ACS-s is always listening

Next generation condition monitoring for vibrating screens & feeders

Work smarter, not harder

Work smarter, not harder

Vibrating screens and feeders operate non-stop in extremely harsh environments, moving tonnes of mass under incredible forces. Even with regimented maintenance, failures still occur. Until recently, the only option was to activate rapid response repair teams when something went wrong. Now there’s a better way.

Long before a vibrating machine fails, there are warning signs that something isn’t right. Traditionally, the industry has relied on the eyes and ears of operators to detect faults, meaning the problem has usually advanced to a serious stage before it’s identified.

Now there is ACS-s.

ACS-s is a revolutionary condition monitoring system for vibrating screens and feeders. The system provides operators and service technicians with real-time data on the condition of their equipment so they can make proactive maintenance decisions that reduce incidence of downtime and high impact repairs, boosting overall operational efficiency.

By listening to the vibration of each machine around the clock, ACS-s detects the moment something is outside of normal parameters. You’ll be alerted at the first signs of imbalance, improper motion, foreign sounds or changes to structural integrity.

Early detection enables operators to take swift action to address the initial fault, preventing a costly failure event, expensive repair operation or loss of production.

With ACS-s, your fleet of screens and feeders can benefit from unprecedented uptime and productivity together with a notable reduction in serious faults and maintenance costs.

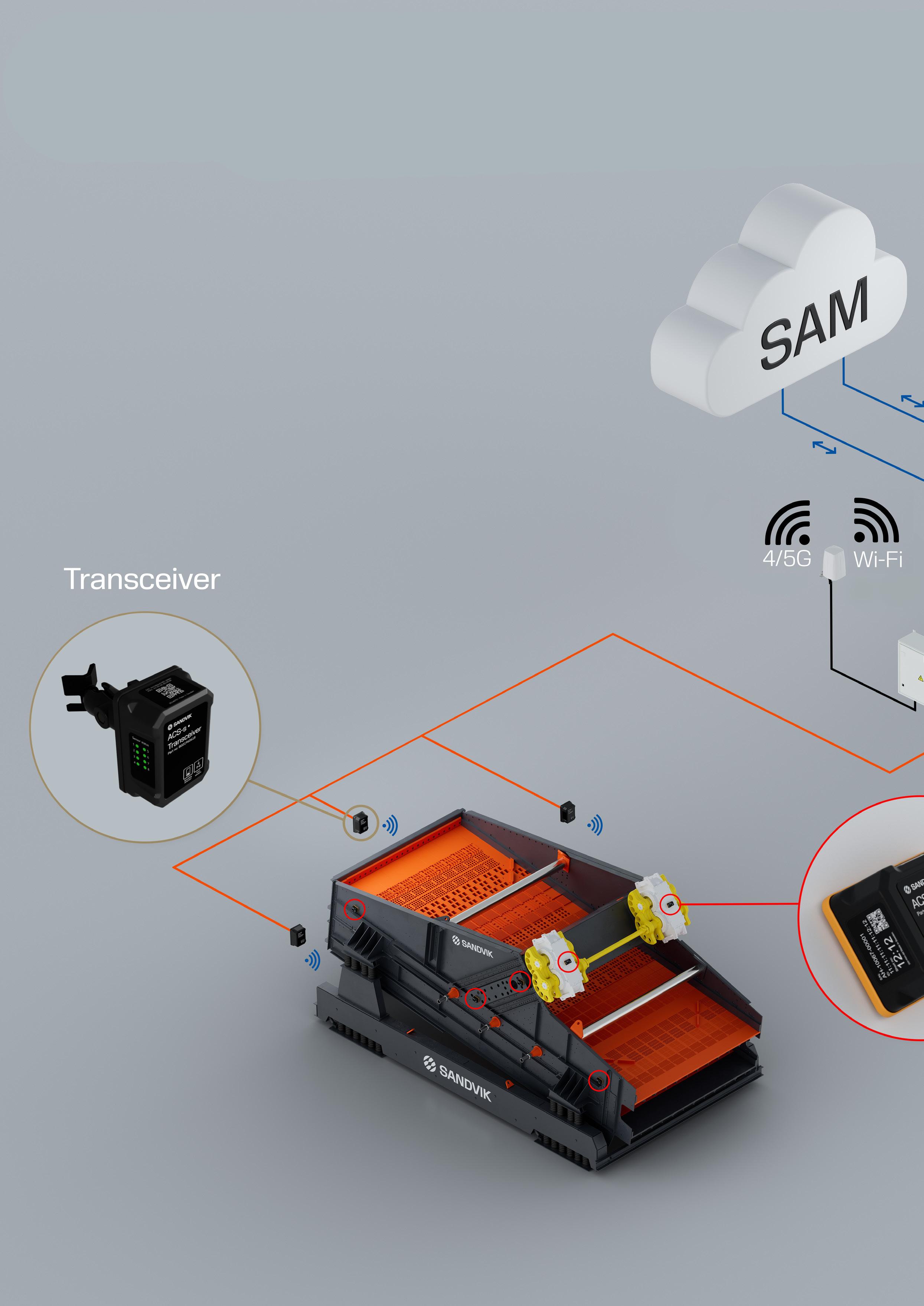

Energy harvesting, wireless sensors with magnetic mounts designed for rapid, non-destructive installation

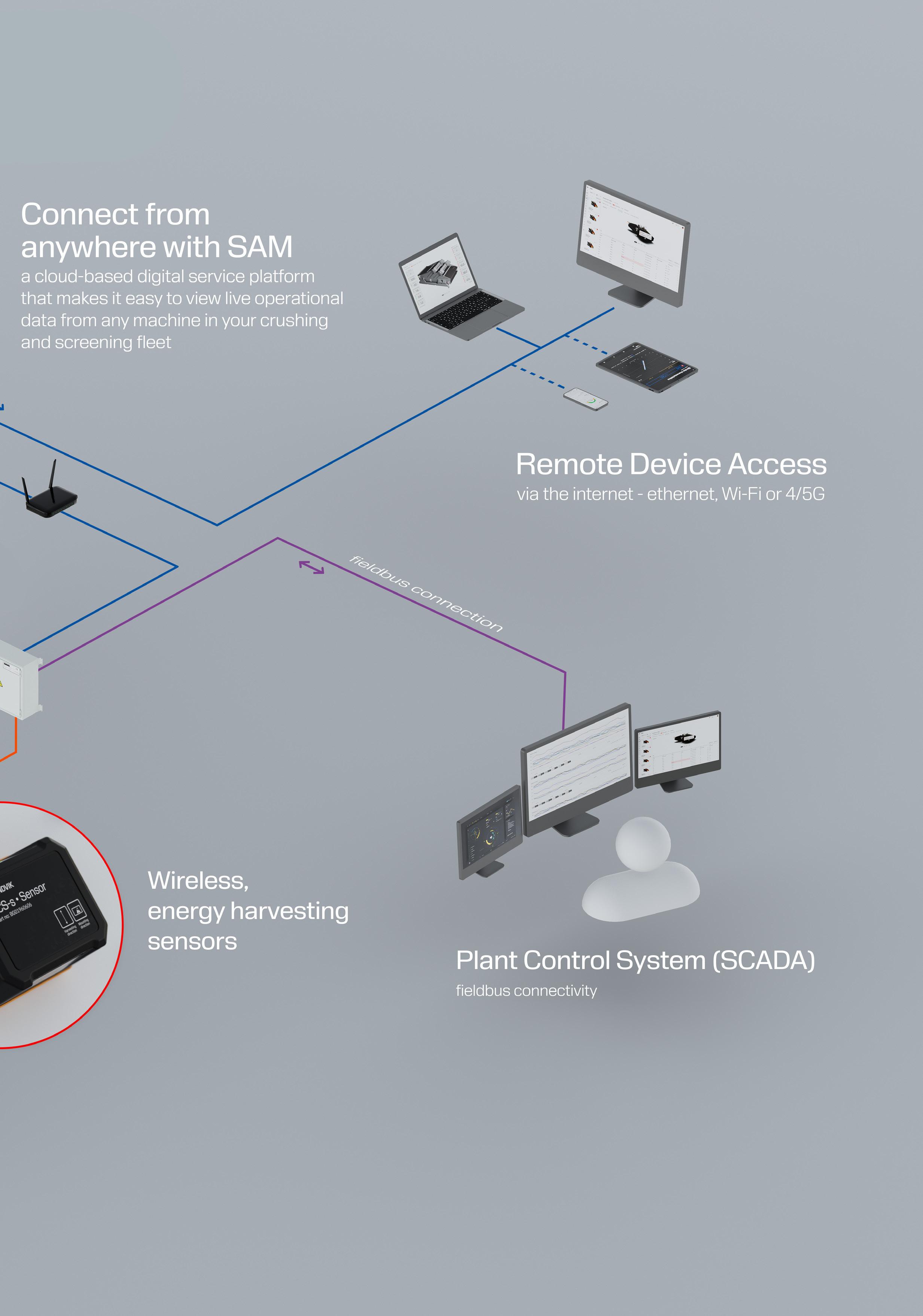

Connect via SAM, our cloud-based digital service platform, and ACS-s becomes collaborative and scalable. SAM also enables you to invite Sandvik service engineers to connect and assist remotely with technical advice and monitoring support.

Scalable like never before ACS-s condition monitoring was designed for scale, easily accommodating the largest of mine sites. You can also customize the sensitivity and detection resolution of ACS-s per machine, scaling each installation according to your requirements, with up to 32 synchronous sensors.

ACS-s is designed to facilitate the highest tier of fault detection and response, with the option to either use your own teams to monitor alerts or leverage Sandvik’s global network of specialist engineers and maintenance teams to provide remote monitoring and situation response direction.

ACS-s can greatly expand your monitoring and diagnostic potential through Sandvik’s global network of engineers and maintenance teams

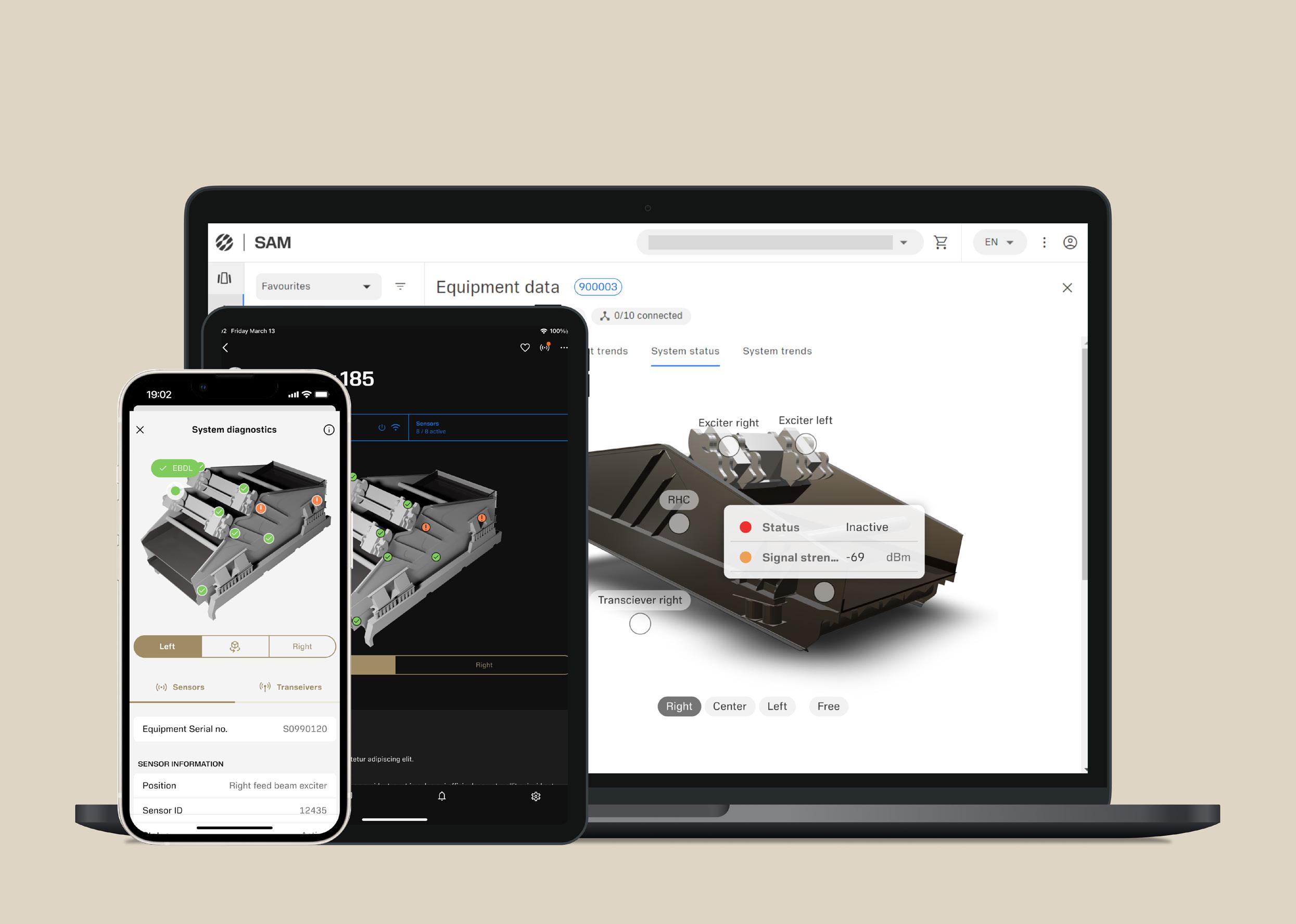

ACS-s turns your mobile device into a monitoring control center, with alerts and system analysis available in realtime. Sophisticated sensors and data processing via SAM, transform raw data into easy-to-understand visualizations that make it easy to understand both the nature of a problem and a productive course of action.

Using fieldbus connectivity, ACS-s can also be configured as an integrated feed to your Plant Control System. This allows live data and alerts to be visualized in your plant control system, alerting operators to a potential issue that can be actioned immediately.

ACS-s was specifically designed with an express setup capability that offers direct connectivity to SAM using LAN or the in-built antenna and router via 4G/5G or Wi-Fi. Together with the magnetically attached, energy harvesting sensors and wireless data transfer, ACS-s could not be easier to install.

Click. Connect. Go.

”Avoiding just one unplanned shutdown typically covers the cost of ACS-s, and that doesn’t even take into account the savings of extended machine lifecycles”

Scan