COTTAM POWER STATION HISTORY BOOK

PROUDLY GENERATING: 1968 - 2019

COTTAM HISTORY IN NUMBERS:

STANDING ON THE SHOULDERS OF GIANTS

STANDING ON THE SHOULDERS OF GIANTS

Scintilla Design

I’d like to take the opportunity to thank you for your dedication and commitment during your time at Cottam. I am immensely proud, as I’m sure you are, to be part of the Electricity Supply Industry and especially to be part of the team which took Cottam to its final operating days. The success of this site is through the people who work within its gates regardless of position or company overalls.

You have been part of a team who have allowed Cottam to perform at its best in some of its most difficult years. A team who have maximised every opportunity and have proven time and time again their worth.

Cottam has played a vital role generating electricity for over 51 years, making a massive contribution to the UK and local economies. It has certainly done its job and I hope you have enjoyed being part of it!

On behalf of the station, I wish you all the very best and good luck for the future.

Yours sincerely

Andy Powell Plant Manager Cottam Power Station October 2019FOREWORD

It may be useful to explain some of the background to the construction of the station and to say something about its early days.

Cottam was planned at a time when the demand for electricity was doubling every ten years. To meet this growth in demand and to enable older small power stations to be closed a construction programme of 500MW units was adopted. Cottam was late in this programme. It was planned with a plant combination different to the other 500MW unit stations and had some new design features.

The 500MW unit programme initially had many teething problems. This added to the plant shortages that were common at this time. It was frequently a struggle to meet the daily maximum demand.

The pressure to “keep the lights on” from plant shortage and the numerous national strikes in key industries engendered a strong sense of public service. That contrasts with the profit focus for those competing in the present energy market.

The site for Cottam was selected because it was close to a coalfield, on the Trent, a source of cooling water and near to a railway line. It joined the line of stations which was to form the main core of the country’s generation capacity.

At this time I was the Deputy Station Manager at Thorpe Marsh and was involved in commissioning two 550MW cross compound units. I was appointed as Station Manager at Cottam in 1965 which was well before the planned commissioning date. It allowed me to have some influence on the later phases of its design and to have time to appoint the staff and to set up the station’s organisation.

During this design stage a mock-up of the unit control panels was constructed in one of the site huts. I arranged for operational staff from running stations to test it by simulating the operation of a unit and to suggest changes to improve the design. This worked very well and I believe the design has been successful.

Since we were late in the 500MW programme, many of the more experienced potential candidates for the senior positions had already been appointed to the earlier stations. Our recruitment policy was to go for talented younger candidates. This policy was very successful and many of the original staff later became Station Managers themselves.

This was a time of near full employment and there was difficulty in recruiting craftsmen. A widespread advertisement program was needed together with arranging the availability of housing with the local council.

As the first Station Manager of Cottam I am delighted to have been asked to write the foreword to this book.

There was a very good, constructive and friendly atmosphere from the beginning and it boded well for the future of the station.

There were a number of set backs before commissioning but all were eventually overcome. Unfortunately I had to leave the station before the first unit was synchronised being promoted to Group Manager and being responsible for five stations including Ratcliffe. Throughout my subsequent career I continued to be involved in some way with Cottam. I was later the Director of Resource Planning for the Midlands Region and had to review and approve Cottam’s annual plans and budgets. A task in which I may have been influenced by my past association.

I was at that time delighted to be invited to open the Cottam Sports and Social club. Later I was called back to name a locomotive “Cottam Power Station”. I remember saying in my short speech that to give a locomotive such a name demanded of it a high standard of performance comparable to that of the station. When I eventually retired I was gratified to receive an inscribed gift from the staff at Cottam.

I am honoured to have been associated with Cottam. A station that has had such a long successful and distinguished history. It has generated a significant quantity of energy which has made a massive contribution to the country’s economy. It has operated efficiently for far longer than anyone could have possibly imagined when it was commissioned and it is still in good operational condition.

Frank Ledger CBE FREng

Frank Ledger CBE FREng

“It is a tribute to the skill and dedication of the staff through the years that Cottam has been so successful.”

STATION SUPERINTENDENTS, MANAGERS

The

Cottam Power Station was built and originally operated by the Central Electricity Generating Board (CEGB) up until privatisation in 1990. During construction and early operation of Cottam, the most senior position on site was the Station Superintendent; a title used by the CEGB up until the 1970’s. Following on from this the position title changed to Station Manager, which remained in use at Cottam through privatisation and into ownership by Powergen. It was also maintained after the sale of Cottam on 1st January 2001 to the London Power Company, a subsidiary of the London Electricity Group, itself a subsidiary of EDF, now EDF Energy.

CEGB’s objectives of the Location Manager were “The overall task of managing materials and finance to provide a safe and secure supply of electricity at minimalFrank Ledger CBE FREng Station Superintendent 1965 - 1967 George H Scott Station Superintendent 1967 - 1976 Keith Wallis Station Manager 1976 - 1983 Derrick Parry Station Manager 1983 - 1987 Peter McGriskin Director of Thermal Production (Inc Cottam & West Burton A) 2003 - 2008 Nigel Beresford Director of Thermal Generation (Inc Cottam & West Burton A) 2008 - 2011

MANAGERS AND DIRECTORS

managing a large power station is to utilise resources, plant, staff, costs”. These objectives still stand the test of time.

In 2003 the decision was taken to bring Cottam and West Burton A together under one management team, led by a Director. Initially this was the Director of Thermal Production; it then became the Director of Thermal Generation and then the Director of Coal Operations. Finally in 2015 Cottam reverted back to a site specific Plant Manager.

Michael Childerley Station Manager 1987 - 1993

Bryan Spilsbury Station Manager 1993 - 1999

Mark Saxilby Station Manager 1999 - 2000

Robert Kennedy Station Manager 2000 - 2003

Paul Morton Plant Manager 2015 - 2016

Darren Ramshaw Plant Manager 2016 - 2018

Michael Childerley Station Manager 1987 - 1993

Bryan Spilsbury Station Manager 1993 - 1999

Mark Saxilby Station Manager 1999 - 2000

Robert Kennedy Station Manager 2000 - 2003

Paul Morton Plant Manager 2015 - 2016

Darren Ramshaw Plant Manager 2016 - 2018

FOREWORD

One visit into the boiler house, turbine hall and main control room during an interview for a modern apprenticeship and I was hooked. I knew this was somewhere I wanted to work and after a four-year apprenticeship, which had me exploring every inch of pipework and operating any item of plant required, I thought I had a solid understanding of how the station worked - but this would only be the start!

It was the engineering that first got me passionate about this site, but it has been the people who have kept me here for nearly 20 years. That friendly atmosphere Frank speaks of has never left Cottam; it’s what truly unites us all and has kept us going regardless of the changing markets or different management directions. Perhaps linked to the original recruitment policy which started Cottam’s operating life, I believe the culture and atmosphere here is one of our biggest successes.

I still get the same feeling today as I did in my early years. The scale, design and engineering involved in building and operating this plant is impressive and there is no better feeling than bringing 4 x 500MW machines online as the sun rises in the morning between the cooling towers, as the rest of the UK is just waking up.

Whether through strikes, privatisation, extreme weather conditions, adverse markets, the change in role from keeping the lights on to being ready when required, we can absolutely say we played our part and should be proud of what we have achieved for the UK’s Electricity Industry.

There have been many different chapters in our station’s life, and we all have our own stories within them, stories that we’ll never forget. This book has been designed to capture those memories. It is a fantastic reflection of our history as well as recognition to all involved in maintaining our high standards and generating proudly to the very end. I would like to thank all involved, especially Steve Hoad in creating such a masterpiece.

I don’t believe my experience of Cottam is too dissimilar to Frank’s or to the many who have worked within its gates.

20 years ago, I would have never expected to be Plant Manager for Cottam or responsible for leading the station to its final generating days. However, having the opportunity to see a station team deliver so much with so little in recent years has been a total privilege.

Cottam’s performance today is because of its people, who are all proud of their contribution to the station. But we are well aware that we would have been unable to make this contribution if it were not for those who have preceded us, our colleagues who stand beside us now and our family and friends who support us through our working lives. It is the humility of all at Cottam to acknowledge that we benefit from what others contribute and that we are Standing on the Shoulders of these Giants.

“There is no better feeling than bringing 4 x 500MW machines online as the sun rises in the morning between the cooling towers, as the rest of the UK is just waking up.”

EARLY HISTORY OF THE COTTAM SITE

A mid-18th century survey of 1769 by John Grundy illustrates Cottam (the first instance of the modern spelling) within a shaded area of ‘ings, meadows and marshes... frequently overflowed by the Trent.’

Early county maps such as Saxton’s survey of Nottinghamshire and Lincolnshire of 1576 and Speed’s survey of 1610 indicate Cottam, spelt ‘Cotehin’ and ‘Coteham’ respectively, with its church on the western banks of the Trent, Speed’s survey showing the village sited close to the southern boundary of the ‘North Clay Division’ of Bassetlaw wapentake.

A mid-18th century survey of 1769 by John Grundy, engineer clearly illustrates Cottam (the first instance of the modern spelling) within a shaded area of ‘ings, meadows and marshes... frequently overflowed by the Trent’; the future power station site occupies an area labelled Treswell Marsh, Rampton Marsh, Treswell Common and Treswell Low Enclosures.

The susceptibility of the land to inundation is reflected by the various dykes indicated, running eastwards towards the river, with the major Seymour Drain annotated as ‘Seameare Dyke and Bank (the western branch of the Mother Drain)’. The area of the station’s northern ash lagoons, east of Cottam village, is marked as ‘South Leverton Marsh’, drained by the Treswell Dyke.

MICKLEHOLME FARM

The map also illustrates the rural, agricultural aspect of the pre-station site, extending between Outgang Road to the north and Torksey Ferry Road to the south, south-west of the village of Cottam and north-west of a sharp, hairpin curve in the Trent.

By this date, the landscape comprises hedged arable fields, including the area to the east of Cottam village, bisected by the irregular drainage channel of ‘Seymour Drain’, running broadly south-north; the fields to the north-east, south of (Treswell) Marsh Lane take the form of long strips, elsewhere of larger, geometric plan.

The Lincoln-Retford Branch line (later ‘Leverton Branch’) of the Manchester, Sheffield and Lincolnshire Railway (MS&LR), opened in 1850, traverses the area from north-west to south-east to the north of the future station site, passing immediately to the south of Cottam village, raised on an embankment and crossing Outgang Road on an overbridge near Floss House.

Fleet Plantation, a Scheduled moated site (Notts HER M4697), is annotated to the south of Torksey Ferry Road.

The Ordnance Survey map of the area 1:10,560 map of 1921 is the first to show Mickleholme Farm, which was demolished in 1964 for construction of the power station.

THE 1960s

Ever-increasing electricity usage in the years after World War II saw demand doubling every ten years and by the winters of 1961-2 and 1962-3, shortfalls of ‘crisis’ proportions were being experienced.

New sites were identified and new and/or improved stations constructed; thereby Midlands regional generation capacity quadrupled over the course of 14 years, from 4,000MW in 1957, rising to 8,000MW by 1966, 14,000MW in 1969 and 16,000MW by 1971. The region produced more than 25% of the electricity used in England and Wales and constituted the major part of the CEGB construction programme of ‘super-stations’ commissioned during the 1960s.

A particularly dense concentration of stations were built in the 1950s and 1960s in the Trent Valley of Derbyshire, Nottinghamshire Staffordshire and Leicestershire, which became known as ‘Megawatt Valley’, the largest concentration of power generation in Europe at the time.

Cottam was one of 13 coal and oil-fired ‘super-stations’ built by the CEGB based around the 500MW turbo-generator set, released for construction during the early 1960s and known colloquially as ‘Hinton’s Heavies’ after Christopher Hinton, CEGB Chairman, 195764. Constructed between 1964 and 1968 at a total cost of c.£79-80 million, Cottam was the tenth of the stations to be completed, being first synchronised to the grid in 1968 and fully commissioned in 1969.

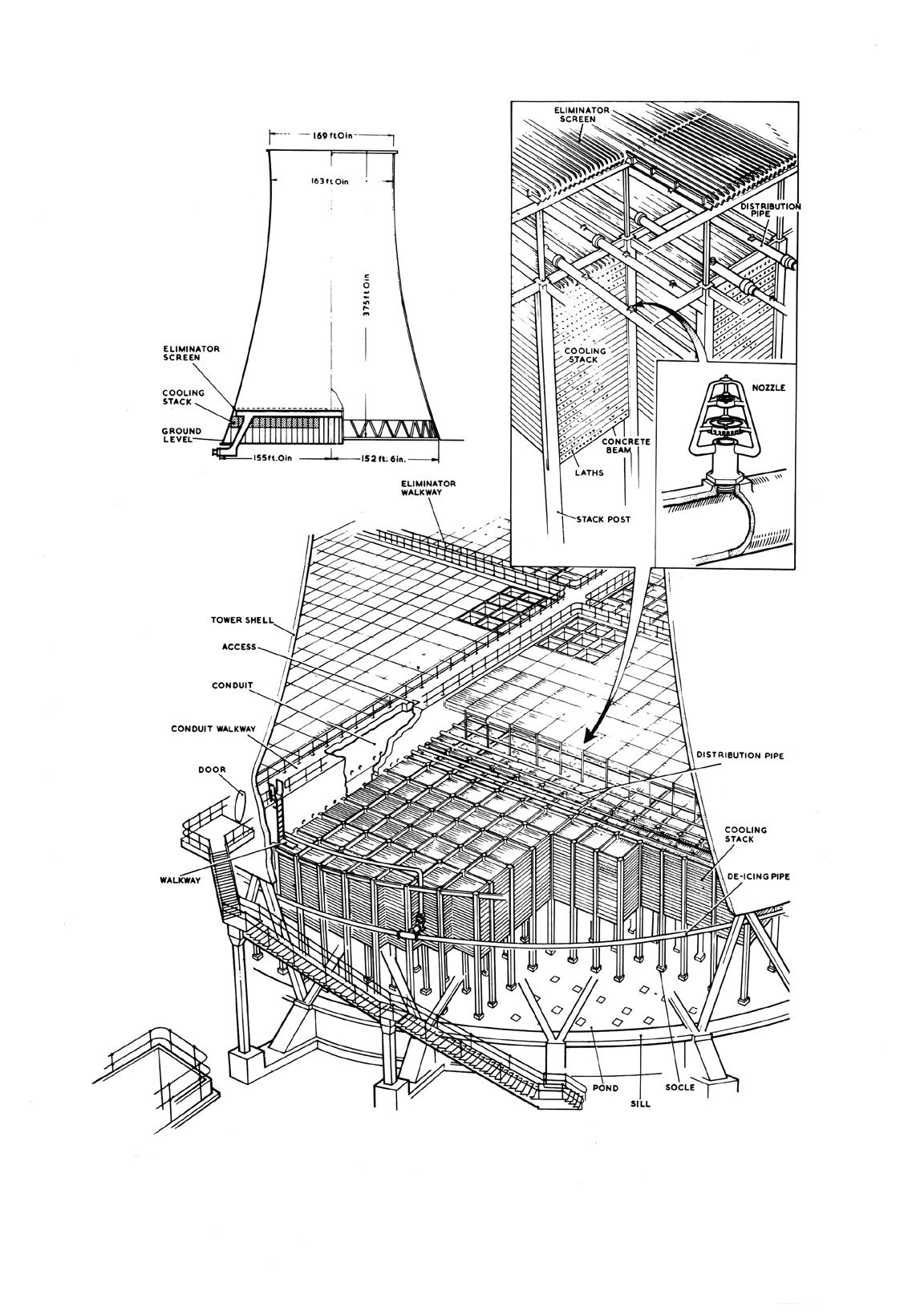

Consent was progressed in relatively short time, without the need for Public Enquiry, and was granted by the Minister of Power on 9th September, 1963. The approved design placed the principal generation buildings to the western side of the site, with turbine hall and boiler house contained within a large conjoined block, served by a bank of precipitators and a single, axially aligned 4-flue stack to the north and an open 400kV switch-yard to the south.

Mickleholme Farm demolished for construction of the power station

Mickleholme Farm demolished for construction of the power station

Cottam Village

The central section of the site is occupied by the cooling tower field, comprising a single block of eight towers in two parallel rows of four, while the extensive coaling plant with associated stock area and enclosing rail loop is located to the east, closest to the Trent. The low lying, floodplain site presented concerns of flooding, and the area of the main process buildings was thus raised by c.3m prior to construction to form an elevated plateau, with 3¼ million cubic yards of material being excavated from a series of ‘borrow pits’ in the area to the east of the station site later used as ash lagoons for the disposal of pulverised fuel and furnace bottom ash.

Site clearance commenced in early 1964 with initial earth-moving raising the level around the future principal generation buildings and the creation of a 50ft. tall earth bund to the north, at Outgang Lane, later planted with

trees and shrubs to partly shield views of the site from Cottam village. Groundworks and foundations were well advanced by May 1965 and construction of the main steel frame for the control block and eastern end of the turbine hall was progressing by November of that year. The erection of the turbine hall and boiler house was approached as a two stage operation with the pile caps for Units 1/2 in place and work on the steel frame / flooring of the eastern end of the block in train before pile caps for Units 3/4 were completed.

The station was brought on line in stages, with Unit 1 being the first to be synchronised to the grid, initially for a period of 1½ hours, on 9th June 1968 just 39 months after work at the site had commenced; the plant was fully commissioned in 1969.

MAIN BUILDING FOUNDATIONS FROM SOUTH EAST

SCREEN EMBANKMENT AND RAILWAYS SIDINGS FROM OUTGANG BRIDGE

MAIN BUILDING FOUNDATIONS FROM SOUTH EAST

SCREEN EMBANKMENT AND RAILWAYS SIDINGS FROM OUTGANG BRIDGE

CHIMNEY, NO. 1, 2, 3 AND 4 FLUES

BOILER HOUSE FROM WEST

CHIMNEY, NO. 1, 2, 3 AND 4 FLUES

BOILER HOUSE FROM WEST

BOILER HOUSE STEELWORK, EAST GABLE

BOILER HOUSE STEELWORK, EAST GABLE

TURBINE HOUSE EAST GABLE

TURBINE HOUSE FROM WEST

STATION SWITCH HOUSE

TURBINE HOUSE EAST GABLE

TURBINE HOUSE FROM WEST

STATION SWITCH HOUSE

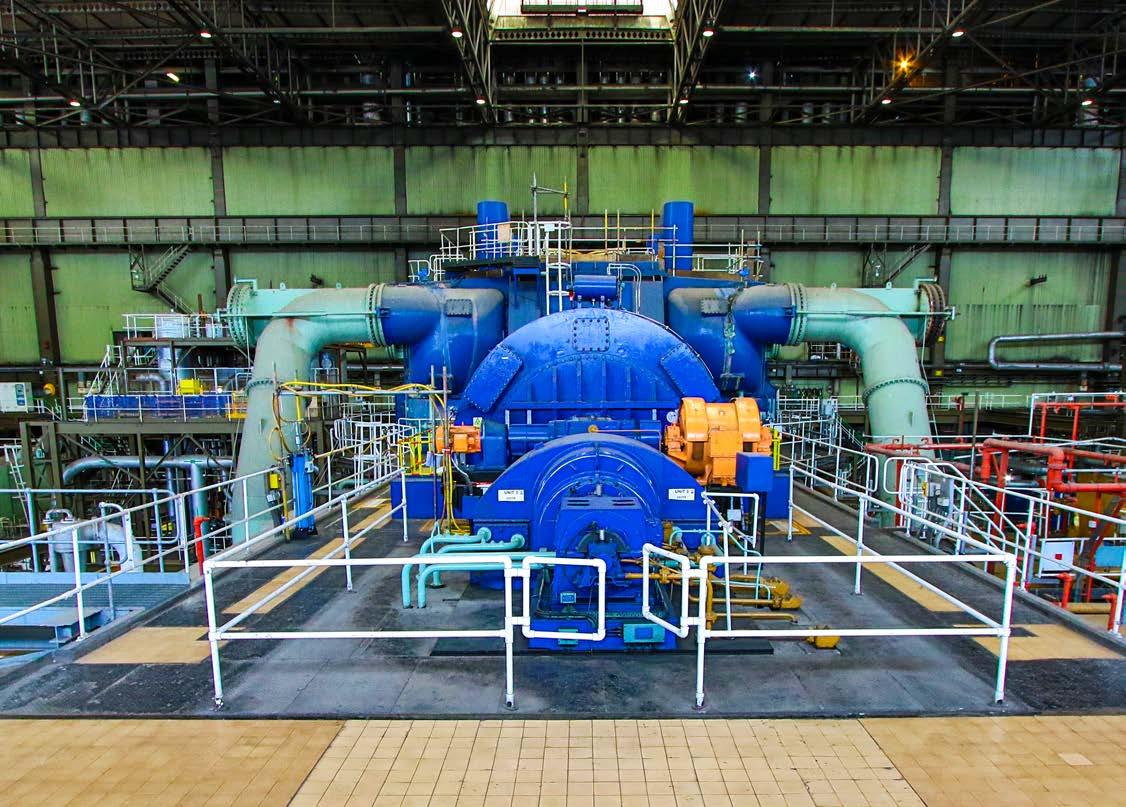

C.W. PUMPHOUSE, GENERAL VIEW

C.W. PUMPHOUSE, GENERAL VIEW

NO.1 TURBO-BLOCK

TOWER ‘A’ AND 6A, 6B CONVEYORS

MAIN BUILDING, SOUTH EAST CORNER

NO.1 BOILER PRECIPITATORS

NO.1 TURBO-BLOCK

TOWER ‘A’ AND 6A, 6B CONVEYORS

MAIN BUILDING, SOUTH EAST CORNER

NO.1 BOILER PRECIPITATORS

All new starters were issued with this introductory handbook of the site.

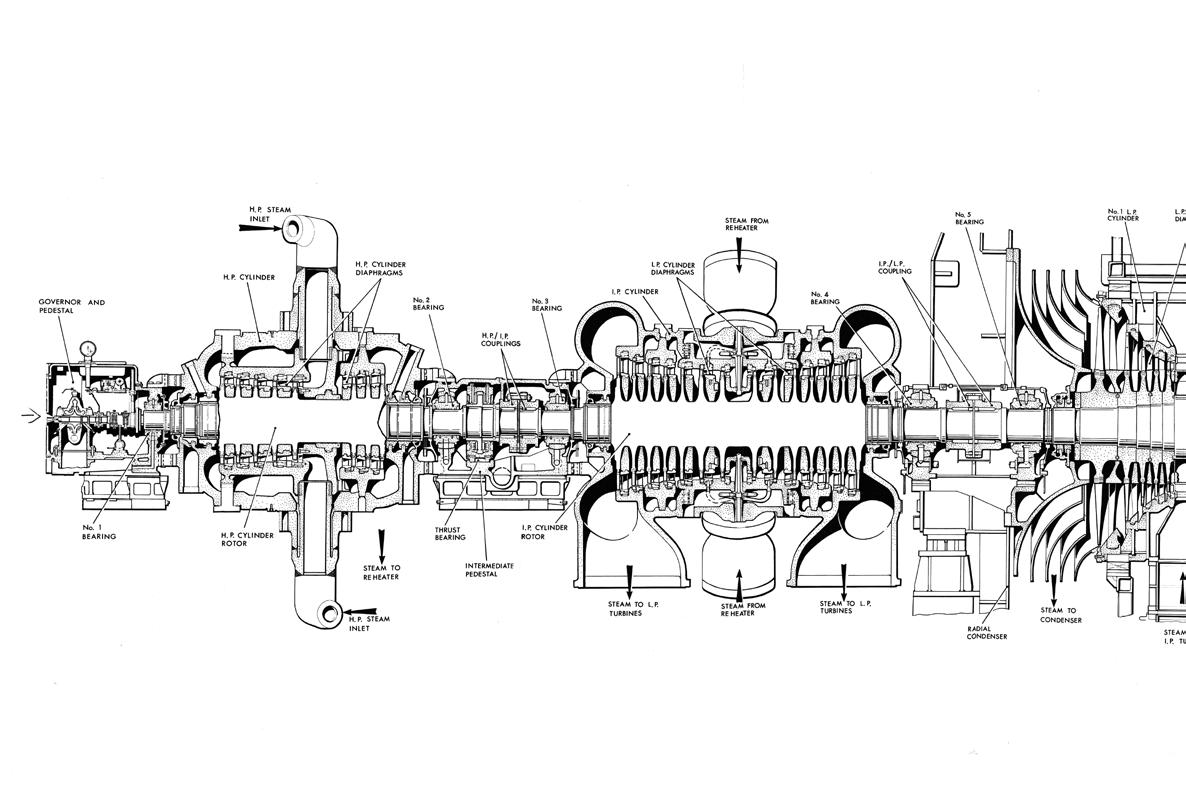

500MW MULTI CYLINDER, IMPULSE-REACTION STEAM TURBINE WITH REHEAT: MANUFACTURED BY ENGLISH ELECTRIC CO LIMITED

UNIT 3 BOILER

UNIT 2 BOILER ASH HOPPER

UNIT 2 BOILER ASH HOPPER

UNIT 3 BOILER

UNIT 2 BOILER ASH HOPPER

UNIT 2 BOILER ASH HOPPER

Station log from 9th June 1968, where it is noted that the first synchronisation to the National Grid of Unit 1 took place at 17:57 hrs

THE CEGB AND POWERGEN YEARS

The core aim of the expansion programme was to focus on a smaller number of ‘Super Stations’, each with an increased capacity based upon the larger units then available.

THE CENTRAL ELECTRICITY GENERATING BOARD

The Central Electricity Generating Board (CEGB) was formed in 1957. The CEGB operated over five geographic regions (North-East, North-West, Midlands, South-West and South-East) with ‘Generating Divisions’ based on ‘Grid Control Centres’ at Newcastle, Leeds, Manchester, Nottingham, Birmingham, Bristol and two near London (East Grinstead and St. Albans)

and a National Control Centre based in London. Three regional ‘project groups’ (North, Midlands and South) were concerned with station construction, while the Transmission Group oversaw the provision of overhead power lines.

An extensive Research and Development section had laboratories at Leatherhead, Marchwood and Berkeley.

THE 500MW UNIT PROGRAMME

By the early 1960s, the 500MW, single-shaft unit became the standard turbo-generator for new stations, generally arranged in combinations of two (1,000MW) or four (2,000MW); of the 13 major new oil- and coal-fired ‘super stations’ based upon the 500MW unit released for construction between 1960 and 1964, all but three (Aberthaw ‘B’, Ironbridge ‘B’ and Rugeley ‘B’) were of 2,000MW output.

The core aim of the expansion programme was to focus generation on a smaller number of ‘super-stations’, each with an increased capacity based upon the larger units then available. Many of the new plants were built in more rural locations, on major rivers and close to the main coalfields or, in the case of oilfired stations, on estuaries close to refineries. The valleys of the Trent in Nottinghamshire, Derbyshire and the Aire in Yorkshire, bordering the Yorkshire, Derbyshire and Nottinghamshire coalfields, experienced particularly intense development.

THE COTTAM ROCKET

The engineer was determined to do it by the book. The alternator rotor needed to be removed from Unit 3 and the service manual said to use a single sling wound around twice. The rigger thought differently, the alternator rotor weighed 64 tonnes and he said you need to use two slings. The engineer overruled him and insisted on doing it his way.

At first it was OK, slowly the alternator rotor was lifted. However, as soon as a thing that big starts to swing there is no stopping it. Gradually, then quickly it shifted towards vertical and slipped right out of the sling. The alternator rotor fell around 30 feet and went clean through a reinforced concrete floor before coming to a halt when it hit a live cable tray suspended from the ceiling in the room below. There was pandemonium, the crane operator was out of his cab in a flash and everyone dived for the nearest exit. Luckily no one was hurt. The alternator rotor stayed where it was, standing straight up looking like a giant nail hammered in to the floor.

GUARDING THE EVIDENCE

It took a few weeks to figure out how best to remove the alternator rotor from its resting place in the concrete floor. While this was happening a pendulum was hung from the top so it could monitor any movement. A young labourer was then given the task of sitting there alone in the room watching to see if anything happened. He was very pleased at being paid overtime for doing this. Who knows what he would have done if it had started to shift!

SAVE IT FOR LATER?

Getting the alternator rotor out of the floor was no easy task. First of all a lifting rig with eye bolts was made to fit over the exposed end. The crane gently pulled it out and the team were able to manoeuvre it to the horizontal so it could be sent away for refurbishment. It was obviously well made because other than being changed from a 7 to a 6 wind it came back with a clean bill of health and is still in service today.

MINERS’ STRIKE AND MASS PICKETING

With the NUR signalmen taking action in support of the striking miners, Cottam couldn’t get coal deliveries by rail. Instead there were massive convoys of lorries bringing the supplies. Most of the time there were a hundred or so pickets outside the gates, it was unpleasant but the stocks still got through.

Then the miners changed their tactics and on a number of occasions there must have been close to two thousand pickets, it turned really nasty. One week they blocked the road with railway sleepers. Another time they charged

the cordon to get in to the station and quite a few policemen ended up in hospital.

The worst though was when they raided the local farms and used bales of straw, feeding troughs and even wood from a cattle shed to set up burning barricades on the Treswell Road. Firemen were called to put out the blaze and the road surface was badly damaged by the heat. Police numbers increased after that and many more pickets were arrested.

COAL PLANT SCRAPER

MICK BECK, KEN ANDERSON AND LEE JACKSON

JOHN SHONE AND BARRY BRIGGS

COAL PLANT SCRAPER

MICK BECK, KEN ANDERSON AND LEE JACKSON

JOHN SHONE AND BARRY BRIGGS

WINNING THE BIG ONE

Winning the Hinton trophy in 1982 is a proud moment in Cottam’s history. Competing against 107 other CEGB power plants, the award effectively proclaimed Cottam as the best run and best kept station in the country.

The trophy was presented to the Station Manager, Keith Wallis, by Junior Energy Minister David Mellor along with CEGB board member Gill Blackman and Midlands Region Director General Jim Porteous

CYNTHIA HOGGARD

A DODGY LOOKING 6 A-SIDE FOOTBALL TEAM

CYNTHIA HOGGARD

A DODGY LOOKING 6 A-SIDE FOOTBALL TEAM

SO NEAR

Back at the end of the ‘70s there were some great sports teams at Cottam. There was a group of people fighting for places; they seemed to do well in just about everything they entered. The footballers were pretty much unbeatable during the ’78 to ’79 season. The team got all the way to the Midland Power Cup final only to have an off day and lose to Drakelow with probably their worst performance of the year.

A TIME OF UNCERTAINTY

The period leading up to privatisation wasn’t good. No one really understood what the changes would mean.

It settled down after a while and in retrospect privatisation opened up career opportunities that didn’t exist before. The problem with the

CEGB was that you were what you were and there you stayed. Powergen did away with that, they got rid of the layers of management and bureaucracy. Instead people were allowed to learn new things and develop in to different areas. Many of those who stayed at Cottam actually did very well from the chances they were given.

COTTAM TIES AND SCARVES

Privatisation was commemorated by the production of special ties and headscarves. The Cottam logo embroidered on the front was designed by an employee, Martin Aldridge, and featured a depiction of the

original chimney stack. The days of CEGB generosity were long gone; if you wanted one it cost £2.00. Martin’s original design has since been updated by our Draughtsman Tom Smart into our 50th Anniversary logo.

MIKE CHILDERLEY AND MERVIN DALTON WITH THE CEGB COMMEMORATIVE PLAQUE

MIKE CHILDERLEY AND MERVIN DALTON WITH THE CEGB COMMEMORATIVE PLAQUE

EMPOWERMENT

The Powergen buzzwords were empowerment and ownership. No one really knew what they meant at first and some were sceptical. Gradually it became clear that what they were talking about was opportunity. Instead of an old style boss telling you what to do, everything turned around and employees told themselves what to do instead. It meant everyone could get on and get things done.

POWERGEN CEO ED WALLIS AND MIKE CHILDERLEY

DERRICK FARTHING

THE COTTAM LOGO DESIGNED BY MARTIN ALDRIDGE

TOM SMART’S COTTAM 50TH LOGO DESIGN

POWERGEN CEO ED WALLIS AND MIKE CHILDERLEY

DERRICK FARTHING

THE COTTAM LOGO DESIGNED BY MARTIN ALDRIDGE

TOM SMART’S COTTAM 50TH LOGO DESIGN

TECHNOLOGY AND AUTOMATION

The initial design of the control room was first class. The horse shoe layout is pure ergonomic efficiency. One person on a swivel chair can review everything; even the hands on the dials were originally arranged to all point one way so any discrepancies would be more noticeable. The whole thing was brilliant in its concept and execution.

In the late ‘70s and early ‘80s Cottam formed a working party to look at computerisation. There were potential benefits, but also some pretty serious downsides. The cost was high, none of the systems had been proven but more importantly the operators were

uncomfortable with the idea. In the end rather than a full APMS it was decided that semi-soft panels were a better way to go.

The thought was that the existing design worked, it simply needed modernising. The analogue displays remained but had computers put behind them. Data loggers were introduced and they gradually incorporated VDUs to enhance status reporting. The original panels seemed to have a direct link with the plant, which created a human connection. The approach was always to hold on to the best bits and make them even better.

WE’VE COME A LONG WAY

It all started with ICL word processors, they had just enough memory to hold a page of typing but everyone thought they were the bee’s knees. The modern world had arrived.

It was only a couple of years after that when Cottam took delivery of their first standalone computers. 5 ¼ inch floppies were used for backing up, they were big brown things that really did flop and had very limited capacity. The word processing software ran on DOS, you had to use lots of mini programmes to make things happen; the text was either green or orange on a black background.

The speed of development was pretty dramatic. By the early ‘90s a proper network had been installed with a central mainframe and user terminals. Kismet Work Management was the big programme, back up happened on to little 3 ½ inch discs at the desktop and there were 16 inch magnetic media for the main frame. It was about the same time that emails started to appear. In the beginning the

addresses were all numerical and you couldn’t attach anything. Similarly, the web didn’t really exist and no one had their own sites.

Most hand held devices now have more capability than the first computers on site. Progress has been spectacular and the benefits to the business are enormous. Who could have foreseen the way things are today when the first foundations were dug out for Cottam back in 1964?

LD66 UPGRADE

In the early days of privatisation all the talk was about gas fired generation. Coal simply couldn’t compete while gas prices were so low. There were even plans to mothball Units 1 and 4.

It wasn’t all doom and gloom, in 1993 Cottam replanted the LD66s on Unit 2. John Hodgson led the team and Nigel Champion was the supervisor. It took around twelve weeks of solid work; many of the processes were so new the team were often learning as they went along.

The end result was fantastic; the machine ran as smooth as anything afterwards. A year later the same upgrade was applied to Unit 3.

It was a massive investment by the company and it was taken as a sign there was confidence in coal for the future. During the same period gas prices had risen dramatically and coal was in favour again. Units 1 and 4 survived and the whole station was back on line.

RAY BACON AND ROY BANISTER

RAY BACON AND ROY BANISTER

SIMON SKELTON AND HIS RATHER UNIQUE MOTOR!

SIMON SKELTON AND HIS RATHER UNIQUE MOTOR!

COTTAM POWER STATION

BOILER TERMINAL CONDITIONS

SOOTBLOWERS

SHARING THE RESPONSIBILITY

Being the first coal fired power station to win ROSPA’s top safety award, The Order of Distinction, was the best feeling as it demonstrated to everyone just how serious Cottam takes safety. Before then the incident books were littered with far too many accidents. It wasn’t until the early ‘90s that Cottam won their first ROSPA bronze. Since then a steady improvement has been marked with a series of silvers, golds and five President Awards.

The pivotal move was extending NEBOSH and IOSH to team leaders and Contract Liaison Officers. That helped to make the team realise that safety wasn’t just about looking after number one, it was being your brother’s keeper as well.

REALISING THE POTENTIAL

When starting out with the nature reserve in 1996 there was basically nothing other than the lagoons and big intentions. Working with the Nottinghamshire Wildlife Trust the plan was to create a natural environment with learning facilities for children.

It took a lot of hard work but the efforts paid off. The soil has blended well with the underlying ash. There are woods, grassland, wetland, a riverside area, walkways and a bird hide. Best of all Cottam managed to get some low cost second hand teaching cabins for use by the local schools.

The wildlife clearly liked the nature reserve. There are kingfishers along the river banks and teal by the thousands in winter. Lapwings have also nested ready to breed in the spring. It’s a place Cottam can be proud of.

BIRD RINGING

Cottam is very special for birds. To begin with the eastern part of the site has a diverse range of habitats and so provides good food and nesting opportunities. Then there’s the fact that it’s a restricted industrial area in an out of the way place, which limits human interventions. Lastly it is an important stop off point for migrating birds following the Trent Valley Flyway.

The benefits of the nature reserve at Cottam were recognised by ornithologist David Fogg long ago. He has been methodically keeping records since 1977. Today, the depth of data available makes his one of the most important long term bird studies of any site anywhere in the UK.

KINGFISHER, A REGULAR VISITOR TO THE COTTAM NATURE RESERVE

KINGFISHER, A REGULAR VISITOR TO THE COTTAM NATURE RESERVE

BRYAN SPILSBURY AND CHRISTINE WALKER AT THEIR LEAVING DO WITH BOBBY DAVRO

DAVID BELLAMY AND KIDS AT THE COTTAM NATURE RESERVE

NIGEL CHAMPION AND STEVIE EDWARDS

ANDREW HOBSON, HELEN WIDDOWSON AND RICHARD DOBSON

BRYAN SPILSBURY AND CHRISTINE WALKER AT THEIR LEAVING DO WITH BOBBY DAVRO

DAVID BELLAMY AND KIDS AT THE COTTAM NATURE RESERVE

NIGEL CHAMPION AND STEVIE EDWARDS

ANDREW HOBSON, HELEN WIDDOWSON AND RICHARD DOBSON

FULL STEAM AHEAD!

EDF ENERGY AND MASSIVE INVESTMENT

In 2000 Cottam Power Station was sold by Powergen PLC for over £400 Million to the London Power Company, a subsidiary of London Electricity Group, which itself was a subsidiary of EDF Energy.

As Cottam staff arrived on the 2nd January 2001 for the first full working day under the ownership of the London Electricity (LE) Group, it was clear something momentous had happened. An LPC sign had replaced the Powergen one at the front gates, new style boiler suits and hard hats were being issued, and staff had easy access to their new LE colleagues through email and the internet.

But despite the new identity, the welcome speeches, the presentations, and the gifts of chocolates and paperweights, it was business as usual. After all, there was a thumping great power station to run!

Day One came at the start of the New Year, but the 166 employees at Cottam had already had time to get accustomed to their new owners. Straight after the deal to buy Cottam from Powergen was announced in the autumn of 2000, the then Chairman and Chief Executive Bruno Lescoeur and an LE board team visited the power station to meet the staff.

This was followed by a number of visits by Angus Norman, Managing Director of the London Power Company, known as LPC, which was set up specifically to manage the LE Group’s generation assets.

In 2003, three UK companies – SEEBoard, London and SWEB were amalgamated to form EDF Energy.

At that time the Cottam workforce made up the majority of Angus’s staff in LPC, as he told us in a welcome speech. “You are very much LPC”, he said. “We expect a lot from you but we are here to support you. Cottam is very important to our vertical integration strategy. We targeted Cottam because we wanted it as part of our portfolio and we intend it to work to full capacity.

We recognise that Cottam is already in the premiership of coal-fired power stations and our aim is to take it to the top of the league.

AN AMAZING ATLANTIC ADVENTURE

Faye Langham and Andy Giles took part in the Atlantic Rowing Challenge, a 3,000 mile endurance event from Tenerife to Barbados known as the world’s toughest rowing race.

They completed the distance in 59 days - four days over the current mixed-crew record - and, although the race did not end as they had hoped, they are rightly proud of their achievement.

In order to take part in the Atlantic Rowing Challenge, Faye and Andy had to spend £48,000, which included the £14,000 entry fee and £15,000 on the boat. Faye even had to re-mortgage her house in order to find her share of the costs, but she had no regrets saying “it was a once-in-alifetime opportunity”. As part of this challenge, Faye and Andy also raised in excess of £6,000 for their chosen charity – the Bluebell Wood Children’s Hospice in Doncaster.

FAYE DOING HER SHIFT AT THE OARS

ANDY SPORTING A RATHER DUBIOUS HAT!

FAYE DOING HER SHIFT AT THE OARS

ANDY SPORTING A RATHER DUBIOUS HAT!

The by-product of the FGD process is synthetic gypsum, all of which is sold into the construction industry.

Limestone is delivered by rail, the train wagons bottom discharge to the conveyor system, which then delivers the limestone to 3 storage silos, each with a storage capacity of 5,000Te, in readiness for milling and then use within the FGD process.

The by-product of the FGD process is synthetic gypsum, all of which is sold into the construction industry. Once produced the gypsum is initially stored in a single 12,000Te silo and discharged to trains for onward delivery via a combined loading/unloading screw feeder arrangement within the silo.

KEITH MABBOTT: SITE SERVICES AND INFRASTRUCTURE TEAM AND DICK OSBORN: EC&I TEAM

KEITH MABBOTT: SITE SERVICES AND INFRASTRUCTURE TEAM AND DICK OSBORN: EC&I TEAM

NICK BRADFORD, ANDY GILES, PETE SMITHSON, FAYE LANGHAM, DOUG SMART AND BOYD JOHNSON DURING THE 2004 KIELDER CHALLENGE

NICK BRADFORD, ANDY GILES, PETE SMITHSON, FAYE LANGHAM, DOUG SMART AND BOYD JOHNSON DURING THE 2004 KIELDER CHALLENGE

NEIL FORD, STEVE MORRIS, CRIS VALLANCE AND RAY LILLEY RED SHIFT

NEIL FORD, STEVE MORRIS, CRIS VALLANCE AND RAY LILLEY RED SHIFT

Rail Coal unloading house, discharge lines

A and B. Trains move through this facility at 0.5MPH, with their bottom hopper gates being activated remotely by automatic, line side equipment, known colloquially as ‘Daleks’. The load being discharged directly into underground track hoppers.

MICK KAVANAGH AND COLIN MAGILL FGD MAINTENANCE TEAM

MICK KAVANAGH AND COLIN MAGILL FGD MAINTENANCE TEAM

MASSIVE FLUE GAS DESULPHURISATION INVESTMENT BY EDF ENERGY

It was a massive investment by the company and we all took it as a sign they’d got confidence in us for the future. The whole station seemed to have a smile on its face!

GYPSUM SILO CONSTRUCTION

WASTE WATER TREATMENT PLANT FOUNDATION WORKS

AERIAL VIEW OF GYPSUM AND LIMESTONE SILOS, AND WASTE WATER TREATMENT PLANT CONSTRUCTION

GYPSUM SILO CONSTRUCTION

WASTE WATER TREATMENT PLANT FOUNDATION WORKS

AERIAL VIEW OF GYPSUM AND LIMESTONE SILOS, AND WASTE WATER TREATMENT PLANT CONSTRUCTION

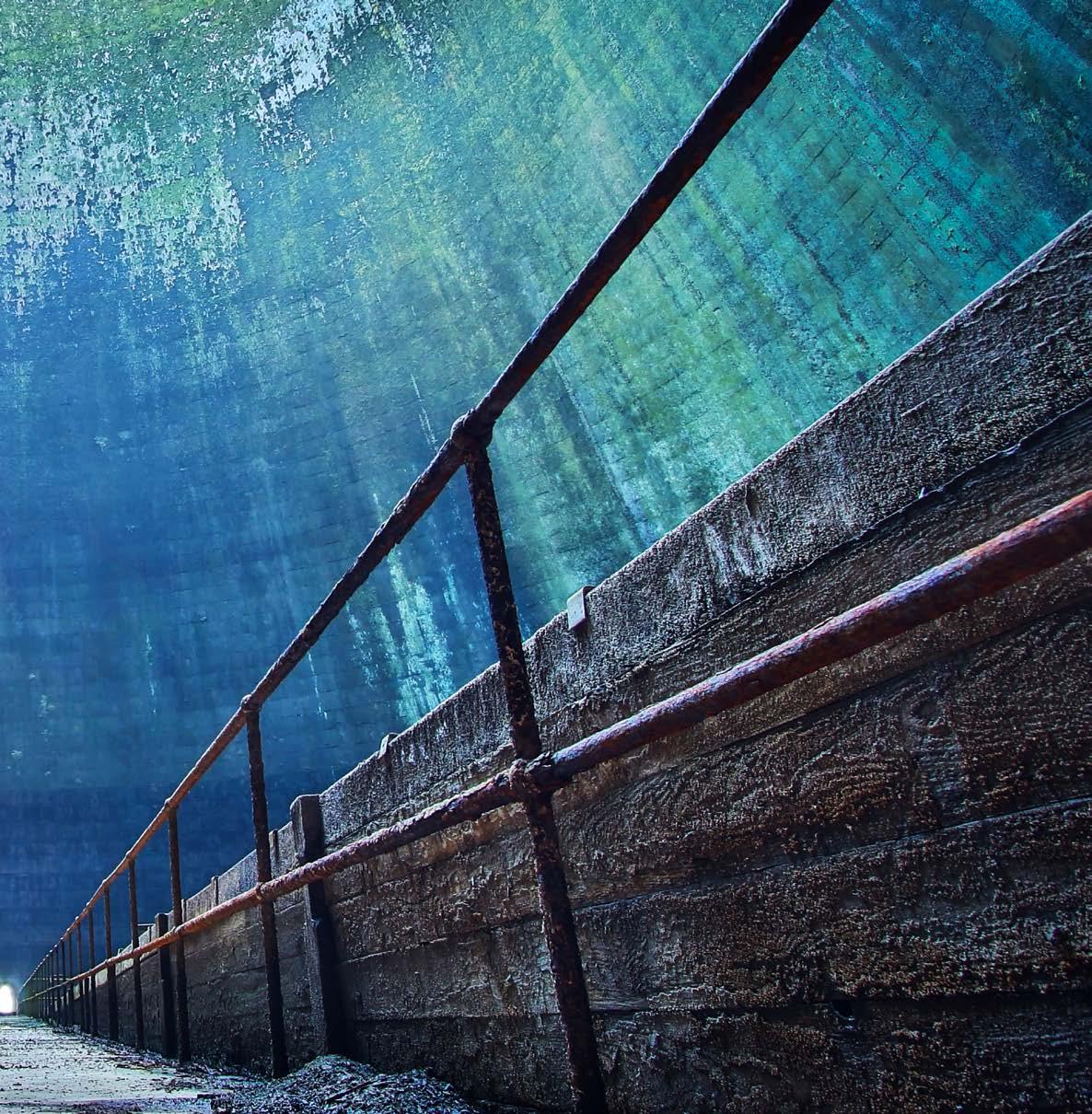

CHIMNEY CORBEL WORK AND INSTALLATION OF THE BOROSILICATE BLOCK WORK TO THE CHIMNEY FLUE INTERNAL SURFACE

FGD PIPEWORK AND ELECTRICAL CABLING SUPPORT STEEL WORK BEING CONSTRUCTED

CHIMNEY CORBEL WORK AND INSTALLATION OF THE BOROSILICATE BLOCK WORK TO THE CHIMNEY FLUE INTERNAL SURFACE

FGD PIPEWORK AND ELECTRICAL CABLING SUPPORT STEEL WORK BEING CONSTRUCTED

In order to comply with gaseous emission requirements stipulated by the EU Large Combustion Plant Directive (LCPD), Cottam was retrofitted with Flue Gas Desulphurisation (FGD) plant at a total cost of £108m, installed in two phases between 2002 and 2007, first to Units 2/3 and subsequently to Units 1/4. The FGD process draws flue gas from the boilers into a series of absorber towers, where it comes into contact with a limestone slurry mixture whereupon up to 93% of the sulphur-dioxide (SO2) is removed before the gas is released to the atmosphere. Also as part of the process the limestone used is converted to Calcium Sulphite, then oxidised by injection of compressed air to form Calcium Sulphate, more commonly known as gypsum.

The introduction of FGD at Cottam witnessed significant additions/modifications to the station including a new unloading/loading house for delivery/export of limestone/ gypsum, new materials storage silos and associated transfer conveyors, a limestone grinding building and waste water treatment plant, together with absorber towers and ducting/fans to the north of the principal generation buildings. FGD installation was by RWE Solutions; with the plant officially opened by Bassetlaw MP Mr. John Mann on 4th October 2007.

GYPSUM SILO COMBINED LOADING / UNLOADING SCREW FEEDER AWAITING INSTALLATION

ABSORBER CONSTRUCTION

LIMESTONE MILL INSTALLATION

In the forefront is the fully operational FGD plant. This plant typically operates at a SO2 removal efficiency of 93%. At its peak it was also producing as a by-product of the FGD

process over 275,000Te of Gypsum, all of which was sold into the construction industry for the manufacture of wall board and plaster products.

OUR PEOPLE AND OUR PLANT

Let’s enjoy what we do best!

On Monday Unit 1 will start us off on our final generating run in the stations 52nd operating year. Having spoken to a number of you I know we share the same views and we are proud to be the ones who take the station to the end.

We estimate around 40 days of unit running will achieve our goal of zero coal stock. As a station we have nothing left to prove, this has been done many times over in recent years and across the station’s history.

Our only job now is to safely get us to the operating finishing line, all I can ask of you is to perform at your best in achieving a finish we all warrant.

Please look out for each other and don’t take risks.

Let’s enjoy what we do best!

Andy

STUART ROBINSON FATHER AND GRANDFATHER OF LEE, HENRY AND FREDDIE OPPOSITE

STUART ROBINSON FATHER AND GRANDFATHER OF LEE, HENRY AND FREDDIE OPPOSITE

HENRY, LEE AND FREDDIE ROBINSON IN THE COAL PLANT CONTROL ROOM

HENRY, LEE AND FREDDIE ROBINSON IN THE COAL PLANT CONTROL ROOM

AN ODE TO COTTAM

It’s not just a job, my family work here too. I celebrate with them, births, marriages, to name but a few, I’ve seen lots of people come and go away. When they retire we beg them to stay. Others get new jobs, we wish them well, They’ll miss us really, their sad smiles tell.

We’ve had a good innings, so we’re told, The station’s 50 and still not cold. Yet Cottam’s cards are on the table

We knew it was coming, it’s OK, we’re stable. When the wind blows, we know we’re surplus, But we’re not the sort of people who like to make a fuss.

When the time comes we’ll all shed a tear For one so magnificent, in the now and here. She’s kept the lights on for so many folk, We checked her and fixed her whenever she broke. So thank you for all you have given, We’ll never forget you had a life worth living.

Katy Jarvis-Morgan KATE CUSICK AND KATY JARVIS-MORGAN

KATE CUSICK AND KATY JARVIS-MORGAN

STEVE CARR AND DOUG SMART

STEVE CARR AND DOUG SMART

STEVE SMITH

STEVE SMITH

ADI BERESFORD, DRAWN BY OUR OWN AMAZING IN HOUSE ARTIST GARY KIRK

ADI BERESFORD, DRAWN BY OUR OWN AMAZING IN HOUSE ARTIST GARY KIRK

JASON DAY, PAUL MORTON, PIERO MAGGIO, SAM BECKETT, LESLEY COX, ANDY POWELL AND TONY COX

JASON DAY, PAUL MORTON, PIERO MAGGIO, SAM BECKETT, LESLEY COX, ANDY POWELL AND TONY COX

CLAIRE MAYFIELD AND RUSS HENDERSON

CLAIRE MAYFIELD AND RUSS HENDERSON

SIMON WOODLEY AND LEE PARKINSON

SIMON WOODLEY AND LEE PARKINSON

SIMONE, ANDY, ADI AND BRIAN

SIMONE, ANDY, ADI AND BRIAN

STEVE FOX AND STEVE DUDLEY

PHIL TALBOT

STEVE FOX AND STEVE DUDLEY

PHIL TALBOT

LEE ANDERSON AND CO

LEE ANDERSON AND CO

C SHIFT PRODUCTION TEAM: RAY LILLEY

C SHIFT PRODUCTION TEAM: RAY LILLEY

MATTHEW BURBRIDGE AND RICHARD DOBSON JULIA AND BEN LINDSAY WITH HERO BEAR

MATTHEW BURBRIDGE AND RICHARD DOBSON JULIA AND BEN LINDSAY WITH HERO BEAR

MATTHEW, TONY EATON FROM HELP FOR HEROES AND RICHARD

MATTHEW, TONY EATON FROM HELP FOR HEROES AND RICHARD

ANDY ARNFIELD PREPARING TO START THE 2017 LONDON MARATHON, WHICH HE RAN IN 4 HOURS, 17 MINUTES AND 21 SECONDS, RAISING MONEY FOR BREAST CANCER NOW

ANDY ARNFIELD PREPARING TO START THE 2017 LONDON MARATHON, WHICH HE RAN IN 4 HOURS, 17 MINUTES AND 21 SECONDS, RAISING MONEY FOR BREAST CANCER NOW

STEVE CHAMBERLAIN, ROBYN PARKER AND BEN LINDSAY AT THE HELP FOR HEROES RECOVERY CENTRE AT CATTERICK

STEVE CHAMBERLAIN, ROBYN PARKER AND BEN LINDSAY AT THE HELP FOR HEROES RECOVERY CENTRE AT CATTERICK

PETE MARLOW, ALAN ANNABLE AND ANDY MIDGLEY

STEVE SANDERS

PETE MARLOW, ALAN ANNABLE AND ANDY MIDGLEY

STEVE SANDERS

DAVE STOCKDALE, JIM TEAR AND PAUL HUFTON

DAVE STOCKDALE, JIM TEAR AND PAUL HUFTON

JOHN DARLINGTON, GRAHAM POULTER AND MARK PETTINGER

JOHN DARLINGTON, GRAHAM POULTER AND MARK PETTINGER

STEVE ‘SANDO’ SANDERSON

STEVE ‘SANDO’ SANDERSON

CARL ANDREW AND DAVID FRETWELL-WALKER

YVONNE BECK, CLAIRE MAYFIELD, KAREN HARTE, SONIA SMITH AND SARAH BAGSHAW

CARL ANDREW AND DAVID FRETWELL-WALKER

YVONNE BECK, CLAIRE MAYFIELD, KAREN HARTE, SONIA SMITH AND SARAH BAGSHAW

JENNY COWAN

LAURA BAXTER

JENNY COWAN

LAURA BAXTER

MATT WYLES, ADI BERESFORD, LYNDA GLEISINGER AND ADI BEMBRIDGE

MATT WYLES, ADI BERESFORD, LYNDA GLEISINGER AND ADI BEMBRIDGE

RACHAEL SERCOMBE

JAMES SEAMAN CENTRE WITH D SHIFT

RACHAEL SERCOMBE

JAMES SEAMAN CENTRE WITH D SHIFT

TREVOR PARSONS

TREVOR PARSONS, STEVE BRIGGS AND TONY BROOMFIELD

TREVOR PARSONS

TREVOR PARSONS, STEVE BRIGGS AND TONY BROOMFIELD

EC&I TEAM - CHRIS REYNOLDS, AARON McBROOM, SAM BENNETT, MATTHEW BURBRIDGE, DAVE SIMMONS, JON SMITH AND TREVOR DAVISON

EC&I TEAM - CHRIS REYNOLDS, AARON McBROOM, SAM BENNETT, MATTHEW BURBRIDGE, DAVE SIMMONS, JON SMITH AND TREVOR DAVISON

BOB WHITE AND JASON PRIEST

NICK DEL-COLLE AND RICKY LEWIS

BOB WHITE AND JASON PRIEST

NICK DEL-COLLE AND RICKY LEWIS

KEITH PALMER

KEITH PALMER

RUSS HENDERSON

DARREN ‘TURBO’ SCOTT

RUSS HENDERSON

DARREN ‘TURBO’ SCOTT

FELICE GALLUCCI, WILL SHEMILT AND SIMON WOODLEY

FELICE GALLUCCI, WILL SHEMILT AND SIMON WOODLEY

DARREN MUSTO, ANDY BENNETT AND LIAM PRIESTLEY

ADI BERESFORD

DARREN MUSTO, ANDY BENNETT AND LIAM PRIESTLEY

ADI BERESFORD

DIAMOND

POWERS JOHN COCKIN AND MARK SHAW

DIAMOND

POWERS JOHN COCKIN AND MARK SHAW

KEITH PALMER

KEITH PALMER

NEIL BRYAN, TURBO AND COLIN MIDDLETON INSIDE A COAL MILL

NEIL BRYAN, TURBO AND COLIN MIDDLETON INSIDE A COAL MILL

STEVE TARREN

STEVE TARREN

PAUL HARRIS KEITH MABBOTT

PAUL HARRIS KEITH MABBOTT

CALLAM ATKINSON AND STEVE DONNER

CALLAM ATKINSON AND STEVE DONNER

Fuel, Ash and Dust Team Manager, Graham Poulter, said: “When the last train arrived on site I found it emotional but I also felt a lot of pride for what we’ve achieved.”

Hargreaves Industrial Services Operations Supervisor, Stuart Robinson, remarked: “I’ve worked at Cottam Power Station for 34 years and it’s been an absolute pleasure. As for the last coal train into Cottam - what a sad day for all concerned.”

GB Railfreight were also present and Train Planning Manager, Peter Smith, said: “It was a landmark moment for both Cottam and GB Railfreight as we’ve all worked closely together over the years. I will miss working with the team at Cottam.”

And finally, Fuel, Ash and Dust Engineer, John Darlington, commented: “It was a sad occasion when the last ever coal train came to Cottam but we made the most of it which reflects the comradery of staff across the site.”

NEIL ATKINSON

NEIL ATKINSON

ADRIAN BREWER, BEX WHITTON AND SARAH ASKEW

ADRIAN BREWER, BEX WHITTON AND SARAH ASKEW

FRANK AND ALMA LEDGER, WITH STEVE HOAD

FRANK AND ALMA LEDGER, WITH STEVE HOAD

23rd SEPTEMBER 2019 FINAL DESYNCHRONISATION

Today, the team at Cottam Power Station desynchronised Unit 1 from the grid at 14:50. The Unit was desynchronised by Neil Davison, Dan Osborn and Martin Jackson, the Shift Manager was James Gregory.

This ends commercial operations at Cottam Power Station, following more than 51 years of safe, reliable generation before closing on 30 September.

This is a moment that is highly poignant for many people at the station and at EDF Energy. Cottam has played a critical role in keeping the lights on in this country for more than half a century. The station has a proud history of generation and a committed workforce. Our people at Cottam, and in Generation and the Corporate Functions supporting the plant, have done an amazing job keeping the station operating this long, and could not have done more.

I visited the station to see the teams earlier this month and was truly touched by the people and their positive reception. Their plant manager Andy Powell could not have done a better job in leading the station during these difficult times.

We should be proud of the plant and its people. I would like to pay tribute to the whole team at Cottam, who have shown pride and dignity in the way they have faced the last day of generation. Now responsibility moves to the Decommissioning Team, which has been formed with people who have worked at Cottam for many years.

DICK OSBORN, STEVE HOAD AND RICHARD YOUNG

DICK OSBORN, STEVE HOAD AND RICHARD YOUNG

KATH BRADLEY AND BARRIE PALFREYMAN

KATH BRADLEY AND BARRIE PALFREYMAN

IAN SNELL, KEVIN BROCKLEBANK, CLIVE MOODY AND ROBERT SPALDING

IAN SNELL, KEVIN BROCKLEBANK, CLIVE MOODY AND ROBERT SPALDING

WILL SHEMILT, MATT WYLES, SIMON WOODLEY, DICK WARD, ROGER CURTIS, JOHN RUNDLE, LEE PARKINSON AND OWYN WALLACE

WILL SHEMILT, MATT WYLES, SIMON WOODLEY, DICK WARD, ROGER CURTIS, JOHN RUNDLE, LEE PARKINSON AND OWYN WALLACE

STEVE WILLERS, GUY LE GEYT AND LESLEY COX

STEVE WILLERS, GUY LE GEYT AND LESLEY COX

STEVE WILLERS AND NIGEL BERESFORD

STEVE WILLERS AND NIGEL BERESFORD

DARREN PICKERING, MALC WILSON AND COLIN BARNES

DARREN PICKERING, MALC WILSON AND COLIN BARNES

ANDY POWELL, TONY BARRY AND BOB PECK

ANDY POWELL, TONY BARRY AND BOB PECK

BOB TAYLOR AND JEFF BRADLEY

BOB TAYLOR AND JEFF BRADLEY

TIM STUBBS AND ROB McCUBBIN

TIM STUBBS AND ROB McCUBBIN

STAN PATTERSON AND KEVIN BROCKLEBANK

STAN PATTERSON AND KEVIN BROCKLEBANK

NIGEL BERESFORD, DICK OSBORN, A SEATED COLIN MORTON AND PAUL MORTON

NIGEL BERESFORD, DICK OSBORN, A SEATED COLIN MORTON AND PAUL MORTON

UNIT 1

First Synchronisation to the National Grid on 9th June 1968 at 17:57hrs

Total Generation: 117,097 GWh

Total Running Hours: 268,921

Total Starts: 3,707

Final Desynchronisation from the National Grid on 23rd September 2019 at 14:50hrs

The Unit Operator was Neil Davison

The Inside Assistant was Dan Osborn

The Control Room Engineer was Martin Jackson

The Shift Manager was James Gregory

UNIT 2

First Synchronisation to the National Grid on 21st June 1969 at 20:00hrs

Total Generation: 125,212 GWh

Total Running Hours: 285,110

Total Starts: 3,209

Final Desynchronisation from the National Grid on 11th September 2019 at 15:47hrs

The Unit Operator was Dave Ayris

The Inside Assistant was Dan Osborn

The Control Room Engineer was Will Gregory

The Shift Manager was James Gregory

UNIT 3

First Synchronisation to the National Grid on 26th October 1969 at 18:39hrs

Total Generation: 129,757 GWh

Total Running Hours: 287,451

Total Starts: 3,003

Final Desynchronisation from the National Grid on 2nd September 2019 at 22:45hrs

The Unit Operator was Dave Ayris

The Inside Assistant was Martin Sills

The Control Room Engineer was Mark Stephens

The Shift Manager was James Gregory

UNIT 4

First Synchronisation to the National Grid on 6th April 1970 at 17:45hrs

Total Generation: 112,694 GWh

Total Running Hours: 257,762

Total Starts: 3,278

Final Desynchronisation from the National Grid on 11th April 2019 at 21:07hrs

The Unit Operator was Tom Shaw

The Inside Assistant was Ian Clements

The Control Room Engineer was Iain Birrell

The Shift Manager was Martin Jackson

ACKNOWLEDGEMENTS

The amazing photography of Adi Beresford

Thanks also go to Steve Willers, Rob McCubbin, Paul Collins, Richard Dobson, Simon Skelton, Simon Wass, Robert Spalding, Graham Woolsey, Laura Baxter, Kate Cusick, Katy Jarvis-Morgan, Trevor Davison, Brian Matthews, Tom Rowland and Dave Beardshaw for their contributions towards this book.

Vanessa Northam, for producing ‘The Queen of the Trent – Celebrating 40 Years of Electricity Production at Cottam’, extracts from which feature in this book.

Ric Tyler for the research and production of the ‘Cottam Power Station Historic Building Record 2018’.

Finally, we would like to thank everyone, past and present, for their dedication and commitment during their time at Cottam. We are all immensely proud to be part of the Electricity Supply Industry and especially to be part of the Cottam Team. The success of this site is through the people who work within its gates regardless of position or company overalls.

The success of this site is through the people who work within its gates regardless of position or company overalls.

EPILOGUE

Firstly I would like to thank Andy Powell for allowing me to bring this book together, which has been a great privilege and something I have thoroughly enjoyed doing.

However, none of this would have been possible without the fantastic photographic work done by Adi Beresford. This year especially, with Adi’s assistance we have been keen to photograph all our people, special events and the plant, which still looks amazing after 51 years of outstanding operation and public service.

I would also like to give special thanks to Scintilla Design, who have advised, designed and produced this book for us. They have been absolute professionals and it’s been great working with them on this project.

Thanks also need to go to Ric Tyler, who we commissioned last year to produce the Cottam Power Station Historic Building Record, some of the material from which is included in this book. Other thanks go out to Paul Collins, for his invaluable proof reading skills, Simon Wass for the selection of technical drawings and FGD construction photos, Kate Cusick for archive photos and text, Katy Jarvis-Morgan for her “Ode to Cottam”, Brain Matthews for his photo mosaic and Laura Baxter for her kind assistance with the text, photographic reproduction and getting things done!

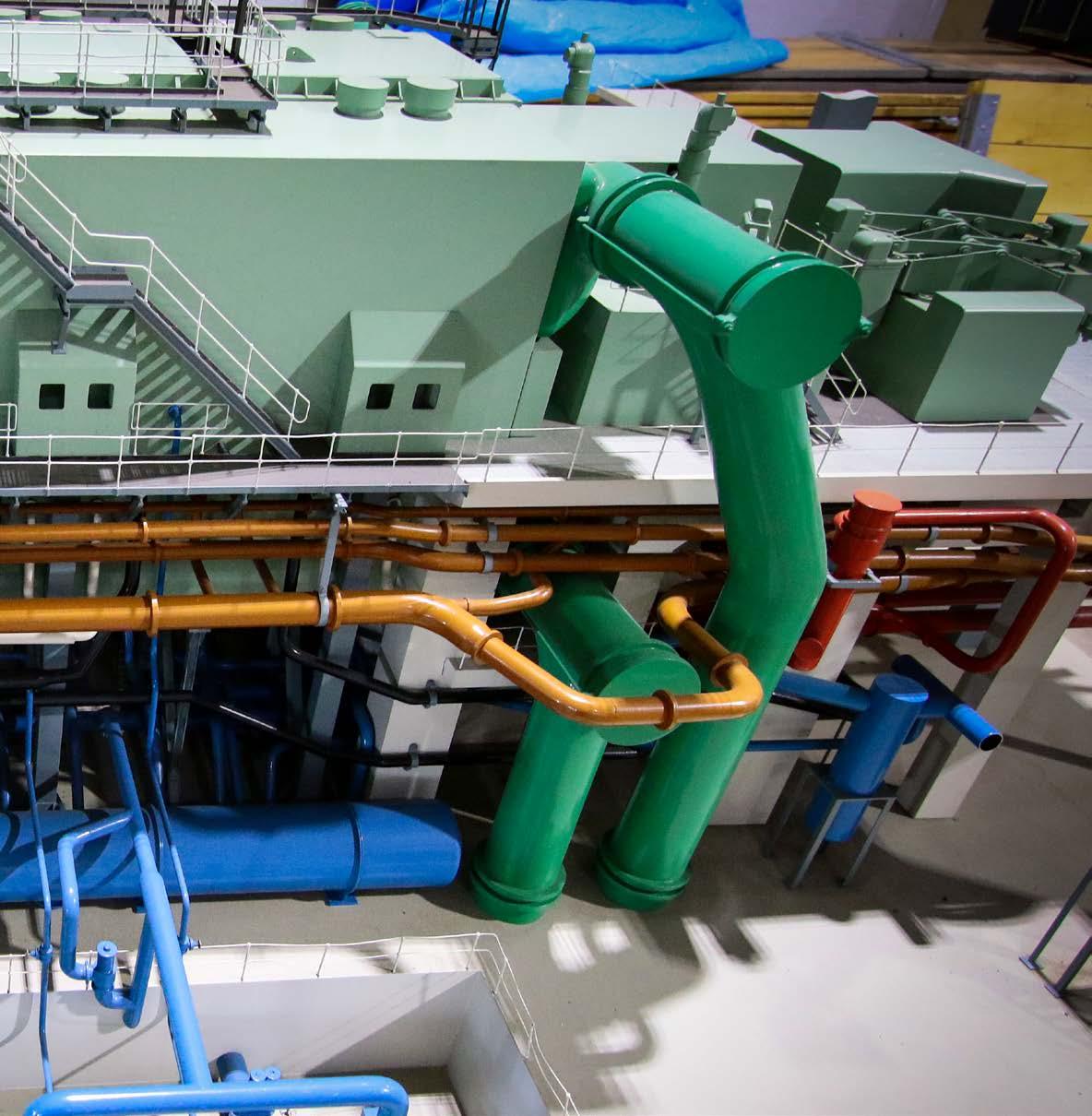

Earlier this year we contacted the Science Museum with the desire to get some part of Cottam into the museum collection. What we didn’t expect, following on from their site visit, was the request to take one of the unit control desks, back panels and overhead canopy and alarms. This far exceeded our expectations and we are extremely grateful to Ben Russell, the Science Museum’s Engineering Curator for making this happen. We have selected Unit 3 for this, which we plan to carefully dismantle early next year and transport to the Science Museum’s facility at Wroughton. While it may be sometime before it gets publicly displayed, Ben has assured us that once it’s in the national collection, it’s there forever. One other surprise from Ben was the fact that the museum has had a fantastic model of Cottam Unit 2 in its collection since 1968. It’s been stored in a crate all this time and again we were lucky enough

to see it earlier this year at Wroughton. It’s still in pristine condition and pictures of it are included in this book.

Finally it was an honour to meet Frank Ledger CBE and his wife Alma. Frank was Cottam’s first Power Station Manager, who later became a senior member of the CEGB Executive Team through to privatisation in 1990.

I do hope you enjoy this book and it provides great memories for you of Cottam Power Station, a great plant, a fantastic place to work, full of amazing people!

Steve Hoad D&D Operations Manager

Steve Hoad D&D Operations Manager

PHOTOGRAPHY

My boss said I have 2 days’ welding for you over at Cottam Power Station; 23 years later I’m still here!

I’ve worked on almost every part of the station, from the coal plant to turbine to kitchen sink. I would never have thought I would be helping document on camera the fantastic people past and present, together with Cottam’s final days on the bars. A privilege it’s been.

Adrian Beresford HCM Mechanical Supervisor

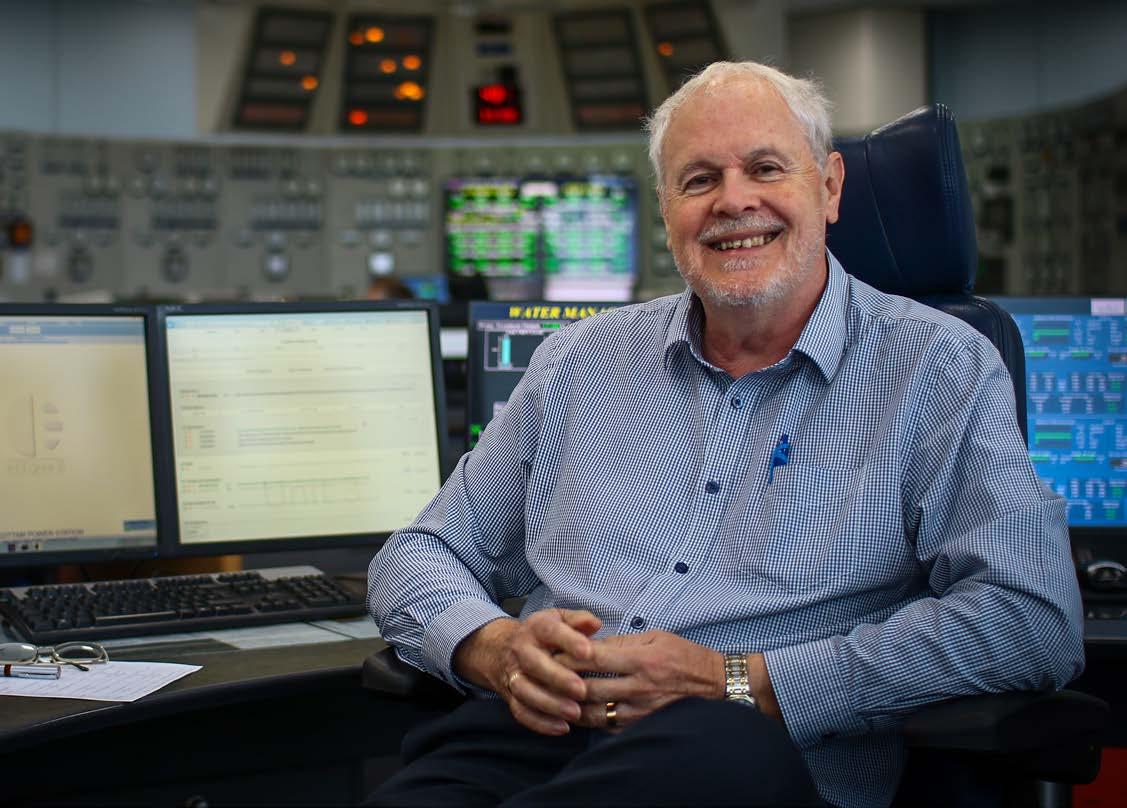

FIRST AND LAST

Separated by five decades, but both with the same business principles: provide an outstanding public service, maintain a safe and reliable plant, but first and foremost realising that this has only been made possible by all our staff past and present.

What an amazing job everyone has done.

Andrew Powell Plant Manager 2018 – to present day

Frank Ledger CBE FREng Station Superintendent 1965 – 1967

Andrew Powell Plant Manager 2018 – to present day

Frank Ledger CBE FREng Station Superintendent 1965 – 1967

The final celebration of our people and Cottam’s achievements. A fun-fuelled evening, with the amazing night time vista of the station looking over everyone.