Empowering People

Issue 12 Winter 2022

Haffmans QC Equipment In-line, At-line, Laboratory, Packaging & Monitoring • Reliable & comparable measuring results • Reduced product loss & faster reaction time • Consistent product quality • Increased process efficiency • Accurate measurement of: air, CO2, O2, N2, TPO, foam and turbidity FOODANDBEVERAGE.PENTAIR.COM Phone: +44 (0) 1905 797 280 Email: Sales.uk@pentair.com Understanding Quality. FOR LIFE.

It’s been another yo-yo of a year – politically, financially and climatically – and as we look ahead to 2023 we can but hope for more stability just over the horizon.

Whether we have yet achieved the ‘new normal’, that was much lauded this time last year as we shook off the last of the Covid restrictions, remains up for debate. But what does it all mean for independent brewers?

Business planning, at least for more than a few weeks at a time in the current climate, remains extremely difficult.

But speaking to SIBA Members recently, it always strikes me how calm you all are in the face of the myriad of challenges being thrown at you. With the alcohol duty freeze cancelled and the new draught duty rate delayed, two potential lifelines have been whipped away in the short term, and while we await more detail of Prime Minister Rishi Sunak’s plans for next

Welcome to the Winter edition of SIBA’s Independent Brewer Magazine

year, we can only hope for some more positive news for small brewers across the country.

At times like these, SIBA’s lobbying work becomes more important than ever. The recent addition of a new Public Affairs and Policy Officer, Will Lockwood (find out more about him in our Meet the Team section on page 15) to the SIBA team could not have come at a better time, and the whole team is concentrated on communicating Members’ concerns and needs to Government and the various everchanging figures within it. This can and does make a real difference. The recent campaign SIBA ran to ‘Make it 20’ helped win a change of policy that means 20 litre containers will now be included in the draught duty rate – a big victory for smaller brewers.

SIBA’s other key focus during this turbulence is to bring brewers together, not only to share updates on the ever-changing political situation, but to share with each other their experiences, ideas and successes – we should never stop learning from our community. To this end I would urge you to make attending your regional SIBA meetings a priority for 2023 – you will find all the dates on the Members’ Toolbox online – as these are invaluable forums where Members help to set the agenda for SIBA HQ. Back to this issue of the magazine, and again, this publication helps in the sharing of Members’ views and experiences so please do get in touch with me directly (contact details below) if there is something you’d like us to feature or if you have news or views you’d like to share.

On our Sustainability Focus on pages 42-47 you will find Eddie Gadd from Gadd’s Ramsgate Brewery sharing his knowledge both as a brewer and an engineer which has led to him

Society of Independent Brewers

PO Box 136, Ripon, North Yorkshire HG4 5WW

Tel: 01765 640 441

www.siba.co.uk

Email: office@siba.co.uk

installing the very first CO2 recovery system designed specifically for small brewers. The system harvests the CO2 produced in the fermentation process, liquifies it for bottling, and enables the brewery either to self-supply or sell it on to other drinks businesses. At a time when CO2 is costly and also subject to supply issues this could be a game-changer for our Members.

Elsewhere, we meet Niall Kennedy, the owner of Wee Beer Shop in Glasgow for our Meet the Retailer feature (see pages 48-53), a small retailer that is also fighting against some serious challenges.

Our Business Profile is Attic Brewery in Birmingham (see pages 34-41) which is a pioneer of the city’s craft beer scene, and we also hear from beer writer Breandán Kearney who offers his take on the influence Belgium continues to have on the UK’s brewing sector.

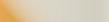

There are also details of SIBA’s new Homebrewing membership and awards (page 17), the launch of our 2023 SIBA Business Awards (pages 24-25), the second installment of our Brewing Apprenticeships feature (see pages 59-63), our guide to the upcoming changes to the alcohol duty system (pages 5657), and lots more.

Happy reading! And please do keep sending me your press releases, updates, news and views to caroline.nodder@siba.co.uk so that we can share your experiences, thoughts and successes in future magazines – the deadline for submissions for our Spring 2023 edition will be January 6th 2023.

Nodder Editor

Editor: Caroline Nodder (caroline.nodder@siba.co.uk)

Published by: Media Alive Limited

Produced on behalf of SIBA by: Media Alive Limited, 2nd Floor, The Red House, 119 Fore Street, Hertford, Hertfordshire SG14 1AX. T: 01992 505 810

Creative Director: Darren Kefford (darren@wearema.co.uk)

Studio Manager: Jon Hardy (jon@wearema.co.uk)

Advertising Manager: Claire Rooney (claire@wearema.co.uk)

Managing Director: Dan Rooney (dan@wearema.co.uk)

Printed by: Stephens & George Print Group Goat Mill Road, Dowlais, Merthyr Tydfil CF48 3TD

www.siba.co.uk | SIBA Independent

3

| Winter 2022

Brewer

Editor’s comment

All rights reserved. No part of this publication may be stored in a retrieval system or transmitted in any form or be any other means, electronic or mechanical, photocopying, recording or otherwise, without the prior permission of SIBA and/or Media Alive Limited. Whilst every effort is made to ensure that the information in this publication is accurate and up-to-date, neither SIBA nor Media Alive Limited take any responsibility for errors or omissions. Opinions expressed in editorial contributions to this publication are those of their respective authors and not necessarily shared either by SIBA or Media Alive Limited.

Welcome to the Winter edition of SIBA’s Independent Brewer Magazine.

Caroline

SIBA Independent Brewer Magazine

4 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk

Cover

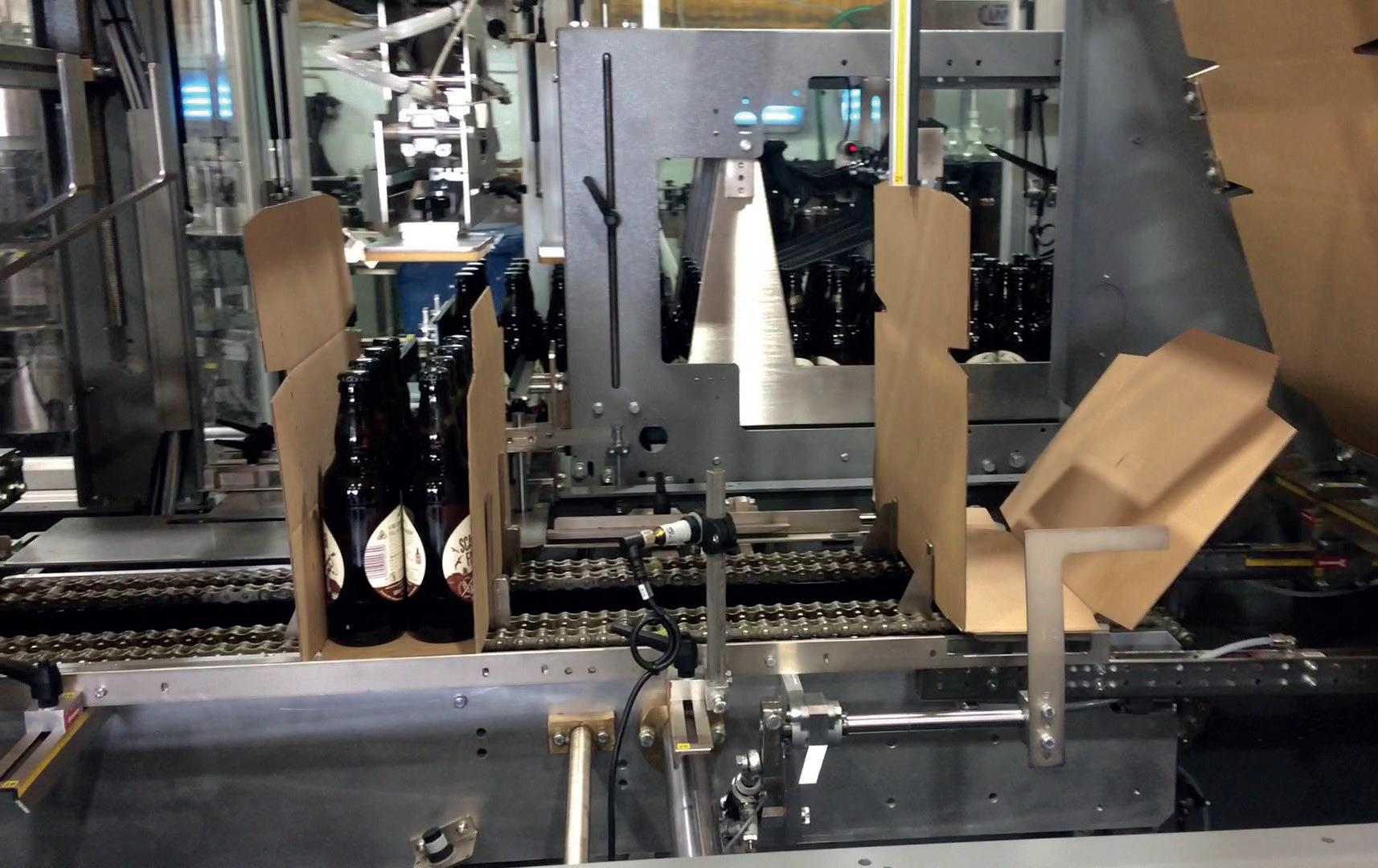

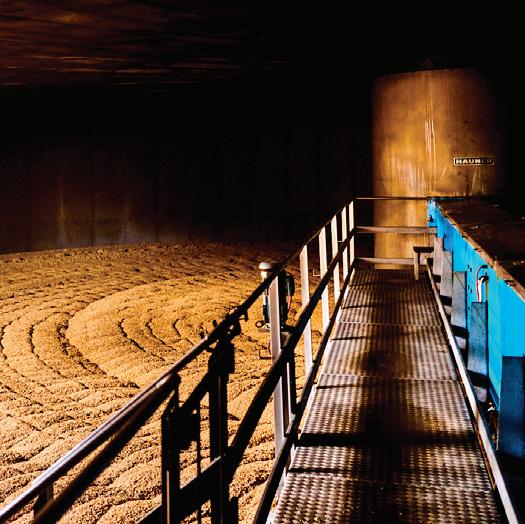

The cover for our winter edition was drawn by our Creative Director Darren Kefford and celebrates the launch of the new ‘Empowering People’ category in the SIBA Business Awards for 2023 (see pages 24-25 for more details)

News

8-15 SIBA News All the news from SIBA HQ 17 SIBA Homebrewer Membership & Awards The launch of a new SIBA membership category and dedicated awards scheme for homebrewers 24-25 SIBA Business Awards 2023 The launch of our latest Business Awards, with a new category added 72-75 SIBA Regional Beer Competitions Results from the East and North West 81-91 Brewery News The latest from our Brewing Members around the UK 95-99 Supplier News Updates from SIBA’s Supplier Associate Members

Comment

7 Chairman's Comment Richard Naisby, SIBA’s Acting National Chair, on SIBA’s focus for 2023 15 Meet the team Introducing SIBA’s new Public Affairs and Policy Officer, Will Lockwood 19 The View From Westminster Our regular political update 22-23 Homebrew In Focus Andy Parker from Elusive Brewing meets the husband and wife team at Baker’s Dozen 32-33 The Belgian Connection Breandán Kearney explores the different ways the beer scene in Belgium has influenced our home market 71 Technical Focus Brewlab’s Dr Keith Thomas on saving your energy 93 Supplier Viewpoint Insurance broker Russell Scanlan offers advice on choosing the right insurance for your business

26-31 SIBA’s SBR@20 Report Highlights from SIBA’s recent report marking the 20th anniversary of the introduction of Small Breweries’ Relief 34-41 Business Profile We meet Oli Hurlow, half of the partnership duo behind Birmingham brewery Attic 42-47 Sustainability Focus Eddie Gadd from Gadd’s Ramsgate Brewery tells us how his newly installed CO2 recovery unit is performing 48-53 Meet The Retailer A profile of SIBA Business Award finalist Wee Beer Shop in Glasgow 55 Taproom Focus Featuring Bristol's Lost & Grounded

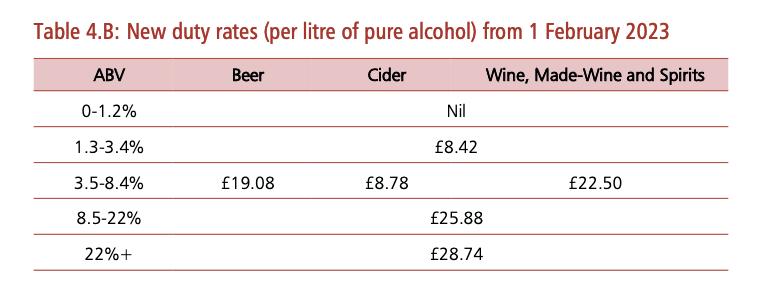

SIBA Guide To Duty Changes Our guide to the upcoming changes being made to the alcohol duty system

Brewing Apprenticeships How can breweries benefit from the sector’s new apprenticeship programme? 65-69 Business Advice Legal, brand & marketing and consumer insight 76-79 Gold Members Premier Systems and Loughran Brewers

Gold & Silver Members Listing of our key sponsors

5 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 Contents

34-41 Empowering People Issue 12 Winter 2022 48-53

Features

56-57

59-63

100

102 Contacts Key SIBA contacts

CONNECTING YOU TO THE INDUSTRY’S BEST PEOPLE & INGREDIENTS THROUGH THE WORLD’S LEADING FARMERS & SUPPLIERS ROB@BREWERSSELECT.CO.UK | JETHRO@BREWERSSELECT.CO.UK | SALES@BREWERSSELECT.CO.UK 01733 889100

For me, working collaboratively, sharing ideas and information amongst fellow brewers, is one of the core principles of SIBA and something which is integral to the success of the organisation.

Stop. Collaborate and listen…

With all the changes in Government of late it can be tempting to think that the big issues are on hold. But for the brewing sector that couldn’t be further from the truth, with far-reaching reforms to alcohol duty just one of the issues facing our sector in 2023.

The alcohol duty reforms are now set to come in as of August 2023 [see pages 56-57 for an overview of the key changes] and SIBA has been lobbying hard to ensure that the changes are as positive as possible for independent craft breweries like yours and mine. One area in which SIBA has had a huge success is in changing the treasury’s decision to limit the new draught duty relief to 40L and larger containers – under recently announced changes this relief will now apply to 20L and 30L containers also.

This change came as a direct result of lobbying from SIBA including a very well-attended event in Parliament, engaging with MPs on this issue and allowing them to be photographed with a keg, a bit like a recent now infamous photograph of a former Prime Minister and Chancellor at a brewery I won’t mention… Now, thanks to SIBA, the size of keg they were holding is actually eligible.

Rising energy costs continue to be a huge issue for the brewing industry, with many colleagues reporting three or even four-fold price rises which make running a viable and profitable brewing businesses extremely difficult. We’re tackling this issue on a number of fronts; firstly putting pressure on Government to

introduce measures which support highenergy consumption businesses – of which breweries are clearly one – and secondly to help brewers gain access to grants, funding and, crucially, knowledge on how we can all make our businesses more sustainable and energyefficient.

I spoke recently to Eddie Gadd of Ramsgate Brewery who has done some landmark work on CO2 recapture at his brewery and I look forward to the learnings he will be sharing with members at BeerX next year, when he delivers what I’m sure will be a very informative talk on the issue [see our Sustainability Focus on pages 42-47 for more on how this system works].

For me, working collaboratively, sharing ideas and information amongst fellow brewers, is one of the core principles of SIBA and something which is integral to the success of the organisation. It’s one of the reasons we will be introducing new changes to our regional meetings in the new year, where each meeting will have informative training sessions alongside the opportunity to meet with fellow brewers over a beer. Ensuring our regional meetings are well-attended, vibrant and engaging events that we all look forward to attending is going

to be a focus of mine and my fellow Regional Directors in the coming months – so if you have any suggestions or feedback which would help us further improve the meetings for you or your team then don’t hesitate to drop me or a member of the SIBA HQ team a line.

One event which SIBA was very proud to once again be involved with was the British Guild of Beer Writers Annual Awards, and in particular the Brewer of the Year Award 2023 which we sponsored. We served a whopping 10 different draught beers at the event in November from the SIBA bar, all of which were Overall Champions from the SIBA Independent Beer Awards National Finals at BeerX earlier this year – it’s just one of the ways in which SIBA helps to promote award-winning members and I look forward to trying the beers with the brewers themselves at the event. Cheers!

Richard Naisby Acting Chairman SIBA

7 www.siba.co.uk | SIBA Independent Brewer | Winter 2022

Chairman’s comment

Richard Naisby steps in as SIBA’s Acting National

Chair

SIBA announced in October that Roy Allkin had stepped down as Chairman with immediate effect to focus on his own business interests.

Richard Naisby, Vice Chairman, will now step in as interim Acting Chairman while a successor is sought. You can read Richard’s first comment piece as Acting Chair in this issue of the magazine on page 7.

Francis Patton, Chair of SIBA’s Executive Board, thanked Roy for his work as Chair saying: “Roy has been an invaluable asset to SIBA in recent years and I hope he will be in a position again in the future to lend his expertise to the organisation."

Big Bog Brewing takes home North West's top beer award

Big Bog Brewing Co has taken home the Overall Champion Cask Beer Award at the SIBA North West Independent Beer Awards 2022, which took place at the Bolton Beer Festival.

Their Gold-winning beer ‘Peat Bog Porter’ wowed judges with "superb balance and drinkability for such a full-flavoured dark beer".

The Overall Silver award winner was Hophurst Brewery APA and Bronze went to Coach House Brewing Hundpowder Mild - all of which went into the final judging having won best in their category.

Rich Midgley forms part of the two-man team at microbrewery Big Bog Brewing, and was onhand to accept the award: "Really surprised to win, there's only two of us that brew and we're really proud of this beer. It's really subtle and drinkable with a good dry finish, we like it and we're just pleased that the judges did too!"

The awards took place ahead of the Bolton Beer Festival at the University of Bolton Stadium, which continued over the weekend. The SIBA Independent Beer Awards are run by and for brewers and are judged by fellow brewers from elsewhere in the UK, as well other representatives from the industry and expert beer judges –making these the much coveted ‘brewers’ choice’ awards in the North West.

North West Independent Beer Awards winners will now go on to the National Finals at the BeerX UK event in Liverpool in March 2022.

Hosting the awards on behalf of SIBA was Buster Grant, Chair of SIBA’s Competitions Committee who said: “The quality of beers at the awards this year were really top-draw and we gave out more Gold medals than ever before, so to be named overall Champion is a huge, huge achievement - very well done to Big Bog and of course all of our other winners.”

For the full list of winners see pages 74-75

Rural England Prosperity Fund

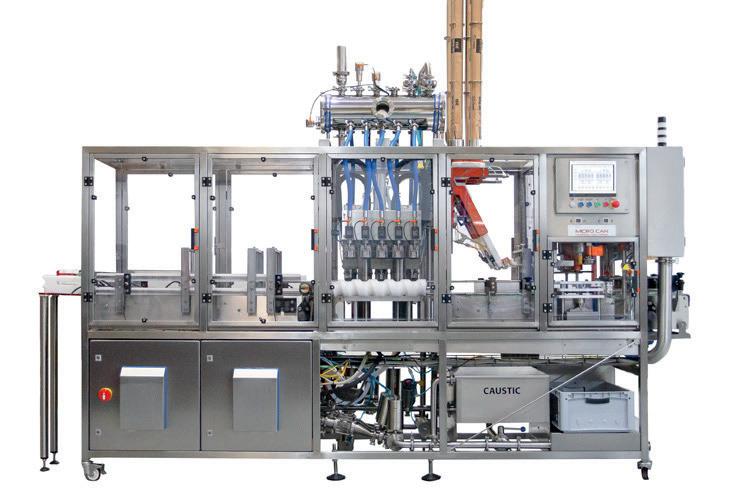

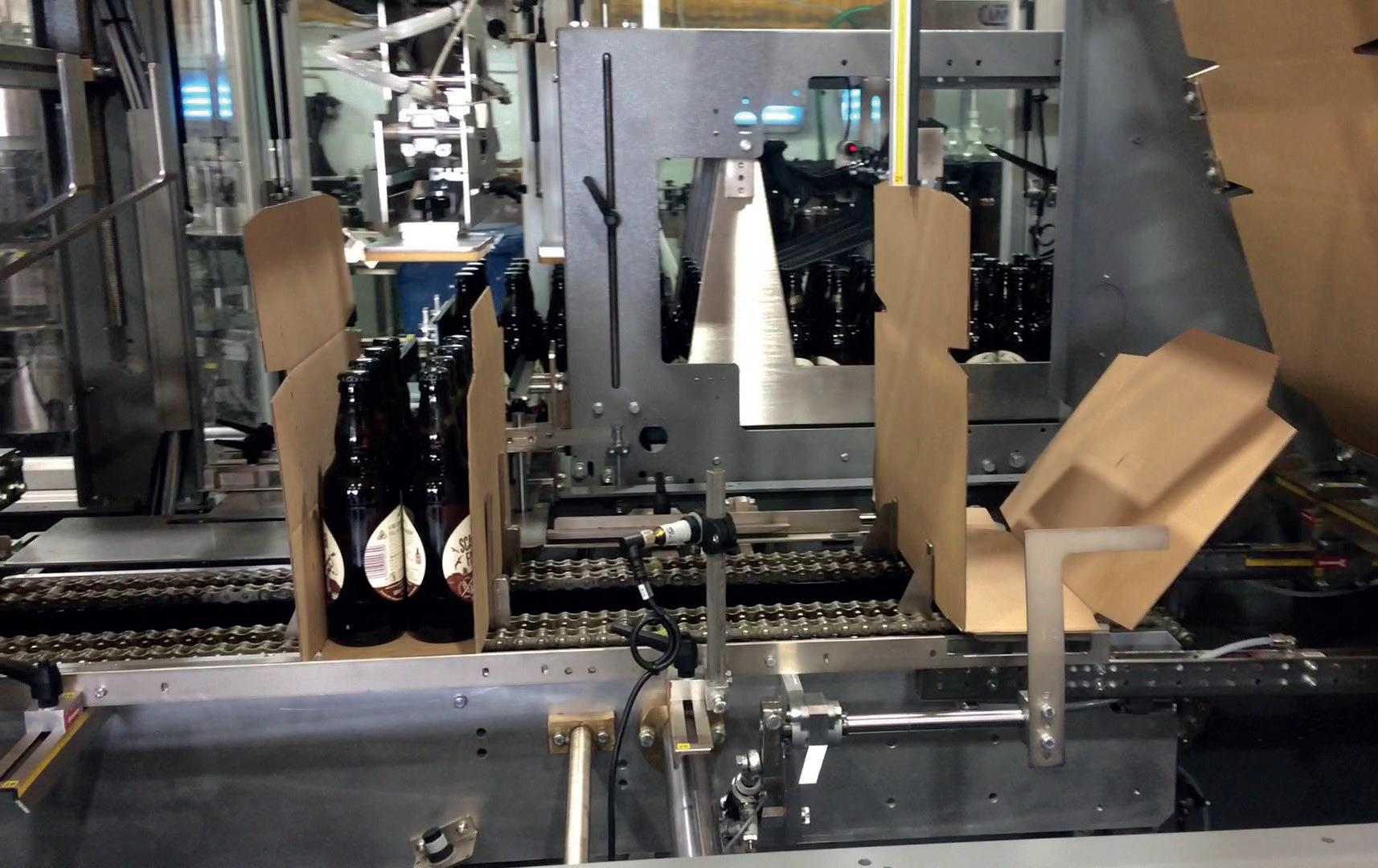

The Government has launched the Rural England Prosperity Fund. This provides capital grant funding for small scale business in rural areas to help improve productivity and strengthen rural economies. There is a total of up to £110 million available for the financial years 23/24 and 24/25 and local authorities will decide how to spend their allocations.

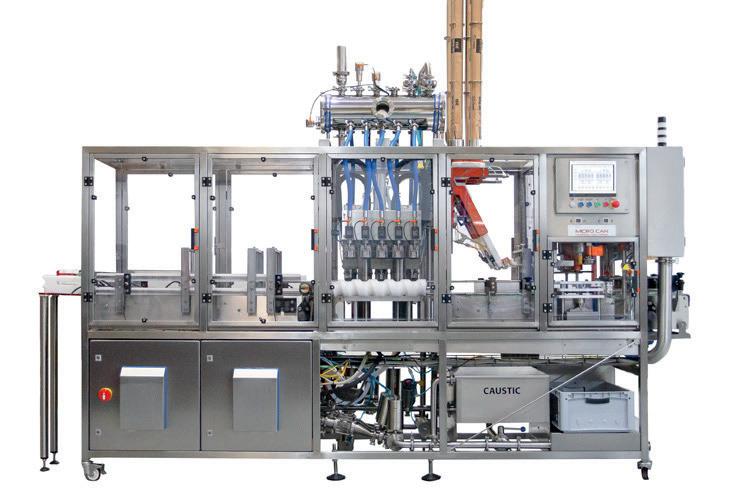

New and existing rural businesses will be able to apply for capital funding for small scale investment, community-centred and circular or social economy projects. This might be to: develop new products and facilities that will be of wider benefit to the local economy. This could be buying equipment for food processing or packaging machinery such as brewing equipment, modernising existing equipment for increased energy efficiency or increased productivity through automation.

You can read more about the rural England prosperity fund here: www.gov.uk/government/publications/rural-england-prosperity-fundprospectus/rural-england-prosperity-fund-prospectus

The SIBA Annual Survey 2022/23 has been launched

The SIBA Annual Survey is a vital resource for us in planning our activities. It also forms the key basis of the SIBA Craft Beer Report launched at BeerX.

This year we have revamped the survey so there are fewer questions to reduce the time it takes to complete.

All SIBA Member Breweries who complete the survey and submit their production figures when requested to do so by the Toolbox no later than 28 February 2023 will be eligible for a prize draw to win a £500 credit voucher with the Supplier Associate of your choice. The winner will be announced at BeerX.

To complete the survey you will need some information including your sales data, pricing information and employee details.

The closing date for entries is strictly Friday 13 January 2023 to provide enough time for the proper analysis of the data ahead of the production of the Craft Beer Report 2023.

To complete the survey please visit: www.surveymonkey. co.uk/r/SIBA2022-23. If you have any questions please email the membership team via membership@siba.co.uk

8 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk SIBA news comment

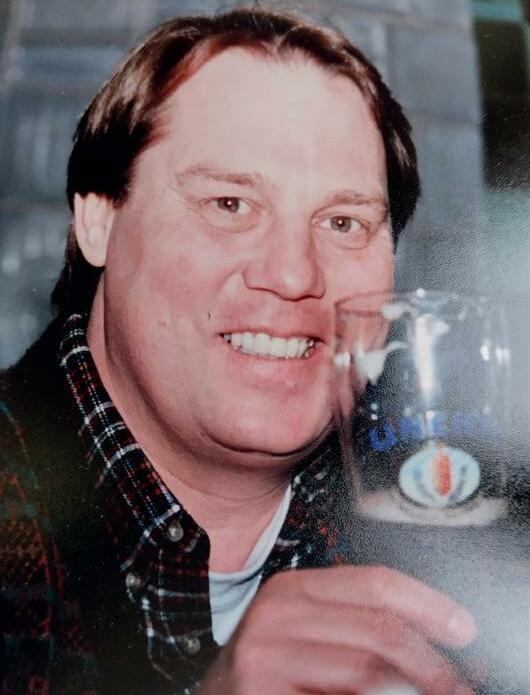

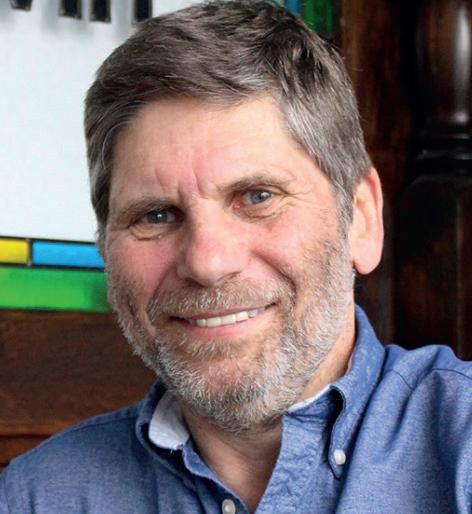

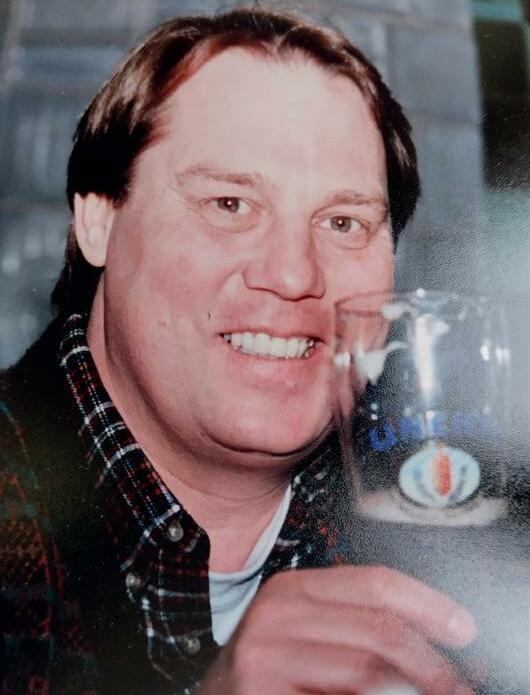

SIBA has appointed former Black Sheep Chairman Andy Slee as its new Chief Executive, bringing a wealth of industry knowledge and experience to the role.

Speaking as the appointment was announced, Andy Slee said: “I am of the passionate belief that small independent breweries are a force for good in the communities they serve - they are the vibrant heart that helps bring people together.

“SIBA represents a huge breadth of independent British brewers. Our job is to help create an environment in which all can thrive in what are very challenging times, and ensure that local beer is a vibrant and growing

part of the British beer landscape. That can only be achieved by helping small independent breweries to thrive. I look forward to working with the SIBA team and all its members to do just that.”

With leadership experience at famed independent brewery Black Sheep, as a NonExecutive Director at Titanic Brewery, as well as prior positions at Coca Cola, Punch Taverns and Bass, Andy brings with him a breadth of top-level lobbying, commercial and membership experience to the role – as well as a personal passion for local independent beer.

Chairman of the SIBA Board, Richard Naisby, welcomed Andy’s appointment, saying: “Andy’s knowledge and passion for the independent

SIBA welcomes new Homebrewer members

Budding brewers now have their chance to join SIBA as the organisation has extended its membership to include Homebrewer Members.

Homebrewer membership is open to all amateur brewers across the UK who want to improve their brewing skills. On offer is entry to SIBA’s brand new Homebrew Beer Awards, judged by professional brewers at the UK’s biggest beer and brewing trade event – BeerX - as well as regular online ‘Ask the Brewer’ sessions, giving homebrewers the opportunity to hone their skills.

As well as the awards, Homebrewer Members will receive a quarterly brewing magazine with a dedicated homebrew section edited by Andy Parker of Elusive Brewing and access

to SIBA’s brewing tools and advice as well as access to regional and national SIBA events and beer competition judging.

SIBA Head of Public Affairs Barry Watts said: “I started as a homebrewer and know how important it is to get access to information and professional advice to improve how I brew. Having SIBA involved means we can help homebrewers get to the next level as well as offering support for those looking to become professional brewers themselves.

“Our new Homebrewer membership offers a fantastic combination of resources, competitions, advice and support with entry to SIBA’s brand new Homebrew Beer Awards and BeerX on offer.”

brewing sector is absolutely evident and I am certain he is the right man to drive forward SIBA in 2023. I look forward to working with him as he delivers a bright and progressive future for the organisation.”

Andy Slee will begin as SIBA Chief Executive on the 1st of January 2023, leading the organisation into the new year.

Andy Parker from Elusive Brewing said: “Homebrewing is a great way to learn about the process, improve your abilities and brew some excellent beers at home. For me as a homebrewer before starting Elusive, I used to knock on doors and chat to brewers to learn about their processes and a scheme like this would have been invaluable at the time.

The SIBA homebrewer membership helps to provide direct access to brewers, suppliers, advice and expertise which are key if you’re looking to improve as a homebrewer.”

This comes as SIBA has extended its membership to include International Brewers and plans to launch a new Bottleshop membership offering advice, guidance and Government lobbying support.

For the first time ever, homebrewers can compete in the SIBA National Homebrew Beer Awards and have the chance to see their beer professionally brewed at an award-winning brewery.

Free to enter for SIBA Homebrewer Members, the competition is now open for registration and will be judged by professional brewers at BeerX – the UK’s biggest beer and brewing trade event in March 2023.

For more information on SIBA Homebrewer membership and awards see page 17 in this magazine or visit www.siba.co.uk/homebrewer

9 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 SIBA news

SIBA appoints Andy Slee as Chief Executive as he bids to ‘create an environment in which independent breweries of all sizes can thrive’

New nationwide homebrew competition to be judged by professionals at UK’s biggest brewing event

10 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk

SIBA campaign success as draught beer duty rate extended

In a statement welcoming the news that the Government has extended the new preferential draught duty rate to include 20L containers as well as those over 30L, then-SIBA Chairman Roy Allkin said: “Small independent brewers will be cheering the announcement that the Government has listened to our concerns and included the 20 and 30 litre containers used by independent brewers in the new draught duty. Our Make it 20 campaign received cross-party support and the change will have a huge impact on the ability of small brewers to benefit from the duty discount.

“Delaying the introduction of the draught duty rate until next summer, as opposed to February as originally planned, will however come as a disappointment to many small brewers who have already factored these changes into their business plans for next year. Combining the successful Small Breweries’ Relief, which is 20 years old this year, with Small Producer Relief is very complex and there will inevitably be winners and losers, especially hitting those brewers making innovative stronger products like Imperial Stouts above 8.5% ABV. We look forward to working with the Exchequer Secretary and Chancellor to get the details right on these changes and ensure that we continue to have a vibrant, dynamic small brewing sector fit for the future.”

SIBA responds to the Scottish Government’s Emergency Budget Review

Responding to the publication of the Scottish Government’s Emergency Budget Review and the announcement on the Scottish Deposit Return Scheme, SIBA Scotland Director Jamie Delap said: “Scotland’s small independent brewers are currently operating on a knife edge trying to survive the combined impacts of energy bill increases and a cost of living crisis. They haven’t yet been able to build the resilience they need to recover from the impacts of the Covid 19 pandemic.

“Small breweries are therefore rightly concerned about the impending Deposit Return Scheme coming next year which they do not have the economic resources or capacity to prepare for or deliver.

“It is therefore encouraging that the Scottish Government has recognised some of the issues facing the scheme in the Emergency Budget Review and have indicated a willingness to amend the online takeback element which currently would prevent any small producer from selling online in Scotland next year.

“However, we would urge the Scottish Government to look again at the requirements for small producers which, as currently designed, are threatening business closures and jobs in Scotland and will lead to reductions in choice and an increase in price. Many small breweries have already told us they will have to stop selling beer in cans and bottles in Scotland because of the multi million pound costs of the scheme to small producers.”

SIBA reacts to scrapping of Alcohol Duty Freeze in emergency statement

SIBA’s then-Chairman Roy Allkin issued a statement in response to the news that the alcohol duty freeze announced by then-Chancellor Kwasi Kwarteng was being scrapped: “The emergency statement by the Chancellor undoes many of the positive measures announced in the mini budget only a few weeks ago, including a welcome freeze in alcohol duty from February next year. Small independent brewers will now have to wait a further few weeks to understand what this means for them, as the shakeup of the overarching alcohol duty system is still expected to go ahead. Again this is creating more uncertainty for small brewers who are facing an extremely challenging trading environment dominated by energy spikes, price increases and a cost of living crisis.

“The Treasury also intends to conduct a review of energy support from next April including incentivising energy efficiency. Small brewers previously called for support through grants to move to Net Zero and improve their energy efficiency through new technology and we hope that the Chancellor will consider this as part of his review."

Invite international breweries you know to join SIBA

SIBA’s International Membership is now live and we would like to encourage all members to reach out to any international breweries you know or have perhaps collaborated with to join as a SIBA International Member.

As a member they get entry into the SIBA International Beer Awards and free entry to BeerX, as well as the opportunity to network with fellow brewers and a range of other membership benefits. Find out more and share information with your contacts here: www.siba.co.uk/international

11

| SIBA Independent Brewer | Winter 2022 SIBA news

www.siba.co.uk

12 KEEP IT REAL with our STANDARD BOTTLES NO PLASTIC LINER PROTECTS FROM UV RAYS KEEPS BEER COOLER FOR LONGER PURE TASTE OF BEER - NOTHING ELSE NATURAL, SUSTAINABLE RAW INGREDIENTS CONTAINS UP TO 65% RECYCLED MATERIALS 100% ENDLESSLY RECYCLABLE QUALITY PACKAGING FOR QUALITY BEER Beatson Clark has a wide range of glass bottles in a variety of shapes and sizes to suit products from beers and real ales, to lagers and ciders. Our standard range can be embossed with your logo or strapline to enhance your branding from only 150k units. BENEFITS OF GLASS INCLUDE: CROWNS CROWNS CROWNS PRINTED

Baker’s Dozen wins best craft keg beer in SIBA East Independent Beer Awards

Baker's Dozen Brewing Co, a husband-and-wife microbrewery in Ketton, Rutland, has taken home the Overall Gold in the SIBA East Independent Keg Beer Awards, beating brewers from across the East of England.

The brewery’s 'Undertow' Session IPA is hazy and full flavoured beer, styled after American New England IPAs but at a more sessionable strength of 4.8% ABV. The beer was named best in class for the Pales Ales before going on to be named the Overall Champion in the final round judging, which sees all of the category winners go head-to-head. All of the winners from the awards will now go on to battle it out at the National finals in Liverpool next year.

The prestigious awards, held at the Legra Tap & Kitchen in Leigh-onSea, were judged by brewers and beer experts and seen very much as the brewers’ choice awards in the industry. All of the beers involved in the competition were also available as part of an 'Independent Beer Awards Tap Takeover' at the Legra Tap and other select venues across Leighon-Sea - giving local beer lovers the chance to taste this years' winners.

Dean and Gill Baker from Baker's Dozen Brewing Co were both on hand to accept their award, with Gill commenting: “We're just shocked and delighted to win, I'm actually shaking! We're over the moon and really didn't expect this."

Leigh-on-Sea Brewery named best in East of England

Leigh-on-Sea Brewery has taken home the overall Gold at the SIBA East Independent Beer Awards, beating brewers from across the East of England, stretching from North Lincolnshire down to Essex and Hertfordshire, as well Norfolk, Suffolk, Cambridgeshire and Bedfordshire.

It was Leigh-on-Sea’s ‘SS9’ – a hefty 9% ABV Imperial Stout with deep flavours of coffee and chocolate – that wowed the expert judges and was named the Overall Champion of the Cask. All of the category winners from the awards will now go on to battle it out at the National finals at BeerX in Liverpool next year.

The awards were held at Elgood’s Brewery in Wisbech prior to their beer festival.

Ian Rydings, Owner and Head Brewer at Leigh-on-Sea Brewery, accepted the award saying: “It’s always been a quality beer but it’s never done as well as this before, it’s amazing to win. It’s just so full of flavour, full of chocolate and coffee flavour that all comes from

Dean added: "What we love about this beer is that while it is hazy and aromatic like you would expect from a New England IPA or Pale Ale, it also has a really good undertow of bitterness - hence the name!"

Commenting on the win was SIBA Head of Comms Neil Walker, who presented the awards: “The quality of beer now available on keg is incredible in the East, with some superb craft lagers, pales ales, IPAs and many international styles now being brewed across the region. The quality of beer in the competition was genuinely excellent and judges had a very tough job separating winners from a very high quality pack. Huge congratulations to all of our Gold award breweries and in particular Dean and Gill from Baker's Dozen who were very deserving winners of the SIBA East Independent Beer Awards Overall Goldgood luck in the national finals!"

Read more about Baker's Dozen in our Homebrew in Focus feature on pages 22-23.

the specialty roasted malts we use, there’s absolutely no additions – it’s a pure stout.”

Commenting on the competition was SIBA Competitions Committee Chair Buster Grant, who presented the awards: “It was great to be back in Wisbech to judge these superb awards and the quality of entries this year was higher than ever. Huge congratulations to all of the winners and in particular Leigh-On-Sea who were named the ‘best of the best’ as Overall Gold Champions, with what is a really special beer.”

For a full list of winners from the event see pages 72-73.

13 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 SIBA news

New SIBA report reveals how landmark Government policy led to UK brewing boom

SIBA published a special report in September to mark the 20-year anniversary of the introduction of Small Breweries’ Relief.

The report revealed the huge impact the policy has had on UK brewing, including the boom in small breweries and a huge increase in the number of different beer styles being brewed.

The ‘SBR @ 20’ report was published by SIBA, which lobbied successfully for the policy some two decades ago.

Small Breweries Relief was introduced by the then Chancellor Gordon Brown with the aim of allowing small breweries to pay a lower rate of duty on the beer they brewed in order to be able to compete with National and Global beer producers. The sliding-scale policy meant the smallest brewers received a 50% rate relief, with the relief gradually reducing depending on the size of the brewery.

Under changes announced last year, Small Breweries’ Relief will be replaced by a new ‘Small Producer Relief’ which will, alongside beer, include other drinks from small producers such as cider. The changes are due to come in from August 2023, but SIBA has raised concerns over various elements of the new system, including the unfair advantage given to cider.

“Massive amounts of thinking has gone into restructuring the whole alcohol duty regime, simplifying it and ‘making the basis of alcohol taxation more economically rational, with fewer distortions and arbitrary distinctions’, yet the massive cider producers will continue to pay half the alcohol duty that brewers do, and now the distortion is in plain sight, glaringly obvious,” said Eddie Gadd, MD of Ramsgate Brewery and long-time campaigner for small brewers.

Read highlights of the SBR@20 report on pages 26-31

How long have you worked for SIBA and what did you do before?

I have worked for SIBA since April 2022, before this I worked for MPs and in the Civil Service.

What does your job role with SIBA involve?

I assist Barry with our Public Affairs and Policy work. This means I speak with politicians regarding issues facing the industry like Deposit Return Schemes and Alcohol Duty and also work on policy initiatives. I have been working on our public affairs presence in Wales recently and have had meetings with around a quarter of the Members of the Senedd discussing DRS. What, in your view, is SIBA’s key purpose?

SIBA’s key purpose is to deliver for its members and make sure they get the most out of membership. For me that means ensuring their voices are heard in the corridors of power.

What made you want to come and work within the independent brewing sector?

I started my early career as a chef in fine dining restaurants across North Yorkshire and have always been interested in beer pairings. From this I started a blog about food and beer, suggesting pairings and reviewing beers. It’s an industry I have been interested in getting into since I left university. I even had an interview offered by SIBA in 2015, but I had just got my first job in Parliament and had to turn it down.

What are you most looking forward to in your role in the coming year?

I am very much looking forward to meeting more members and learning even more about the industry. I am also looking forward to pushing our agenda further in Wales.

What has most surprised you about SIBA since you joined?

The effectiveness of SIBA’s public affairs. Having worked in politics for a long time I know how hard it is to affect change, but this is something SIBA does very well.

What issues can you help SIBA members with and how should they contact you?

I am willing to help SIBA members with any issues they have, if they need briefings, help with setting up meetings with their local MP or just any queries in general I am always happy to help. The best way to get in touch is via e-mail on will.lockwood@siba.co.uk

What do you like to do outside work?

I love to cook, my kitchen is full of kitchen gadgets, which drives my wife crazy. I love travelling and going for walks in the beautiful Peak District where I live!

What is your favourite beer and where would you most like to drink it?

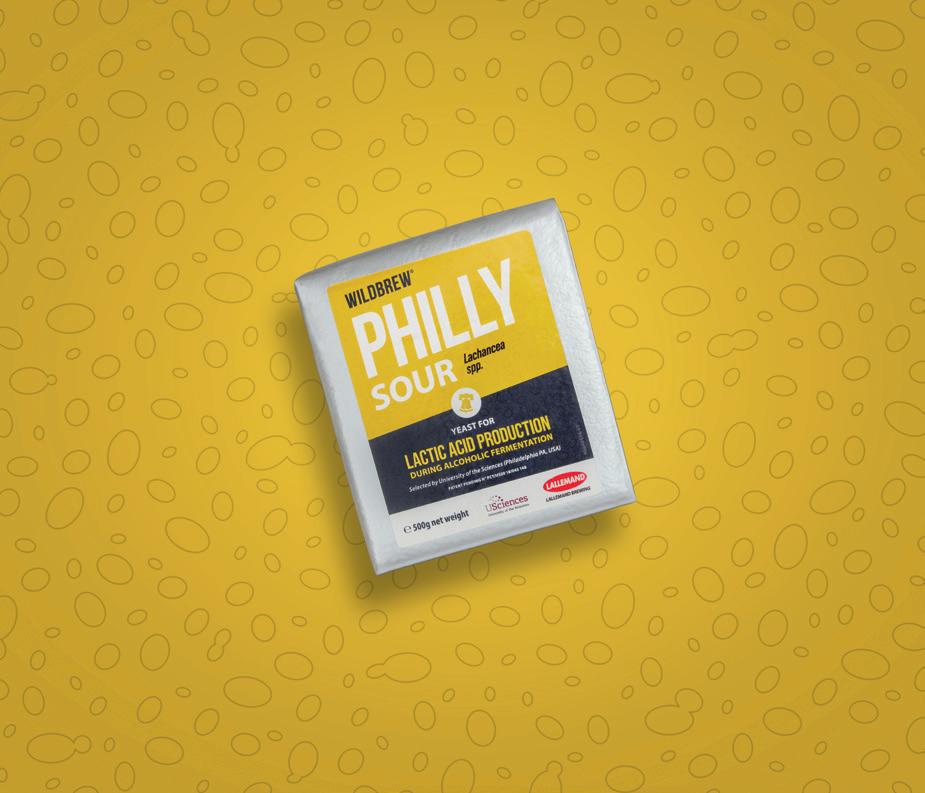

At the moment I am very much into sour beer, so a beautiful sour beer on a sunny beach in Crete sounds lovely on this rainy October morning!

15 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 SIBA news

Meet the Team Name: Will Lockwood Job Title: SIBA Public Affairs and Policy Officer Contact email: will.lockwood@siba.co.uk

- Determination of alcohol, density, extract, and further quality parameters - Optional

and

your

- Easiest

beer, wine, and spirits in

production

- Full

COMPLETE BEVERAGE ANALYSIS IN ONE MEASURING CYCLE FROM RAW MATERIAL TO FINISHED PRODUCT Get in touch: www.anton-paar.com

measurement of turbidity, color,

pH value, based on

needs

analysis of

various

stages

compliance with standard reference methods

SIBA Homebrewer Membership

Are you a homebrewer wanting to improve your brewing skills? Then join as a SIBA Homebrewer Member today. SIBA Homebrewer Membership gives you access to brewing advice, information and a wide range of member benefits such as discounted brewing supplies, networking opportunities with fellow amateur and professional brewers, beer judging training, and free entry to the UK’s biggest beer and brewing event – BeerX UK.

Membership benefits include

• Quarterly brewing magazine with a dedicated home brew recipe section (see pages 22-23)

• Entry into BeerX – the UK’s biggest brewing event

• Regular online ‘Ask the Brewer’ sessions for technical Q&A and advice

• Access to SIBA’s ‘Member Toolbox’ offering business and brewing tools and advice on going pro

• Attend regional and national SIBA events, judge at SIBA beer competitions and come along to social gatherings

• NEW! Opportunity to judge SIBA’s Bottle & Can Independent Beer Awards remotely (via Zoom, December 2022) – judging professionally brewed beers from across the UK with other experienced beer judges. All beers (1 to 2 cases) posted out to Homebrewer Members for judging free of charge.

• NEW! Entry into SIBA’s National Homebrew Beer Awards taking place at BeerX (see details below)

SIBA launches Homebrew Beer Awardsset to take place at BeerX 2023

For the first time ever, homebrewers can compete in the SIBA National Homebrew Beer Awards and have the chance to see their beer professionally brewed at an award-winning brewery. Free to enter for SIBA Homebrewer Members, the competition opened for registration in November and will be judged by professional brewers at BeerX – the UK’s biggest beer and brewing trade event in March 2023. This year we have partnered exclusively with Yakima Chief Hops to provide Homebrewer Members with their new experimental hop HBC 586 which has been described as “a large medley of fruit flavours…mango, guava, lychee, citrus with herbal notes”. Entrants are challenged to brew the best single hop pale ale which showcases the full potential of this exciting new hop variety.

“Giving homebrewers access to one of Yakima Chief’s latest experimental hop varieties gives them the opportunity to push the boundaries of hopforward brewing while being directly involved with Yakima Chief’s Elite Trials programme,” said Robbie Harrigan, Home Brew Sales Manager for Yakima Chief in Europe. “Professional brewers have only recently had access to this incredible new hop, and we can’t wait to see what homebrewers create with it.”

The homebrewer who sees their beer named the Overall Champion in the SIBA Homebrew Beer Awards will have the opportunity to help scaleup their recipe for production at Quantock Brewery in the South West. This multi-award winning craft brewery is increasingly known for its hop forward beers such as its unique “Obsessed With” single hop range.

Quantock Director Cheryl Ford said: “We started as every homebrewer did experimenting in our garage and now we’ve had the chance to develop and expand our own independent brewery making beers enjoyed around the country. It’s great to see that SIBA has expanded to include homebrewers who are the future of our industry and we can’t wait to invite the winner to join us here for a day of brewing.”

For more information on SIBA Homebrewer membership or to join please visit www.siba.co.uk/homebrewer/.

17 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 Homebrewer Membership & Awards

est 1984 or call 01404 892100 See us at EQUIPMENT SERVICE SUPPORT sales@vigoltd.com vigoltd.com @VigoLtd Equipping the Nation’s Drink Producers Bottle fillers & labellers Brewhouses, tanks/chilling Craft canning lines Keg washers & fillers Engineering Support Carefully chosen equipment from renowned manufacturers. Back-up, maintenance & repair by our team of multi-skilled Vigo engineers.

The view from Westminster

It’s all change again in Parliament as the shambolic Mini-Budget announcements in September led to another Prime Minister and a new set of Ministers. SIBA has spent the last few months getting to know the new Ministerial crop and now faces having to start again with a brand new team. By my count we are now on our eighth Exchequer Secretary since the Government began the review of Small Breweries’ Relief (SBR) in 2018 and yet this issue has not yet been completely resolved.

As it currently stands there’s two big issues coming your way in August next year which breweries need to start preparing for. The first is the complete overhaul of the alcohol duty system which sees SBR become part of a souped-up Small Producer Relief. The second is the Scottish Deposit Return Scheme which impacts all small pack sales in Scotland.

Alcohol duty system

The Government finally published its update on the alcohol duty changes in September which included significant wins for SIBA and small independent brewers. The fundamental redesign, which will now be introduced in August next year, will transform the alcohol duty system. You can read my guide to the changes in this copy of the SIBA magazine (see pages 56-57) or see the detailed briefings available online on the Toolbox.

Amongst the changes there was success for our Make It 20 campaign, with the Government including 20L and 30L containers in the new draught duty relief – the 5% reduction in duty for beer placed in kegs and casks. Alongside that, the Government is intending to expand the farmgate exemption to include small breweries and has accepted SIBA’s view on the average ABV to set the new tapers. SIBA is also pushing

SIBA continues to lobby for changes and we’ve had a great deal of engagement with the Minister with three meetings in only a couple of months.

for transitional relief so that breweries don’t have to recalculate duty twice (or potentially three times if they don’t freeze duty) next year. One issue that has arisen in the latest version of the changes is its impact on growlers and crowlers. Currently as drafted it would mean that a pub cannot ‘repackage’ beer into takeaway containers, which would negatively impact community pubs alongside taprooms and brewery shops. This is something that SIBA and others are working with the Government to address and hopefully find a solution.

Scottish DRS

In Scotland, the Government continues to plod along with the Deposit Return Scheme – which sees a deposit added to each can and bottle sold. If you sell into Scotland, even online or via a bottleshop’s webshop, you’ll have to register and pay fees to cover the costs. The window to register opens in December and closes at the end of February. If you are not registered before 1 March you will not be allowed to sell cans and bottles in Scotland so it’s very important that you take the time to register. SIBA continues to lobby for changes and we’ve had a great deal of engagement with the Minister with three meetings in only a couple of months. They’ve listened to our concerns about the online takeback service which we’re now expecting to be reconsidered. Hopefully we’ll get some positive movement on small producers as well.

Get your beer into Parliament

A great way to engage with your MP is to have your beer poured in Parliament. You can have your cask ale chosen as the guest ale for the Strangers’ Bar. It’s a great opportunity to come down to Parliament, have some photos taken to send to the local press and lobby your local MP for changes. We can be there to support you all the way, including on the day in Parliament if you wish. If you decide you want to request your beer be served in the Strangers’ bar, please either e-mail will.lockwood@siba.co.uk or your local MP who will be able to assist you.

Barry Watts is Head of Public Affairs and Policy at SIBA. He covers political relations and policy for SIBA members. He can be contacted at barry.watts@siba. co.uk or 07977837804.

19 www.siba.co.uk | SIBA Independent Brewer | Winter 2022

view from Westminster

The

Caught by the Undertow

Elusive Brewing’s Andy Parker, who was recently named Brewer of the Year by the Guild of British Beer Writers, meets one half of the husband and wife team behind Baker’s Dozen brewery, Dean Baker, to find out more about the origins of his New England IPA, Undertow…

22 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk

in focus

Homebrew

A visit to New Hampshire for a friend’s wedding in 2013 started a love affair with New England IPAs for husband and wife team Dean and Jill Baker, two years before Baker’s Dozen would brew their first commercial beers.

Dean recalls the moment fondly: “Being the diligent planner that I am, I started looking around for breweries during our stay in Boston and came across a new start-up brewery called Trillium that had been going for just a couple of months. When we arrived at the brewery, they didn't have a licence to drink on the premises and were only doing growler fills, but there were a few bars just down the road where we could try their beers. On the 23rd of August 2013 I tried my first New England IPAs. I forget the name of the bar but remember trying Congress Street and Fort Point. They were thick and murky in appearance with an incredible aroma. Both fresh and amazingly fruity on the palate with a fairly low level of bitterness.”

Trillium has since gained a reputation for brewing some of the world’s best examples of the New England IPA style and the brewery’s beers are highly sought after. However, like the origins of this now ubiquitous style, the story of how Baker’s Dozen came into being started much earlier. “My parents used to run pubs, so I grew up in the trade and have always loved cask beer,” explains Dean. “I cut my teeth in and around Nottingham on Home Ales Bitter. And in 2005 Jill and I took on our own pub in Stamford (The Jolly Brewer) where cask beer was our focus. In wanting to run the best business that we could, we sought to educate ourselves, staff and customers as much as possible about the products that we were serving them, and that's probably the beginning of our story.” Around the same time, John Kimmich of The Alchemist Brewery in Waterbury (Vermont) was developing his recipe for Heady Topper – widely recognised as the origin of the New England IPA style. This thirst for knowledge about the product they were serving at the Jolly Brewer inevitably lead Dean towards learning to brew: “I was quite keen to learn more about the brewing process and how different styles were produced and that's when it all started to get out of hand! In early 2012 I went on a brewing course at Brewlab in Sunderland, then bought a 50 litre brew kit. Several brews later and we were planning on either spending all our savings on buying a house or a load of stainless steel, hard work and sleepless nights. We still don't own a house!”

Baker’s Dozen moved into its commercial brewing premises in 2015 and, inspired by those early encounters with the New England styles, has gone on to win several regional awards including overall winner in the 2022 SIBA East Keg Competition with New England Pale Ale, Undertow.

“To my mind, those early examples I tried had a little more bitterness than the New England style beers that we see in our bars and bottle shops nowadays,” Dean reflects, “So when we looked to brew our first commercial example we wanted to look back to our first experience of the style and add that little extra dimension to the beer, that for my taste is often missingan undertow of bitterness.”

So when we looked to brew our first commercial example we wanted to look back to our first experience of the style and add that little extra dimension to the beer, that for my taste is often missing.

The New England style is characterised by its juicy, citrus and floral hop notes, with a heavy emphasis on aroma. They are hazy in appearance and generally have a much lower bitterness than other sub-categories of the IPA style. They are known for having a full, smooth mouthfeel. In constructing the recipe for Undertow, Dean focused on that aspect: “The grist is fairly simple, but makes sure there's plenty of body for that full mouthfeel. A decent whack of Carapils ensures there's plenty of dextrins to cling on to those hop compounds and the Golden Naked Oats give a creamy silky finish.”

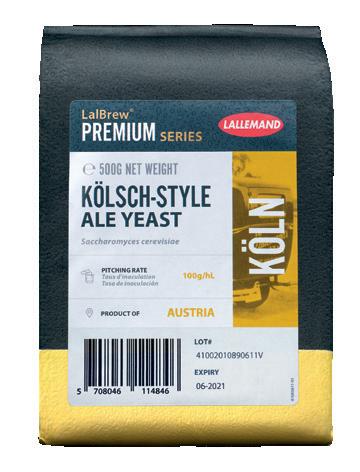

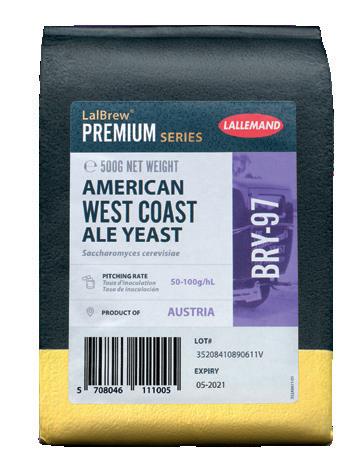

To layer the citrus notes, the beer is fermented with a New England yeast strain, which is pitched at 18C and allowed to free-rise to 19C. Dry hops are added during active fermentation, when the beer reaches 1.020. This serves two purposes, as Dean explains: “This has the added benefit of both utilising biotransformation of hop compounds as well as allowing us to carbonate the beer naturally using the spunding valve.”

After dry hopping, the beer is left at 19C for one day before being allowed to naturally rise to 22C for a diacetyl rest before being cold crashed and packaged.

23 www.siba.co.uk | SIBA Independent Brewer | Winter 2022

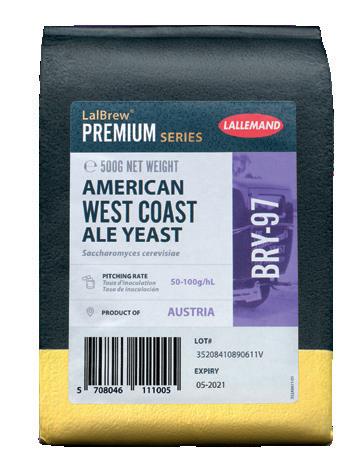

Homebrew in focus OG: 1047 FG: 1010 ABV 4.8% Grain Bill: Simpsons Low Colour Golden Promise 4kg (80%) Simpsons Golden Naked Oats 500g (10%) Weyermann Carapils 500g (10%) Hops: 13g Citra 15 mins 13g Nelson Sauvin 15 mins 25g Citra 3 mins 25g Nelson Sauvin 3 mins 37g Citra F/O 37g Nelson Sauvin F/O Dry Hop (@ 1020) 62g Citra 62g Nelson Sauvin Baker's Dozen Brewing Co. Undertow

WINNER best craft keg beer East of England

SIBA Business Awards 2023

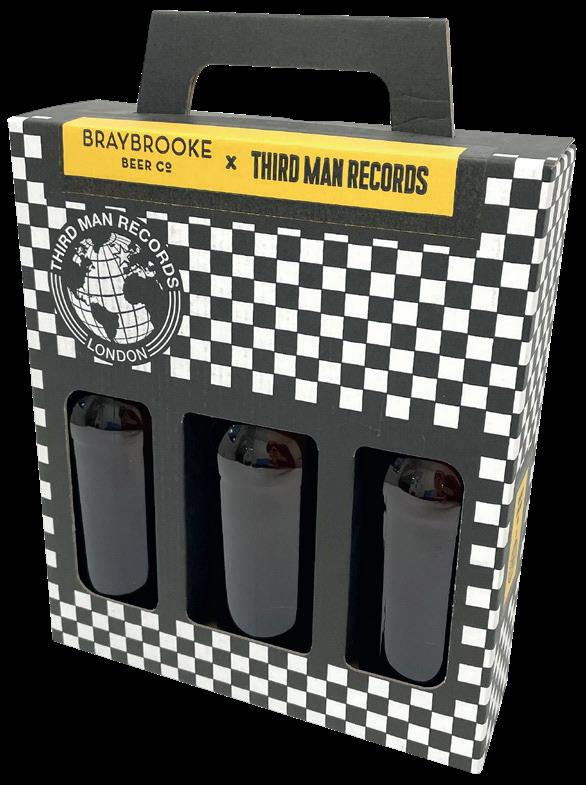

As part of the launch of the SIBA Business Awards 2023, SIBA has revealed a new “Empowering People" Award which seeks to highlight the best breweries in the UK to work for.

The award aims to celebrate independent craft breweries which go above and beyond for the members of their team; empowering staff to achieve more in their professional career, introducing initiatives and incentives which create a positive working environment, or providing benefits or support mechanisms which encourage a happier healthier life for employees.

“The brewing sector is an incredibly hands-on and collaborative industry and the wellbeing of employees is at the forefront of all successful brewing businesses. This new award seeks to highlight the breweries in the UK who are not only supporting their staff but helping them to have a happier, more successful working life,” said Neil Walker, SIBA head of Comms.

The SIBA Business Awards seek to congratulate excellence in the brewing industry across a variety of categories, from pump clip, can and bottle design, to efforts taken by brewers to make their business more sustainable, innovative or successful, as well as naming the UK’s best pubs, bars and retailers of craft beer from independent breweries.

Christian Barden, UK & Europe CEO of Konvoy, which is sponsoring the new Empowering People Award as well as the overall Brewery Business of the Year award for 2023, said: “I’m really proud to be supporting SIBA’s new award for Empowering People. Having been part of and built businesses across various organisations and continents it’s always empowered people that are encouraged to dream and work together with mutual trust and respect that create long term success stories. It’s so easily forgotten when the pressure is on but that’s actually when it matters most.

“High performing teams are always about smiling faces and great results, and that’s the environment we’ll keep building at Konvoy. It all comes down to empowerment at every level, which is what my leaders create for me too. I look forward to seeing the great entries from breweries across the UK that are striving to do the same.”

The new categories introduced last year for the “UK’s Best Independent Craft Beer Retailer – Online”, “UK’s Best Independent Craft Brewery Webshop” and “Community Engagement” will also return for the 2023 Awards following huge interest from the industry.

“The SIBA Business Awards have evolved in response to changing consumer habits over recent years, as more people look to purchase beer online or discover their local brewery taproom. Independent craft breweries are embedded in their local communities and these awards highlight the businesses doing it better than anyone else in the UK.” Neil added.

The SIBA Business Awards 2023 are judged by a panel of industry experts and presented at the UK’s biggest beer and brewing event – BeerX UK in Liverpool, March 2023.

For more information about the awards or to find out how to enter visit www.siba.co.uk/businessawards

Official Category Criteria

Marketing Implementation

For all aspects of effective marketing and communication strategy, including general or specific campaigns, promotions, PR, social media activity, product launches etc.

Entries must stand out from the crowd for marketing initiative, effective communication, a PR opportunity seized, or imagination and creativity deployed in the increasingly competitive virtual world of social networking.

Sustainable Business

For taking the ethics of environmental awareness and sustainable business operation way beyond the norm, with either a single innovative initiative or a holistic strategy for sustainability.

Entries must show how measures implemented in the brewery, such as production processes, energy economies, recycling and packaging, are minimising environmental impact to the benefit of both brewery and community.

Community Engagement

This award highlights breweries who have shown an outstanding commitment to engaging with their local community, supporting local initiatives, or raising money for charitable causes through events and fundraisers.

Entrants should demonstrate how the brewery is integrated into and supports the local community; either through a single successful initiative or a range of activities which engage local people.

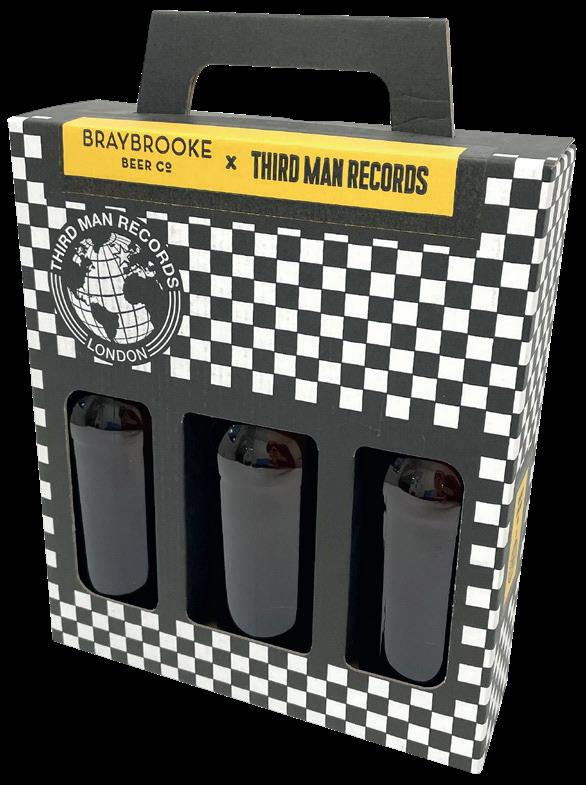

Individual Design

For a single design of bottle, can or pump clip that clearly stands out, gains point-of-sale market advantage and ultimately drives the purchase of a brewery product.

Strong traditional designs are welcome, but entries are also sought for contemporary and original artwork that puts a brewery’s beers at the forefront of the evolution of point-of-sale as an essential marketing tool.

Multiple entries from a brewery are welcome, but should be entered separately and any entries which contain a range of designs within a ‘concept’ or ‘brand’ should be entered into the Total Concept Design Category below.

24 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk

SIBA Business Awards 2023

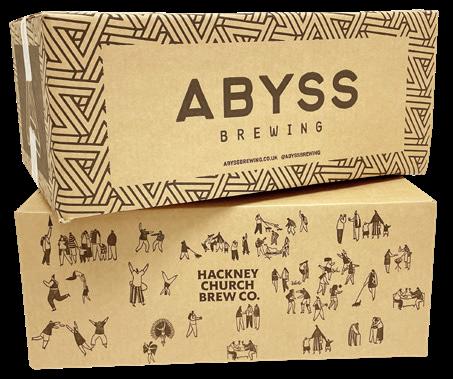

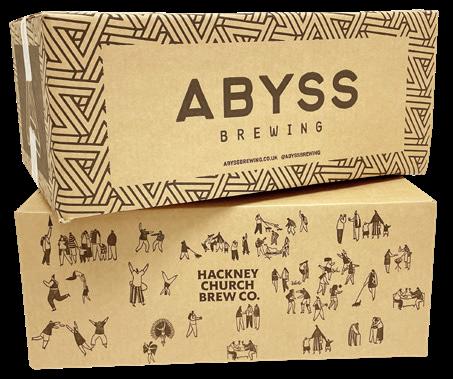

Concept Design

For the design concept behind a range of beers from a brewery, or a brewery’s entire branding and design strategy. Entries must provide details of all aspects of the design concept and how it creates a distinct market identity, setting the brand apart in an intensely competitive field.

Business Innovation

For breweries that have shown true innovation in their business. This could be anything from a bold export operation getting beer in to the hands of new consumers or an internal innovation which has improved efficiency or profitability. This broad category should be entered by any brewery who believe they have done something innovative within the industry.

Commercial Achievement

The commercial achievement award should be entered by breweries that have experienced commercial success in one or all areas of their business. Whether it is a brewery starting from scratch or an established brewer expanding their reach, the commercial achievement award aims to highlight the most business savvy from our industry.

UK’s Best Independent Craft Brewery Taproom

For Taprooms which are located within, or in very close proximity to, working independent craft breweries.

Judges will be looking for an extraordinary commitment to serving the best quality and range of independent craft beers (including cask, keg, bottles or cans) in a welcoming and attractive environment.

This award is specifically for Brewery Taprooms and not for ‘Brewery Tap’ pubs or off-site ‘Taprooms’ not located within or near to the owner brewery. If you are a brewery with an off-site Taproom or Brewery Tap pub then you can enter this into the relevant Best Independent Craft Beer Bar or Pub category.

UK’s Best Independent Craft Brewery Webshop

This new award names the UK’s best independent craft brewery webshop. Entries should demonstrate how the brewery webshop offers a positive user experience, intuitive and attractive design, and of course excellent customer service.

This award is open only to webshops run by independent craft breweries on their own website, and is not for online retailers (for this see retailer category below).

UK’s Best Independent Craft Beer Retailer – Multiple

UK’s Best Independent Craft Beer Bar or Pub – City

For pubs or bars which have shown an extraordinary commitment to serving the best quality and range of independent craft beers (including cask, keg, bottle or can). This award is specifically for pubs or bars located in urban, city, town centre, or suburban locations across the UK.

UK’s Best Independent Craft Beer Bar or Pub – Rural

For pubs or bars which have shown an extraordinary commitment to serving the best quality and range of independent craft beers (including cask, keg, bottle or can). This award is specifically for pubs or bars located in rural, village, or isolated locations across the UK.

Best Independent Craft Beer Promotion

This award is for breweries, contentproducers, agencies or other businesses within the beer industry who have shown innovation and success in promoting beer to either consumer or trade audiences.

Empowering People

This award highlights independent craft breweries who go above and beyond for the members of their team; empowering people to achieve more in their professional career, introducing initiatives and incentives which create a positive working environment, making efforts to promote diversity and inclusivity, or providing benefits or support mechanisms which encourage a happier healthier life for employees.

This award seeks to congratulate breweries who put their team well-being at the heart of their business.

For independent retailers selling beer from multiple locations. Entrants can be specialist craft beer shops, or businesses which have recently shown a commitment to promoting independent craft beer, but must be an independent business with fewer than 10 outlets.

UK’s Best Independent Craft Beer Retailer – Single

For independent retailers selling beer from a single location. Entrants can be specialist craft beer shops, or businesses which have recently shown a commitment to promoting independent craft beer, but must be an independent business trading from a single location.

UK’s Best Independent Craft Beer Retailer – Online

For independent retailers based in the UK selling beer online. Entrants can be specialist craft beer retailers, or online retailers which have recently shown a commitment to promoting independent craft beer, but must be an independent business.

(Please note this award is not for brewery webshops, which have their own separate award above).

This award is looking for the UK's best beer festivals, video or audio beer content, tutored beer tastings, hosted beer events (in-person or online), or other promotions of beer via apps, point of sale, or any other means which have the aim of promoting independent craft beer in the UK.

Supplier Associate of the Year

This award seeks to highlight the UK’s best SIBA Supplier Associate and is SIBA Brewing Member nominated.

From brewing ingredient suppliers and brewery fabricators, to business consultants and agencies, The Supplier Associate of the Year is a company which has shown a real understanding of brewery needs and actively supported independent craft brewing businesses throughout the year.

SIBA Brewery Business of the Year

This judges’ choice award is the top prize at the SIBA Business Awards and is presented to the brewery who have, across a variety of areas, shown themselves to be running an outstanding brewing business which sets themselves apart from the competition.

25 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 SIBA Business Awards 2023

NEW ! Cover Story

People Issue 12 Winter 2022

Empowering

SBR @20

Highlights from SIBA’S SBR 20th anniversary report

It has been 20 years since the introduction of Small Breweries’ Relief (SBR), and to mark this momentous anniversary SIBA produced a report on the background to this industry-changing piece of legislation and how it has shaped the evolution of the UK’s craft beer scene since. Here we bring you some of the highlights from the report, but to read it in full go to: www.siba.co.uk/wp-content/uploads/2022/10/SBR@20-Report-2022.pdf

How the campaign for SBR began

This SBR report celebrates 20 years of a revolutionary beer duty system but the story of Sliding Scale (SS) which became Progressive Beer Duty and was renamed Small Breweries’ Relief, starts over 20 years before its introduction. In fact, SS was the main reason SIBA was formed by the “father” of micro brewing, Peter Austin, and a handful of compatriots.

Through the 80s the concept of a progressive beer system developed mainly as a result of us responding to the probing of MPs. From “it's great idea” through “how much will it cost and who will have it?” This showed the need to create a workable system. However, our naïve attempts did have one effect: it was recognised as a concept in the Monopolies investigation into “The Supply of Beer” in 1989 which resulted in the industry shattering “Beer Orders”. These frustratingly did not include our dream. But what would a scheme look like? We needed to find a structure so I started looking and thinking. The start was the EU laws surrounding the coming of the single market in 1993. We were intimately involved in the creation of the laws surrounding the calculation of beer duty and with those consultations we built a trust with HM Customs and Excise. In fact, we agreed a duty structure which was quite contrary to that which the national brewers wanted. It was a major step to changing the balance of power in the industry.

These discussions lead me to realise that any type of scheme would have to reflect the parameters allowed within EU law. These were written in such a way to allow great flexibility so I set about trying to devise a scheme suitable for the UK which would naturally benefit the little guys! After many months of fruitless thinking I had the “Eureka” moment: there was one thing that the EU laws did not prevent: they did not prevent breweries being given a base discount even if they were very much bigger. So, I had the concept. It was then a matter of maths, fiddling around with production levels and percentage discounts. With a solid scheme we would be able to see the real cost and have a workable system to present to government.

So, why was PBD so important? Well, I started my brewery in 1982 and it was so very difficult to sell beer then. Why? Well, first of all the idea of small local breweries was in its infancy and so there was little palpable demand from the customer so no pressure on a licensee to stock an unknown beer. More important though was the simple fact that every new account opened was descended on by beer reps who basically had all the discounting powers available to keep us new brewers out of the market which was dominated by the tied house system. This severely limited where we could sell beer: for years we were chasing our tails just to survive and facing monthly beer duty bills which we would have to fund ourselves as it was a production tax and not a sales tax. Indeed those days were pre-credit cards so everything had to be cash! In that time so many people started up and failed as the dice were loaded against them. I used to say, I went bust several times but had

a hopeless accountant who never noticed much less told me!

We failed to get a progressive beer system in place through the 90s despite constant campaigning as the Conservative governments and especially their MPs received huge funding from the beer industry: this is detailed in Lord Young's 1990 autobiography.

But in May 1997 the political landscape changed with the coming of a new Labour government with whom we had been discussing PBD whilst they were in Opposition. They were great if frustrating years and many contributed along the way who need mention of but you have the bones of the campaign. We still had to wait for another three years until we learnt that the concept had been accepted and a further two before we could celebrate its introduction. Let the revolution continue!

Dave Roberts is a former SIBA Chairman

26 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk SBR@20

RELIEF: 20TH ANNIVERSARY SBR @20

SMALL BREWERIES’

The need for SBR

The acute problems that faced small brewers were brought home to me in 2002 when Martin Kemp, who ran the Pitfield Brewery in North London, told me he was closing the plant. The cause was not one that faced bigger brewers: his van had broken down, he couldn’t afford to repair it and as a result couldn’t deliver to pubs.

The loss of Pitfield would have been a disaster. Back in 1987, when it was run by Martin with his partner Rob Jones, it had won the Champion Beer of Britain top award with its Dark Star ale. It put not just Pitfield but the whole of the small brewers section in the spotlight and proved that minnows could brew just as good beer as regional and national producers.

Around the same time, when I went to Nottingham to write a piece about the Castle Rock Brewery, managing director Colin Wilde greeted me in his office and said: “I’ll just sign this cheque to HMRC and then we can chat.” I looked over his shoulder and winced at the eye-watering amount of money he was signing away.

“Is that a year’s duty?” I asked. Colin laughed. “You must be joking – that’s one month’s.” He agreed he had to make and sell a lot of beer before he could start to make a profit.

And then came the momentous announcement in 2002 from Chancellor Gordon Brown that he was introducing Progressive Beer Duty that would give small brewers a much-needed tax break: “It will mean cheap beer in time for the World Cup!” he said to cheers from all sides of the Commons. It was a typical piece of politicians’ hyperbole but nevertheless it did mark a breakthrough for small independent brewers. It was the culmination

of their long campaign for a duty scheme that would recognise how they struggled to survive in a beer market dominated by big brewers and their famous “economies of scale”.

PBR as it was first known had been a long, hard struggle. Back in 1980 I had been invited by Peter Austin, known as the father of craft brewing in Britain and founder of Ringwood Brewery, to attend a meeting in an East London pub. The idea was to set up an organisation that, among other aims, would argue the case to government for lower rates of duty for small producers.

As a non-brewer I was there to offer advice on press relations. From that event came a series of meetings with politicians and civil servants to discuss excise duty and the particular problems faced by small producers in a market increasingly dominated by national and global brewers.

Economies of scale means more than just ultra-efficient, spick-and-span modern breweries controlled by computers. Big brewers are able to use their muscle to buy raw materials such as malt and hops at discounts small brewers can only dream about. It’s estimated that when AB InBev, the world’s beer colossus, bought Modelo in Mexico it stripped 20 per cent of production costs from the company. The result – as any visit to a supermarket will prove – is that the products of the global giants can be sold as cheaply as bottled water.

PBR is one of the most significant events in British brewing history. In the 1970s a consumer revolt against big brewers and their infamous keg beers led to CAMRA and a halt to takeovers and mergers that were destroying choice. CAMRA also opened up the market, allowing a new breed of small brewers to fire their mash tuns and coppers and, most importantly, to innovate and

offer fresh and exciting beers alongside standard mild and bitter.

It was the early members of SIBA who introduced the first Golden Ales that changed the image of beer for younger drinkers and challenged the hegemony of over-promoted British apologies for genuine lager.

The introduction of PBR, later called Small Breweries’ Relief, allowed a small army of mustard-keen brewers – some former homebrewers, others refugees from bigger producers – to set up shop and offer a wider variety of beers to thirsty drinkers. I was a close observer: as editor of the annual Good Beer Guide, I had to shoe-horn all brewers into its pages. In 2000, the guide ran to 600 pages, now it’s close to 1,000 with most of the space taken up by brewers, who number more than 1,800.

As we celebrate the success of SBR we are also keenly aware of the challenges that lie ahead. With pubs and breweries closing as a result of the ravages of Covid and lockdown, the industry needs more support. Crucially, a steep cut in duty for all draught beer is needed to encourage consumers to return to pubs.

But as we raise a glass to salute such pioneers as Dave Roberts, Keith Bott, Carola Brown and the other SIBA pioneers, we can measure their achievements by going to a freetrade pub or beer festival, looking along the line of pumps and saluting the remarkable choice they have made possible.

Roger Protz is a writer, journalist and campaigner and former editor of CAMRA’s Good Beer Guide

27 www.siba.co.uk | SIBA Independent Brewer | Winter 2022

SBR@20 Continued on page 29

28 Winter 2022 | SIBA Independent Brewer | www.siba.co.uk Quality assured performance guaranteed IMPROVE PRODUCT QUALITY REDUCE PROCESS COST IMPROVE PROCESS EFFICIENCY REDUCE BEER LOSSES www.abvickers.com | abvickers@lallemand.com KETTLE FININGS Compac CG, Breakbright tablets YEAST NUTRIENTS Yeastlife O, Yeastlife Extra, Servomyces BEER CLARIFICATION Proto ne, Protosol, Vic ne, Liquid Isinglass, Alpha oc Paste FOAM STABILISERS Drifoam, Foamaid, Allfoam PVPP/SILICA GELS Alphaclar (PVPP), Britesorb (Silica hydrogel) ENZYMES Betaglucanase, Alpha amylase, ALDC, Aromazyme ANTI FOAMS Foamsol ANTI- OXIDANTS Vicant

The long campaign for SBR is won

Twenty years after Small Breweries’ Relief (SBR) was introduced, with more than 10,000 people directly employed by breweries and another 33,000 in a supply chain that didn’t exist before, I think it is fair to say the policy has been a success.

In 2002, as I drove to the Maltings Beer Festival I received a call from Damian McBride from Her Majesty’s Treasury, letting me know that the nigh on 20 year campaign for SBR, then called Progressive Beer Duty, had been successful and apologising for the way in which it was going to be announced. The Chancellor Gordon Brown then revealed in his budget that beer duty would be halved for smaller brewers which meant that

customers would enjoy cheaper beer during the upcoming World Cup. I remember feeling numb, after campaigning tirelessly for such a long time I couldn’t take in the enormity of what we had achieved. Dave Roberts was the architect of the scheme, Peter Haydon had done a huge amount of work and Nick Stafford was finding practical ways to supply beer to pubcos, challenging the tied model. Between us, along with all the trustees of SIBA, we had successfully convinced Government that investing in smaller breweries was not only worthwhile but would go some way to improving access to a market that was becoming even more foreclosed.

We had spoken to countless politicians, swathes of Customs and Excise officials, travelled to Brussels at the behest of John Bridgman the then head of the Office of Fair Trading (OFT), who recognised our plight and brought pressure to bear on our behalf, and pulled as many publicity stunts as we could think of.

So why, in 2002, were we successful? In his book Damian McBride describes the success as “my finest hour as a civil servant”. He had coached us, worked behind the scenes to garner political support and seen off what he described as “the slick lobbyists representing the big companies” all to make a point and to spite officials who resisted change. Add to this John Healey’s appointment as Economic Secretary to the Treasury, John has always been a huge

2019 there were over 100 members of the LBA, the vast majority of which were independently owned. It seems clear that this exponential growth was a direct result of the introduction of SBR in 2002 and led to the extensive innovation that came with the explosion of new breweries.

supporter of beer and pubs and recognised the levelling of the playing field that SBR offered.

Looking back it wasn’t our amazing lobbying nor our political nous that had won the day, it was a great big helping of serendipity and, most importantly, we sang from the heart, were passionate about creating a fairer system, pragmatic in what we called for and eternally positive. At no point did we ask for others to foot the bill, we avoided bad mouthing others in our industry or sector and we spelt out how the investment would benefit all.

Now 20 years on, as I look at an independent brewing industry thriving, with opportunity for all, large and small, that employs huge numbers of incredibly passionate people who care about what they consume and how it’s made, that sits at the beating heart of communities and that continues to challenge and innovate, I am hugely proud of what we achieved. The fight isn’t over, tough times lie ahead, we are still fighting to access the market and the price differential between the on- and the off-trade continues to make sofas more appealing than bar stools, but if SIBA stays focussed on finding pragmatic solutions, challenges woefully thought through legislation and champions Great British Beer we have hope.

Cheers

Keith Bott is owner of Titanic Brewery and a former SIBA Chairman

"SBR gave Abbeydale Brewery the confidence to invest to grow from a hobby business, employing just two people besides myself, into the thriving brewery it is today - now employing around 50 people across the brewery and our pub."

Patrick Morton, Abbeydale Brewery

The brewer’s perspective

As a new brewery founded in late 2012, Small Breweries’ Relief had created an environment in which we and many other small start-up breweries could launch and flourish. Without the SBR subsidy in beer duty, it is unlikely that we would have been able to overcome the significant barriers to entry into the sector.

The brewing scene we entered into in London was changing rapidly: by the end of 2012, there were 35 brewing members of the London Brewers Alliance (LBA), up from around 15 in 2010, and it felt like we were arriving late to the party. This boom in breweries continued and by

It is safe to say that without the duty relief available to us as a small brewery it would have been much harder, if not impossible, to get Five Points off the ground in the first place. We enjoyed four years of the full 50% relief available which allowed us to invest in additional capacity and more efficient equipment, and moreover grow the business in a sustainable manner. As a communityfocused brewery, we were also able to create employment opportunities in the local area, become the first Living Wage accredited brewery, help to set up an apprenticeship scheme with Hackney Community College and Hackney Council, and generally contribute to the economy.

I struggle to believe that without the introduction of SBR we would have the same thriving beer scene that we do today, with the expansive range of beer styles brewed by independent breweries across the UK - something that all beer drinkers should be grateful for!

Greg Hobbs is Director of Brewing at The Five Points Brewing Company

"Would we be here without SBR? No. Would we be able to offer beers to pubs without SBR? No. Would the British beer scene be better without it? NO!"

Tony Pygott, 8 Sail Brewery

"This is our brewery's 25th anniversary year. This means that we spent 5 years trying to compete against the largest breweries in the country while paying a full rate of duty. No matter how hard we pushed, we struggled to build momentum without eating up all our profit. After SBR was introduced, we had cash to invest immediately in extra casks and vessels - after 5 years we could expand and take on staff. I cannot emphasise enough the way that it changed our business."

Christopher Gooch, Teme Valley Brewery

"It was a great idea when introduced in 2002 and initially helped many breweries, like Hogs Back, who were established in 1992. However the design was not well thought through and it needed an initial change in 2003 to address a catastrophic short term cliff edge, and should have been reviewed again 5 years later when it became evident that it was acting both as an encouragement to market entry but a constraint on growth past the artificial 5,000 hectolitre barrier. The new proposals are much better and will help business growth, but it is very frustrating that it has been delayed until the summer of '23, rather than February. But at least there is a firm commitment to positive reform and the whole Industry can reunite to focus on how to save the cask ale sector."

Rupert Thompson, Hogs Back Brewery

29 www.siba.co.uk | SIBA Independent Brewer | Winter 2022 SBR@20

Continued on page 31

Great beer needs a filler that ensures the highest product quality. Especially for small and medium-sized breweries, our compact fillers offer the same innovative technology as larger KHS fillers. In addition, KHS stands for maximum reliability, keeping lines running steadily at a very high level – supported by our dependable on-site service. Our filling systems are available for all types of bottles, cans, and kegs. Would you like to know more? Please contact us at www.khs.com

DESERVE THE BEST FILLING SYSTEMS.

KHS brings state-of-the-art technology to craft breweries.

The future of SBR and craft beer