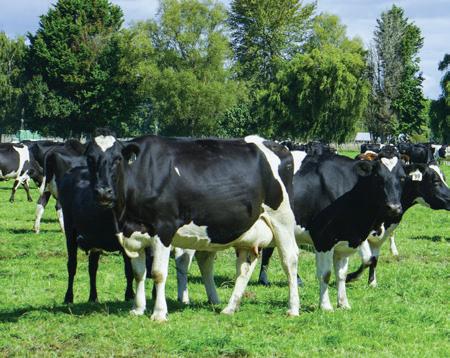

With another challenging year behind us, from Covid restrictions, to high interest rates and changing regulations, we want to thank all our dedicated farmers for your resilience and continuing to support New Zealand through some tough times. The dedication and effort you put in every single day is why you, the farmers, are the backbone of this great country. From the 4am milkings that wind up in our morning flat whites. To the endless hours in the field that ends up in our midday sandwich. Thanks for keeping us growing.

Power Farming is proud to support New Zealand’s farmers and bring attention to the great work they do. We are committed to working with you and being an extension of your team. That includes understanding the challenges you face and providing the right equipment for the right job to help your farm thrive. We look forward to taking on 2023 right by your side. Power Farming NZ

EDITOR

Sudesh Kissun sudeshk@ruralnews.co.nz

PUBLISHER

Brian Hight bh@ruralnews.co.nz

GENERAL MANAGER

Adam Fricker adamf@ruralnews.co.nz

ADVERTISING

Upper North Island: Stephen Pollard stephenp@ruralnews.co.nz Ph: 021 963 166

Central North Island: Lisa Wise lisaw@ruralnews.co.nz Ph: 027 369 9218

Lower North Island: Ron Mackay Ph: 021 453 914

South Island: Kaye Sutherland kayes@ruralnews.co.nz Ph: 021 221 1994

PRODUCTION

David Ferguson davef@ruralnews.co.nz Becky Williams beckyw@ruralnews.co.nz

SUBSCRIPTIONS

Julie Beech julieb@ruralnews.co.nz Ph: 0w1-190 3144

PUBLISHING & PRE-PRESS

Rural News Group PO Box 331100, Takapuna, Auckland 0740 Ph: 09 307 0399

Location: Lower Floor, 29 Northcroft Street, Takapuna, Auckland 0622

SINCE TAKING ON the role as LIC’s chief executive a year ago, I’ve had the pleasure of connecting with hundreds of farmers from right across the country.

I always leave these visits inspired by the way our sector is adapting to the challenges we are facing, and optimistic about the opportunities that lie ahead.

With climate change regulations imminent and a heightened focus on the need to meet sustainability goals, our sector is facing increased pressure to reduce emissions.

We’ve seen a significant shift in the uptake of farming technologies to support this which have no doubt helped to play a role in driving efficiencies on farm and will continue to do so in future.

But alongside this is the important role of precision genetic technology to improve our national dairy herd and support the sustainability of dairy farming businesses.

As a sector we don’t need more cows, we need the best cows.

The best cows produce milk in a more efficient and sustainable way, and innovative technologies and research are key drivers to help us do exactly that.

As we look towards the future, there’s a lot to be excited about.

Industry investment into research and development is helping our sector on its journey to meet climate targets and initial findings from current research initiatives are promising.

The methane research programme we are running alongside CRV and funded by the New Zealand Agricultural Greenhouse Gas Research Centre (NZAGRC) is in its third year investigating the link between a bull’s genetics and its methane emissions.

The latest findings from this research confirmed that bulls’ genetics do play a role in how much methane they emit–a significant step towards enabling farmers to breed lower methane-emitting cows in the future.

Published by Rural News Group Ltd. Unless directly attributed, opinions expressed in the magazine are not necessarily those of Rural News Group and/or its directors or management.

Getting the Basics Right is published annually.

If we focus on breeding the best cows, we can meet the challenges our sector is facing head-on and continue to be the world’s most efficient dairy milk producers.

Our data shows that in the last five years, herds that consistently use LIC genetics have almost doubled the speed of improvement in their herds over the last decade-achieving an average genetic gain of 19gBW each year.

This acceleration of genetic gain and

With climate change bringing rising temperatures, our research to improve heat tolerance in dairy cows could become a hugely valuable tool to help farmers protect the welfare of their animals and ensure they are resilient to the changing climate.

If this breeding programme continues to progress as expected, Kiwi farmers will be able to breed heat tolerant cows by 2029, which is an exciting prospect.

The decisions we make today will help to shape how our industry looks tomorrow, and I firmly believe that by investing in the right technology and breeding the best cows faster, we will have along, exciting and sustainable future ahead of us.

FOR MOST OF my career, the focus of farming was production and profit. It was quite simple; you produced as much product as you could at the right price, and you made money. In the last five years the business of farming has faced many changes resulting in farmers having to reconsider how they operate. That said, there are some things that won’t change. These are the basics. They are the fundamentals which farmers should continue to focus on to make their businesses profitable, sustainable, and compliant. So, what are these basics?

The relationship between homegrown feed and profit has been

well known for many years. Farmers who grow and harvest large amounts of feed are more likely to make more money than those that produce less homegrown feed.

With pasture yields relatively stable (and even declining in some areas), growing crops on farm has become an important tool to increase homegrown feed. Maize is one the best crops to grow because it is high yielding and produces quality feed that supports a pasture-based system. While historically maize silage was used as part of a regrassing programme, in recent years, many farmers are using maize to grow more feed, more reliably. The result is the same, more feed grown per hectare across the whole farm.

How much extra feed grown depends on the farm. For example, a

100ha farm growing 14 tDM pasture per hectare and cropping 15% in a maize silage and annual ryegrass rotation can lift overall drymatter production by around 1.65 tDM/ha across the whole farm. That’s a lot of extra drymatter!

KEEP FEED COSTS UNDER CONTROL.

As with the relationship between home grown feed and profit, there is also a strong relationship between farm working expenses and profit. The latest DairyNZ Economic Survey clearly shows that feed is the single biggest production cost. On many farms feed costs make up around 25% of total farm working expenses. Any reduction in feed costs will have a positive impact on farm working expenses.

Growing some maize silage on land

•

•

• High Flow

•

• Compact Robust construction

•

•

•

•

MFV2025D 20/25mm

MFV20D 20mm

MFV25D 25mm

MFV32D 32mm

•

FEATURES

• High Flow

• Fully Adjustable Mounting

•

• High • Keep oper min

• Adj from 5

• Deta

• 15mmsizes

TPV20D 20mm

TPV25D 25mm

TPV32D 32mm

controlled by the farmer will, in most cases, help reduce the overall cost of feed. Take for example the farmer who is progressively regrassing the farm through growing maize silage. Let’s assume the area to be regrassed is producing around 8tDM/ha during the maize growing period. If the farm has relatively high fertility, maize will cost about 16c/kgDM in the stack (excluding regrassing costs and any benefits from regrassing). The net feed cost (maize grown minus pasture foregone) is 26c/kgDM. For those farmers buying in maize silage, growing a proportion of their requirement on-farm allows them to average down their feed cost.

New Zealand dairy systems are

pasture based. Managing pasture well is one of the basics farmers need to get right.

In recent years, varying climate has made managing pasture very difficult. Bouts of extreme dry (like last summer) or extended periods of wet (like this spring) mean farmers need to have other tools in their toolbox to enable them to manage pasture.

Maize silage is one of these tools. When there is not enough pasture, maize silage can be fed to create substitution, building cover and preventing over grazing of pasture. When it is too wet, maize silage enables cows to be stood off paddocks to prevent damage to pasture through preventing pugging. And then when there is enough pasture, maize silage can remain in the stack to be used

later when it is needed.

DAIRY FARM.

Farmers in many areas across New Zealand are now being required to reduce their nitrogen (N) and phosphorus (P) loss. Maize silage is set to become a key tool in this process.

Cows urinate excess dietary nitrogen onto pasture, increasing the risk of leaching and nitrous oxide loss. For much or the year pasture has too much protein.

On the other hand, maize silage is a low protein feed (7-8% crude protein). Feeding maize can dilute dietary protein levels and reduce N leaching.

Maize is a deep-rooted crop that can extract water and nutrients from a depth two to three times greater than typical pasture species (e.g. ryegrass/white clover). Because it has a high demand for nitrogen (N) and potassium (K) - (12kg N and 10kg K for every 1tDM removed), it can be used to remove excess N and K from effluent blocks.

This reduces the risk of nutrient leaching and lowers the chance of milk fever caused by feeding high potassium pasture to springers.

A recently published modelling study lead by Dr Pierre Beukes from DairyNZ, showed a significant reduction in N loss when a future farm was compared to a typical Waikato System 2 type farm.

The study showed that when a farm system which included a feed pad, lower N use, a dedicated cropping block (maize silage in summer and annual ryegrass catch crop in winter), higher BW cows, and a lower replacement rate was compared to a typical Waikato farm, there was a 26% reduction in N leaching, a 16% increase in milk production and a slight decrease in profit (4%).

The science behind the value of having mature cows achieve a BCS of 5 (5.5 for 1st and 2nd calvers) is rock solid. However, many farmers still struggle to get achieve this target. Cows which calve at BCS 5 vs. BCS

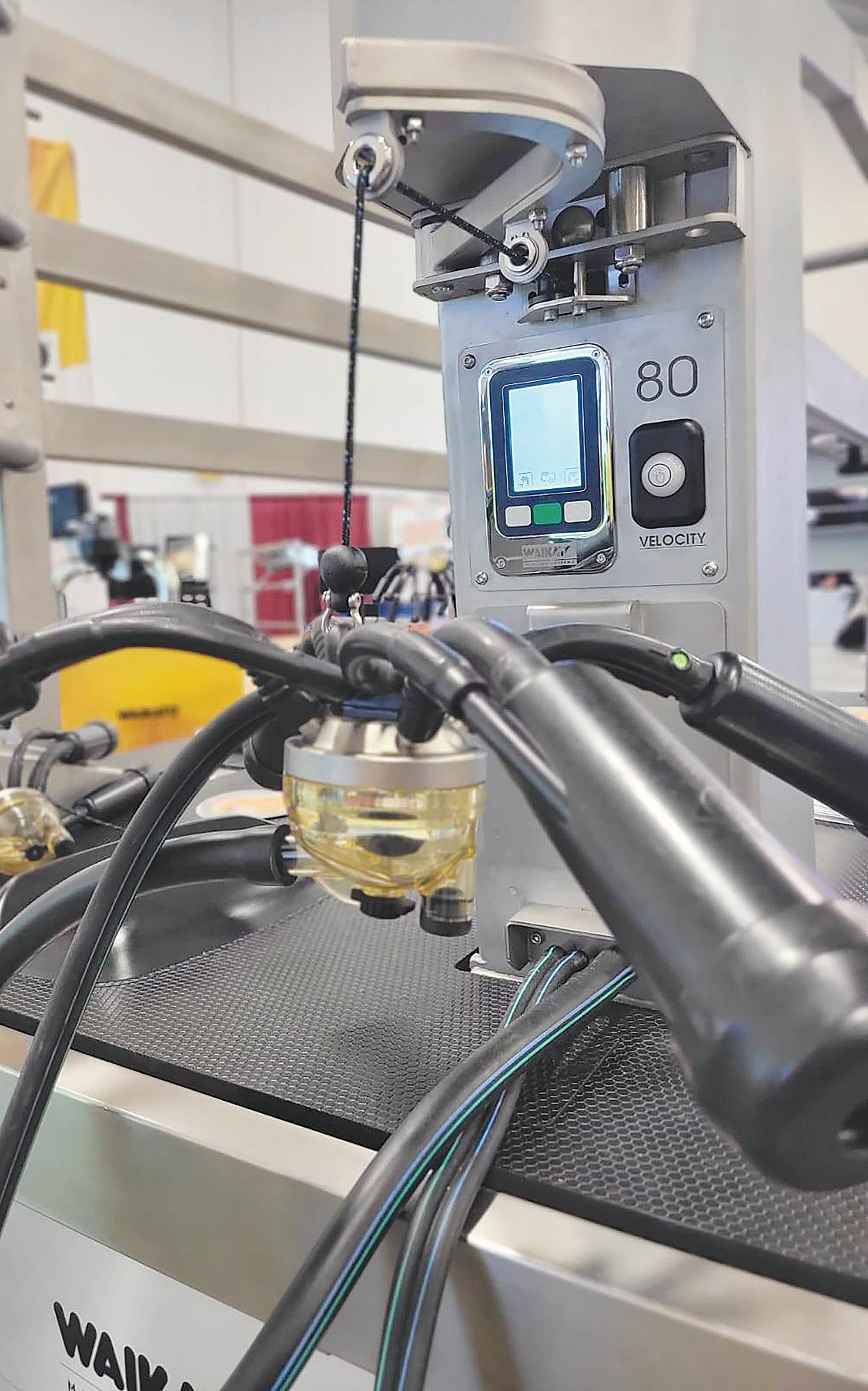

Whether you’re looking to increase cow throughput, combat labour challenges, gain more insights or improve udder health, GEA offers a range of innovative solutions to meet the demands of every kind of farming business.

Rotary and herringbone systems

Cow collar technology

Dairy and udder health automation

FIL hygiene and animal health

For better farming, contact your local GEA Service Partner or call us on 0800 GEA FARM.

4 will produce an additional 12 - 15 kgMS over the season and will get in calf 8-10 days earlier.

Feeding around 180 kgDM/cow of maize silage over winter will lift cows by 1 BCS. The return from extra milk and more days in milk more than covers the cost of the extra maize silage required to put on the extra

condition. It is a no brainer. Some of the early research into feeding supplements to dairy cows in New Zealand was conducted around 25 years ago at the Waimate West Demonstration Farm in South Taranaki. The data showed using maize silage to fill feed deficits could generate high response rates (see

Table 1). While this now old data, the truth remains the same. The trial showed an increase in net profit per hectare (EFS) of 23% and 28% from the spring and autumn fed herds when compared to the control. This was achieved through more days in milk by using maize silage to turn a dry day into a milking day.

Maintaining herd health needs proactive management and responsible antibiotic use. Combining animal health checks with your regular herd tests is a simple way to monitor health while looking for variations in herd performance.

Using samples from your herd test, LIC’s animal health testing can identify diseases such as BVD, Johne’s and Staph aureus mastitis before they cost you a fortune. It can also confirm pregnancy and identify animals that produce A2 beta casein milk.

Adding any of these easy and convenient tests is one of the smart moves you can make today to get more insight into your herd’s health and status, all from a drop of milk.*

Talk to your LIC Agri Manager today about setting up regular herd testing with animal health checks.

*Minimum sample volume and sample numbers apply.

There's always room for improvement

Horticulture has been taking advantage of the benefits of foliar feeding for many years where spraying equipment has evolved to apply agricultural remedies including liquid fertilisers to hard-to-reach foliage.

In recent years there have been vast improvements made in tow-behind spray units suitable for pasture spraying. These allow farmers the flexibility to choose when, where

and what to spray. Contract spraying services have also improved recently.

Global events have raised the cost of almost all fertiliser products internationally.

This has forced farmers to try more efficient ways of applying their fertiliser. Foliar fertilising is targeted and efficient.

Society and authorities are less tolerant of environmental problems caused in part by heavy applications of fertiliser and pressure has been

placed on farmers to reduce their annual fertiliser inputs.

A foliar fertiliser (liquid fertiliser) is a fertiliser product that is designed to be applied directly to the leaves of the plant. Although the first recorded use of foliar fertilisers was in 1843, this practice remained limited for years.

A lot of research has been done on the benefits of foliar fertilising in

the last 30 years. It was noticed that applying synthetic chemical fertilisers like urea, phosphates, and potassium salts etc could be absorbed directly by the plants and provide fertilising benefits, and that if this was done, the amount of fertiliser could be reduced.

There were limitations as not enough was known about how to penetrate the waxy cuticles of foliage or even why this occurred at all.

Use of chelating agents such as Ethylenediaminetetraacetic Acid (EDTA) have been used to improve trace mineral uptake, but environmental concerns are beginning to limit the use of EDTA. In recent years, the benefits of amino acids as chelating agents have been proven and these are becoming more widely used.

Application or dose rates can be calculated to suit the requirements of analysis and pasture management practises. Using a liquid becomes more precise, resulting in more economical use of fertiliser input, providing cost savings.

Feeds directly through the foliage as well as through the soil and roots to feed plants as efficiently as possible. It’s understood that application of nutrients via the foliage requires considerably smaller quantities of the nutrients than their application via the soil.

When soil conditions such as drought or cold conditions limit the availability of nutrients to the plant from the soil through transpiration.

Reduces the waste of fertiliser

through leaching, runoff or volatilisation as occurs with many solid fertilisers.

Reduces the risk of over fertilising that has been found to have detrimental effects on beneficial soil organisms such as earthworms and beneficial microbes such as nitrogen fixing bacteria.

In liquid form, the nutrients are already in a plant available form, ready to start immediately upon the process of feeding and growing

PETA Dispensers offer the simplest way to administer a variety of animal health remedies through the drinking water.

Available at NZ farming suppliers or your local vet. More information available at www.peta.co.nz.

Controls bloat easily. Available in 12 or 24 hour options.

the plant, whilst also nurturing the biological activity in the soil.

Faster uptake of nutrients resulting in quick response especially when nutrient deficiencies are present. This could be due to low nutrient levels in the soil or conditions such as low pH that prevents nutrient availability.

Ideal method for the concept of a little more often which reduces waste and improves soil health when formulated correctly.

Complex mixtures of nutrients and trace minerals can be formulated and applied increasing the flexibility of foliar fertilising. In addition, agricultural chemicals such as fungicides can be applied simultaneously to reduce costs.

Foliar feeding is more targeted and thus more environmentally friendly than bulk soil applied fertiliser. In addition to the fact that amino acids have been found to be very useful chelating agents for trace minerals such as iron and zinc, and commercially synthesised amino acids like glycine (commonly used as chelating agents in some commercial foliar fertilisers), research has shown that mixed amino acids have additional benefits, some of which are:

• Attract moisture to the foliage to which they have been applied, which in turn assists with amino acid and other nutrient absorption.

• They act as building blocks for proteins that are essential for plant growth and function.

• They stimulate plant growth and

Prevents facial eczema. Available in 24 or 48 hour options.

For magnesium, trace elements and salts. Available in 24 or 48 hour options.

Foliar feeding is more targeted and thus more environmentally friendly than bulk soil applied fertiliser. In addition to the fact that amino acids have been found to be very useful chelating agents for trace minerals such as iron and zinc, and commercially synthesised amino acids like glycine (commonly used as chelating agents in some commercial foliar fertilisers), research has shown that mixed amino acids have additional benefits.

enzyme production and activity.

• They work synergistically with other nutrients to the benefit of the plant.

• They reduce fertiliser requirement by complexing nutrients and helping to transport them to where they are needed in the plant.

• They contain not only nitrogen but carbon and some like methionine and cystine also contain sulphur.

• They have a stimulating effect on root growth which in turn allows for more efficient absorption of nutrients from the soil.

• They improve photosynthesis, resulting in higher carbohydrate production which benefits the plant

and the beneficial root dwelling organisms.

• They also feed the beneficial organisms living within the plant that help the plant in different ways including fighting off disease and plant eating insects.

Dr Peter Kauzal, a veterinary scientist who worked in Australia fifty years ago, developed Nitrosol liquid fertiliser by using a by-product of the New Zealand agricultural industry with a good source of nitrogen, phosphorous and potassium. He identified that the soil, and therefore pasture, plants and crops were lacking vital nutrients, trace elements and minerals. Agricultural stock

health was struggling in some areas due to the shortage of critical trace minerals that had caused problems, none more-so than the so-called “bush sickness” in New Zealand, due to natural deficiencies of cobalt in our volcanic soils.

Kauzal strongly believed that the best way of providing the deficient minerals was through the pasture that the stock was grazing on, and so he went about developing a liquid fertiliser that could be sprayed onto the pasture and be rapidly absorbed by the pasture to stimulate good pasture growth, as well as provide the essential minerals that were in short supply.

PASTURE COVER AND quality have a direct impact on your herd’s milk production and often enough, reproductive performance. For this reason, getting pasture and feed management planning right is an important part of supporting your herd throughout the spring season.

At the start of calving, it is essential that your herd’s body condition score (BCS) is as close as possible to the ideal condition score of 5.0. This will support your herd immediately after calving when they cannot eat enough to maintain their body condition and produce milk at the required level.

Heifers’ BCS should sit at a score of 5.5 to provide a buffer against condition score loss. If achieved, this will support their reproductive capabilities, as heifers typically have a longer anoestrus period (days to first cycle) than cows. If heifers have a lower than 5.5 BCS, it can have a detrimental effect on their reproduction performance.

The key is to get your pre-grazing and post-grazing covers right.

To ensure your farm has sufficient pasture cover at the first and second rounds, farmers must have a good pasture wedge; whereby all pasture on farm is at different growth stages. The type of feed on farm ranges from the area just grazed through to the area next to be grazed, resulting in a range of pasture cover over the whole farm.

The first phase is a slow regrowth

period particularly after a severe grazing. There is little leaf area available to capture sunlight for photosynthesis.

The second phase is the period of most rapid growth after leaf area has increased and most sunlight is being captured.

The third phase is when pasture height increases and growth slows, as the pasture reaches ceiling herbage mass. At this stage there is some shading of leaf area and pasture loss in the form of decay is common. At ceiling herbage mass, pasture growth and loss are similar, therefore net pasture accumulation stops.

It is essential to plan your farm management events for the first rotation and identify springer cow grazing and first milking pasture areas. These need to be in suitable

areas of the farm with reasonable access to the dairy and sheds for calf rearing. The springer area should be somewhere that freshly calved cows won’t be walking past every day. These areas need to be closed from grazing to ensure pasture covers are in the right places on farm at the start of calving.

The spring rotation (first round) grazing planner should be completed as a guide. This is essential to prevent the rotation from speeding up too fast after the start of calving. In the spring, it is critical that the first grazing round is slow, often 42-56 days from the start of calving, so that pasture is conserved and carried through until balance date. Farmers should aim to be geared up for a fast rotation when pasture growth exceeds the herd’s requirements.

To make sure that pasture growth is at the required level in early spring, it is necessary that the farm cover doesn’t get too low. Having a very low pasture cover in late winter/early spring means that it will stay low. Most farms at moderate stocking rate (2.8-3.3 cows/ha) require an average farm pasture cover of 2,200-2,400 kgDM/ha at the start of calving.

If you are on a fast rotation immediately after calving it will ensure that in this early period the cows are well fed, but they may be fed less over the spring period. Typically, rotations which are too fast immediately after calving result in a large feed deficit in September. This usually persists through to early October which causes cows to be poorly fed at mating time.

During the second round, emphasis needs to be placed on ensuring that high quality pasture is provided to

the herd. Once the stem-to-leaf ratio increases and seed heads appear, the digestibility and metabolisable energy (ME) content of the feed decreases quickly.

Rotation lengths of 18 to 24 days are generally ideal, although each individual farm has different circumstances.

In the spring, any pasture cover needs to be preserved until pasture growth exceeds cow demand per hectare. It is critical that the minimum pasture cover that you reach in the spring is not below 1,900 kgDM/ha (ideally this should not drop below 2,000 kgDM/ha). At covers below 1,900 kgDM/ha the leaf area is such that pasture growth rates are lower than what they would otherwise be had the cover been 2,000 kgDM/ ha, hence it takes much longer for the spring growth to come away (growth could decrease as much as 30 to 50%).

For the period when pasture growth exceeds herd demand, pasture not required by the herd should be removed to ensure quality is maintained. Management decisions on how much and when to remove areas for conservation must be proactive rather than reactive. If not enough pasture is removed, the cows will under graze and quality will decline. If too much is removed, then the herd will be underfed.

For example, let’s consider a farm that is stocked at three cows per hectare and has a herd that requires 54kg DM/day (3 x 18kg DM/ cow/day). When pasture growth is 70-80kg DM/ha/day surplus pasture can accumulate quickly, and prompt decisions must be made. At this time, a 240-cow herd on a 20-day round will be grazing four hectares a day. This means that at a growth rate of 72kg DM/ha/day, approximately 25%

of the farm should be closed for silage; 54/72 = 75% of the farm required for grazing. This is a large area to close at one time. Being proactive means noticing a surplus early and taking small areas out one at a time. The decision to conserve must be made as soon as a surplus is noticed, otherwise you run the risk of leaving it too late.

Silage paddocks should be out of the rotation for as little time as possible. Regrowth after cutting is significantly better for paddocks only shut up for 35-40 days compared to 60 days. The shorter time to harvest also produces higher quality silage due to the pasture being less mature (the ‘ideal’ being that the grass cut for silage could in fact be grazed by the cows).

A rough rule of thumb from mid October until early February is that you should only be able to see 4-6 days of grazing in front of you. Less than this and you run the risk of your pasture cover decreasing. More than this and a surplus is likely to occur causing pre-grazing pasture covers to become too high.

Timing is critical in all spring management decisions. By investing more time to better monitor pasture covers and focusing on fully utilising pasture, we can make the cost to produce a milksolid more profitable through informed decisions.

■ ENVIRONMENTAL AND ECONOMIC performance and sustainability of our agriculture, including forestry, can be greatly influenced by soil quality.

Bala Tikkisetty Senior technical advisor, Waikato Regional CouncilSoil physical condition – commonly referred to as ‘soil structure’ – has an important influence on farm economics and environment.

Soil structure determines the porosity, strength and stability of a soil. For all practical purposes, these are the most important soil physical properties because they influence the movement and storage of water in the soil, the ability of roots to penetrate and grow in the soil and withdraw water and nutrients, and finally the ability of a soil to resist erosion.

A well-structured soil has many stable aggregates with a wide range of sizes.

It contains a large number of pores, both within and between those aggregates, which maintain the correct balance of air and water in the soil and also allows easy emergence of seedlings and growth of plant roots.

Poorly structured soil either does not have aggregates of many different sizes or the aggregates are packed tightly together with few pores. Poor structure in a light textured soil results in unstable aggregates and the soil appears fine and powdery. Poor soil structure can markedly increase the risk of wind erosion.

Over half the total soil volume consists of pores in a well-structured soil and about 40% of these pores are very small and nearly always filled with water held so tightly that plant roots cannot withdraw it.

The proportions of sand, silt,

clay and organic matter determine volumes of these small pores.

Medium size pores retain water, which can be taken up by the roots. The volume of these pores determines the water holding capacity of a soil and therefore its susceptibility to drought.

Large pores (macropores) are the structural soil pores, and are important for infiltration of water into the soil, drainage of excess water from the soil, aeration of the root zone, and as passages for root growth in the soil.

The two main forms of soil structural damage are aggregate

breakdown and soil compaction.

Aggregate is caused by some natural processes, such as wet/ dry and freeze/thaw cycles. Soils comprising mostly of silt and sand, with only a small proportion of clay, are most susceptible because these soils are only loosely bound.

Organic matter is a major soil binding constituent, so soils with low organic matter are particularly susceptible. Cultivation significantly reduces soil organic matter content and can rapidly result in serious aggregate breakdown with the risk of erosion, crusting, and poor infiltration of rain and irrigation water.

Soil compaction is the compression

or squeezing of a soil. Soil compaction reduces the number and volume of large soil pores (macropores) and increases soil density. Large pores are important for the movement of water and gases in the soil. Small pores are responsible for water and mineral storage.

A well-structured soil has a macroporosity of 15-20 per cent. Soils differ in their resistance to compaction because of their difference in texture, mineralogy, organic matter content and water content. The wetter a soil is the greater its susceptibility to damage, because water reduces soil cohesion and lubricates the movement of aggregates.

With compaction, the proportion of fine pores is increased, causing a decrease in water drainage and air exchange. Plant root growth is also restricted, causing a decline in the plant’s ability to absorb water and nutrients.

Farm machinery and heavy animal grazing is the source of compaction especially in wet conditions.

Pugging results in immediate loss of pasture production, through a loss in plant number, tiller number, and reduction in nitrogen fixation. So, pugging limits nitrogen supply, pasture production and consequently animal production.

Decline in soil physical properties takes considerable expense and many years to correct, and can increase the risk of soil erosion by water or wind.

So, safeguarding the soil for present and future generations is a

key task of land managers.

Practices that damage soil include over-cultivation, under or over-fertilisation, decreased or increased water abstraction, indiscriminate use of pesticides and other agri-chemicals, clearing natural vegetation, intensive farming practices, and very importantly, failure to maintain soil organic matter levels.

Average soil carbon stocks in New Zealand’s agricultural soils estimated at about 100 tonnes per hectare in the top 30cm, any change in soil carbon could make a significant contribution to carbon footprints at national, industry and farm scales.

Farmers face a new environmental issue, with recent research showing some dairy soils are losing more carbon and nitrogen than dry stock and hill country areas. Dairy farms on non-allophanic soils have lost an average of one tonne of soil carbon per hectare a year in some parts of the country.

Biologically active carbon is the most important part of the soil carbon and how it is distributed through the soil profile is equally important. Soil carbon is found primarily in organic forms, which make up soil organic matter.

A number of international agreements and conventions are likely to influence the management of soils in the near future.

If agricultural soils were to be used as carbon sinks, there would be a greater need and responsibility by farmers and land managers to increase the soil organic carbon content of their soils.

Soil carbon is mostly found in the decomposed remains of plant and animal matter and in soil microbes. Soil carbon shouldn’t be confused with soil organic matter. About 40-50 per cent of soil organic matter is soil carbon by weight.

In order to achieve increases in soil carbon content, it would be necessary to achieve the maximum uptake of various land management practices that contribute to soil sustainability.

The development of sustainable soil management practices clearly requires a multidisciplinary approach to find the best solutions. As we look for those answers, it will be the wise farmer who keeps an eye on these issues given their ability to influence the bottom line.

There are various tools that are available to farmers and land managers to allow them to assess the physical/nutrient state of their own soils.

A technique called visual soil assessment (VSA), developed by well-known soil scientist Graham Shepherd, has become popular. It involves soil structure in top soil being visually assessed and scored by comparing it with a pictorial description of structural condition.

VSA has been a good tool in assessing soil quality at farmer level and the results are easy to interpret and understand.

For further details and advice, please contact Bala Tikkisetty at Waikato Regional Council on 0800 800 401.

FODDER BEET OFFERS many benefits as an alternative crop to brassicas in your rotation, with less impact on the environment and greater flexibility of use.

However, it also presents some nutritional risks that require careful management and attention to detail.

Fodder beet is a unique feed, different from most feeds we offer dairy cows. This is primarily due to the bulb’s high soluble sugar content (65-75% of dry matter; DM), low crude

protein (7-12% of DM) and phosphorus content (0.08-0.2% of DM). Fodder beet bulb typically makes up 75-90% of the crop’s DM.

When offering diets containing fodder beet, it’s important to ensure you’re supplying your animals with sufficient all-round nutrition, particularly when fodder beet makes up a large proportion of the diet. Inadequate nutrition can negatively affect animal health and performance, including delayed initiation

of lactation, reduced peak milk production, inefficient rumen function, reduced growth and development of youngstock, and increased incidences of metabolic disease and acidosis. As such, it’s important to know what you’re feeding.

To accurately allocate feed, make sure you yield your crop two to three weeks prior to feeding. Yield the leaf

It’s important to know what you’re feeding and how you’re feeding it, writes DairyNZ scientist Roshean WoodsFodder beet is a unique feed, different from most feeds offered to dairy cows.

and the bulb separately so you can determine the proportion of each. It’s also important to accurately allocate supplementary feeds, for example, by knowing DM content and bale weights, or having scales on your silage wagon.

Transition your cows onto fodder beet crops gradually and follow the recommendation of increasing allocation by no more than 1kg every

HERE ARE SOME reasons to consider fodder beet for your farm system:

• High energy is great for putting body condition on cows.

• Higher yield potential means you can use a smaller area for winter grazing, compared with brassicas.

• Great option for areas with brassica disease.

• Can be grazed in the paddock, or lifted and stored.

• Potentially, creates lower nitrate leaching than kale due to the bulb’s low protein content.

• Cows on fodder beet emit less methane than when on kale or pasture. But, consider also the risks outlined in this article.

second day up to their full allocation. This allows the animals’ rumen microbes to adapt to the change in feed type, particularly the bulb’s high sugar content. A careful transition helps to prevent acidosis and other diseases, such as liver dysfunction and deferred ketosis. Check out our recommendations for transitioning at dairynz.co.nz/fodder-beet-transitioning

We advise you not to use published nutritional values for fodder beet. Instead, test your own leaf and bulb, and supplementary feeds, through a commercial lab. Why? Because research has identified considerable variation in the nutritional profiles of fodder beet’s leaf and bulb. Leaf and bulb also have very different nutritional profiles, and the relative proportion of each changes signifi-

Transition

cantly during the growing and feeding phases: from a high of 35% leaf in autumn to a low of 10% in late winter, depending on climatic conditions.

Using DairyNZ’s FeedChecker calculator (dairynz.co.nz/feedchecker) is a robust way to check your diets before feeding, to identify any potential nutritional imbalances. FeedChecker has recently been updated with improved input options. You can now enter your leaf and bulb feed test results as custom feeds, and include the DM content, leaf percentage, bulb percentage, and utilisation. Other new features include a section to help with crop allocation and break size calculations.

If in doubt about feeding fodder beet, talk to your vet or nutritionist.

As cows approach calving, their demand for metabolisable protein increases to support increased foetal growth and to develop mammary tissue.

• Fodder beet has many benefits, but known nutritional risks require careful management.

• Fodder beet should be fed with an appropriate supplement or pasture.

Test feeds to ensure you’re supplying sufficient nutrition.

• Take particular care with cows eating fodder beet in late gestation.

This usually happens in mid- to late winter and often coincides with a decline in protein intake as the crop on offer has a higher proportion (up to 90%) of low-protein bulbs. It’s important to ensure you’re offering sufficient protein in late pregnancy by either transitioning cows off fodder beet four weeks pre-calving or offering a higher-protein supplement or pasture alongside the fodder beet.

In-calf dairy cows on these low-protein bulb-dominant fodder beet crops often bag up closer to calving than those on grass or kale, increasing the risk of calving on crop. Some simple ways to reduce this risk are:

• early pregnancy scan to accurately date pregnancies for drafting cows off crop into the springer mob

• understand the implications of bull gestation length on expected calving date

• don’t rely solely on visual appearance of the udder for springer drafting.

The ‘Making Fodder Beet Sustainable for Dairy Cattle’ project was funded by the Sustainable Farming Fund (contract 405512) administered by the Ministry for Primary Industries, PGGWrightson Seeds, and the dairy farmers of New Zealand through DairyNZ Inc.

Article kindly supplied by DairyNZ –previously published in Inside Dairy.

When mating time starts to approach, it’s important to consider the cost of supplements and the time spent feeding them out – time that might be better spent on heat detection. DairyNZ’s Chris Glassey explains.

CAN COWS GET in calf on a pastureonly diet?

Yes. If there’s adequate feed, such as pasture residuals of 1,500-1,600kg DM/ha and good pasture allocation, there are no reproductive benefits from feeding additional supplements.

Also, if intakes are restricted during the mating period (due to a feed deficit, prolonged adverse weather or poor pasture utilisation) then reproduction is likely to be reduced less than expected.

This was shown in a Taranaki trial with 770 cows, which involved 2 herds being offered high and low pasture allowances for a 14-day period during mating.

The low pasture allowance was severe resulting in intake of only 8kg DM/cow/day and MS/cow/day dropped by 26%. Six-week in-calf rate dropped to 71% for the low pasture allowance compared with 78% for the high pasture allowance, and the final in calf rate were similar at 93 and 94% for each herd.

Yes, if energy supplied by pasture is adequate. Past research shows there’s no impact on submission, conception, 6-week in-calf or final pregnancy rates when dietary supplements are removed just before mating.

No, it’s only one factor. Others are genetics, bull management, heat detection, cow health, calving pattern, heifer management, non-cyclers, and cow condition at calving and mating.

Nutrition is only one factor that affects reproduction.

BCS at mating is a key driver of cow cycling and the 6-week in-calf rate. This is largely set by BCS at calving (so aim for targets of 5.5 for two- and three-year-olds and 5.0 for older cows). Cows naturally lose body condition after calving, based on genetics and BCS at calving.

Providing additional feed would have little effect on reducing this loss. Instead, focus on achieving target grazing residuals so there’s good quality pasture available during mating.

It’s up to you to decide whether the cost (including time and labour) involved in feeding out supplements is justified by need and any benefits.

If you do decide to use supplements, it doesn’t matter what kind: it’s the megajoules of metabolisable

energy per kilogram of dry matter (MJME/kg DM), and the cost, that count.

See dairynz.co.nz/supplements –and check out our booklet on Feeding cows in spring at dairynz.co.nz/publications/feed

• Save your time and money: if there is enough pasture, pasture is enough.

In most cases, you’ll only need to feed supplements if there is a deficit in early lactation.

• Choose supplements based on cents/MJ ME – focus on feed energy, not type of feed.

When a cow is suffering from heat stress, one of the major issues they face is a reduced feed intake.

OVER THE WARMER months, your cows are at a higher risk of heat stress.

Cows will generate heat in the process of producing milk, digesting feed, as well as absorbing heat while out in the sun. Heat stress in cows occurs when they are producing more heat than they are able to get rid of through sweating, respiration or air regulation (such as a breeze or wind, or by fans indoors).

An overabundance of heat in cows can lead to higher levels of stress, which can affect milk production, fertility, increase the risk of other diseases such as lameness, and impaired immune function.

Cows experiencing heat stress will exhibit behaviour such as seeking shade, loss of appetite, crowding together for increased shade, panting, drooling, and standing in water or next to troughs.

Heat stress in dairy cattle is probably the most overlooked seasonal problem here in New Zealand. Production drops rapidly as the heat increases, and most farmers simply accept this as a normal seasonal issue that they are powerless to address. The truth is, there are a number of nutritional strategies that can be used in order to mitigate the effects of heat stress.

When a cow is suffering from heat

stress, one of the major issues they face is a reduced feed intake. With reduced feed intake and an increase in drooling, availability of saliva is reduced which can disrupt the pH of the rumen and lead to acidosis. A healthy rumen is needed for milk yield as well as animal health.

Much scientific work has been done around the study of heat stress and how to mitigate the issues it creates. It is therefore important that ruminant animals during periods of high humidity are provided with sufficient nutrients in order to counteract heat stress and maintain strong immunity.

Feed additives shown to work well against heat stress are those that promote good rumen pH stability, and include additives such as rumen buffers and live yeast. Other additives that underpin healthy rumen function and immunity are trace minerals such as cobalt, selenium, zinc and chromium. Seaweed extract has also

been well studied to show excellent results.

By providing your herd with an easily digestible, nutrient-packed animal tonic that can be blended

easily into their feed or added into their water, you ensure that they have the correct balance in place to mitigate the effects of this summer heat stress.

You expect your farm machinery to go the distance, and McIntosh deliverrs machinery built to the highest quality standards. We’ve thought about the rugged and unpredictable conditions on so many New Zealand farms and engineered a range of machinery that wont let you down when the going gets tough.

DairyNZ explains what you should consider to successfully wean calves, including how calf weight and meal intake will help calves develop into healthy heifers.

MAKING SURE A heifer is fully prepared before weaning reduces the chance she will need preferential treatment post-weaning.

Preferentially managing small groups of animals to try and “catch them up” to the group is timeconsuming and can be difficult to manage, so it is best avoided by good early management.

Is the calf:

• Consuming the desired amount of feed? Is its rumen sufficiently developed?

• Meeting its weight-for-age target, based on its breed and/or the rearing system?

• At the minimum age for the rearing

system?

• Able to compete within a group?

Weaning can be a challenging time for a calf, for two main reasons: Their main source of nutrients switches from liquid to solids. They are exposed to new bugs as they enter new environments.

“Sprayfo Blue is easy to prepare, it smells nice and it feels like it should… the calves like it, they transition to grass well, and they become well-conditioned animals.”

Dairy farmer Jenna McLeod says that rearing with a CMR is not only more cost-effective, but her calves grow better: they reach target weights quickly and transition to weaning with no growth check.

Jenna has reared her calves (190 in autumn and 480 in spring) on AgriVantage’s Sprayfo Blue whey-based milk replacer for 4 seasons. She also has Launchpad18 and Biopect in her toolkit. She calls Launchpad18 “a game changer” in getting calves off to the best start and says that Biopect “can literally get calves off the ground”.

Scan

Calves can become stressed from changes in housing, competition in new groups and general husbandry practices (for example diet changes, vaccinations). Weaning will be more successful if your calves are only exposed to one stressor at a time.

A calf’s rumen development is the most important factor to consider when making the weaning decision. The only way this can be assessed is by measuring the amount of concentrate or pasture they are readily eating, which should be at least 1 kg/ day of meal or 2 kg/day of pasture. Any change to the quantity or type of feed needs to be measured. Just as it takes time to develop the rumen,

time is key in transitioning from calf meal to a full pasture diet. Farmer experience indicates that a two-week gap between each diet change will help transition calves to a full pasture diet (for example, weaning off milk with meal concentrate, to a full pasture diet).

New-born calves have high dietary protein requirements, this requirement declines as they age. A higher crude protein intake should lead to higher growth rates. If using calf meal, look for products that contain 20% crude protein for calves on milk and 17% crude protein for weaned calves to meet total dietary

requirements.

Individual heifers should reach a minimum weight prior to weaning. Although no specific weaning weight has been defined by research, the type of rearing system will affect the target weaning weight. Common weights used for weaning are 70kg for Jerseys, 80kg for Friesian Jersey Crossbreds, and 90kg for Friesians.

Heifers need to be competing with the group before they are weaned. Any that are not, should be held back.

When weaning calves off milk,

it is recommended to use a gradual process, removing milk slowly over 1-2 weeks.

This will allow the calf time to adjust to the lower level of milk and increase solid feed intakes accordingly. Be sure to monitor calf behaviour and meal intake over this time to identify any calves that may be struggling.

If the calves have been eating meal whilst on milk, keep the meal in their diet for at least two weeks after weaning from milk.

This will help to reduce the growth check (period of slow growth during feeding transition) as their rumen adjusts to digesting higher levels of pasture.

After 2 weeks, if pasture supply and quality are adequate to meet your desired growth rates, meal may also be removed.

Sometimes animals do not thrive post-weaning so weigh them within 7-10 days to make sure they have

• Fully weaned and off milk for at least two weeks

• Competing in the mob

• Meet minimum weight target

• Drenched and vaccinated

• In good health

gained weight from weaning. If they’re not thriving post-weaning they may need continued access to calf meal, regardless of weight or age.

Relocation can result in growth checks or be a trigger for animal health issues including pneumonia, scouring and parasites.

Recently weaned calves are at

• Transitioned onto a full pasture diet or supplement provided for transition

• Mob average meets weight-for-age target; grazing together as a group; prepared for transport

• Lightest animal within 10% of mob average, assuming they are a similar breed

particular risk as they will be undergoing changes in diet, rumen development, and may be moving from individual or small group care to larger mob management. Relocation adds to the risk: younger, more recently weaned animals are more at risk.

For more information visit www. dairynz.co.nz/weaning

• Article kindly supplied by DairyNZ.

NOW VETS AND farmers are starting to get a handle on what it means to develop and implement a wellbeing plan for a herd, it’s worth looking at how to keep the momentum: how to take it beyond compliance and take advantage of a

must-do for everyone’s benefit.

As understanding develops of what Fonterra requires under the Co-operative Difference framework, the feeling of being overwhelmed by additional compliance is lessening. But the framework will continue

to evolve as Fonterra responds to requests from its customers.

Areas will focus on transparency around animal care tailored to New Zealand’s unique farming practices. We need to work hard to showcase the good our farmers are doing and

the positive lives of our production animals.

For everyone involved, especially vets and farmers, the process needs to be simple and efficient. Vets need the confidence and tools to have conversations to develop wellbeing plans. And it needs to be more than just compliance. How can we all take advantage of the opportunity and get the most out of it?

Using the wellbeing plan is a good basis for the seasonal relationship between the veterinary business and the dairy farm. It is an overview that highlights current performance and encourages improvement. The plan can then determine which activities should happen and when.

It also creates accountability, if you agreed to do something you can hold each other accountable and make it happen. And if you tried but didn’t get the results you were after, you can determine another tactic and keep a record of what has and hasn’t been working.

The topics covered also help bring the vet onto the same page as the farmer. It encourages conversations that vets generally might not get a chance to dive deeper into and helps them understand some of the motives or identify where they could add value with information and considerations.

Thorough discussion and data collection can also help identify areas a clinic can concentrate resources on. Perhaps there is a pressing issue surrounding lameness, or clinical mastitis and with limited time and

resources, it can be hard to cover everything. Having information can helps identify where farmers are struggling the most and help focus efforts on those areas to get the best return.

Of course, any opportunity to proactively manage a herd helps the farming and veterinary business save time and money. If a conversation during the development of a wellbeing plan leads to preventing production loss or losing animals, the return on investment is significant.

While it can be challenging adapting to our changing landscape, we must appreciate the opportunities it offers too.

Data is king and having clear information at your fingertips helps relationships between vets and farmers as well as the outcomes businesses are striving for.

WelFarm has just established an automated link that allows us

to notify Fonterra when a farm has completed their Animal Wellbeing Plan with their vet through the WelFarm portal.

This means one less piece of paper Fonterra suppliers will need to gather when preparing for their on-farm assessment. And the plans are stored in the portal, so when farms do want to refer to them, they can easily log in to find it, which saves sifting through emails or requesting another copy from their vet.

Recognising we were in a unique position connecting vets and farmers through the wider WelFarm programme, we developed our Animal Wellbeing Plan template in response to the updated requirements from Fonterra for the Co-operative Difference.

If a farm is using the wider WelFarm programme some of their metrics feed into the Animal Wellbeing Plan directly which gives vets and farmers more information to discuss as they develop their plans.

It made sense to us to include a simple method to help farmers develop their Animal Wellbeing Plans and leverage their data further.

And having a consistent approach to develop plans is valuable for farmers, Fonterra and the wider sector and using our system gives peace of mind as our template is live and gets updated as Fonterra’s requirements evolve, which saves any back and forth if any updates were missed.

Talk to your vet about getting your next Animal Wellbeing Plan through the WelFarm portal.

TRANSITIONING DRY COWS on a maintenance-only, lower-energy diet to a high performing, lactating animal in a high stress environment is something most New Zealand dairy farmers know something about. But the concept and complexities of transitioning remain for many, often clouded by conflicting information not always suited to New Zealand’s unique “grass first” approach.

Dusting with magnesium oxide is the most common and basic type of transition practiced.

The point of magnesium dusting is to ensure the herd receives sufficient magnesium to prevent hypomagnesaemia or “grass staggers” that result from lowered magnesium levels in pasture.

Often Kiwi farmers will adopt a transition programme aimed at lowering the dietary cation-anion difference in the cow’s bloodstream. Commonly called the DCAD diet, this aims to push the cow’s diet into acidic or “negative” levels, by feeding anionic salts, usually in the form of magnesium chloride.

The aim of this is to improve the cow’s ability to mobilise calcium from her skeleton, helping increase the levels in her blood stream and reduce hypocalcaemia or milk fever.

However, DCAD transition diets were not developed with New Zealand’s pasture based dairy system in mind and require high proportions of “low cation” feed like maize silage or soy in them to work effectively.

But grass is the highest proportion of a typical kiwi cow’s diet, and it means the cation (positive) level is too high for a DCAD diet to pull down into negative or acidic territory.

For a DCAD diet to work, an NZ dairy farmer would have to drop his cows’ grass intake to a minimal level

(3 kgDM per head per day). That is simply not practical; it means the valuable nutrients grass supplies would have to be sourced elsewhere and would be far from cost effective.

Furthermore, a DCAD diet with the usual low proportion of grass in it does not provide an external source of calcium to the cow. It only enables her to mobilise the reserve of calcium more efficiently that she holds in her skeleton.

Just as a bank account never has an unlimited amount of money, neither does a dairy cow’s body have an unlimited amount of calcium to cash in and push out in the form of milk every season.

A cow will on average lose 500g of calcium from her skeleton every lactation season. Australian research indicates that could be as high as 1.5kg. A cow producing 10 litres of colostrum can lose 23g of calcium in one milking alone.

This loss can be accelerated over spring-time, not only by the DCAD diet she has been fed prior to calving, but also by the sharp surge in milk production.

It is in turn only worsened by a pasture sward that is often eaten before the optimal 30-35 day period when pasture nutrient status is at its peak, including for calcium content.

To make matters worse, a cow

needs good vitamin D levels sourced from the sun to help absorb calcium, and that sunshine is often lacking in early spring when her need for it is greatest.

Even when she is optimally fed, a cow will remain in calcium deficit for the first six to nine weeks postcalving, with her output in milk well ahead of input.

It means she is mining her skeleton, and hopefully gaining some of it back over the late lactation-dry period.

But she will typically enter each

lactation with lower levels of calcium than the one before.

Over time her rumen will slow and become less efficient, she eats less, loses energy, and becomes more susceptible to infection and disease. Ultimately, she will succumb to metritis, infertility, mastitis or lameness and exit the herd before her time.

But a calcium deficiency from the start of lactation can’t be fixed through a dollop of calcium administered early on.

Calcium cannot be force fed in a single dose, instead it requires a

constant trickle of a “little, often” to maintain bone health.

To help manage the critical transition period so dairy cows have a healthier and more productive lactation, Sollus has developed Tranzsol.

Tranzsol enables cows to activate their dietary calcium rather than compromising their skeletal calcium store.

Lime-flour combined with a patented form of activated vitamin D (Hy-D) ensures she can receive an effective, regular dose of calcium over transition. Hy-D enables her to absorb

that calcium.

New Zealand studies have shown under a Tranzsol transition diet calcium blood concentrations have been lifted by 30% compared to DCAD diets.

This diet means cows can receive half their maintenance diet in what Kiwi farmers grow best, as grass. This compares to only about a fifth of the diet being grass in an ‘optimal’ DCAD feed regime.

Kiwi cows have been bred with the best “grass first” genetics in the world, with potential to produce at least their bodyweight in milk solids.

Just as a bank account never has an unlimited amount of money, neither does a dairy cow’s body have an unlimited amount of calcium to cash in and push out in the form of milk every season.

PROFITABLE DAIRY

HERDS are built on a foundation of continuous improvement in efficiency and output.

Cows which produce more milk per kilogram of feed consumed will inevitably be more profitable than less efficient animals. Similarly, herds which have a lower replacement rate are more profitable than herds with a higher replacement rate because rearing replacement animals is costly, plus first and second lactation animals produce 15 and 25% less milk than older cows in their third or subsequent lactation animals.

Careful selection of genetics is a tool to help improve efficiency. Another important consideration is heifer management from birth through to first calving – which can affect the lifetime productivity of an animal and affect profitability of the herd.

Data from New Zealand herds has shown that, regardless of the breed of heifer, there is a strong positive relationship between body weight

throughout rearing and first lactation milk production (Handcock et al., 2019), while heifers which are heavier at 12 months of age have greater cumulative milk production through to their third lactation (Handcock et al., 2020).

What is particularly interesting though is the magnitude of the effect that good feeding and management in the first eight weeks of life can have on the lifetime productivity of a dairy heifer.

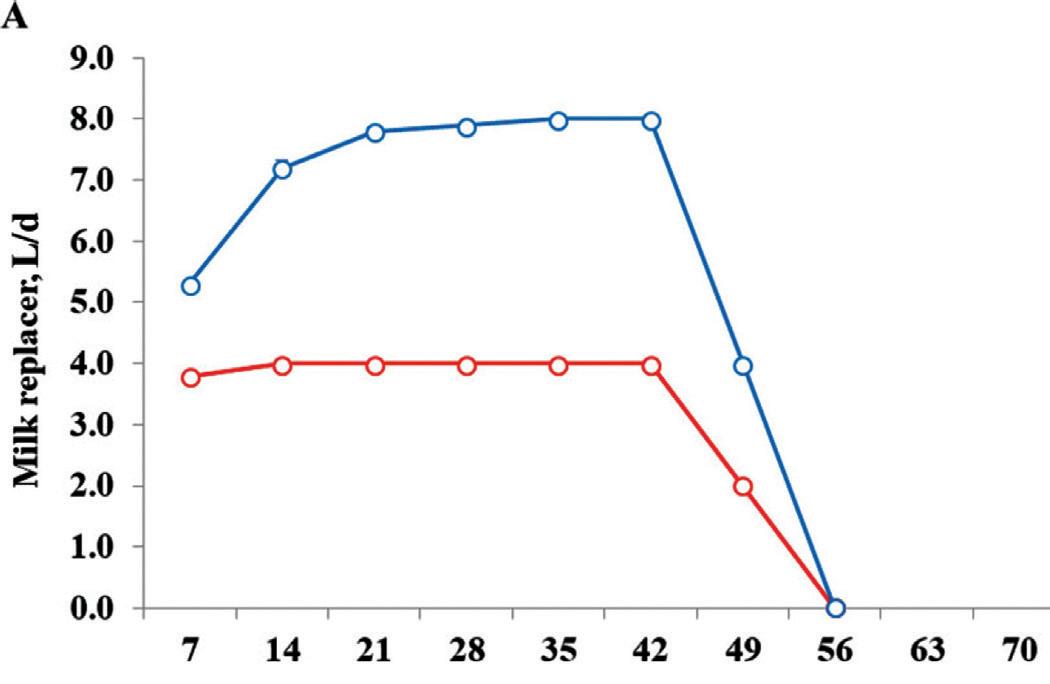

In a long-term trial carried out by Trouw Nutreco between 2014 and 2020, 86 heifers were fed either 4L or 8L of milk replacer from 2 days of age

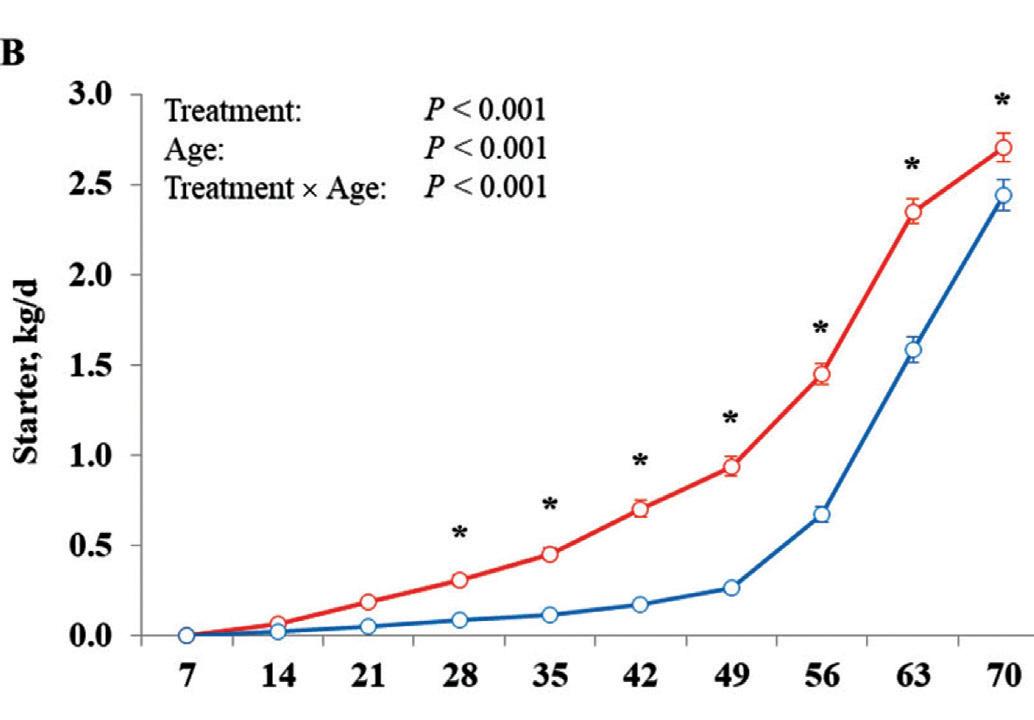

through to 42 days of age and weaned by 56 days of age (figure 1). Both groups of calves were offered ad libitum access to fresh water, calf starter and wheat straw.

From 56 days of age, calves were all fed the same. As expected, those calves allocated a greater volume of milk grew faster and achieved a higher bodyweight by weaning age (figure 2).

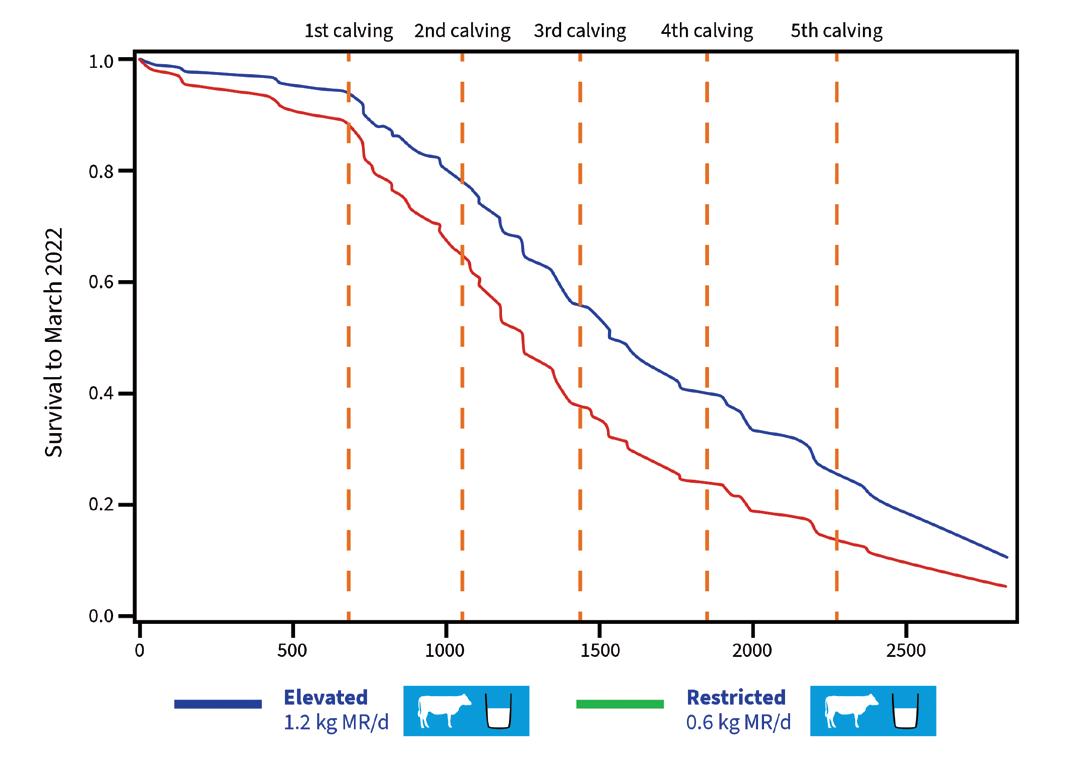

In addition to early growth rates, the survival of heifers and production in their first and second lactation was also measured (Figure 3).

By first calving, 93% of heifers fed 8L of milk remained in the herd compared to only 88% of those heifers fed 4L of milk, while by the start of their 3rd lactation only 37% of heifers fed 4L of milk survived compared to 53% of heifers fed 8L of milk.

Surviving heifers fed 8L of milk were also more efficient converters of feed into milk, producing more milk fat than surviving heifers fed 4L of milk, an effect which carried through into the second lactation.

In the trial carried out

by Trouw Nutreco, calves were fed either 4 or 8L of milk replacer for the first 56 days of life, but there are many other ways in which growth rate and development in early life can be positively impacted.

Ensuring adequate colostrum intake within the first 12 hours of birth not only helps to ensure that the young calf receives adequate immunoglobulins to help protect them against disease but also provides essential growth factors which help drive early gut development and growth. Implementing a colostrum management plan to ensure that colostrum is high quality (>22% brix), is clean and free of contamination, and that calves are fed at least 5% of their body weight within 12 hours of birth and again within 24 hours, may seem complicated, but the returns are worth it. International research shows a strong correlation between blood IgG levels and heifer growth and efficiency of feed utilisation.

Although researchers in the trial described above reported the effect of increasing the volume of milk fed on the performance of heifers, they were in fact comparing the effect of increasing the availability of nutrients to the calves –an effect which can also be achieved by feeding a more digestible milk or milk replacer.

Practical experience of

farmers in New Zealand has shown the benefits of feeding a highly digestible milk replacer, providing more digestible nutrients per kilogram, on the effect of calf growth rates (figure 4).

Under New Zealand conditions, and particularly with the labour shortages currently being experienced on farm, once a day feeding systems are commonplace. Inevitably these systems limit the volume of milk which can be fed to a calf and consequently nutrient intake and early growth rates are restricted. Fortifying whole milk or using milk replacer at an increased mixing rate in these systems allows greater intake of nutrients, faster early growth and ultimately better lifetime productivity.

Although pre-weaning growth rates have the potential to dramatically influence lifetime productivity, growth checks post weaning undo some of the good work done in early life. So, it is important when considering calf to nutrition to consider both pre and post-weaning nutrition and how to optimise both without compromising one

or the other.

Ensuring clean, fresh, palatable hard feed is freely available for calves from day old helps to encourage early feed intake and helps to support early rumen development, easing the transition from milk to hard feeds and pasture. The high starch content of a good quality calf meal or pellet is vital for the development of rumen papillae, essential for the efficient absorption of volatile fatty acids produced through bacterial fermentation of pasture and hard feeds in the rumen.

Feeding a high quality, highly digestible, wheybased milk replacer as part of your milk feeding programme, either as the primary milk source, as a follow-on feed after transition milk and prior to weaning, or as part of a fortified milk feeding programme can help to encourage early intake of hard feed while still supporting rapid early growth and development.

It is also important to recognise that disease challenges, either because of high pathogen load in a shed or surrounding environment, poor air quality, and cold stress increase the proportion of

nutrients which the animal uses for maintenance, leaving less for growth.

Good shed design to ensure adequate air-flow and the absence of draught and thorough cleaning and disinfection of the shed prior to the arrival of calves

are all important in helping to support optimal growth rates.

Also, ensure the pH of the animal environment is not too alkaline.

• Article supplied by AgriVantage.

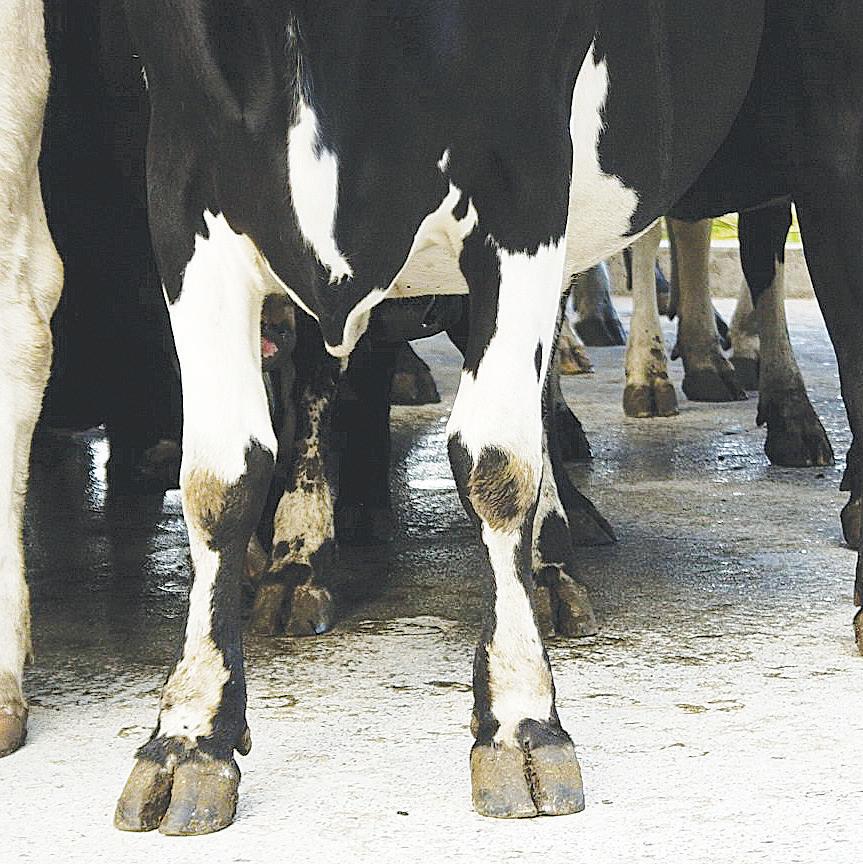

HAVE YOU EVER had a locomotion score performed on your herd? Not sure what they are for or what to do with the information after you’ve received the results? Let’s explore the value of locomotion scoring.

Lame cows cost a farm business from the reduced production, impaired reproductive performance and being susceptible to premature culling. The rough figures estimate a case of lameness costs the business $250, which equates to almost $15,000 for the average 419 cow herd with an average of 14% incidence.

From the 2021/22 season data within WelFarm, it shows an average of 4% of cows were scored 2 or 3 at their locomotion scores performed in early lactation. These are cows that are in the main herd and not previously identified. This means that 4% were picked up and treated sooner before the lameness escalated and they cost the business significant time and money.

Farmers find it frustrating and time consuming to manage lame cows and it poses significant public

perception risks, as well as being considered a serious animal welfare problem.

There are two elements to tackle when managing lameness in a herd; treating affected cows and reducing the incidence and risk.

When a locomotion score is performed it can be used to assess if there are lame cows that need treating. It also shows if there are cows developing lameness that need observing and may need their feet lifted to check. It also shows what the incidence of lameness is looking like

and whether there is a need to review herd management.

A simple system of scoring cows from 0 through to 3, where 0 is normal with good mobility, and 3 is severely lame. Once each cow has been scored, a plan of attack for treating lame cows can be implemented.

Score 0 cows are not lame with a normal gait.

Score 1 cows are slightly lame. They walk unevenly but it can be hard to identify the lame leg. These cows need careful monitoring to ensure lameness does not develop further, and may benefit from having the feet lifted and checked.

Score 2 cows are moderately lame. It is possible to identify the lame leg and they should be drafted, examined and treated as soon as practical.

Score 3 cows are severely lame and should be drafted, examined and treated within 24 hours. They may require a vet. Lame cows should not be made to walk far and should be kept on pasture.

Penny Mehrtens MSD Animal Health ■

Penny Mehrtens MSD Animal Health ■

IT IS WELL known that Bovine Viral Diarrhoea (BVD) is an expensive viral disease of cattle in New Zealand, and is estimated to cost $150 million per year. Recent economic modelling has shown that an active BVD infection in an average dairy herd of 400 cows costs about $70,000/year, and 95% of dairy herds have evidence of past exposure.

BVD can seem complicated and has several layers, so let’s start with naïve animals and herds. These animals

have never been exposed to BVD and are susceptible to a BVD infection. Therefore, if you test a naïve animal or group of naïve animals, you will find no BVD antibodies or BVD virus in their blood, milk or body tissues.

If naive animals are exposed and become infected, they become transiently infected (TI). TI animals may or may not show signs of infection, which could include pneumonia, diarrhoea, milk drop,

high somatic cell count, pregnancy loss and immune suppression. Transient infections are where the main costs associated with BVD are incurred, with each transient infection that occurs during mating costing approximately $90/animal.

Once an animal has been exposed and infected they then become immune. If you test an immune cow or group of immune cows, you will find no BVD virus, but will find BVD antibodies in their blood and milk.

However, TI animals are not the real underlying issue of BVD on farms, Persistently Infected animal’s (PI) are. A PI animal is formed when naïve cows are exposed to BVD virus when they are 40-150 days pregnant. The cow becomes immune to BVD but the fetus, if it survives, becomes a PI and remains a PI until it dies. PIs go on to shed the BVD virus in their saliva, faeces and reproductive secretions for their entire lives, and are the source of future BVD transmission to other naïve cows or herds.

From an economic and animal health perspective it is important to put BVD control measures in place, including; finding and eliminating PIs, preventing new PIs from being created, biosecurity and vaccination.

With 95% of dairy herds showing evidence of past exposure (BVD antibody detectable in bulk tank milk), utilising the available tools to identify the BVD status on farm is critical.

Bulk milk testing for BVD antibodies 2-3 times/year is a great starting point to monitor for levels of infection in your herds. If the antibody level is indicative of active infection (S/P >0.75) then it is best to get your vet involved ASAP, especially in the lead up to mating. At this point, milk may be tested for virus itself, or

your vet may suggest blood testing animals to try to find and then cull any potential PI’s.

Next is to check all replacements as calves, this can be done simply via an ear notch or a blood test. Ideally all calves should be tested, and any PI calves identified and culled before the planned start of mating. This then means that no new PI’s are present on farm at the time of mating, therefore minimising the risk of future PI formation.

After testing comes biosecurity, best described by the “in, out, over” system.

All animals coming “into” the herd need to be tested and/or vaccinated before coming in, and written proof should be provided. This includes bulls and leased animals. A further layer of protection is to spell yards for 7 days between groups of introduced animals.

Then “out” are the animals that have been sent off farm (out) for

grazing and then will come back to the farm. These animals are at risk of contracting BVD while off the farm. If pregnant, they may produce a PI calf that can bring BVD back on to the farm. Therefore, vaccination of all pregnant stock before sending away for grazing is advisable.

Last is “over”, which is what can happen over the fence. BVD is spread by close nose to nose contact so make sure that boundary fences are adequate, ideally double fenced if possible. Also care when moving stock down roads or shared laneways is important to avoid close contact.

The last tool after monitoring, culling and biosecurity is vaccination.

Best practice is to use a premium vaccine like Bovilis BVD to support your biosecurity plan. Not only does the vaccine reduce the severity of transient infections, but the vaccine has also demonstrated 6 months of fetal protection following the initial sensitiser and booster, and 12 months

of fetal protection following a third dose (for example, an annual booster). This is the longest demonstrated duration of fetal protection available in New Zealand. Twelve months of fetal protection covers the herd’s entire risk period for PI formation and continues to protect pregnancies from the late gestation effects of BVD.

Furthermore, vaccinating so your herd has 12 months of fetal protection provides flexibility around the timing of the annual booster; if you need to give your annual herd booster pre-calving or even at pregnancy testing time rather than pre-mating, the subsequent mating season’s unborn calves will still be protected from BVD.

All animals that are at risk of PI contact should be vaccinated; this includes pregnant animals that are sent away for grazing. Furthermore, service bulls should also be vaccinated annually as part of a BVD protection plan.

www.ruralnewsgroup.co.nz

If nights are cold, even in summer, and the milk production of your herd holds up through summer, does that mean your cows aren’t experiencing heat stress? DairyNZ’s Jac McGowan investigates.

WE ALL HAVE an ideal body temperature range, within which we feel comfortable and our immune system and organs function properly. For adult humans, that’s 36.1-37.2°C; for cows, it’s 37.8-39.2°C. Although cows have a higher body temperature than us, they’re less comfortable in warm conditions.

Cows generate enormous amounts of energy digesting food and producing milk. This is handy during winter but a challenge during summer, when cows absorb more heat and it’s harder to maintain an ideal body temperature.

The main way cows get rid of excess heat is by evaporation, which means increased respiration rate, panting and, to a limited extent, sweating. We also see them change their behaviour,

standing up more and congregating around troughs or shade. When this isn’t enough, and their body temperature rises above 39.3°C, their milk yield falls because they eat less and reduce their metabolic rate.

Heat stress usually peaks in mid- to late afternoon. There’s typically some relief at night when lower temperatures allow the cow to dissipate excess heat. Once her body temperature is back in the normal range, her appetite returns, and she may be able to eat enough overnight to compensate for lower intakes during the day.

Milk production isn’t the best indicator of heat stress.

Though warm conditions don’t

Cool nights eliminate heat stress Busted:

While cool nights may reduce the impact of hot days on milk production, cows may still be experiencing heat stress. The best indicator is the cows themselves. Are they grazing and moving easily? Are they loitering or being bullish around troughs or shade? What is their breathing rate?

always lead to reduced milk production, they can still affect welfare. When animals are uncomfortable or they can’t get what they need, like water when they’re thirsty or shade when they’re hot, it affects their mental state as well as physical. For example, lack of shade or water results in increased aggression. And ‘grumpy’ is a common description for cows being milked in a hot shed.

I’VE BEEN READING a book recently, written by a farmer, that questions how we deal with or react to our changing seasonal climates.

The author’s challenge was that, as farmers, we try to solve current and future problems using historical methods and thinking.

Well, that certainly got me thinking!

Whether (or weather!, pun intended!) we like it or not, the seasons are changing, and we’re getting intense seasonal patterns more often.

Total rainfall over the past years

has been close to average, but the spread in the months has become extremely dry in autumn and very wet in winter. We now have seasons occurring where, here in the Waikato, we can grow more in June than we can from February to April combined.

As a consultant I try to provide solutions to problems and adapt these to the physical and human capital available. This varies widely farm-tofarm.

With the advent of cheap supplements being able to be delivered within 48 hours of making a phone call, many seem content to solve the

lack of pasture growth with that quick option. Some are making money doing that, and some know they are merely running to stand still.

Some alternative way to adapt to climate change that I see farms moving toward are:

• Calving date

• Moving to either split-calving or all-autumn calving has been increasing in the North Island. I think this trend will continue, but farmers will need increasing levels of compliance capital to manage the risks for the environment and animals.

However, with the lateness of the droughts breaking in mid-April to mid-May, even calving in the autumn has its challenges. That’s why many are slowing bringing the calving date to a winter calving event, with mid-June being not uncommon. The question to ponder is ‘what happens when a real rough and cold winter arrives back as an anomaly?’

As a way to reduce the effects on feed pressure from calving earlier, a small reduction in stocking rate can help offset this. Industry observers would agree that many herds miss an opportunity to express their full potential in ‘annual milksolids produced’ due directly to underfeeding.

When was the last time you looked at your comparative stocking rate (CSR)?

To maximise the efficiencies of cost-of-cows and cost-of-land, you’re looking for a CSR of 80kg of liveweight per tonne of feed supplied.

Another sweet spot is to look at whether you’re reaching annual milksolid production targets that are equivalent to 90% of liveweight?

If you’re not reaching those levels and have enough contour to manage surplus feed in spring with mowers, then lowering the stocking rate can help through the drier months.

Also worth investigating is to question what pasture species and crops are better than ryegrass to buffer through the dry summers and autumns?

A lot of good research is going on in this space, proving what can be grown either as a mono-culture crop or as a multi-species pasture.

Again, there is merit in moving our

‘How can I retain and farm the little water I have through these dry months?’

‘How can I retain the moisture I have, and what species have the ability to drag moisture from deeper than that of ryegrass and clover?’