The CMS Smartline and Proline Waterjets offers customers off all levels an accurate, cost effective waterjet cutting system. Smartline is designed to redefine industry standards of excellence by improving operating efficiency, while maintaining CMS’ renowned reputation for unparalleled construction and working quality. It includes all the safety and performance features typical of CMS Waterjet machines, in a brand new, innovative, and compact design. The Proline is packed with a multitude of features for increased accuracy and performance. Waterhets are the preferred method for cutting materials that are sensitive to high temperatures generated by other methods such as laser and plasma systems. The advantage of the Italian CMS Waterjet is that they manufacture the complete package from the machine structure, pump, controls and software.

Cost efficient and economical cutting

01

Open frame for quick loading and unloading of material.

03

02

0.035 mm of positioning accuracy and +/- 0.025 mm of repeatability over the entire area to ensure unrivalled quality and cutting accuracy.

An integrated electric cabinet in the tank frame gives the machine a reduced footprint.

04 05

Cut through anything with powerful waterjet profiling technology.

Optional additions to suit your requirements and budget.

Easyjet is a complete CAD/CAM suite for all-round management of every aspect of the 3 and 5-axis waterjet machining, that eliminates the purchasing costs, maintenance and training of further third-party software products.

Aluminium cast uprights with an electro welded steel bridge, designed with reinforcement ribs erases the vibrations during cutting and guarantees consistent, high performance.

Customise the gantry unit with multiple 3 axis cutting heads on a spreader bar, with manual distance adjustments to increase the productivity on flat panels for regular or consistent shape cutting.

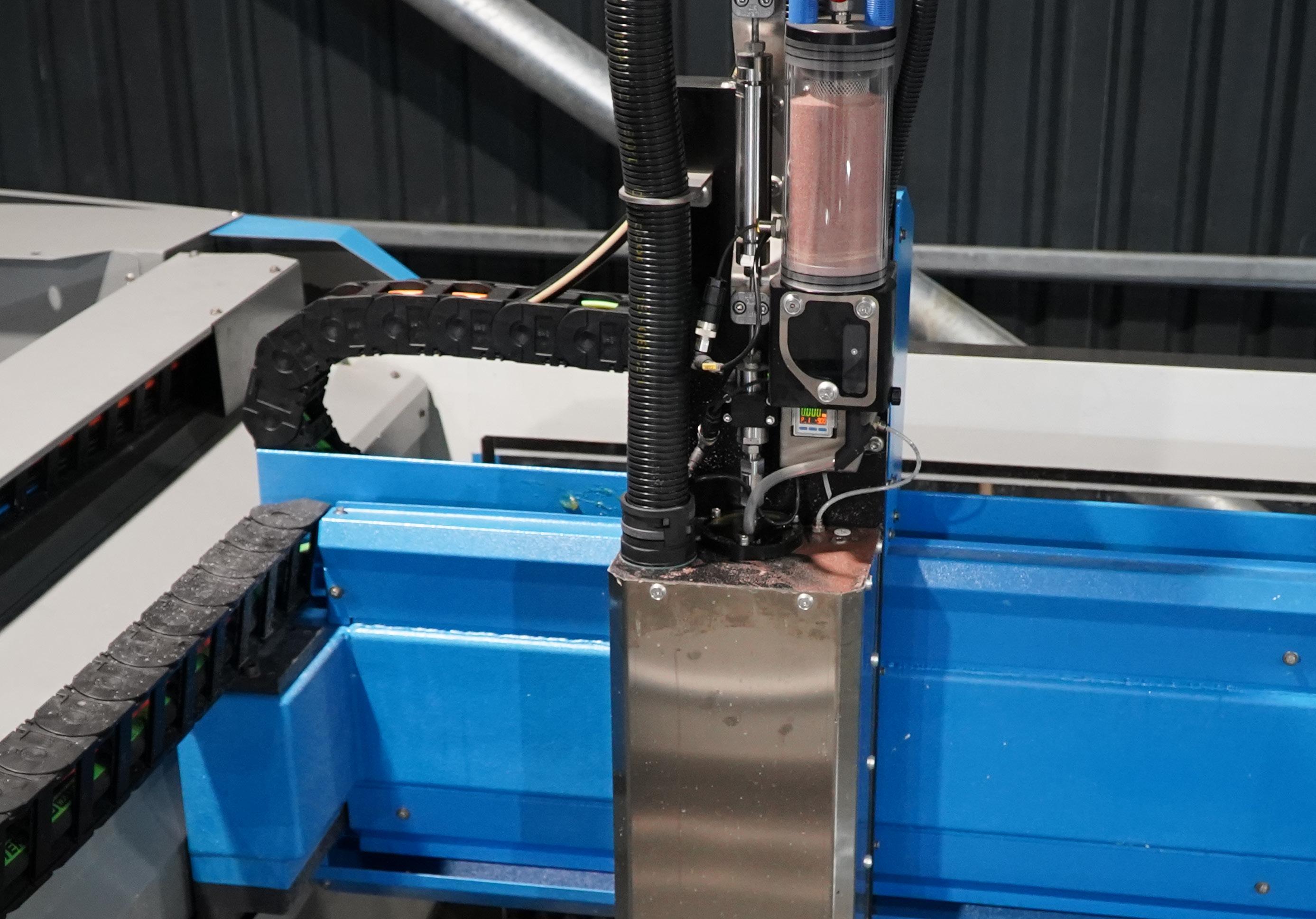

The bellows for X-axis and the labyrinth panels on the Y-axis protect the linear guides and racks from water, dust and abrasive materials.

Automatic lubrication of all axes for reduced maintenance processes and procedures.

PROBE DETECTION SYSTEM

A probe system, continuous or periodic, available also with a large ring for foam or glass cutting. It enables the machine to maintain the same distance from the material being cut at all times even if the material is not perfectly flat.

Our Flagship Waterjet Cutting Machine.

PRODUCTIVE

Up to 2 electric actuators of 4150 bar or 6200 bar to ensure maximum productivity and cutting versatility of waterjet technology on hard or thick materials.

ACCURACY

0.035 mm of positioning accuracy and +/- 0.025 mm of repeatability over the entire area to ensure unrivalled quality and cutting accuracy.

MODULAR

The integrated electric cabinet in the tank frame reducing the footprint of the machine.

04

VERSATILITY

New sizes and a wide range of accessories and standard arrangements for faster and less expensive retrofits.

05

03 02

INTEGRATED

The Proline features a built-in Intensifier Chamber, reducing the overall footprint of the machine.

CUT THROUGH ANYTHING

A waterjet can cut through virtually any material, metal, plastic, nylon, acrylic, glass or stone.

“If you can’t cut it with a Waterjet, you can’t cut it at all!”

PRV Engineering take control of their prototyping with a Waterjet

PRV Engineering Ltd is based in Pontypool, South Wales. They manufacture a range of products for a multitude of industries. Offering an array of services including general and precision engineering, the production of machined components and turned parts, wet spray painting, powder coating, steel fabrication, installation and maintenance, structural and architectural steelwork, and more.

“It has allowed us to service those industries that we couldn’t access before. It has very much met our expectations. It has allowed us to do what we could not do before, without subcontracting out. It has allowed us to take control of prototyping. It does the job quickly, and allows us to cut all sorts of things that we couldn’t previously do.’’

Simon Jones CEO & MDRead or watch the full Case Study here.

The optional JD5ax features open up new cutting opportunities on a wide range of materials, maximizing the operational flexibility on the 5-axis waterjet CMS systems and ensuring very high standards of accuracy and quality of pieces obtained by an abrasive water jet.

INFINITE ROTATING AXIS

The innovative JD5ax head reduces taper while cutting at higher speed, without affecting the finished parts.

JD5ax is made up of a infinite rotary axis (C), an entirely new feature, and a tilting axis B) up to +/-60°, all designed and produced by CMS engineers.

FUTURE READY

Easyjet is a complete CAD/CAM suite for allround management of every aspect of the 3 and 5-axis waterjet machining, that eliminates the purchasing costs, maintenance and training of further third-party software products.

An integrated, automatic dredging system for a “no maintenance” abrasive removal process drastically reduces the amount of maintenance required to keep a waterjet operational.

The integrated Probe System ensures a consistent cutting height for all materials, even if the material is uneven.

DREDGING SYSTEM PROBE SYSTEM

The heavy-duty gantry is stabilised with no compromises on quality and durability of the machine.

25+ UK Wide Service Engineers

AIR

Ideal for cleaning cut parts and the cutting bed at the end of the material cutting cycle.

INTEGRATED PIPE CUTTING

The optional Pipe Axis Spindle further increases the Proline’s functionality, perfect for profiling tubes or sections.

The powder free labyrinth panels keep the linear guides and racks clear from water, dust and abrasives, reducing maintenance and downtime.

The tethered hand control allows for quick adjustments on the fly in the middle of a cutting cycle.

This optional innovative system featuring a camera built into the Z axis, allowing the work area to be framed and acquire one or more origins on the material due to be cut.

HMI CMC

The 21.5’’ Touch Screen display offers the operator a simple and intuitive interface that allows all system functions to be controlled.

OPTIONAL CUTTING CAMERA

PRESSURISED ABRASIVE FEEDING SYSTEM

The Proline features twin 330 kgs tanks for abrasive material. Allowing the machine to be refilled during operation.

Front and rear doors with pneumatic movement to protect the cutting area and reduce the water and abrasive back-splashes.

AUTOMATIC SAFETY DOORS

LASER FOCUSED

Optional Lasers can be added for absolute positioning and alignment purposes.

INTENSIFIER CHAMBER

The Proline features a built-in, removable intensifier chamber within the body of the machine. This reduces the foot-print of the overall machine and ensures easy-access for maintenance.

Automatic laser detection system of the cutting head alignment with respect to the rotaton center of the C Axis & B Axis.

Forced injection CNC controlled automatic lubrication of the main axes X, Y and Z, numerically controlled at pre-set intervals.

Abrasive garnet feeding device with adjustable flow in a range of 100 - 1400 g/min. The presence of a digital vacuum sensor allows the monitoring of the conditions of the cutting head (opening, focusing device, mixing chambers) and detect any clogging or blockages of the abrasive garnet.

£500,000+ of UK based Spares

The Proline catch tank is produced in stainless-steel with a V structure that can support a maximum load of 1000 kg/m2(version with load up to 1800 kg/m2 available on request). Over time, the stainless-steel walls guarantee maximum resistance to corrosion, that prevents the structure from weakening.

LOWER MAINTENANCE COSTS

CONSTANT OUTLET PRESSURE FOR BETTER CUT QUALITY

REDUNDANT ARCHITECTURE TO AVOID MACHINE DOWNTIME

HIGH EFFICIENCY: GREEN EFFICIENCY

REDUCED ENVIRONMENTAL

IMPACT: GREEN ENVIRONMENT

REDUCTION OF MAINTENANCE COSTS: GREEN MAINTENANCE

REDUCTION OF CONSUMPTION AND OPERATING COSTS

CMS has created a new concept of very high pressure intensifiers, enriched with technological contents, to meet the needs of the most demanding users. The original technological concept foresees that the intensifiers are equipped with several pressure multipliers: independent, parallel and electronically synchronized. This innovative solution makes it possible to obtain an always constant pressure, avoiding the drops typical of traditional opposing cylinder intensifiers.

VERY SILENT OPERATION

LOWER ELECTRICITY CONSUMPTION: GREEN ENERGY

Two/three parallel, independent and electronically synchronized intensifiers, which enables an always constant pressure.

REDUCED MAINTENANCE THANKS

TO THE USE OF 80% FEWER STRUCTURAL COMPONENTS

BUILT-IN AUTOCLAVE

CAN BE INSTALLED ON ANY WATER JET MACHINE

HIGH LEVEL OF EFFICIENCY: UP TO 60%

MORE THAN TRADITIONAL INTENSIFIERS

Tecnocut greenjet evo is a ground breaking, highly efficient, electric pump. A top-performance torque servomotor supplies a very highpressure level while removing the hydraulic unit and up to 80% of components compared to a traditional hydraulic intensifier.

CMS brought about a new concept in ultra-high pressure intensifiers, enhanced by technological solutions designed to satisfy the needs of most demanding users. This new technology is based on an intensifier equipped with several pressure multipliers independent, parallel and electronically synchronized. This innovative solution results in an ever-constant pressure avoiding any drops typical of traditional oppose-cylinder intensifiers.

If the CMS waterjet cutter is the beast that will get the job done, then its beating heart is surely the waterjet pump and that is what we are going to look at a little more closely; each of the options in the CMS range has its benefits, so getting it right is a very big deal… How do you choose which one is best for you?

Incoming power supply is the first and most vital factor to consider, as increased ampage is needed for greater pump horsepowers. Thickness of your materials is another common question we come across, but generally; whatever fits between the cutting base and the machine head is fair game to be cut, as you increase in motor size of course, then the quicker that cutting process will be. Therefore if you know your incoming power supply, you can select the right pump for the cutting time that you and your production require.

Read the full blog here.

*See overleaf for some indicative floorplans

Other model’s floor plan’s available on request.

Scan this QR Code to see the CMS Proline waterjet cutting machine in action on our YouTube Channel

For more information, pricing, and availability, please contact the sales team at Selmach Machinery:

E: sales@selmach.com

T: 01432 346 579

W: www.selmach.com

“With today’s ever evolving technology and the automation of so many manufacturing processes, we strive to constantly improve and develop machines that will exceed your needs and stand the test of time”