Managing Energy for the Sustainable Factory

Rahul Garg, VP of Industrial Machinery, Siemens Digital Industries Software

A One-Stop Shop — The Robotics of FANUC

Seeing is Believing

CNC Automation in Smart Factories

Russell Riddiford, President of ANCA Americas

How AM Improves Sustainability Across the Supply Chain

Max Siebert, CEO and Co-Founder of BASF-owned, Replique

Robots in the Cloud

A Cloud is Born

IndustrialMachineryDigest.com | Q1 2023

The Industrial Machinery Digest Robotics & Automation Quarterly Resource!

The Best Tool Cabinet You Will Ever Buy GUARANTEED 100%MADE IN THE USA INEVERY WAY WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 MADE BY AMERICAN CRAFTSMEN IN THE USA sales@storloc.com

4 | IMDQ | Q1 2023 6 EDITORIAL DIRECTION 8 INDUSTRY NEWS 12 CASE STUDY Managing Energy for the Sustainable Factory By: Rahul Garg, VP of Industrial Machinery Siemens Digital Industries Software 16 COMPANY PROFILE A One-Stop Shop — The Robotics of FANUC 22 INTEGRATIONS Seeing is Believing 24 MACHINES CNC Automation in Smart Factories By

President of ANCA Americas How AM Improves Sustainability Across the Supply Chain By Max

of BASF-owned, Replique 28 SOFTWARE & CLOUDWARE Robots in the Cloud A Cloud is Born 42 PRODUCT SHOWCASE 44 BUYER'S GUIDE FEATURED 49 SURPLUS GUIDE FEATURED 52 SURPLUS BUYING & SELLING 56 CLASSIFIEDS 57 ADVERTISER INDEX 12 16 22 28 24 QUARTER 1 2023 Table of ConTenTs

Russell Riddiford,

Siebert, CEO and Co-Founder

Lifting

Application

Lifts up to 500 lbs! Ergonomic Portable Lightweight Meets OSHA & ASME

Customized Safety

Devices For Any

SAFETY FIRST Prevent Lifting Injuries

AGRO-HYTOS HYDRAULIC PRODUCTS

FILTRATION… The range of filter solutions implemented at Argo-Hytos extends from fixed-position industrial plants to highly mobile applications, primarily tailored to individual customer requirements. As a result of their vast experience with custom applications over a wide variety of sectors, Argo-Hytos offers a comprehensive range of innovation standard solutions: Suction Filters; Return and Return-Suction Filters; Pressure/ High Pressure Filters; Filling and Ventilating Filters; Filter Accessories; Sensor Technology.

FLUID AND MOTION CONTROL…

DIRECTIONAL CONTROL VALVES D02/D03/D05/D07/D08: Argo-Hytos DC and dual frequency AC coils can be rotated to locate connectors to your need. DIN, Deutsch Flying Leads and Wire Box Connection are available as standard Manual Override. Full line of Sandwich Controls.

FIVE SERIES OF VALVES RATE TO 5000 PSI: RPE3-04, providing 8.0 GPM; RPE3-06, providing 21.0 GPM; RPE4-10, providing 37.0 GPM; RPE4-16, providing 80.0 GPM; RPE4-25, providing 160.0 GPM

GEAR PUMPS: Argo-Hytos gear pumps provide high reliability, high volumetric efficiency, and low noise levels over the entire operating range.

THREE SERIES: GP1-P, maximum pressures from 2300-4350 flows 1.0 gpm; GP1-T, maximum pressures from 1700-4200, flows 1.0 to 17.0 gpm; GP1-Q, maximum pressures from 2900-4500, flows 7.1 to 42.8 gpm.

William C. Strickland III, Publisher william.strickland@indmacdig.com

800-366-0676 ext. 103 | Fax: 866-826-5918

Trey Bell, Editor-in-Chief trey@indmacdig.com

800-366-0676 ext. 104 | Fax: 866-826-5918

Brian Self, Associate Editor assoc.editor@indmacdig.com

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Adrienne Gallender, Media Adviser agallender@indmacdig.com 888-407-7737

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com

6 | IMD Q1 2023

source media llc 360 A PUBLICATION OF: Source 360 Media LLC 3590-B Hwy 31 South PMB #233 Pelham, AL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individuals. Publisher reserves the right to reject nonqualified subscribers. One-year subscription to nonqualified individuals in the United States: $96.00. Single copies available (prepaid only) $20.00 each. Alabama Automotive Manufacturers Association SERVING AMERICAN MANUFACTURERS FOR OVER 37 YEARS North America’s Manufacturing Resource for Industry Professionals Since 1986 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money!

7355 N. Lawndale Ave., PO Box 6, Skokie, IL 60076 PHONE: 847-676-2910 FAX: 847-676-0365 WWW.MACMHYDRAULIC.COM

VICE HOOK ACCESSORY

WE

WE

WE AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS

In additional to air tools, we offer accessories and abrasives for complete process solutions with the know-how to get the job done right.

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

LISTEN.

OBSERVE.

Ask about a no-obligation demonstration on any product in our line. OPTIMIZE. ABRASIVE POWER TOOLS & PROCESS SOLUTIONS SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com |

Something For Everyone

We really have content in this quarterly edition for all of our readers - no matter your specialty or focus. Our theme is Robotics & Automation, to which we tried to stay true - but in a sign of the times, we also incorporated an underlying focus on Sustainable Manufacturing. Our planet is important for us and for our future generations, so this sub-theme is equally important.

Max Siebert, CEO of Replique, hits home with a thoughtful piece on the impact of Additive Manufacturing to the sustainability of supply chains. Sustainability comes in many shapes and sizes (we will also showcase a company in our April 2023 edition that has 100% reusability of production scrap) as Max makes some key observations, especially in comparing the injection molding costs of parts. Extending the viewpoint in our Case Study section, Rahul Garg, VP of Industrial Machinery, Siemens Digital Industries Software, discusses how software and digitalization improves sustainability in manufacturing by enabling more precise decision making for energy saving operational efficiencies. It’s spot on and a nice summary of digitalization impact potential in the smart factory.

We put together an overview of Cloud Software that is focused on management and configuration of robots through the cloud. Three of the biggest cloud infrastructure players in the world, Google, Microsoft, and Amazon have offerings to support this approach. Be sure to check out “Robots in the Cloud.”

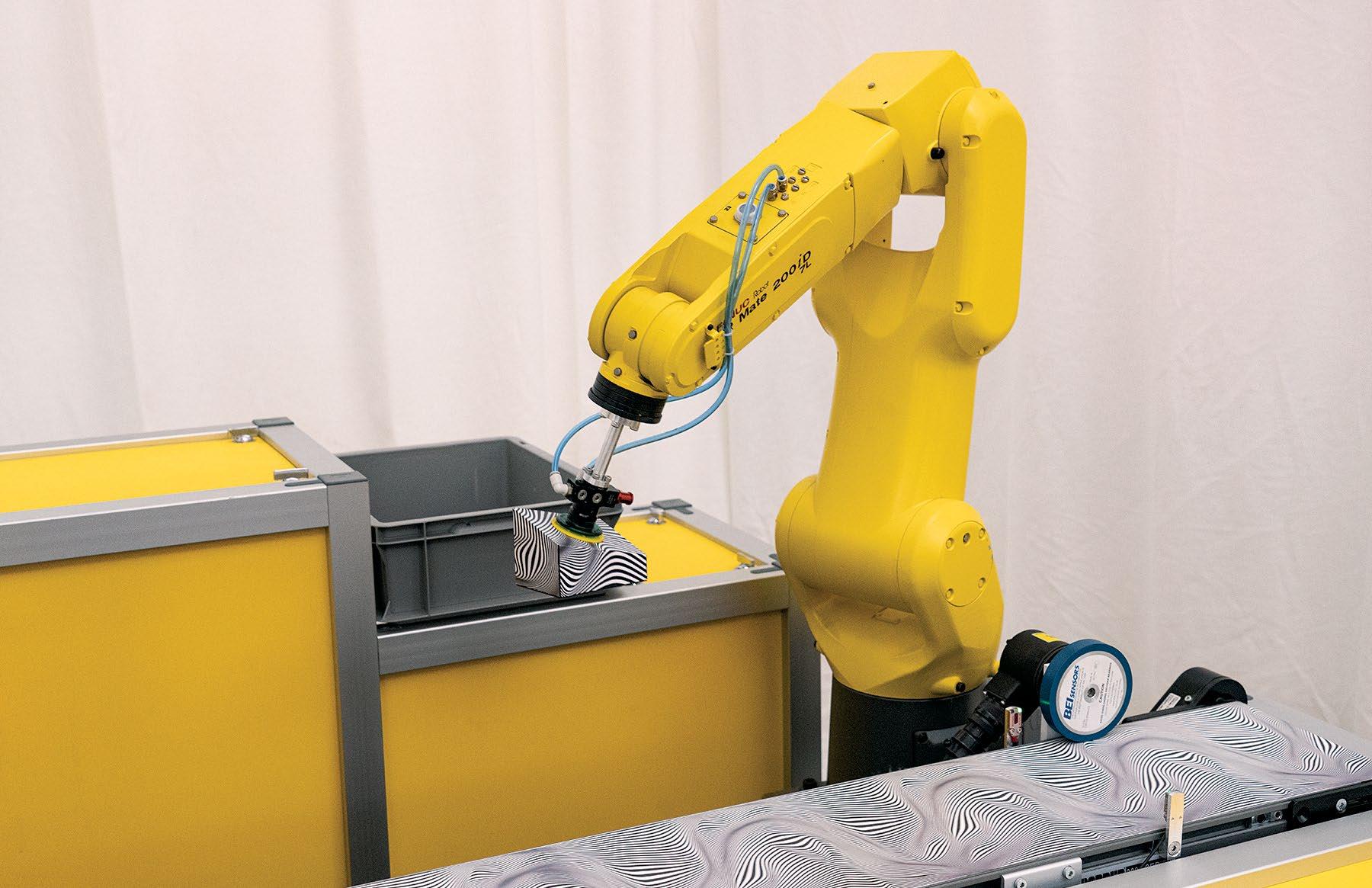

In our Company Profile, we take a deep dive into some of the Robotic offerings of FANUC. This is truly a Roboticfocused company (we know there are others as well), with offerings from Cobots to specifically focused work center robots. There is also an offering around lasers - I bring this up because in our April edition we will feature an insightful piece on how lasers have become our modern “lightsabers” in manufacturing today.

Our Integrations section features a broad look at Machine Vision Inspection systems, including one approach on how to retrofit your systems with software or other components, rather than making a new purchase. As optics and image processing capabilities have improved, so have these automated inspection systems. We highlight some emerging trends in this space, and discuss the components of Machine Vision Inspection. Add in some Industry News, Product Showcases, and some CNC Automation and you have our 2023 Q1 edition. Enjoy - and be sure to send me feedback - trey@indmacdig.com

Keep on building.

Trey Bell – Editor in Chief trey@indmacdig.com

8 | IMD Q1 2023 ediTorial direCTion

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! CABLE VS CHAIN With

Subscribe now to receive FREE news on upcoming auctions! YOUR

our user-friendly website, users can easily find the type of auction they are looking for, regardless of size or location. The site has the latest technology to make it simple for users to engage with an auction of interest.

COMPLETE AUCTION RESOURCE

AMERICAN-MADE SHEARS & PRESS BRAKES

Hydraulic Shears: 1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com

Rapid Robotics Partners With Yaskawa Motoman to Expand Solutions for Industrial Robotic Arms

Through a new partnership with Yaskawa Motoman, the SF-based robotic workforce solutions company is bringing its rapid deployment speeds & next-gen service to industrial applications

Rapid Robotics announced today a brand-new integration with Yaskawa America, Inc., Motoman Robotics Div. (Yaskawa Motoman) that will bring industrial capabilities to Rapid Robotics’ Rapid Machine Operator (RMO). The company is now integrated with the entire Yaskawa robotics portfolio, and can deliver more speed, higher payload and increased performance to a greater number of North American manufacturers with a more diverse range of needs.

“Since our founding in 2019, Rapid Robotics has been committed to providing manufacturers with a holistic workforce solution in the form of accessible, low-risk automation,” said Jordan Kretchmer, CEO and Co-Founder of Rapid Robotics. “Today, we’re able to deliver on that commitment better than ever through our partnership with Yaskawa Motoman and their legacy of industrial expertise.”

By combining advanced computer vision, artificial intelligence and instinctive learning with as-a-service

characteristics including cloud connectivity, monthly leasing and 24/7 support, Rapid Robotics has been able to democratize automation in the face of an intense workforce shortage. Now, with the Yaskawa portfolio as an integrated part of Rapid Robotics’ suite of solutions, manufacturers needing an industrial-size solution who previously could not automate due to traditional barriers like cost, inflexibility or lengthy deployments, can make those automation dreams a reality.

“A trusted name in industrial automation for over a hundred years, Yaskawa is an established leader in the robotics market. A partnership with Rapid Robotics opens the door to automation for a large number of enterprises that have previously found it difficult or intimidating to deploy robotic solutions,” says Chris Caldwell, Product

10 | IMDQ | Q1 2023 indus Try news industrial Machinery digest's industry news features the latest news and press releases from some of the industries top companies. WANT TO BE FEATURED? Send your press releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com Streamlining Credential Processes Bringing Global Technology to a Local Level Manufacturing IndustrialMachineryDigest.com October2021 MANUFACTURING SHOWCASE: FEATURED STORIES: Cincinnati, Inc. IMPACTING DROP ZONE Wildeck Provides Increased Safety for Moving Palletized Loads the » Empowering Employees » Surpassing Energy Savings Manufacturer in Oxnard, CA experiences the benefits of Green Hydraulic Power Units » Lifting Higher Combi-PPT - A High Capacity Powered Pallet Truck Streamlining Control Siemens Offers Optimized Control Panel Construction to Machine Tool Builders IndustrialMachineryDigest.com March 2019 IndustrialMachineryDigest.com June2021 ESTABLISHED IN 1986 AND IS THE INDUSTRY’S Most Extensive Industrial Publication. GETTING BACK TO WORK!! 2021 INDUSTRIAL MACHINERY DIGEST’S INDUSTRY NEWS

Manager of Yaskawa Motoman. “Yaskawa is excited for the opportunity to offer truly industrial solutions, expanding Rapid Robotics’ capabilities while providing improved cycle-times and return-on-investment for end users. By combining strengths, Rapid Robotics’ advanced vision systems and state-of-the-art AI allow Yaskawa’s full line of robotic manipulators to shift repetitive or dangerous tasks away from your human workforce, freeing them to perform more fulfilling work.”

A trademark of Rapid Robotics’ solutions is an unprecedented speed of deployment. This holds true for the new industrial RMO due to the company’s modular approach to work cell design. Streamlined industrial Yaskawa robots with robust capabilities take full advantage of that approach, avoiding interference with peripheral devices, and keeping the installation space of an industrial RMO work cell minimal. A key feature of this re-imagined work cell is an innovative mobile robot pedestal with modular fixturing. The mobile pedestal gives this light industrial arm the same flexibility as Rapid Robotics’ collaborative robot (cobot) solution as the pedestal can be easily moved or reconfigured and then re-locked into place by a single person.

Historically, industrial robotic arms can be more challenging and time-consuming to deploy than their cobot counterparts, especially outside of mass production environments, due to their complexity and the extensive safety measures required. Rapid Robotics’ industrial RMO

offers all the flexibility of a cobot solution while meeting all mandatory safety measures with the added payload, speed and reach of a traditional industrial arm.

For more information, please visit www.motoman.com or call (937) 847-6200.

Rollomatic Inc. appoints new Chief Executive Officer

Rollomatic Inc., a subsidiary of Rollomatic Holding Switzerland, announces the appointment of Joe Kane as CEO of Rollomatic Inc. as of January 1st, 2023.

Rollomatic is a world-leading builder of CNC tool/ cutter and peel grinding machines as well as laser cutting machines based in Le Landeron, Switzerland. Their North American headquarter is in Mundelein, IL with a state-ofthe-art machine demonstration and customer support facility. Their sister company, Strausak Inc., is located in the same building.

While being CEO of Rollomatic Inc., Joe Kane will continue to hold his position as CEO of Strausak Inc. The combined companies will further fill out their global presence in providing top solutions for precision tool grinding and other manufacturing applications.

Joe will continue to be based in the company's North America office located in Mundelein, IL. In this position, Joe will oversee all areas related to the operation of the two companies. Joe will lead a team of 4 senior managers who

DID YOU KNOW TORMACH SELLS PLASMA TABLES?

Premium features make better parts.

• Closed-loop servo motors for reliable accuracy

• Floating head with Digital Torch Height Control that help make cuts to uneven surfaces like corrugated metal

• Standard breakaway torch holder with collision detection to minimize machine damage if things go wrong

• Minimized run times with fast rapids (1,000 in./min., 400 in./min. cuts) and acceleration (30 in./sec.²)

• Integrated water table mounted on sliding rails, ideal for cutting pipes and larger parts

• The only plasma table built with PathPilot, Tormach’s award-winning CNC controller, and access to PathPilot HUB, Tormach’s browser-based version of PathPilot

INDUSTRIA L MACHINERY DIGEST COM IMD | 11 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

CNC MILLS | CNC LATHES | CNC PLASMA TABLES | CNC ROUTERS | INDUSTRIAL ROBOTS | AUTOMATIC FEED BANDSAWS

Learn more and build yours at tormach.com/1300PL/IMD

supervise sales and operations on a cross-functional basis.

“Joe’s impressive track record working as COO of Rollomatic Inc. and his ability to communicate and relate to people make him the ideal leader. Such qualities are key to expanding the brand name and drive the ever-evolving new technologies of the companies. We fully expect that his talents will support the profitable growth of the Rollomatic and Strausak business”, said Eric Schwarzenbach, retiring President of Rollomatic Inc. Mundelein, IL. “Joe has proven repeatedly that he has the combination of capability, ambition and high level of customer engagement that will allow the Rollomatic Group to continue to expand and gain market share in North America.”

Prior to joining Strausak Inc. as CEO in 2017, Joe spent over 14 years in the manufacturing and quality industry where he began as a Metrology Technician with the United States Marine Corps. He later translated these skills and expanded his career into product and national sales manager positions where he set up distribution and service channels throughout North America for CNC machine tool companies specializing in automated turnkey solutions for production machining.

Rollomatic Inc., located in Mundelein, Illinois, is a subsidiary of Rollomatic SA, a privately-owned Swiss company established in 1989 in Le Landeron, Switzerland. The US Headquarter was launched in 1994 to provide local customer service and support throughout the U.S., Mexico and Canada.

This location features a 29,000 sq. ft. building with a showroom and training area as well as warehouse and engineering offices. This showroom provides an ideal atmosphere for machine demonstrations, software training and test grinding, while offering an opportunity to explore the latest Rollomatic offerings.

Rollomatic is looking to the future with its partners such as the EPFL (Swiss Technical University in research, teaching and innovation) so it can be right at the center of the innovations and in-depth discussions shaping the Fourth Industrial Revolution. True to its Swiss origins, the company operates at the highest level of precision and offers 100% Swiss-built products and services. Rollomatic is in constant pursuit of excellence in quality and accuracy.

PMT Premier Machine Tools Limited acquired by Seco Tools

As of February 1st, 2023, the Irish company PMT Premier Machine Tools Ltd (PMT), a supplier of machining solutions for the medical industry, will become part of the products and services offering from Seco. With this acquisition Seco will increase its presence in the medical segment offering integrated manufacturing solutions.

PMT will continue to operate as an independent company and sell its products and services under the PMT brand. PMT are specialists in machining solutions for the medical industry. Its business consists of supplying cutting tools and providing expertise, alongside a thriving machine tool supply business. All current PMT offerings will continue in the future.

PMT has been successful in building a strong reputation, particularly in its home country of Ireland. With PMT joining the Seco family, Seco has strengthened its offering in the medical device, and will build on its success worldwide.

“Seco and PMT have enjoyed a close and successful working relationship for many years” says Stefan Steenstrup, President of Seco. “Our offer to our customers has been further enhanced with PMT joining the Seco Tools family” he continues.

SINTX Technologies Announces Its New Utah Armor Facility Is Fully Operational

Facility will produce high-performance ceramic armor products for personnel, aircraft, and vehicles

SINTX Technologies, Inc. (www.sintx.com) (NASDAQ: SINT; “SINTX” or the “Company”), an original equipment manufacturer of advanced ceramics, announced today that equipment installation along with key renovations and upgrades to its SINTX Armor facility in Salt Lake City are now complete. This milestone is the result of an intensive effort by the SINTX team to upgrade the facility’s infrastructure and install armor manufacturing equipment that was acquired from Ohio-based B4C LLC.

SINTX Armor is a 10,000 square-foot facility that can manufacture high-performance ceramic armor plates for personnel, aircraft, and vehicles. Products include 100% boron carbide (BoroShockTM), which is a high-strength material designed to protect special forces against high-velocity projectiles. Another product, DuraShockTM, is a composite of boron carbide and silicon carbide that is designed to protect law enforcement personnel.

SINTX’s BoroShockTM and DuraShockTM are advanced material technologies that combine light weight with resistance to projectiles. These features are desired in modern armor systems that must balance high levels of protection against user comfort and mobility. Ceramic armor products are in demand by defense and law enforcement departments worldwide, especially since such products have a finite shelf life, and as newer technologies offer advantages over previous versions.

“SINTX Armor reiterates our commitment toward meeting the global demand for protective ceramic armor,” said Dr. Sonny Bal, CEO of SINTX. “Our expertise in advanced ceramics has positioned us as a leader and innovator in the protective armor industry well into the future.”

After the purchase of B4C LLC and a technology collaboration with Precision Ceramics USA in 2021, SINTX Armor was established as a subsidiary of SINTX Technologies. Since then, SINTX Armor has encountered strong interest and received requests from many customers to evaluate its products. SINTX Armor expects a robust order book in the first half of 2023 and looks forward to participating in the global ceramic armor market – which is projected to reach USD $3.5 billion 2027.

For more information on SINTX Technologies or its materials platform, visit www.sintx.com.

12 | IMDQ | Q1 2023

The Manufacturing Technology Series connects decision-makers from diverse industries with leading suppliers of advanced manufacturing technology, equipment and tooling. Don’t miss the most important manufacturing technology events in the U.S. in 2023. The Manufacturing Technology Series 2023: Four Regions . One Mission . Visit mtseries.com to learn more. Feb. 21-23, 2023 May 16-18, 2023 Oct. 24-26, 2023 Nov. 7-9, 2023

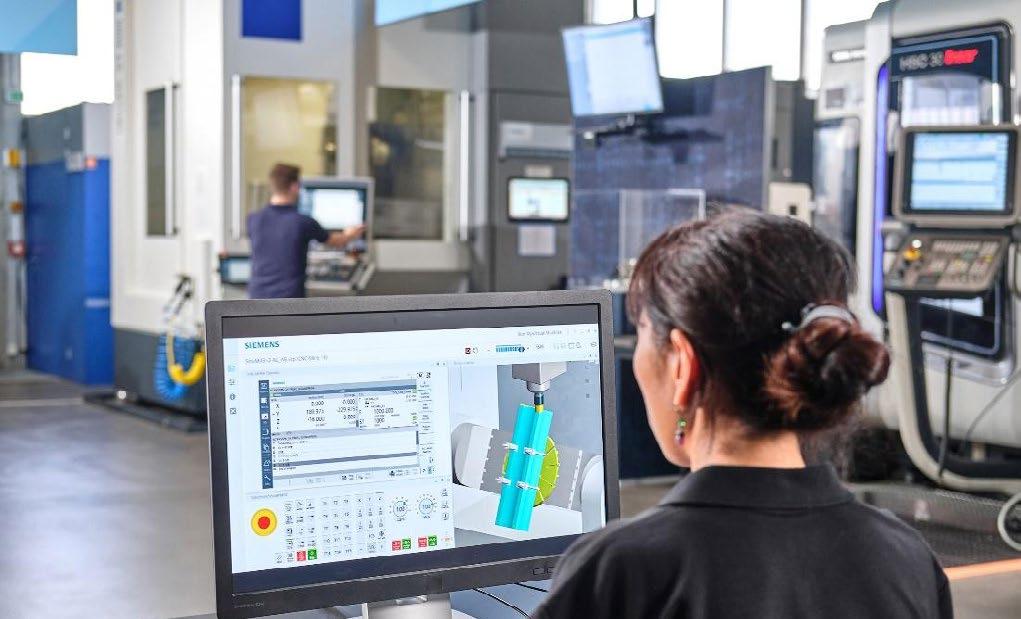

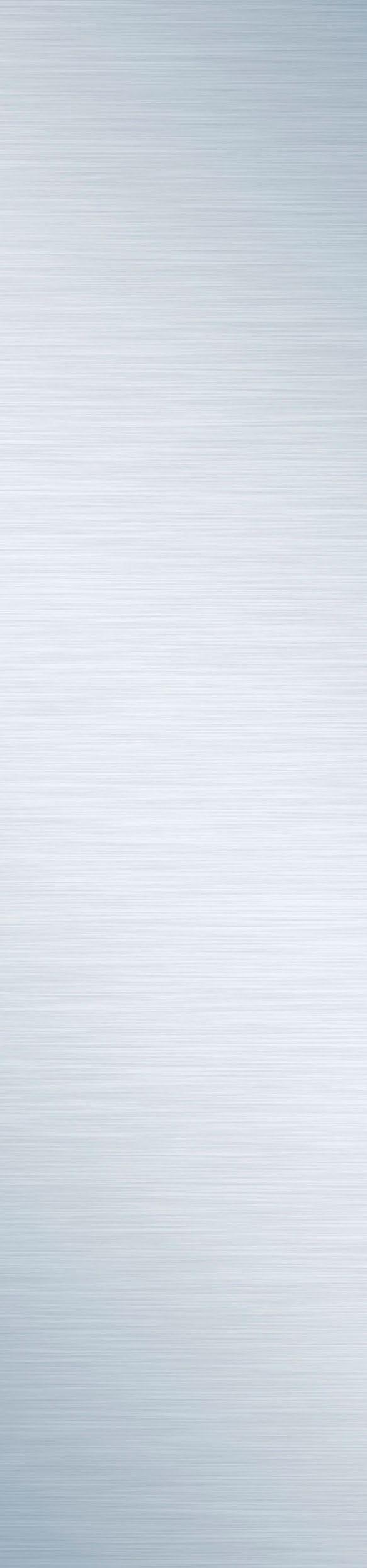

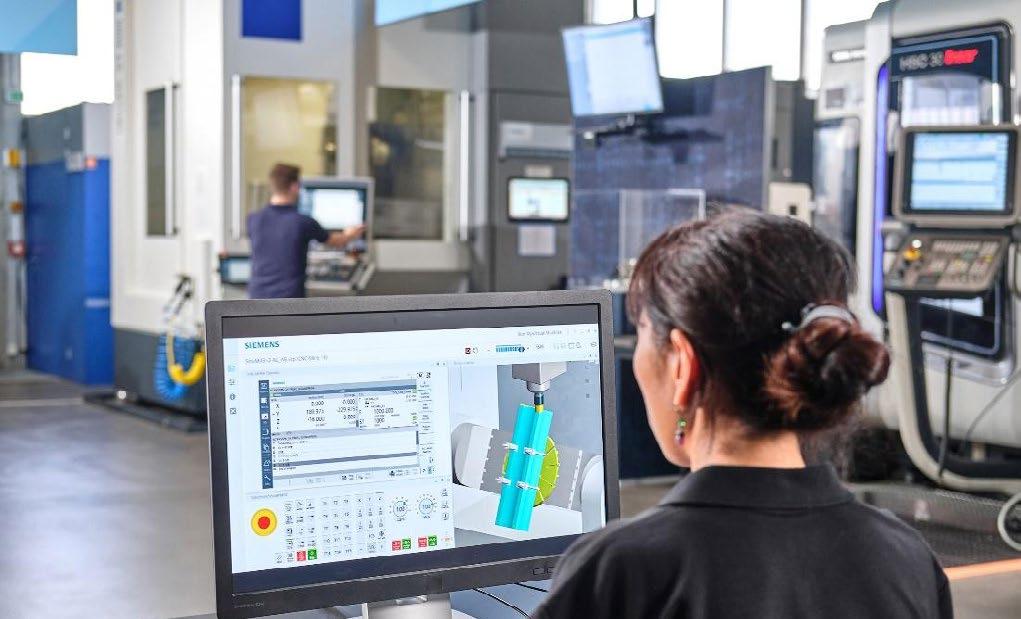

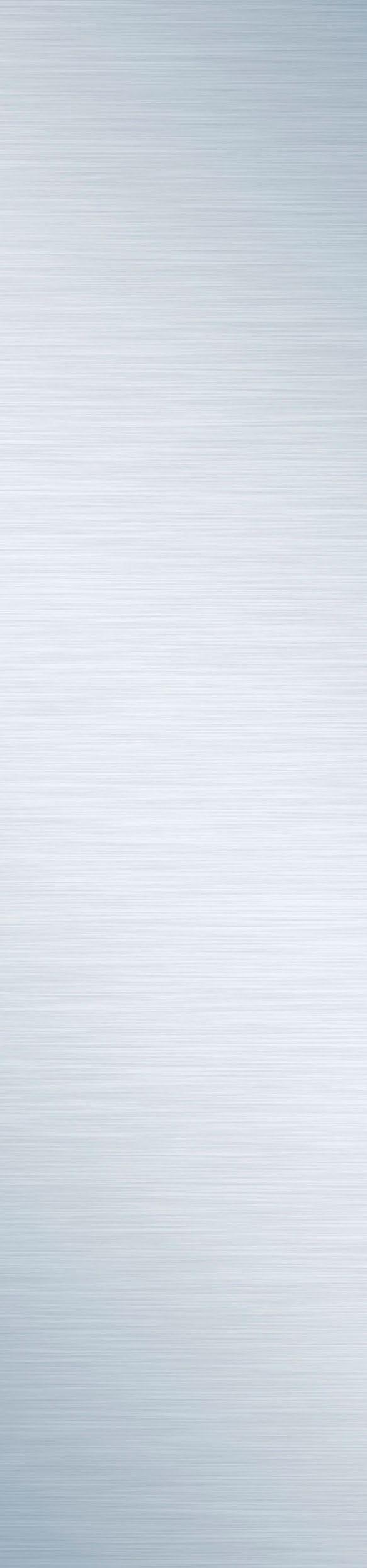

Managing Energy for the Sustainable Factory

By: Rahul Garg, VP of Industrial Machinery, Siemens Digital Industries Software

By: Rahul Garg, VP of Industrial Machinery, Siemens Digital Industries Software

Sustainability is vital for the manufacturing engines of the world that consume substantial energy. The spiraling price of power is increasing this urgency as it is forcing many regional factories to curtail production or even shut down. Now more than ever, manufacturers globally are determined to address this critical issue, which has put pressure on both the industrial machinery industry and factory operations to aggressively deliver capabilities for a more a sustainable factory to meet these pressing energy directives.

The most effective path to sustainable process, environment, and products is embracing digitalization. With a comprehensive digitalization strategy, it is now feasible to design, develop and deploy smart machines and optimize factory operations to achieve the ultimate zero downtime, zero harm and zero waste.

Digitalization to achieve optimal performance and sustainability

Manufacturers are committing to digitalization to achieve a new level of smart manufacturing. Digitalization delivers more data and better data—key for boosting operational

efficiencies to achieve a host of benefits: high availability, maximized factory utilization, and real-time management of supply chains. Equally important, digitalization enables manufacturers to track and lower energy consumption in the short term while leading to greater sustainability overall and the sought-after triple zero of manufacturing.

To improve energy usage and sustainability requires a deep understanding of operations. If you can measure it, you can optimize it. In my role as vice president of industrial machinery at Siemens Digital Industries Software, I am constantly talking with manufacturers and over time have observed that there are 3 steps for effectively implementing digitalization:

1. IT/OT fusion for actionable insights—the initial step is gathering rich, useful data generated by the factory operations technology (OT). The goal is to amass sufficient information to uncover actionable insights. Data is collected across a wide variety of physical sensing technologies, including programmable logic controllers (PLCs), sensors and gauges, IoT devices, etc. Then IT is used to store, retrieve, process, analyze, and recommend action on digital

14 | IMDQ | Q1 2023 Case sTudy

data extracted from OT. It is important to identify key indicators like carbon footprint, performance and profitability early on so that the right data is collected and analyzed.

Extending beyond the factory walls, it is critical to have a clear understanding of the supplier ecosystem. Not only does this provide awareness of cost, timelines and potential disruptions, but also it enables measurement of carbon intensity and resource utilization up and down the value chain. A connected industrial ecosystem, from suppliers and distributors to energy producers, is required to identify new opportunities for partnering and sustainably growing together.

2. Closed-loop manufacturing for continuous improvement—once all the relevant data is available on an ongoing basis, it is possible to create a connected feedback loop. This can be used to continuously hone the cost, time and quality of the manufacturing process while minimizing energy consumption. In short, it tightens the alignment of the as-planned product with the as-built and as-used product in a continuous, iterative process. Engineering teams can receive timely manufacturing feedback to expedite problem resolution and ensure optimal manufacturing that effectively leads to the goal of zero downtime. At the same time, operations can be continuously refined for the most efficient energy usage. This requires linking energy and production data to fine tune the energy consumption of specific machines, as well as the energy productivity of the whole plant to drive sustainable industrial innovation.

3. Closed-loop quality for maximum sustainability with manufacturing being continuously enhanced, it is now possible to pursue optimal product quality that includes long-term sustainability goals—such as zero waste. Closed-loop quality ensures complete visibility of quality-related metrics from planning through delivering on the quality of the completed product. Organizations that establish closed-loop quality processes achieve a median product compliance rate of 99 percent, with a majority performance ranging from 97-100 percent. That means near zero waste without compromising on product performance or sustainability.

Digital twin for energy-aware factory operations

This three-step approach to digitalization, once implemented, supports a comprehensive digital twin of the manufacturing environment. This is a critical game-changer for manufacturers positioning themselves for the future. The digital twin is a virtual, digital replica of the physical objects of an entire machine or the entire manufacturing system or the entire shop floor in a digital environment.

The IT and OT convergence delivers continuous real-time data to increasing the fidelity of the comprehensive digital version of the factory over time. This means that while the factory operates, the digital twin

provides a physically accurate simulation that combines the virtual and physical worlds.

The comprehensive digital twin is the basis for improving operations via simulation using the digital model. This includes optimizing operations, predicting maintenance, enabling more efficient commissioning, better changeovers and faster production line changes.

Moreover, the digital twin can be used to simulate and enhance the energy efficiency of the individual machines tool paths, the entire manufacturing line and even the movement of materials in the factory based on real data. The result is lower energy usage without sacrificing on quality or production throughput goals.

Energy efficiency today for a more sustainability future

Digitalization is the best path for lowering manufacturing energy consumption today while pursuing long-term sustainability goals. The immediate result is lower energy usage due to augment machine efficiency and approaching the goal of zero downtime, zero harm, zero waste. Over time, however, is where the real rewards are reaped. The digital twin for optimizing operations and product quality, combined with a robust connected industrial ecosystem, will lead to a lasting, sustainable future.

ABOUT THE AUTHOR:

Rahul Garg is the Vice President for Industrial Machinery at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

INDUSTRIA L MACHINERY DIGEST COM IMD | 15 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

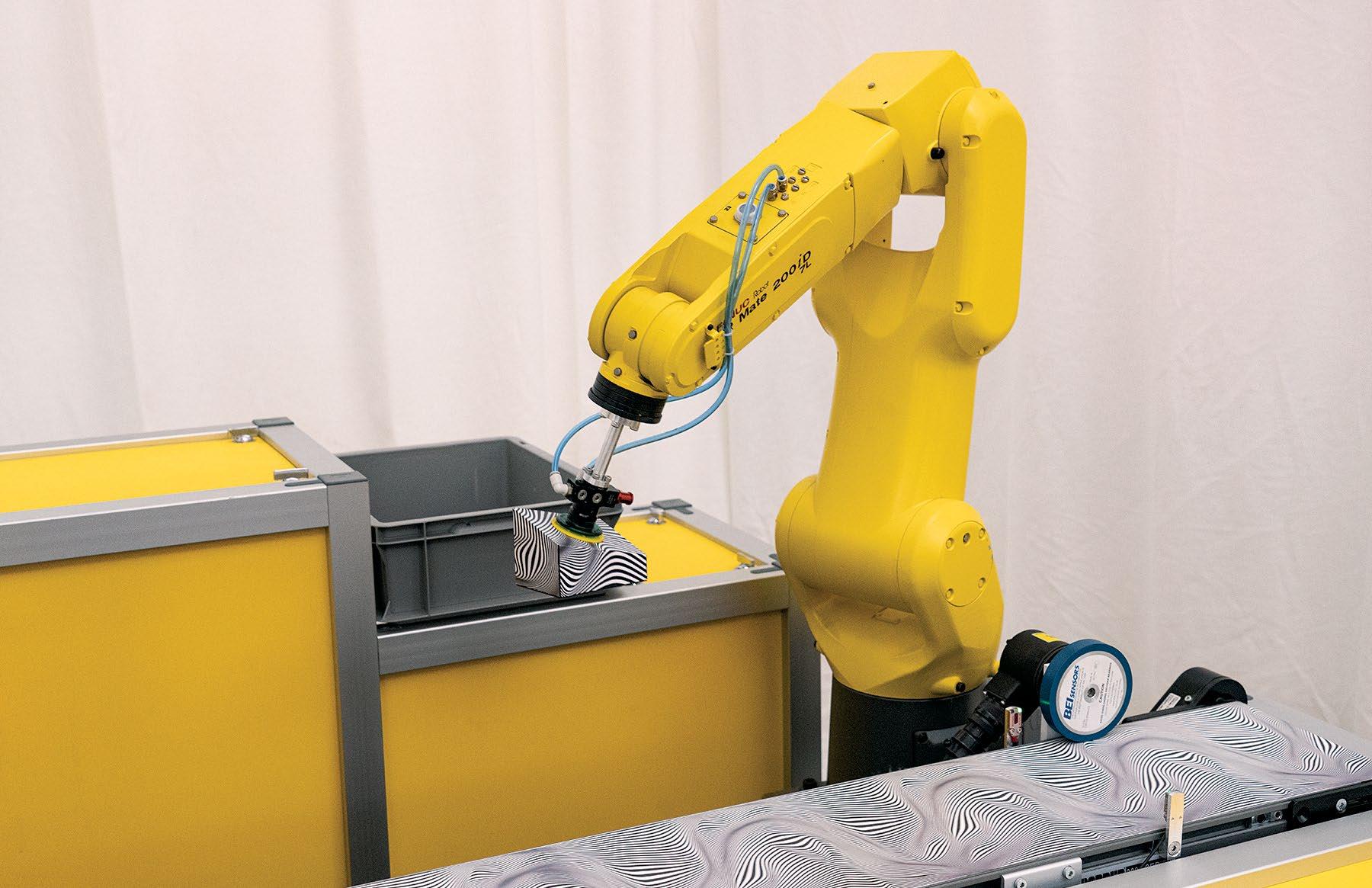

A One-Stop Shop — The Robotics of FANUC

FANUC Corporation is a leading global manufacturer of factory automation solutions, robotics, and CNC systems. Established in 1956 and headquartered in Oshino, Yamanashi, Japan, the company's primary focus is on developing advanced technologies and products to increase the efficiency and productivity of manufacturing processes across various industries.

FANUC's product portfolio includes:

» Industrial Robots: FANUC designs, manufactures, and supplies a wide range of robotic systems for various applications, including assembly, material handling, welding, painting, and more. Their robots are known for their precision, speed, and reliability.

» CNC Systems: FANUC is a leading provider of CNC systems that control the operation of machine tools, such as milling machines, lathes, and grinding machines. These systems are designed for high precision, accuracy,

and reliability, making them an integral part of advanced manufacturing processes.

» RoboMachines: The company also develops and markets RoboDrills, RoboShots, and RoboCuts –high-speed and high-precision machining centers, injection molding machines, and wire-cut electric discharge machines, respectively.

» RoboCobots: FANUC's collaborative robots, or "cobots," are designed to work alongside humans in various manufacturing and assembly tasks, emphasizing safety and ease of use.

» IoT and AI Solutions: To support the Industry 4.0 revolution, FANUC offers various IoT (Internet of Things) and AI (Artificial Intelligence) solutions, such as the FIELD system (FANUC Intelligent Edge Link & Drive), which enables advanced monitoring, analysis, and optimization of manufacturing processes.

16 | IMDQ | Q1 2023 CoMpany profile

200% PROOF LOAD TESTED EACH RING HAS SERIAL NUMBERS ORDERS SHIPPED SAME DAY RATED LOAD 400 LBS - 250,000 LBS Forged Street Plate™ Swivel Hoist Rings Side Load Hoist Rings Hoist Ring Kits Pivots180° Swivels 360° Drop Forged Hoist Rings Mold Handler™ Swivel & Pivot Hoist Rings Round Base Swivel & Pivot Hoist Rings Forged Swivel Hoist Rings 800-752-7229 | SALES@ACTEKMFG.COM | ACTEKMFG.COM ISO 9001 HOIST RINGS ACTEK

FANUC has a global presence, with subsidiaries and sales offices in numerous countries, including the United States, Germany, China, and India. The company is committed to innovation, investing heavily in research and development to maintain its position as a market leader in industrial automation and robotics.

FANUC's SCARA robots are a series of industrial robotic arms designed specifically for high-speed, precision applications in assembly, material handling, packaging, and other similar tasks. SCARA stands for Selective Compliance Assembly Robot Arm, which refers to the robot's design that enables precise horizontal movements while maintaining rigidity in the vertical axis. This design allows SCARA robots to perform quick and accurate pick-and-place, assembly, and other operations efficiently.

FANUC's SCARA robot lineup includes models with varying payload capacities, reaches, and other features to accommodate a wide range of applications and industries. Some key features of FANUC SCARA robots include:

» High speed and precision: FANUC SCARA robots are designed to perform tasks at incredibly fast speeds while maintaining high levels of accuracy and repeatability. This makes them ideal for high-throughput assembly lines and other time-sensitive operations.

» Compact design: With their small footprint and slim profiles, FANUC SCARA robots can be easily integrated into existing production lines, making them an attractive option for manufacturers looking to optimize space and improve efficiency.

» Integrated controller and vision system: FANUC SCARA robots come with an integrated controller, simplifying installation and reducing overall system complexity. They can also be equipped with FANUC's iRVision system, a built-in machine vision capability that enables the robot to recognize and handle parts without the need for additional sensors or external vision systems.

» User-friendly programming: FANUC SCARA robots can be programmed using FANUC's intuitive software, which simplifies the process of creating and managing robot programs, even for users with limited robotics experience.

» Versatile applications: FANUC SCARA robots can be used for various tasks, such as assembly, material handling, packaging, testing, dispensing, and more. This versatility makes them suitable for a wide range of industries, including automotive, electronics, consumer goods, pharmaceuticals, and more.

FANUC offers a diverse range of robotic and collaborative robot (cobot) arms designed to enhance productivity, precision, and efficiency in various industries and applications.

» Industrial Robot Arms: FANUC's industrial robot lineup includes models with varying payload capacities, reaches, and configurations, such as articulated, delta, and SCARA robots. These robots are suitable for a wide range of tasks, including assembly, material handling, welding, painting, and more. They

18 | IMDQ | Q1 2023

are known for their speed, precision, reliability, and versatility, making them ideal for manufacturing and automation processes.

» Co-bot Arms: FANUC's collaborative robots, also known as "cobots," are designed to work safely alongside humans in various tasks, including assembly, material handling, and machine tending. These robots typically have lower payload capacities and limited reach compared to traditional industrial robots. Cobots are equipped with safety features, such as force and torque sensors, to prevent accidents and minimize risks in human-robot interactions. They are user-friendly, easy to program, and can be deployed quickly with minimal disruption to existing workflows.

FANUC's robot and cobot arms cater to diverse applications and industries, including automotive, electronics, consumer goods, pharmaceuticals, and more. The company is continuously investing in research and development to enhance its product portfolio and maintain its position as a market leader in industrial automation and robotics.

Cox Manufacturing, a precision parts manufacturer based in the United States, implemented FANUC robots to improve productivity, efficiency, and competitiveness in their manufacturing processes. The integration of FANUC robots allowed the company to address challenges such as labor shortages, increasing production demands, and maintaining high levels of quality and precision.

Key aspects of FANUC robots implementation at Cox Manufacturing include:

» Automating repetitive tasks: FANUC robots were deployed to perform repetitive tasks, such as material handling and machine tending, freeing up human workers to focus on more complex, value-added tasks that require critical thinking and problem-solving skills.

» Increased productivity and efficiency: By integrating FANUC robots into their production lines, Cox Manufacturing was able to increase throughput and maintain consistent production levels, reducing downtime and ensuring timely delivery of products to customers.

» Improved precision and quality: FANUC robots offer high levels of accuracy and repeatability, which helped Cox Manufacturing maintain the stringent quality standards required in precision parts manufacturing.

» Addressing labor shortages: FANUC robots helped Cox Manufacturing overcome the challenge of finding skilled labor by automating tasks that would otherwise require manual labor, allowing the company to maintain production levels despite a tight labor market.

» Enhanced competitiveness: The implementation of FANUC robots allowed Cox Manufacturing to remain competitive in the global market by reducing production costs, improving product quality, and increasing overall efficiency.

Cox Manufacturing successfully integrated FANUC robots into their manufacturing processes, resulting in increased productivity, improved precision and quality, and enhanced competitiveness. The use of automation and robotics enabled the company to address labor shortages and maintain a strong position in the precision parts manufacturing industry.

FANUC's robotic laser systems are advanced automation solutions designed for various laser processing applications, such as cutting, welding, and marking. These systems combine FANUC's reliable industrial robot arms with state-of-the-art laser technology to deliver high precision, speed, and flexibility in manufacturing processes.

Key aspects of FANUC's robotic laser systems include:

» Versatility: FANUC's robotic laser systems are suitable for a wide range of applications, including laser cutting of metals and non-metals, laser welding of automotive components and electronics, and laser marking for traceability and identification purposes. They can be integrated into various industries, such as automotive, aerospace, electronics, and medical device manufacturing.

» Precision and accuracy: FANUC's robotic laser systems offer high levels of precision and accuracy, ensuring consistent quality and reduced material waste. They are capable of performing intricate cuts and welds on a variety of materials, including metals, plastics, and composites.

» Speed and efficiency: The integration of FANUC robots with laser systems allows for high-speed laser processing, resulting in increased productivity and reduced cycle times. The systems can handle multiple tasks simultaneously and can be quickly reprogrammed for different jobs, contributing to overall efficiency.

» Integration and flexibility: FANUC's robotic laser systems can be easily integrated into existing production lines and are compatible with various laser sources, including CO2, fiber, and diode lasers. This flexibility enables manufacturers to choose the most suitable laser technology for their specific needs.

» User-friendly programming: FANUC's robotic laser systems can be programmed using the company's intuitive software, making it easy for users to create and manage robot programs even with limited robotics experience.

FANUC's robotic laser systems offer versatile, precise, and efficient laser processing solutions for various industries and applications. By combining FANUC's reliable industrial robot arms with advanced laser technology, these systems help manufacturers increase productivity, improve product quality, and enhance competitiveness in the global market.

For more information on FANUC and all of their robotic offerings, visit their website at www.fanucamerica.com.

INDUSTRIA L MACHINERY DIGEST COM IMD | 19

Seeing is Believing

Machine vision inspection is an essential technology that has significantly impacted the manufacturing industry. The global machine vision market size is valued at USD 10.7 billion in 2020 and expected to reach USD 14.7 billion by 2025, growing at a CAGR of 6.5% over that time. This includes the value of installed systems as well as the value of components, software, and services related to machine vision. The technology has undergone a series of developments over the years since its inception in the 1970s and 1980s. Today, machine vision systems are widely used across different sectors, including automotive, aerospace, electronics, and pharmaceuticals.

The use of machine vision technology in manufacturing is set to increase in the coming years. In addition to its current applications, machine vision is expected to be integrated with other technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), to improve its functionality and performance.

Making Machine Vision Systems Work for You

A machine vision system consists of various components that work together to capture, process, and analyze images of products or components. The essential components of a machine vision system include a camera, lighting, optics, image processing hardware and software, a display, and a control system.

One of the key benefits of machine vision is its ability to perform tasks that would be difficult or impossible for

human inspectors. Machine vision systems can operate 24/7 without fatigue and inspect products at a much higher speed and accuracy than human inspectors. This makes them ideal for applications such as sorting, quality control, and defect detection.

Machine vision systems can also be programmed to detect a wide range of defects and irregularities, including those that might be missed by human inspectors. This helps to improve product quality and reduce waste, and can also help to ensure compliance with industry regulations and standards.

The primary application of machine vision in manufacturing is quality control. Machine vision systems can be used to inspect products for defects such as scratches, dents, or other imperfections. By detecting these defects early in the manufacturing process, manufacturers can reduce waste and improve product quality.

In addition, machine vision systems can be used for dimensional measurement to ensure that products are within specified tolerances. This is particularly important in industries such as aerospace and automotive, where tight tolerances are critical to ensuring product performance and safety.

Another application of machine vision is in sorting and classification. Machine vision systems can be used to sort products based on criteria such as size, shape, color, or texture. This is useful for applications such as packaging,

20 | IMDQ | Q1 2023

inTegraTions

where products need to be sorted and packaged in a specific way.

Despite the many benefits of machine vision, there are some challenges to implementing this technology in manufacturing. One of the primary challenges is the complexity of the systems, which requires specialized expertise to design, install, and maintain. In addition, machine vision systems can be expensive, particularly for applications that require high-speed cameras or specialized hardware.

However, as the technology continues to evolve and become more accessible, we can expect to see more widespread adoption of machine vision in manufacturing. With its ability to improve efficiency, quality, and safety, machine vision is driving the transformation of modern manufacturing.

Using Software for Upgrading Systems

Retrofitting an industrial visual inspection system is one way of upgrading or modifying an existing system to improve its performance or functionality. This can be a cost-effective way to enhance the capabilities of an older system or to adapt it to changing manufacturing requirements.

The specific steps involved in retrofitting a visual inspection system can vary depending on the system and the desired upgrades. However, careful planning and execution of the retrofit plan can ensure that the upgraded system meets the requirements and operates effectively.

There is an alternative solution to retrofitting of which many quality managers and plant managers are not fully aware. If a software solution is equipment-agnostic, meaning it is designed to operate with hardware from different vendors rather than being exclusive to one, you can bring new capacity to old investments.

If your existing image acquisition equipment is perfectly okay in terms of image quality and illumination, then the software was the problem. Leveraging your existing hardware by finding a software solution that will work in tandem with it is a good path for consideration. Lean AI is currently putting this theory into practice with a leading powder metal company in Canada. Lean AI’s artificial intelligence algorithms are designed to work with any hardware, so the software can make use of cameras and computer hardware already in the plant, removing the need for the customer to rip out existing equipment and start again. Retrofitting in this way saves time, money and reduces risk.

Emerging Trends

One of the emerging trends in machine vision is the use of deep learning algorithms for image recognition and analysis. Deep learning algorithms can enable machine vision systems to learn and adapt to new situations and make more accurate and reliable decisions. This can significantly improve the performance of machine vision

systems in areas such as defect detection, quality control, and object recognition.

Another emerging trend in machine vision is the use of 3D imaging technology. 3D imaging can provide more detailed and accurate information about the shape, size, and position of objects, which can be useful for applications such as robotics, autonomous vehicles, and medical imaging.

Machine vision systems are a critical technology driving the transformation of modern manufacturing. With its ability to improve efficiency, quality, and safety, machine vision is an essential component of many modern manufacturing systems. Despite some challenges, the continued evolution and accessibility of machine vision technology are likely to result in its increasing adoption in manufacturing in the years to come. Retrofitting an industrial visual inspection system is one way to upgrade or modify an existing system to enhance its capabilities or adapt it to changing manufacturing requirements. As the technology continues to evolve, we can expect to see more advanced and sophisticated machine vision systems integrated with other technologies to provide more accurate, reliable, and efficient manufacturing solutions.

Suppliers of these systems include companies such as Keyence Corporation (www.keyence.com), Epson Corporation (www.epson.com), Matrox® Imaging, now part of Zebra Technologies Corporation, as well as several software providers.

INDUSTRIA L MACHINERY DIGEST COM IMD | 21

www.coxreels.com FOLLOW US: TOLL FREE | 800.269.7335 PRO GRADE HOSE, CORD, & CABLE REELS quality matters. every time. AIR / WATER | HYDRAULIC | PNEUMATIC | VACUUM | WELDING | POWER CORD SOLUTIONS FOR: AND MORE IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

CNC Automation in Smart Factories

By Russell Riddiford, President of ANCA Americas

Manufacturing has moved on from simple cutting tools. Your customers expect you to create high-quality tools from top-end materials, with little room for error. It’s now about the end-to-end process, from sourcing the best materials to providing the best customer experience, and it relies on networked machines and devices. As expectations for cutting tools have changed, so has the equipment you use to stay competitive. The types of CNC machines you use can make or break your position in your toolmaking niche.

Future factories need software as much as hardware

You may have heard of toasters that know when we’re running out of bread, or devices that know they need servicing before we do. They are the cheap thrills of the Internet of Things (IoT). But your factory can also benefit substantially from the Internet of Things, whether it’s predicting when a machine needs to be serviced, monitoring its performance or noticing when stock levels are low. (And, maybe, adding a USB-connected sandwich press to the lunchroom.)

That’s where software becomes key. Smart factories that want the benefits of the IoT rely on connectivity. Machines must have access to software that connects them to an internal network, where every part of the system is able to interact. You might even connect them to a wider network, using information from customer and supplier networks to create more streamlined processes.

Software can have an impact in other ways, too. Our latest product introduced new features to cutting tools, allowing for more complex cutting tool geometries. Some industries have different requirements. For example, aerospace and power generation use hard and soft materials requiring different geometries of cutters for machining them. We have introduced new geometries in software to manufacture special cutters for those processes.

The right software is also a vital component in having different types of CNC machines “talk” to each other. In the past, machines using different protocols, or from different manufacturers, might not have been able to interact with systems inside the factory. Software on the machines allows them to send data to a central location, where it can be distributed in a form every machine – and person –can understand.

Some types of CNC machines can come with you on the journey

We’ve found that around 95% of machines in use today are

10 years old or less. That’s good news for your factory –often they are still capable of moving to the latest software and adding on accessories that can be used in automation. For example, you might be able to retrofit:

» Laser measurement

» Network connectivity

» Electrical controls

» Operating systems

» Automated processes and libraries

Retrofits mean you can avoid replacing your machines wholesale. Updating them one-by-one will allow you to keep your factory running with minimal downtime and cost so your customer engagement is not disrupted.

Functionality is always improving and expanding. CNC machines aren’t phones – you won’t be installing cutters or grinders that can fit in your pocket or fold up –but a machine of the same size will do more than it does now. The types of CNC machines you were installing fifteen years ago are being replaced by better, faster and more comprehensive models. For example, CNC milling machines have moved from four-axis to six-axis and have added spiralling to their capability. As the machines improve so do their cutting processes and productivity, becoming faster, more precise, and easier to monitor.

Take it one step at a time. Refit or replace machines that will give you the quickest wins, updating your factory’s capability quickly and cost-effectively.

Closed-loop manufacturing is coming – with or without you

Looking to the future is vital. Don’t upgrade or replace your CNC machines without considering what business advantages you are trying to achieve. In your smart factory, you’ll be competing not only on range and precision,

22 | IMDQ | Q1 2023 MaChines

but also in terms of specialization, customer experience and time to market. CNC machines that make it easier to build to order will allow you to carry less stock, lower upfront costs and reduce inefficiencies. Marketleading smart factories need to know exactly what their customers need and that’s exactly what newer machines will provide.

And then there’s complete business transformation. Over the next 5-10 years, tool manufacturers will be using their technology to completely eliminate waste – and they’re planning for it already. This ‘closed-loop’ approach to manufacturing means only ordering and using exactly what you need. Nothing will be sent to landfill or left on the factory floor. It’s a world which will be better for the environment, better for customers, and better for your bottom line.

There are many options for bringing your CNC machines into the future. Whether you retrofit software and accessories, or replace your machines with the latest models, you’re investing in a future that’s efficient, connected and more profitable.

INDUSTRIA L MACHINERY DIGEST COM IMD | 23 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

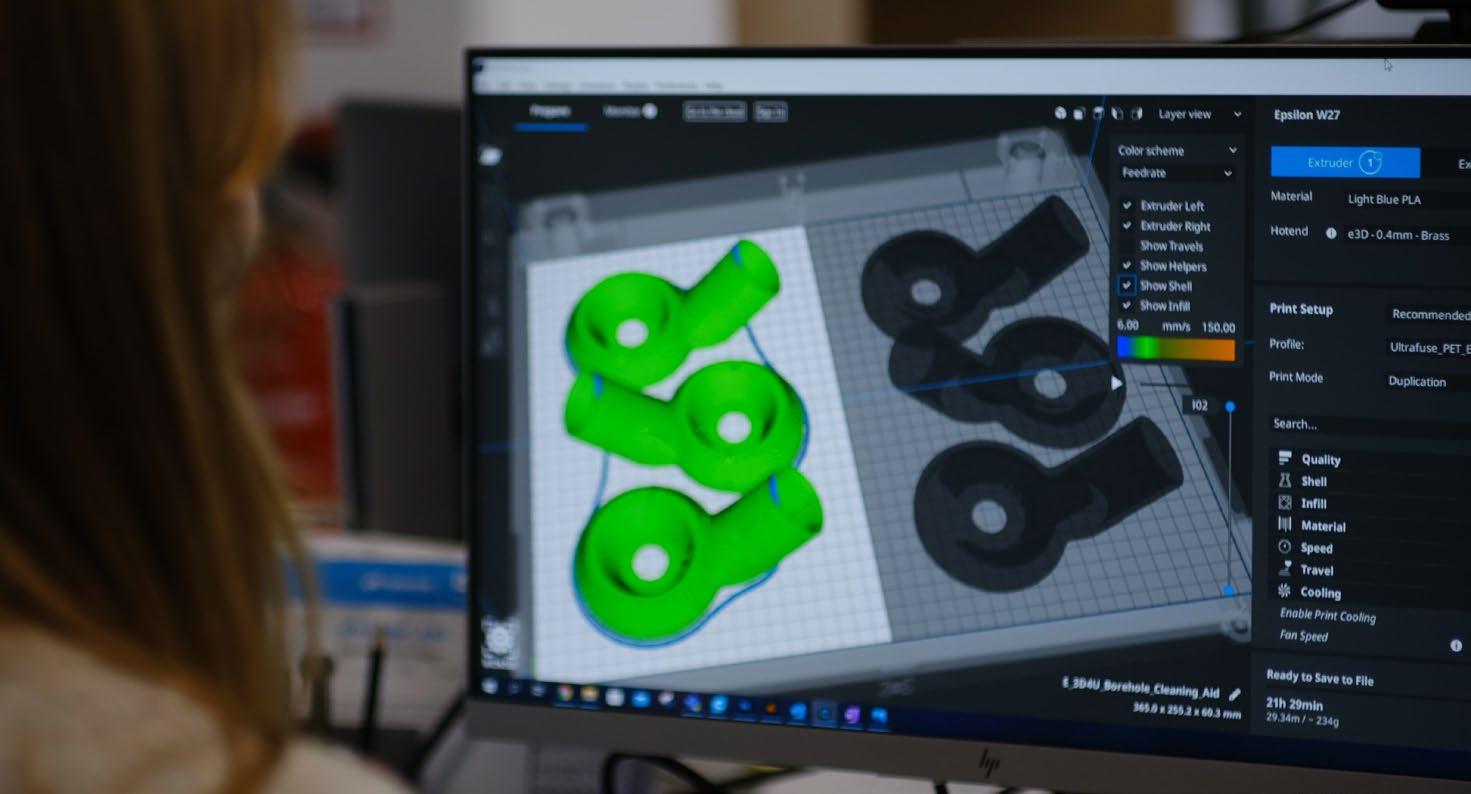

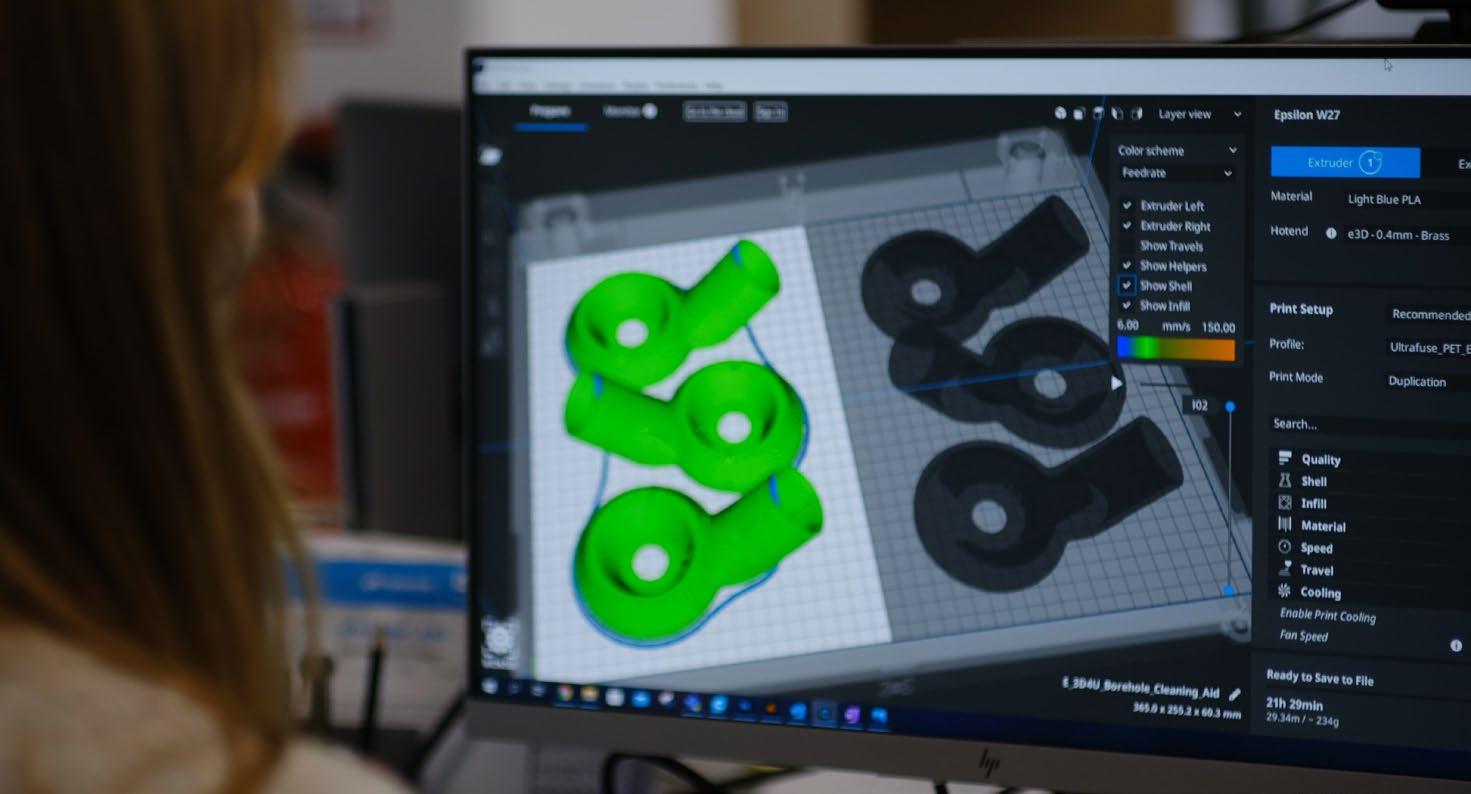

How AM Improves Sustainability Across the Supply Chain

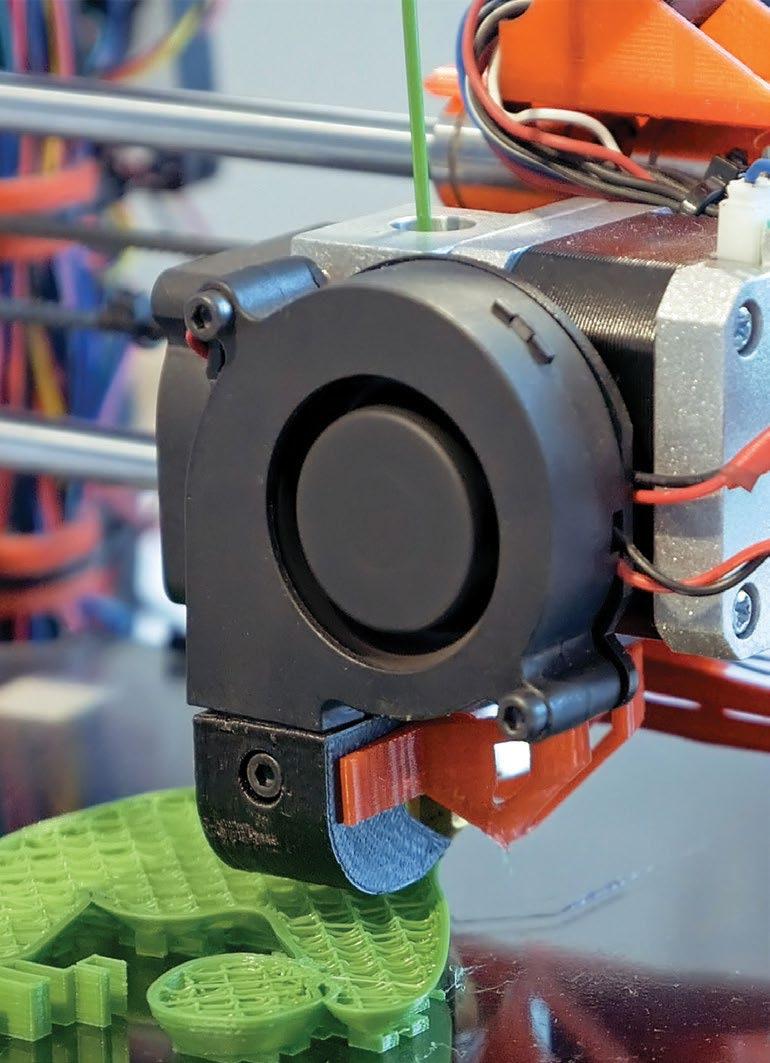

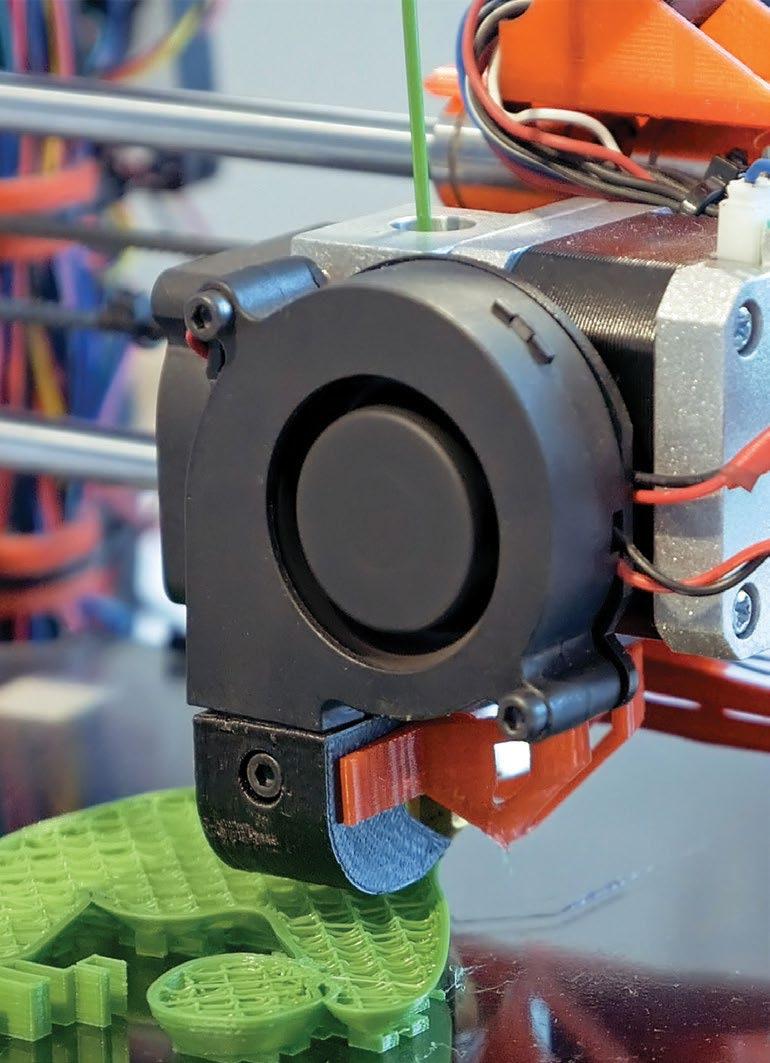

Individuals and businesses are becoming increasingly aware of the importance of sustainability, in turn making it a bigger part of our daily lives. This now extends to the production sector, driven forward by end customer demands, and new industry regulations. In this feature, Max Siebert, CEO of Replique, discusses how additive manufacturing (AM) can offer an efficient and environmentally friendly solution for production and supply chains.

Additive manufacturing allows sustainable design

AM offers a whole new way of designing products which allows the creation of topology optimized designs. By redesigning, the 3D printed part can accomplish the same task, and even improve the performance compared to the original part, while using less material. Companies can therefore also improve a part consisting of several pieces and print it in only one unit (part consolidation). This results in less material and energy consumption during production compared with traditional methods. In turn, this reduces time spent as less parts need manufacturing and assembling. Additionally, part consolidation can offer better performing parts with increased durability.

AM can drastically reduce material consumption during production

In production, manufacturers look at two essential factors: material consumption and energy efficiency. In traditional manufacturing methods there is always material waste. For example, in subtractive manufacturing, like CNC, manufacturers start with a block of solid material and remove material to achieve a final shape. In AM however, the material usage is much more efficient.

Fused Deposition Modelling (FDM) provides a good example; parts are built layer by layer, adding only the material that is needed, so other than support structures there is no wasted material. Other AM technology using powders or resins works differently. In powder and resinbased AM a full layer of material is built, which is then

processed by a laser or fusing agent, dependent on the used technology. After the first material layer is processed, a new full layer is added until the part is finished. As any unprocessed powder or resin can be reused for the next print, it is possible to achieve no material wastage.

Conversely, support structures and failed prints are often needed, especially for more complicated parts. It is common for test parts to be wasted before finding the right printing parameters and build orientation. However, developments in simulation now allow us to predict potential printing issues beforehand, therefore reducing waste in production.

Looking at the energy consumption during production, is AM really sustainable?

Due to very individual use cases, the answer for this is not simple. Differences in machine, product and process characteristics make comparability of traditional methods and AM difficult. Compared with subtractive methods, AM can be more energy efficient, especially when considering the lesser material consumption. However, compared to injection molding, energy consumption of AM is generally acknowledged to be higher due to a much longer production time per part. However, other factors such as energy consumption in producing the mold, production volume and material efficiency must be considered. When looking into lower volumes, AM is a more energy efficient option.

The production on-demand will reduce waste in warehousing

As well as during production, AM also delivers sustainability benefits in the supply chain. Other manufacturing methods often require a minimum lot size to make production cost efficient, often leading to overproduction and parts stored as inventory. This not only increases storage costs, but also potential wastage if the parts are not sold. For companies offering spare parts, this can be a huge problem. Companies are usually bound to suppliers, who often stipulate huge minimum order quantities, even if only a few spare parts are needed.

With AM it is possible and affordable to produce only the number of parts that are needed. No huge inventories need to be created because the parts can be produced on demand. Replique’s 3D4U project with Miele demonstrates this well, where Miele’s end-customers can order parts via Miele’s online shop which are then printed and shipped straight to the customer. All within a promised total lead time of five working days, including shipping, it shows that

24 | IMDQ | Q1 2023 MaChines

Max Siebert, CEO and Co-Founder of BASF-owned, Replique

AM can offer fast and affordable parts while avoiding waste.

Minimized transport routes will reduce CO2 emissions

The introduction of AM has produced a shift from linear manufacturing, with centralized distribution, to a decentralized network of suppliers, production partners and customers. This is enabled by low investment costs, as one machine can produce a variety of parts. Minimizing transport movements of course comes with a positive impact for the environment, as the carbon footprint of each part is reduced. Parts are then shipped to wherever they are needed, which could be on the other side of the world. This also reduces lead time, especially beneficial in times of supply chain disruptions.

So, in summary, incorporated as part of a print on-demand model, AM can reduce a company’s energy consumption, material waste and carbon footprint. This also comes with benefits to supply chain operability. Traditional supply chains require several steps, each prone

to disruption, whereas AM shortens the supply chain and makes it more resilient.

Max Siebert is CEO and Co-Founder of BASF-owned, Replique, which offers an industrial 3D printing platform that enables OEMs to provide parts on-demand anytime and anywhere to their customers through a global, decentralized and secured 3D printing network. As an end-to-end solution, Replique supports its customers along the entire value chain, including design, technology and material selection, and digital warehousing.

INDUSTRIA L MACHINERY DIGEST COM IMD | 25 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Robots in the Cloud

a Cloud is born

Leveraging someone else’s computer has never been more acceptable and encouraged. But it has to be your space, your virtual session, on some type of hosted, multi-tenant environment that may have hundreds of computers balancing CPU loads and inbound transaction requests from all over the internet - and we call it cloud computing. The concept of cloud computing has evolved over time, and pinpointing the exact date of the first cloud-based software is not straightforward. However, a key milestone in the development of cloud-based software came with the launch of Salesforce in 1999. Salesforce introduced the idea of delivering enterprise applications over the internet, eliminating the need for companies to maintain their own hardware and software.

The term "cloud computing" itself began to gain traction in the mid-2000s, with major technology companies such as Amazon, Google, and Microsoft investing in the development of cloud-based platforms and services. Amazon Web Services (AWS), for example, was launched in 2006, providing a suite

of cloud-based infrastructure and computing services that enabled businesses to access scalable computing resources over the internet.

As cloud computing gained momentum, an increasing number of cloud-based software applications and services emerged, offering solutions for various industries and use cases. Today, cloud-based software covers a wide range of applications, including productivity tools, data storage, analytics, machine learning, and more.

The Ever Increasing Role of Robots

Robots have been widely adopted in industrial manufacturing over the past few decades, and their usage continues to grow. Since the introduction of the first industrial robot, the Unimate, in the early 1960s, robotics has evolved to become an essential component of modern manufacturing processes. In today’s industrial manufacturing world, as the breadth of capabilities for robotic automation expands and adoption increases, one

26 | IMDQ | Q1 2023 sof T ware/Cloudware

MAY 10-11, 2023 OREGON CONVENTION CENTER PORTLAND, OR INNOVATION. TECHNOLOGY. PRODUCTIVITY. OWNED & PRODUCED BY: FOR EXHIBITING INFO, CONTACT JOYCE LORTZ: JLORTZ@FACILITIESEXPO.COM | (410) 598-3535 REGISTER FOR FREE AT: MACHINETOOLEXPOS.COM

of the biggest beneficiaries of cloud computing could be managing and configuring robots.

The automotive industry was among the first to adopt robotic technology on a large scale, with robots being used for tasks such as welding, painting, and assembly. Today, robots are employed across a broad range of industries, including electronics, aerospace, pharmaceuticals, food and beverage, and many more.

Some key areas where robots have been adopted in industrial manufacturing include:

» Assembly: Robots can be programmed to perform repetitive tasks, such as assembling components, with high precision and speed, leading to increased productivity and reduced human error.

» Material handling: Robots can be used to transport raw materials, finished products, or waste materials, increasing efficiency and reducing the risk of injury for human workers.

» Welding: Robotic welding systems provide consistent, high-quality welds while reducing the need for skilled welders and improving workplace safety.

» Painting and coating: Robots can apply consistent layers of paint or other coatings, improving product quality and reducing waste.

» Inspection and quality control: Vision systems and sensors can be integrated with robots to inspect products for defects or perform other quality control tasks.

» Palletizing and packaging: Robots can quickly and accurately stack and package products, improving efficiency and reducing labor costs.

The adoption of robots in industrial manufacturing has been facilitated by advancements in technology, such as improvements in sensor technology, machine vision, and artificial intelligence. Additionally, the development of collaborative robots, or cobots, has

further expanded the scope of robotic applications. Cobots are designed to work safely alongside humans, allowing for more flexibility and versatility in manufacturing processes. As robotics technology continues to advance and become more cost-effective, it is expected that the adoption of robots in industrial manufacturing will continue to grow, leading to further improvements in productivity, safety, and efficiency.

Merging Cloud and Robot

While it is difficult to pinpoint a single cloud-based software as having the biggest impact on robotics, multiple solutions have significantly influenced the field. One notable platform is ROS (Robot Operating System). While not exclusively cloud-based, ROS has been widely adopted and integrated with various cloud computing services, allowing for enhanced capabilities in robotic applications.

ROS provides a flexible and modular framework for developing robot software and has played a significant role in advancing robotics research and development. By integrating ROS with cloud computing, developers can benefit from increased computational power, storage, and scalability, allowing for more complex and sophisticated robotic systems.

In addition to ROS, other cloud-based software solutions and platforms have contributed to robotics development, including:

» Google Cloud Robotics: A platform that combines Google's cloud services with machine learning and AI tools to enable advanced robotic applications.

» Microsoft Azure Robotics: Offers a suite of cloud services and tools that help developers build, simulate, and manage robotic systems.

» Amazon Web Services (AWS) RoboMaker: A cloud service that helps developers build, test, and deploy intelligent robotic applications at scale.

These cloud-based software solutions have significantly impacted

the field of robotics by providing tools and infrastructure for improved collaboration, data processing, and machine learning capabilities.

Many robot companies offer configuration of their robots remotely via the cloud, enabling users to manage, monitor, and control robotic systems from anywhere with an internet connection. Some of the prominent companies that provide such capabilities are:

» Universal Robots: A leading manufacturer of collaborative robots (cobots), Universal Robots offers a cloud-based platform called UR+ that enables remote monitoring, management, and configuration of their robots.

» ABB Robotics: ABB's Ability platform allows users to connect, monitor, and remotely configure their ABB robots and robotic systems through the cloud.

» KUKA Robotics: KUKA Connect is a cloud-based software platform that enables users to access, monitor, and configure KUKA robots and systems from anywhere in the world.

» FANUC: FANUC offers the FIELD system (FANUC Intelligent Edge Link and Drive), which connects their robots and CNC machines to the cloud for remote monitoring, management, and optimization.

» iRobot: iRobot, the company behind the Roomba vacuum cleaner, offers cloud-connected devices that can be remotely controlled and configured via their mobile app.

These companies are just a few examples (and by no means intended to be the absolute list) of the growing trend of integrating cloud connectivity with robotic systems. The ability to remotely configure and manage robots via the cloud provides users with increased flexibility, faster troubleshooting, and improved efficiency in deploying and maintaining robotic systems. It is critical for evolving the Smart Factory of Now.

28 | IMDQ | Q1 2023

www.IndustrialMachineryDigest.com SERVING AMERICAN MANUFACTURERS FOR OVER 37 YEARS THAT FEELING YOU GET WHEN YOU READ AND YOU’RE IN THE KNOW! SUBSCRIBE AND STAY INFORMED North America’s Manufacturing Resource for Industry Professionals Since 1986

PRODUCT SHOWCASE

Industrial Machinery Digest's Monthly Product Showcase features the latest from some of the manufacturing industry's top suppliers.

Suhner to Unveil New Robotic Electric Force Compliance System at AUTOMATE

The new EFC-02 combines a century of Suhner's abrasives and material removal expertise with smart automation for the highest surface quality results.

Recognizing the role robotics plays in adding efficiency and lowering production costs for manufacturers of all types and sizes, Suhner continues to expand its robotics offering. The fully electric EFC-02 delivers precise, constant force throughout robotic grinding, sanding and deburring processes – resulting in superior, consistent surface quality.

The EFC-02 is the lightest and smallest in its category, making it a good solution for material removal and surface finishing in tight, narrow spaces that traditional robotics cannot reach. Simple robot programming and advanced functionality in line with smart manufacturing and Industry 4.0 make the EFC-02 a perfect solution for both large- and small-batch production.

For maximum efficiency, the EFC-02 is compatible with Suhner's angle grinders, orbital sanders, polishers and straight grinders. This is combined with Suhner's comprehensive abrasives offering from all the industry's leading manufacturers.

This newest addition to Suhner's robotics offering was thoughtfully designed based on decades of process

know-how in material removal – matching the right tool to the right abrasive to achieve the quality surface finish necessary for a wide range of applications. The company will showcase the EFC-02 at Booth #1850 at the upcoming AUTOMATE 2023, May 22-25, in Detroit, MI.

Scotchman Industries

Introduces the GAA-600-90

CNC Automatic Upcut

Scotchman Industries is proud to introduce the GAA-600-90 CNC, Automatic Upcut Circular Cold Saw, the newest addition to our non-ferrous saw line. The GAA-600-90 CNC is a large capacity upcut automatic saw with 600mm (24") diameter carbide blade for cutting non-ferrous materials at 90° up to 8" square or round and 14” x 4” rectangle.

The precision CNC control stores 10 programs, with each program

containing up to 30 different cut lengths and quantities, which can easily be created or adjusted right on the machine at any time. Programs can also be imported through UBS port.

The saw uses a robust shuttle feed design featuring a 27” ballscrew servomotor automatic feeder. Adjustable length selector from 0.200" to 20" and unlimited stroke and adjustable cutting and feeding speeds provides more versatility to customize the saws operation to fit specific requirements. Three horizontal and three vertical pneumatic clamps

30 | IMDQ | Q1 2023 produCT showCase

WANT TO BE FEATURED? Send your latest product information to editorial@indmacdig.com

secure the workpiece during the cutting process assuring the highest cut length tolerances, ± 0.0006" per index.

GAA-600 CNC saw standard features include: a 7.5 hp motor that delivers a cutting speed of 3,000 rpm, pneumatic mist coolant system, powered hood lift and LED lighting, a base designed with 2 chip extraction ports makes it easy to couple with a chip vacuum, meets CE standards, 230 volt or 460 volt configurations, and backed by Scotchman Industries' 2-year warranty on parts.

KUKA Automation for Human/ Machine Collaboration

During the ATX West 2023 show, KUKA Robotics showcased several new technologies geared specifically for safely automating those manufacturing processes where humans interact with robots on a regular basis. Among those technologies are the new LBR iisy cobot, the new KUKA KMP 600-S diffDrive automated mobile platform and the company’s LBR iiwa robot incorporated into an automated mobile robotic material-handling system.

Referred to as Sensitive Cobotic technology, KUKA’s LBR iisy represents the future of automation. The cobot is ready-to-use automation that quickly and easily integrates into any manufacturing application from pre-defined production processes to open, unstructured work environments with unpredictable conditions from one job to the next.

Whether loading/unloading machines, assembling components or packaging, the cobot provides increased versatility and can be immediately operated by anyone from an automation expert to a cobotics newcomer. Featuring various operator levels, the user-friendly system adapts to the corresponding level of user knowledge.

Ready to use right out of the box, the LBR iisy allows for use in more applications than ever before, including those so simple that most wouldn’t think they could be automated. Operating the iiQKA.OS system and supported by the iiQKA Ecosystem, the LBR iisy is ready for use in a matter of minutes – depending on pre-configured options – from unpacking to productive work. As such, the cobot also eliminates long training times or having to learn complex programming techniques.

With six axes, a 3-kg payload, 600-mm maximum reach and 18.8-kg overall weight, the LBR iisy is well suited for overcoming the challenges posed by confined workspaces. KUKA also offers the LBR iisy in 11-kg and 15-kg payload versions.

As the perfect collision-free coworker, KUKA’s new KMP 600-S diffDrive mobile platform takes intralogistics to a new level – especially in the consumer goods manufacturing industry. The platform provides a new automated guided vehicle system with high-speed support for production intralogistics and a payload of up to 600 kg. At the same time, the KMP 600-S diffDrive is ideally equipped for the tough everyday environment of industrial production. Its IP 54 design always enables it to work reliably even under adverse conditions – including water spray and dust.

For maximum safety and flexibility all KUKA mobile platforms, including the KMP 600-S, guarantee employees maximum freedom of movement without the need for safety fencing. Laser scanners mounted at the front and rear provide maximum safety and allow for high speeds in all directions of travel when cycle times require it. Additionally, the KMP 600-S diffDrive uses eight safety zones at both the front and rear – customizable for vehicle speeds and specific applications.

INDUSTRIA L MACHINERY DIGEST COM IMD | 31 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Developed in partnership with the world's largest semiconductor fabricators, the mobile robotic solution KUKA demonstrated at ATX West reliably transfers materials in areas unsuitable for traditional automated material handling systems. As the first of its kind, the KUKA mobile robotic wafer-handling system for human/machine collaboration offers an ideal solution for material transport of 200mm or 300mm wafer boxes and SMIF boxes, open cassette machine loading and unloading.

The system combines a KUKA LBR iiwa 14 R820 CR robot mounted on one of the company‘s KMP 200 CR automated mobile platforms. Both the robot and mobile platform are cleanroom class ISO 3 rated and feature advanced safety and navigational functionality. For simplicity and ease of use, the solution is completely integrated with one controller for the robot, platform and navigation as well as one software solution for all three

SprutCAM X Robot now includes models of almost 700 robot mechanisms from worldrenowned manufacturers

» Robots, including heavy-duty and cobots

» Single axis, 2-axis and 3-axis positioners

» Actuators, including moving grippers (end effectors)

» Railing

» Fixed objects such as tables, controllers, and fencing

The developers team at SprutCAM Tech keeps the library up-to-date with the most popular equipment. Manufacturers and integrators can request to add a 3D model of a robot or another piece of equipment to the MachineMaker online library by emailing info@sprutcam.com.

Universal Robots Predicts 2023 Automation Trends Helping Manufacturers Meet New-Year Goals

The collaborative robot pioneer and market front runner has announced January as “National Cobot Awareness Month,” spearheading new products and initiatives prompting manufacturers to address hiring woes and production challenges.

Gone are the days of manufacturers buying a robot arm only to struggle figuring out how to integrate it in an application cell. Turnkey robotic solutions, complete with all hardware, software, sensors and interfaces, will be powerful automation drivers in 2023, according to Universal Robots:

“In 2023, cobot automation will become more sophisticated yet more straightforward to use,” predicts Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots (UR). “We are going to continue seeing phenomenal growth within complete robotic systems for applications such as welding, palletizing and machine tending, propelled by UR partners creating full solutions powered by our collaborative robot arms.”

In 2022, the number of models in the online Robot library was increased by three times

SprutCAM X Robot software, developed by SprutCAM Tech Ltd. in Limassol, Cyprus, provides a convenient and natural programming environment that simulates the interaction between an engineer, robot, tool, and product as closely as possible.

To develop a control program for an industrial robot and simulate all robot functions in a virtual environment, a technologist-programmer needs to create a realworld cell with robot equipment and production components in a CAM system or integrate a cell from external software. The Machine Maker add-on, a zero-code robot cell builder for SprutCAM X, allows manufacturers and integrators to quickly create an accurate digital twins of any robotic cell using an online library that supports the largest selection of industrial robot brands.

The online Robot library now includes 675 components from brands such as KUKA, Fanuc, ABB, TeknoMotor, AMB (Kress), SCHUNK, OnRobot, Joulin, Schmalz, Regal, Universal Robots, Güdel, Meltio, among others:

Sales of UR cobots for integration in OEM (Original Equipment Manufacturers) solutions grew about 50% in 2022. UR enters the new year with more than 80 OEM partners integrating UR cobots in turnkey systems, and over 300 UR+ partners launching application kits and components certified to work seamlessly with the UR cobots.

Cobot welders a key growth driver