13 minute read

PRODUCT SHOWCASE

PRODUCTSHOWCASE

WANT TO BE FEATURED? Send your latest product information to editorial@indmacdig.com

IMD's Monthly Product Showcase features the latest from some of the manufacturing industry's top suppliers.

Patented No Drip Air Atomizing Nozzles Conserve Precious Liquids EXAIR’s new 1/8 NPT No Drip Internal Mix Air Atomizing Spray Nozzles mix liquid and air inside the nozzle and produce the finest atomization of liquids. The new, patented No Drip Internal Mix Atomizing Spray Nozzles work in the same way our standard atomizing nozzles do, but have the added benefit of positively stopping liquid flow when compressed air is shut off. When spraying any type of liquid, post-spray liquid flow can cause big problems. Drips occurring after spraying waste precious resources such as expensive coatings, chemicals or water, and are now eliminated with EXAIR’s patented design. Unwanted drips can ruin product function on sealing or mating surfaces and can ruin the appearance of painted or coated finishes. EXAIR’s No Drip Air Atomizing Nozzles are ideal where no post-spray drip is permissible. When the compressed air supply is shut off, the no drip nozzle positively seals off the flow of liquid eliminating the possibility of drips.

» For more information, visit www.exair.com

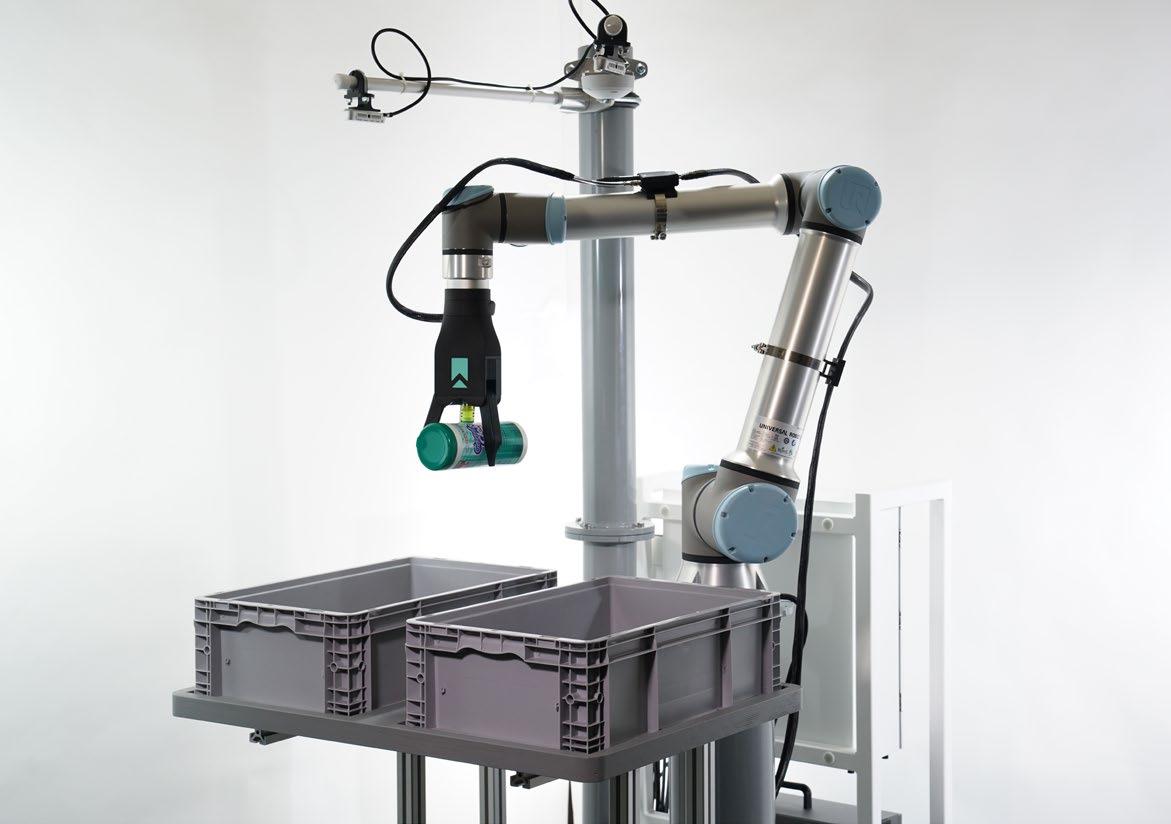

ABB and Covariant Partner to Deploy Integrated AI Robotic Solutions ABB, the world-leading supplier of industrial robots, and Silicon Valley AI start-up, Covariant, today announced a partnership to bring AI-enabled robotics solutions to market, starting with a fully autonomous warehouse order fulfilment solution. The partnership brings together the two companies with a shared vision for robotics enabled by AI, where intelligent robots work alongside humans in dynamic environments, collectively learning and improving with every task completed. Given the accelerated global growth experienced in the e-commerce sector, ABB identified a significant opportunity for AI-enabled robotics solutions across a broad range of applications including logistics, warehousing, and parcels and mail sorting.

ATI Industrial Automation

has introduced the AOV-10 Axially-Compliant Orbital Sander ATI Industrial Automation has introduced the AOV-10 Axially-Compliant Orbital Sander, specifically designed for robotic surface preparation and finishing. With built-in compliance, the AOV-10 is well-suited for many different robotic applications—even those that require a light touch. A pneumaticallyactuated compliance mechanism allows for dynamic control of contact forces and ensures an ideal result every time. The compliance force is adjustable to accommodate a wide variety of applications. Double-acting motion offsets the weight of the tool to produce the desired finish no matter how it is oriented. Users can mount the AOV-10 directly to their robot or to a fixture, in any orientation, including upside-down.

BIG KAISER Adds New Inserts BIG KAISER Precision Tooling is adding more than 30 pressedgeometry carbide inserts for its tools. The new insert design is the result of extensive research and testing. The new grades and geometries offer improved chip control due to optimized chip breakers, even when boring gummy materials like low-carbon or stainless steel and Improved coatings for increased speed and better wear resistance. More positive cutting geometries reduce cutting forces, chatter and vibration when used in deep-hole boring operations and provide longer tool life. The new inserts off up to 20 percent savings when compared to current grades

» For more information, visit www.bigkaiser.com

Dillon Hard Jaws Feature Diamond-Shaped Serrations for Increased Pull-Down Effect Hard Jaws from Dillon Manufacturing, Inc., feature diamond shaped serrations for increased pull down effect which reduces part slippage and push back from using a bar feeder. The aggressive serrations on the gripping surfaces are also ideal for cast parts, scaly parts or parts with imperfections. The hard jaws are available in one-step or two-step sets and are reversible for OD or ID chucking. Only one set is necessary to cover a wide clamping range. Dillon hard jaws are available in standard sizes from stock and in different mounting configurations including serrated, T&G, Acme, and square serrated key types to fit all brands of chucks.

» For more information, visit www.dillonmfg.com

High-Throughput DMP Flex 350 Metal 3D Printer from GF Machining Solutions The robust, flexible DMP Flex 350 enables efficient 24/7 production of very dense, pure metal parts from 11 ready-to-run challenging alloys, including thoroughly qualified Inconel, titanium, cobalt chrome, aluminum and steel. Improved gas flow technology produces more-uniform part quality throughout the build area. The DMP Flex 350 guarantees excellent microstructure density, stable mechanical properties and consistent powder quality for high-quality parts. Total cost of ownership remains low thanks to high powder recyclability, low consumables usage and a long-lasting process filter. For the ultimate in flexibility, the DMP Flex 350 upgrades to the DMP Factory 350, with integrated powder management system, high-performance sieving and automated powder conveyance.

» For more information, visit www.gfms.com

Power Skiving with Integrated Cutter Resharpening Delivers High Quality, Reduced cost A fully integrated on-board cutter resharpening unit is now available for Gleason vertical Power Skiving machines, allowing for the completely automated resharpening of cutters used in the production of both soft and hardened gears up to 600 mm in workpiece diameter. By automating cutter resharpening operations, Gleason Power Skiving machines require minimum operator involvement, greatly reducing the time typically required for frequent tool changes and subsequent first-part inspection cycles. Additionally, the usual cost for external tool refurbishment can be avoided. . The integrated cutter resharpening unit then executes the necessary grinding strokes while the cutter performs the infeed and the indexing from tooth to tooth.

» For more information, visit www.gleason.com

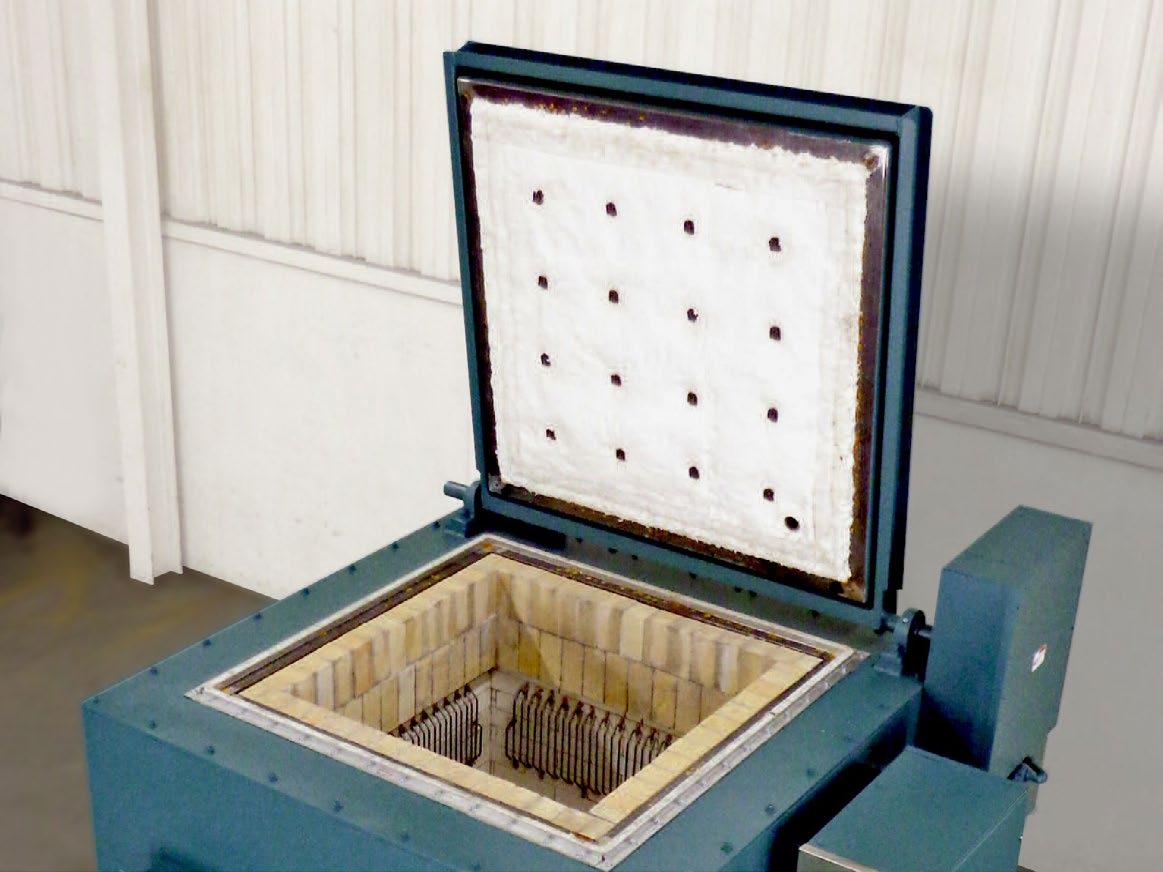

2200F° Inert Atmosphere Pit Furnace from Grieve No. 1040 is a 2200°F inert atmosphere pit furnace from Grieve, currently used for heat treating automotive parts in baskets at the customer’s facility. Workspace dimensions of this furnace measure 36” wide x 36” deep x 48” high. 78 KW are installed in heavy gauge, high temperature Kanthal AF alloy wire heating elements of rod overbend design and powered through a low voltage transformer to heat the workload. Inert atmosphere construction includes continuously welded outer shell, high temperature door gasket, sealed heater terminal boxes, inert atmosphere inlet, outlet, flow meter and manual gas valve.

» For more information, visit www.grievecorp.com

C-FRAME PRESSES

• Heavy Gauge Steel Design • Press Bed bolted on, not welded, to prevent distortion. • Large press bed to accommodate a variety of tooling other than just punching. • Pump, motor, valve and reservoir are all easily accessible for maintenance. • Large rectangular tubes used at base of machine to give safe, instant portability.

WE CAN BUILD A CUSTOM MACHINE FOR YOU!

GROB Systems to Highlight Machining Centers GROB’s G-Series, which includes the G350, G550 and G750 5-axis universal machining centers offers limitless possibilities for milling parts made of the most diverse materials. They are ideal for the aerospace industry, where complex components with high cutting volumes need to be achieved. Each machining center features a compact design, maximum milling performance, high visibility and optimized work area access. The Access-Series, featuring basic models G350a and G550a, include more features than ever before, which are backed by GROB’s more than 90 years of experience with machine tools. These 5-axis universal machining centers have short payback time, yet still deliver the best machining quality for production facility.

The Multigrind ® CB XL 5-axis CNC grinding center machines The development of the Multigrind ® CB XL model was a challenge for the engineers from Haas Schleifmaschinen because of

significantly larger part dimensions and weights. The design task

included maintaining “small part” microns accuracy even on larger

parts. No small task. The solution was based on the award-winning,

flagship Multigrind ® CB, a model designed from the beginning to be adapted and deployed for future demanding grinding tasks. This

new CB XL grinding center has much of the same structural design

as the CB, but with a “stretched” X-axis and machine table. Due to its

symmetric design, the Haas Multigrind ® CB XL maintains stability and rigidity, regardless of part length.

» For more information, visit www.multigrind.com

New Norton Disc Grinding Wheels Offer Over 30% Longer Wheel Life Saint-Gobain Abrasives announced the introduction of its new Norton Stellar inserted-nut grinding wheels for double and single disc grinding that offer improved wheel life, increased parts per wheel and lower cost per part. The new grinding wheels are ideal for a wide range of industries including automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining. Norton Stellar grinding wheels have an over 30 percent longer wheel life than existing disc grinding products and require less dressing and parameter changes for increased productivity. The new wheels also have an improved material removal rate of more than 15 percent.

» For more information, visit www.nortonabrasives.com

OnRobot Launches New 3-Finger Electric Gripper Ideal for CNC machine tending The 3FG15 three-finger gripper’s design, specifically developed for machine-tending tasks, automatically centers workpieces, resulting in a strong, stable grip and precise placement in machine chucks. With a gripping force from 10 N to 240 N, the 3FG15 competes with much less flexible finger grippers. The gripper is also ideal for packaging and palletizing applications, and is seamlessly compatible with any major collaborative or light industrial robot arm through OnRobot’s new award-winning One System Solution, the platform that provides a unified mechanical and electrical interface between the robot arms and any OnRobot EoAT.

» For more information, visit www.onrobot.com

char-lynn hydraulic products

low speed high-torque motors… The Char-Lynn motor range consists of three major types based on the valving used to distribute fluid through the Orbit gear set (geroler or gerotor), Spool Valve, Disc Valve and VIS (Valve-in-Star). A variety of displacement sizes are available in each of the three motor types to provide a wide range of speeds and torques.

steering control units… offer these advantages: • Minimal steering linkage reduces cost, provides design flexibility. • Complete isolation of load forces from the control station. • Continuous, unlimited control action with low output torque. • Wide selection of control circuits and meter sizes. • Works with many kinds of power steering pumps or fluid supply.

gear pumps… Eaton Series 26 gear pumps with 13-tooth gears minimizes flow ripple to reduce noise and vibration. Bearing lubrication system uses inlet oil rather than high pressure oil, improving volumetric efficiency and power output. The 13 available displacements and many mounting configurations provide for an easy retrofit. Other series available.

7355 N. Lawndale Ave., PO Box 6, Skokie, IL 60076 Phone: 847-676-2910 Fax: 847-676-0365

High-Precision Scotchman Accu-Table The Scotchman Industry Accu-Table helps simplify critical control measurements. The high-precision caliper table measures material

up to 16 feett. long to an accuracy of +/-0.004 inches. Its Windows ®

Tablet PC reads and stores measurements and can be accessed wirelessly over a network. The machine is available in 8-, 10-, 12-, 14-, and 16-feett. lengths. It offers repeatability of ±0.0015 inch. Readings are displayed in inch or metric conversions. Accu-Table has capabilities for creating custom measuring solutions including calculating Statistical Process Control (SPC) data, creating graphs, charts and important production information. Made in USA.

» For more information, visit scotchman.com

Seco QC Modular Toolholder Simplifies Swiss-style Machining For ease of use, the Seco QC Modular Toolholder allows users to remove both cutting heads and inserts as a single assembly,

quickly index them and reinstall. Manufacturers may also use this

system to exchange cutting heads and inserts with a second set for

even greater efficiency. The QC cutting head also features double

carbide pins for accurate, consistent and secure insert mounting

and indexing. Seco Jetstream Tooling ® technology precisely directs high-pressure coolant through the QC Toolholder to the cutting

zone. Seco Jetstream Tooling ® Duo, available on a selection of cutting heads, adds a second coolant channel to the underside

of the holder. The second coolant channel can be switched off if needed for even more versatile machining.

» For more information, visit www.secotools.com

SPRINTER MACHINES… • Provide reliable, low cost, ink code marking. • May be mounted in any orientation. • The sealed ink system allows discontinuous operations with immediate start-up of comparable previous impressions. • Can be modified or made to order for your particular marking application.

Model 22 Pass/Fail Dot Marking Machine

INDUSTRIAL INK MARKING SYSTEMS

SPRINTER MARKING supplies all the basic, optional and auxiliary equipment, as well as, operating supplies for normal code-marking operations.

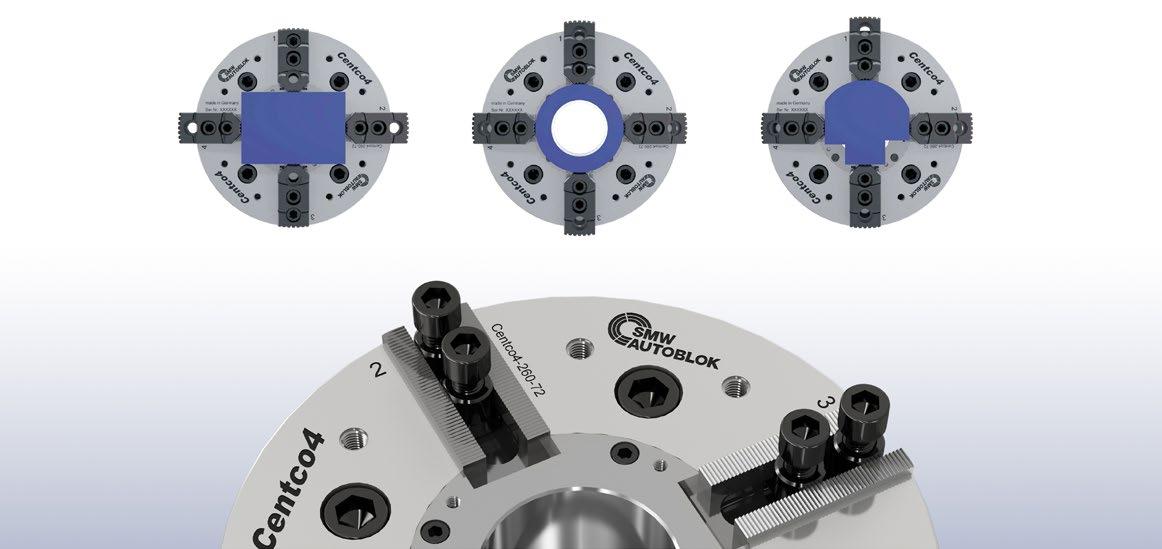

Clamp Virtually Any Workpiece Geometry with the Centco4 SMW Autoblok introduces the versatile four-in-one Centco4 2+2 self-centering and compensating chuck. The Centco4’s superb engineering and flexibility enables it to securely and efficiently clamp virtually any type or shape of geometric part including round, cubic, angular and irregular. The Centco4 is available in both power and manual models and is ideal for deformation-sensitive workpieces. The 4-jaw Centco4 provides four times less deformation as compared with three-jaw clamping and can be used on all industryspecific machine tools. The ability to handle virtually any part shape means fewer chuck change-outs and vastly reduced downtime. Diverse manual and hydraulic applications include turning, milling, inspection and finishing operations.

Suhner Offers EconoMaster ® Drilling Units for ValuePriced Production Use Suhner introduces the EconoMaster ® line of drilling units, affordably priced at under

$3000 for the basic unit, in

stock for immediate delivery

or customizable to suit the

particular operation. This

economical solution is

ideal for multiple

materials

composite,

plastic and foam. Because these units are entirely produced at the

Suhner factory in Rome, Georgia, response times for delivery and

customized construction are fast. The EconoMaster ® drilling unit features low power and air consumption, adjustable motor housing,

adjustable total stroke up to 4”, hydraulic feed control cylinder, J33 taper spindle end, 0-1/2” drill chuck.

» For more information, visit www.suhner.com/en

Universal Robots and RightHand Robotics Cobot-Powered Fulfillment Solutions With e-commerce generating the greatest year-over-year growth of all U.S. retail industries, there is now more warehousing space being built in the U.S. than projected warehousing jobs required to fill that space. When thousands of supply chain professionals were asked in a recent Materials Handling Institute survey what technologies would yield the greatest boost to productivity, ‘Robotics and Automation’ was their answer. RightHand Robotics’ RightPick platform has successfully completed many millions of picks autonomously across numerous industries, including e-commerce, retail, pharmaceuticals, grocery, and more

» For more information, visit www.universal-robots.com

New MU5 double-sided indexable insert boosts reliability in steel and stainless turning With forged parts, particularly in automotive production, Walter’s MU5 geometry minimizes crater wear and enables reliable and fully automated production. For users with changing material demands and smaller batch sizes, the MU5 is appealing due to its universal use in steel and stainless materials. These characteristics of the MU5 insert are due to its positive macro- geometry, while maintaining a negative clearance. Other features include an open chip breaker groove for long tool life and soft cutting features, a V-shaped chip breaker for improved chip breakage, and a curved cutting edge yielding high surface finish quality.