APRIL - JUNE 2019

PROFINISHER G E N E R A L I N D U S T R I A L C O AT I N G S

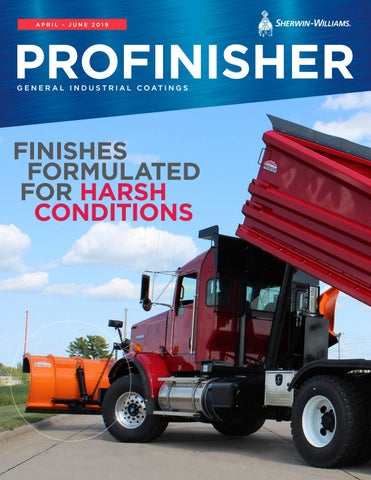

FINISHES FORMULATED FOR HARSH CONDITIONS

WELCOME

PROFINISHER April - June 2019

IN THIS ISSUE

Finishes Formulated for Harsh Conditions

COLOR SURROUNDS US

Almost every purchasing decision we make is influenced by color – from buying a new shirt to buying a new car. In fact, studies show that 90% of the reason we buy a product is based on our subconscious visual assessment of color, material, and surface finish (CMF) and that color impacts our comprehension, communication, and understanding by 73%.

We Have Your Booth Covered

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Comes to Life: DesignHouse Opens its Doors .

. . . . . . . . . .

3

4-5 6-7

From these statistics we would assume that color will basically sell itself – but what if the economy shifts, technology advances, the environment evolves, manufacturing accelerates, or customer preferences change? Sherwin-Williams has built a team to consider all of these variables and to also identify and deliver the right color, at the right time, at the right price – giving you the competitive advantage. The recently completed Sherwin-Williams DesignHouse in Minneapolis, is the place where inspiration lives and color comes alive. At DesignHouse, our experts are collaborating with our global product design and manufacturing customers to forecast the next color trends and develop the latest in custom color, performance, aesthetic, and application. We create color selection tools to simplify your specification process, providing color confidence. The possibilities for color exploration are endless with our goal to establish custom finishes that give products their appeal and purchasing power at market.

KIKI REDHEAD, CMG

Color is our passion – exploring the “what if?” is our obsession.

Color & Trend Lead Performance Coatings Group General Industrial Division

The talented Sherwin-Williams DesignHouse team is your resource.

EQUIPMENT & SUPPLIES

We provide more than coatings. Our complete product finishing solution includes over 10,000 brand-name equipment and supplies to address the entire process, from sanding to shipping. Our dedicated experts also work with a diverse group of suppliers and manufacturers to serve all of your finishing needs, including providing on-site support to help you enhance your line. Contact your General Industrial Coatings Sales Representative or visit oem.sherwin-williams.com/ equipmentandsupplies to learn more.

for a Better Finish

2 | SHERWIN-WILLIAMS PROFINISHER

We welcome you to DesignHouse for CMF design and development. It’s time to embrace your colorful, competitive advantage.

EQUIPMENT & SUPPLIES FOR A BETTER FINISH

The Sherwin-Williams Equipment and Supplies program includes over 10,000 brand-name tools at guaranteed competitive pricing. For more information and to request a quote, contact your General Industrial Coatings Sales Representative.

WE HAVE YOUR BOOTH COVERED

BoothBox Mini Magnet

Hose & GunHanger - Magnet

BoothBox 2 - Magnet

Box Hanger

SW131-9003

SW145-6953

SW148-4807

SW1003-04468

Exhaust Filters (22-gram fiberglass)

Cube Exhaust Filter

Size 20” x 20” (50/CS)

SW No. SW6511-02147

Size 41” x 300’

SW No. SW6511-02170

20” x 25” (50/CS)

SW6511-02154

48” x 300’

SW927-8946

30” x 300’

SW572-1113

84” x 300’

SW6511-0225

36” x 300’

SW927-8920

Size 20” x 20” x 15” 2-pk (8/CS)

SW No. SW6511-02261

Exhaust Filters

(15-gram fiberglass) Size SW No. 20” x 20” (50/CS) SW6511-02675 20” x 25” (50/CS)

SW6511-02683

48” x 300’

SW111-0139

84” x 300’

SW6511-02246

Mixing Cups Bottle with Brush Size 2 oz / 50-pk

SW No. SW6509-77655

Size 2 oz / 500-pk

SW No. SW882-1290

Size 80 oz / 50-pk

SW No. SW6504-23528

8 oz / 100-pk

SW6504-23510

135 oz / 50-pk

SW6504-23460

16 oz / 100-pk

SW6504-23551

150 oz / 50-pk

32 oz / 100-pk

SW6504-23452

3.5 gal / 12-pk

PROFINISHER TIP Remain Attentive to Settings

Paint Sock

SW6509-78778

Size Premium / 20-pk

SW No. SW6510-12973

SW6504-23478

Standard / 24-pk

SW6509-47542

Settings are a hugely overlooked part of the application process. Minor adjustments in fluid and air pressures can drastically change the outcome of a finished product, especially with low gloss or metallic coatings — Greg Sherwood, Technical Service Representative

oem.sherwin-williams.com/equipmentandsupplies | 3

FINISHES FORMULATED FOR HARSH CONDITIONS

Offering a complete line of snow removal equipment augmented with dependable customization options, Henderson Products provides customers with the competitive edge COMPETITIVE SOLUTIONS What began as a company manufacturing agricultural products in 1946, has since evolved into a leading supplier of work truck equipment for municipal ice and snow control. Henderson Products, based in Manchester, IA, manufactures and installs products that give customers the performance they need, coated with finishes to ensure their durability. Henderson Products and Sherwin-Williams began a working relationship back in 2010, with initial business on their powder coat line. The equipment manufacturer is now in the process of transitioning to SherwinWilliams as their preferred liquid coatings supplier as well. 4 | SHERWIN-WILLIAMS PROFINISHER

“The biggest reason we partnered with Sherwin-Williams was that we gained better coverage and hide with a lower film usage,” said Jason Trenkamp, Business Unit Manager – Paint at Henderson Products. Henderson went from requiring 4-5 mils from their previous paint to 2.4 mils with Polane® SP Primer and Polane® 8890 Polyurethane. The company is now able to finish with a single wet coat application instead of the two coats they were applying with their previous paint and primer. “This has saved us on paint usage, spray booth filters, PPE, and time,” said Trenkamp.

DELIVERING DURABILITY Henderson strives to bring a competitive edge to the work truck equipment market by carrying a full product line, where most of their competitors do not. The manufacturer develops an array of snow and ice control equipment from dump bodies and snow plows, to sand and salt spreaders, as well as brine production systems. One of the company’s most popular products is their MARK™ E dump truck body, which is used year round for hauling rock, gravel, and sand, and is also used to feed tailgate spreaders to distribute salt and sand on the roads during the winter. Henderson’s equipment, such as these truck bodies, are exposed to

extensive amounts of salt, extreme weather exposure, and rigorous wear and tear from continuous use. The high-performance coatings supplied by Sherwin-Williams enhance the durability of the snow and ice equipment – providing resistance to corrosion, abrasion, and color fade. In addition, Henderson’s newest product offering is ProHitch™, a first-of-its-kind adjustable hitch that brings innovation to the snow removal equipment industry by providing optimal control for multiple styles of snow plows. The ProHitch is coated with Sherwin-Williams Powdura® Super Durable powder coating to provide superior wear and corrosion prevention. Using this powder technology, the ProHitch is built to last. “We’re pushing for the best customer service in the industry, and part of that is having products that stand up to harsh conditions,” said Mark Jackson, marketing representative at Henderson Products.

“I can’t say enough about the tech support we have received from both the service rep, Tim Stage, their operations manager, Colin Nolan, and their sales rep, Bob Frary.” – Jason Trenkamp, Business Unit Manager – Paint at Henderson Products

CUSTOMIZED SERVICE While snow and ice literally create a demand for Henderson’s business, the company’s main objective is to exceed customer needs by manufacturing state-ofthe-art products. Each region throughout North America experiences different weather and environmental elements. Henderson factors in these conditions to offer a wide range of products with customizable options – providing the features, functions, and performance customers desire for their specific location. Customers can begin tailoring their equipment needs by specifying product options, such as tailgate styles or head sheet configurations for truck bodies. However, customized solutions also come in the form of coatings based on desired color options or turnaround times. The SherwinWilliams Genesis® G2 series offers a full vibrant automotive color palette, ready for customers to receive the same day and in smaller quantities, such as one gallon. For more precise color matching and additional performance characteristics, Polane® 8890 is also used to provide a highperformance finish.

Sherwin-Williams coatings additionally provide color harmony with batch-to-batch consistency across Henderson’s offerings. “This means we initiated one color standard for all three applications – powder, liquid, and touchups,” said Timothy Stage, a Technical Services Representative at Sherwin-Williams. Henderson has nearly limitless options for their customers to choose from, and teaming up with Sherwin-Williams further enhances these personalized offerings. “Everybody wants something different,” said Jackson. “And we can deliver on that.”

COLOR COMES TO LIFE

DesignHouse Opens its Doors for Color Collaboration

A first-of-its-kind facility for the industrial market, Sherwin-Williams DesignHouse – located in Minneapolis, MN – is a unique space where designers and customers can collaborate, discover inspiration, and receive assistance with increasing speed to market for new colors and products. WHERE INSPIRATION LIVES DesignHouse, inspired by expanding color needs in industrial coatings, is a design ecosystem where experts help to reduce the time it takes to create new colors, harmonize colors developed for different substrates and technologies, and provide a global network to deliver finishes on time, every time.

6 | SHERWIN-WILLIAMS PROFINISHER

“We created DesignHouse to have a home for all of the color and finish work that needs to happen with our customers,” said Ashley Cribb, Sherwin-Williams General Industrial Market Segment Director. “It’s a place that should inspire customers, while also demonstrating our credibility as color leaders.”

Under the leadership of industry color expert, Kiki Redhead CMG, DesignHouse offers guests everything from trend information to color design, development, and application assistance. “Talking about color and design is a unique language – and we wanted someone that was fluent in design,” Cribb said of bringing Redhead on board. “Kiki’s background

is ideal – she understands the trends that impact our customers and she has the expertise to work with our labs on formulations. It’s a great combination for our customers.”

WHERE COLOR COMES ALIVE At DesignHouse, CMF specialists empower you to bring color and finish to life for your customers, while exploring endless possibilities by asking ‘what if’ questions: “What if paint could look like marble? What if powder could have texture?” “It is a highly creative space – you feel it from the moment you walk in,” Redhead remarked. “But it’s also a space where we can be really productive.” Dedicated to collaboration and driven by curiosity, the DesignHouse team is comprised of color authorities who bring expertise on how to produce finishes that customers desire. “We believe that color, material, and finish (CMF) play a vital role in the aesthetic appearance of a product, in conjunction with performance and durability,” Redhead stated. “Our lab team is the heart of what makes DesignHouse possible,” Cribb commented. Redhead added, “the collaboration and opportunities we have with current and

“It’s a place that should inspire customers, while also demonstrating our credibility as color leaders.” – Ashley Cribb, Sherwin-Williams General Industrial Market Segment Director

future customers here is exciting and having the lab working directly with us brings tremendous value.”

EMBRACE YOUR COMPETITIVE ADVANTAGE Having an impactful DesignHouse experience is simple - with four workshops from which to choose. Discuss industrial color and finishing trends in half- or full-day sessions. A three-day workshop is available, where participants develop matches for one to three pre-selected colors. The full workshop is a week long and attendees develop iterations for three to eight colors selected before attending. The space will also host a variety of other industry activities and events throughout the year. “We are lucky to have access to the best color experts, chemists, and technologists in the world – and I’m so happy that we now have a space where we can showcase their skills in a new way,” Cribb concluded. “DesignHouse is getting customers excited

to work on color with us, and that’s the highest compliment we could receive.” “This is truly the place where you can come and get any part of the product development process that you need from us,” Redhead added. “We offer inspiration, trend information, new technologies, and ways to cut costs. There is no other design center in industrial coatings that can offer the full package like DesignHouse.” To learn more about DesignHouse or to schedule a visit, contact your local SherwinWilliams General Industrial Representative.

SAVE BIG

WITH WAGNER

2K SYSTEMS Reduce wasted time, money and material with 2K precision www.wagnersystemsinc.com

2K Smart

• Simple and intuitive operation • 2 and 3 component processing capabilities • Patented dosing system for ultimate mixing accuracy • Single and multi-color selection with recipe control • Fast ROI through increased production • 1:1 to 50:1 mix ratio capability

TwinControl

• Set up in minutes • Stroke sensor technology eliminates troublesome flow meters • Pre-assembled with A, B, and flush pumps • Low and high pressure versions • Gun flush box and electrostatic connections available • 1:1 to 20:1 mix ratio capability

Control Your Coatings Layer Check your material to reduce scrap and optimize coating quality with non-destructive measurements