An Exclusive Dive into Rootstock Software's Vision and Impact With Stu Johnson — Vice President of Product Marketing at Rootstock Software The Value of the Cloud for Manufacturing ERP Anatomy of a Tailstock Rebuild-Repair Inspection, analysis, engineering execution, and inventory back-up are in the mix for Riten Industries’ downtime maintenance formula. Murata Machinery USA Celebrates 50 Years of Automation in North America Taming Unruly Metals: No Problem for Kasto Saws Leifeld presents new machine for the production of robust hydrogen tanks Those Who Adapt The Fastest Win Radwell.com UNWANTED INVENTORY TAKING UP VALUABLE SPACE? Radwell.com purchases industrial automation product BENEFITS -Lower warehousing costs - Increases cash flow -Liquidate aging inventory -Liquidate slow-moving inventory -Eliminate used or overstock inventory -Increases warehouse space -A better option than placing it in a dumpster -Go Green Selling your surplus inventory to us gives you a financial return on products you’d normally pay to have it disposed of. Radwell’s Asset Recovery Service always provides FREE freight service for your surplus stock. hether you have one facility or multiple our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars SELLING TO US IS AS EASY AS Gather it 1. 2. 3. Box it Arrange free pick up Radwell.com - 800.884.5500 - sellto@radwell.com 5/22/2020 4:20:26 PM Whether you have one facility or multiple facilities, our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars to your bottom line. BENEFITS • Lower warehousing costs • Increases cash flow •Liquidate aging inventory • Liquidate slow-moving inventory • Eliminate used or overstock inventory • Increases warehouse space Radwell.com Radwell.com UNWANTED INVENTORY TAKING UP VALUABLE SPACE? Radwell.com purchases industrial automation product BENEFITS -Lower warehousing costs - Increases cash flow -Liquidate aging inventory -Liquidate slow-moving inventory -Eliminate used or overstock inventory -Increases warehouse space -A better option than placing it in a dumpster -Go Green Selling your surplus inventory to us gives you a financial return on products you’d normally pay to have it disposed of. Radwell’s Asset Recovery Service always provides FREE freight service for your surplus stock. hether you have one facility or multiple our Asset Recovery program is an exceptional resource for your company. We offer cash for parts and products you don’t need. In many cases, selling your excess inventory to Radwell gives you the opportunity of adding dollars SELLING TO US IS AS EASY AS Gather it 1. 2. 3. Box it Arrange free pick up Radwell.com - 800.884.5500 - sellto@radwell.com 5/22/2020 4:20:26 PM Radwell-FC-01-2022.indd 1 12/16/21 3:32 PM IndustrialMachineryDigest.com | March 2024 North America’s Manufacturing Resource for Industry Professionals Since 1986

Highly

LENZKESUSA.COM | 540-381-1533 | INFO@LENZKESUSA.COM THE QUICK ROUTE TO FLEXIBLE WORKHOLDING SPARE PARTS & ACCESSORIES MULTI-QUICK SERIES CHAIN CLAMP MULTI-QUICK SERIES SELF-CENTERING VISE Clamping solutions for all types of machines

clamping pressure for small clamping torque

Strong

adjustable through integrated sliding plate

clamping, short set-up time, quick release action

adjustability horizontal and vertical Our MQ Series may be used as an extension to the machine plate THE LENZKES DIFFERENCE: OVER 100,000 SATISFIED CUSTOMERS WORLDWIDE, LENZKES IS RENOWNED FOR ITS HIGH-QUALITY WORK-HOLDING SOLUTIONS 45

Fast

Step-less

4 | IMD March 2024 8 EDITORIAL DIRECTION 10 INDUSTRY NEWS 18 BUSINESS 4.0 The Value of the Cloud for Manufacturing ERP By: Andrew MacMillen 20 TALKING SHOP An Exclusive Dive into Rootstock Software's Vision and Impact With Stu Johnson — Vice President of Product Marketing at Rootstock Software 24 SAFETY & MAINTENANCE Anatomy of a Tailstock Rebuild-Repair Inspection, analysis, engineering execution, and inventory back-up are in the mix for Riten Industries’ downtime maintenance formula. By: Kent Hizer, Riten Industries, Inc 26 MANUFACTURING SHOWCASE Murata Machinery USA Celebrates 50 Years of Automation in North America 28 INDUSTRIAL AUTOMATION Taming Unruly Metals: No Problem for Kasto Saws 30 WORKFORCE DEVELOPMENT ProShop ERP Partners with Purdue University's Industrial Engineering School to Revolutionize Manufacturing Education 32 NEW TECHNOLOGY Leifeld presents new machine for the production of robust hydrogen tanks 34 PROCESS Welding for a Better Climate 38 INDUSTRY INSIGHT Those Who Adapt The Fastest Win 40 PRODUCT SHOWCASE 47 SURPLUS BUYING & SELLING 49 CLASSIFIEDS 50 ADVERTISER INDEX March 2024 20 18 28 32 ON THE COVER cover Sponsor: radwell cover Image: Fronius TABLE OF CONTENTS

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

additional to air tools, we offer accessories and abrasives for complete process solutions with the know-how to get the

right.

about a no-obligation demonstration on any

in our line. ABRASIVE POWER TOOLS & PROCESS SOLUTIONS SINCE 1969 AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS WE LISTEN. WE OBSERVE. WE INNOVATE. Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com |

In

job done

Ask

product

North America’s Manufacturing Resource for Industry Professionals Since 1986

William c. Strickland III, Publisher william.strickland@indmacdig.com 800-366-0676 ext. 103 | Fax: 866-826-5918

adrienne Gallender, associate Publisher/Media advisor agallender@indmacdig.com 847-612-1572 | Fax: 847-559-2909

Brian Self, associate Editor brian@indmacdig.com 800-366-0676 ext. 104 | Fax: 866-826-5918

Shane Bell, creative Director sbell@indmacdig.com

SALES

Lisa hanschu, Sr. account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William c. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS

Susan Strickland, accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B hwy 31 South, Suite 233, Pelham, aL 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com

6 | IMD March 2024

source media llc 360 A PUBLICATION OF: Source 360 Media LLC 3590-B hwy 31 South PMB #233 Pelham, aL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individuals. Publisher reserves the right to reject nonqualified subscribers. One-year subscription to nonqualified individuals in the United States: $96.00. Single copies available (prepaid only) $20.00 each. Alabama Automotive Manufacturers Association

Tool Cabinet You Will Ever Buy GUARANTEED 100%MADE IN THE USA INEVERY WAY WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 MADE BY AMERICAN CRAFTSMEN IN THE USA sales@storloc.com

The Best

a s we welcome the rejuvenating energy of spring, our March issue is infused with themes of innovation, sustainability, and the evolution of manufacturing processes. This edition of Industrial Machinery Digest is crafted to navigate the intersections of tradition and technology, reflecting on how the industry's past informs its future.

andrew MacMillen's exploration into cloud-based ErP solutions marks a pivotal shift towards efficiency and competitiveness in "Business 4.0", emphasizing the delicate balance between embracing new technologies and optimizing existing operations. This narrative of adaptation and advancement threads through our exclusive interview with Stu Johnson of rootstock Software, where we delve into how cloud ErP systems are not merely tools but catalysts for growth and innovation in manufacturing.

Our focus on "Safety Maintenance" and the pioneering work of riten Industries in tailstock rebuild-repair underlines the critical importance of maintenance, repair, and the strategic management of downtime in preserving machinery life and ensuring operational continuity.

celebrating milestones and embracing future challenges, we spotlight Murata Machinery USa's 50th anniversary of automation excellence in North america. This feature story is a testament to the enduring impact of innovation and leadership in transforming the automation landscape.

Further, we highlight the partnership between ProShop ErP and Purdue University's Industrial Engineering School, a collaboration poised to revolutionize manufacturing education by equipping students with the tools and knowledge for the future of smart manufacturing.

Introducing new technologies, we present Leifeld's advanced machine for the production of hydrogen tanks, showcasing the industry's commitment to safety, flexibility, and sustainability. Similarly, the "Process" section, with a focus on heizomat Gerätebau + Energiesysteme Gmbh, illustrates how modern welding techniques are contributing to environmental sustainability.

concluding with an insight into the industry's adaptability, we explore how innovations like the TKX changer series are making automation more flexible, ensuring that manufacturers can stay competitive in a rapidly evolving marketplace.

This issue is a mosaic of stories that together paint a picture of an industry at the cusp of a new era, where tradition meets innovation, and challenges beckon solutions. Thank you for joining us on this journey, and we look forward to continuing to bring you the insights and stories that shape our industry.

SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS

SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS

William Strickland THE BEST ADVICE I CAN GIVE YOU IS TO SUBSCRIBE TO NEWSLETTERS! Business & Workforce Development Fabrication & Manufacturing Showcase Products & New Technology Industry Insight, Safety & Maintenance Manufacturing Process & Automation

What’s in YOUR InBox?

William Strickland THE BEST ADVICE I CAN GIVE YOU IS TO SUBSCRIBE TO NEWSLETTERS! Business & Workforce Development Fabrication & Manufacturing Showcase Products & New Technology Industry Insight, Safety & Maintenance Manufacturing Process & Automation

What’s in YOUR InBox?

8 | IMD March 2024 EDITORIAL DIRECTION

William Strickland Publisher, IMD www.IndustrialMachineryDigest.com

SHEARS & PRESS BRAKES

Hydraulic Shears:

1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com

MADE IN THE USA

6K recognized on Global cleantech 100 for Second Year in a row

6K, a leader in the production of advanced materials for batteries and additive manufacturing, has been recognized on the 2024 Global cleantech 100 list for the second consecutive year. The Global cleantech 100 showcases the top private companies in the cleantech ecosystem, highlighting innovators with promising technologies and business models addressing the climate and environmental crisis. 6K's inclusion is primarily attributed to the success of its UniMelt® Microwave Plasma Production Platform, a sustainable, production-scale microwave plasma process that significantly enhances the production of metal additive manufacturing powders and battery materials. This technology offers a cleaner, faster alternative to traditional processes, reducing carbon emissions and production times dramatically. The recognition also builds on 6K's recent achievements, including a $50 million award from the US Department of Energy for its PluscaM battery material production plant and a $23.4 million grant for upcycling critical metals. cleantech Group cEO richard Youngman lauded 6K as a leader driving positive change towards a sustainable future. The report underscores the importance of digitalization, decarbonization, and resource efficiency in building a cleaner industrial future.

allison Transmission awarded $83.3 Million contract for abrams Tank Modernization

allison Transmission has received an $83.3 million contract to supply upgraded and new X1100 transmissions for the abrams Main Battle Tank variants used by the U.S. army and Foreign Military Sales customers. This contract, spanning January to December 2024, aims to meet the performance demands of the abrams tanks, combining new technology

with existing hardware for a cost-effective, zero-mileage transmission solution. The upgrade supports the abrams System Enhancement Package version 3 tanks, ensuring the tank remains the world's most capable battle vehicle. This contract highlights allison's long-standing commitment to quality, reliability, and innovation, supporting U.S. army readiness and performance objectives while continuing its history of excellence in defense programs.

Beckhoff USa Promotes

alec abkemeier to Software Product Manager

Beckhoff USa has promoted alec abkemeier to Software Product Manager, focusing on test and measurement technologies. With a strong background in measurement software and hardware, abkemeier's role will enhance Beckhoff's market share in industries requiring advanced data acquisition

10 | IMD March 2024 INDUSTRY NEWS Industrial Machinery Digest's Industry News features the latest news and press releases from some of the industry's top companies. WANT TO BE FEATURED? Send your press releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com INDUSTRY

NEWS

Allison Transmission Awarded $83.3 Million Contract for Abrams Tank Modernization

Alec Abkemeier

OPTIMIZE YOUR WORKSPACE SAFETY FIRST Available in both CHAIN & CABLE Configurations Customizable height and reach to best fit your space. Ergonomic positioning for easy low strain use. Create a safe, efficient work environment. The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com

and power monitoring. his responsibilities will include product ownership for TwincaT 3 LabVIEW™ Interface software and involvement with other high-speed, high-accuracy measurement technologies. Prior to this role, abkemeier contributed significantly to Beckhoff's test and measurement applications through his expertise in automation engineering and LabVIEW™, positioning him to lead Beckhoff's innovations in test and measurement solutions.

Flexxbotics and Zaptic Win hexagon’s Third ‘Sixth Sense’ cohort

hexagon’s Manufacturing Intelligence division has announced Flexxbotics and Zaptic as winners of its third ‘Sixth Sense’ cohort, a program for advanced manufacturing startups. Following an intense competition, these companies were selected for their solutions in workcell digitization and connected manufacturing worker platforms, respectively. The winners will gain access to hexagon's resources for global expansion, including potential funding and visibility on hexagon's Nexus platform. This initiative is part of hexagon's commitment to fostering innovation in automation and productivity within the manufacturing industry, supporting startups in addressing automation and digital transformation challenges.

Vention and Flexxbotics Partner for advanced robotic Machine Tending

Vention and Flexxbotics have announced a partnership to offer a combined solution for robotic workcell digitalization, particularly in machine tending within machining environments. This collaboration integrates Flexxbotics’ advanced robot machine tending solutions with Vention’s Manufacturing automation Platform, enabling customers to design and deploy efficient, tailored automation solutions. The partnership aims to address challenges such as production reshoring, labor shortages, and salary inflation by providing turnkey automation solutions. With Flexxbotics’ expertise in workcell digitalization, this partnership promises to enhance productivity and enable "lights out" manufacturing through advanced robot-driven process control and optimization.

E-Drive Days Event by Gleason: revolutionizing

E-Drive

Gear Design, Manufacturing,

and Inspection Gleason corporation announces its special online event, E-Drive Days, scheduled for March 11-14, 2024. This four-day event is designed to educate participants on the intricacies of designing, manufacturing, and inspecting e-drive gears, with a special focus on minimizing gear noise—a critical concern in e-drive transmissions. Each day is dedicated to a unique aspect of e-drive technology, offering both newcomers and experts valuable insights into overcoming the specific challenges of e-drive transmission design, manufacture, and inspection.

The event will delve into the complexities of gear design for e-drives, highlighting how gear geometry,

modifications, and manufacturing deviations can address individual requirements. It will also explore strength calculation nuances due to frequent torque direction changes and the importance of noise excitation calculation for NVh (Noise, Vibration, and harshness) analysis and gearbox optimization.

Manufacturing technologies and processes tailored for e-drive gears will be showcased, including hobbing, chamfer cutting, shaping, Power Skiving, threaded wheel grinding, and gear honing. Innovations such as hard Power Skiving and Polish Grinding will be presented to highlight advancements in soft machining and hard finishing of e-drive gears.

The third day will focus on gear metrology, with experts discussing the latest hardware and software solutions for accurate gear noise measurement and analysis. This includes understanding the sources of gear noise and showcasing tools for real-time inspection and quality monitoring in the production flow.

concluding the event, Gleason will introduce the coniflex® Pro design and manufacturing system, specially suited for e-drive differentials requiring higher strength and reliability. This system, part of the GEMS® design software suite, offers sophisticated FE a analysis tools for comprehensive strength analysis of gears.

E-Drive Days aims to provide a comprehensive learning experience with three sessions each day, accommodating participants from different regions. registration and more information are available at www. gleason.com/edd24.

hWarobotics advances North american E-commerce with cutting-Edge aSrS Technology for Darwynn hWarobotics is making significant inroads into the North american market by providing Darwynn, a canadian e-commerce fulfillment specialist, with its advanced shuttle automated Storage and retrieval System (aSrS) technology. This collaboration aims to enhance order fulfillment operations at Darwynn's Toronto facility, showcasing a multi-level shuttle system designed to streamline logistics and inventory management.

The system, which boasts 24 carts, 10,368 storage locations, and 6 goods lifts, is engineered to handle 20,000 individual SKUs, increasing throughput to 2,400 bins/hour. This implementation marks a significant step in Darwynn's business expansion, addressing the growing demand for efficient, scalable, and sustainable logistics solutions.

12 | IMD March 2024

hWa robotics' technology is celebrated for optimizing inventory management, enhancing operational efficiency, and expanding storage capacity, all while reducing business costs and error rates. The integration of this shuttle a SrS system into Darwynn's operations exemplifies the future of intelligent logistics, promising enhanced service quality and reliability for e-commerce platforms.

This partnership not only solidifies hWa robotics' position in the North a merican logistics market but also underlines the company's commitment to innovation and customer success. With plans for further expansion and a focus on providing comprehensive post-sales support, hWa robotics is poised to transform the logistics and warehousing industry across North a merica.

hypertherm associates celebrates the Production of the 10,000th Ma XPrO200 System

hypertherm a ssociates, a leader in industrial cutting systems and software, recently announced the assembly of its 10,000th Ma XPrO200® plasma cutting system. This milestone is attributed to the widespread adoption of the Ma XPrO200® by manufacturers and fabricators globally, who rely on its high productivity, robust reliability, and low operating costs for a range of applications.

The M a XPrO200® is celebrated for its solid cutting power and capacity, catering to the needs of diverse industries without necessitating high-definition cutting. hypertherm's focus on customer-driven innovation and attention to market trends has ensured the M a XPrO200® remains a preferred choice for those seeking reliable and efficient cutting solutions.

This achievement underscores hypertherm's commitment to delivering quality and durability in its products, reflecting the company's understanding of the manufacturing landscape and its challenges. The M a XPrO200®'s success is a testament to hypertherm's ability to design and innovate in alignment with its customers' business goals, marking a significant contribution to the industrial cutting sector.

Global Manufacturing Outlook for 2024: cautious Optimism amid challenges

The global manufacturing sector is bracing for a challenging 2024, with expected contractions in several regions. however, a mild recovery is anticipated in 2025, according to Interact analysis. The semiconductor segment is poised for a better outlook in 2024, contrasting with the general manufacturing downturn. The a sia-Pacific region leads in growth prospects with a 2.9% caGr , followed by the US and Europe, both at 2.4%.

This forecast reflects the varied impacts of economic policies, market trends, and global challenges on manufacturing. The US and Germany, for instance, are expected to face less severe contractions compared to the pandemic's peak, highlighting resilience in certain sectors. The semiconductor machinery sector, buoyed by

INDUST rI a L MACHINERY DIGEST cOM IMD | 13

www.coxreels.com FOLLOW US: TOLL FREE | 800.269.7335 PRO GRADE HOSE, CORD, & CABLE REELS AIR / WATER | HYDRAULIC | PNEUMATIC | VACUUM | WELDING | POWER SOLUTIONS FOR: AND MORE quality matters. every time.

legislative support in North a merica, shows robust order growth, indicating a divergent path from the broader manufacturing slowdown.

Interact a nalysis emphasizes the importance of adapting to these trends, with detailed insights into the manufacturing landscape over the next five years. This outlook serves as a crucial guide for industry stakeholders navigating the complexities of a rapidly evolving sector.

KOYO Machinery USa Integrates with JTEKT Machinery americas corporation

KOYO Machinery USa , renowned for its precision grinding machines and systems, has formally integrated into JTEKT Machinery americas corporation. This strategic move is part of JTEKT corporation's global brand unification initiative, aiming to enhance efficiency and synergize operations across its group companies.

This merger expands JTEKT Machinery's offerings, combining KOYO's grinding technology with JTEKT's comprehensive range of products, services, and customer support. The integration promises customers increased service responsiveness, a broader support organization, and enhanced engineering resources, among other benefits.

KOYO Machinery will maintain its operational presence in the Detroit area, transitioning to JTEKT Machinery's facility in Wixom, Michigan. This change is designed to streamline customer service, ensuring a seamless transition for existing KOYO Machinery customers. The merger underscores JTEKT's commitment to delivering end-to-end manufacturing solutions from a single, trusted source, highlighting the synergy between KOYO's grinding expertise and JTEKT's broader manufacturing capabilities.

Kyle Teeter Takes the helm as Plant Manager at Mack's Statesville

Facility

Mack Molding announces Kyle Teeter as the new Plant Manager for its Statesville, N.c ., facility, marking a significant addition to the company's leadership team. Teeter, with over 15 years of experience in manufacturing operations, engineering, and quality roles, brings a wealth of expertise in cross-functional team management, safety, employee engagement, and customer satisfaction. his appointment is expected to steer the Statesville team towards successful program production for Mack's customers.

Before joining Mack, Teeter demonstrated his leadership and engineering prowess at Parker hannifin’s Precision Fluidics Division, overseeing all site-wide activities. his diverse background, including significant roles at Parker hannifin and academic credentials from

North c arolina State University, positions him as a versatile leader within the manufacturing sector.

Mack's Southern Division also welcomes new talents to its Sales and Engineering, and Manufacturing Engineering teams. Devon Knight and Jonathan Shafer join as Program Managers, each bringing a unique set of skills and experience to the table. c ate Lewis has been appointed as a Manufacturing Engineer, ready to contribute with her fresh perspective and recent academic achievements.

These strategic appointments underscore Mack's commitment to enhancing its leadership and operational capabilities, promising a new era of growth and innovation for the company and its clients.

MODEX 2024: The Premier Manufacturing and Supply chain Event

MODEX 2024, set to take place in atlanta from March 11-14, is anticipated to be the largest manufacturing and supply chain trade event of the year. With over 1,175 exhibitors and 200 sessions, the event promises an immersive experience into the latest in material handling, logistics, and supply chain technologies. high-profile keynotes, including insights from UPS's Bill Seward and aI expert Gerd Leonhard, will address the most pressing issues and innovations in the industry.

The MODEX conference will feature extensive educational sessions and panels, diving deep into trends, best practices, and emerging technologies. highlights include discussions on smart ports, the impact of aI, and previews of the MhI 2024 a nnual Industry report. Special events like MhI Industry Night with colin Jost and forums focusing on women in the supply chain and young professionals will offer networking and learning opportunities.

MODEX 2024 is not just an event but a comprehensive platform for professionals to explore solutions, engage with experts, and envision the future of manufacturing and supply chains. It represents a pivotal moment for industry leaders to gather insights, forge connections, and drive innovation.

Pac Machinery: Leading the charge in Sustainable Packaging

Pac Machinery's FW 650SI Flow Wrapper has been named a finalist in the MhI Innovation awards for the "Best Innovation in Sustainability" category. This recognition highlights Pac Machinery's commitment to environmentally-friendly packaging solutions, marking a significant advancement in the industry's efforts to reduce plastic use.

The FW 650SI Flow Wrapper is designed for industries requiring high-speed flow wrapping but looking to achieve sustainability goals. The machine's compatibility with Pac 's Fiberflex® paper packaging material offers a recyclable solution, reducing plastic waste. This innovation is a testament to Pac Machinery's dedication to environmental

14 | IMD March 2024

Kyle Teeter

stewardship and its role in helping companies embrace sustainable packaging practices.

The MhI Innovation awards underscore the importance of sustainability in the supply chain industry, and Pac Machinery's recognition in this category emphasizes its contribution to promoting eco-friendly solutions. a s the industry continues to prioritize sustainability, Pac Machinery's achievements set a benchmark for innovation and environmental responsibility.

PostProcess Technologies achieves Milestone with 40th Patent

PostProcess Technologies has been granted its 40th patent, marking a significant achievement in the company's journey towards revolutionizing additive manufacturing post-processing. The patent for their cONNEc T3D® Software Platform underscores PostProcess Technologies' commitment to innovation and leadership in automated post-processing solutions.

This milestone highlights the company's dedication to advancing the additive manufacturing industry with a combination of software, hardware, and chemistry. PostProcess Technologies' solutions address critical challenges in post-processing, improving efficiency, consistency, quality, and safety in manufacturing operations.

With this latest patent, PostProcess Technologies not only strengthens its position as a pioneer in the field but also reinforces its commitment to delivering groundbreaking solutions. The company's continued investment in research and development promises further advancements, supporting manufacturers in unlocking the full potential of additive manufacturing.

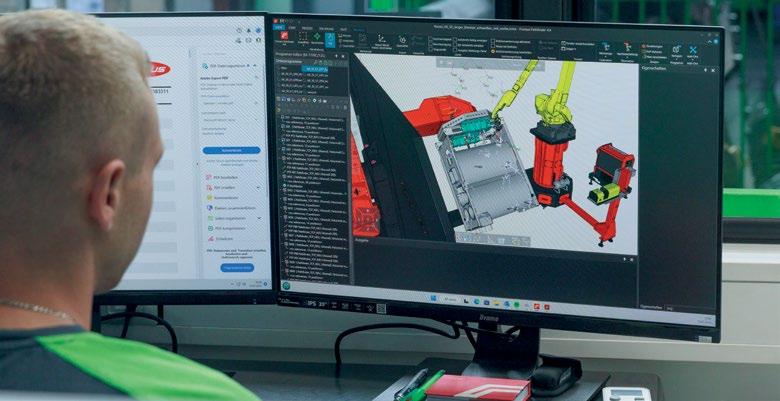

rEJOOL adopts Siemens Xcelerator to revolutionize hydrogen compressors

rEJOOL, a hydrogen compression startup, has embraced Siemens Xcelerator as a Service portfolio to accelerate the development and market introduction of its PIONYr hydrogen compression technology. This strategic adoption aims to establish a digital twin-based development process, enhancing rEJOOL's product engineering, simulation activities, and collaboration with suppliers and customers.

Utilizing Siemens' NX software and Teamcenter ® X solution, rEJOOL is poised to redefine hydrogen compression with its innovative, compact, and oil-less piston compressors. The collaboration underscores the importance of digital transformation in developing sustainable technologies and Siemens' role in supporting startups like rEJOOL to achieve their ambitious goals.

This partnership not only facilitates rEJOOL's mission to set new standards in the hydrogen industry but also exemplifies Siemens' commitment to fostering innovation and sustainability through its cloud-ready software solutions.

Thompson Energy Solutions Fuels Industrial Engine Innovation in West Tennessee and North Mississippi

Thompson Energy Solutions, a division of Thompson Machinery, is expanding its presence in Memphis, Tennessee, to spearhead the development of customized solutions for industrial engines. These engines, vital for applications ranging from rock crushing equipment to irrigation pumps, are central to the operations of Original Equipment Manufacturers (OEMs) across various off-road applications. The choice of c aterpillar engines and the extensive c at dealer network, including Thompson Energy Solutions, is pivotal for OEMs aiming for product durability and superior performance in demanding environments.

INDUST rI a L MACHINERY DIGEST cOM IMD | 15

C-FRAME PRESSES HYDRAULIC MACHINES OF IOWA A Division of Betenbender Mfg. Inc Phone: 319.435.2378 | Fax: 319.435.2262 www.betenbender.com • Heavy Gauge Steel Design • Press Bed bolted on, not welded, to prevent distortion. • Large press bed to accommodate a variety of tooling other than just punching. • Pump, motor, valve and reservoir are all easily accessible for maintenance. • Large rectangular tubes used at base of machine to give safe, instant portability. WE CAN BUILD A CUSTOM MACHINE FOR YOU!

West Tennessee, identified as an ideal logistics corridor, along with strategic locations in Mississippi, offers OEMs lucrative opportunities for relocation, thanks to its excellent workforce and logistics capabilities. These regions are becoming increasingly attractive for OEMs looking to mitigate supply chain challenges and workforce shortages by being closer to suppliers, customers, and major commerce routes.

The recent addition of Jonathan Gwaltney as the new Industrial Engines Sales Manager at Thompson brings a fresh perspective and extensive experience to the team. his background in design, product engineering, and project management is expected to drive innovation and enhance customer satisfaction in this rapidly evolving market segment.

TrUMPF and The Exploration company: Pioneering 3D Printing in Spacecraft Manufacturing

TrUMPF, a leading German technology company, is collaborating with The Exploration company, a European space startup, to manufacture core spacecraft components using 3D printing. This partnership aims to leverage TrUMPF's manufacturing and application expertise to produce parts for the Nyx Earth and Nyx Moon spacecraft, utilizing metal 3D printing for the huracán and Mistral engines. The collaboration seeks to enhance cost-efficiency and sustainability in space missions by making the huracán engine reusable and refuelable with bio-methane and oxygen.

The use of 3D printing in aerospace manufacturing offers significant advantages, such as weight reduction, complexity minimization, and the potential for rapid prototyping. TrUMPF's technology allows for the efficient use of materials, reducing waste and enabling the production of components with complex geometries that traditional manufacturing methods cannot achieve.

This initiative marks a significant step towards commercializing space travel, with The Exploration company planning its first earth-orbit mission in 2026 and moon missions starting in 2028. The partnership underscores the growing importance of additive manufacturing in the aerospace industry, promising to revolutionize how spacecraft are designed and built.

UL Solutions certifies Siemens Using Digital Modeling for rapid Innovation

UL Solutions has granted Siemens the first certification using digital modeling, a landmark achievement for product innovation and market speed. This certification, applied to Siemens' new SINaMIcS G220 drives, highlights the potential of digital modeling and simulation to streamline compliance, enhance product design, and reduce the time and cost associated with bringing new innovations to market.

By integrating verified and validated digital models with physical tests, UL Solutions is pioneering a more efficient pathway for product development and certification. This approach not only saves resources by reducing the need for multiple prototypes but also offers deeper technical insights into product safety and performance.

Siemens' utilization of a digital twin for the SINa MIc S G220 drives underscores the transformative impact of digital technologies on product development. This collaboration between UL Solutions and Siemens exemplifies how digital innovation can drive faster, more efficient, and cost-effective product certification processes, setting a new standard for the industry.

Velo3D and Kratos: advancing Defense Manufacturing with Metal additive Technology

Velo3D, Inc., a leader in metal additive manufacturing technology, announces that Kratos SrE, Inc., a subsidiary of Kratos Defense & Security Solutions, Inc., has acquired a Velo3D Sapphire printer. This acquisition supports Kratos's efforts to revolutionize its supply chains by facilitating the rapid and cost-efficient production of metal parts for the defense industry.

Kratos SrE will utilize the Velo3D metal additive manufacturing solution in its rapid

16 | IMD March 2024

prototyping and manufacturing center to enhance the vertical integration of critical supply chains. This technology enables Kratos to maintain its competitive edge in the defense sector by reducing lead times, lowering costs, and accelerating innovation in part design for existing platforms.

Velo3D's fully integrated solution, recognized for its ability to produce mission-critical parts, underscores the increasing adoption of additive manufacturing in the defense industry. The collaboration between Velo3D and Kratos exemplifies the transformative potential of additive manufacturing in supporting national defense objectives and fostering innovation in manufacturing processes.

West Ohio Tool Showcases advanced Tooling Solutions at ShOT Show 2024

West Ohio Tool co. returned to the ShOT Show 2024 in Las Vegas, further establishing its reputation as a leading tooling manufacturer for the defense and aerospace industries. Building on its success from the previous year, West Ohio Tool presented its advanced carbide and polycrystalline diamond (PcD) custom tooling solutions, emphasizing its innovative EdgeX4 tools that significantly reduce cost per hole.

The company's participation underscored its commitment to providing advanced custom tooling solutions and highlighted its numerous certifications,

including the recently acquired a S9100D certification. This certification not only validates West Ohio Tool's quality management systems but also facilitates its expansion into government, defense, and aerospace markets.

By addressing industry challenges such as tool delivery times, West Ohio Tool demonstrated its ability to deliver custom tools 75% faster than industry averages. The company's engagement at ShOT Show 2024 exemplified its dedication to innovation, quality, and customer satisfaction in the rapidly evolving tooling industry.

INDUST rI a L MACHINERY DIGEST cOM IMD | 17

CLEAN IT RIGHT. CLEAN IT WITH Simplify cleaning in your facility with the ultimate all-in-one solution! Pre-moistened wipes are easy to use, portable, and come in pre-measured portions. Whether it’s removing tough soils like grease and paint, or disinfecting and sanitizing common surfaces, SCRUBS® has the right wipe to do the job. FIND A DISTRIBUTOR TO PURCHASE 800.241.8334 www.itwprobrands.com/brand/scrubs

The Value of the Cloud for Manufacturing ERP

By: Andrew MacMillen

In an era of increasing competition and rising costs, manufacturers must find a competitive edge wherever possible. Moving their on-premises enterprise resource planning (ErP) solutions to the cloud represents an opportunity to modernize day-to-day operations and update technological capabilities. The upfront requirements of carrying out such a large- scale project have kept many from abandoning their current business processes. however, new benefits, such as increased access to the application and company data, now outweigh the costs of maintaining the status quo. Manufacturers will always face constant pressure to improve performance, and those who successfully leverage new cloud-enabled capabilities will distinguish themselves both now, and in the future.

OVErVIEW

a s manufacturers face increasing competition and resource constraints, they need modern ErP systems that are secure, scalable and can improve organizational visibility. companies are beginning to realize the value and importance of data and analytics for decision making.

The data silos that often occur in legacy, on-premises deployments hinder both daily activities and high-level strategy objectives. a s manufacturing operations grow in both size and complexity, ErP software must be able to extend and accommodate the changes that naturally occur with successful companies.

Other factors driving manufacturing Er P deployments to the cloud include rising software maintenance costs and burdensome maintenance processes that are necessary to keep on- premises deployments running. cloud solutions have a lower total cost of ownership (TcO) when compared to similarly sized legacy Er P implementations that are internally managed (Nucleus research s102 – The cloud benefits companies of any size, September 2018).

Moving to the cloud, and consolidating costs and services into a single package, forces customers to review their existing business processes and evaluate the usefulness they bring to their overall objectives.

WhY cLOUDEr FOr MaNUFacTUrErS

From research conducted on manufacturing customers

18 | IMD March 2024 BUSINESS 4.0

who migrated from on-premises ErP deployments to the cloud, Nucleus identified four areas that companies cited as key factors in the decision:

rEDUcED IT cOMPLEXITY

Simplifying technology setups was the most common reason for transitioning to cloud ErP solutions among manufacturing companies. Those who switched were able to consolidate many of their siloed processes into a single platform. cloud migrations also enable companies to delegate application security and update management to the vendor.

Keeping up with update schedules for various systems often becomes overwhelming, and it’s all too easy for a company to end up with multiple versions behind the current update. The change allows the vendor to deliver performance and uptime improvements much more quickly, compared to legacy on-premises deployments. companies who moved to the cloud were able to eliminate unnecessary solutions and redeploy IT resources to different value-add work because of their decreased administrative responsibilities.

INcrE a SED BUSINESS aGILITY

cloud technology enables greater responsiveness and increases organizations’ ability to process and respond to changing business environments. a s internet speed and connectivity have improved, highly visible and crossfunctional ErP systems have democratized responsibilities that previously required specialized knowledge and experience. With new advancements in usability and real-time access to company data, cloud ErP users can react quickly to changes and see how the subsequent ripple effects will influence their business. customers can also create new dashboards or reports natively without needing to draw in IT resources. a s a result, users can ask questions and drill down into data for insights, resulting in more streamlined operations and decisionmaking processes.

INDUSTrY 4.0 caPaBILITIES

By migrating ErP deployments to the cloud, manufacturing customers can leverage new functionalities that don’t come as quickly to on-premises systems. New data configurations and sophisticated analytics are necessary for modern functionalities such as predictive analytics and improved security and are usually more widely available on cloud deployments. With ErP data in the cloud, manufacturing customers can supplement conventional analytics with machine learning to identify areas of weaker performance and provide contextual insights that can reduce costs and increase productivity. Functionalities such as predictive maintenance that rely on the Internet of Things (IoT) often require cloud frameworks in order to deliver value to customers, which can further entice manufacturers to leave their familiar on-premises ErP deployments.

KEY 2 BENEFITS

Despite the high upfront costs of transitioning from on-premises deployments, manufacturers still realized significant benefits from their cloud Er P implementations. Nucleus identified three key benefit areas from customers moving their on-premises Er P workloads to the cloud:

reduced costs. By transitioning from an on-premises legacy system to a cloud solution, customers can reduce operational costs by eliminating equipment and related IT department resources. reducing the burden of support for customers led to cost savings as the associated headcount was reduced or redeployed away from managing system updates and integrations.

Increased user productivity. cloud ErP solutions enable users to access and leverage company data from anywhere with an Internet-enabled device. With readily available information, customers saved time on performing analysis and generating reports while redeploying resources to new value-add tasks that were made possible through cloud deployments. Many customers were able to automate repetitive accounting and reporting tasks to save time and increase the productivity of all of their ErP users.

Improved organizational visibility. cloud ErP systems enable manufacturing organizations to improve access to data by breaking down information silos to provide interdepartmental visibility to customer data. On the cloud platform, finance and operations staff can collaborate to reduce friction between departments, resulting in more productive daily activities. cloud ErP deployments can deliver value to organizations by helping them pinpoint inefficiencies and develop new workflows to improve performance.

LOOKING ahE aD

While many customers are not in a position to undertake a full cloud transition for their ErP deployments, the benefits of moving to the cloud are becoming too large to ignore.

Nucleus observed that eliminating the costs associated with maintaining an on-premises deployment helped customers identify areas in need of improvement and streamline their operations. The advancements to employee productivity and organizational visibility enabled customers to develop new use cases for their ErP software, despite the high costs of transitioning away from on-premises deployments.

Some manufacturing ErP customers are currently unable to move away from their on- premises ErP systems, but centralizing processes in the cloud and adopting a standardized data model are necessary steps towards long-term success. Nucleus expects that the growth of cloud deployments will accelerate as next-generation capabilities, such as predictive analytics, mature and become easier to adopt. The flexibility and extensibility of cloud ErP deployments will drive value for manufacturers as long as they are willing to forego their outdated legacy practices.

INDUST rI a L MACHINERY DIGEST cOM IMD | 19 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

aI is seen not as a job threat but as a solution to improve productivity and address tasks that humans prefer not to do.

FEATURING:

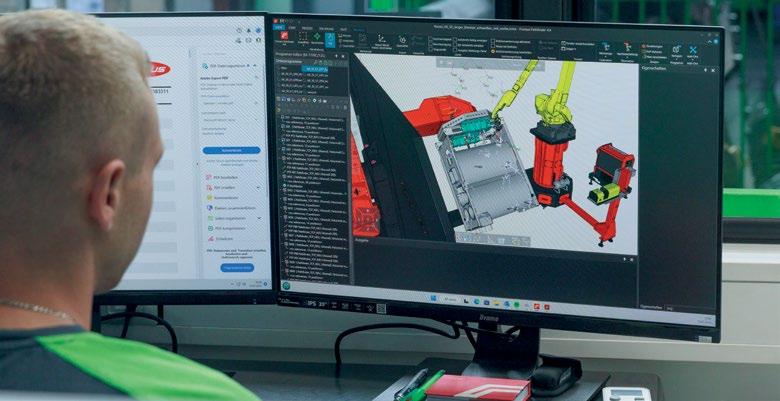

TALKING SHOP WITH: Stu Johnson — Vice President of Product Marketing at Rootstock Software

An Exclusive Dive into Rootstock Software's Vision and Impact

In an era where the manufacturing landscape is constantly evolving, driven by technological advancements and shifting global dynamics, companies are seeking solutions that not only streamline operations but also provide the agility to adapt to change. rootstock Software emerges as a beacon in this transformative period, offering a Manufacturing cloud ErP solution that is not just a tool, but a catalyst for growth and innovation. Built on the robust Salesforce Platform, rootstock Software is designed to propel manufacturers into the future, enabling them to scale operations, meet emerging customer needs, and navigate the challenges of a post-pandemic world with unparalleled efficiency and visibility. In this exclusive interview, we delve into the core of rootstock Software's mission, exploring how it empowers manufacturers worldwide and the visionary approach that makes it a leader in the ErP industry.

can you start by telling us a bit about yourself and rootstock Software?

I'm Stu Johnson, Vice President of Product Marketing at rootstock Software, with a 35-year career mostly in enterprise software, from caD/caM, PDM, MES, and now ErP. rootstock is a cloud-first ErP solution specifically designed for manufacturing, built on the Salesforce platform. This gives us access to a vast ecosystem and allows manufacturers to easily build out their IT stack with a plug-and-play approach.

With so many ErP systems out there, how does rootstock differentiate itself?

The key differentiator for rootstock is our focus on manufacturing. Our ErP is built on what I like to call a manufacturing operating system. Unlike other ErPs that need to configure manufacturing processes, rootstock integrates these processes natively. Our system intertwines inventory management, work orders, and supply chain processes seamlessly, making everything from order placement to costing automatic.

You mentioned a new winter release focused on financials. can you elaborate on its importance?

Our winter release significantly enhances the financial management capabilities within our ErP. It addresses a

20 | IMD March 2024

TALKING SHOP

critical balance manufacturers must achieve between demand, production capacity, and the uncertainties of the supply chain, all pivoting around financials. This balance is vital for maintaining profitability, and our latest updates aim to boost the productivity of financial teams and improve their quality of life.

Why is the financial aspect increasingly crucial for manufacturers today?

cash flow and cost management are paramount in manufacturing. Inventory represents a significant cost, and managing it efficiently can significantly impact profitability. Our ErP provides visibility into financials, allowing businesses to make informed decisions rapidly. This real-time data is essential for small manufacturers who need to scale without losing sight of their financial health.

how is the aI revolution impacting manufacturing, and how is rootstock preparing for it?

The manufacturing industry is traditionally cautious about adopting new technologies, but aI is starting to make its mark. Our focus has been on preparing our data platform for aI, recognizing that predictive aI and the insights it can provide are becoming invaluable. Interestingly, our survey showed that manufacturers are not afraid aI will take jobs; instead, they see aI as a tool to enhance productivity and improve job satisfaction by taking over undesirable tasks.

In the context of aI and manufacturing, what trends are you observing?

There's a significant shift towards investing in aI, with many manufacturers planning to increase their aI investments by double digits. This is partly driven by the ongoing labor shortage in the industry. aI is seen not as a job threat but as a solution to improve productivity and address tasks that humans prefer not to do. The industry is moving towards a more sophisticated use of aI to augment human work and enhance efficiency.

Rootstock Software: Empowering Modern Manufacturing with Cloud ERP

rootstock Software stands at the forefront of manufacturing innovation, offering a cloud ErP solution that propels manufacturers into the future. In the rapidly evolving post-pandemic landscape, rootstock equips businesses with the tools necessary to scale, adapt, and succeed amidst constant change. Built natively on the Salesforce Platform, rootstock Software delivers unparalleled agility and comprehensive visibility, enabling manufacturers to meet customer demands, overcome challenges, and drive accelerated growth.

A Global Force in Discrete Manufacturing

Since its inception in 2008, rootstock Software has cemented its status as a global powerhouse, serving an

INDUST rI a L MACHINERY DIGEST cOM IMD | 21

ANSI AGMA SAE DIN G e a r , S p l i n e & R a c k T o o l i n g 847-395-9707 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

www.IndustrialMachineryDigest.com SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS THE BEST ADVICE I CAN GIVE YOU IS TO SUBSCRIBE TO NEWSLETTERS! North America’s Manufacturing Resource for Industry Professionals Since 1986 Business & Workforce Development Fabrication & Manufacturing Showcase Products & New Technology Industry Insight, Safety & Maintenance Manufacturing Process & Automation What’s in YOUR InBox?

expansive customer base across North america, Europe, and a sia Pacific. available exclusively through the Salesforce appExchange, rootstock caters to a diverse range of discrete manufacturing companies. From burgeoning small businesses to large multinational corporations, rootstock’s scalable solutions support manufacturers at every stage of growth.

Unifying Teams with Advanced ERP Solutions

rootstock's Manufacturing ErP solutions are designed for the modern manufacturing landscape, offering real-time management capabilities for manufacturing and supply chain operations. With rootstock, teams can effortlessly manage multiple sites

Configurable, Scalable, and Adaptable rootstock's agile platform, coupled with its extensive partner ecosystem, offers unmatched flexibility to address evolving business needs. The ErP system integrates seamlessly with native Salesforce sales and accounting apps, as well as third-party solutions from Workday, avalara, and Bringg/Zenkraft, facilitating out-of-the-box connectivity and collaboration. rootstock's partner network, composed of seasoned manufacturing and technology experts, further enhances implementation and technological capabilities.

Recognized Excellence in ERP Solutions

rootstock Software has received numerous accolades for its innovative

rootstock's commitment to delivering award-winning software platforms that meet the demanding requirements of modern manufacturers.

A Commitment to Customer Success

at the heart of rootstock's mission is a dedication to customer success and satisfaction. With a team boasting hundreds of years of combined experience in manufacturing partnerships, rootstock prioritizes the growth, profitability, and customer experience of its clients. Through high-quality, personalized support, rootstock Software ensures successful implementations and fosters long-term business partnerships.

rootstock Software is not just a

INDUST rI a L MACHINERY DIGEST cOM IMD | 23

AGE | EFFICIEN CY COMBILIF C M Y CM MY CY CMY K Fabtech 8in x 4.75in Ad Mark.pdf 1 08/18/2023 17:33 Save up to 100% more sto rage Before you invest in upgrading the infrastructure of your warehouse find out how Combilift could dramatically increase storage, improve productivity and enhance safety. Our warehouse design consultancy service is FREE and without obligation. When combined with our material handling solutions we can deliver possible space savings of up to 100%. So contact us today to arrange a site survey!

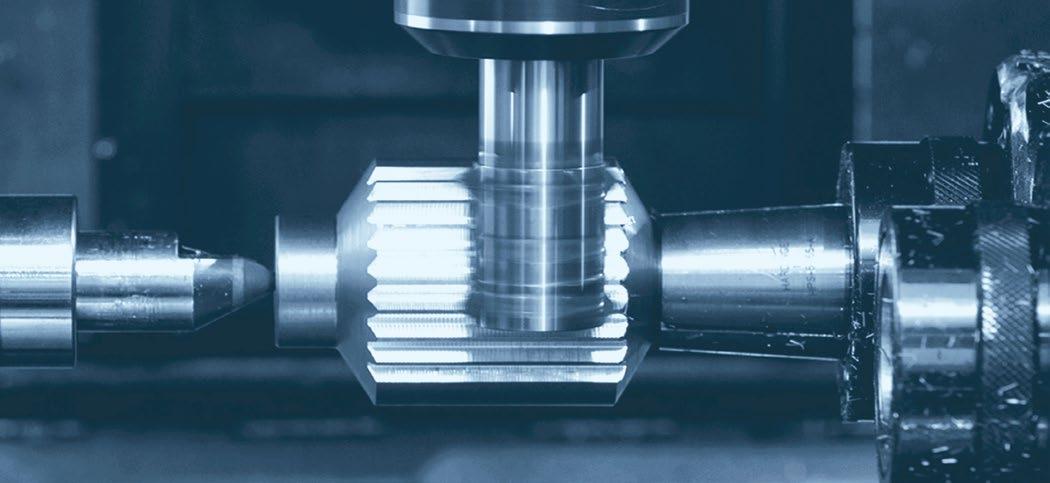

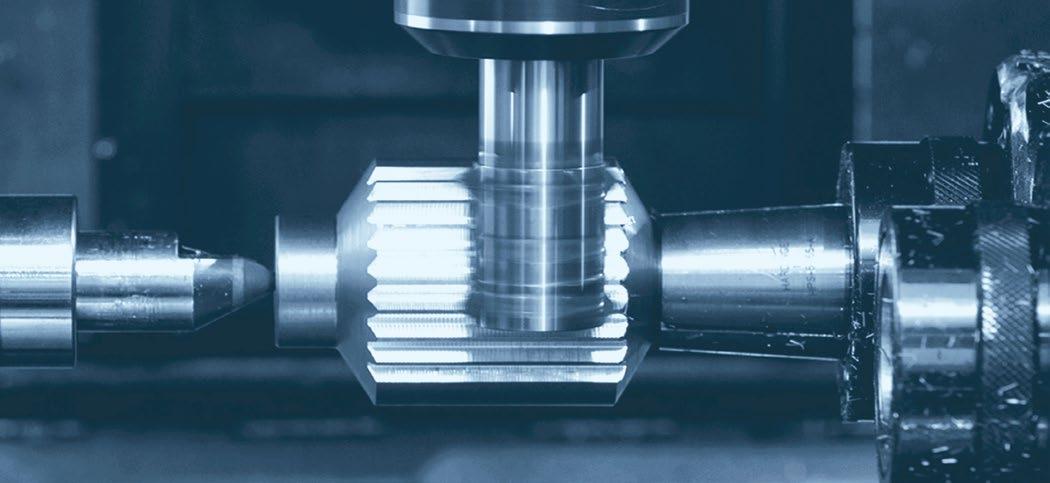

Anatomy of a Tailstock Rebuild-Repair

Inspection, analysis, engineering execution, and inventory back-up are in the mix for Riten Industries’ downtime maintenance formula.

By: Kent Hizer, Riten Industries, Inc

Established in 1969, riten Industries, Inc. is the largest domestic manufacturer of live centers, dead centers, and face drivers in the work holding industry.

a growing part of their re-engineering platform, riten is at the forefront of leveraging solutions to eliminate costly machine downtime due to tailstock failure. The fact is that a lot of machinery becomes obsolete before its time, and the original OEM may not exist anymore to provide timely replacements. If a machine becomes obsolete, riten has developed a dedicated tailstock ‘rebuild-repair’ program that includes a bearing assembly inventory platform that allows manufacturers to strategically schedule downtime.

rITEN TaILSTOcK rEBUILD-rEPaIr PrOcESS

» The Morse taper ID (if the spindle has an ID taper instead of a point)

STEP THREE

Some tailstock projects are quoted by riten based on existing lathe assembly drawings. a budgetary proposal is provided for a repair based on these drawings, with the understanding that it is subject to change based on the condition of the tool as received. From there, riten executes their established tailstock repair process.

STEP ONE

Upon receipt, the tool is photographed and a project folder is assigned containing detailed inspection forms tailored to the scope of the project. riten’s repair Department then disassembles the tool−documenting the process with notes and photographs specific to each step.

Once the tool is fully disassembled, a bill of material is created detailing all the essential components.

STEP TWO

The components go to Inspection, where a visual review is performed in addition to taking vital measurements. all of the key inspections and fits are documented in the project folder, which details both the inspection process and the expected inspections. Key inspection variables include:

» The fit between the quill OD and the tailstock ID

» The fit between the quill ID and the OD of the bearings

» The spindle bearing journals and the bearing ID

» The spindle point and the bearing journals between centers to determine concentricity

The folder goes to quoting, where an engineer reviews the scope of the project and the inspection findings. a quote is then created based on the condition of the spindle as received.

STEP FOUR

The inspection findings and the preliminary quote are presented to the customer. Based on feedback from the customer, the scope of work is finalized. a lso, if it is determined that if the parts don’t exist, they will proceed to retrofit, rebuild, redesign headstock or tailstock assemblies.

DEISTEr MachINE / rEBUILD-rEPaIr caSE-IN-POINT

Since 1912, Deister Machine company, Inc. (Deister: Fort Wayne, IN) has been a leader in manufacturing quality specialized vibrating equipment for the mining, quarrying, and allied industries. The family-owned and operated company is a preferred manufacturer of vibrating feeding, scalping, and screening equipment. Deister is known for delivering reliable separating and sizing equipment that is engineered to operate hour-after-hour, day-after-day, with minimum attention and maintenance. Their products are uniquely engineered to significantly increase efficiency and productivity within key aggregate industries including: crushed stone, sand, gravel, asphalt, coal, coke, slag, and ore processing.

24 | IMD March 2024

SAFETY & MAINTENANCE

Complete tailstock showing replaceable point

Deister’s dedicated aggregate capital equipment portfolio includes machinery for inclined screens, high-speed screens, horizontal screens, asphalt-batch plant, asphalt-drum mix, dewatering screens, feeders and grizzlys, and electro-mechanical feeders. In 2006, Deister realized that their lathes required excessively frequent maintenance, which was affecting their production output and resulting in costly downtime. In turn, they contacted riten who swiftly performed essential inspection-and-failure analysis on one of their two lathes.

Based on their findings, riten designed and manufactured a new quill with an upgraded four-piece bearing design. This new design was an upgrade with more capacity than the existing bearing design. They also designed and manufactured a replaceable point spindle instead of the existing solid spindle, since the customer noted that the spindle points of their existing lathes were easily damaged. This new design was highly efficient and performed much better than the old design.

a year later, however, Deister came back with a desire to achieve additional bearing life. riten then initiated a review of the application on-site and discovered that part of the process involved an eccentric load that they were not aware of. Eccentric loads are very hard on both the bearing assembly and the spindle of the lathe.

The review revealed that Deister was turning shafts that weigh between 1,500–3,000 pounds. Once these are turned complete, they cut a new center hole that is offset (not on-center) and turn a new bearing journal−resulting in a shaft that is unbalanced. In effect, a heavy, eccentric shaft spinning at high rPM can literally walk-the-machine across the floor, which is extremely hard on the equipment and its effective lifespan. however, this shaft design is key to the performance of equipment Deister is known for.

again, after reviewing the application on-site, riten suggested key changes to both the process and their selection of dead centers. In addition to premature wear on the bearing assemblies, they were breaking dead centers−a vital safety concern. In many cases, their center hole sizes were inadequate, therefore, charts were provided that specified minimum center hole sizes based on the weight of the part.

additionally, the bearing assembly in the new unit was upgraded to a matched set of six angular contact bearings. The existing four-bearing assembly was replaced with a six-bearing assembly in the same custom quill. When designing the quill, room was left in the assembly for additional bearings−if they proved necessary.

another key downtime dilemma is delivery on a bearing assembly, which can be anywhere from 12–20 weeks depending on availability of the base bearing. The bearing manufacturer starts with a standard high precision bearing and reworks them into a six-bearing matched set. riten orders and inventories a spare bearing assembly with every customer repair. This is essential for limiting production downtime for a repair−reducing downtime to 2–3 weeks vs. 3–5 months for the repair.

cONcLUSION

Between 2006 & 2010, riten upgraded a total of three Deister lathes−two of which are identical. They all share the same bearing assembly and replaceable point. The upgrade included manufacturing new quills with replaceable point spindles and honing the tailstock to fit. Notably, the new tools were installed on-site.

With this established ‘shut-down elimination’ program in place, Deister continues to have riten refurbish one of their lathes each year during their slow season−with each lathe being refurbished approximately every 2–4 years depending on their usage.

according to riten’s V.P. of Manufacturing, Mitchell Kirby, “It’s imperative for companies to perform critical maintenance during seasonal downtimes on their lathes. Depending on business levels, more companies send us their damaged units annually for either refurbishment and/ or replacement. We also manufacture spare identical quill assemblies for inventory. With this in place, we can limit their downtime to 3-5 days to remove the existing unit and mount the spare, whereas delivery on a replacement unit could be 14-18 weeks.”

ABOUT RITEN INDUSTRIES

Since 1933, riten Industries, Inc. has established itself as the largest domestic manufacturer of Live and Dead centers and Face Drivers. With thousands of standard products in this focused area, no other company can match our experience and engineering skill to meet the demanding needs of the work holding industry. Made-inthe-USa at riten’s 35,000 sq. ft. production facility in central Ohio, we boast the industry’s broadest line of standard products and can also design custom specials to meet a customer’s unique needs. Our quality system is certified annually to meet the demanding requirements of ISO-9001: 2015. Notably, riten also has a dedicated full-time department for repairing and rebuilding used live and dead centers−the only one of its kind in North america.

For more information:

Visit: www.riten.com or www.riten.com/services/tailstock-repair

Author: Kent Hizer / Riten Industries, Inc. / 574.850.4118 / k.hizer@riten.com. Editorial & Photo Contact: Ray Farrar / Method Media LLC / 216.861.0862 / rayf@methmedia.net

INDUST rI a L MACHINERY DIGEST cOM IMD | 25

IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

New bearing assembly with the old-style solid nose, prior to redesign of nose.

Murata Machinery USA Celebrates 50 Years of Automation in North America

Murata Machinery USa (Muratec), a leading manufacturer of game-changing industrial automation, celebrates its 50th anniversary across North america. Various activities are planned throughout 2024 to commemorate Muratec's golden year.

Operating as a subsidiary of Kyoto, Japan-based Murata Machinery Ltd., Murata Machinery USa provides sales, service, and support for the Muratec brand in the United States, canada, and Mexico, as well as overseas in Ireland. Muratec has a rich history of innovation and leadership in North america, revolutionizing the automation landscape with groundbreaking solutions that are often the first of their kind, the only ones available, or the world's fastest.

“Murata Machinery USa has been a beacon of excellence, driving industrial innovation and achieving continental success,” said Toshiyuki Komori, President and cEO, Murata Machinery USa . “Unwavering in our commitment, we aim to propel the Muratec brand of end-to-end automation to new heights across North america, helping customers maintain their competitive edge with automation.”

In May 1974, Murata Machinery Ltd. established Murata of america, Inc. in charlotte, Nc , initially focusing on textile

machinery. In October 1989, it acquired the Wiedemann Division from the Warner & Swasey company, creating Murata Wiedemann, Inc. The unified brand "Muratec" was introduced in October 1991. By June 2002, the company consolidated its U.S. subsidiaries, Murata of america, Inc. and Murata Wiedemann, Inc., into Murata Machinery USa , Inc. Throughout North america, Muratec expanded its automation portfolio to encompass material handling, machine tools, fabrication technology, and cleanroom automation solutions, showcasing a broadened range of offerings.

historic Innovation across Four Divisions

For over five decades, Muratec’s breakthroughs have marked many turning points in automation, helping our customers enhance their competitive efficiencies across diverse industries. Some of these significant innovations in automation advances include:

» Textiles: Muratec revolutionized textile manufacturing with Spinning, Winding, Twisting, and Texturizing Machines. This led to the invention of air-Jet Spinning, which utilized high-pressure air to enhance the texture and bulkiness of yarns at higher production speeds.

26 | IMD March 2024

MANUFACTURING SHOWCASE

The MF30510HL is a combination machine based on a turret punch press with fiber laser cutting added.

Other advancements supporting textile manufacturing included the automatic Winder that seamlessly linked with ring Spinning Machines. The game-changing VOrTEX machine was introduced in 1997 and evolved into the VOrTEX 870 in 2011, creating the world’s fastest spinning machine that eliminated roving and Winding with over 6,000 units installed globally.

» Logistics & automation (L&a): In the 1990s, Muratec revolutionized North american automotive Stamping with an integrated turnkey solution, effortlessly combining Die handling, Blank Processing, Stamping Warehousing, and Transport control. This streamlined processes and minimized waste by integrating automated Storage and retrieval Systems (aSrS) and automated Guided Vehicles ( aGV), reshaping the automotive sector's logistics and material handling approach. Muratec positioned itself as a key industry influencer of versatile automation systems covering high-rise warehouses, unmanned transporting systems, robotic automation, and cutting-edge factory automation.

» clean Factory automation (cFa): a s a cleanroom industry leader, Muratec invented cutting-edge floor and overhead transport systems (OhTs) to optimize fabrication processes, maximize space, and ensure product integrity with minimal vibration. These solutions set industry benchmarks that smoothly interfaced with customer Manufacturing Execution Systems (MES)

and tools, establishing a new standard in boosting productivity, reliability, and operational excellence. Muratec is one of the world's largest semiconductor clean room automated manufacturers.

» Machine Tools Division (MTD): In 1980, Muratec revolutionized cN c machining with the MW25, the inaugural twin-spindle automated chucker lathe that seamlessly integrated automation with an industryfirst gantry loader. Then, in 1994, Muratec set a new industry standard by inventing the world's first electric servo motor cN c turret punch press. The MOTO rUM 2000 was known for its eco-friendly design, low noise, and highly productive hydraulic oil-less operation, inspiring numerous imitations and knockoffs. Muratec's machine tools, spanning turning, sheet metal fabrication, and automated handling systems combine high speed and precision through cutting-edge control technology.

In 2024, Muratec will mark 50 years of automation innovation with initiatives. In September, new innovative machinery will be introduced along with ten (10) cutting-edge machine demonstrations at the 2024 International Manufacturing Technology Show, Sept. 9-14, at Mccormick Place in chicago, Booth 338844. Discover Muratec’s diverse range of automation solutions engineered for use across various industries by exploring its newly revamped website at www.muratec-usa.com.

INDUST rI a L MACHINERY DIGEST cOM IMD | 27

Form your own inserts. • Cost savings (up to 90%) • High load threads - stronger joints • High process reliability • Faster production cycles Advantages & Benefits • No special machinery required • Small investment • Increased material thickness • Long tool life 773-290-1040 | info@formdrill-usa.com | www.formdrill-usa.com • Chipless process • Innovative technology suitable for steel, stainless steel, copper, brass, and aluminum Drill. Tap. Assemble. IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Taming Unruly Metals: No Problem for KASTO Saws

More capacity, shorter cutting times and precise cutting results: Metal distributor Langley Alloys was looking for more efficient sawing technology. The result: new band saws by KASTO, with which the British company can also process hard-to-cut metals.

Langley alloys knows its way around materials that are considered "difficult" in the industry. The company from Newcastle sells bars, tubes and sheets made of high-performance metals, but is also active as a component manufacturer. 70 employees take care of cutting duplex or super-duplex stainless steels, high-strength austenitic stainless steels, copper-nickel and nickel-based alloys. customers from different industries trust in the precision, reliability and expertise of the specialised trader. The spectrum ranges from small workshops and the automotive industry to large steel constructors for bridges, industrial buildings or ships.

The challenge

Langley alloys' saw fleet reached its limits after ten yearsan expansion of capacity was not possible with the existing

machines. In addition, the lack of space in the production hall prevented the acquisition of further band saws. The specialist had clear ideas about his new sawing solution: in any case, it should be possible to use carbide bands in order to achieve shorter cutting times for larger stocks of nickel alloys. With this idea, Langley alloys approached K aSTO's UK branch in Milton Keynes to discuss possible options.

The Solution

For several years band saws of the K aSTOtec ac 4, K aSTOwin a 4.6 and K aSTOwin pro ac 5.6, have been processing their difficult-to-cut metals. Langley alloys were able to significantly increase the cutting capacity and precision - without complex monitoring.

Thanks to the improved cNc control of the K aSTO machines, the employees can set up the different sawing

28 | IMD March 2024

INDUSTRIAL AUTOMATION

Metal distributor Langley Alloys relies on band saws from KASTO for the machining of difficult-to-cut alloys. Image credits: KASTO Maschinenbau GmbH & Co. KG

jobs faster, utilising the machines to correctly set the speed and feed for each job, not having to rely on the operator’s knowledge – this opens up a greater potential for operator selection!

The K aSTO saws handle all sawing jobs at Langley alloys with very little down-time. If there are any problems, the K aSTO Ltd. Service Team are always quickly on-site to service or maintain them. Since the purchase of the very first K aSTO saw 6 years ago, the metal specialist have 8 K aSTO machines in daily use across their UK sites – Very soon to be expanded!

The conclusion

"K aSTO's band saws are ideal for cutting our difficult materials. here we wanted to become more efficient, and we have succeeded with the new acquisitions," Managing Director rodney rice explains the decision.

ABOUT KASTO:

The K a STO Group, located in achern in Baden, Germany, (K a STO Maschinenbau Gmbh & co. KG) specialises in sawing, storage, and automation technology for metal bar stock. The company is the world market and technology leader for metal sawing machines, semi-automatic and automatic storage systems for metal bar stock and sheet metal, automated handling equipment for metal bars, sheets, and cut-pieces including the necessary, intelligent software. With 180 years of experience, K a STO is one of the oldest family-owned businesses in Europe. 170 patents, more than 140,000 sawing machines sold across the globe, and over 2,300 installed automated storage systems are a reflection of the company's success. Besides the subsidiary plant in Schalkau located in Thüringia, K a STO also operates subsidiaries in England, France, Singapore, china, Switzerland, and the USa , and has sales and service partners in many other countries.

For more information, see: www.kasto.com

251 937 09 Scan or Call for a FREE Quot IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

ProShop ERP Partners with Purdue University's Industrial Engineering School to Revolutionize Manufacturing Education

ProShop ErP, a leading software solution for precision manufacturing companies, has entered into a partnership with the Industrial Engineering School (IE) at Purdue University, donating seats of their ProShop Digital Ecosystem to help the school establish a state-ofthe-art manufacturing lab of the future. The IE program is ranked number two in the United States by U.S. News & World report, having invested heavily in the infrastructure and technology to best prepare students for careers in such areas as smart manufacturing, supply chain resiliency, and aI and Machine Learning among others. The ProShop Ecosystem will play a big part in the creation of a 10,000 square-foot automated “factory floor” in the school’s manufacturing lab space to teach and perform lights out manufacturing operations. Students will eventually be taught how to implement a lights out process from beginning to end, creating an overarching control system to manage

production planning, scheduling, inventory, PM planning, and finished goods, tracking every aspect of the manufacturing process. The ProShop Ecosystem will be used as the shop’s inventory management and ErP system to help control the entire shop floor, helping faculty and students to store and access quality documents for fixturing, setup, and tool setups and images of equipment. They will be able to track raw goods, raw materials, and tool inventory.

The ProShop Ecosystem will also be used to track and manage 3D print, metrology, laser, and human integration labs on different floors. IE is also installing chip manufacturing equipment after being designated one of the major chip-making hubs in the U.S. combine that with other assorted equipment and there is a lot to be tracked throughout the school.

additionally, ProShop ErP’s ability to help streamline certification and regulation documentation is

30 | IMD March 2024 WORKFORCE DEVELOPMENT

well-known and will be beneficial in helping the school to prove that OSha and other certifications and training have taken place.

It was a aron ramsey, IE’s Director of Industrial relations, who first connected with a drian Sansonetti, ProShop Er P’s Director of Global Project Management Office and ProShop Oceania while Sansonetti was networking within the manufacturing community in the state of Indiana. a fter learning of the school’s needs, Sansonetti traveled to West Lafayette and demonstrated the different system functions that could meet those needs.

“ProShop’s ErP software perfectly aligns with our operational requirements, providing comprehensive tracking and management capabilities vital for our activities," said craig Zehrung, PhD., the Principal Laboratory Operations Specialist in IE. "Our goal is to extend its application to fully leverage its extensive functionalities towards achieving a fully automated, or 'lights out,' manufacturing environment. We are committed to evolving into a facility that operates autonomously, leveraging advanced aI and computer control systems. This initiative also offers practical learning opportunities for students, connecting academic knowledge with real-world experience.”

The partnership is a win-win for the school, its students and ProShop ErP.

“We can help facilitate the connections for students to get real world industry experience with leading manufacturing companies,” said Sansonetti. “It helps our clients but it’s also meaningful for the students who need to be able to work on real projects and solve real problems. There is a synchronicity in that we are both trying to achieve the same thing which is upskilling industry with best practices. The Purdue School of Industrial Engineering is graduating world-class students.”

ABOUT PROSHOP ERP

ProShop ErP delivers manufacturing software by deeply understanding our client’s challenges in order to meaningfully improve their businesses and in turn, their communities.

ProShop is the industry’s only dedicated ErP/QMS/MES management software built by manufacturers for manufacturers. They are fanatical about managing every detail of machine shops in a paperless and web-based environment, including the enterprise resource management (ErP) functions necessary to run offices, the quality management system (QMS) functions to manage a S9100 systems, and the manufacturing execution system (MES) functions to ensure the shop floor is running at peak efficiency, while helping clients.

For more information browse https://proshoperp.com/proshopsafe or call 1-800-990-4046.

INDUST rI a L MACHINERY DIGEST cOM IMD | 31 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986