights, traits, health treatments or any other specific notes against the

animal’s ear tag.

“There are no more guesstimates or using fiddly weigh tapes and unruly pieces of paper that get lost,” he says.

“This technology means you get an accurate measure every time and it’s recorded against the animal’s ear tag. And it’s all stored in a complete system that you can access either from your phone or download onto your PC after each session.

“This type of data tells you when your animals reach their target weights

for processing so you can make the most of the payment schedules.

“They tell you how breeding stock are tracking going into breeding season and they give you a solid measure of how young stock are performing and if there are any potential health issues to address.

“This autumn farmers are set up well heading into winter,” says Weir.

“But the challenge is to keep looking ahead to see how you can make the most of the opportunities presented.”

Weighing and EID technology now allows farmers to track each animal’s performance across each weighing session, automatically loading weights, traits, health treatments or any other specific notes against the animal’s ear tag.

JESSICA MARSHALL jessica@ruralnews.co.nz

JESSICA MARSHALL jessica@ruralnews.co.nz

COULD IT be that pelletised minerals is the thing that makes the difference in a herd? Louise Cook, general manager of the Southern Demonstration & Research Farm for Southern Dairy Hub, seems to think so.

The research farm runs four herds with 740 cows – two herds of 140 cows and two herds of 230 cows – and she says that making the switch to pelletised minerals has made a huge difference, both in terms of staff morale and time management.

Cook says that over the past four years, minerals would have to be dusted, a job she says takes approximately 45 minutes.

“We’d be dusting min-

erals right through until January,” she told Dairy News

“The person fetching herds is busy at the best of times with the comings and goings we have on the farm,” she says. “So, that 45 minutes was time they weren’t able to spend having a quick assessment on feed levels and residuals in the paddock and whether more or less feed was needed and what changes we might need to make.”

She says the decision was made last year to switch to the CP Lime Solutions Vitalise pellets to be able to free up time for staff on-farm.

“The decision around trying to do it was around making time for people so they could focus on better decision making and get a pay back from making more milk and more efficiency deci-

sions.”

At the time, they had considered an in-line dispenser. The downside of that option, she says, is

that staff wouldn’t have necessarily known if the dispenser broke down.

So, with the pelletised option, which is mixed

into the herd’s grain, Cook says the staff knew the cows were getting fed and getting the necessary nutrients as well.

“So, we’ve had the cows get what they need without the team being over-busy on a really manual task.

“We’ve seen a lot more milk out this year [because] the team were better able to manage the pasture on the days where there wasn’t enough or… the days where there was too much,” Cook says.

She says that morale has improved about the farm because of the time the pelletised minerals have given back to staff.

Cook says that when they had the dusting issue, when there had been extended periods of wet weather, there would be metabolic issues because the cows weren’t getting as many minerals as they needed.

“All of those things went away… when times are tough and the weath-

er’s poor, the last thing you want to be dealing with is metabolics.

“We’re not feeding on a feedpad, it’s not like we can just go and dust onto the feedpad, we were dusting out in the paddock and so, when you had a wet September, it was all getting washed off again,” she says.

“So, the guys have loved that we don’t have those niggly complications come back in. They’ve really enjoyed not having to dust.”

For the team at the research farm, Cook says, it has made a typically busy afternoon less stressful.

“At the end of the day, what I need them to be doing is making sure cows are fed well. So, giving them time to do that became quite an easy decision and we believe it has certainly paid back.”

30 MAY

DEADLINE: 17 May

23 May

‘TRIED AND tested for more than 15 years’ was a phrase that came to mind when an ex-dairy farmer in Taranaki decided to set up a fencing business in the Manawatu and had a post rammer on the shopping list.

Dylan Eaves set up Deades Handyman Services to service a growing client list in a 150km radius from his Fielding base.

Specialising in farm fencing, post and rails, forestry gates and deer fencing, Eaves prides himself in quality work, leading to repeat business, backed by a significant investment in high-end machinery.

At the heart of the

system, a Kinghitter post driver plays a huge part in the one-man operation erecting up to 1km of fencing over five days.

Combining an Expander Series machine mated to a Terminator base has helped transform the post driver from a standard rear-mounted machine to one that can now work to the side of the tractor instead. The design means that the unit can easily be swapped back to the original format if conditions or terrain demand it.

Featuring a 230kg counterweight, the Terminator set-up offers 950mm of side shift, meaning that driving beside a fence line and shifting the driver into line is easier said than done.

Looking at the

AMAZONE’S NEW AmaSpread

2 terminal is said to provide users with simple menu navigation of the ZA-V Profis Control weigh cell fertiliser spreader.

All spreading information is shown constantly on the 4.3inch colour display, while allimportant functions such as application rate and the position of the border spreading device can be actuated directly using a back-lit button. Additionally, spreading rates, area covered, work-

Expander driver in more detail, the machine utilises a 6mm Bisalloy reinforced mast design, with a telescopic shifting between heights of 3.1 to 5m, offering the capability to drive any standard

ing time and material-specific settings for up to 10 different fertilisers can be stored and recalled, while the terminal also allows for variable rate application in relation to forward speed, the manual switching of up to six partwidth sections and the use of the Profis weighing system.

The 200Hz weighing system is said to provide precise spread rate regulation which, says Amazone, results in a constant application rate, even

post sizes in any terrain or environment.

This includes wooded tree lines, where the mast can be lowered for ease of access, then extended once in position, for the likes of deer fencing or

with varying fertiliser quality. Combined with the optional tilt sensor, it guarantees precise weighing results, even on sloping ground. A further feature allows operators to switch between side, boundary or watercourse spreading modes when using the optional Limiter V+ border spreading system. Other options include a hopper low level sensor and the integration of work light control via the terminal.

predator exclusion systems.

Other features include a 340kg lead-filled hammer, 300mm of mast shift and the custom designed Soft Touch system for controlled

starts and finishes.

A 6-bank hydraulic valve bank incorporates a spare outlet making it easy to combine with the Terminator base. Other details include a 50mm heavy-duty post cap

with nylon slides, complemented by a hydraulic top link and side-shift systems.

Eaves says he’s been running the machine for about a year now, mounted on the back of a 115hp Fendt 412 tractor, chosen for “comfort and speed on the highway between jobs, but also safety and precise positioning and control at work, by virtue of the CVT transmission”.

He also notes that the general build and durability of the Kinghitter product means that it’s been faultless, even ramming posts into rocky outcrops.

“Importantly, it’s very easy to use, has a great layout for all the tools you require in a working day and should last for a very long time,” he says. www.kinghitter.com

low engine speeds.

MASSEY FERGUSON has announced the arrival of the MF1800 and MF2800 compact tractors, said to be premium workhorses built on a reputation for nimble, versatile, and reliable performance.

The addition of the new Series to the existing MFGC1700 and MF2600 models is said to deliver a comprehensive compact range, suitable for smaller farms, lifestyle blocks, or horticultural and landscaping businesses.

Both machines offer enough weight to put power to the ground, while also delivering excellent stability and lifting performance, the E Series compact tractors range from 34.9 to 57.3 engine horsepower, delivered by the wellknown Iseki diesel engines.

The E Series are equipped with a cast steel rear end and cast front axle, 4-wheel drive, and high-capacity hydraulics, providing the weight, muscle, and traction necessary to handle demanding tasks.

The 1835E and 1840E models feature a turbocharged 1.83litre, 3-cylinder engine delivering 34.5 and 39.4 engine horsepower respectively, while the larger-chassis 2850E and 2860E models utilise a 2.43-litre turbocharged 4-cylinder engine, delivering 48.8 and 57.3 engine horsepower.

Liquid-cooled for increased durability, the engines meet final Tier IV emissions standards.

Designed with ease of servicing and maintenance in mind, the tractors offer significant hydraulic capacity thanks to the dual-pump highflow system that provides more responsive power at

All E Series models feature an open station with a wide, uncluttered platform, offering ample space and comfort for the operator, with all controls logically arranged and easy to understand.

The E Series feature 3-range hydrostatic transmission, with the 1800E models offering a Category I, rear 3-point hitch and the 2800E models a Cat. I/II 3-point hitch with up to 1100kg lift capacity and a 540-rpm rear PTO as standard.

Four models ranging from 35 to 60 engine horsepower make up the 1800 and 2800M series that feature 4-wheel drive and a choice of factoryinstalled cab and openstation ROPS models.

The 1800 M Series tractors feature 1.83litre, 3-cylinder Iseki diesel engines delivering 36.2 or 39.4hp, while the 2800M Series uses a 2.43-litre, 4-cylinder Iseki powerplant for 48.8 to 60.3hp, all to Tier IV emission standards.

The M Series premium compacts are equipped with 3-range hydrostatic transmission, allowing operators to reach the target speed within each range, without shifting gears.

Dual foot-pedal controls offer easy forward/reverse direction changes, while cruise control allows set-andforget function for a desired speed.

The ROPS models, along with tilt-steering and a flat platform, feature a premium seat and a new thumbcontrolled throttle that is also available on cab models. The standard cab models feature dual lockable, entry/exit doors, tilt steering and heating/ air conditioning.

LEASE FROM 1869* $ + GST PER MONTH

REASONS TO CHOOSE BVL FOR YOUR NEXT MIXER WAGON:

1: Fastest Mixing Speed

- Asymmetrical mixing wedges

- Power mixing auger

- Rolled mixing chamber walls

3: Nationwide Backup and Support

- Four branches nationwide

- Factory trained technicians

- Significant par ts stock holding

2: Longest Lasting Mixer Wagon

- Double overlapped welding

- High qualit y German steel

- Robust truck style chassis

- Double anti spill ring

Scan the QR code to find out which BvL Mixer Wagon would best suit your farming operation: