PAGE 3

WINTER GRAZING

Southland is prepared

Page 39

DAIRY EXPO

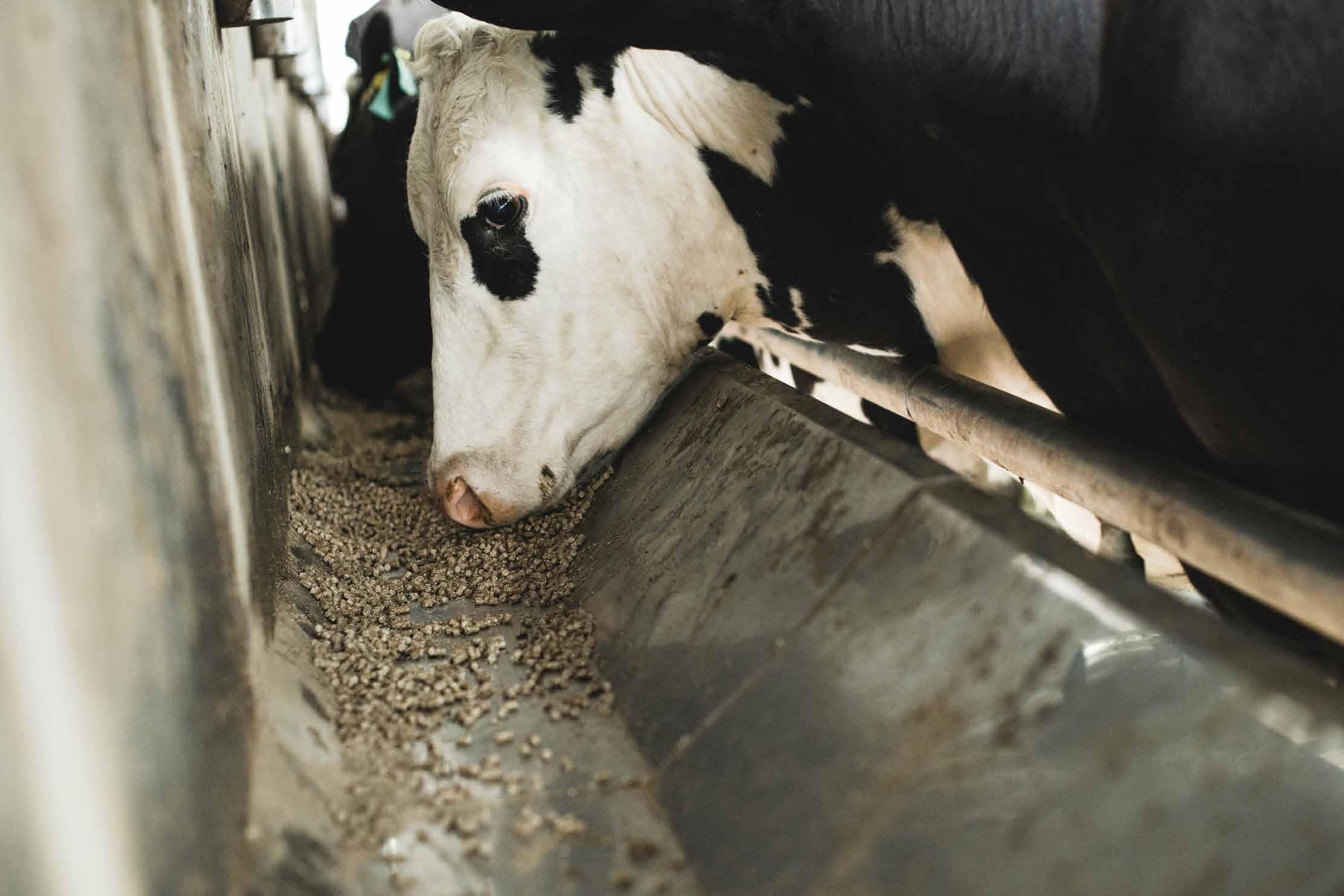

Pelletised rations

Page 22

PAGE 3

WINTER GRAZING

Southland is prepared

Page 39

DAIRY EXPO

Pelletised rations

Page 22

“Through challenging times, we play an integral part in connecting rural people to each other and to the communities.”

– Rural Support Trust national chair Michelle Ruddell

ations in automatic milking he essence of true pasture-based esent the DairyRobot.

PAGE 4

Picture this. It’s a beautiful evening in February 2026. The paddock you’re standing in used to be one of your worst. Today, it’s your best – new grass and clover are humming, the cows are full and happy.

Making this happen starts right now, if it hasn’t already, according to a leading pasture expert.

“The better organised you are ahead of autumn sowing, the closer you are to pasture you’ll be proud of in 12 months’ time.”

“The better organised you are ahead of autumn sowing, the closer you are to pasture you’ll be proud of in 12 months’ time,” Graham Kerr says.

“Over half the lifetime growth and persistence of new pasture is already set in place before the seed even goes into the ground.”

With 30-plus years’ experience, Barenbrug’s pasture specialist says he’s seen too much new grass tip over too soon for want of careful preparation leading up to sowing day.

The good news? You still have about a month to make sure this autumn is your most successful pasture renewal season yet.

“It’s all about planning,” Graham says. “Whether it’s ordering seed early, so you know you’ll get the

cultivars you want, or booking your drilling contractor now to beat the rush, set yourself up for success.

“What often happens is that as soon as conditions are right, everyone wants to sow new pasture

at once and there is huge pressure on the seed supply chain, as well as contractor availability.”

Another key task to tick off this month is tackling any weeds or pests that will jeopardise new pasture establishment.

Greasy cutworm, for example, was ‘dreadful’ this past spring, and could still pose a real risk to autumnsown grass and clover.

Many paddocks destined for new grass will have already been summer cropped as part of the renewal process.

But Graham says the improved dairy payout offers an opportunity to upgrade poor existing pastures too, generating better feed growth and quality in 2025/26.

“Grass to grass renewal is a great way to put yourself on the front foot for next season, rather than having to live with pastures you know are not pulling their weight.

“With the conditions we’ve had this summer, they might be green. But it’s well worth checking how the cows are performing on them to make sure they’re actually growing quality feed, rather than weeds and unpalatable grass species.”

• For more top tops on autumn pasture renewal, including a free pasture health check, contact Barenbrug today.

PETER BURKE peterb@ruralnews.co.nz

AG FIRST chief executive James Allen says dairy farmer optimism is on the rise.

This comes on the back of some very positive financial news about the payout with ASB bank forecasting a milk price of $10.25/kgMS.

Allen says there’s going to be some very strong cash flows this season, all being well, and adds that this may extend into next season. He says interest rates are coming down and inflation appears to be under control.

“So, there is definitely a bounce back and more optimism among farmers,” he says.

In terms of the season, Allen says it’s a bit of a mixed bag. He says Southland had a challenging season and Canterbury is looking pretty strong with some moisture there saving a bit on irrigation. He says Taranaki has been drying out a bit but rain in the past few days has helped the situation.

“Waikato is dry and there is probably an orange flag there. But probably most farmers have got a year’s supply of supplement tucked away and just about all our clients are planning to use that supplement to extend lactation,” he says.

He says overall Northland was getting extremely dry but now it has had a reprieve with recent rain

Meanwhile on the West Coast of the South Island, things are tough according to Fed Farmers local dairy chair Frano Volckman who farms 900 cows at Karamea.

The soils on the West Coast are stoney and need regular rain to

counteract any soil moisture deficit. He says much of the coast had a record wet spring which posed challenges and says they are now well and truly dried out and in much need of rain. To deal with the variable weather, Volckman says many farmers have been dipping into their silage reserves just because of the lack of growth with the heat and dry.

“Hopefully we’ll get a few kind months and can bank some more silage to take through to the winter. But I think people will have dipped well into their reserves which will put a bit of pressure coming into the winter,” he says.

Despite the variable weather, Volckman says milk production levels across the coast have held and people have done a really good job keeping their cows in good condition and feeding them well in order to maintain production.

AS A dairy farmer for 22 years, Michelle Ruddell knows the challenges of navigating through the highs and lows of farming.

And, as the new national chair of Rural Support Trust, she also knows the importance of one-on-one support provided to farmers and growers experiencing tough times.

Ruddell took over the chairmanship in September. She also chairs RST Te Tai Tokerau. She has first-hand experience working with farmers under the pump. She joined the RST in 2018 as an agricultural facilitator. During the Mycoplasma. bovis outbreak, she worked with four affected farmers in Northland. As Northland chair, she was also at the forefront of helping farmers recover after Cyclone Gabrielle hit two years ago.

Ruddell admits being initially daunted when elected as RST national chair.

wai, 30km northwest of Whangarei.

“I feel energised and am looking forward to making a lasting impact.”

MICHELLE RUDDELL and her husband Troy are contract milkers on a 350ha farm.

They milk 800 cows and do split calving – in autumn and spring.

The couple employ two full-time staff. Ruddell looks after the accounts and the calf rearing business while raising their three teenage girls.

Ruddell says life on farm is challenging as “you ride the highs and go pretty low through the lows and dark days”.

She doesn’t think women in the dairy industry give themselves enough credit for what they do.

“I’m immensely proud of all dairy women - the support they provide to family, partners and husbands.

“Some days, it’s easier some days amazing and other days hard.

“You live breath and work under the same roof 24/7.

“There aren’t too many places to hide when things get tough. For me the mental challenge has been hard, switching off from farmer to wife, sometime having to take that stress home.”

strong team.

Rural Support Trust, started as a voluntary grassroots organisation as early as the late 1980s, to help support farmers and has gained increased awareness through its services within rural communities and in particular the one-on-one support provided to farmers and growers.

It has 14 regional selfgoverning branches.

Ruddell admits that funding remains a challenge. While the Ministry for Primary Industries provides some funding, it’s nowhere near meeting RST’s operational costs. It relies on donations and fund raising to make ends meet. “Currently it is hard; it’s great to have some MPI funding but that doesn’t come close to meeting operational costs. To meet the shortfall, regions must fundraise,” she says.

with the national body to secure sponsorships for which Ruddell is grateful.

Ruddell points out that the regional organisations are run by mostly volunteers and rely on inkind donations.

“We are grateful to our volunteers, but the challenge is with our workload increasing, how long can these volunteers carry on.”

within three months.

“The key points will be why Rural Support Trust matters, the value we provide and why we should be funded.”

Another avenue of funding could be other government ministries. Ruddell says there’s a great overlap with what they do in the health and mental health space.

ag facilitators working with farmers and growers has jumped from six to 20. The number of active cases that used to between 35 to 40 two years ago has crept up to 150.

RST.

“We have a very important role in helping with the wellbeing of farmers and growers.

“Our ag facilitators across the region are getting more and more work, they are having to employ more ag facilitators to meet that demand.”

“Through challenging times, we play an integral part in connecting rural people to each other and to the communities.

“At first it was overwhelming, but I quickly pushed the self-doubt to the side. I know I’m capable and have got the ability to lead the organisation,” she told Dairy News on her farm at Pipi-

“Perhaps it’s time to look at other ministries, like health,” she adds.

“So, we play a really pivotal role in that oneon-one support and walk alongside farmers and growers.” SUDESH

The national body has to ensure a sustainable organisation and secure funding to run the 300-

The RST has a close working relationship with Fonterra with a sponsorship manager from the co-op working closely

To address the funding challenge, RST is working with social enterprise The Ākina Foundation to tell its story, which reflects the RST’s importance to farming communities.

Ruddell says the report should be ready

Ruddell is in no doubt that the RST is “absolutely making an impact”.

Case numbers are increasing year-on-year, she points out. In Northland, the number of

Ruddell notes that another reason for the jump in cases is RST’s growing profile.

She says more farmers are now referring someone they know, who needs support, to the

“Another key role has been connecting farmers to rural professionals with specialist skillset for challenges faced, be it financial advice, legal advice, counselling or employment advice.

$10,300

$1,000*

SUDESH KISSUN sudeshk@ruralnews.co.nz

CANTERBURY MILK pro-

cessor Synlait is confident of retaining its farmer supplier base following a turnaround in its financial performance.

Acting chief executive Tim Carter told Dairy News that last week’s announcement of new milk premiums for its South Island farmer suppliers “is a tangible way to show them that we are back on track”.

Carter says the response from farmers has been “very positive”.

The listed company has signalled that it expects half-year earnings before interest, taxes, depreciation, and amortization (EBITDA) to January 31 to be in the range of $58 million to $63 million. Last year the company reported a bottom-line loss of $70m.

To keep its South Island supplier base, many of whom had issued notice of cessation of supply to the company, Synlait has announced new premiums.

Carter says that while “the job is not yet done”, the company has made a good start to recover.

He admits that farmer suppliers want surety that Synlait is here for the long term.

“Since 2000s, we have delivered consistent performance except for last few years.

“Our farmers are rightly asking for surety that we are here for the long term.”

Carter says the positive financial forecast and the new milk premiums go hand-in-hand.

“Without our farmers and their milk, we have no business.”

Synlait says it will pay 10c/kgMS premium to South Island farmers committed to a future with Synlait without a cease notice in place. The premium will be in place for the next three seasons, and paid on top of Synlait’s base milk price and in addition to the incentives for specialty milk and its Lead With Pride programme.

The company will also amend milk supply agreements to enhance cashflow security – guaranteeing, from the current season, an average Synlait milk price that matches the market base milk price, and from next season, to match the market advance rate.

Carter says the Synlait team has worked extremely hard to lift productivity and performance in the past six months.

“The announcement demonstrates the huge progress being made and, while we cannot take our foot off the pedal, we are pleased to announce we expect to return to profitability at our upcoming half year result,” he says.

“Farmers are an important backbone to our business. To further recognise that, we have increased our commitment to existing and new South Island suppli-

ers with additional premiums in place for each of the following three seasons. We are confident this will secure our milk supply which is critical to our future.”

REACTION TO the Government’s major overhaul of the country’s seven crown research organisations has so far been largely positive.

The plan is to merge these into just three entities, to be known as public research organisations (PRO’s).

This will see the creation of a PRO called Bioeconomy which will bring together AgResearch, Manaaki Whenua – Landcare Research, Plant & Food Research and Scion.

The creation of an Earth Sciences PRO will bring together NIWA and GNS and, as already signalled, will see MetService become a whollyowned subsidiary of NIWA.

The former ESR will become the Health and Forensic Science Services PRO with a ‘new’ focus. Finally, a new advanced technology PRO will deliver research, capability, and commercial outreach around advanced technologies such as artificial intelli-

gence, synthetic biology, and quantum. Gone is Callaghan Innovation with the Government saying its functions will be spread among other PRO’s.

A new agency, Invest New Zealand, will be set up as a one-stop-shop for foreign direct investment, to help the Government reach its goal of doubling exports by 2034.

The process and future direction of the new entities will be over-

seen by a new Prime Minister’s science, innovation and technology advisory council. The plan is to have that in place within the new few months with further decisions to be taken on a proposed national IP policy for research and wider incentives for commercialisation, including the operation of technology transfer offices in universities and PRO’s.

Science Minister at the time of the announce-

ment, Judith Collins says the reforms are about maximising value for the $1.2 billion the Government invests in science funding each year. She says they want the new organisations to be adaptable and responsive to government priorities, well-coordinated and avoid unnecessary duplication.

“This work, along with our move to overturn what has effectively been a 30-year ban on gene

technology, will unlock enormous opportunities for our science sector and New Zealanders. The changes are extensive, but they will ensure a science system that generates maximum value for the economy and, therefore, for New Zealanders,” she says.

Legislation creating the reforms is expected to be passed by the end of the year and the new organisations up and running by 2026.

THE CEO of Ag First, James Allen, says it’s not possible to make any detailed assessment of the proposals because the detail has yet to be revealed, but he says he can understand the intent of the proposal.

“What I haven’t seen is any mention of a significant increase in the amount of money for research funding, so I am not clear about what this means for on-farm research.

“There is a clear mandate for the Government around increasing productivity in NZ because that’s what’s going to get the country out its economic hole. So, what this means for on-farm productivity and research around that is what I want to see,” he says.

One of the issues troubling scientists has been the complicated and convoluted bidding process for science funding from MBIE and its predecessor.

Allen says this process soaks up an inordinate amount of time and resources for science managers.

“If the new reforms cuts this down and bring efficiency, that is great, but I suspect that, like all these things, will take time to work through, which begs the question of how long it will take before those efficiencies are gained,” he says.

He says another key factor will be just how agile the new Bioscience PRO will be, given its likely size. James Allen says a lot will depend on who’s leading it and how they can instil a culture of rapid decision making. He says in the business world the catch cry is that the faster an organisation can adapt, the greater its chance of survival.

The CRI’s themselves are supportive of the changes. The convenor of the CRI’s chairs, Kim Wallace, says they are pleased that ESR will keep its current independent status and are happy to see plans to grow something in the ‘big tech’ space.

Wallace says if the changes are done well, they have the potential to enhance the system to create science that will drive NZ’s economic prosperity.

INCREASED FARMER

spending on genetics and animal health has boosted LIC’s half-year profit.

The farmer co-operative posted a net profit after tax of $39 million for six months ending November 30, up 35% over the previous year.

Total revenue rose 8% to $185m. The co-op has also signalled a full-year underlying earnings range of $18m to $22m.

It says the improved results can be attributed to improved economic conditions and farmers choosing to invest in LIC’s products and services like fresh sexed semen, GeneMark Genomics and animal health testing.

LIC board chair Corrigan Sowman expressed pride in the co-operative’s progress, saying,

LIC IS evaluating its strategy to ensure alignment with farmers’ needs and future opportunities.

“To continue delivering for our farmer shareholders, we are revisiting our strategy to ensure it is fit for purpose,” says chief executive David Chin.

“This includes planning for future investments that benefit our farmers. We’ll share updates on this work in the first half of 2025.”

“I am incredibly pleased to see farmers continue to recognise the value of investing in productive herds and resilient farms.

“As a generational co-operative and world leader in pasture-based dairy herd improvement, we will continue to work alongside farmers to improve the profitability and efficiency of the national dairy herd.

As your board chair, I look forward to working with the LIC board and management to continue

delivering value for our farmer shareholders.”

Reflecting on the first half of the financial year, LIC chief executive David Chin noted that the cooperative’s investments are delivering tangible outcomes for farmers.

“We are making significant progress toward breeding cows with lower methane emissions,” Chin says.

“Our research (funded by the New Zealand Agricultural Greenhouse Gas Research Centre) has

confirmed that genetic variation influences how much methane heifers produce.

“We are now one step closer to breeding lowemission cows.

“The next step is the building of a state-ofthe-art research barn to enable large-scale monitoring of lactating cows.

We are proud to contribute to emissions reductions and look forward to offering farmers low methane-emitting genetics soon.”

In addition to methane research, LIC continues to lead in herd improvement through its genomic evaluation tools.

“The launch of our

new Genomic product in July 2024 has seen significant uptake from farmers,” Chin says.

“We’ve now surpassed a major milestone, genotyping over 1 million animals. This milestone reflects the growing trust farmers place in these tools to help accelerate the genetic gain in their herds.”

LIC’s commitment to operational excellence has also delivered outstanding results for the fresh sexed semen product.

“The performance of our fresh sexed semen product has exceeded expectations, with 18-24 day non-return rates now within 1% of conventional fresh semen,” says Chin.

“This allows farmers to achieve even better results by breeding from their highest-performing cows.”

Farmers’ focus on herd health is also evident, as demonstrated by a significant increase in Johnes Disease testing. Testing rates have doubled in the first six months of the season compared to 2023, reflecting a growing focus on disease management.

DONALD TRUMP may fancy, and like to get, a Nobel prize for peace, but his chances of getting one for history is mission impossible.

This was after Trump claimed it was an American who first split the atom. Sorry Donald old boy, any kiwi who has seen a $NZ100 bill will recognise the face of Lord Ernest Rutherford of Nelson on the front, and it was he who first split the atom in 1917 at Manchester University. Rutherford was born in Brightwater near Nelson, quite a few km’s from the US of A. Oh and by the way, he won the Nobel prize for chemistry.

Next Trump will claim Phar Lap as a great American racehorse or claim a US citizen invented the pavlova.

A MATE of Milking It’s was recently walking down the main street of the hub of the Horowhenua, Levin, when he saw a ‘pop up shop’ designed to show locals the new toll road bypass from Otaki and past Levin.

Being a tad curious, he started to read the signage in the window, which has been there apparently for several months.

Great idea, they thought, but pity about the spelling. NZTA (Waka Kotahi) states that work is due to “STARRT in 2025”. It seems that despite having a colony of ‘comms’ people in NZTA, none can use spell-check or proofread.

Maybe Transport Minister, Chris Bishop, needs to get his CEO to employ an official spellchecker so we don’t see signs in the future that read “Bee wear – rode werks a hed” .

THE FATE of methane inhibitor Bovaer in NZ farming is still up in the air.

While many countries, including Australia, have approved the use of the feed additive, authorities in NZ are still grappling with allowing NZ dairy farmers to use it.

Controversy erupted just before Christmas, when BBC’s Inside Science podcast reported on a social media backlash to well-known brands of milk, butter and cheese sold at major United Kingdom supermarkets, produced using milk from lower-methane cows.

After false rumours Fonterra was using the product, the dairy giant tweeted last month that food safety and quality were its “number one priority” and that Bovaer had not been approved for use on New Zealand farms.

Back in business?

IS CANTERBURY milk processor Synlait back in business?

After announcing a turnaround in its financial performance, the listed company recorded a 50% rise its share price - from 40c to 60c.

However, it’s worth noting that one year ago, Synlait’s share price was around 80c and two years ago around $3.50/share.

So, the jury is still out on whether Synlait can regain the confidence of investors and of its farmer suppliers, most of whom had earlier indicated their desire to withdraw supply in two years.

WILL THE latest science reforms make the difference that the government hopes?

In theory the idea of merging the ag related science institutes into one conglomerate has merit. Will this avoid duplication? – one hopes so. Will the money given to the new PRO be better spent and will it result in reduced overheads? – again in theory yes or is that a maybe?

There are some good aspects to the reforms including removing the ban on gene technology and setting up an organisation to get more investment into the science sector. While the narrative around the announcement has a good feel about it, its actions not words that will determine success and we have yet to be told what this restructuring will cost. We have also got to get proof that the system will be streamlined so that scientists don’t spend days writing up bids for money for their projects. The present system according to many scientists’ reeks of unnecessary bureaucratic complexity. Many CRI’s have whole departments dedicated to dealing with bids for what sometimes is for small sums of money. So why wasn’t MBIE, the science funder reviewed at the same time?

Science is the key to the success of our primary sector and it’s adoption by farmers, growers and supporting industries. That can only happen when the science is communicated well and made relevant to them. Back in the 1970’s and 80’s NZ this was very good at this, but over time the close connection between farmers and industry and scientists has somewhat faded.

The late Professor Alan MacDiarmid, who won the Nobel prize for chemistry, once told me that there was no point in doing science unless it is communicated properly. Will these reforms deliver that – who knows?

– Peter Burke

• Peter is the founder and life member of Science Communicators Association of NZ and has worked as a journalist in the primary and science sectors for more than 50 years

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

by: Rural News Group Printed by: Inkwise NZ Ltd Contacts: Editorial: sudeshk@ruralnews.co.nz

Advertising material: davef@ruralnews.co.nz

Rural News on-line: www.ruralnews.co.nz

Subscriptions: subsrndn@ruralnews.co.nz

Publisher: Brian Hight Ph 09-307 0399

General Manager: Adam Fricker Ph 021-842 226

Editor: Sudesh Kissun Ph 021-963 177

Machinery Editor: Mark Daniel Ph 021-906 723 markd@ruralnews.co.nz

Reporters: Peter Burke Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech Ph 021-190 3144

Production: Dave Ferguson Ph 027-272 5372

Becky Williams Ph 021-100 4831

Digital Strategist: Jessica Marshall Ph 021 0232 6446

AUCKLAND SALES CONTACT: Stephen Pollard Ph 021-963 166 stephenp@ruralnews.co.nz

WAIKATO & WELLINGTON SALES CONTACT: Lisa Wise Ph 027-369 9218 lisaw@ruralnews.co.nz

SOUTH ISLAND SALES REPRESENTATIVE: Kaye Sutherland Ph 021-221 1994 kayes@ruralnews.co.nz

WELCOME TO the

second annual NZ Dairy Expo at Matamata – an event created to bring together the best of the New Zealand dairy industry in a focused, grassroots environment where dairy farmers and rural professionals can meet, talk, compare products, and make smart decisions for their farms.

Born out of need, the Covid-19 pandemic made overseas labour harder to come by, so dairy farmers turned increasingly to automation and technology to simplify systems and reduce costs. This highlighted the importance of creating an event where motivated farmers could directly engage with businesses offering the latest tools, technology, and solutions.

Register and attend the New Zealand Dairy Expo to win a Milwaukee M18 Cordless Grease Gun Starter Kit.

What: NZ Dairy Expo

When: February 11th and 12th, 2025 Where: Bedford Park, Matamata

Time: 8.30am to 3pm

Register on website: nzdairyexpo.co.nz Entry is free!

Unlike regional and national field days, the NZ Dairy Expo is specifically for dairy farmers, where every exhibitor has something valuable to offer, whether it’s innovative technology, quality infrastructure, or essential services or advice. We keep it free for farmers, without unnecessary cost but with a key focus, so you won’t find container loads of lifestyle products or unrelated goods here.

This event is proudly

run by a small team of people who are passionate about supporting NZ’s dairy sector whose key aim is to create a meaningful Expo, not make a profit. We don’t take sponsorship from big corporates because we believe in maintaining our independence, allowing us to steer the event in a direction that best serves the industry, without any external influence.

Hosted at Bedford

Park, the home of the UMS Rugby Club, it’s our way of giving back to the local community, supporting junior rugby, and helping sustain the club itself.

Running from 8:30am to 3:00pm on Tuesday 11th and Wednesday 12th February, the timing is scheduled to fit between milkings, so you can attend without disrupting busy schedules.

While registration isn’t mandatory, we encourage you to sign up online in advance so we can ensure there are enough amenities

for everyone. Signing up online at www.dairyexpo. co.nz or on arrival at the gate offers visitors the chance to win and to take home a daily prize of a Milwaukee M18 Cordless Grease Gun and starter pack.

With over 120 exhibitors spread across more than two hectares, we recommend allowing yourself 3 to 4 hours to fully explore the Expo. We’ve encouraged our exhibitors to focus on what really matters,

from bringing their best people, offering straightforward, practical solutions, without the need to spend a fortune on site fit-outs.

Whether you’re here to learn, network, or find a solution, we hope you

enjoy your time at the Expo. Thank you for supporting an event that’s by the industry, for the industry.

We hope to see you around the grounds!

• Amanda Hodgson is the owner of NZ Dairy Expo

DAIRY AND beef farmers

could be eligible for lower interest lending options for financing Halter on their farms, with ANZ, ASB and BNZ now offering a pathway to sustainability loans for New Zealand’s largest virtual fencing provider.

The lending options provide a potential opportunity for greater affordability and access to Halter’s virtual fencing system used by hundreds of farmers and are open to existing and prospective Halter customers who meet eligibility, lending and identification criteria.

The banks’ preferential rates are based on: ANZ’s business green loan floating rates, ASB’s special purpose base rate and BNZ’s reduced floating and fixed rates, tailored to individual clients.

Halter notes that products/rates are subject to change. Lending and eligibility criteria, terms, conditions, and fees may apply.

Farmers also receive a 10% discount from Halter for paying 2-years up front via the sustainability loans, with the flexibility of monthly repayments.

For example, compared to average term loan lending rates, a typical 500 herd dairy farm could save up to $4,700 across two years through a lower interest sustainability loan and Halter discount. This example, for demonstration purposes only, is based on a 6.15% interest rate and 10% Halter discount for 2-year upfront payment terms.

“These offerings unlock pathways to sustainable lending across

the lion’s share of rural lenders and is another step towards helping Halter farmers run more productive, sustainable and resilient farms,” says Halter partnerships man ager Steve Crowhurst.

“As well as driving farm performance and profitability, Halter is a tool that helps farmers easily deploy sustainable farming practices out lined by industry bodies. Halter incorporates vir tual fencing and herd ing, precision pasture management, and animal health and location moni toring.”

Halter farmers are advancing their sus tainability outcomes by reducing fuel through less farm vehicle use (some by up to 47%), increas ing pasture harvest and therefore reducing the need for supplements, and reducing nitrogen via more strategic application informed by cow loca tion data.

They can also improve

fertility which reduces the number of heifer replacements needed on farm and therefore overall farm emissions.

Halter’s virtual

ity and bandwidth to farm in a way that mitigates impact on the environment.”

Halter farmers are achieving financial gains by generating more milk in the vat and the potential to achieve better live weight gains.

Farmers interested in these sustainability loans can visit www.HalterHQ. com/financing or speak to their bank’s relationship manager.

Farmers banking with Westpac and Rabobank can also reach out to their relationship manager for alternative lending options for Halter services.

@dairy_news

PASTURE RENEWAL is the process of replacing older, less productive pastures with a completely new pasture.

Often this is taking the worst or most underperforming paddock on the farm and attempting to make them the highest performing. To achieve this, several checks need to be made to get a successful pasture renewal result.

According to Agricom, the most important is to identify the reason for the paddock underperforming to start with:

Checking the paddock fertility

Identifying issues of drainage or compaction

Identifying the weed and weed grass species limiting productivity

Identifying the insect pests that mostly influence your pasture pro-

duction and persistence

Agricom says this process will identify whether you can do a double spray grass-to-grass programme or whether you require a cropping rotation to reach your end goal of a productive persistent pasture.

“Replacing poor producing paddocks with new pasture is one of the simplest ways to invest on farm for a significant and relatively predictable return. The higher your farm’s performance, the more it can gain from intensified pasture renewal. And it isn’t only for ‘high input’ farms - any kind of farm or grazing-based business can benefit from pasture renewal.”

New pasture is much more productive, says Agricom. Most pastures deteriorate from a

number of causes - weed invasion, particularly low quality grasses like paspalum and Mercer grass, dry conditions, wet/ flooding, poor fertility, poor drainage, diseases, insects, pugging, soil compaction, overgrazing and poor management.

Over time, the population of desirable, productive plants in a pasture declines, while undesirable or unproductive plants increase and pastures become ‘runout’. Old pastures produce less drymatter, are lower in metabolisable energy (ME) and have reduced stock performance. This

decline compounds as the pasture ages.

Successful pasture renewal can increase DM/ ha/year by around 3–6 tonnes. This is true for all farms – the extent to which the extra production can be converted into additional income varies.

According to DairyNZ, renewing pasture is crucial for maintaining healthy dairy farms, and there are four primary methods to consider: cultivation, spray-drilling, undersowing, and oversowing. Each method has its pros and cons, with factors like cost, time, and specific pas-

THE CORRECT rate of pasture renewal for a farm varies depending on the state of the pastures, and the goals of the operation.

Barenbrug covers how to assess pasture performance across a farm and plan accordingly.

Rate of renewal

Pasture renewal programmes vary widely across NZ, ranging from 0% to over 30% of the farm area each year.

Dairy farm renewal averages about 8% compared to 2-5% on sheep farms. The percentage of a farm renewed also determines how long a pasture must last, for example a 5% rate of renewal means a pasture must last 20 years.

Benefit of renewal

The benefit of new pasture is the gains it will deliver over existing pasture.

So it’s important to estimate the current pasture performance versus potential.

Pasture growth varies widely be -

ture conditions influencing the choice of renewal approach.

DairyNZ advises farmers to choose the method that aligns with their farm’s needs and conditions.

There are four main ways to renew pasture, cultivation, spray-drilling, undersowing and oversowing.

Cultivation

Involves breaking up the soil prior to sowing with the likes of a plough, power harrow, discs or rotocrumbler. It is necessary where there is a need to eliminate compaction or levelling, or lime incorporation is required.

Advantages

■ Most consistent results

■ Eliminates compaction

■ Best pest & weed control

■ Can level paddock

■ Can incorporate lime

■ Allows good soil coverage by seed

Disadvantages

■ Most expensive method

■ Slower to first grazing (6-10 weeks)

■ Softer and more prone to pugging during establishment

Spray and drill

A direct-drill is used to sow treated seed into an uncultivated paddock after existing pasture killed by herbicide.

Advantages

■ Herbicide controls competition

■ Less expensive and less time consuming than cultivation

tween individual paddocks across every farm. On flat farms there is typically a 100% difference in DM yield between best and worst paddocks. This difference is much higher on hill country properties.

Growth differences between dairy paddocks of 6 t DM/ha are common. This means under-performing paddocks may produce 300 kg MS/ha less than better ones (based on 75% utilisation and 15 kg DM/kg MS conversion).

Measuring paddock performance

Comparing the performance of individual paddocks allows you to quantify the potential gains of pasture renewal on the farm.

The best paddocks show what can be achieved, with the difference between those and the worst illustrating the potential for improvement, provided paddocks share similar topography and soil type.

■ Quicker to first grazing (6 weeks)

■ White clover establishment is possible (see below)

■ Long term solution

Disadvantages

■ Less opportunity to correct pH

■ Won’t fix soil compaction or level paddock

■ May revert to old pasture more quickly than cultivated paddocks

■ Two drill passes at half the seeding rate are desirable to achieve dense pasture

■ Loss of pasture production after spraying White clover establishment (after killing existing pasture) Drill ryegrass using

the main-seed box. Drop white clover seed onto the soil surface from the small-seeds box in front of coulters sowing the ryegrass. Cover seed with a brush or bar harrow.

Undersowing

Use a direct-drill to sow treated seed into existing pasture. Works very well in the narrow window of time when a pasture has thinned out but has not yet been overtaken by weed ingression. Use after extended dry conditions where large areas need to be sown, or after winter pugging damage. Results are variable where it’s used in pastures too dense for

the new seedlings to establish well.

Advantages

■ Cheap and simple

■ Allows large areas to be done

■ Italian or hybrid can boost winter-early spring growth

Disadvantages

■ Doesn’t work in dense pastures

■ Doesn’t control problem weeds

■ Not suitable for white clover establishment

■ Usually only a temporary fix

Oversowing

Treated seed is broadcasted on to the surface of the soil.

Generally used to repair smaller areas, for

example after pugging damage, or to establish white clover in spring into pastures where the land is too steep or stony for cultivation.

Not recommended for improvement of lowland pastures due to high seeding mortality.

Sowing rates are generally higher, as establish-

ment rates of seed placed on the ground surface are lower.

Advantages

■ Can introduce legumes & N fixation

■ Can apply with fertiliser

Disadvantages

■ Variable results

■ Hard to control competition

DEPENDING ON your perspective, dairy farming brings with it the joys or problem of dealing with animal waste, be it liquid slurries or more solid manures.

With the growing cost of synthetic fertilisers slashing bottom lines, the use of natural manures can help augment soil fertility and make a positive financial impact.

FarmChief imports and distributes the UKbuilt West Dual Muck Spreader, a watertight, side-discharge machine that offers the benefits of being able to spread liquid slurries or heavy, solid farmyard manures and all grades of product in between.

Featuring a heavy-duty

tub design, the five-model range offers capacities of 5.9 to 13.6 cubic metres, with tare weights of three to five tonnes, with horsepower requirements of around 70 to 130hp.

At the heart of the

•

•

machine, in the base of the tub, a heavy-duty auger, mounted on an 80mm diameter shaft sitting on long-lasting bushes, rotating at 10rpm, serves to keep the manure agitated and

moving towards the front of the machine.

At the forward end of the rotor, close-coupled impellors ensure a smooth flow of material to a side-mounted, underslung, rigid impel-

lor, rotating at 500rpm, that creates an even spread. During operation, a mechanically driven, continuously oscillating side plate helps stop any bridging or stopping of material as it moves for-

ward. Designed to disperse the material in a fine spread pattern of up to 21m, depending on material, the discharge rotor features reversible and replaceable tips to ensure a long service life.

At the discharge point, a hydraulically adjustable guillotine door allows accurate control of spreading rate, while the spreading rotor is complemented by a springloaded lower housing to pass without damaging the machine.

The main driveline is protected from overload by a shear-bolt on the input shaft.

A low centre of gravity and large flotation tyres mean the load is spread evenly, helping to reduce ground compaction in the paddock, while also improving the towing experience on both the road and on rolling country. Given the overall weight of the loaded unit, hydraulic brakes are fitted standard for safe stopping a control.

Visit Farmchief at site number 8.

MAKING FARMING easy is what the TechniPharm team says it lives for.

With a 35-year reputation in the market pace, the company says their products solutions are innovative and well proven.

One of their innovations, the Dungbuster Auto yard cleaning system, is now employed at many dairy sheds around the country. And when it comes to measuring productivity improvements, Dungbuster is at the top of the list, the company says.

With most yards taking between one to two hours a day to clean by manual yard hose, it’s a “labour sucker”.

“With Dungbuster this time requirement is eliminated: That is not a 100% productivity improvement or a 1000% improvement, it’s an eliminating improvement.

“Freeing up time for far more important jobs or creating more time to recharge for the day ahead, or an evening game or outing with the family.

“Additional benefits amount to reduced water use, reduced effluent creation, reduced power use, and reduced greenhouse gasses. All in all the investment in Dungbuster delivers and continues to deliver day after day.”

Technipham points out that one of their long term users of Dunbustger has described it ‘as a game changer on my farm’.

Talk to the TechniPharm team on site 17 at Dairy Expo and inspect their other Make Farming Ezy solutions in hoofcare, animal handling, yards, effluent storage and general tools and aids.

PRIMARY ITO has a wide range of work-based training options to help you grow the skills and knowledge of your staff in 2025.

Our team and I will be at the Dairy Expo to talk you through the options, from entry level skills to micro-credentials (bitesized pieces of learning), apprenticeships, and more. We’d be delighted to share what’s involved and help identify the best options for your team.

This year is the perfect time to train your staff, with several exciting initiatives available now at 50% off fees in 2025 The popular 50% off fees for agriculture training has been extended into 2025. This is available for our NZ Certificates (Level 3 and 4).

In the face of ongoing cost pressures on farmers, this offer aims to help make training more accessible for all. We look forward to seeing even more of you take advantage of this fantastic offer this year.

Apprenticeship Boost payment for employers

The Government has extended the Apprenticeship Boost payment into 2025, with up to $6,000 available for agriculture employers with first-year apprentices.

This is excellent news for employers looking to take on, train and retain new workers.

The payment of $500 a month from Work and

Income is only for firstyear apprentices. It recognises the time and effort made by employers taking on new staff, and the value that workbased training adds to a business.

Short courses for all visa holders

Primary ITO has launched two new dairy short courses that provide affordable and flexible options for all dairy staff, no matter their visa or residency status.

The Dairy Basics: Milking course covers key knowledge in milking and dairy plant hygiene. This includes describing and reporting on milking problems, risks to on-farm milk quality, and how to prevent and implement solutions to milk quality problems.

The Dairy Basics: Effluent course provides knowledge on effluent

management at all stages, from production to storage and spreading. It also covers monitoring a dairy effluent management system.

Developed in response to industry demand, both courses are suitable for farm assistants and relief or experienced milkers who want to develop or refresh their knowledge. They are available any time of year.

Learners will take part in one or two short offjob workshops, where they will complete a workbook, engage in interactive activities to put theory into practice, and share knowledge and

experiences with other course participants. These courses are non-formal, meaning learners will not complete any formal assessment. They will receive a certificate of attendance upon completion. Each course has a similar level of content to a Level 3 programme.

Find information on all of these exciting initiatives on our website (primaryito.ac.nz). Or come and chat to our friendly team at the Dairy Expo –site 25. We look forward to seeing you there!

• Marianne Awburn is sector manager for agriculture for Primary ITO.

PRECISION SLURRY

says they are effluent application specialists who pride themselves in

leading the way in cleaning out any system –fully utilising the nutrients often seen as a

problem on farms.

Owner operators Glen Crafar, his wife Paula, and Robert Crafar have

been farming their whole lives and have a wealth of experience in how to stir

and spread the most difficult of jobs.

Based in Reporoa and

servicing the Central Plateau, Bay of Plenty and South Waikato, Precision Slurry has a full range of specialised equipment to tackle any job:

■ Lined and unlined ponds

■ Above ground tanks

■ Bladders

■ Weeping walls

■ Sumps

The modern fleet is well equipped with GPS systems, application rate control and proof of placement. Nutrient analysis is also available.

Precision Slurry says customers are pleasantly surprised, commenting ‘l didn’t know the pond

was that deep’ or ‘I didn’t think you’d get it that empty’.

It says the slurry that’s spread is rocket fuel for grass growth, often transforming weaker paddocks to strong ones.

“Effluent is hundreds of tonnes of fertiliser which is already on farm, that just needs to be well stirred and spread onto the land so it can start producing more feed.

“In most cases the fertiliser value outweighs the cost of applying it, not to mention the operational benefits of having a de-sludged effluent system.”

ECOBAG™ is fully contained so you are fully covered for unwanted added rain water and objects which “may get into the pond” No issues with liner gas bubbles as this system is fully contained and gas can escape trough the sides.

Less or no evaporation of valuable N, almost no smell and no crusting ever.

System includes

for

FOR OVER 40 years, Williams Engineering has been trusted by farmers across New Zealand and beyond to deliver simple, reliable, and cost-effective effluent solutions that make farm life easier.

With decades of experience, we’ve built a trusted network of dealers in New Zealand and beyond to ensure farmers benefit from practical effluent solutions that save time and reduce your workload over the long-term.

At Williams Effluent Solutions, we understand that every farm is unique, so our team works closely with customers to create a customised system that supports a farm’s productivity, while ensuring regulatory compliance and environmental sustainability guidelines are fully met.

Our goal is to help implement a solution that reduces stress and keeps an operation running smoothly, without relying on extra labour.

Our services include effluent system design and compliance, on-farm installation and servicing, concrete infrastructure and manufactured products –so are you ready for peace of mind with a reliable effluent system?

-Supplied by Williams Engineering

EFFLUENT IS a valuable source of nutrients.

Good effluent management on a dairy farm not only saves on fertiliser costs and enhances soil health but also helps prevent animal health problems associated with high potassium levels in the soil.

Good effluent management is also important to ensure compliance with the relevant regional plan rules, which are in place to protect the health of ground water and surface water.

Effluent must only be applied at a rate suitable for the soil conditions. Any ponding of effluent on the land surface following application is

unlawful. It is important that you know how much the irrigator is applying, adjust application rates according to soil conditions and know how concentrated the effluent is.

Effluent storage facility should also be correctly sized for individual farm system and management. The Dairy Effluent Storage Calculator (DESC), from DairyNZ, is an excellent tool for determining the volume of storage required for farm dairy effluent system. Accredited Effluent System Designers and Dairy Effluent WOF assessors can assist in ensuring this calculation is accurate and appropriate for the farming

operation. They can also provide suggestions on where system efficiencies

can be improved. Having adequate storage means that a farm:

■ Can defer irrigation in wet weather when soil conditions are unsuit-

able to irrigate.

■ Lower the risk of effluent ponding, runoff and leaching to groundwater in wet weather.

■ Have the ability to irrigate effluent when plant uptake is maximised.

■ Can store effluent during mechanical breakdown.

■ Can defer irrigation during busy times e.g. calving.

■ Increasing your effluent application area means that a farm can:

■ Spread nutrients further, reducing fertiliser requirements and associated costs.

■ Slow the build-up of potassium in effluent

paddocks which can lead to animal health problems.

■ Have more flexibility in grazing around effluent applications and safer withholding periods prior to grazing.

Waikato Regional Council encourages farmers to develop an effluent management plan (EMP) for their particular farm. To get value from the EMP it should be tailored to the farm effluent system, farming operation and resources. All farm staff should be inducted and trained in operating the farm effluent system and understand the content of the EMP.

Precision Slurry customers always comment “l didn’t know the pond was that deep” or “I didn’t think you’d get it that empty” and the slurry that’s spread is rocket fuel for grass growth often transforming weaker paddocks to strong ones. Call now for a free consultation 027-4716 199 Check out what we can do at www.precisionslurry.co.nz

Precision Slurry are effluent application specialists who pride themselves in leading the way in cleaning out any system - fully utilising the nutrients often seen as a problem on farms. Owner operators Glen, Paula (Glen’s wife) and Robert Crafar have been farming their whole lives and have a wealth of experience in how to stir and spread the most difficult of jobs. Based in Reporoa and servicing the Central Plateau, Bay of Plenty and South Waikato Precision Slurry has a full range of specialised equipment to tackle any job whether it be: • Lined and unlined ponds • Above ground tanks • Bladders • Weeping walls • Sumps. The modern fleet is well equipped with gps systems, application rate control and proof of placement. Nutrient analysis is also available.

Effluent is 100’s of tonnes of fertiliser which is already on farm that just needs to be well stirred and spread onto the land so it can start producing more feed. ‘In most cases the fertiliser value out weighs the cost of applying it not to mention the operational benefits of having a de-sludged effluent system.’

FOR OVER 20 years

Advantage Plastics has been manufacturing and supplying New Zealandwide a large range of onfarm storage & handling equipment.

From storage silos, portable hoppers to feeders, to name a few, all products are manufactured from polyethylene, the benefits of which have been proven and

tested on the largest farms throughout New Zealand.

With a recent increased range of products for the dairy industry, which included a

large range of calf meal equipment, the company says it is to make your life on farm easier and more efficient.

“Always keen to listen to feedback and having manufactured customised solutions for years, we saw an opportunity with several of our customers to utilise our Smart Stakkas into a feed out trailer, with an unloading auger that could be operated from your vehicle, side by or quad bike.

“This would help a lot on farm, especially when feeding out into troughs, by removing the need for back braking work of manhandling bags etc.”

This has resulted in a 1-tonne feedout trailer, released last year. With many improvements over

time, the company says it has become the ultimate solution needed on farm, proven by many, saving time and money. Key features include a heavy duty trailer which is hot dipped galvanised, 5-inch foldaway auger that reduces the unit’s overall width making it safer for transport, it is fast discharging, it has a slide gate to reduce flow if needed, and remote on/ off switch which allows ease of use from a distance and means the operator is kept safe. Designed to be powered by a portable generator, the feedout trailer can be used for several applications, making it a worthwhile investment. Visit site number 35 or www.advantageplastics. co.nz

DTS, NEW Zealand’s leading manufacturer of stainless steel vats and refrigeration technologies, is spearheading a groundbreaking initiative to phase out R404A refrigerant gas, a major contributor to greenhouse gas emissions.

Long used in dairy, horticulture, and commercial cooling systems, R404A is known for its high global warming potential (GWP) of 3922 and skyrocketing costs. DTS is replacing it with R449A, a more environmentally friendly and energy-efficient alternative with a GWP of just 1397 – one-third that of R404A.

Luke Walker, DTS national sales and service manager, explains the rationale behind the initiative.

“Many producers

don’t realise the environmental and financial impact of their refrigerant until a leak occurs and they’re hit with an expensive re-gassing bill,” says Walker.

“By swapping R404A for R449A, we’re not only reducing costs but also making a significant positive impact on the environment.”

The swap-out is part of DTS’s proactive service contracts and is designed to be seamless and costneutral. The transition requires minimal adjustments, such as a valve replacement in some systems, and poses no additional operating risks. DTS says R449A not only reduces environmental harm but also improves energy efficiency by up to 10%, which translates to lower power consumption and further emis-

sion reductions. Farmers like Cam Lewis, a fourthgeneration steward of the Dunoon property in Foxton, are embracing the initiative.

“This decision was an absolute no-brainer,” says Lewis. “For us, it’s about

balancing environmental responsibility with financial practicality. The swap ticks all the boxes—it’s seamless, cost-neutral, and reduces our exposure to the soaring costs of R404A.”

DTS says its com-

mitment to sustainability goes beyond simple replacements. The company has already extracted four tonnes of R404A from New Zealand’s cooling systems in the first year of its campaign. This equates

to preventing 10,000 tonnes of CO₂e emissions—equivalent to the emissions from driving a diesel vehicle 60 million kilometres. With around 700 tonnes of R404A still circulating in New Zealand’s refrigerated food chain, DTS aims to remove at least another four tonnes in the coming year.

Gavin Thwaites, CEO of DTS, highlights the broader implications of the initiative.

“The transition away from harmful refrigerants like R404A is a critical step for a sustainable future. Every reduction counts, and we’re committed to helping New Zealand producers make this change efficiently and responsibly.”

Beyond the immediate benefits of the swap, DTS is exploring partnerships

with government and industry players to accelerate the transition. The company is also investing in new technologies and manufacturing practices to reduce reliance on harmful hydrocarbon gases across the dairy and cold food chain sectors.

As Walker concludes, “DTS is more than a manufacturer—we’re problem-solvers and innovators. Our mission is to help New Zealand producers build sustainable, efficient operations that align with the environmental challenges of today and tomorrow.”

DTS’s initiative reflects its commitment to leadership in innovation and sustainability, setting a benchmark for New Zealand’s refrigeration and agribusiness sectors while paving the way for a greener future.

WAIKATO-BASED

Owner Damian Silvester says they are committed to providing practical solutions to keep businesses running smoothly.

“Our services go well beyond basic electrical work – we are here to solve the problems that can bring a farm to a halt,” he told Dairy News.

The company’s expertise includes setting up and maintaining advanced milking systems, ensuring that every component from the vacuum pump to the rotary platform operates at peak efficiency. This includes upgrading old systems to reduce electricity costs, resulting in reduced downtime, alongside improved milk quality and yield.

“We understand that

“We are here to solve the problems that can bring a farm to a halt.”

every dairy farm is different, so we can tailor solutions to the specific needs of each operation.

“Whether it’s maintaining your existing set up or simplifying plant start-up processes for relief staff so you can get off the farm, or even adapting equipment for your farm’s layout, we bring a deep understanding of dairy farming to every situation. We also can integrate smart technology for remote mon-

itoring and work with HALO Monitoring Systems to provide customised water and effluent management solutions.”

Silvester says downtime on a dairy farm can be costly, so they offer 24/7 service to address issues quickly, which in turn helps ensure milk production continues without interruption.

In the event of a power outage, the company uses its trailermounted CAT generator, “Jenny” to get things back on track.

The company also help farms reduce their energy costs through practical advice and solutions, from upgrading to LED lighting to exploring solar power options for more sustainability.

PPP INDUSTRIES Ltd, established in 1962, is a leading supplier of agricultural equipment in New Zealand.

The company also exports products to over 20 countries.

PPP specialises in dairy shed feed systems for both herringbone and rotary sheds for milking cows, goats, and sheep.

In addition to robust feed systems, the company offers a variety of silo sizes, as well as milling and storage options.

PPP developed & designed and then installed the first in-shed feed system in New Zealand in 1967. Since this first installation PPP have constantly updated systems to meet farmers requirements coupled with advances in technology.

As feed types that farmers use with their in-shed feeding have changed, PPP has developed a system that can easily handle difficult products such as palm kernel expeller (PKE).

Benefits of in-shed feed systems are many.

It saves time: cows are fed whilst being milked. Wastage compared to paddock meal feeding is zero.

It helps mitigate erratic weather patterns and their potential to disrupt pastures and subsequently milk solid production, with a flick of a switch or a pull of a lever.

Animals can receive a nutritious complement of minerals & additives and repairs & maintenance are minimal.

PPP has a large team of agents offering nationwide back up support for service and parts.

PPP also offers a range of silos sizes. PPP has been installing effluent separators since 2002; these systems have been used on dairy and pig farmers, as well as to truck wash stations and the meatworks.

In 2013, PPP began to import and supply to NZ farmers grass and maize silage inoculant.

The inoculant has been developed in the US and, at a very competitive price, it has helped many farmers in the North and South Island.

IN THE ever-evolving landscape of dairy farming, the quest for optimal nutrition is paramount.

For New Zealand dairy farmers, the choice of feed can significantly impact the health and productivity of their herds.

Among the various options available, pelletised dairy rations stand out as a superior choice. In this article we look at why you might consider opting for pellets.

Consistency

Pelletised dairy rations offer a level of consistency that other feed types are hard-pressed to beat. Each pellet is formulated to contain a balanced mix of nutrients, which means that every cow receives exactly the same high-quality diet. This uniformity can go some distance towards

helping maintain the herd health and productivity, as there are no variations in the nutrient intake that could lead to deficiencies or imbalances.

Digestibility

The process of pelletising feed involves grinding the ingredients to a fine powder before compressing them into pellets. This increases the surface area of the feed, making it easier for cows to digest and absorb the nutrients. Improved digestibility means that cows can extract more energy and nutrients from the same amount of feed, leading to better overall health and milk production.

Less waste, easier to handle

Pelletised feeds are also less prone to wastage compared with loose feeds. The compact nature of pellets means

they are less likely to be blown away by the wind or trampled underfoot. This not only ensures that more of the feed is consumed by the cows, but also helps reduce the overall feed costs for farmers. Pelletised dairy rations are also easy to handle and store. They take up less space and

can be stored for long periods without spoiling (provided they are kept dry). In a country with such varied terrain and climate – and the logistical challenges they bring – this convenience is of particular benefit.

Better feed conversion ratios

Studies have shown

that cows fed pelletised rations tend to have better feed conversion ratios. This means they produce more milk per unit of feed consumed compared to cows on alternate feeds. Improved feed efficiency translates to higher profitability for farmers, as they can achieve greater milk

yields without increasing their feed costs.

Precise & eco

Pelletised feeds can also contribute to more sustainable farming practices. The precision in formulation means that there is less likelihood of overfeeding or underfeeding, which can lead to nutrient runoff and envi-

ronmental pollution. By optimising the nutrient intake of cows, farmers can reduce their environmental footprint and promote more sustainable dairy farming practices.

In conclusion, pelletised dairy rations offer numerous advantages over alternate feeds for New Zealand dairy cows. Their consistency, enhanced digestibility, reduced waste, convenience, improved feed efficiency, and environmental benefits make them a superior choice for modern dairy farming. By adopting pelletised feeds, New Zealand dairy farmers can help safeguard the health and productivity of their herds while also promoting sustainable farming practices.

*Article supplied by CopRice @dairy_news facebook.com/dairynews

A RISING somatic cell count (SCC) today can mean lower profits tomorrow.

With this season’s payout, this could mean lower milk volumes and higher costs that leave farmers out of pocket.

DairySmart says it uses AI to help farmers tackle mastitis by identifying pathogens, providing precise detection, and sustainable solutions. This reduces economic pressures and improves herd health, enhancing farmers’ bottom lines.

In New Zealand, the annual cost of this disease is estimated to exceed $200 million, while globally, it surpasses $35 billion. The extensive use of antibiotics increases economic costs and raises concerns about antibiotic resistance, leading to regulatory changes in many countries.

The global industry has put in measures to combat antimicrobial resistance (AMR). Last year, over 1 million lives were lost due to AMR-resistant bacteria - projected to rise to 10 million deaths/year by 2050.

In New Zealand, the discovery of antibioticresistant bacteria Staph aureus (MRSA) in several dairy herds highlights the urgent need for rigorous testing of milk to identify resistant bacteria. It’s essential that we accu-

rately test cows to mitigate the risk of spreading these pathogens in our herds.

DairySmart received the NZPI Technology Innovation Award in 2023 and says it continues to make progress in a competitive landscape with its precise diagnostics and user-friendly reporting for farmers and veterinarians.

The company follows an evidence-based approach, and says independent testing confirms it has market-leading accuracy.

DairySmart’s userfriendly technology has been attractive to European veterinary clinics and their farmers due to mandatory reductions in antibiotic usage; with similar regulations anticipated for New Zealand.

The company says European clinics often prefer DairySmart’s solutions, citing “enhanced speed, comprehensive reporting, and improved accuracy as key factors in their transition from other products”.

It says an independent scientific review found that DairySmart’s SmartScreen before autumn dry-off effectively treats infections while significantly reducing antibiotics. “This supports sustainable farming and offers economic benefits.

Some farmers have seen a 90% reduction in antibiotic use, 55% less mas-

titis, and $30 extra per cow from savings and increased milk production with DairySmart.

“DairySmart’s patented aseptic milk sampling technology facilitates rapid and precise pathogen testing, extending beyond mastitis detection. This technology has led to a notable increase in demand for Johnes testing.”

As DairySmart grows, it says it remains committed to advancing agricultural technology and promoting responsible farming practices through on-farm support and innovation. The company aspires to lead in on-farm pathogen diagnostics and support.

Ben Davidson is the CEO and veterinary advisor. The company is increasing its operations in New Zealand and meeting demand from British and various European markets. It offers services to clients in over 12 countries, including Netherlands, Norway, and Ukraine.

The DairySmart board is implementing steps to manage this expansion, describing it as a “great challenge to be facing.” Their successful capital raise is nearing its target, which will be used to enhance DairySmart’s artificial intelligence capabilities towards achieving 99% accuracy and expand their diagnostic services.

BLUE PACIFIC Minerals

is a well-established New Zealand-owned company based in the heart of the South Waikato, Tokoroa.

The company is proud to serve the agricul-

tural community with a wide range of products designed to promote the health and productivity of animals and crops.

At the core of the business is zeolite, a

remarkable natural mineral that Blue Pacific mines and processes right here in South Waikato.

Zeolite has earned its reputation as a trusted component in many agricultural solutions due to its unique properties, including its ability to bind toxins and enhance nutrient absorption.

“Our commitment to processing this min-

A DairySmart Smart Screen at dry-off will identify which of your cows have bacteria in their udders, and which species are the problem to address Fast turn around- with every cow’s results detailed

Comprehensive report to take the right actions for each cow

Identify all Staph.aureus cows and stop the spread next season

Only treat cows that need it, use less antibiotics & save money

Start next season with confidence knowing your herd is clean

NOW FOR EARLY BIRD DISCOUNT

eral locally ensures that we maintain the highest quality standards while supporting our regional economy,” the company says.

“Our product range includes well-known names like OptiCalf and Optimate. Optimate is a standout herd feed supplement, featuring ACVM approval as a toxin binder.

“This product combines zeolite with probiotics and essential minerals to deliver a comprehensive nutritional solution for livestock. Designed to support peak health and performance, Optimate has become a trusted choice for farmers looking to improve the well-being of their herds.”

the soil with vital trace elements and minerals.

With a focus on sustainability, their liquid fertilisers enable farmers to use fewer units of nitrogen, achieve precision application, and incorporate essential nutrients tailored to their specific soil needs.

This approach not only supports healthier crops but also contributes to better environmental outcomes.

peak condition, ensuring they perform at their best.

“Blue Pacific Minerals is committed to supporting New Zealand farmers by providing effective solutions that enhance animal health, improve soil fertility, and boost productivity. Our dedication to innovation and quality has made us a trusted partner in the agricultural sector.

See

Learn

In addition to feed supplements, Blue Pacific Minerals also offers an innovative range of liquid fertilisers. These products are formulated to enhance crop and pasture growth while replenishing

One of Blue Pacific’s unique offerings is Stock Rock, a race rock specifically designed to eliminate stone bruising and provide safe, comfortable pathways for cows heading to the farm dairy. By promoting faster and safer movement, Stock Rock helps to enhance overall productivity and reduce animal stress, says the company.

“We also cater to the equine industry with a range of products developed to keep horses in

“We invite you to learn more about our products and their benefits by visiting our stand at the Dairy Expo.

“Whether you’re interested in improving herd health with our feed supplements, optimising pasture growth with our liquid fertilisers, or exploring solutions like Stock Rock for better farm infrastructure, our team is ready to assist you. Together, we can help your farm achieve peak performance and sustainability.”

SMAXTEC’S BOLUS

technology supports early detection of potential diseases, enabling preventive measures to improve herd health and reproductive outcomes.

smaXtec says the bolus provides precise insights directly from within the cow, operating reliably inside the reticulum – unlike external sensors, which can be easily affected by environmental factors, especially in grazing systems. It measures inner body temperature with unrivalled accuracy (±0.01°C), tracks water intake, drinking cycles, rumination based on reticulum contractions, and overall activity. This precise data enables the earliest possible detection of potential diseases, long before visible symptoms appear, by instantly alerting farmers via smart-

phone or computer for timely intervention.

Focus on prevention

David Thompson, who runs a 305-cow farm in Feilding, ManawatūWhanganui, says he received three temperature alerts over three days.

“The vet confirmed pneumonia, even though the cow appeared fine. Without smaXtec, I wouldn’t have noticed it until 3-4 days later.”

Sarah Neilson from South Taranaki, managing a herd of 340 cows, adds that it’s been about prevention rather than cure.

“When we had a case of twisted bowel, we caught it early. It had just started when we were able to get the vet to remedy it.

“He had the thermometer in the cow and said, ‘I will never have

• Let Goodwood sort your animal bedding this season

• Bonnie the Cow Animal Bedding and Herd Shelter Stand-Off Pad readily available, as well as Animal Bedding for Compost Barns

• Product available across Waikato, BOP, and Central Plateau

• Delivered direct to you, when you need it

• Made using 100% recycled untreated timber for the health and comfort of your herd

to deal with that ever again—this is such reliable data.’ Now, the vet checks the smaXtec data first because the temperature alerts are always accurate.”

Supporting productivity and profitability

The company says early detection with smaXtec allows for milder treatments and reduces the need for antibiot-

ics, which can help lower treatment costs and support stable milk yields. The system also provides insights that enhance heat detection, support reproduction and conception rates, and optimise the calving and mating process.

Hayden Lawrence, who runs a 430-cow farm in Taranaki, observes: “Using smaXtec has

improved heat detection, reduced mastitis cases by 64%, and cut costs by 56%. It has become an essential part of our routine, saving us time by reviewing health data before each milking.”

For more information visit their website www. smaxtec.com/en/new-zealand/ or contact via info@ smaxtec.com.

TO MARK International

Day of Education on January 24, 2025, state farmer Pāmu (Landcorp) announced the commencement of its Apprenticeship Scheme, designed to equip the next generation of farmers with the skills, knowledge, and experience needed for a thriving career in agriculture.

The nine apprentices, many of whom were in high school just last year, have begun settling into farm life over the past two weeks of onboarding at Aratiatia Farm in the Central North Island. Donning their high-vis uniforms and work boots, the apprentices from diverse backgrounds and geographies, are adjusting to their new roles.

The first cohort of

apprentices brings a wealth of enthusiasm and aspirations to the programme. From aspiring head shepherds to future farm owners, each apprentice is eager to learn, contribute, and grow.

The scheme offers apprentices a unique opportunity to gain hands-on experience in both dairy and livestock

farming while working toward Level 3 and 4 Primary ITO qualifications.

Apprentices will gain practical skills including animal husbandry, stock rotation, pasture management, and vehicle operation.

The first year offers a broad foundation before apprentices specialise in either dairy or livestock in their second year, with

a guaranteed permanent role at Pāmu upon completion.

Carl Carmichael, farm manager at Aratiatia and a dedicated mentor to the apprentices, emphasises the importance of supporting young people in the agricultural sector.

“It’s incredibly rewarding to guide young farmers as they find their feet in the industry.

Watching them grow and develop into confident, skilled individuals is what it’s all about,” says Carmichael.

Supporting the apprentices is Gary Brady, Pāmu apprenticeship scheme manager, who brings decades of experience in agriculture, education, and mentoring.

“For me, it’s about building confidence and

self-belief in these young people. This programme isn’t just about farming— it’s about helping them develop as individuals,” he explains.

“We’re preparing these apprentices not just for a job but for a lifetime of farming excellence. It’s about respecting the land, embracing innovation, and leaving a legacy for future generations.”

Pāmu chief executive Mark Leslie says: “As the apprentices embark on their journey, we look forward to the long-term impact this programme will have on New Zealand’s agricultural future. By investing in young talent, Pāmu is building a stronger, more resilient industry that prioritises innovation, sustainability, and community.”

The apprenticeship scheme aligns with commitment of Pāmu to sustainable progress, supported by the ASB Sustainable Progress Initiatives. This $1 million partnership funds innovative industry-good projects, including methane reduction research, smart agri-data tools, and the Pāmu Apprenticeship Scheme.

Pāmu is the brand name for Landcorp Farming Limited, a stateowned enterprise with 112 farms across the country. Pāmu exists to enhance the future of agriculture for generations and is focused on running a profitable and efficient business where farming activities positively impact ecosystems and communities.

ZARA WILLIAMS’ personal and professional growth has seen her presented with the top award at the 2025 World Wide Sires national all dairy breeds youth camp.

The 17-year-old from Palmerston North was presented with the Paramount Cup – awarded to the top allrounder – at the conclusion of the Youth Camp, held in Wyndham from January 4-7. She was also presented with the title of top senior handler.

Holstein Friesian NZ field officer and youth camp co-ordinator Amelia Griffin said she was impressed with the level of growth and development

Zara had demonstrated over the past three years she had attended Youth Camp.

“Over the last few years Zara has shown growth – not only within herself, but in her ability to work with others, particularly younger kids,” Griffin said. “She is such an incredible young woman.”

Each year Holstein Friesian NZ hosts the youth camp, which is designed to upskill young people aged 10-21 interested in showing and handling dairy cattle.

Held over four days, the camp allows young people to make friends,