Growers under the pump!

Sudesh Kissun

NEW REGULATIONS and compliance issues are making it harder for grow ers to continue producing fresh and healthy vegetables for New Zealanders.

That’s the view of new Pukekohe Vegetable Growers Association (PVGA) president Kirit Makan.

Makan told Hort News that growers are anxious. He says they are uncertain what regulations will be imposed on

their farming operations around water and land use and the environment.

“We are here to produce fresh and healthy vegetables for New Zealanders and it’s getting harder and harder for us,” Makan explains.

The PVGA represents 180 growers – covering an area from Warkworth, north of Auckland to South Waikato.

Most growers are based in the Puke kohe hub – an area comprising 4,359 hectares of some of New Zealand’s most fertile and productive soils.

The area’s temperate, forgiving cli mate and proximity to essential trans port routes makes it ideally located to supply year-round vegetables to Auck land and the rest of New Zealand.

However, like farmers around the country, PVGA members are also under pressure to make further improve ments to farming around fertiliser usage and water quality.

Makan says like other farmers his members use fertiliser to produce mar ketable yield of crops. He says lowering

fertiliser input would push some grow ers out of business.

“We just don’t throw fertiliser down just for the sake of it, we need to put it down to get a marketable crop that we can sell,” he adds.

“The economics of that would be I won’t have a marketable crop and growing potatoes just wouldn’t be viable for me.”

Makan says vegetable growers, like other farmers, are keen to reduce their inputs like fertiliser.

He believes, over time, technology will come along and help growers over time reduce their fertiliser footprint.

On water supply, farmers aren’t sure what the new regulations will look like.

All growers around Pukekohe have resource consents for bore and ground water takes which will need to be renewed in coming years.

Makan says while Pukekohe has been carved out of the National Policy Statement for water, there are “too many unknowns”.

SMARTSPRAYER

HORTNEWS OCTOBER 2022, ISSUE 26 print) online)WWW.HORTNEWS.CO.NZ prices down.

sudeshk@ruralnews.co.nz

Pukekohe Vegetable Growers Association (PVGA) president Kirit Makan says compliance and regulation is making it harder for growers to continue producing fresh and healthy vegetables for New Zealanders.

BA ORCHARD SPRAYER 2000 or 3000 litre models 920mm fan with 2 speed gearbox 10 roll over nozzles per side Manual, electric or autorate control

® Up to 93% reduction in spray loss on the ground Up to 87% reduction in airborne drift Up to 73% reduction of spray consumption *As per research by USDA Talk to our spraying experts to help with your horticultural spraying requirements. 0800 833 538 | www.bapumpsandsprayers.comTHE EST ROUND

Second time’s the trick for Young Grower of the Year winner

Peter Burke peterb@ruralnews.co.nz

Peter Burke peterb@ruralnews.co.nz

MERYN WHITEHEAD, a 28-year-old supervisor at Vailima Orchards at Hope, near Nelson, is the 2022 Young Grower of the Year.

The announcement was made at a gala dinner held in Nelson recently.

Whitehead was one of six regional finalists who vied for the grand title. This involved ear lier local competitions and was followed by a series of practical and theoretical horticul ture modules across two days – just before the final announcement. The competition encourages young people to take up a career in horticulture, as well as celebrating their success in the industry.

This was the second time Whitehead has entered the competition and says the experience has been valuable.

“It is a real privilege to be named the winner of this year’s competi tion, especially given the impressive talent on dis play. It has been an amaz ing experience that has boosted my confidence, provided networking opportunities and devel oped my horticulture skills,” she says. “Taking part in this event and meeting other passionate growers has reaffirmed

my passion for this career and my love of growing.”

Whitehead says horti culture is such a reward

ing industry to be involved in, with so much potential and opportuni ties for all.

“I can’t wait for what the next chapter in this industry brings. HortNZ president,

Barry O’Neil, says the cali bre of this year’s contes tants was exceptional.

“It’s great to see such multi-talented young people emerging as the horticulture industry’s future leaders.”

He says horticulture has had more than its fair share of challenges over the past couple of years – especially with labour supply, adverse climate events, shipping disrup tions, and the increasing cost and complexity of growing.

“These young people are well aware of these challenges and will be the generation who lead our industry through the next phase of this indus try’s development,” O’Neil says.

“They see the potential of our industry to nour ish a local and interna tional consumer base that is more conscious of how its food is grown and gets to the table. These young growers are also excited by the career opportuni ties the New Zealand hor ticulture industry offers them.”

This year’s other final ists were: Sarah Dobson of Pukekohe, Maatu Akonga from Hawke’s Bay, Jacob Coombridge, Central Otago, Maninder Singh, Gisborne and Laura Schultz from Bay of Plenty.

Best of Maori hort on show in 2023

MĀORI INVOLVED in the horticulture sector are being urged to sign up and enter next year’s Ahu whenua Trophy competition in Māori Horticulture.

Entries are now open for the competition. It was launched by HortNZ president Barry O’Neil at his organisation’s AGM in Nelson recently.

The Ahuwhenua Trophy is held annually and over a three-year cycle covers dairy, sheep and beef and horticulture. The inaugural competition for horticul ture was held in 2020.

The competition objective is to recognise excel lence in Māori horticulture and is open to individ ual Māori running horticultural operations, as well as other entities – such as Māori trusts and incorpo rations.

O’Neil says the competition showcases the tremen dous work that Māori are doing to further the indus try, as well as their own iwi and whānau.

“The inaugural 2020 horticulture competition highlighted an intrinsic commitment to the whenua, awa and people,” he says. “I look forward to the coming year as once again, we work together to pro mote passion and good practice, as the kaitiaki of Aotearoa.”

Chair of the Ahuwhenua Committee, which runs the competition, Nukuhia Hadfield says in the past decade more Māori have become major investors in the horticulture sector and this has resulted in good financial returns and jobs for its people. She says there is still much more to do but is sure with the positive publicity that the Ahuwhenua Trophy competition generates, more Māori will be encouraged to become involved in the sector.

“In all the major horticultural areas around the country, there is clear evidence that Māori are set ting up new horticultural businesses or further devel oping established ones and are major contributors to a sector, which in the past year earned $6.5 billion for the economy of NZ,” she says.

Hadfield is urging Māori horticultural enterprises to take the next step and showcase their operations to Aotearoa by entering this competition. She says this is a unique opportunity to demonstrate the innovation and quality, along with genuine sustainability which sits behind Māori horticultural businesses.

Entries close Friday 9 December and the final ists will be announced in February 2023. After that field days will be held in April/May and the winner will be announced at an awards dinner in Tauranga in June 2023.

OCTOBER 20222 HORTNEWS

Young Grower of the Year winner Meryn Whitehead says taking part in the contest has reaffirmed her passion for a horticulture career and love of growing.

FOLLOW US:

Only one piece of the puzzle

PRODUCTIVE LAND is just one of the ingredi ents for growers to deliver fresh healthy food to New Zealanders, says Horticul ture NZ.

Together with produc tive land, growers need labour, access to freshwa ter, less compliance and lower input costs, says Hort NZ chief executive Nadine Tunley.

She made these com ments following the Government’s recently released National Policy Statement for Highly Pro ductive Land (NPS-HPL), designed to protect the country’s most productive land and providing secu rity for both domestic food supply and primary exports.

According to Tunley, HortNZ has been advo

that recognises the importance of the best soils and ensures that they are prioritised for what they are best for –producing healthy vegeta bles and fruit.

“All along we have said that with good planning, New Zealand can have fresh vegetables and fruit, and houses,” she says.

Tunley notes that HortNZ will continue its advocacy to ensure that growers can sustainably and profitably use highly productive land.

“Our fight will go on. It’s no use protect ing our best land if grow ers cannot get access to inputs like freshwater, are bogged down with com pliance, and can’t afford fertiliser or to transport their produce,” she adds.

“At the same time, growers need to know they have a skilful and

pack. We also need to ensure that growers can afford to invest in new growing methods, in response to climate change.”

in one of these areas for their viability to be com promised, which could mean vegetables and fruit cannot be sustainably grown in New Zealand in

Damien O’Connor points out that over the last 20 years, about 35,000 hect ares of highly produc tive land has been carved up for urban or rural res

been converted to life style blocks

“Once land is built on, it can no longer be used to grow food and fibre. That’s why we are moving

especially in our main food production areas like Auckland, Waikato, Hawke’s Bay, Horow henua and Canterbury,” O’Connor says.

He says highly produc tive land provides food for New Zealanders, sig nificant economic and employment benefits to communities and under pins the value of New Zealand’s primary sector.

“Our Fit for a Better World roadmap that we developed with the sector will add $44 billion over 10 years to our primary sector exports but is dependent on maintain ing access to our highly productive soils,” he notes.

He claims the NPSHPL enhances protection for highly productive land giving farmers, growers, and other food producers certainty into the future,

3OCTOBER 2022 HORTNEWS

Sudesh

Kissun sudeshk@ruralnews.co.nz Hort NZ says protecting productive land is just one of the ingredients for growers to deliver fresh healthy food to New Zealanders. • Deutz Tier 3 4-cylinder engine • True four wheel breaking and 100% locking differential • 3,000kg rear lift capacity • A range of wheel configurations for various row widths and canopy heights Agroplus 80.4F Keyline We’re ready to do whatever it takes to keep you growing this Spring. Deal’s not quite right? Ask our team about our flexi finance options. FROM $39,990*DRIVE-AWAY TODAY *Terms, conditions & normal lending criteria applies. 30% deposit, 2.95% interest rate, monthly payments over a 36 month term. GST paid month 3. While stocks last. Offer ends 31st October 2022. Phone 0800 801 888 | deutztractors.co.nz | powerfarming.co.nzPF97339

RSE cap finally lifted

HORTICULTURE NEW Zealand has welcomed the recent Government decision to increase the Recognised Seasonal Employer (RSE) scheme.

In late September, Immigration Minister Michael Wood lifted the current RSE cap by 3,000 to 19,000 for the coming season.

In setting the new cap, Wood said the Gov ernment also took into consideration concerns expressed about work ing conditions from RSE workers.

“The wellbeing of RSE workers is a priority for us, and we have worked with industry and unions to introduce a new provi sion, that employers will be required to provide a sick leave entitlement to RSE workers.

“That is in addition

to the pre-existing mini mum wage requirement of $22.10, which we intro duced during the pan demic.”

HortNZ chief execu tive, Nadine Tunley says

the move will give grow ers confidence to con tinue to invest as they go into the 2022-2023 har vest season.

“Any decision that helps our industry

address its chronic labour shortage is good news.”

However, Tunley says the horticulture industry is eager to continue to work with the Government on a

substantive review of the RSE scheme, to ensure it is fit for purpose and delivers for the Pacific and its people, as well as our horticulture industry.

“We want to build

on the past 15 years and ensure the ongoing suc cess of the scheme in a post-Covid world.”

But there has been some criticism of the Government decision with ACT saying the change is ‘too little too late’.

“The sensible policy change would have been to remove the cap on the number of RSEs com pletely, like Australia’s scheme,” ACT’s Immigra tion spokesperson James McDowall says.

ONE, UNITED VOICE VITAL!

LAST MONTH’S welcome announce ment by the Government that the RSE cap for 2022-2023 would increase to 19,000 came after weeks of discussions, where it was obvious that all of horticulture is different.

but the Government, at many levels, does not understand. Yes, I hear you say, “well they should” and I used to think that as well. However, I have learnt that with finite resources and more often than not, tight to unre alistic timeframes, we need to choose our battles.

The Govern ment expects the horticulture sector to come to it with one point of view. It does not have the time or inclination to deal with us all separately. This situa tion means that between us, we often need to quickly come to a shared posi tion and communicate that succinctly and clearly to the Government, as the final decision maker.

Early next year, a substantive review of the RSE scheme will get underway. In this review, it will be imperative that we come together as effectively and effi ciently as possible to articulate growers’ views and be united. If we cannot do

“Capping the scheme creates untold problems. Employers fight over a ‘quota’ that must be allo cated to each one. The allocation formula is not fair and leads to delays and disappointment year after year.”

He says the RSE scheme is a win-winwin for the primary industries, our pacific friends and neighbours, and New Zealand’s geopolitical aims of a more united and democratic pacific.

this, we risk losing our seat at the table.

The reality is you all have different views because you are looking at things from your part of the sector’s perspec tive.

That is what we, as your represen tatives, would expect. However, me and my team’s role is to col late and distil all these different views and present the best col

HortNZ can only do this if we are trusted and have a thorough understand ing of the dynamics and challenges of commer cial fruit and vegeta ble growing in New Zealand. To be confi dent in our views, we need growers to talk to us, their product groups and district associations, who then need to work with us to form a collec tive response.

This will definitely need to happen in the review of the RSE scheme next year. The Government is counting on there being one team at the negotiating table (which includes viticulture for this topic).

If we cannot come together as one team, we will be unable to ensure that the RSE scheme continues to enjoy the success that it has over the past 15 years.

• Nadine Tunley is chief executive of Hort NZ.

OCTOBER 20224 HORTNEWS

Nadine Tunley

Nadine Tunley

“The wellbeing of RSE workers is a priority for us, and we have worked with industry and unions to introduce a new provision, that employers will be required to provide a sick leave entitlement to RSE workers.”

Last month the current RSE cap was lifted by 3,000

to 19,000 for the

coming season.

David Anderson

Large-scale Maori horticulture project for Northland

THE GOVERNMENT is sinking nearly $1 mil lion into a major horticul ture project in Northland to enhance Māori-owned land in the province.

Agriculture and Rural Communities Minis ter Damien O’Connor claims the $975,000 will help members of the Tupuānuku Collective explore the potential of their land and to create jobs.

The collective is made up of representatives from 13 whānau, hapū and iwi landowners – cov ering more than 35,000 hectares from the Far

A FEASIBILITY study is being car ried out to see if almonds can be grown sustainably in Hawke’s Bay.

The Plant and Food Research project has backing from central and local government, alongside Picot Productions Limited – the Nelson-based producers of the Pic’s brand nut spreads.

“We’re already supporting peanut growing trials in North land – now it’s almonds’ turn,” says Steve Penno, MPI’s director of investment programmes.

“The first step is to see whether we can successfully pro duce almonds with a low carbon footprint at scale and for a com petitive price in New Zealand.”

MPI is investing $67,000 through the Sustainable Food and Fibre Futures fund (SFF Futures) in the $100,000 project.

Plant and Food Research busi ness manager Declan Graham said the goal is to provide diver sification opportunities for local dry stock farmers – rather than trying to replicate the large-scale almond monocrop system of Cal ifornia.

“Ideally farmers will be able to set aside some of their pasto ral land for growing almonds, as a way of diversifying and deriv ing better value from their land.”

AgFirst will undertake a finan cial analysis as part of the project. They will consider the economics of setting up a profitable almond orchard system – factoring in market prices, climatic volatility, and environmental sustainability challenges.

“We need to understand whether Kiwis would prefer to

buy New Zealand almonds and whether growers would be able to get the returns they need,” Graham says.

If the feasibility study shows almond growing has promise, the next step would be growing trials.

“We’d look at experimenting with the Future Orchard Plant ing Systems (FOPS) approach, which optimises the use of sun light for higher yields and qual ity,” Graham adds.

“We’d also investigate if we can grow almonds using less water compared to commercial practices overseas, as well as an integrated pest management approach.”

Graham says almonds were first introduced to New Zealand by Chinese goldminers during the Otago goldrush in the 1860s.

“We’ve already done some blue skies work to understand the almonds growing in the hills in Otago,” he adds.

“We’re also analysing the almond crop grown by a local Hawke’s Bay farmer.

“Our research to date indicates that Hawke’s Bay’s climate is ideal for almonds. There’s not enough chilling in Northland and the Otago cultivars can be damaged by late frosts,” Graham explains.

“Given almonds flower early, they won’t interfere with other crops in the Hawke’s Bay region.”

Central Hawke’s Bay District Council mayor Alex Walker says the aims of the project fit well with the council’s economic development strategy.

North down to the Kaip ara district. It was funded by MPI’s Māori Agri business extension pro gramme.

O’Connor says North land’s potential to grow food is substantial and this investment will enable landowners to get on-the-ground support to identify the best crops to grow in their district and to assess the availability of water for irrigation.

“Accessing water and building the necessary infrastructure, such as dams, will play a vital role in lifting the productivity of this whenua, especially as our climate changes. A key part of the two-year project will be to deliver a workforce capability development strategy to support the creation of new jobs,” he says.

O’Connor says contrac tors will investigate water accessibility and storage, map soil types and sup port the collective’s mem bers to lodge consents and get investment ready.

He adds that the Minis try of Social Development (MSD) is also support ing the project by helping to determine workforce requirements and training needed to provide yearround employment.

In 2020, horticulture was worth $386 million to the Northland region, with kiwifruit and avoca dos the largest revenue and export earners. In total, NZ earns $6.7 bil lion annually from horti culture.

O’Connor says since 2019, MPI’s Māori Agri business team has part nered with Māori clusters across the country, help ing Māori landowners access support and exper tise. He claims this has resulted in more than 30 approved whenua/land development proposals.

Extra regionally-based advisers and facilitators will also be hired to sup port the expansion of Māori agribusiness ser vices into new regions across the country.

ESCORTED TOURS 2022/23

"Hassle free travel for mature travellers’’

• FAR NORTH & BAY OF ISLANDS (4 spots available)

7 days, depart 17 September. A leisurely coach tour of the Far North including the new Hundertwasser Art Centre and day trip to Cape Reinga.

• EAST COAST & NAPIER (6 spots available)

8 days, depart 21 September A unique and exciting tour around the East Cape and return via the Northern Explorer train

• CHATHAM ISLANDS DISCOVERY 8 days, depart 20 October A special place for a safe and relaxing close to home all inclusive holiday.

• BEST OF THE SOUTH ISLAND

days, depart 22 November A spectacular trip around the many highlights of the South Island taking in the wonders of Tekapo, Twizel, Stewart Island day excursion, the Milford Sound and Queenstown. Overnight cruise on the Milford Sound

• NEW PLYMOUTH 'CHRISTMAS LIGHTS'

days, depart 23 December A Christmas get away featuring the magnificent light display at Pukekura Park along with some great sightseeing during the trip.

• WAIKIKI BEACH & HAWAII CRUISE

11 days, depart 25 May 2023 A 'Pride of America' cruise for 7 nights with a Waikiki highlights 3 day stop over including Pearl Harbor and Oahu round Island tour.

• TAHITI & SOCIETY ISLANDS CRUISE

10 days, depart 21 July 2023 Set sail on board Le Paul Gauguin for an unforgettable journey to discover idyllic sands and atolls. Tour includes flights to/from Papeete.

details

5OCTOBER 2022 HORTNEWS

Peter

Burke peterb@ruralnews.co.nz ‘NUTTY’ IDEA OF NZ

Agriculture

Minister Damien O’Connor claims the investment will enable landowners to get on-theground support to identify the best crops to grow in their district. @rural_news facebook.com/ruralnews

15

5

For full

Phone 0800 11 60 60 www.travelwiseholidays.co.nz TRANSTAK BIN TRAILERS Designed and Manufactured in NZ for Over 25 years TRANSTAK® 3000LT ❱❱ 6 Bin Capacity for shifting high volumes of fruit “Thanks to all the Transtak Team, your bin trailers are amazing!!” – Horticultural Contractor *TERMS AND CONDITIONS APPLY www.transtak.co.nz • sales@transtak.co.nz 0800 303 063 TRANSTAK BIN TRAILERS Designed and Manufactured in NZ for Over 25 years TRANSTAK 1500LE ❱❱ Fast and efficient bin shifting capability with 3-4 bin capacity ❱❱ Transtak's Soft-Ride suspension system ensures fruit protection. ❱❱ Single hydraulic connection and forklift design provides simplicity of operation ❱❱ Few moving parts ensuring low maintenance requirements Extremely durable construction backed by warranty www.transtak.co.nz • sales@transtak.co.nz 0800 303 063 *TERMS AND CONDITIONS APPLY “Thanks to all the Transtak Team, your bin trailers are amazing!!” – Horticultural Contractor 8 different models available from 2-6 bin capacity ®TRANSTAK® 1500LE ❱❱ NEW 2022 design 150mm narrower to improve performance within rows. ❱❱ Fast and efficient bin shifting capability with 3-4 bin capacity. ❱❱ Single hydraulic connection and forklift design provides simplicity of operation. 8 different models available from 2-12 bins capacity ❱❱ Transtak’s Soft-Ride suspen sion system ensures fruit protection. ❱❱ Few moving parts ensuring low maintenance requirements. ❱❱ Extremely durable construction backed by *3 year warranty.

The super salad maker!

On the outskirts of Gisborne a huge new greenhouse is being erected, complete with its own water supply, to potentially help make the town the 'salad capital of NZ'. Peter Burke explains.

LEADERBRAND IS one of the largest horticultural commercial growing companies in the country.

It is based in Gisborne, but has growing sites in Pukekohe, Matamata and Canterbury. While it grows a variety of crops, it has a big focus on producing ready-toeat salad packs, which are sold in supermarkets around the country.

With that strong focus on producing salad packs throughout the year and to overcome some of the vagaries of climate, chief executive Richard Burke (no relation to Peter) set in place a strategy to achieve that goal and put Gisborne on the map at the same time.

“The Marlborough region owns grapes, Hawkes Bay owns apple and Bay of Plenty owns kiwifruit and we felt if we could establish a structure that would allow us to expand our salad business, then Gisborne could lay claim to be the salad capital of NZ,” he told Hort News

Right now, Leaderbrand is in the process of erecting this massive glass house. It is 10.7 hectares in size and supported by a dam that holds 40 million litres of water to irrigate the facility – all at a cost of a cool $15 million-plus.

Burke says at Leaderbrand they dream big and says once you start to dream it sets you on the path to achieving that dream. He says the company noted that the development of intensive, high value horticulture was something that was strong around the world.

However, he says while this was happening, as a company it was focused on updating and building new factories and infrastructure to develop its salad business.

There was little money

available for large capital development – until the Provincial Growth Fund emerged.

“We were talking to some people connected to the PGF and they said to us if capital wasn’t a problem what sort of project would you run,” Burke explains. “And they were really looking at it from the angle of economic development and jobs for the region, which was the PGF mantra. We felt with our investment in salads that a covered production system would really cement our position in that area.”

So, the decision was made to go with the project and a loan of $15 million was arranged with Leaderbrand also chipping in some cash. The aim says Burke was to ensure the company’s operation remains competitive and that challenge will only be proven when the glasshouse is fully operational.

The huge glasshouse was sourced from France, but at time of signing the deal no one predicted that Covid19 would arrive. With the ensuing lockdowns, border closures and the inability to get people from overseas to NZ to scope and measure up the site, the later start constructing the actual greenhouse was challenging.

“It took us a long time to confirm all that by Zoom which was hard work. Part of it was because no one here had the experience of putting a facility up like this,” Burke told Hort News

“It was recommended that a European company come and do it so we could learn and then when we expanded we had that knowledge ourselves.”

THE TASTE OF SOIL

ONE OF the unique features of this glasshouse is that all the plants will be grown in soil – unlike many others which use hydroponics or another medium in which grow crops. Burke says the decision to grow in soil will mean that extra work is necessary to get it back into shape for growing. He says indoor farming is great from a supply point of view but adds that there was a special motive for growing in the soil – taste.

“We are not ready to give it up yet. While indoor factory farming is great, the question we had is what impact does it have in regard to taste?” he told Hort News

“We have been a business that’s been focused on tastes – whether it’s been sweet corn, watermelon squash and even broccoli. Taste is a big factor to us which comes with the variety of the plant, harvest timing, maturity and freshness. We’ll also be looking at leaf integrity, leaf toughness and whole lot of other things. We wanted to move indoors and work in the soil and see the impact of taste first and then take the next steps,” he says.

The crops that will be grown in the greenhouse will be the various leafy ones that make up the salads – such as lettuce, spinach and also some herbs. These will be

grown and cut in the same way as the present outdoor crops. Burke says the glass house won’t be a full replace ment for outdoor crops.

Currently, about three hectares of the site is now under glass and some cover crops are being grown as well as some trial crops to get an early understanding of how the system works. Burke says they hope to have the project

completed this summer.

The other unique feature is the so-called dam – large enough to stage a yachting regatta.

The water for this will come from the roof of the glasshouse and to all intents and purposes make the facility self-sufficient.

“But as you know, Gisborne can be unreliable with rainfall and also too reli

able as well,” Burke explains.

“We have got 40 million litres there which we think will last for a period of 50 or 60 days without rain. But we have the capacity to add to this out of our current consents – so we have back up.”

In the meantime, the resi dents of Gisborne are eagerly watching and waiting to see the completion and outcome of this giant salad maker.

OCTOBER 20226 HORTNEWS

Leaderbrand is in the process of erecting this massive $15 million glass house, that is 10.7 hectares in size and supported by a dam that holds 40 million litres of water to irrigate the facility.

Leaderbrand chief executive Richard Burke says the company has a business that’s focused on taste.

Watching over your horticulture crops so you don’t have to. Delivering a complete suite of crop protection solutions for today’s horticulturists. Our portfolio of powerful, proven products has helped growers from one end of New Zealand to the other create and maintain thriving businesses, and has earned us an excellent reputation in horticultural crop protection. Our suite of insecticides and fungicides provide growers with everything they need in the war against pests and diseases. Visit corteva.co.nz to view our range of products and online horticultural resources. INSECTICIDE Qalcova ™ active Naturalyte™ Entrust™ SC FUNGICIDE Kocide®Opti™ INSECTICIDE Prodigy™ INSECTICIDE Isoclast™ active INSECTICIDE Jemvelva active Sparta™ INSECTICIDE Jemvelva ™ active Uphold™ INSECTICIDE Fenamite™ FUNGICIDE Fontelis® FUNGICIDE Talendo® FUNGICIDE ZORVEC ™ Enicade FUNGICIDE NEOTEC Dithane Rainshield Visit us at corteva.co.nz ®, ™ Trademarks of Corteva Agriscience and their affiliated companies. COR-RNHHORT-CTA0018

Apricots come to fruition

THREE NEW apricot vari eties will be picked this summer after almost two decades of research and development.

NZ Summerfresh Ltd says the new varieties –NZsummer2, NZsummer3 and NZsummer4 – are under trial in Central Otago and parts of the North Island.

Developed by Plant & Food Research and the summerfruit indus try, NZ Summerfresh Ltd has been established to commercialise new apri cot cultivars under devel opment for nearly two decades.

More than 50,000 trees spanning 60 hect ares are under trial in Central Otago and parts of the North Island. The trees are with a mix of long-standing summer fruit producers and newer

growers who are trial ling the varieties under licence.

“These varieties are substantially better than nearly every other apricot I know of and could be the best in the world, [with] the potential to revitalise and relaunch the premium apricot category on the global stage,” says inaugural NZ Summerfresh Ltd chairman Stephen Darling.

Described as intensely sweet and juicy with a crisper texture and highcolour profile, two vari eties (NZsummer2, NZsummer3) store longer to achieve a longer sell ing period and will target export markets. The other variety (NZsummer4) will target the domestic market.

The varieties will span a successive season from December to late Febru

ary, with initial market targets of Asia, Australia and the United States.

“Australia is an impor tant market because our season complements

Australian product well, arriving after local prod uct, therefore extending the season. Consumers in Asia favour apricots with increased sweetness, low

acidity and bright colour – characteristics we deliver,” Darling says.

Initial volumes this summer will be small, with trials sent to key

customers and consum ers, then growing sub stantially as more fruit develops, with full pro duction expected from 2025-2027.

NZ Summerfresh Ltd founding director Roger Brownlie, who is also chair of Summerfruit NZ and a grower, says the long journey to commer cialisation has been the result of years of hard work across multiple fields.

“It took until 2013 to get to the point that three [varieties] reached the elite stage for evaluation.

It has taken three chief executives, teams of Plant & Food scientists, indus try collaboration and grower efforts.”

Following its inaugu ral annual general meet ing on August 8, Darling and Brownlie said NZ Summerfresh Ltd would transition to a grower

co-operative. The new co-op will commercialise the proprietary variet ies for export and domes tic consumption from late summer 2022-2023. The aim is to give growers and shareholders the chance to “control their destiny and work for a common benefit”.

Darling says next steps included develop ing a strategic commer cial framework including branding and marketing plans, identifying export markets and establishing optimal harvesting and quality standards.

A growers’ forum is being established to help with technical infor mation and transfer of knowledge, with nego tiations underway with Plant & Food Research on a further two apricot vari eties.

OCTOBER 20228 HORTNEWS

Leo Argent Three new apricot varieties will be picked this summer after almost two decades of R&D. @rural_news facebook.com/ruralnews RURAL NEWS TO ALL FARMERS, FOR ALL FARMERS Delivering to your mailbox for over 30 years www.ruralnews.co.nz

Tomato growers really feeling the squeeze

THE COST of produc ing tomatoes is pushing smaller growers out of the industry.

Tomatoes NZ chair Barry O’Neil says some growers are not replant ing full areas of their glasshouses because they do not have enough labour.

“My board has been concerned for some time we keep getting push back – from consumers, the media, from policy makers, from government – that the price of toma toes is so high that grow ers must be creaming it,” he told Hort News

For instance, tomatoes might have been priced at $14/kg for loose tomatoes in the supermarket over winter.

“Little do the people realise that the cost of producing tomatoes is such that a number of growers have stopped growing,” he says. “Over the last four years, 25% of our smaller growers have left tomato growing either to grow cucumbers or leave all together.”

O’Neil believes covered cropping is the future in terms of resilience to cli mate change and manag ing inputs and outputs. However, he says that policy settings need to be right to allow this to be viable.

Tomatoes NZ has

released a discussion doc ument outlining some of the major issues facing the industry.

“We have raised the issues of food security in the document. In New Zealand we may think we don’t have a problem with food security because we export so much food,” he told Hort News. “But the reality is, with fresh vegetables – and in this case fresh tomatoes – it’s becoming more difficult to grow and succeed as a business. If we are not careful we will end up importing frozen vegeta bles and tomatoes from countries that don’t have the same restrictions.”

O’Neil says a new glasshouse might cost about $3million/ha to

set up and get operating and a huge investment is required.

“The number one issue is labour. It is not a wage thing, how much we are paying, the labour is just not available.”

He says tomatoes are nearly a full 12-month crop but a number of growers are not replant ing the full area of their glasshouses because they don’t have any certainty of labour.

“We recognise every one is in the same boat, it is not just the tomato industry suffering from labour shortages. But surely, as a country, we can be more open minded and work more proac tively to get the right labour settings with

migrant labour, especially those which will sup port our industries to suc ceed rather than to shut down.”

O’Neil says another concern for the sector is energy. “Energy costs have increased by more than 50% over the last 12 months. Energy is already in the ETS scheme, so with the heating of glass houses we are already impacted by the ETS,” O’Neil explains. “Whereas other countries produc ing tomatoes internation ally are not. We have a disconnect, with respect to some of the costs and policy settings we have in New Zealand, compared to our competitors.

He says the industry is committed to becoming

carbon neutral.

“But we can’t do it on our own, so a transi tion to a future that will be economically viable as well as sustainable is really critical.”

O’Neil adds that bios ecurity has also been a huge problem for the sector.

“We have spent hun dreds of millions of dol lars over the last few years in responding to biosecurity events that weren’t of our direct making,” he explains. “But as an industry we are dependent on imported seeds and so we get, with those seeds, problems coming in, which as an industry we are forced to pick up the cost and respond to.”

HOT AIR COSTLY

THE HEATING energy dynamic is particularly important for tomato growing.

O’Neil says heating costs for glasshouse tomatoes is the second highest cost for production after labour.

“For our business the cost of heating doubling will have a real impact.”

He believes that a very real scenario for New Zealand is that tomatoes will be produced outside of NZ if we can’t address some of these policy issues and get the industry viable.

O’Neil explains that ETS industrial offsets are meant to support growers – so they are not disadvantaged by imported Australian toma toes. Those industrial offsets are down to 60% (they were at 95%) and are reducing every year.

“With every auction of carbon units growers are being more and more exposed to the true cost of carbon.”

He’s heard one grower say the cost was about $50,000 per hectare.

“They can’t grow at that sort of level.”

O’Neil says the sector is trying to work with government and get more dialogue on how to transition to renewables.

“There are two issues. There is a transition needing financing to move to renewables –how can the government support the sector in that, and the second one is the certainty of the supply of renewable heat fuel, if that is wood biomass or whatever. There needs to be certainty in the market,” he adds.

“If I am a tomato grower, I am not going to spend $12 million changing my boiler to a wood biomass, to then find I can’t use it every day because I can’t access enough wood biomass. That is just an example.”

O’Neil says the industry needs policies that will help and support transitioning to viable covered cropping for the future.

9OCTOBER 2022 HORTNEWS

Pam Tipa

Tomatoes NZ chair Barry O’Neil says costs of producing tomatoes is pushing smaller growers out of the industry.

More food from less!

IT’S THE stuff of science fiction – vertical gardens growing enough food to support communi ties – and it’s coming to a neighbourhood near you.

That’s one of the take homes from this year’s Wall Street Journal’s Global Food Forum. I was in Chicago for the forum.

Horticulture is vulner able to even subtle cli mate changes, and this is leading to a scramble to develop new variet ies (and, in some cases rediscovering old ones) that are ‘hardy’ to chang ing conditions. The clear objective, of course, is the ability to continue to pro duce food for a hungry planet.

Imagine then, the excitement when you hear of production sys tems that use fewer resources, produce more, and (to an extent) are pro tected from environmen tal vagaries.

Locally we are seeing production methods that are partially adapt ing to climate change, such as cherries produced using technology to pro tect them from frost and rain. But the real benefit of innovation is reducing all inputs – including the costs of transportation to get products to market.

Vertical gardens have the ability to shift pro duction facilities to close to where the market is,

reducing the need to shift leafy greens from the West Coast of the USA to the East Coast, for exam ple. Not only are trans portation costs reduced but so too is food wastage (valuable ‘shelf life’ time is not lost during trans portation), along with water use, pesticides, and land. Interestingly, these techniques are either at, or close to, price parity with conventional grow ing methods.

Where food can’t be produced in a vertical set ting, technology is being used to develop plants that are more resilient.

Ponsi Trivisvavet from Inari, a US-based seed developer, describes gene editing as a process for unlocking the potential of existing species using CRISPR technology.

CRISPR is relatively new and is described by Trivisvavet as speed ing up natural processes, asserting that the work that they do happens in nature but is slow. The objective of Inari’s work is to decrease land use, water, and nitrogen fertil isers in grain production. Genetic modification (the addition of a foreign gene) takes 16 years and costs around $130 mil lion US$ per product. In comparison, gene-editing takes about one third of the time and one tenth of the cost.

Other examples of CRISPR development

were provided by Tom Adams of Pairwise, where they are developing a leafy green that tastes like a lettuce with the nutri tional value of kale, seed less blackberries (85% of eaters don’t like the seeds), stone fruit with out stones and cherries grown without pits and on bushes rather than trees.

In response to a ques tion about consumer acceptability, Adams was philosophical, suggest ing that about 30% of the population (gener ally younger consum ers) are really excited about the technology and around 20% of the popu lation will never be. His focus is on working with the remaining group to increase acceptability.

The need for fewer inputs is, in part, driven by global supply chain challenges and geopol itics. US Secretary of Agriculture Tom Vilsack expressed concern for the costs of inputs for farm ers noting that this will be worse next year (because most seed and other inputs are already pur chased). The US Depart ment of Agriculture is proactively focusing on a “conservation reserve service” which includes investing in technology and innovation to reduce on-farm inputs.

Vilsack’s concern about reliance on fer tiliser from overseas

OCTOBER 202210 HORTNEWS

Helen Darling

Helen Darling believes new innovations will continue to challenge traditional farming and growing practices.

2023 Edna Calendar T: 09-307 0399 then press 1 to be put through to reception E: julieb@ruralnews.co.nz ORDER NOW! ❱❱ $25 including post & packaging ❱❱ 12 of Edna’s best cartoons ❱❱ 330mm x 240mm, spiral bound EDNA!! EDNA CALENDAR 2023 “You do realise Edna, if we start to float, you’ll be breaking the law banning live animal shipments!” “Break my New Year resolution? no way – it must be the Aussie bushfires you can smell!” RURAL NEWSTO ALL FOR FARMERS HORTNEWS SUNDAY MONDAY TUESDAY WEDNESDAY THURSDAY FRIDAY SATURDAY 1 2 3 4 5 6 87 9 10 11 12 13 1514 16 17 18 19 20 2221 23 24 25 26 27 2928 30 31 1 2 3 4 JANUARY FEBRUARY NEW OBSERVED YEARS ANNIVERSARY ANNIVERSARY

Bumper crops keeping kumara prices down

Sudesh Kissun

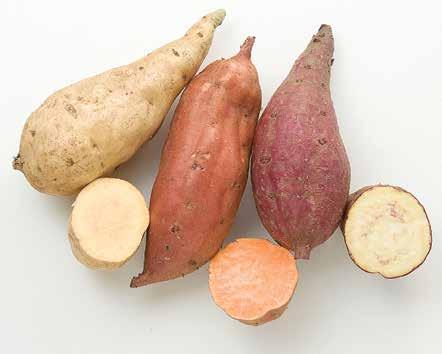

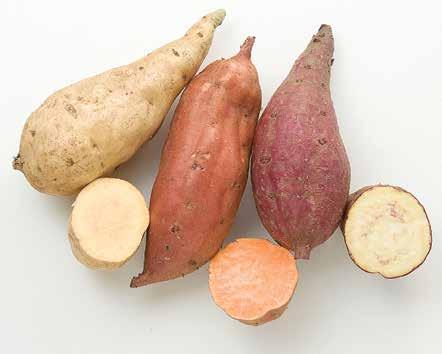

BUMPER KUMARA crops over the past two years are keeping prices down across all varieties.

Some kumara growers are responding by reducing their planting areas to focus on other parts of their business like dairy and beef.

Prices for orange kumara have dropped below $2/kg, while red kumara prices are also down, hovering around $3.50/kg.

Warm, dry conditions led to the 2021 crop being 35% higher than the previous season and about 25,000 tonnes were harvested.

Vegetables NZ director and Northland kumara grower Warwick Simpson told Hort News that the 2022 yield has also been higher for most. Growers are trying to cope with the drop in revenue.

KUMARA IN NZ

KUMARA WAS brought to NZ over one thou sand years ago from the Pacific islands by early Māori settlers.

The majority of kumara is grown in North land, in the Dargaville and Northern Wairoa regions where soil type and climatic condi tions suit it perfectly.

There are different varieties of kumara, however, only three are commercially avail able in New Zealand. The most common is the red-skinned Owairaka Red, which has a creamy white flesh and is sold as Red.

Gold kumara, sometimes sold as Toka Toka Gold, has a golden skin and flesh and a sweeter taste than red.

Orange kumara has a rich orange flesh and is sweeter than both red and gold.

“They are tightening their belt, reducing their spending and hoping next season is better,” he says. “Some growers are reducing area to focus on other elements of their business, for example dairy or beef.”

The bumper crop last year took growers a

month longer to sell their crop, cutting the 2022 selling season by a month as well.

“A particularly large oversupply of orange kumara is bringing the price down, but this is bringing down the price of red as well,” Simpson says.

Growers say a large oversupply of kumara is bringing the price down.

Planting for the new season will start this month. Many growers finished putting in seedbeds to grow plants and slips which are then cut and planted out in the paddock.

Simpson believes that, like other farmers, kumara growers are

enduring challenging times.

“I think we’re in a particularly bad situation at the moment because of the high cost of living and we’re just starting to come out the other side of Covid,” he explains.

“High cost of living is causing consumers to

Lend a helping mandarin!

WEST AUCKLAND community foundation The Trusts is calling on Kiwis with citrus fruit trees on their properties to pick sur plus fruit and donate it to those in need, rather than let it go to waste.

Chief executive Allan Pol lard says citrus fruits such as oranges, grapefruit, lemons and mandarins are currently in season and food rescue chari ties like Fair Food can often collect the produce from those willing to pick it.

“Winter, along with Christ mas and back to school, are the months with the highest levels

of need,” he adds. “Thousands of whānau in our communities are facing the perfect storm of seasonal cost pressures for thousands of members of our community.”

The Trusts also provides financial support to Fair Food, which aims to provide food for 5,000 vulnerable families and deliver 75,000 meals this winter.

Fair Food supplies over 50 Auckland community groups with over 2.4 million meals per year. It has also opened a ‘Con scious Kitchen’ to teach com munity members the principles

of upcycling food – taking food matter that would normally be discarded as waste and turning it into something more useful e.g. coffee grounds as fertiliser.

Around a third of all food produced globally is wasted. However, staff at Fair Food receive and each day hand-sort around a tonne of discarded food provided by supermarkets, growers and manufacturers.

The surplus produce would otherwise be destined for land fill, generating an estimated 540 tonnes of greenhouse gases annually.

Fair Food chief financial

officer Deborah McLaughlin says the poverty gap is widen ing, with pandemic-driven food shortages, inflation and winter heating costs all impacting already vulnerable families.

She says around 40% of Kiwi households experience food insecurity and 19% of children live in homes where consistency of food supply is a concern.

Pollard says it is critical that organisations like Fair Food be given the support of corporates to allow them to continue their work during peak seasons of need. – Leo Argent

buy less fresh vegetables, resulting in oversupply and low prices.”

Covid has also made the overall labour situation difficult because of the lack of backpackers, and difficulties around the Recognised Seasonal Employer (RSE) scheme.

While most growers use casual labourers for preparing seedbeds, Simpson says the labour issue could arise when planting starts.

“We’ll find out how the labour situation really is when we start planting,” he told Hort News

“With some luck, the removal of Covid restrictions will see backpackers back in, and our labour challenges will be eased. Once we get past those, things will improve.”

Simpson says other challenges facing growers right now include dramatically increased fuel and fertiliser prices. He adds that there are some long-term challenges including tighter controls on agrichemicals, freshwater farm plans and climate change (both the effects and compliance), which will need to be worked through.

FELCO

LOPPERS

FELCO POWER TOOLS

11OCTOBER 2022 HORTNEWS

sudeshk@ruralnews.co.nz

Kiwis with citrus fruit trees on their properties are encouraged to pick surplus fruit and donate it to those in need. Available at your local FELCO Stockist. Heiniger is the exclusive FELCO distributor and authorised service centre in NZ - contact us to find a FELCO dealer near you. (03) 349 8282 | heiniger.co.nz Swiss precision. Made to last.

211

The perfect balance of power and manoeuvrability. The FELCO 211 range feature lightweight aluminium handles for comfortable cutting and curved cutting heads to pull in and easily slice through branches

Power through even the biggest jobs with ease. Designed to act as an extension of your body, the new FELCO Power Blade series feature lightweight, ergonomic handles for comfortable pruning all day long. NEW

Tough times for growers in the strawberry patch

WHETHER OVERSEAS

casual workers arrive in time to make a difference for this year’s strawberry season is the big question, says Strawberry Grow ers NZ’s (SGNZ) chairman Anthony Rakich.

The past two years have been difficult with no visitors, no new RSE workers allowed in and those that were here were getting tired.

“Things are changing now. We are going to get backpackers in, we will get tourists in, the RSE’s are coming back,” he told Hort News

Whether there will be enough in time “will be interesting”, Rakich says.

Some under cover growers are already pick ing and the season will be well under way next month (October).

“I am personally con cerned there is plenty of other work for people and I can only offer parttime work. I don’t have full-time employment for them,” he says.

Rakich believes many smaller growers will be in the same boat. He already knows he has lost good workers from last year as the best ones are snapped up by full-time employ ers.

“I rely on local work ers, really the people who have been with me for a long time that keep coming back,” he

explains. “Usually they find other family mem bers, other people they know who want to work. That has always been how I’ve got workers. But things are changing.”

Rakich says the RSE scheme is not feasible for smaller growers. But for the wider industry, SGNZ is talking with HortNZ about the RSE scheme, having the cap lifted so there are more coming in early enough.

SGNZ has about 180 members. The industry has shrunk a little. Rakich says there’s about 11.5 million plants this year as

HOMEWARD BOUND

RAKICH SAYS exports are not a huge part of the NZ strawberry industry now.

“Covid, transport, rising costs etc have had an effect so the amount exported is certainly down. That of course puts more pressure on the local market,” he told Hort News

“The last few years with Covid have been tough. There has not been much export and there’s been a lot of fruit on the local market at times.”

He believes it will take a while for exports to come back.

“Our industry body has been trying to get access to Vietnam. We have been working that for three years. There’s a good market there,” Rakich adds.

“But there’s a process to go through with MPI and with their equiva lent in Vietnam and hopefully we will have our documents ready to go to Vietnam soon. That will open up a new market.”

NZ strawberries are exported to about 18 other countries according to SGNZ’s website but the main markets are in Asia.

compared to 12-12.5 mil lion in the last couple of years.

“We haven’t quite got all the numbers in yet. We have come back a bit, lost a few growers. A few growers this year have cut back because of labour. They probably had prob lems last year getting labour.

“I don’t want to see it drop any more. At least maybe stay there or increase a little bit. But you’ve still got to sell your fruit and you still have to pick it.”

Rakich sees the indus try moving more towards

under cover but it will take time.

Growers that grow under cover, most of whom also do hydro ponics, can extend their season – some go to May or even June. They will be finishing picking as they plant for the new season.

Those growing in the ground have to prepare their soil which can mean pulling out plants as early as January in case of a wet March or April.

So Rakich says more growers are growing under tunnels and he sees it as the future of the industry. He says the only problem is the cost of set ting up.

“That initial capital expense is huge. So, for a big grower to change everything over… it could be millions of dollars. They have got to work out whether it is worth it.”

Rakich believes it’s the way to go but it will take a while to change over.

The big talk over seas is mechanical pick ers, he says. A number of different companies are developing robots to pick strawberries, but there’s still some issues. Speed is one and they have to pick ripe fruit.

“It will happen, because there’s a lot of companies investing money to do it because the labour problem is a worldwide thing.”

OCTOBER 202212 HORTNEWS

Pam Tipa

@rural_news facebook.com/ruralnews

Strawberry Growers NZ chairman Anthony Rakich says the past two years have been a tough time for the industry.

Fischer GL4 Hydraulic precision sensor both sides Fischer BV2 Expandable deck2 mowers in 1 Fischer SL Mower Hydraulic precision sensor one side SPRAY-FREE FOR A GREENER FUTURE Helping you grow greener with Italian made Fischer. Best in class for inter-row under vine mowing. Join the movement for less glyphosate. Regular mowing destroys weeds. Stock available now. Request a demo: 0800 00 22 09. sales@farmshop.co.nz www.farmshop.co.nz Distributed in New Zealand by Farmshop / Maximising farm yields & reducing downtime / sales@farmshop.co.nz / 0800 00 22 09 / www.farmshop.co.nz

GRAND FINAL DINNER & AWARDS CEREMONY Tickets available from Eventbrite , link on website www.younghort.co.nz , email info@younghort.co.nz or Ph: 09 294 7129 Join our MC for the evening: David Downs, CMInstD Genetically Modified Optimist David is CEO of The New Zealand Story and a director on several boards, including Chair of The Icehouse. David is an ex-comedian, TV and radio actor, semi-finalist for New Zealander of the Year, cancer survivor and a published author of books No.8 Re-wired, No.8 Recharged, A Mild Touch of the Cancer, and Silver Linings 6.00pm, Wednesday 9th November, 2022 Karaka Bloodstock, Auckland $195 INCL GST OR $1950 PER TABLE OF 10 Be quick, get your tickets now for the Join us as we celebrate our 2022 Young Horticulturist Competition Award Winners and watch as our Young Horticulturist Winner is crowned

Growing more, less impact

Growing fruit and vegetables contributes to New Zealand's agricultural greenhouse gas emissions. At Woodhaven Gardens, near Levin, Jay Clarke and his family have been figuring out how to reduce their impact on the climate.

WOODHAVEN GARDENS was established by the Clarke family in 1978 on the fertile plains of the Horowhenua region.

The farm now grows 24 different vegetable crops across more than 1,800 hectares. It employs around 250 staff and, annually, the business sells 27 million individ ual vegetable units –about 10% of the national supply.

“Vegetable growing is a complex undertak ing, whether you’re doing it for one crop or 24,” explains Jay, son of Wood haven’s founders John and Honora Clarke. “Our business isn’t one single farm; it’s spread out over 127 paddocks with 50 kilometres between the most northern and south ern properties.”

He adds that in order to understand their envi ronmental impact, they’ve had to get to know all

those paddocks individ ually.

Like many vegetable growers, the Clarke family didn’t know anything about agricultural greenhouse gas emissions when they started out. However, achieving good outcomes for their business, their community and the environment has always been front and centre.

The Clarke’s journey to understanding their emissions began when they were looking at ways to reduce nutrient leaching. They were approached by scientists at Massey University who helped them understand the impact of nitrogen fertiliser not only on freshwater, but also on the climate.

Nitrous oxide is a potent and long-lived greenhouse gas that comes from a range of sources, includ

WOODHAVEN GARDENS

• Family business established 1978.

• Grows 24 different vegetable crops acrossmore than 1,800 hectares.

• Employs around 250 people.

• Annually sells 27 million individual vegetableunits, which is about 10% of the nationalsupply.

• Considered a leader in research for thevegetable industry – contributing time,money and land in order to measure andprovide evidence.

• Located on the fertile plains of theHorowhenua.

MONITORING AND MEASURING

In 2019/20, Woodhaven Gardens emitted 588 tonnes of nitrous oxide, expressed as ‘carbon dioxide-equivalent’ – just under half what was emitted two years prior.

That is the equivalent of taking over 300 cars off the road.

Jay Clarke says the team at Woodhaven Gardens works hard to produce the most amount of food for the least amount of fertiliser.

Here are the main things they’ve been doing to manage their nitrogen use:

Developed expertise in the crops they grow - understanding each one’s growth cycle and fertiliser requirements.

Regular soil testing (via a Nitrate Quick test) to find out how much nitrogen is already in the root zone.

Investment in precision agriculture systems to ensure fertil iser is applied exactly where it is needed and tight to the root zone, at the right rate and the right time.

“We GPS’ed our tractors so we know that our inputs go exactly where we want them to, and we don’t get fertiliser in the parts of the farm that don’t need it,” Clarke says.

The team at Woodhaven also pay attention to the health of the soil, using crop rotation and cover crops to further minimise the need for fertiliser.

“I never thought we’d get as far as this,” adds Clarke. “But by changing a whole lot of little things, and being willing to try different things, we’ve been able to add it all up and have a major impact. It’s something we’re really proud of.”

He says they are continuing to learn as they go and there are still parts of the system that need work. This includes monitoring whether new, lower levels of fertiliser are sustainable across all seasons in the longer term.

ing farming. In agricul ture, it is emitted into the atmosphere when microorganisms in the soil act on nitrogen introduced either by animal urine or dung, legume plants or nitrogen-based fertilis ers. Methane is another powerful greenhouse gas emitted from farm ing livestock. But for most horticulture growers, the focus is on nitrous oxide emissions from nitrogen

fertiliser use.

“Figuring that out was actually really helpful for us because it meant we were getting a twopronged approach,” says Jay Clarke. “We were already looking at nitro gen for freshwater qual ity. By tackling that, we’ve also been able to lower our greenhouse gas emis sions.”

For horticulture pro ducers like the Clarkes,

greenhouse gas emis sions are directly linked to nitrogen fertiliser use. A small amount of carbon dioxide is also emitted from lime or dolomite use.

Horticulture New Zea land and MPI have devel oped a simple Excel spreadsheet that calcu lates the emissions from a horticultural operation.

• Reproduced courtesy of: www.agmatters.co.nz

OCTOBER 202214 HORTNEWS

Jay Clarke and his family have been figuring out how to reduce their impact on the climate.

Woodhaven Gardens grows over

21

types of vegetables.

Conversion kits for hi-clearance tractors

WHILE SOME trac tor manufacturers make high clearance versions for increased underbelly room in high value crops, these are usually based around the utility ver sions of their product offerings.

It seems that there is also demand for high clearance units in higher specification tractors, given the experiences of one UK-based specialised manufacturer. The wide variety of different crops that can benefit from the high-clearance treatment include brassicas, celery, fennel, maize and sugar cane.

The company recently

received a request for a Hi-Crop kit to convert an existing tractor to accom modate state-of-the-art robotic harvesting equip ment, which would not have been possible with out additional clearance.

British company County Driveline Engi neering, based in Ash ford, Kent began when it rescued the name and active intellectual prop erty rights from the longstanding Knighton-based County Tractors. It then proceeded to develop pro totype Hi-Crop kits.

Starting out with a Case MXU 100, the first 2wd kit started evalua tion with CNH at Basil don in July 2006. After a few design updates, the sale of the first commer

cial unit was in 2008.

The first 4wd kit was developed for a Case IH Maxxum in 2011, while the initial 4wd kit for a New Holland tractor was

fitted to a T6000 in Janu ary 2012.

Currently supplying around a dozen Hi-Crop kits a year, the most pop ular model for conver

sion is the New Holland T6.155AC. Germany is currently the most impor tant export market where Hi-Crop is popular with asparagus growers. It is

USING FOLIAR FERTILISERS

Bernard Kimble

A FOLIAR fertiliser is a product that is designed to be applied directly to the leaves of the plant.

Although the first recorded use of foliar fertilisers was in 1843, the prac tice remained limited for years. A lot of research has been done on the ben efits of foliar fertilising during the last 30 years.

Applying synthetic chemical fer tilisers – like urea, phosphates and potassium salts etc – can be absorbed directly by the plants. However, while this provided fertilising benefits, there are limitations as not enough

is known about how to penetrate the waxy cuticles of foliage or even why this occurs at all.

Use of chelating agents such as Ethylenediaminetetraacetic Acid (EDTA) have been used to improve plant trace mineral uptake. However, environmental concerns are begin ning to limit the use of EDTA.

In recent years the benefits of amino acids as chelating agents have been proven and these are becoming more widely used. Foliar feeding has been found to be beneficial in the fol lowing ways:

When soil conditions such as drought or cold conditions limit the

availability of nutrients to the plant from the soil through transpiration.

Reducing the waste of fertiliser through leaching, runoff or volatili sation as occurs with many solid fer tilisers.

Reducing the risk of over fertilising that has been found to have detrimen tal effects on beneficial soil organisms – such as earthworms and beneficial microbes such as nitrogen fixing bac teria. Faster uptake of nutrients result ing in quick response especially when nutrient deficiencies are present. This could be due to low nutrient levels in the soil or conditions such as low pH that prevents nutrient availability.

also popular with Dutch bulb and flower growers.

Strangely, they have only just supplied the first kit in the UK, fitted to a Case IH Maxxum 125. This used custom drop housings in the Hi-Crop kit to elevate the exist ing axles by up to 350mm. This led, when combined with larger diameter and taller profile tyres, gains of over 500mm of extra height, nearly 90% more than the manufacturer’s standard clearance.

More recently, the company has expanded its range of Hi-Crop con version kits, to fit the latest New Holland T7s and equivalent Case IH Pumas. Available in 60, 72 and 80-inch track widths, the combined front and

rear drop-box assem blies add between 700 and 800kg to the tractors overall weight.

However, it is said to have no impact on han dling and the tractors drivetrain efficiency is maintained, while gearing can deliver creep speeds down to 90 metres per hour.

The kits are manufac tured in the company’s own foundry in Kent, sup plied ready for painting in red oxide, the bolt-on housings are said to take around a day to install on the donor tractor with suitable lifting equip ment.

www.countyengi neering.co.uk

@rural_news

facebook.com/ruralnews

The ideal method for the concept is ‘a little more often’, which cuts waste and improves soil health when formu lated correctly.

Foliar feeding is more targeted and thus more environmentally friendly than bulk soil applied fertiliser. In addition, amino acids have been found to be very useful chelating agents for trace minerals – such as iron, zinc and commercially synthesised amino acids like glycine (commonly used as chelat ing agents in some commercial foliar fertilisers).

They reduce fertiliser requirement by complexing nutrients and helping to transport them to where they are

needed in the plant. They contain not only nitrogen but carbon, while some like methionine and cystine also con tain sulphur.

They have a stimulating effect on root growth, which allows for more efficient absorption of nutrients from the soil. They improve photosynthe sis, resulting in higher carbohydrate production, which benefits the plant and root dwelling organisms.

They also feed the beneficial organisms living within the plant, which fight off disease and plant eating insects.

• Bernard Kimble is a technical manager at Nitrosol Ltd.

15OCTOBER 2022 HORTNEWS

Mark Daniel

markd@ruralnews.co.nz

British company County Driveline Engineering has developed a Hi-Crop kit to convert an existing tractor.

Are you hitting your target market? Contact your local sales representative for more information ✔ BREAKING NEWS ✔ MACHINERY REVIEWS ✔ MANAGEMENT STORIES ✔ AND MUCH MORE... HORTNEWS RURAL NEWS TO ALL FARMERS, FOR ALL FARMERS Auckland Stephen Pollard Ph 021-963 166 Waikato Lisa Wise Ph 027-369 9218 Wellington Ron Mackay Ph 021-453 914 Christchurch Kaye Sutherland Ph 021-221 1994

Big stubble, no trouble!

GERMAN MANUFACTURER Claas

has released the world’s first corn picker with an integrated stubble buster for one-pass harvesting and mulching.

The Stubble Cracker was developed for the Claas Corio four, five, six and eight-row corn pickers. It features one rotating plate per row, each equipped with two specially developed mallets with a special coating, which crush and splice any stubble below the first internode.

The unit is attached to the frame of the harvester via a threepoint linkage. This allows three-dimensional ground tracking, via a skid plate that ensures a constant distance between the flails and the ground in all operating conditions.

This also helps optimise performance and reduce wear.

Designed to be operated at a speed

of 1,200 rpm, the mechanically driven rotors are monitored by the harvester’s CEBIS system, which send the

Claas has released the world’s first corn picker with an integrated stubble

operator a message if rotor speeds decrease.

Twin hydraulic rams lift the rotors if there is a risk of overload, or they

encounter obstacles. Meanwhile, a ratchet-style overload system protects the rotor drive line.

In addition, the

cracker unit is raised automatically when reversing or raising the picker.

The Stubble Cracker

system for the eightrow CORIO 875 FC adds around 400kg to the overall weight and is said to require around 32 extra horsepower.

While this means a little extra fuel consumption of 2 litres/ ha, the system eliminates follow up passes with a mulcher, knife rollers or supplementary tillage.

Independent studies have demonstrated fuel savings of 30% and a 50% reduction in labour requirements, when compared to performing an additional or secondary mulching operation. From an agronomy point of view, Claas Harvest Centre product manager –Lexion, Luke Wheeler, says the new unit allows faster decomposition of corn stubble and helps to break the lifecycle of fungal diseases and insect pests.

OCTOBER 202216 HORTNEWS

Mark Daniel markd@ruralnews.co.nz

buster for one-pass harvesting and mulching. HORTNEWS Introducing Hort News, a national publication serving the needs of our booming horticulture sector. Distributed with the leading national farming publication Rural News, Hort News will be delivered to all key horticulture regions nationwide. It is the complete solution for readers and advertisers, covering every aspect of the wider horticulture industry – news, agribusiness, management, markets, machinery and technology. Contact: STEPHEN POLLARD Auckland Sales Representative Ph 021 963 166 LISA WISE Waikato Sales Representative Ph 027 369 9218 RON MACKAY Wellington Sales Representative Ph 021 453 914 KAYE SUTHERLAND Christchurch Sales Representative Ph 021 221 1994RURAL NEWS TO ALL FARMERS, FOR ALL FARMERS Publishers of • It’s the one-stop way to reach the horticultural sector • News and information for all types of growers • 10,000 nationwide distribution • Sent out with the trusted and established publication Rural News HORTNEWS NOVEMBER 2021 ISSUE 19 ISSN 2624-3490 printISSN 2624-3504 WWW.HORTNEWS.CO.NZ Bumper cherry –predictedcrop Page 7Sweet result for hort!SOME HORTICULTURE farmers arealso bracing for financial relief fromthe proposed free trade agreementbetween New Zealand and the UnitedKingdom. Apple, pear and onion growers areamong those set to benefit althoughers.notasbigmajormeatanddairyexport AlanNZApplesandPearschiefexecutive PollardsaysatthemomenttheUKis a $100 million market for growers,consistently ranking in the top two orthree. “We have a quota between Augustand December where volume above that quota attracts an 8% tariff,” hetold Hort News Under the proposed FTA, the tariffon pears will be removed on day one,with the tariff on apples reducing overthree years “So, there is some financial relief andwebenefitfromamorewelcoming regulatory environment,” says Pollard.Onion growers will face zero tarifffrom day one. The tariff on New Zealand onions is currently 8%. NewZealand currently exports $11 millionworth of onions to the United KingdomOnionsannually. NZ chief executive JamesKuperus says the FTA will ensure thatthis country’s onion exports continueto grow as the world comes to terms with Covid. “Trade and exporting benefits a diverse range of New Zealandbusinesses,” he says.“Without clear trading arrangements, improved market access andreduced tariffs, it is extremely difficult totoexportfromthebottomoftheworld larger economies like the UnitedKingdom. “Of immediate benefit the onion sectoristheexpectationoftariffsbeing eliminated on onions, once the agreement comes into force.”The New Zealand Governmentannounced the details of an “in-principle” New Zealand-UK FTA last weekas trade officials neared completingthe deal after little more than a yearof negotiations. Kuperus says the NZ onion sector is extremely grateful forthe hard work of New Zealand’s nego tiatorsanddiplomatswhohaveworked tirelessly to conclude this agreement.“The New Zealand team has had toatjoinZoomcallswiththeircounterparts night,extremelyinconvenienttimesofthe for example.”The conclusion of this agreement willbenefitoniongrowersandregional communities, from Pukekohe to Canterbury. Onions are an important rotation crop for many vegetable growers.Having onions in a rotation allowsgrowers to rotate between other cropssuch as lettuces, potatoes, carrots etc,which helps to control pestsand diseases. In 2019, the NewZealandonionindustrywasworth $200 million back to the grower, 85%of which came from exports. Mean dealwhileApicultureNewZealandsaysthe industrywillbeagreatoutcomeforthebee andwillimprovecompetitive nessinoneoftheirlargestexportmar kets. The UK consistently ranks as oneof top three export markets for NewZealand honey and is worth $70 million annually. “We have strong tieswith UK customers, with a long history of exporting high-quality honeyproducts there. However, the currentin-quota tariff rate of 16 per cent hasbeenasignificantbarriertotrade,”says KarinKos,chiefexecutiveofApiculture New Zealand. Sudesh Kissun sudeshk@ruralnews.co.nz GETTING READY! MANGAWEKAASPARAGUSmanagerSamRaineyoverseesan80hectareasparagusinthecentralNorthIsland.WhenHortNewsvisitedthepropertyinlateSeptember,Raineyandhisstaffwereinthefinalstagesofpreparingfortheharvest.Thepackhousewasbeingsetupandatthesametimethefirstspearsofasparaguswerestartingtoappear.Whilethetotalsizeofthepropertyis80hectares,theywillpickjust65hectaresthisseason–whichequatestoupto250tonnes.Seestorypages4and5. Replacement Spray Pumps & Spray KitsWebbline Agriculture is a directimporter/reseller of a full rangeof pumps from market-leadingmanufacturers, along with service kitsand accessories. Large range in stock.Dealer enquiries are welcome. View online www.webbline.co.nz Contact Ben 021 819 482 | ben.boakes@webbline.co.nz WAIKATO •CANTERBURY • SOUTHLAND branches NOW PUBLISHED MONTHLY! To book your advert contact your local sales rep

Peter Burke peterb@ruralnews.co.nz

Peter Burke peterb@ruralnews.co.nz