8 minute read

Aerospace: Support Initiative

AEROSPACE INDUSTRY SUPPORT INITIATIVE

- PUNCHING ABOVE ITS WEIGHT

Advertisement

In a well-functioning economy, as in the natural world, the big gorillas in each sector dominate the ecosystem while hierarchies of organisations evolve below them to create the diversity and abundance for the whole to thrive. The aerospace industry is no exception.

MARIÉ BOTHA IS A KEY player in stimulating the small to medium enterprise segment of the industry as Programme Manager of the Aerospace Industry Support Initiative (AISI). This is where the innovations and technology breakthroughs are mostly found so it is vital that the green sprouts are nurtured and fed.

AISI is a programme of the Council for Scientific and Industrial Research (CSIR), under the Department of Trade, Industry and Competition (the dtic). It was established in 2006 as part of government’s strategy of improving competitiveness in the sector with a specific emphasis on industrialisation of technology and technology-based supplier development. In the post-Covid world and with South Africa’s economy under strain, driving localisation and exports are now its top priorities.

Botha emphasises the need for a strong product platform to drive the industry, which is experiencing a serious skills exodus. The Rooivalk helicopter was that platform in days of old, but with nothing to replace it and Denel’s years of mismanagement placing its future in jeopardy, the entire ecosystem is in danger of collapsing. It is in this unstable environment that AISI aims to make a difference to the businesses lower down the food chain: the start-ups and emerging businesses that rely on larger customers to prosper. With a limited annual budget of around R20 million its efforts have had a remarkable impact, boosting advanced design and manufacturing capabilities in the sector leading to innovation, job creation and a boost to exports.

the dtic

Marié Botha heads up the the dtic's AISI.

The AISI’s Technology-Based Supplier Development intervention provides enabling mechanisms to assist industry to improve productivity, implement quality management systems, optimise operations and integration into global supply chains.

Its Industry Development and Technology Support programme focuses on advancing production innovation such as the use of advanced manufacturing and other fourth industrial revolution technologies to build more durable, compact and efficient products.

Beneficiaries supported have projects at a technology readiness level 4, above which are companies with technology proven in the laboratory and being up-scaled for industrialisation. They are supported with funding, strategic advice, skills development and market access through networking along the supply chain. Access to new and existing processes, products and methods is also facilitated to ensure that beneficiaries develop products and services, which enable them to exploit multiple market opportunities. AISI’s greatest need, according to Botha, is more focused government support and more local customers. In trying to supplement its limited budget and support capabilities, AISI has a partnership with the Small Enterprise Development Agency and Small Enterprise Finance Agency, both reporting to the Department of Small Business Development. On the radar is an effort to tap into international funds but this is some way off, Botha says.

The success of AISI has prompted the dtic and CSIR to expand its support model into other sectors such as automotive manufacturing, medical devices and energy. If South Africa is going to succeed in keeping and attracting hi-tech skills and develop its export profile, government and the private sector will need to re-double their efforts to work collaboratively, with ambitious targets and the resources to match. AISI is a shining example of how much can be done with a little.

Companies wishing to apply to AISI should look out for their annual request for submissions which can be found on their website https://aisi.csir.co.za/

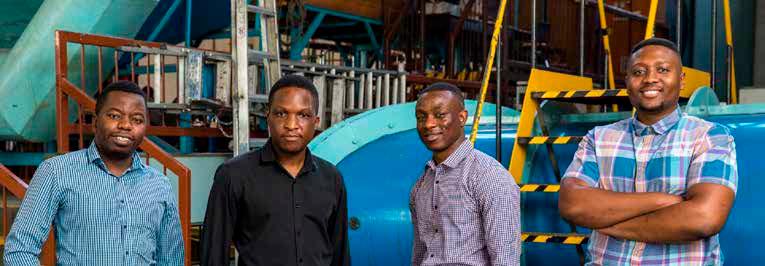

The Proceptworks team of Dalumuzi Dube, Nigel Nkundhlande, Ischmael Chiremba and Edmond Moyo.

SOME NOTABLE SUCCESSES

AISI’s Technology-based supplier development programme have had a number of notable successes in the African aerospace sector.

Beneficiary name: Cape Aerospace Technologies Project in progress: 400 N Gas Turbine Industrialisation Product market: Recreational aviation aircraft and unmanned systems

project has been completed and is the outcome of an AISI-initiated roadmapping exercise. To get a sense of scale, their micro-engine will be mounted on an airframe in a limited space and must conform to an “envelope” with an engine diameter of 147 mm, an engine length of 380 mm and a total weight of less than 4kg. David Krige, Managing Director & Head of Propulsion Systems, explains, “the critical and major components for engine operation are the impeller, the diffuser, the combustion chamber, and the turbine stator and rotor. These are the internal Cape Aerospace Technologies (CAT) with a limited annual components making all things possible for the specialises in the design and budget of around engine. Therefore, they manufacture of propulsion systems based on gas R20 million, its must be designed to match one another.” turbine technology and associated electronic control systems. After the successful efforts have had a remarkable impact Cape Aerospace Technologies ascribes its industrialisation of a 250 success to its meticulous N gas turbine engine, with in-house design-tosupport from AISI, is has set its sights on building manufacture process, including engine and subsystem and commercialising a 400 N engine in a three year assembly and testing. Krige confirms that Cape project. Aerospace Technologies will localise up to 80% of the 400 N content. This Cape Town based company has a three decade history stretching back to the 1980s when it designed and built the first pulse jet in South Africa. Today, in close collaboration with Stellenbosch University it is focusing on micro and small engines aimed at the recreational aircraft and defence industries. The 400 N project has been planned in six stages and is currently ahead of schedule. Phase 1 of this three-year Beneficiary name: Jonker Sailplanes Project in progress: 24m Wingspan Open Class JS Product market: Recreational aviation aircraft

Potchefstroom-based Jonker Sailplanes is the only significant manufacturer of sailplanes outside Europe

The CAT 400 turbine assembly, is an AISI assisted product development. the dtic

and has successfully exported the JS1C Revelation and the JS3 Rapture. The company has made good progress during the first phase of a three-year project based on an AISI-initiated roadmapping exercise, for the design and industrialisation of a new model, the JS2-24 with a 24.5m wingspan.

Says Uys Jonker, Managing Director, “this development is in response to international market demand, and the fact that competition in the Open Class in recent years from the EB29R sailplane has meant that we need to innovate to meet our competition head-on.”

The team at Jonker Sailplanes worked with the North-West University on the relevant aerodynamic research and engineering for this product to outclass any competition. Basic aerodynamic research was conducted to develop better profiles, reduced drag of all interfacing surfaces and to optimise plan forms. The 24.5m wing design presented challenges stemming from the aerodynamic requirement for a long, slender and thin wing, while the structural design required a wing with a larger cross section. Jonker confirms, “It required five design iterations to enable the convergence of the conflicting structural and aerodynamic requirements.” Several design challenges were addressed in Phase 1, some of which were fully resolved while others will be addressed during the next phase. These included the design of the structure at the wing root area, which requires further design verification; driving of the flaperons at four stations to reduce twist deformation which impacts performance; design of the wingtip lockpin to fit under the flaperon driver tube; and a new airbrake design with an extra lift arm in the middle to pull down the airbrake cap.

CSIR Windtunnel.

Beneficiary name: Proceptworks Project completed: Sentian UAV Product market: Unmanned systems

100% black-owned Proceptworks, based in the Maboneng precinct in Johannesburg, is the brainchild of four engineering students from the University of the Witwatersrand who had a vision to build a drone manufacturing company. Formed in 2015, it progressed rapidly and was the SMME and Overall Winner of the 2019 ATNS AVI Awards and Runner Up in the 2019 SACAA Civil Aviation Industry Awards: Aviation Innovation category.

AISI is proud of its association with the world beating Jonker Sailplanes.

Under their direction, significant progress on the development of a uniquely South African modular unmanned aerial vehicle (UAV), dubbed Sentian, has seen the airborne platform completed by the end of 2020. Conceptualised as a ‘drone for good’ in the service of humanity, this UAV has the potential to support and help all forms of sustainable life. Examples include the use of its payload to deliver critical medical supplies or to provide surveillance of crops.

“It is one of the most exciting projects we are supporting”, says AISI Programme Manager Marié Botha. It’s an exemplar for young, black engineers to aspire to and fits exactly the profile of the new generation businesses AISI aims to support.” Dalumuzi Dube, Edmond Moyo, Ishmael Chiremba and Nigel Nkundhlande of Proceptworks are satisfied with the outcomes achieved over the past year. The team built a quadcopter as an experimental test bed to ascertain flight dynamics for performance and stability as well as takeoff and landing capabilities. The quadcopter outperformed expectations for flight, vertical takeoff, landing and hovering, as well as stability.”

These results were then used to configure the systems required for control and flight, notably the flight controller (for which Pixhawk, a sophisticated autopilot system, was utilised) and the ground control system. Successful flight tests were conducted at James and Ethel Gray Park, Johannesburg, a model plane flying venue.

the dtic

Department: Trade, Industry and Competition