PHILI PPINE

VOL. 1. No. 4 January-February 2013

THE MAGAZINE FOR CONSTRUCTION PROFESSIONALS

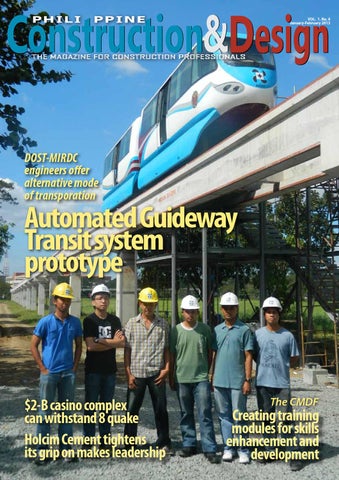

DOST-MIRDC engineers offer alternative mode of transporation

Automated Guideway Transit system prototype

$2-B casino complex can withstand 8 quake Holcim Cement tightens its grip on makes leadership

The CMDF

Creating training modules for skills enhancement and development January-February 2013

Philippine Construction&Design

|  1

2

| Philippine Construction&Design January-February 2013

from the editor

Second Beginning The start of the year is always a welcome occasion as it ushers in many new beginnings. We look at January 2013 as a fresh start; a period of hope and anticipation. For Philippine Construction & Design, we foresee a fruitful year. If we were quite uncertain during the last half of 2012 when we gave birth to our e-magazine, we are optimistic that this first month of the year will bring abundant blessings and comfort to us and our readers. We are featuring the Automated Guideway Transit (AGT) prototype, an alternative mode of urban transportation, designed by Filipino engineers from the government agency MIRDCDoST. Though our gains have been modest, I remain upbeat as our readership is slowly increasing. For the January 2013 issue we are featuring the $2-B Belle Grande Casino and Hotel complex at the Aseana Business Park, the fast becoming mix-used property development complex in the metropolis. Inspired by the positive response to our e-magazine, we are adding new features for our January 2013 issue. In our Profiles section, we will regularly feature a contractor (Filipinas Dravo Corporation), an engineer (Engr. Chris Gonzales) and an architect (Arch. FelinoPalafox, Jr.), companies and personalities that shape and reshape the construction landscape. As we give you important news and interesting features in the construction industry here and abroad,we also give our e-magazine a human touch; after all the industry is composed of professionals from whom we can draw inspirations from. Do keep on reading Philippine Construction & Design as we bring you closer to the people and the stories that make the construction industry what it is today.

contents CONSTRUCTION NEWS

02 Calendar of Events

07 International Report A$5bn Melbourne regional rail link project gets green light

04 News Roundup

10 Association News

Bicol International Airport to replace Legazpi Airport

PICE challenges the engineering mind with “Rubies”

FEATURES

12 Industry Report

20 Architect Profile

14 Special Report

22 Engineer Profile

16 Cover Story

24 Contractor Profile

The CMDF: Creating training modules for skills enhancement and development

AGT system promotes environment-friendly transportation

A shaky career that guaranteed safety Filipinas Dravo Corporation

DOST-MIRDC Engineerings offer alternative mode of transportation

26 Suppliers Profile

18 Project Report-Private

Holcim Cement tightens its grip on market leadership

$2-B casino complex can withstand 8 quake

CONSTRUCTION MANAGEMENT

28 Project Managament

32 Human Resource Management

30 Sales & Marketing

34 Products & Technology

Timely resolution of jobsite conflicts preserves productivity

Waste management in construction sites

-Rodolfo de Guzman

ON THE COVER

Arch. Felino A. Palafox, Jr. Creating imprints in the global architectural scene

Concrete Pipe-making Machine

Closing sales without really trying

37 Price Movements

Construction materials prices in NCR show downtrend in the 4Q

The Metal Industry Research and Development Center (MIRDC) of the Department of Science and Technology (DoST) has spearheaded the development of the automated guideway transit (AGT) system as an alternative mode of mass transportation in urban areas. Shown on the cover is the prototype test track with two coaches at the University of the Philippines Diliman campus covering a distance of 465 meters with the young DoST engineers (left to right) Franz Libao, Elljay Mutuc, Brian Rasco, Ryan Roldan, Jesus Tanchuco III, and Christian Ibanez.

PHILIP PINE

THE MAGAZINE FOR CONSTRUCTION PROFESSIONALS

Executive Publisher: Editor-in-Chief: Graphic Artist: Contributing Writers:

Josette Adiong Rodolfo de Guzman Anabelle Flores Ed Velasco Katherine V. Marfal Advertising Sales Executive: Rochelle C. Cuevas Administrative Assistant: Cherie Flores

The Philippine Construction & Design is an e-magazine published monthly by Saiber Media Inc., with business address at Unit 1524 City & Land Mega Plaza, ADB Ave. cor. Garnet Rd., Ortigas Center, Pasig City. Official website is www.philippineconstructionanddesign.com., e-mail address: saibermediainc@yahoo.com.ph Publisher Mr. William L. Ogan. For your editorial, online subscription and advertising placement, please contact (632) 945.8510 | 687-1430. Please send your comments and suggestion’s to saibercraft@yahoo.com. Copyright ©2012 All rights reserved. January-February 2013

Philippine Construction&Design

| 1

calendar of events July 2013-November 2013 Kitchen and Bath Expo Brazil July 3-5, 2013 International trade show and conference for kitchen and bathroom fixtures and accessories in South America Venue: Sao Paulo, Brazil CHFE-China International Housing and Furnishing Exposition July 5-8, 2013

The twice a year event called China International Housing and Furnishing Exposition will highlight development in real estate, building materials, housing decorations, and household products. Venue: Ningbo, China

BuildTechAsia July 24-26, 2013

This once a year event showcases construction machineries, construction vehicles and equipment, building materials and electrical and mechanical engineering technologies. Venue: Singapore, Singapore

Aseanwood Woodtech Malaysia (WTM) August 21-24, 2013

This biennial event showcases Malaysian woodworking machineries, timber processing and furniture manufacturing, supplies exhibition and conference incorporating furniture and forest products. Venue: Kuala Lumpur, Malaysia

ESBUILD August 2013

This once a year exhibition showcases construction materials and indoor decoration concepts with inclusion of energy-saving products and advanced building materials. Venue: Shanghai, China

MatExpo September 4-8, 2013

This biennial exposition and international trade fair showcases construction machineries, construction techniques and materials, wood industry products, road building technologies and civil engineering techniques. Venue: Kortrijk, Belgium

Bauma Africa September 18-19, 2013

This once a year event features the latest technologies for wooden construction, manufacture and supply of wooden construction assembly, prefabricated construction materials, and wooden accessories. Venue: St. Petersburg, Russia

Bangkok RHVAC October 9-13, 2013

This biennial exhibition highlights the important materials and technologies in refrigeration, heating, ventilation and air conditioning; including parts, materials, tools and equipment and services. Venue: Bangkok, Thailand

Home Improvement & Design Expo October 26, 2013

This twice a year exposition showcases home improvement products and design coming from renowned decorators, builders, remodelers, designers and suppliers. Venue: Blaine, Minnesota, USA

Construction Diyarbakir October 2013

This event highlights the latest in construction materials and technologies from the Middle East that include natural gas, heating, air conditioning, cooling, construction machineries, natural stones and marble products. Venue: Diyarbakir, Turkey

The Infrastructure Show October 2013

This yearly event is being held to provide an ideal forum for civil engineers to share information and the latest innovations in undertaking infrastructure projects. Venue: Birmingham, United Kingdom

TIGIS October 2013

This yearly event dubbed as the Taiwan International Green Industry Show features innovative green technology products that include LED lighting, electrical vehicles, wind power, recycling, fuel cells, anti-pollution devices, green building materials and water treatment technologies. Venue: Taipei, Taiwan

Buildex Calgary November 2013

This international fair features construction machineries, building materials machineries, and construction vehicles and equipment. Venue: Johannesburg, South Africa

This annual event is geared towards promoting concerns of property managers, facility and operations managers, building owners on building design and managing real estate. There will be about more than 225 exhibitors and 35 educational seminars. Venue: Calgary, Canada

Marble, Granite & Ceramics Indonesia September 2013

HVAC/R Philippines November 2013

This biennial international trade fair features the latest in marble, granite and ceramic products. On exhibit are machineries, materials and equipment for producing and installing construction materials. Venue: Jakarta, Indonesia

2

Wooden Construction October 8-10, 2013

| Philippine Construction&Design  January-February 2013

This yearly event features technologies, products and services in the field of ventilation, heating, air conditioning and refrigeration. There will be exhibits of innovative products and conferences. Venue: Pasay City, Philippines

January-February 2013

Philippine Construction&Design

|  3

www.quezoncity.olx.com.ph

news roundup

Century Properties Group builds 8-tower Commonwealth residences The Century Properties Group, with vast experience in providing high-end condominiums and other real estate development projects, has embarked on a P 4.1 billion housing project in a 4.4-hectare property along Commonwealth Avenue in Quezon City.

The 8-tower project, called the Residences at Commonwealth, will rise beside the Don Antonio Heights; one of the more prominent residential communities in the area. Each tower is named after well-known personalities with the first building called Osmena West after one of the Philippine presidents. It will have 11 floors with 200 units. It will be delivered by 2015. Other towers will be called Quezon, Roxas and Quirino and will rise to 22 storeys high. All in all, the project will have 2,300 units that ranges from 21 to 72 square meters in floor area. Amenities include pocket gardens, athletic boot camp area, two full-sized basketball courts, a multi-level clubhouse, sunken badminton courts, and three tree houses. The architectural design was executed by the award-winning company Broadway Malyan.

The existing airport in Legazpi City in Albay, Bicol region will soon give way to a more modern Bicol International Airport to be constructed in Daraga, Albay. The move to build an international airport in the region with international standards is in conjunction with the government’s thrust to promote local and international tourism and to spur trade and commerce in the area. The project involves the construction of the passenger and cargo terminal buildings. It will also have modern security and

www.wowlegazpi.com

Bicol International Airport to replace Legazpi Airport

navigational aid equipment that will ensure safety and efficiency in airport operations.

www.sfilipinoanglers.org

$700M coal-fired power plant generates 400 MW for Luzon grid

4

| Philippine Construction&Design January-February 2013

Team Energy Philippines sealed a joint venture agreement with the Aboitiz Group for the construction of the 3rd power plant in Pagbilao, Quezon to the tune of between $600 million to $700 million. The power plant is expected to generate additional 400 megawatts (MW) of electricity for the Luzon grid. The new plant will augment the output of the existing 735 MW Pagbilao coal plant and the 1,200 MW Sual coal plant in Pangasinan. The plant will use the pulverized coal boiler technology that burns low-quality coal from Indonesia at $70 per metric ton. The target market for the electricity produced in this new plant is the industrial companies, private utilities and electric cooperatives. Groundbreaking is on the first quarter of 2013 and will be operational by December 2015.

Robinsons Land, one of the country’s biggest property developers whose roots can be traced in Cebu, is building its 38th and largest shopping mall in the city. The Gokongwei business empire is constructing the Robinsons Galleria Cebu on a 4.6-hectare property along Gen. Maxilom on the North Reclamation area that will include commercial establishments, office spaces for business process outsourcing firms and the first Cebu branch of the GoHotels chain. The building will be seven storeys high with a gross floor area of 156,000 square meters. The hotel will have 153 rooms. The mall will occupy four levels with a total gross leasable area of 56,000 square meters. The BPO offices will have three floors with roughly 9,000 square meters. Robinsons Galleria Cebu joins Robinsons Fuente and Robinsons Cybergate Cebu in the masterplan for the Gen. Maxilom property. It is scheduled to open its doors in 2014.

www.e-rockwell.com

Robinsons Land builds its 38th and biggest mall in Cebu

www.robinsonslandcebuproperties.blogspot.com

NEWS ROUNDUP

Rockwell Land allots P26.3B for its mixed-use condo portfolio Expansion seems to be the name of the game for Rockwell Land Corporation as it embarks on several projects near the Rockwell Center in Makati. The Lopez-owned property development company has allotted P26.3 billion for development of mixedused complexes in Makati and Pasig City. Rockwell Land started construction of The Proscenium last quarter of 2012 that will have five high-end residential towers for a total cost of P17.1 billion. It will have leasable area of about 15,000 square meters. The company hired the services of Canadian architect Carlos Ott who incidentally designed the Burj Al Arab in Dubai. Together with The Proscenium, the 20-storey Lopez Tower will rise on the 3.6 hectare property along JP Rizal Street in Makati City that will become the corporate headquarters of the Lopez Group of Companies. This is targeted to be completed by December 2014. Other developments include the Lopez Museum; the P7.6 billion The Grove, the 50-storey Edades tower, and the 205 Santolan, a 105-unit townhouse .

P 43.3B CALAX project gets NEDA nod

www.pinoyprogress.com / www.skycrapercity.com

The proposed Cavite-Laguna Expressway (CALAX) project has finally gotten the nod of the National Economic and Development Authority (Neda) Investment Coordination Committee-Cabinet Committee after thorough study of its positive impact to the development of economic activity in this part of the Southern Tagalog corridor. The CALAX project involves the construction of a 4-lane, 47.018-kilometer expressway. The road will be from the end of the Cavite Expressway in Kawit, Cavite up to the Mamplasan Interchange of the South Luzon Expressway (Slex) in Binan, Laguna. The project aims to provide a reliable access road for the fast and efficient transport of goods in the Cavite and Laguna areas that are rapidly developing as vital industrial and commercial hubs in the region. The CALAX will be funded in part through the public-private partnership (PPP) program of the government and the official development assistance (ODA) program of the Japan International Cooperation Agency or JICA.

January-February 2013

Philippine Construction&Design

|  5

PPP projects seen as prime mover of construction growth

www.portcalls.com

The private construction sector is expected to rebound by this year from a slowdown in 2012 despite the many condominium projects seen in the metropolis and key cities in the country. According to news article disclosures by NEDA assistant director-general for planning Ruperto P. Macuja, the private construction sector has somehow reached a point of saturation after several quarters of growth. This observation was shared by one of the prominent economists in the country, Prof. Benjamin E. Diokno of the UP School of Economics, who said that construction contracted by 6.2% that started in 2011 due to slowdown in government projects. The increase in government infrastructure spending as well as the rapid rolling off of public-private partnership (PPP) projects will be the key to spur private construction to a more upbeat pace. The Tokyo-based real estate market expert David C. Fan also disclosed to the Philippine Daily Inquirer that faster approval of PPP projects will help move private construction faster. Likewise, the introduction of the Real Estate Investment Trusts or REIT, that allows the general public to purchase stocks of real estate companies, will provide investors with more available capital to fuel its property development projects.

www.directionsonweb.blogspot.com

Thai oil firm PTT expands PHL operations with P1.5B investment The largest oil firm in Thailand, through its Philippine subsidiary PTT Philippines Corporation, gears up for an expansion program from 2012 to 2016 with aggregate investment of P1.5 billion. According to PTT Philippines president and CEO Wisarn Chawalitanon, the parent company in Thailand has approved the five year expansion plan to construct between 75 to 80 new retail stations in Luzon and the Visayas particularly in Cebu. The company aims to increase its presence in the country to have 125 to 130 new retail stations by 2016. Around P250-300 million is earmarked every year for construction of 15 stations annually. At the same time, the company is planning to put up a terminal in San Fernando, Pampanga and another terminal in Southern Luzon to facilitate deliveries and handling of its oil products in the target areas. PTT has set aside P250 million for each terminal.

www.iloiloonline.blogspot.com

news roundup

DoTC focuses on ports development The Department of Transportation and Communication (DoTC), through the Philippine Ports Authority (PPA), has earmarked P556 million for the construction of seven ports in major strategic areas in the country. This initiative was made in anticipation of the increase in passengers and cargoes brought about by the strengthening of the domestic economy. According to DoTC Secretary Mar Roxas, the biggest project will be the Commercial Port Complex in Iloilo to cost P 183.2 million. It will involve the excavation of the existing seabed, construction of shear keys, new port lighting system, installation of interlocking concrete blocks pavement, and lateral drainage system. The project getting the second biggest share of the budget at P 91.2 million is the Ormoc Port in Leyte. It will also involve seabed excavation and construction of new lighting system, concrete pavement and back-up roll-on, roll-off (Roro) ramp. Other portions of the budget will go to improvement of Dumangas Port (P 63.2 million), Tabaco Port in Albay (P52.6 million) and Lucena Port (P33.2 million). Further, P 76.6 million will be spent for the rehabilitation of Pier 1 in Dumaguete Port and P 65.2 million allocated for construction of back-up area, Roro ramp and lighting system of the Pio Duran Port in Albay.

www.business.inquirer.net

MPIC-SMC Jv to start construction of NLEX-SLEX Connector road project

6

The joint venture between Metro Pacific Investments Corporation (MPIC) and San Miguel Corporation (SMC) bagged the P45 billion North and South Luzon Expressways (NLEX-SLEX) Connector Road project. This initiative will substantially reduce travel time from north to south thereby paving the way for faster delivery of goods and services. The project includes the 21-kilometer NLEX-SLEX expressway connector and the eight-kilometer harbour link that will create a direct link between the ports in the north and the south. Likewise, it will connect the Ninoy Aquino International Airport to Clark Freeport Zone. The travel time will be a 75-minute uninterrupted drive and the road allows bigger vehicle capacity to accommodate transport trucks and heavy delivery vehicles. According to former Department of Transportation and Communications (DoTC) Secretary Mar Roxas, the project is now up for a Swiss challenge and will generate about 8,000 new jobs once the construction begins.

| Philippine Construction&Design  January-February 2013

international report

www,worldconstructionnetwork.com

A$5bn Melbourne regional rail link project gets green light

The harnessing of wind energy has been in the forefront of development in Italy. Recently, Fera, an Italian developer, has awarded a project to Vestas in the region of Tuscany to supply wind turbines that can generate up to 19.8 megawatts of electricity. It involves the procurement of 11 Vestas V100 1.8MW turbines for the project called Santa Luce Wind Project. The purchase includes the 15-year service agreement. According to Vestas Italia General Manager Rainer Karan, the turbines were ideal for the wind conditions in Tuscany and the project is within their expertise in the 2MW platform.

www.railway-technology.com

Italian developer Fera awards 20MW deal to Vestas

The work on the 7.5-kilometer Footscray to Deer Park section of the A$5 billion regional rail link project has commenced in the third quarter of last year. The project aims to improve the rail transit service to regional Victoria and west of Melbourne. According to Australia Infrastructure and Transport Minister Anthony Albanese, the rail project will benefit the more than four million residents of the area. The West Footscray station will be equipped with a lift, ramps and stairs to ensure maximum accessibility. The project is undertaken by the Regional Rail Link Authority in partnership with construction firm Balfour Beatty, Sinclair Knight Merz, V/Line, Thiess and Parsons Brinckerhoff.

www.worldhighways.com

Project contractor Arabtec Construction is building two 185-meter high skyscrapers in the new business district of West Bay in Doha dubbed Twin Towers Qatar. The project will have office spaces and hotel rooms that will occupy the 48 storeys with multi-storey parking spaces, three at the podium level and two in the basement level. The Doka climbing formwork SKE50 is deployed for the two CIP concrete cores that are being climbed with the use of 94 automatic climbers and the 1800 m2 of Large-area formwork Top 50. Doka Qatar used the modular design concept for the craneindependent automatic climbing formwork system that is efficient and economical. The project also used the 2.40 m wide platforms of the cranejumped formwork system MF240 that provided ample space for safe working condition. On the other hand, the Doka 1-2-4 floor slab system was used for the typical floors and the high slab supports in the podium level were provided by Load-bearing towers Staxo 40.

www.Ida-design.co.uk

Arabtec Construction deploys Doka climbing formwork in Twin Towers Qatar

LDA Design inks Mumbai luxury landscape deal

LDA Design inked a $2 billion deal for the landscape commission of a luxury residential scheme in Mumbai, India by developer Omkar. It incorporates a multi-stage landscape project that includes four acres of landscape podium atop a 12-storey car park in the west Worli district. Other amenities included in the commission are an amphitheatre, a skywalk with lush tree canopy, swimming pools and cricket nets. The ground floor landscape is adorned with waterfalls and a sales pavilion that is now a landmark structure in the area. According to LDA Design, the project adopts the leading edge CNC technology and 3D modelling in making the world class design anchored on the rich heritage and history of Mumbai. The designers were inspired by the linked-island geography and Worli textile designs. The project involves three towers with triplex penthouses that incorporated outdoor gardens. LDA Design worked closely with interior design firm HBA London and architectural company Foster & Partners. The project is due for delivery by 2016.

January-February 2013

Philippine Construction&Design

|  7

international report

Statoil Norway awards hull construction to Technip Statoil, an energy company in Norway has awarded the construction of the hull for the world’s largest Spar platform on the Aasta Hansteen field to the consortium of Technip and Hyundai Heavy Industries (HHI) for an estimated contract cost of NOK 4 billion. Aasta Hansteen platform is the first of its kind in the Norwegian continental shelf (NCS) with recoverable reserves of 47 billion standard cubic meters (scm) of gas and 0.8 million scm of condensate. The platform is the first Spar with storage capacity of 25,000 scm of condensate, enabling Statoil to export gas through the Norwegian Sea Gas Infrastructure (NSGI). The manufacturing of the hull will be done in South Korea and be transported using the largest heavy-lift carrier. Thereafter, Technip will execute the design and deliver the hull ready for mating with platform topsides in Norway. The project deliveries will be completed by December 2015 and production expected to start in 2016.

www.inhabitat.com

FIFA/Olympic-standard stadium to rise in Addis Ababa A coffee bean shaped stadium will rise in Addis Ababa, Ethiopia; a design that symbolizes the country’s major source of income. This unique stadium will be part of a sports village that will further promote sports activities in the country. The design architecture was executed by the Doha-based Australian firm Designsport and Australian LAVA (Laboratory for Visionary Architecture) in cooperation with JDAW, a local architectural firm. The partnership recently won the international architecture competition to design a national stadium and sports village. The sports complex sits on a 60-hectare property that includes a stadium with a sunken arena that has a 60,000 seating capacity, an aquatic center, an athletics track, sports halls, residential village, and retail and commercial stores. The headquarters of the Federal Sport Commission will be inside the complex. The materials used for the façade of the stadium were adapted from Ethiopian culture that is the Massob, an Ethiopian communal serving basket made out of woven grass. The roof of the stadium is made of intelligent membrane that looks like a cloud when view from afar. Construction will begin in 2014.

www.gcaptain.com

BGR Energy Systems builds tallest cooling tower in India There are two cooling towers being built by BGR Energy Systems www.constructionweekonline.com in Kalisindh in India for Kalisindh Thermal Energy Plant. The project is part of the $820 million facility with funds coming from the Rajasthan Government. When completed, the plant will generate up to 1200MW of electricity. When completed, the two towers will be the tallest so far in the world measuring up to 202 meters; two meters higher than the record holder, the cooling towers in Niederaussem in Germany. The complexity of the project necessitated the use of two 21CJ290 tower cranes provided by Comansa Jie. The crane provider is a joint venture between the Chinese company and the Spanish crane manufacturer Linden Comansa. The two tower cranes have a maximum load capacity of 18 tonnes each and a jib length of 74 meters. With this equipment, the contractor is able to reach the tower’s base with a diameter size of 142 meters. The cranes were jacked-up with a hydraulic cage in various phases until it reached the height of 217 meters.

Jv led by Tav Construction wins Abu Dhabi Airport project

www.constructionweekonline.com

8

| Philippine Construction&Design January-February 2013

The construction of the Midfield Terminal Building of the Abu Dhabi Airport was awarded to a consortium that includes Tav Construction, Arabtec and Consolidated Contractors International Company. The project involves the construction of the 700,000 square meter terminal building as part of the strategic infrastructure project undertaken by the Abu Dhabi Airport Company to improve its facilities. When completed the airport is expected to serve 30 million passengers a year. The contract awarded in June 2012 will be finished by the first quarter of 2017. The new terminal will be home to the Itihad Airways.

Saudi Arabia’s Pension Fund to bid out largest housing project The Saudi Arabia Pension Fund is offering for bids the largest real estate development project in the kingdom that will involve housing units in Jeddah. According to reports from Bloomberg, the project will have 7,340 apartments and villas constructed alongside with a hospital and a hotel on a 2.6 million square meter property near the King Abdulaziz International Airport. When tenders are received and the contract awarded, the complete project will be done in two phases: the first phase will involve construction of apartment units with each measuring 800 square meters and the second phase is allotted for the construction of villas with an area of 300 square meters each.

Swarovski lights up Amanora Park towers in India

www.indiconcretejungle.blogspot.in |www.flicker.com

www.saudibathpoolandspa.com

international report

The dazzle of glittering lights and crystals will soon highlight the futuristic architectural design of the Amanora Gateway Towers 1 in Pune, India. This first luxury residential project is undertaken by City Corporation Ltd., considered as one of India’s leading developers of townships and the prestigious Amanora Park. The tower has a total height of 150 meters with 45 storeys. When completed, the structure will be the tallest skyscraper in the area. The project combines the luxurious features offered by Swarovski Lighting and the exclusive designs of personal spaces as prescribed by the developer City Corporation. Situated on 14 acres of land, Gateway Towers 1 has 700 units of high end apartments. Luxury is experienced in penthouse units with private pools. The building includes green terraces and sky bridges. The lobby, sky deck and the clubhouse carry the Swarovski crystal design.

www.unstudio.com

The former UIC Building in Singapore, once referred to as the tallest structure in the citystate when it was built in 1973, is slowly transforming into a futuristic skyscraper called V on Shenton. The building is designed by world renowned Ben van Berkel of UNStudio, showcasing architectural innovations with the incorporation of a façade of four to five different textures following the basic hexagon shape that create patterns with angles and shading devices adjusted to Singapore’s climatic conditions. The unique design uses “chamfers” that frame each tower. Chamfers are lines that unify the composition of the residential tower, the office tower and the plinth. The design then varies with the time of day when chamfers look smooth against the textured surfaces of the building. Three sky gardens and sky lobbies provide a 360-degree view of the city. The building surface totals 85,507 square meters situated on 6,778 square meters of prime property. The height of the residential tower is 237 meters with 53 storeys while the office tower reaches 123 meters high and 23 storeys. The local architect is Architects 61 Pte Ltd.. Structural engineer is the DE Consultants (S) Pte Ltd.

www.tra-velo-gve.co.uk

V on Shenton twin towers showcase architectural innovations

Oman’s Tender Board opens bidding for $485M construction projects The state of Oman has designated its Tender Board to bid out the approved $485 million worth of construction project packages to fast track its infrastructure program. The first phase of the Al Batinah Southern Expressway project worth $358 million was awarded to Galfar Engineering & Contracting in the first quarter of 2012, the budget of which is over and above the current approval. Immediately to follow is the bidding for the $320.6 million package for the second phase. Other projects in the pipeline are the following: $60 million water supply line from a desalination plant in Al Ghubra to Muscat; $24.5 million first phase of a water project in Wilayat of ARustaq in the Governorate of South Al Batinah; $28.4 million fishing harbour project in Wilayat of Barka at South Al Batinah; the $7.4 million road projects in the north of the Salalah Ring Road in Dhofar; and the $4.6 million coastal protection works at Widam Al Sahel.

January-February 2013

Philippine Construction&Design

| 9

Association news

PICE challenges the engineering mind with “Rubies” The Philippine Institute of Civil Engineers or PICE has once more put a challenge to the analytical minds of young engineering students on the occasion of its 75th anniversary celebration held at the Cebu International Convention Center in Mandaue City, Cebu, Philippines. The contest, dubbed Engineering Creativity Design Competition: Engineering Design the Way It Shouldn’t Be, drew inspiration from the Rube Goldberg Design Competition or simply referred to as “Rubies”. Reuben Goldberg was a famous cartoonist known for his outrageous contraptions like a garage door opener. His drawings depicted complex but logical machines crafted from ordinary household materials used to perform even the most trivial activities. As such, the competition allows engineering student participants to play around the designs to create complex solutions to simple problems. According to PICE organizers, the competition was held to challenge civil engineering students, who are incidentally PICE student chapter members, to gain different perspectives on how things work and to come up with various solutions to the same problem. The contest consisted of designing a Rube Goldberg Machine that simply called “burst a balloon”. This was a test of analytical skills, creativity, innovativeness and a mindset of “thinking outside the box”. The winners of the competition will get cash prizes and plaques of distinction.

PCA President Manalo joins the CMDF Board of Directors The current president of the Philippine Constructors Association (PCA), Augusto F. Manalo, has joined the Board of Directors of the Construction Manpower Development Foundation (CMDF), the training arm of the department of Trade and Industry (DTI) for skills development in the construction industry. Manalo held different positions in the PCA in the past and also served as president of the Association of Carriers and Equipment Lessors (ACEL) in 1988-1989. He will join the five-man board of CMDF currently chaired by Rodolfo C. Menguita from D.M. Consunji Inc. Other members of the board include Technical Education and Skills Development Authority (TESDA) Deputy Director General Atty. Teodoro C. Pascua; DATEM Construction president Liberito Espiritu; and EDCOP Consultancy Company Vice Chairman Rogelio Lombos. CMDF, presently headed by executive director Jesus Motoomull, is mandated to provide education and skills training to tradesmen, engineers, supervisors and PCA president Augusto Manalo (third from right) joins the CMDF Board of construction project managers to equip them with the Directors with DTI officials led by Sec. Gregory Domingo (2nd from left) and latest technology, methods and practices to be globally TESDA Deputy Director General Atty. Teodoro C. Pascua. competitive.

10

| Philippine Construction&Design January-February 2013

UAP-PGBI hosts 4th Roundtable discussions on sustainable design and construction The United Architects of the Philippines (UAP) and the Philippine Green Building Initiatives, Inc. (PGBI) hosted the 4th Roundtable Discussion on Sustainable Approach to Design and Construction last November 8-9 at the the SMX Convention Center in Pasay City, Philippines. The two-day event sponsored fora and discussions on sustainable development and green building technologies. The main activities included the following: a) presentation of the Union Internationale des Architectes (UIA) Region IV Work Program on Responsible Architecture; b) grand launching of the PGBI GREEN Rating System; and c) an exhibition of new products and international trends by the Philippine Society of Ventilating, Air Conditioning and Refrigerating Engineers (PSVARE) as organized by PHILCONSTRUCT.

MEMBER

MEMBER

CATERPILLAR • KOMATSU • CUMMINS KOBELCO • KATO • ISUZU For All your Heavy Equipment needs -since 1950-

Equipment Sales, Rental & Parts Lifting & Material handling equipment: Forklifts, Cranes & Truck trailers, Earthmoving & Specialized equipment: Bulldozers, Payloaders, Backhoes, Graders, Power Generators, Air Compressors & Concrete Pumps. Services Equipment Trade Testing, Equipment on-site inspection/evaluation, Equipment repairs & Preventive maintenance.

Location of Major Plants & Facilities BORMAHECO, INC. Main Office : 1191 Vito Cruz Extension, Makati City Tel. Nos. (632): 890-1901; 890-1909; 890-1904; 897-0932/34; 890-2346; 899-5982 Fax Nos.: (632) 897-1378; 895-9715 E-mail: operations@bormaheco.com Butuan Office : Address: Km. 2 C.G. Aquino, Butuan City Tel. No.: (085) 342-5166; 225-2559 Fax No.: (085) 341-8670 Cebu Office : 272 Bormaheco Bldg., Burgos cor. Cortez Ave., Alang-alang, Mandaue City 6000 Telefax No.: (032) 346-8261 Davao Office: J.P. Laurel Ave., Bojada, Davao City, 8000 Tel. Nos.: (082) 227-5333; 221-7063 Telefax. No.: 221-7062 Bacolod Office: Bo. Tangub, Bacolod City 6100 Tel. Nos.: (034) 432-0021 Telefax No.: (034) 434-2523

URL: http://www.josabhiparquet.webs.com

Parquet design:

3D Diamond

Quality Living is our Commitment Wall

Ceiling

Bird’s Eye

Hollow Block

Whirpool Floor

Warehouse Rentals EPZA, Cavite/Km. 17 So Super Highway

Double Mat Waeve

Linara

Double Sawali

Mat Waeve

Strips Block

Sinawali

Decking

Services Offered:

Josabhi Parquet

T&G Floors, floor decking, Wood

Trading & Construction services

parquet, wooden plank, artistic floor, 234 T. Morato ave., ext. Quezon City walls and ceiling, furnitures, floor Tel. Nos.: (02) 543-8471; 565-3670 Telefax: (02) 411-7139 sandig/resanding, wood staining, wood Mobile: 0928-9655000 | 0917-9099949 | 0932-5557-333 bleaching, varnishing, repair URL: http://www.josabhiparquet.webs.com Email Add: josabhi@yahoo.com.ph January-February 2013

Philippine Construction&Design

| 11

industry report

www.philconstruct.com

The CMDF

Creating training modules for skills enhancement and development By Rodolfo de Guzman

A boost to the local construction industry

T

he construction industry, as a vital player in nation building, has to remain dynamic and responsive to its needs and be competitive in the local and international market. It is therefore imperative for all stakeholders, like government agencies, private contracting companies and the labour sector to also do their share in aiding the industry to translate economic development into tangible gains. Since the construction industry is labour intensive, it is therefore imminent for the construction manpower resource to be accorded the necessary logistical support

12

coming from both the government and the private sector. The labour force, composed of engineers, masons, carpenters, welders,steel workers and other skilled labourers, has to stay attuned to the changes happening around them. The fast pace of development in the construction industry with updated construction practices, techniques and processes must therefore be acquired by the local construction industry as well. In the Philippines, through the initiatives of the Philippine Constructors Association or PCA, a manpower development

| Philippine Construction&Design  January-February 2013

foundation was created in 1981 primarily to serve the local construction industry. Later on it became known as the Construction Manpower Development Foundation or CMDF. The strength of foundation The Construction Manpower Development Foundation now carries the torch for the local construction industry in the promotion of technical and managerial skills enhancement, manpower training and development, occupational safety, equipment operations and human resource management.

industry report

For its vision the CMDF aspires to be the leading instrument of change to effectively empower the local human resources to be globally competitive. The CMDF mission states that it is committed to create an environment conducive to the development and improvement of human resources in the construction industry that will be able to provide services with the highest standards both locally and abroad. The CMDF is structured similar to a learning institute where facilities are available for trainings, teach-ins, seminars, symposia and other skills enhancement programs. The foundation has its offices in Makati where there are classrooms, laboratories and workshops for intensive skills training. For three decades, the CMDF has been serving the construction industry with its four major assistance programs, namely: productivity trainings, orientation seminars on construction skills, skills testing and certification, and training facility rental.

Training modules With the thrust to provide comprehensive training, the CMDF’s productivity and competency enhancement program includes five areas of competency, namely: Construction Management, Construction Safety, Building Construction and Electrical Works, Mechanical Works, and Specialized Skills Course on Heavy Equipment Operation and Heavy Equipment Maintenance. Construction Management seminars are designed in line with the construction managers certification program with reference to the Project Management Body of Knowledge of the United States. The program is open to individuals and groups. The program touches on specialized topics, namely: construction project management, construction project contract management, construction project work planning and scheduling, construction project schedule control, construction project resource planning and cost estimating, construction project budgeting and cost control, construction project quality planning and assurance, construction project quality control and improvement and human relations. The seminars last from a day to about three days and course fees range from P1,300 to P4,000. The Construction Safety seminars are geared towards compliance to the Department of Labor and Employment (DoLE) Order 13 in accrediting safety officers. The two modules under the programs are Construction Safety and Health course for Site Safety Officers for five consecutive days and Road Construction Safety and Traffic Control for three days. The Building Construction and Electrical Works seminars are designed for construction engineers and skilled workers with focus on new methods and techniques classified into two categories; supervisory course and technical skills training. Included in the former are rebar works, formworks, concreting works, masonry works, materials testing and building electrical works. For the latter, it includes motor test and control, building wiring electrician, rebar fabricator/ installer and masonry works. Improvement of technical skills is prioritized with the Mechanical Works seminars, again designed for new methods and techniques in equipment operations and upgrading technical skills. The program includes the following: heavy equipment operation and maintenance management, plumbing works for supervisors, welding

works for supervisors, general plumbing works, and general welding works. The course usually takes three days and held at the CMDF Cavite training center. Lastly, the CMDF conducts Specialized Skills Course on Heavy Equipment Operation and Maintenance for equipment operators and supervisors. The heavy equipment operation module includes operation of bulldozers, motor graders, hydraulic excavators, wheel loaders, forklifts, and motor graders. The heavy equipment maintenance module zeroes in on engine overhauling, electrical system, fuel system, and hydraulic system. Each module lasts for about two days and are all done at the CMDF Cavite training center. Logistics The CMDF is equipped with various equipment, machineries and training facilities to address the basic and advance courses they offer. In collaboration with the Department of Trade and Industry (DTI), the CMDF-DTI Training Center in Dasmarinas, Cavite was put up to provide a permanent venue for skills trainings, seminars and workshops. It is situated on a seven-hectare lot complete with dormitories with air conditioning; function rooms that can accommodate 25 to 80 participants; and recreational facilities like swimming pool, billiards, table tennis and basketball courts. Miscellaneous services Despite being a training institute for the construction industry, the CMDF is also tasked with other skills assessment functions. Similar to the Technology Education and Skills Development Authority or TESDA, CMDF also conducts competency assessment and certification. This service enables trainees to receive certificates of competency that they can use in applying for jobs locally and abroad. The other services CMDF extends are the following: Training Needs Analysis (TNA), Training System Installation (TSI), and Job-site Coaching or On-site Training and Testing. Likewise, the CMDF also accommodates requests for academic field trips for students of engineering and technical schools and orientation seminars also for students and private companies involved in the construction business. Accomplishments, Projections and plans, Globally competitive.

January-February 2013

Philippine Construction&Design

|   13

special report

AGT system promotes environmentfriendly transportation Automation answers the need for safe and fast commuting

A

s the rate of urbanization increases and the number of new vehicles continue to rise, the demand for a more efficient mode of transportation has become immediate. A city like Metro Manila with a limited land area of 638.55 square kilometres and a growing population will eventually need a transportation system that allows maximum mobility at affordable costs. Soon, the total of 5,092 kilometers of roads will no longer be enough to handle the volume of vehicles that use them every day. Metropolitan Manila composed of 16 cities and 1 municipality with a total population of around 21.3 million based

14

on 2011 statistics will need reliable mass transportation systems if it is to move forward with its economic development goals. Although there are already mass transportation systems in place like the 17.2-kilometer Light Rail Transit (LRT) 1from Baclaran to Monumento, the 13.8-kilometer LRT 2 from Santolan, Pasig to Recto in Manila, and the MRT 3 from Baclaran to North Avenue in Quezon City, there is still a great number of commuters that are not accommodated. Because of this, other commuters still rely on public utility buses and jeepneys

| Philippine Construction&Design  January-February 2013

plying the major thoroughfares like Epifanio delos Santos Avenue (Edsa), Aurora Boulevard, Quezon Avenue, Espana Street, Roxas Boulevard, and C-5 Road (Osmena Highway). But with limited space for roads, commuting by bus or jeepneys can be a harrowing experience due to traffic gridlocks that will take you one hour just to traverse a 10-kilometer stretch. Coupled with poor urban planning, unregulated number of vehicles, burgeoning population, the proliferation of illegal structures on sidewalks and streets, the metropolis is shrinking every day. As a result, the socio-economic pressures are

getting higher and higher as productivity and efficiency are slowly being eroded. The solution now lies on the incorporation of a comprehensive transport system that will augment and support the current mass transit systems like the LRT and MRT.

technology. Other commercial establishments made use of AGT systems. The world famous amusement parks built the Walt Disney World Monorail System and the Toronto Zoo Domain Ride. In Los Angeles, the Getty Center made use of a verticallyoriented AGT that carries visitors from the parking lot off the Interstate 405 to a hill in Brentwood.

Since the AGT runs on its own tracks, the travel time from one end to the other end of the route is dramatically reduced compared to commuting by bus or motor vehicles. This generates savings in terms of time and fuel cost. Also, the occurrence of accidents is close to zero unlike vehicles on the road. Lastly, the most beneficial feature of the AGT is the absence of air pollution since it is powered by electricity.

AGT origins As the LRT and MRT systems address the need of commuters in the major thoroughfares, the AGT system is there to support and link the commuters coming AGT plus AGT connects the world from secondary and tertiary roads to the The AGT was developed to serve the The AGT system can be employed to mass transit systems. in-between market of commuters. It augment the existing LRT and MRT lines AGT is an acronym for automatic was created for transporting a particular in Metromanila. Since not all commuters guideway transit, a term used to refer to number of people that can no longer be reside near the LRT and MRT stations, the a fully automated, driverless and grade- accommodated by buses or too small for the AGT system can be constructed on side separated transit system where the vehicles conventional subway system that catering to streets and avenues in selected areas in the or coaches are equipped with rubber tires a higher density area. metropolis. and are guided and supported by a guideway By introducing the AGT as an alternative Instead of riding the tricycles, jeepneys or for the entire length of the route. mode of transportation for lesser density pedicabs (bicycles with side cars) from their The AGT is not a new technology. It has areas, the problem of ferrying commuters on homes to the stations, commuters can ride been in use even in the early 60’s particularly fixed routes can be addressed. the AGT in comfort and safety. in airports where people The AGT are transported using that is fully Together with the personal rapid transit concept, the PMS or people automated and mover system. Similar grade-separated the AGT system was developed in 1968 from funding technologies are applied rail transit by the US Department of Transportation. During that system to different variations can depending on the load time, many aerospace companies were slowing down serve as a shuttle capacity. There is the service running operations after the termination of the Project Apollo on a back-andmore complex mass transit systems like the forth trip that is and the end of the Vietnam War. Vancouver Sky Train usually referred and the simpler ones to as hectometric called personal rapid transit (PRT) made of The AGT is ideal for smaller roads and (designed for a few hundred meters). small car-like vehicles. streets as they require lesser areas for the Each train or coach of the AGT can Together with the personal rapid transit construction of infrastructures like concrete accommodate around 20 passengers that concept, the AGT system was developed in posts and guideways. Also it is more is often referred to as group rapid transit 1968 from funding by the US Department economical than the subway system because (GRT). of Transportation. During that time, many they use smaller sized vehicles usually The AGT system is widely used in other aerospace companies were slowing down composed of only two to four train coaches. countries as well. It is more prevalent in operations after the termination of the Project The AGT does not require construction of airports like Frankfurt International Airport, Apollo and the end of the Vietnam War. In expensive tunnels like subways as they are Germany; Hong Kong International Airport; anticipation of the possible need for PRTs as erected on elevated tracks. Kuala Lumpur International Airport, mass transit system by the start of the 1970’s Because of its smaller dimension Malaysia; London Heathrow Airport in the up to the 80’s, these companies like Boeing compared to larger systems of mass transit, UK; Osaka Kansai International Airport in and General Motors shifted its operations the capital costs involved in building the Japan, Paris Charles de Gaulle International to manufacture AGTs. But the projected AGT is far lesser than the LRT or MRT with Airport in France; and New York John F. demand did not materialize and only one larger load capacities. The components of the Kennedy International Airport in the United small AGT design was constructed called AGT are smaller and lighter and therefore States among others. the Morgantown PRT in West Virginia. cheaper like the suspension system, track In other urbanized cities, the AGT system The technology behind the AGT later support, axles and even the loading and has become a staple means of transportation. on found its widespread use in other unloading stations. Likewise, the lighter load There are AGTs in Tokyo, the Yurikamome, commercial applications. The LTV Airtrans allows for a variety of suspension methods Nippori-Toneri Line that opened in 2007; was constructed at the Dallas-Fort Worth to choose from like steel wheels or rubber the Bukit Panjang Light Rapid Transit International Airport and went into full tires or air cushion vehicles or maglevs. in Singapore; the Muzha Line in Taipei; operation in 1975. Thereafter, more airports The other benefit of the AGT is its the Scarborough RT in Toronto, Ontario; adapted the technology especially to connect automated feature that reduces the headways Docklands Light Railway in London, UK; terminals to parking lots. Today, most and operational costs that would otherwise and the Metromover in Miami, Florida. airports around the world make use of this be paid to crews. -(pc&d rpg)

January-February 2013

Philippine Construction&Design

| 15

COVER STORY

DOST-MIRDC engineers offer alternative mode of transportation Automated Guideway Transit system prototype is put to the test

Photos and Story by: Rodolfo de Guzman

T

he Metal Industry Research and Development Center or MIRDC has successfully constructed a prototype of the automated guideway transit system or AGT at the University of the Philipines in Diliman campus. The aim is to provide an alternative mode of transportation in the metropolis. With the worsening traffic conditions in urbanized areas like Metromanila, this development may yet be the answer to the daily woes of the commuting public. MIRDC is a research institute attached to the Department of Science and Technology (DOST), a government agency whose mandate is to create and promote Filipino inventions and new technologies that can be applied for commercial and industrial use. Tasked to undertake this project is a team of young engineers from MIRDC composed of Engineer Bryan Rasco (a civil engineer), Engineer Ryan Alvin Roldan (an electrical engineer), Engineer Jorge Gucos (a mechanical engineer) Senior Science Research Specialist Rea C. Castro and Engineer Jonathan Q. Puerto, Team Leader and Officer in Charge of the Office of the Deputy Executive Director for Research and Development of MIRDC. The AGT project has a funding of P60 16

With the UP prototype, we will be testing it further even “ though we already have positive results from the DOST model simply because the former is elevated”

--- Engr. Jorge Gucos

million coming from the department’s budget and when found viable, the technology will be offered to interested private companies that are looking for investments in the transportation business. A novel idea The idea of coming up with an automated guideway transit system or AGT similar to the existing Light Railway Transit (LRT) and Metro Railway Transit (MRT) started with Department of Science and Technology (DOST) Secretary Mario Montejo. The worsening traffic condition and air pollution in the metropolis were two of the reasons why the idea was conceptualized. Likewise, the experiment aims to reduce travel time by commuters, increase efficiency and productivity of people and energy conservation to lessen dependence

| Philippine Construction&Design January-February 2013

on fossil fuels. The lead agency, MIRDC, is being assisted by the Philippine Council for Industry, Energy and Emerging Technology Research and Development (PCIEERD). Also, other government agencies were consulted prior to implementation like the Department of Transportation and Communications (DOTC), the University of the Philippines Diliman, the Department of Public Works and Highways (DPWH) and the Philippine Institute of Volcanology and Seismology or Philvocs. AGT prototype The prototype being developed is called the automated guideway transit system or simply AGT. “It is quite similar to the existing LRT and MRT lines. The difference is that the AGT is smaller in scale since it is not really intended as a mass transit

the team also determined that the physical location, terrain and volume of traffic inside the university campus are ideal factors for a test area. They also considered the prospect of acceptability. The team believed that the university is the appropriate venue to test a new idea since most students and faculty are known to be more open-minded and receptive to novel initiatives.

“

It is quite similar to the existing LRT and MRT lines. The difference is that the AGT is smaller in scale since it is not really intended as a mass transit system.

”

–Engr. Jonathan Puerto

system,” explained Engr. Jonathan Puerto. The prototype is being developed to be used for secondary and tertiary roads where the present mode of transportation are tricycles, pedicabs or where people simply walk to reach the main thoroughfares to ride the LRT and MRT train. According to Engr. Puerto, the design was made to fit the narrow streets of Metromanila as it can maneuver in a very small turning radius of up to 13 meters. The entire system will only cover a distance of 465 meters which the team of engineers said was just the right length for a prototype to be able to assess fully its viability as well as determine the function, operation and possibly the possible flaws of the design if there are any. “The prototype is composed of four major sections or components. The first one is the rolling stock that is composed of the chassis, bogie, axles, and coaches. The second is the electrical control system that includes the electric motors and transformers. The third component is the elevated track made up of the reinforced concrete columns, the steel rail tracks, concrete platforms and side walls. The last portion is made up of the loading and unloading stations,” said Engr. Puerto. There will be a total of 25 columns to be erected for the entire length of the railway. “Each column is made of reinforced concrete with steel bars to give it strength and stability and will stand up to 4.2 meters in height,” revealed Engr. Bryan Rasco, the civil engineer in the team. The prototype was designed to carry two coaches with a maximum capacity of 30 passengers per coach. The team also stated that the load capacity of each coach is roughly 30 tons. Each axle can carry 7.5 tons maximum and each coach is fitted with four axles. Tailor-made design system The AGT system was designed to have slightly unique features that the team can be proud of. The team said that the design of the physical look is uniquely Filipino although the concept behind the technology is not new and has been used by other countries as early as the 70’s and 80’s. The style of the mechanical components

was also designed locally. Although the electric motors and insulators were sourced from India, most of the parts were made locally following the specifications given by the team of engineers. “We need not reinvent the wheel; what we did was we studied the concepts and technology and adapted them to local conditions. We also put in our own innovations especially on the design of the coaches,” stated Engr. Puerto. UP Diliman Since it is a government funded project, they decided to put it up at the University of the Philippines Diliman campus, the premier university in the country. They believe the state university’s reputation will lend credence to the project aside from the technical assistance that the UP College of Engineering will provide. With other considerations to think of,

Foreseen benefits The prototype is simply an experiment to see if the idea will work. A 500-meter prototype is simultaneously being tested at the DOST compound and is already working with positive results. “With the UP prototype, we will be testing it further even though we already have positive results from the DOST model simply because the former is elevated,” said Engr. Jorge Gucos. It is expected that the prototype will register the projected economic and social benefits that the team envisioned in the first place. Since the system will be running on electricity, there will be no pollutants released in the air. It will be more economical compared to using buses and jeepneys that use gasoline. Also, the benefit of the AGT is the possibility of zero accident since it will run above ground. For so many years of operation, the LRT and MRT have not reported any accident that can be attributed to vehicular accidents. When the UP AGT prototype operation has been fully evaluated and found to be feasible for commercial use, the DOST-MIRDC will simply make the technology available for private investors or the government through DOTC for implementation. When this happens, the transportation system in the metropolis will truly be revolutionized.

Steelworkers are being done on the ramp leading to the AGT coaches as entry and exit points.

January-February 2013

Philippine Construction&Design

| 17

project report-private

Casino in Manila-Belle grande

$2-B casino complex can withstand 8 quake Belle Grande Leisure and Entertainment Hub Stands on reclaimed land covered in piles By Ed Velasco

BUSINESS is about taking risks, so says an old adage.

T

his adage perfectly fits business mogul Henry Sy as the mall and banking tycoon is set to inaugurate his $2-billion Belle Grande Leisure and Entertainment Hub at Aseana Boulevard in Paranaque City sometime this year. The place where a new casinoentertainment-leisure park will be nestled is very close to the future site of the more ambitious Entertainment (E)-City of the Philippine Amusement and Gaming Corporation (Pagcor). What separates the two multibillion dollar projects is that the Henry Syowned investment is already starting while the Pagcor project has yet to start late this year. Belle’s casino project will

18

put to three the casino-entertainment complexes in the area. The other one, Bloomberry Resorts Corporation is owned by pier and mining mogul Enrique Razon. The expected mushrooming of casino complexes will put the Philippines in the same league as Macau, the gambling Mecca in the world, in the next three years in terms of revenues. Sy’s casino investment is a gambit as his bigger rival, Pagcor, will be a $10 billion investment in a 100-hectare complex within the area. This early, Belle Corporation has a clear vision as to why it is diversifying in the casino business. “Yes sir, we aim to

| Philippine Construction&Design January-February 2013

www.casinoinmanila.com

rival E-City. This is business; and business is about taking new ventures,” explains Ethel Manalo, Belle senior marketing specialist. Actually, the casino project of Belle will not only rival E-City but also the three other operators who were granted licenses to operate similar project. Meeting competition Maybe people will think that the Belle Grande Leisure and Entertainment Hub is far smaller than its three other competitors but those behind the Belle project are not in the business of running away from competition. Belle’s venture into the casino business is the result of Pagcor’s awarding four casino licenses in 2008 and 2009 to operate in the Manila Bay area. The four slots have been filled up less than 60 days after Pagcor announced it. It went to Resorts World, Bloomberry, Universal Entertainment Corp. and Belle Corporation. “We can offer what other casinos can offer,” Manalo continued. A bird’s eye view of the Belle casino and leisure park: total area of 7 hectares, 45 meters high edifice, 880 hotel rooms classified as 4, 5 and 6 stars, four 3D cinemas and a shopping mall. The 880-room hotel will be operated by three international hotel brands led by Radisson. The casino project alone will

“

If the foundation is put on piles, it is totally safe from collapsing even during a magnitude-8 earthquake

”

- former president explained be nestled on a 3.6 hectare property while the mall will be on a 2.5-hectare lot. Belle Grande’s location is strategic since it is at the center of Aseana Business Park in Parañaque City, just 50 meters away from the Department of Foreign Affairs office and other commercial and office buildings. It will have a total gaming area of 1.8 hectares surrounded by food and beverage outlets and luxury retail stores at the margins. The company broke ground for the mall component in February 2012 and is expected to finish the retail complex by mid-2014. The mall will have 60,000 to 90,000 square meters of retail space. The mall will also have a world-class performing arts theater. Despite the size of the project, there will be no special construction features, plans or materials. The project, however, will concentrate on building a strong foundation because it is located in a reclaimed area. Foundation under piles The foundation of the $-2 billion casino-mall complex is very stable because it lies under solid piles. One of the contractors of the casino-malls to be built in the reclaimed area, DM Consunji, Inc., has done a lengthy research before finally deciding where to build the structure. Filipinas Dravo Corp., the architectural and engineering consultant of DMCI, said the main objective of putting its foundation under piles is to transfer the load of the structure to the hard soil underground. “Putting it on piles is an engineering solution practiced by engineers worldwide,” said Isaac David, Filipinas Dravo Corp.’s president for 16 years and now connected to its sister firm, the MTD-Sltc of Malaysia.

www.pinoyprogress.com

Putting the foundation under piles will also address flooding because the structure can be elevated from the ground at any height at the discretion of the owner/developer. Another purpose for putting the foundation on piles is to avoid liquefaction in the event of a powerful earthquake. “If the foundation is put on piles, it is totally safe from collapsing even during a magnitude-8 earthquake,” David explained. Before the developer determined the final elevation of the structure from the piles, DM Consunji Inc. has already determined the maximum flood level as input to the final architectural and engineering design of the project. David said the reclamation of around 660 hectares of Manila Bay from 1976 to 1981 can be considered almost perfect as there have been no flooding incidences recorded in the area even during heavy rain. The successful reclamation of the area served as an engineering model for other countries. Hong Kong, Portugal, Macau, Jakarta in Indonesia and Brunei part of Borneo island, replicated the same with their own reclamation projects. New gaming center Once operational, the Belle project will be like a new Resorts World, a casino complex that offers the same services as most casinos around the world do. Belle would have to undertake a second round of financing to meet the frontloading of expenses arising from Pagcor’s

new requirement. Gaming licensees were required to put up their proposed hotel component of the project first before the casino can start operation. Pagcor also said the firm must change the number of hotel rooms so it can qualify as an integrated casino and tourism hub. If it becomes a certified tourism hub, the Department of Tourism will include it in the list of recommended tourist destinations. Center of investments Manalo said they decided to locate at Aseana because the potential of the area for profitability is very big compared to other places like Global City, Ortigas or Makati. “Almost all major investments are here.” Manalo also said their firm is not worried by the fact that E-City will be funded by Wynn Resorts, the biggest casino operator in the world. Wynn owns casino operation in two of the most expensive hotels in Las Vegas, Nevada— the MGM Grand and Mandalay Bay. E-City, which will start construction late this year, will be located in a 100-hectare complex in front of Heritage Hotel in Edsa. The putting up of casino complexes in the area will eventually turn the place like a Las Vegas that was transformed from a desert area into an entertainment hub in the 1950s.

January-February 2013

Philippine Construction&Design

| 19

ARCHITECT PROFILE

“

The firm is composed of teams and the architectural team usually proposes the plans that bear the general concepts that are unique, memorable and identifiable

www.business.inquirer.net

”

Arch. Felino A. Palafox, Jr.

Arch. Felino A. Palafox, Jr.

Creating imprints in the global architectural scene By: Katherine Verances Marfal

“Make no little plans; they have no magic to stir men’s blood and probably will themselves not be realized. Make big plans; aim high in hope and work, remembering that a noble, logical diagram once recorded will not die.”

T

he above quote from Daniel Burnham became the inspiration of Architect Felino A. Palafox, Jr. to reach his current stature. Palafox is fourth in a family of ten siblings. His father was a lay minister and doctor while her mother was a teacher. Back when he was a kid, he would enjoy making townships, group of buildings, mountains, bridges, and rivers while they were in the beach. That early, he had shown interest in constructing and making designs. Yet, at his young age, he also wanted to become a priest. “We always attend the mass as a family. I also became a mass

20

server when I was a child” Palafox recalled. In his teenage years, he entered the seminary in New Manila, Quezon City. During weekends, he would visit his uncle who was working as an engineer for the Ayala company. He saw the transformation of various construction projects in Makati and this influenced him to change his vocation from becoming a priest to be an architect. He went out of the seminary and studied Bachelor of Science in Architecture at the University of Santo Tomas and graduated in 1972.

| Philippine Construction&Design January-February 2013

–Arch. Felino A. Palafox, Jr.

Promising career His first job was as an architect-urban planner in Dubai in the United Arab Emirates. This job gave him the opportunity to transform a desert into a garden city. He had a great stay in Dubai earning him a lot of experience and personal fulfillment. “With my work, my family and I were able to travel very often. My family life was great when I was working in Dubai” he said. At that time, Palafox was the youngest architect-urban planner in Dubai. He was also the only Southeast Asian architect in Dubai at that time. After many years, he was encouraged by his uncle to go back to the Philippines. When he came back, he was hired by Henry Sy and the late Zobel. Later on, he became an architect-urban planner for Ayala Corporation. He worked with the firm for six and a half years. One of his major projects was the development of the Ayala Center in Makati City. Despite his enviable achievements, the young Palafox was far from being complacent and was looking for more challenges in his career. So, at the young age of 39, he made a bold move; he retired from work. Palafox Associates rising In 1989, Palafox Associates was born with only just three staff. The firm is engaged in architectural design, urban planning, master planning and site planning. It later on diversified in creating project development studies, interior design, landscape architecture and engineering. In December 1991, the company was registered as a professional partnership firm and since then has gained international exposure with work commissions from over 30 countries. The firm has been involved in the architectural design of more than 10 billion square meters of building area and master planned over 100 communities covering more than five million square meters of land all over the world. Palafox Associates has worked with

internationally known firms in the field of planning and architecture, landscape architecture and engineering. To name a few, the firm collaborated with Skidmore Owings & Merril (SOM); RTKL; Helmuth Obata Kassabaum Inc. (HOK); Duany, Plater-Zyberk & Company (DPZ); and the Jerde Partnership. Also, Palafox Associates worked with topnotch golf course architects like Jack Nicklaus, Robert Trent Jones, Jr., Tom Weiskopf, and Greg Norman. The Palafox teams The world-renowned architectural firm is composed of diverse groups that tackle conceptual design with different approaches to every project. As designers, the firm adopts no distinct style but considers the uniqueness of the site and the goals of its clients. “The firm is composed of teams and the architectural team usually proposes the plans that bear the general concepts that are unique, memorable and identifiable,” disclosed Palafox. To express concepts, visual imagery aids the clients to what architectural concept is most apt for the project proposed. Aside from conceptual imagery, Palafox Associates’ architectural team renders alternatives on plans and elevations that do not limit the choices but allow the clients to explore the many possibilities of other conceptual designs. Among the services offered include site analysis, space programming, space allocation, conceptual design, schematic design, design development, constructionworking drawing, and site supervision project development. On the other hand, the engineering team is proficient in the design and construction of structures and systems. It has two groups, namely: engineering design and site engineering. The former prepares the design development drawings, provides technical consultancy, and assist in selection and approval of materials to be used.

plant site; the Robinsons Starmills; the SM Southmall and SM City Fairview, two revolutionary shopping malls that departed from the run-of-the-mill and hackneyed box-shaped shopping centers. The firm has also developed golf course communities like Sta. Elena Golf and Country Club and the Manila Southwoods. It has designed and developed master planned residential communities like The Promenade, Pacific Heights, La Marea and the Grand Centennial Homes. With this, the company carried out work on entertainment, leisure and business communities like the Ecocentrum in Laguna and the First Philippine Industrial Park in Batangas. In other parts of the world, Palafox Associates did the architectural and interior design for the Qatar Twin Towers, Qatar; Jing Shen Plaza (Phase 2) in Beijing, China; Building 927, Ho Chi Minh City, Vietnam and West End Estates, Punjab, India. Other international projects include, among others, Pinnacles Development, Monterey, California; Sharm City of Stars, Egypt; Jabal Khandama Master Plan, Saudi Arabia; Saipan Golf and Country Club; Al Sharaf Shopping Center, United Arab Emirates; Tok Bali Fish Port and Tourism Estate, Malaysia; the Tzu Chi Convention Center, Taiwan; and the Jakarta Urban Transit, Indonesia. To date, Palafox Associates is the first Filipino architectural firm to be cited in the World’s Top 500 Architectural Firms of the World Architecture Magazine. In 2006, it ranked 94th-holding the distinction of being the only Southeast Asian firm to be included in the list. Last year, Palafox Associates ranked 89th in the world-ranking dominated by American, European, Japanese, Australian and Chinese firms. Moreover, the firm was certified ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) by the TUV

of Germany in architecture, urban planning, master planning, interior design, landscape architecture and engineering. The imprint With all the accolades, awards and recognitions that Architect Felino A. Palafox, Jr. has received, he remained vigilant in his advocacy to create architectural and building designs that blend with nature. In all his projects, be it a shopping center or an industrial estate or a residential enclave, Palafox always follow his firm’s Four Guiding Principles: Professionalism, Excellence, Nature and the Environment. He and his firm recognizes that they are merely borrowing the environment from future generations; therefore they endeavor to minimize the impact of their actions, plans and designs, and on the other hand, enhance the environment and minimize the negative impact of development. “I remember one of my professors in Life and Career Balance who asked us; if you die tonight, how will you write your eulogy and think who among your friends will write your eulogy?” disclosed Palafox. He was the only Asian and the first Filipino to study Life and Career Balance in Harvard University. This question left him with a thought on what legacy he can leave behind. “I am not exactly a saint but I am a very prayerful person. And I can risk my life to expose corruption because I believe that telling the truth could make a difference in our society,” Palafox described. “Even if you’re the best architect in the world but if you practice your profession with the society of corruption you will never take the full benefit of getting the highest potential,” he ended.

Milestones Palafox Associates, under the able leadership of its founder, continues to plan and design world class and state-of-theart architectural developments that leave a certain imprint in the lives of those who use the firm’s creations. Examples of these innovative development initiatives introduced through the firm’s signature projects are as follows: the Rockwell Center in Makati City, an inner city revitalization project of a former power Arch. Palafox with Ilocanos Norte Governor Imee Marcos (left) and with his architechural staff in his office (right).

January-February 2013

Philippine Construction&Design

| 21

engineer profile

A shaky career that guaranteed safety Engr. Christopher Gonzales’ path to success By Ed Velasco