Robotics

Solving the Manufacturing Workforce Crisis

Robots Can Support The Future of Bioplastics

Economical manufacturing with bioplastics needs 6-axis robots

Innovating Steel Processing: Carl Spaeter Hamburg Unveils Advanced Preservation Line

CMM Controller Retrofits Enable MultiSensor Inspection

Co-ordinate measuring machine still capable of aerospace-standard quality control after 26 years

Extraordinary Insights Mined by Analyzing Mass of Measurement Data

A new generation of specialized software is helping manufacturers to collect, track and monitor all collected data to unlock the full value of analytics.

IndustrialMachineryDigest.com | Q1 2024

The Industrial Machinery Digest

& Automation Quarterly Resource!

caldwellinc.com 800.628.4263 815.229.5667 AVAILABLE ONLY AT ACP TURNADO SETTING NEW STANDARDS FOR SAFE LIFTING • Now up to M1000 (UNC 4") • Up to 30% higher WLL • No more transverse loads • No unexpected sagging of the load • No more worst case! .................... DOWNLOAD THE ACP TURNADO BROCHURE HERE MEETS OR EXCEEDS ASME B30.26 REQUIREMENTS A GAME CHANGER FOR LIFTING POINTS

4 | IMDQ | Q1 2024 6 EDITORIAL DIRECTION 8 INDUSTRY NEWS 16 CASE STUDY Solving the Manufacturing Workforce Crisis 20 COMPANY PROFILE Robots Can Support The Future of Bioplastics Economical manufacturing with bioplastics needs 6-axis robots 22 INTEGRATIONS Innovating Steel Processing: Carl Spaeter Hamburg Unveils Advanced Preservation Line 26 MACHINES CMM Controller Retrofits Enable Multi-Sensor Inspection Co-ordinate measuring machine still capable of aerospacestandard quality control after 26 years 28 SOFTWARE & CLOUDWARE Extraordinary Insights Mined by Analyzing Mass of Measurement Data A new generation of specialized software is helping manufacturers to collect, track and monitor all collected data to unlock the full value of analytics. 32 PRODUCT SHOWCASE 40 BUYER'S GUIDE FEATURED 45 SURPLUS GUIDE FEATURED 48 SURPLUS BUYING & SELLING 50 CLASSIFIEDS 51 ADVERTISER INDEX 16 20 22 26 QUARTER 1 2024 Table of ConTenTs

OPTIMIZE YOUR WORKSPACE SAFETY FIRST Available in both CHAIN & CABLE Configurations Customizable height and reach to best fit your space. Ergonomic positioning for easy low strain use. Create a safe, efficient work environment. The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com

North America’s Manufacturing Resource for Industry Professionals Since 1986

SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS

William C. Strickland III, Publisher william.strickland@indmacdig.com

800-366-0676 ext. 103 | Fax: 866-826-5918

Adrienne Gallender, Associate Publisher/Media Advisor agallender@indmacdig.com 847-612-1572 | Fax: 847-559-2909

Brian Self, Associate Editor brian@indmacdig.com

800-366-0676 ext. 104 | Fax: 866-826-5918

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com

785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Susan Strickland, Accounting susan@indmacdig.com

205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com

6 | IMD Q1 2024

source media llc 360 A PUBLICATION OF: Source 360 Media LLC 3590-B Hwy 31 South PMB #233 Pelham, AL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individuals. Publisher reserves the right to reject nonqualified subscribers. One-year subscription to nonqualified individuals in the United States: $96.00. Single copies available (prepaid only) $20.00 each. Alabama Automotive Manufacturers Association ACTEKMFG.COM 200% PROOF LOAD TESTED INDIVIDUALLY SERIAL NUMBERED FOR BETTER TRACEABILITY ORDERS SHIPPED SAME DAY RATED LOAD 400 LBS - 250,000 LBS 800-752-7229 | SALES@ACTEKMFG.COM HOIST RINGS ACTEK Forged Street Plate™ Swivel Hoist Rings Side Load Hoist Rings Hoist Ring Kits Pivots180° Swivels 360° Drop Forged Hoist Rings Mold Handler™ Swivel & Pivot Hoist Rings Round Base Swivel & Pivot Hoist Rings Forged Swivel Hoist Rings ISO 9001

Best Tool Cabinet You Will Ever Buy GUARANTEED 100%MADE IN THE USA INEVERY WAY WWW.STORLOC.COM • 1-800-STORLOC 1-800-786-7562 MADE BY AMERICAN CRAFTSMEN IN THE USA sales@storloc.com

The

As we usher in 2024 with anticipation and readiness for the evolving landscape of automation and robotics, we stand at the cusp of a transformative era. The first quarter has already heralded significant developments that promise to reshape our industry, offering both challenges and opportunities for innovation, growth, and societal impact.

One such groundbreaking story that we're thrilled to highlight is the documentary "Unturning Steel," sponsored by Tractian. This film delves into the lives of military veterans transitioning into the manufacturing sector, underscoring the profound contributions these individuals can make. At a time when the manufacturing industry seeks resilience against global pressures, the documentary posits veterans as invaluable assets capable of fortifying the sector. Their discipline, leadership, and technical skills could indeed be the catalyst for revitalizing American manufacturing, ensuring its competitiveness on the global stage.

Adding to the narrative of innovation, Upwing Energy's adoption of metal additive manufacturing (AM) marks a significant leap towards operational efficiency and product optimization. Their successful integration of AM into the production of the Subsurface Compressor System (SCS) underscores the potential of cutting-edge technology to enhance manufacturing processes. It's a testament to the industry's forward momentum, embracing advancements that promise not only to streamline production but also to extend the lifespan and performance of critical components.

Moreover, the expansion efforts of Wintriss Controls Group and its new partnerships reflect a strategic move to widen its influence across the U.S., enhancing service delivery and customer engagement. Such expansions are not merely business growth strategies but also pivotal steps towards strengthening the fabric of our industry’s infrastructure, ensuring accessibility, and responsiveness to evolving market needs.

These narratives are more than isolated developments; they represent the broader dynamics of an industry in transition. From leveraging the untapped potential of veterans to integrating advanced manufacturing technologies and expanding service networks, each story contributes to a larger dialogue about the future of automation and robotics.

As we navigate through 2024, let's remain attuned to these transformative journeys, recognizing the interconnectedness of technological advancement, human potential, and societal progress. May we all draw inspiration, insight, and motivation from these stories, forging ahead with a renewed commitment to excellence and innovation.

Here's to a year of breakthroughs, resilience, and growth.

Regards,

William Strickland Publisher, IMDQ

8 | IMD Q1 2024 ediTorial direCTion

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! CABLE VS CHAIN With our user-friendly website, users can easily find the type of auction they are looking for, regardless of size or location. The site has the latest technology to make it simple for users to engage with an auction of interest. Subscribe now to receive FREE news on upcoming auctions! YOUR COMPLETE AUCTION RESOURCE William Strickland

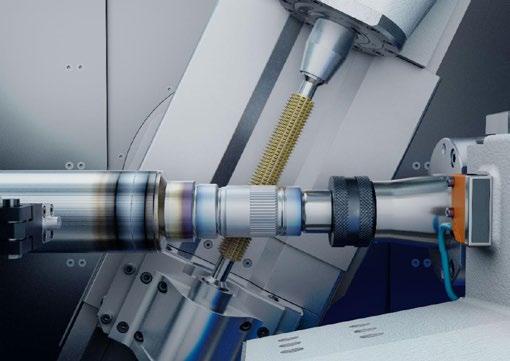

ANCA Celebrates 50 Years of Innovation in Precision Cutting Tools

ANCA, an Australian company recognized globally for its high-tech CNC tool and cutter grinders, marks its 50th anniversary, showcasing a significant contribution to industrial progress. The company has sold over 10,000 5-axis CNC machines worldwide, aiding in the creation of approximately 1.1 billion cutting tools. Founded in 1974 by Pat Boland and Pat McCluskey, ANCA has remained at the forefront of technological innovation, heavily investing in research and development, which accounts for about 10% of its revenue. This investment has led to numerous industry firsts, such as the first probe for digitizing tools and the first full 3D simulation of the grinding process.

ANCA's products, which include a wide range of CNC grinding machines, robot arms, and software solutions, are used by leading manufacturers such as Boeing and Rolls-Royce. The company prides itself on solving customer problems, contributing to its success in the highly competitive tool and cutter market. The company's success is attributed to a combination of family involvement, a passion for technology, and a commitment to innovation.

To celebrate its 50th year, ANCA is hosting global events, including open houses and seminars, highlighting new products and technological developments. The company's enduring legacy is underpinned by a close-knit community of customers and a relentless pursuit of technological excellence, setting the stage for continued innovation and growth in the years to come.

Dorner Appoints New Business Development Manager

Dorner announces the appointment of Dave Giffels as its new Business Development Manager, tasked with driving growth in the industrial and automation conveyor business into new markets and customer bases. With a rich history in automation sales, including 12 years with Bosch selling palletized conveyor systems, Giffels brings extensive experience from the material handling industry. He aims to leverage Dorner's long-standing reputation for quality conveyor systems to foster growth and explore new opportunities.

Giffels plans to implement a solutions-based sales approach, emphasizing understanding customer operations and tailoring solutions to meet specific goals. His role will involve close collaboration with customers, channel partners, and the sales team to identify and develop new business opportunities, reflecting his commitment to building upon Dorner's success and expanding its reach in the market.

10 | IMDQ | Q1 2024 indus Try news industrial Machinery digest's industry news features the latest news and press releases from some of the industries top companies. WANT TO BE FEATURED? Send your press releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com INDUSTRY NEWS

Pat Boland and Pat McCluskey

Dave Giffels

EMH Unveils New Crane Solutions at MODEX 2024

Engineered Material Handling (EMH) showcased their latest AL Systems™ Workstation Cranes and NOMAD® Free-Standing Cranes at MODEX 2024, offering innovative solutions for a wide range of lifting applications. The AL System™ Workstation Cranes, designed for flexibility and ease of installation, support capacities up to 2,200 lbs and feature lightweight aluminum tracks and an exclusive T-Slot design for easy rail splicing. Available in Lamp Post and Jib Crane styles, these cranes serve multiple applications across industries.

The NOMAD® Free-Standing Cranes, designed for modularity and flexibility, can accommodate loads from 2 to 10 tons, with widths up to 50 feet and heights up to 25 feet, making them suitable for environments where traditional overhead installations are challenging. The base plate design allows for installation without footers, and their modular nature ensures easy assembly and relocation. EMH's commitment to innovation is evident in these solutions, designed to meet diverse material handling needs while ensuring efficiency and safety.

InduSuite Introduces WeldCloud Assembly for Enhanced Weld Traceability

InduSuite has launched WeldCloud Assembly, a cloudbased application designed to revolutionize welding production traceability. This digital platform enables the recording of weld session data directly from welding power sources and offers instant comparison with Weld Procedure Specifications (WPS). Alerts are issued for welds outside WPS parameters, facilitating immediate corrective action.

WeldCloud Assembly provides a Global Dashboard for project management, offering insights into production states, completion rates, and repair rates, enhancing managerial oversight and efficiency. The app aims to streamline documentation, compliance, and traceability requirements, particularly in industries requiring rigorous accountability. By digitizing data collection and analysis, WeldCloud Assembly promises to improve production efficiency, quality assurance, and project management in welding operations.

FANUC America Demonstrates Automation Innovations at Modex 2024

FANUC America showcased its latest robotic and automation technologies at Modex 2024, designed to enhance supply chain resilience. Highlights included demonstrations of FANUC CRX cobots in order fulfillment applications, showcasing their flexibility and scalability.

FANUC also presented solutions for automated palletizing/ depalletizing and retail induction, emphasizing the role of AI and vision technology in improving efficiency and accuracy.

The event demonstrated FANUC's commitment to providing innovative solutions for warehousing and logistics, aiming to reduce labor costs and increase productivity. By integrating robots with advanced vision

and AI technologies, FANUC offers scalable, efficient solutions for a range of applications, from order fulfillment to palletizing, underscoring its role as a leader in automation technology.

Flexxbotics Enhances Robot Compatibility with Leading CNC Machines

Flexxbotics announced significant advancements in robot machine tending connectivity, making its technology compatible with a range of CNC machinery from brands like HURCO, Makino, and Nakamura-Tome. This compatibility is powered by Flexxbotics’ FlexxCORE technology, enabling seamless communication between robots and CNC machines. The technology aims to optimize machining environments, ensuring higher yields and increased efficiency.

By supporting a wide array of communication protocols and integrating with various CNC control systems, Flexxbotics addresses common challenges in CNC automation projects, such as communication barriers that can lead to quality issues. This initiative represents a step forward in realizing the potential of smart factories, where robots play a central role in manufacturing operations.

GROB Systems Announces Major Expansion of U.S. Manufacturing Facility

GROB Systems, Inc., a leading developer of manufacturing systems and machine tools, has initiated a significant expansion at its Bluffton, Ohio, headquarters. This expansion includes a 135,000 sq. ft. addition, increasing the facility's size by 35% and adding 200 new jobs. The $24.0 million project will enhance production and shipping capabilities, featuring two new depressed docks for improved logistics. This expansion reflects GROB's commitment to the U.S. manufacturing sector and its intent to boost production of innovative manufacturing systems, particularly for battery production. With a history of more than 30 years in the U.S., GROB continues to invest in local talent and technology, aiming to complete the expansion by March 2025.

INDUSTRIA L MACHINERY DIGEST COM IMD | 11 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

FANUC America Demonstrates Automation Innovations at Modex 2024

Hexagon's Volume Graphics Wins Top Industry Award

Hexagon's Volume Graphics software has secured the top spot in the 3D Scanning or Metrology category at the prestigious 3D Printing Industry Awards in London. Celebrated for its excellence in CT data analysis across various sectors, Volume Graphics is pivotal for manufacturers in improving part inspection and design. This recognition underscores the software's impact in advancing manufacturing methods and materials through high-precision, non-destructive evaluation techniques. Volume Graphics' success at the awards highlights its team's dedication to innovation and excellence in the rapidly evolving field of industrial CT scanning.

Flexxbotics and Zaptic Triumph in Hexagon’s 'Sixth Sense' Startup Cohort

Hexagon’s Manufacturing Intelligence division has announced Flexxbotics and Zaptic as the winners of its third 'Sixth Sense' cohort for startups. This accolade acknowledges their contributions to automating and digitizing the manufacturing industry. Flexxbotics is recognized for its work in workcell digitization for robotdriven manufacturing, while Zaptic is honored for its connected worker platform. The winners will receive access to Hexagon's global resources, including potential funding and visibility on Hexagon's Nexus platform, signaling a significant step towards enhancing industry automation and productivity.

MHI Hosts Record-Breaking MODEX 2024 Event

MHI's MODEX 2024 has set new records for attendance and exhibitor participation, with over 48,733 registered supply chain professionals. The event, the largest in its history, showcased cutting-edge supply chain technologies and innovations across 580,000 net square feet. This year's MODEX featured digital supply chain solutions, including AI, robotics, and IoT, reflecting the industry's focus on resilience, sustainability, and real-time operations optimization. The event's success highlights the dynamic nature of the supply chain industry and its commitment to addressing contemporary challenges through technological advancements.

Pemamek Appoints New Application Manager for Wind Energy Segment

Pemamek Ltd., a leader in welding automation, has appointed Juhani Tuomola as the Application Manager of its Wind Energy segment. Tuomola will lead technical sales efforts, focusing on automated welding solutions for wind towers and foundations. With over two years of experience as an Application Engineer in Pemamek's Wind Energy segment, Tuomola brings valuable expertise and insights into the industry's evolving needs. His role underlines Pemamek's commitment to offering turnkey solutions that support the growth of the wind energy market and its customers.

SMX Industrial Solutions Welcomes New CFO

SMX Industrial Solutions announces Neal Glassett as its new Vice President and Chief Financial Officer. Bringing extensive experience in financial management and strategic planning, Glassett's appointment underscores SMX's dedication to growth and operational excellence. His expertise in leading financial strategies for manufacturing environments will be crucial for SMX's success in the dynamic market. Glassett's leadership is expected to enhance the company's financial operations and support its growth objectives, reinforcing SMX's position as a leading provider of steel fabrication solutions.

TRUMPF Inc. Enhances Leadership Team with Key Appointments

TRUMPF Inc. has announced significant leadership appointments to further strengthen its position in the manufacturing solutions sector. Adi Buerkler, with a 26-year tenure at TRUMPF, takes on the role of product manager for TruLaser Tube and Weld. Grant Fergusson, with extensive manufacturing sales experience, is appointed as product manager for TruLaser 2D laser cutting machinery. Daniel Pfisterer is promoted to national sales manager for TruTool portable power tools. These appointments highlight TRUMPF's commitment to excellence in providing advanced machine tools and laser technology solutions.

Tractian Sponsors "Unturning Steel" Documentary Featuring Veterans in Manufacturing

Tractian, a pioneer in hardware and software solutions for the US manufacturing industry, proudly announces its Title

12 | IMDQ | Q1 2024

Hexagon's Volume Graphics Wins Top Industry Award

Adi Buerkler

Grant Fergusson

Daniel Pfisterer

H Y PNEU M AT. C O M • 414 - 423 - 740 0 Hypneumat-Q-09-2018.indd 1 8/23/18 9:33

Sponsorship of "Unturning Steel," a documentary spotlighting the integration of military veterans into American manufacturing.

Scheduled for release in Spring, the film follows Bill Leahy's mission to offer veterans a significant role in revitalizing the manufacturing sector. Partnering with the University of TennesseeKnoxville, Leahy has developed a program aimed at equipping veterans with the skills and support needed to transition into the manufacturing workforce.

The documentary underscores the challenges faced by both veterans and the manufacturing industry, highlighting the potential of veterans to drive American manufacturing's resurgence. "Unturning Steel" is inspired by Leahy's personal journey and the concept of "Turning Steel," a phrase used by Navy SEALs that symbolizes the beginning of a mission.

The film aims to mirror this ethos, showcasing the relentless effort to reintegrate veterans into a sector vital for the nation's economy.

Tractian's sponsorship aligns with its commitment to the "MADE IN AMERICA" ethos and the enhancement of veterans' roles within the manufacturing community. The documentary aspires to shed light on the untapped potential of veterans, suggesting their discipline and skills could be key to confronting the competitive challenges facing US manufacturing, especially against the backdrop of rising pressures from global competitors like China.

Upwing Energy Integrates Additive Manufacturing to Enhance Compressor Module Production

Upwing Energy, a trailblazer in gas technology, has announced the incorporation of metal additive manufacturing (AM) into its production process. This advancement, made in collaboration with Velo3D, aims to optimize the manufacturing timelines for its Subsurface Compressor System (SCS), crucial for natural gas well deployments. The SCS, known for its innovative multistage hybrid axial compressor design, benefits significantly from AM, particularly in manufacturing complex rotor designs from Inconel 718.

The transition to metal AM has allowed Upwing to reduce the engineering-to-assembly process for SCS

compressor rotors to just 10 weeks. This method not only facilitates the production of more complex designs but also enhances part performance and longevity. Tensile tests confirm that the AM Inconel 718 parts meet ASTM F3055 requirements, demonstrating the effectiveness of AM in producing durable, high-quality components for demanding applications like gas compression.

Upwing's shift to additive manufacturing underscores its commitment to innovation and excellence, enabling scalable and adaptable production. The company's rigorous testing of AM components under operational conditions further validates the resilience and performance of the parts, marking a significant step forward in the application of additive manufacturing in the energy sector.

Wintriss Expands U.S. Sales and Service Coverage with New Partnerships

Wintriss Controls Group, a leader in press automation and safety controls, has broadened its U.S. sales and service footprint through strategic partnerships. Midwest Press and Automation (MPA), LLC, already a key distributor, has extended its coverage to Southern Ohio and Kentucky, alongside its existing territories. As North America's largest Wintriss stocking dealer, MPA is poised to provide comprehensive sales and service support, including turnkey installations.

Furthermore, Wintriss has partnered with Southern Press Solutions in Blairsville, Georgia, to cover Alabama and Georgia. Founded in 2021 with over a decade of press machine service expertise, Southern Press Solutions aims to bring Wintriss's industry-leading technology to its new territories.

These expansions reflect Wintriss's commitment to delivering exceptional sales and service experiences across the U.S. By collaborating with distributors experienced in using, demonstrating, and servicing press controls, Wintriss ensures customers receive optimal support. This strategy aligns with the company's dedication to maintaining its position as a frontrunner in press automation solutions.

14 | IMDQ | Q1 2024

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

additional to air tools, we offer accessories and abrasives for complete process solutions with the know-how to get the

right.

about a no-obligation demonstration on any

in our line. ABRASIVE POWER TOOLS & PROCESS SOLUTIONS SINCE 1969 AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS WE LISTEN. WE OBSERVE. WE INNOVATE. Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com |

In

job done

Ask

product

Solving the Manufacturing Workforce Crisis

There are currently about 12.5 million manufacturing jobs in the U.S., comprising over 8 percent of the U.S. workforce. Given the improved state of manufacturing in the U.S., one might expect these numbers to increase. Unfortunately, the manufacturing industry is experiencing a labor shortage. While older skilled workers are retiring, manufacturers are struggling to attract new, younger workers. Furthermore, many younger workers lack the appropriate skills for these new jobs. With low unemployment and a tight labor market in the U.S., many of these workers can and often do seek employment elsewhere. Study after study indicates that the shortage is expected to continue beyond this year, potentially resulting in large revenue losses and escalating this situation into a full-blown crisis for manufacturers.

What’s Behind This Labor Shortage?

Global Impact

» Retiring Workers: It is estimated that baby boomers will be retiring from all sectors at a rate of 10,000 a day in the United States over the next 19 years. As they depart, they take with them years of experience and technical skills.

» Not Enough Young Workers: The manufacturing industry is not attracting enough millennial workers, who often have a negative perception of manufacturing jobs and seek employment in other industries.

» Manufacturing Skills Gap: Young Americans lack the appropriate science, technology, engineering, and math (STEM) education for skilled jobs in manufacturing. Those who do possess a STEM education often overlook the manufacturing industry, frequently favoring the tech industry. With advanced technologies becoming prevalent in the manufacturing industry, it is more critical than ever to find workers with the right skills.

An economic ripple effect from the manufacturing workforce crisis is inevitable. A recent study by Deloitte and The Manufacturing Institute predicts that $454 billion in manufacturing GDP could be at risk in 2028, with more than $2.5 trillion at risk over the next decade. Local economies will also suffer. When companies can no longer fill positions from the available labor pool, they may relocate to more favorable locations, leaving cities and counties with empty factories and diminished tax revenues.

Manufacturers in the U.S. are not alone in facing a workforce crisis; it is a global issue. According to a quarterly economic survey by the National Association of Manufacturers (NAM), the global manufacturing industry is expected to experience a shortfall of more than two million workers by 2020. By 2030, the shortage could reach nearly 8 million workers, leading to potential revenue losses as high as $600 billion. A recent Korn Ferry study found that by 2030, Japan could fail to generate $194.61 billion in revenue due to labor shortages, equivalent to 3% of the country's economy. Germany, already a manufacturing leader, could face revenue shortfalls of $77.93 billion by 2030. The study also noted that manufacturing in Hong Kong and Singapore might suffer significantly from the labor shortage.

Recent Studies

Recent studies corroborate the reality of the labor shortage in manufacturing. Let's examine some of these studies in detail.

Leading Edge Alliance Survey

A survey of more than 350 manufacturers by the Leading Edge Alliance, an association of accounting and consulting firms, found that while most manufacturers are optimistic about sales, they are more pessimistic about finding skilled labor. Survey responses underscore this concern: 52% of respondents identified finding skilled labor as their biggest obstacle to growth, 43% stated that addressing the labor shortage is their top priority for 2019, and 62% expect to increase hiring at their company in 2019.

16 | IMDQ | Q1 2024

Case sTudy

SHEARS & PRESS BRAKES

Hydraulic Shears:

1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com

MADE IN THE USA

Korn Ferry Report

According to a recent report from the global consulting firm Korn Ferry, the shortage of skilled manufacturing workers is expected to escalate over the next decade. The forecast suggests the shortage could increase to 383,000 by 2030, amounting to more than 10% of all highly skilled workers. The report highlights that, while China and Russia currently enjoy labor surpluses, by 2030, all countries except India are expected to face shortages of highly skilled manufacturing workers. In Hong Kong, already grappling with this labor shortage, the shortfall of these workers could constitute up to 80% of the industry's workforce. Thus, the workforce crisis is not only a challenge for the United States but for manufacturers globally.

Manufacturers’ Outlook Survey from the National Association of Manufacturers (NAM)

The NAM's quarterly survey of 718 member manufacturers revealed acute awareness and concern about the labor shortage. Key findings include:

» 4% of respondents identified the inability to attract and retain workers as the most significant threat to their business.

» 4% of respondents acknowledged turning down new business due to the labor shortage, and 33.2% reported delaying expansion efforts.

» More than 58% anticipated increasing their workforce over the next year, with 23.1% expecting employment growth of 5% or more.

These insights underscore the pressing need for solutions to the manufacturing labor shortage, which is impacting business operations and growth potential.

Deloitte and The Manufacturing Institute Skills Gap Study

This study further illuminates the growing chasm between available jobs and qualified workers to fill them. It found that half of all open positions for skilled workers in U.S. manufacturing remain unfilled due to the skills gap. Such jobs, requiring specific training or skill sets, can take

months to fill. The study predicts that 4 million positions are likely to remain unfilled between 2018 and 2028, posing a potential economic impact of $2.5 trillion. The skills gap in manufacturing is anticipated to grow from 488,000 open jobs today to over two million by 2028. Respondents cited the main reasons for the difficulty in filling these skilled positions as the negative perception of the manufacturing industry (45%), a shift in the skills desired due to advanced technologies (36%), and the retirement of baby boomers (36%).

Solving the Manufacturing Workforce Crisis

Despite the optimism in global manufacturing regarding revenue growth, the industry faces a significant labor

18 | IMDQ | Q1 2024

shortage. The NAM's quarterly economic survey predicts a shortfall of almost eight million workers by 2030, potentially resulting in revenue losses as high as $600 billion. The primary causes of this crisis include retiring baby boomers, a lack of younger workers to replace them, and a skills gap wherein many young workers lack the necessary STEM skills for manufacturing jobs.

Strategies for Addressing the Workforce Crisis:

» Manufacturers are actively seeking solutions to this labor shortage by:

» Introducing learning and development programs to enhance skills.

» Increasing flexibility in hiring processes to include candidates with less experience but promising potential.

» Implementing knowledge transfer programs that allow retiring workers to pass on their skills to younger employees.

» Increasing wages and offering competitive benefits and signing bonuses to make manufacturing jobs more attractive to younger generations.

» Adopting automated technologies like Cloud ERP to appeal to young workers proficient in digital skills.

Learning and Development Programs

Developing partnerships with local community colleges or trade schools has proven effective in attracting workers to the manufacturing sector. Such programs enable manufacturers to target students with an inherent interest in manufacturing, going beyond traditional recruitment methods like job fairs and automated online searches.

In-House Training

In addition to external partnerships, manufacturers are establishing in-house training programs to continuously develop the skills of their workforce. These programs are beneficial for everyone involved, enhancing the company's skill base while fostering a sense of achievement and loyalty among employees.

Hiring Flexibility

To compete with industries perceived as more glamorous, such as high tech and software, manufacturing firms are becoming more flexible in their hiring criteria, focusing on potential rather than just experience.

Increased Wages, Benefits, and Signing Bonuses

Understanding that competitive compensation is key to attracting talent, manufacturers are increasing wages and offering comprehensive benefits packages.

Knowledge Transfer and Digital Transformation

Knowledge transfer programs are crucial for retaining the invaluable experience of retiring workers. Additionally, embracing digital transformation and automation is essential for attracting digitally savvy young workers.

Summary

Addressing the manufacturing workforce crisis requires a multifaceted approach, including training and development, flexible hiring practices, competitive compensation, and embracing digital technologies. By adopting these strategies, the manufacturing industry can overcome current challenges and secure a skilled and sustainable workforce for the future.

INDUSTRIA L MACHINERY DIGEST COM IMD | 19

Robots Can Support The Future of Bioplastics

economical manufacturing with bioplastics needs 6-axis robots

The bioplastics market is tipped to reach $215 billion by the end of 2027, growing in sectors including consumer electronics, medical applications, agricultural machinery and more. Advanced automation will be essential to ensure products are of the highest quality and accurately cut, formed and measured. Here, Nigel Smith, CEO at TM Robotics, explains how the use of robots in injection moulding processes, including its recentlyexpanded 6-axis robot range, can help manufacturers embrace a bioplastic future.

Bioplastics are made from sugar that comes from corn, sugar cane or sugar beets. They are more environmentally friendly than traditional plastics manufacturing since they can be made from renewable resources. This type of plastic is rising in popularity as an alternative to petroleum-based plastics, as manufacturers become increasingly conscious of plastic waste littering our oceans.

While there are real opportunities in bioplastics, there are also challenges. Like all plastic moulding operations, production runs, both small and large, must run uninterrupted to produce a certain number of products per hour. There must be standards in place for loading and unloading moulds in a predictable and efficient fashion, and smooth working between machines and human workers on the production line. These standards must be met for injection moulding, one of the most common manufacturing processes.

Longer arms

For robots in bioplastics, six may be the magic number. 6-axis robots are among the most widely-used industrial machines, and are already known as being the trusted workhorse of injection molding applications. However, many manufacturers are still reluctant to invest in robots — why is this?

Cost and space are common barriers for many manufacturers. But another, less reported, obstacle is that many manufacturers are wary of the cultural and procedural changes that robotics may demand. That includes whether their human production line workers have the technical understanding and skills required to use robots.

Manufacturers are wary of stepping away from the established ways of doings things — whether it’s a production process, method of communication, or a trusted machine or tool — as such a change invites risk. First, robot designs must fit into smaller spaces to suit manufacturers’ growing concerns over “machine real estate,” meaning robots must fit their goal that every square metre of production space is used for production. Second, in its Digital Factories 2020 report, Pricewaterhouse Coopers (PwC) cites “insufficient digital company culture, or a reluctance on the part of human workers to embrace digital change,” as an obstacle to robotising production lines.

Nevertheless, the good news is that robots are increasingly evolving to apply to manufacturers existing ways of doing things. They are becoming smaller, faster and more flexible and adaptable to specific production lines.

TM Robotics, the premier partner of Shibaura Machine — formerly known as Toshiba Machine — robotics, offers a greater variety of robots, having recently expanded their range to offer an even more comprehensive choice of its

20 | IMDQ | Q1 2024 CoMpany profile

six-axis robots to suit all applications — including bioplastics.

Crucially, these robots are also easily integrated with Shibaura Machine’s injection moulding machines. Among the newest equipment is the SXIII range of injection moulding machines. The all-electric range is an enhanced performance model that provides significantly faster injection speeds than traditional moulding equipment. When paired with a fast cycle 6-axis robot for loading and unloading, manufacturers can expect increased throughput.

TM Robotics’ series of verticallyarticulated, 6-axis robots are available in three models that all offer low headroom, wider reach and other benefits. Each robot has varying reach and payload specifications, and a longer arm length compared with previous robot ranges. They include its TVL range that are compact, lightweight and space saving, but with all the functionality of a 6-axis robot.

But, of the growing options available, how can manufacturers be sure to choose the right robots for them?

And there is the newest TVM range of highly productive, reliable robots aimed at a multitude of industries, including automotive components, medical, packaging and pharmaceutical ― and plastics. The largest, the TVM1500, provides a maximum reach of 1715 millimeters, the TVM1200 can reach up to 1418 millimeters and the smallest model, the TVM900, provides a maximum reach of up to 1124 millimeters. In addition to three distinctive arm lengths, the operating range of each model can be expanded by mounting the robot on an optional linear actuator.

The machines are designed for enhanced versability and performance, with a streamlined design. With these features, the range can provide support significantly faster loading and unloading speeds for moulding applications. But, what about the reluctance of human workers to embrace digital change?

Easy to program

Plug and play installation is now very much a reality. Robots themselves are becoming easier to program, which makes it easier to win the buy-in of human workers while also reducing training costs. The end result is better collaborations between machines and human workers on injection molding lines.

As McKinsey & Company puts it: “The production systems of the future will still require people in many of the roles they hold today, but the nature of those roles will change. Operators will need new capabilities as low-skill tasks are automated and increasingly sophisticated equipment requires skilled people to run it.”

This is where a trusted partner like TM Robotics comes into play. Its team has a cumulative 75 years of experience working with Shibaura Machine equipment, and has long supplied robots for loading and unloading of injection moulding applications. Through its expertise, manufacturers can find their ideal automated injection moulding set up.

As bioplastics grow in popularity over the coming decade, expanded automation will be crucial for ensuring injection moulding is as economically viable as the bioplastics themselves. To this end, 6-axis robots can play a vital behind-the-scene role in helping to reduce the levels of plastic waste littering Earth’s oceans and environment.

ABOUT TM ROBOTICS

TM Robotics has installed thousands of robots in factories throughout the world, including North and South America, India, Russia, Europe, the Middle East, Africa and Australia. Many of the top manufacturing companies depend on TM Robotics’ product offerings for their reliability, performance, and overall value.

In partnership with Shibaura Machine, TM Robotics is the only company that offers a comprehensive range of all three categories of robots; 6-axis, SCARA, and Cartesian. These are designed and built in-house.

TM Robotics delivers cutting-edge solutions, training, and support services for industrial and commercial applications.

For More Information:

Please visit www.tmrobotics.co.uk

INDUSTRIA L MACHINERY DIGEST COM IMD | 21 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Innovating Steel Processing: Carl Spaeter Hamburg Unveils Advanced Preservation Line

In order to meet customer demands more swiftly and efficiently, Carl Spaeter Hamburg has expanded its range of manufacturing equipment with the introduction of a preservation line, KON 34/6-HD from Rösler. This line, which combines shot blasting and painting in a single system, is capable of handling steel components up to 3,200 mm wide, 400 mm high, and a maximum length of 21.2 meters. Equipped with two paint systems, the line has been perfectly integrated into an existing building that houses an overhead crane. This new addition not only allows for a higher material throughput but also enhances the entire production flow, leading to reduced lead times.

Founded in 1905 in Hamburg as a hardware store, Carl Spaeter Hamburg has grown to become one of the leading steel suppliers for retailers, mechanical contractors, and industrial manufacturers in Northern Germany and beyond. The company’s success hinges on its broad range of steel products, a vast inventory exceeding 25,000 tons, swift delivery times, high operational flexibility, and an array of steel processing and refinement services. Mike Barz, General Manager at Carl Spaeter Hamburg, shares,

"Since our existing shot blast & painting line had reached the end of its usable life, and with an aim to enhance our customer support, we opted for the KON 34/6-HD from Rösler." Rösler, based in Untermerzbach, Southern Germany, secured this significant purchase by tailoring its equipment concept to meet customer needs, impressing with both the quality and robust design of its equipment, and showcasing several reference plants in the field. Reyk Hagelberg, Plant Manager at Carl Spaeter Hamburg, adds, "Rösler, with our input, quickly developed a viable equipment concept perfectly adapted to our existing building and technical requirements."

Fully Automatic, Energy-Saving Shot Blasting

A pivotal requirement was the line's ability to handle steel components of specified dimensions and to ensure that steel plates, regardless of thickness, would be cleaned with consistent, high-quality results. Additionally, it was essential that all surface areas and edges of steel beams were perfectly blasted and received optimal paint coverage. Given that the steel components can weigh up to twelve

22 | IMDQ | Q1 2024

inTegraTions

24 | IMDQ | Q1 2024 www.IndustrialMachineryDigest.com SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS THE BEST ADVICE I CAN GIVE YOU IS TO SUBSCRIBE TO NEWSLETTERS! North America’s Manufacturing Resource for Industry Professionals Since 1986 Business & Workforce Development Fabrication & Manufacturing Showcase Products & New Technology Industry Insight, Safety & Maintenance Manufacturing Process & Automation What’s in YOUR InBox?

tons, the design of the roller conveyors and cross transport systems needed to be exceptionally sturdy.

Special sensors measure the dimensions of steel components placed on the inlet roller conveyor. The PLC then automatically adjusts the number of turbines required for cleaning. Other parameters, such as travel speed, paint type, and thickness, are programmed into the PLC and accessible from the operating panel. Initially, components pass through a pre-heater to avoid introducing moisture into the shot blast machine, with the exhaust air from the pre-heater being redirected to the paint dryer to expedite drying.

The machine housing is constructed from manganese steel, and the blast chamber is lined with overlapping manganese steel liners. Eight Gamma 400G high-performance turbines, each with a 22 kW drive power, ensure the cleanliness standard of SA 2.5 is reliably met at speeds of up to 4 meters/minute. The Gamma turbines, featuring curved "Y" design throwing blades, offer up to 20% higher blast performance while reducing energy consumption. A combined brush-off/blow-off system at the blast chamber's exit ensures the removal of residual blast media and dust.

Low Paint Usage and Minimal Overspray

The preservation line incorporates two independent paint application systems to meet various coating requirements, including the use of a water-based primer. Sensors precisely measure workpiece dimensions, allowing for exact programming of the spray guns. This precision minimizes overspray and paint waste. The effective paint filter captures any residual overspray, significantly reducing dust load in the air to levels well below official standards.

Optimized Manufacturing Processes and Material Flow

The new preservation line's workpiece transport system has been integrated into an existing building, enhancing material handling flexibility. The setup, spanning over 42,000 square meters, includes roller conveyors and cross-transport systems for efficient intermediate storage

and transport of steel components. "With the new preservation line and enhanced processing capabilities, we can respond to customer requests more rapidly and efficiently, thereby reducing our lead times. Furthermore, this addition streamlines our workflow and logistical setup, benefitting both our employees and production efficiency," concludes Mike Barz.

For more information:

Visit www.rosler.com.

INDUSTRIA L MACHINERY DIGEST COM IMD | 25

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! VICE HOOK ACCESSORY

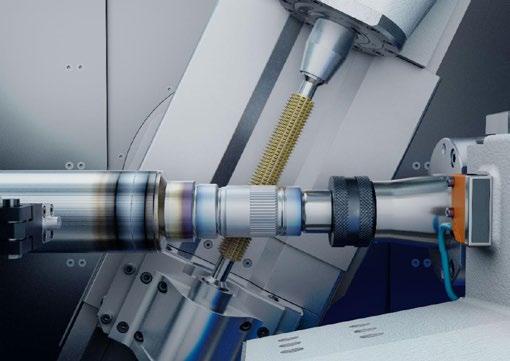

CMM Controller Retrofits Enable Multi-Sensor Inspection

Co-ordinate measuring machine still capable of aerospace-standard quality control after 26 years

At one of two factory units in Devizes operated by sealing specialists Cross Manufacturing (www. crossmanufacturing.com), two co-ordinate measuring machines (CMMs) built by LK Metrology (www. LKmetrology.com) in 1997 and 2007 have been given a new lease of life following an upgrade. It involved the OEM future-proofing operation of both machines by retrofitting multi-wired NMC300 controllers with updated firmware and software. Among the many advantages is the ability to deploy different types of sensors in addition to touch-trigger probes. Within the scope of the project, two new Renishaw PH10MQ motorized probe heads were also fitted.

As a result of the improvements, the sealing design and manufacturing specialist has immediately gained the ability to use the Renishaw SP25M tactile scanning probe it has purchased, which it is hoped will cut metrology cycle times by at least one-third when implemented in early 2024. Additional types of contact and non-contact sensors may be integrated in the future should Cross Manufacturing choose to extend the CMMs’ capability and consolidate other automatic measuring functions into a single metrology routine.

Located on the shop floor in one of two adjacent sites in Devizes, the CMMs are an LK G90C 10.10.8 and an LK Evo 15.15.10 having nominal inspection volumes of 1,000 x 1,000 x 800 mm and 1,500 x 1,500 x 1,000 mm respectively. They fulfil a critical role serving the turning section, where brush seals ranging in size from 6 feet (1.83 metres) down to 4 inches (102 mm) in diameter are produced in small batches for high-temperature gas turbine applications in aerospace and power generation. The former sector accounts for the vast majority of throughput, particularly for the US market, more than 80% of the manufacturer’s output being exported. It is the British company’s undisputed world leadership in the technology that motivates aerospace OEMs overseas as well as in Britain to source brush seals and allied equipment from Cross Manufacturing.

The company’s senior project manager Mark Bolwell explained, “The vast majority of our parts are 100% inspected. Upgrading our CMMs means that we will be able to increase throughput by introducing tactile scanning, allowing us to support ever increasing demand without having to invest in another CMM at this time. We are

supported admirably by LK’s applications engineers, all of whom are knowledgeable and never cease to be helpful.

“It is testament to the build quality of the LK machines that, so many years after they were built, they are still able to underpin our metrology and traceability requirements. The manufacturer’s UKAS-certified engineers calibrate them annually and every morning we cross-reference the accuracy of the two machines using a calibration ring to ensure the measurements are verified.”

Dave Eldridge, lead inspector for the aerospace and the powergen products added, “Despite their age, the CMMs measure tolerances from ±0.002” (±51 microns) down to ±0.0002” (±5.1 microns), a level of process capability that requires a very high measurement uncertainty. Almost every part we inspect is symmetrical and relatively flat, whether it is a finish-machined product, a segment of a large ring, or a fixture for securing components during batch production.

“Most feature measurements are consequently 2D and three-quarters consist of CTQ (critical to quality) for ensuring correct fit and performance in a turbine. Surface finish is generally in the range 32 to 64 CLA, which is currently checked separately on other equipment. However, now that we have multi-sensor capability as a result of the retrofits, we may decide to carry out that function in-cycle on the CMMs using an LK surface roughness probe, saving a second inspection operation.”

Repeated transfer of parts between the lathes and the CMMs on the shop floor is frequently needed for everything from pre-manufacturing checks through to final part inspection and sign-off. In the case of aerospace brush seals, certification is nearly always performed by

26 | IMDQ | Q1 2024 MaChines

trained Cross Manufacturing personnel on behalf of the customer under source released parts agreements. Similar is performed on a large proportion of the products destined for the powergen sector.

About 20 shop floor staff have been trained by LK to use the uprated CMMs, five of whom are also qualified to create and optimise inspection cycles using LK’s CAMIO 2021 programming, analysis and reporting software. Most recently, an offline CAMIO station was supplied to enable programming while inspection is in progress on the CMMs. LK continues to supply ongoing consultancy, engineering support and helpdesk advice from its Castle Donington headquarters.

ABOUT LK METROLOGY

LK Metrology is renowned for innovative metrology solutions and services. The company’s products, including coordinate measuring machines (CMM), portable measuring arms and metrology software, are used worldwide to control and improve the quality of manufactured components. Its precision technology underpins the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

Established in England in 1963, LK Metrology has an impressive heritage in metrology dating back to the birth of CMM technology. Founded by CMM pioneer Norman Key and his father-in-law Jim Lowther, LK Metrology is credited with many of the CMM industry’s firsts including the first bridge-type design, first OEM to integrate computers, first to use a touch trigger probe, first to develop inspection software, first to use all air bearings and granite guideways, first to use carbon fibre composite spindles, first to use microprocessor-controlled drive systems, first to produce a truly thermally stable CMM and first to produce a high-accuracy horizontal-spindle CMM.

In 2018, LK Metrology was relaunched as an independent

several years as a division of Nikon Metrology. Headquartered in the UK, LK's CMM development and production are at the company’s facility in Castle Donington. Sales and support offices are located in the UK, North America, Belgium, France, Germany, Italy and China, supplemented by a worldwide distributor network.

INDUSTRIA L MACHINERY DIGEST COM IMD | 27 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! WHY SKY HOOK?

CMM manufacturer after

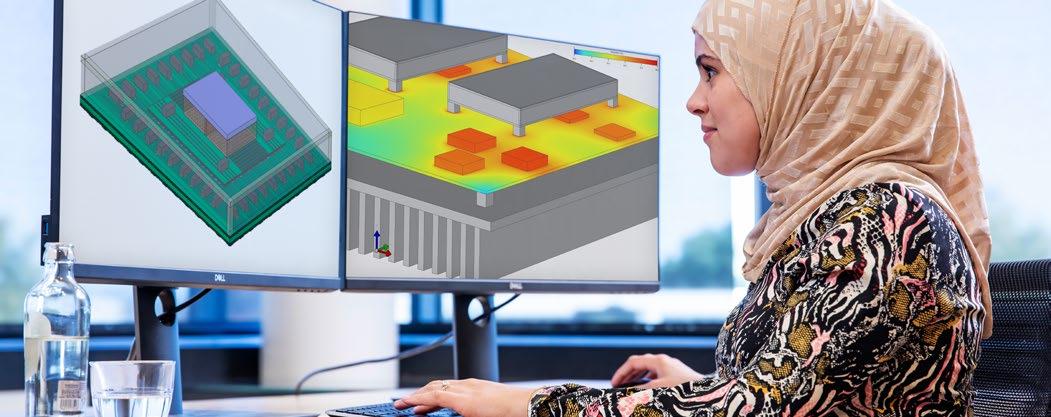

Extraordinary Insights Mined by Analyzing Mass of Measurement Data

a new generation of specialized software is helping manufacturers to collect, track and monitor all collected data to unlock the full value of analytics.

By Del Williams

In essentially every field of manufacturing today, professionals use sophisticated equipment to track and report data collected while measuring and testing raw materials, in-process components, and finished products. However, many organizations struggle to efficiently gather, monitor, and analyze the vast amount of information they accumulate. This lack of comprehensive and global approach hinders the effective utilization of data analytics to derive valuable insights from raw data. The result is often missed opportunities to make strategic decisions, enhance performance, increase productivity, and ultimately improve profitability.

As Peter Sondergaard, Senior Vice President and Global Head of Research at Gartner, Inc. shared, “Information is the oil of the 21st century, and analytics is the combustion engine.” Just like oil, data has tremendous potential value but only when it is effectively gathered and utilized.

However, with all the materials, instruments, and applications involved in modern manufacturing, it can be challenging to capture, track, assess, and effectively use the flood of data that is generated on a timely basis. According to the Forbes article Big Data: 20 Mind-Boggling Facts Everyone Must Read, “At the moment less than 0.5% of all data is ever analyzed and used.”

28 | IMDQ | Q1 2024 sof T ware/Cloudware

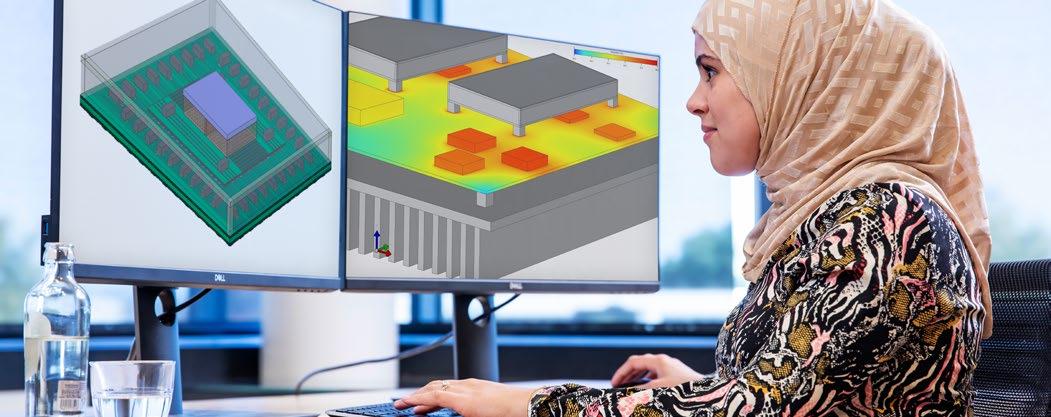

Specialized software is aiding manufacturers in efficiently collecting, tracking, and monitoring data for enhanced analytics.

Now industry innovation is helping manufacturers to gain key insights into their products and processes by enabling them to effectively interpret data from every test given even at mass volumes.

“Having access to tools that allow you to automatically store, track, and analyze the information gathered [from test instruments] can help processors unlock the greatest potential value from their ideas, processes, and products. This kind of analysis means users can take logs of test results and let the data “speak for itself” to help engineers and management recognize patterns and draw accurate conclusions. In some cases, the data analysis may help them make accurate predictions to drive future growth,” says John Bogart, Managing Director of Kett US, a manufacturer of a full range of moisture and organic composition analyzers.

Data Tracking and Analysis Simplified

To help manufacturers attain the utmost value from their data, OEMs have developed a new generation of software to streamline the collection and analysis of production

According to Bogart, effective data tracking and analysis offers significant benefits to many areas within manufacturing from R&D, process engineering, and plant management to quality assurance, maintenance, corporate management, and even regulatory compliance.

The Many Benefits of Data Tracking

For manufacturers, implementing an effective data tracking system can be crucial to maintaining quality assurance and ensuring optimal results for a product or process.

For example, it can reduce or eliminate measurement or labeling errors at every phase of the process. This can help to ensure safety, which is particularly important in fields where precision is key such as medicine, construction, and engineering.

Logging and analyzing data can provide much needed transparency for quality assurance. Data tracking streamlines auditing by providing a definitive means to examine quality and workflow analysis. Ongoing tracking can help to pinpoint exactly where an issue arises, making it easier to investigate and address any manufacturing problems.

Tracking and analyzing data can also identify important patterns and trends in testing.

“Being able to automatically and effortlessly log data not only means you can review information from previous tests, but also analyze the data, draw conclusions, and make informed decisions for the future rather than merely reacting to problems as they occur,” says Bogart.

INDUSTRIA L MACHINERY DIGEST COM IMD | 29 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! ERGONOMICS & SAFETY

In manufacturing today, professionals use sophisticated equipment to track and report data collected while measuring and testing raw materials, in-process components, and finished products.

measurement data.

As an example, Kett has introduced its Tracker™ System, a data collection and analysis software solution that gives organizations the ability to monitor, synthesize, display, and report information from manufacturing related measurement devices over time. This can include, for instance, factors such as the moisture measurement or organic composition analysis of everything from raw inputs to finished products.

The system is comprised of a collection of software programs that allow processors to log and analyze data they collect on each device. The single analyzer version is a database with display and output functions for a single Kett measurement device. Using multiple analyzers gives users the ability to simultaneously collect, display, monitor, and send out data from several devices all in one place.

A positioning module allows users to add location data for instrument readings and other measurements. This enables integration of the information with linear actuators and/or robotics, which can facilitate making real-time adjustments in production equipment as required to improve quality or efficiency.

The Tracker™ Software allows integrating data collection tables and graphs as needed from non-Kett devices, making the system a one-stop-shop for

manufacturing data collection and analysis. The system provides modules for distributed data management so multiple authorized users can view, analyze, manage, and send out process control management data simultaneously.

“The Tracker™ System is designed to serve as a single collection point for data and analysis that can be applied across all sectors and industries,” says Bogart.

The data tracking and analysis system delivers even more value for manufacturers when used in conjunction with smart measurement devices. On the production floor, “smart” equates with the ability to continually monitor conditions such as product and input moisture content in real-time to optimize quality. Assessing proper moisture level in products and processes is essential for many reasons such as meeting regulatory standards, ensuring proper chemical reactions and drying, maximizing shelf life

30 | IMDQ | Q1 2024

The right equipment can efficiently gather, monitor, and analyze the vast amount of information accumulated while measuring and testing materials.

and deterring mold, as well as increasing selling price and decreasing shipping cost.

One example is Kett’s KB30 in-line NIR moisture meter system. With a response time of 0.2 seconds, +/0.01% accuracy, and a moisture measurement range of 0.00-100.0%, the device can be used to assess extremely variable and rapidly changing products, as well as processes where quality is critical. The quick response time enables faster production line rates with superior moisture measurement. It has been used in various industrial production lines to test pharmaceuticals, chemicals, foods, textiles, minerals, lubricants, pulp/paper goods, and personal care products.

According to Bogart, the technology is “smart” because all of the calculations are performed inside the sensor and measurements are sent on a 24/7 basis to smartphones, PCs, and other devices without having to be directly connected. If desired, these instruments can prompt operators and managers with alerts as needed.

When the smart device’s monitoring capabilities are integrated with accompanying Kett Tracker™ data collection and analysis software, improved error detection, defect analysis, and product quality result.

“With all these meticulous readings and with every instrument geared toward accuracy in every moment,

comes a great deal of data,” explains Bogart. “It only makes sense to provide a place to store, track, and analyze all this information. This is a wealth of information that’s right at their fingertips, and the right lens can unlock this information.”

As an example, when two smart sensors were used to run different production lines at a manufacturer, the devices’ real-time capability detected periodic, wildly fluctuating moisture values that caused their extrusion process to go out of control. After investigation, it was determined that the manufacturer’s electrical circuits had not been adequately isolated from the effects of a nearby power plant’s operation on shared power lines.

As more industries and sectors look to improve their processes and inform their decisions, effectively collecting and analyzing data will become even more critical. Manufacturers that take advantage of the latest tools to track and analyze their data will not only improve their production quality and efficiency but also position themselves for growth in the future.

For more information,

Contact Kett: call 800-438-5388; email support@kett.com; or visit www.kett.com.

INDUSTRIA L MACHINERY DIGEST COM IMD | 31

The right measuring device can help manufacturers make strategic decisions, enhance performance, increase productivity, and ultimately improve profitability.

PRODUCT SHOWCASE

Industrial Machinery Digest's Monthly Product Showcase features the latest from some of the manufacturing industry's top suppliers.

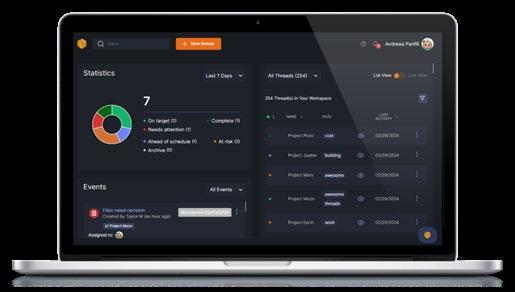

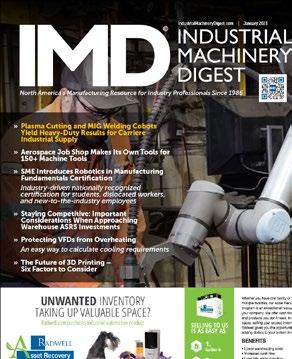

Authentise Enhances Collaborative Engineering with AI and 3D Annotations

Authentise announces significant updates to Threads, its collaborative tool designed for R&D and industrial engineering teams. Now available for free, Threads introduces features such as native 3D model annotations and AI-generated suggestions, aimed at streamlining product development processes. Developed in collaboration with major users like the US Department of Defense and Boeing, Threads facilitates seamless engineering projects management. Its AI capabilities offer efficient milestone tracking and synthesize conversation summaries, enhancing team communication. Accessible on secure cloud platforms, Threads simplifies complex discussions, ensuring a synchronized team approach to 3D models. Authentise's initiative reflects its commitment to accelerating innovation and efficiency in engineering workflows.

Bruker Alicona Showcases Optical Metrology

Innovations at Control 2024

Bruker Alicona will present its latest optical 3D measurement technologies at Control 2024, focusing on user-friendliness and affordability. The highlight, FocusX, offers advanced measurement capabilities at a competitive price, blending roughness and coordinate measurement in a single device. This system revolutionizes precision measurement with features like "Vertical Focus Probing," allowing for the measurement of steep flanks and rough surfaces. Additionally, Bruker Alicona introduces software enhancements like One Click Roughness and Round Tool

Alignment, simplifying operation and automating tasks. These innovations underscore Bruker Alicona's commitment to making optical 3D metrology accessible to a broader range of users.

Coxreels Introduces High-Visibility Safety Hose Reels

Coxreels announces the launch of its High-Visibility Safety Hose Reels, enhancing workplace safety by increasing hose and cable awareness. These reels feature hybrid bright yellow hoses with a white stripe, designed to reduce trip hazards and improve safety during use. Available in various series, the high-visibility hose combines the durability of rubber with the lightweight benefits of PVC. Additionally, incorporating EZ-Coil controlled retraction and high-visibility hose into Coxreels reels significantly elevates workplace safety standards. This innovation demonstrates Coxreels' commitment to providing comprehensive reel solutions that prioritize safety and efficiency.

32 | IMDQ | Q1 2024 produCT showCase

FEATURED? Send your latest product information to editorial@indmacdig.com

WANT TO BE

Bruker Alicona Showcases Optical Metrology Innovations at Control 2024

E-Z Lok Introduces Press-in Inserts for Enhanced Plastic Assembly

E-Z Lok unveils E-Z Press™, its latest range of threaded press-in inserts designed for post-molding installation in plastics. These inserts offer a cost-effective solution for enhancing torque resistance and durability in assembled products. The unique slotted design with a diamond-knurled exterior ensures optimal insertion and secure fitting. Available in flush, flanged, and reverse slot styles, E-Z Press™ inserts support versatile application needs. This innovation streamlines manufacturing processes by eliminating the need for post-molding thread chasing, demonstrating E-Z Lok's dedication to improving assembly efficiency and product quality.

ensures high-quality gear production with fast cycle times, addressing the growing e-mobility sector's needs. Its design features, including a rigid milling head and horizontal workpiece arrangement, facilitate smooth operation and exceptional gear quality. The HLC 150 H can be integrated into comprehensive production lines, further streamlining rotor shaft manufacturing. This advancement highlights EMAG Koepfer's commitment to providing efficient solutions for the burgeoning electric vehicle market.

EnerSys® Innovations Unveiled at MODEX 2024

EMAG Develops Custom-Fit Robotic Automation Solutions for Efficient Production

EMAG showcases its prowess in integrating custom-fit robotic automation solutions with its high-performance machines, optimizing parts flow in production environments. Catering to diverse requirements, EMAG's robots support various feeding systems, enhancing process efficiency and autonomy. Solutions range from infeed/ outfeed belts and palletizers to bin picking and drawer systems, each tailored to specific production needs. These robotic solutions are adaptable, ensuring seamless integration into existing production setups. EMAG's approach emphasizes workpiece and process requirements, offering flexible, high-quality automation solutions that respond to contemporary manufacturing challenges.

EMAG Koepfer's Gear Hobbing Machine Elevates E-Car Rotor Shaft Production

EMAG Koepfer introduces the HLC 150 H gear hobbing machine, designed to meet the high-precision gear cutting demands of electric car rotor shafts. This machine

EnerSys® showcased its latest solutions for optimizing industrial applications at MODEX 2024, emphasizing customer-driven innovations. The company highlighted the challenges in the motive power industry and their strategic responses to these challenges, focusing on labor challenges and environmental sustainability. The NexSys® AIR wireless charger, designed for AGV fleets, eliminates the need for manual charging maintenance, promoting productivity and

MOTORS… The Char-Lynn motor range consists of three major types based on the valving used to distribute fluid through the Orbit gear set (geroler or gerotor), Spool Valve, Disc Valve and VIS (Valve-in-Star). A variety of displacement sizes are available in each of the three motor types to provide a wide range of speeds and torques.

STEERING CONTROL UNITS… offer these advantages:

• Minimal steering linkage reduces cost, provides design flexibility.

• Complete isolation of load forces from the control station.

• Continuous, unlimited control action with low output torque.

• Wide selection of control circuits and meter sizes.

• Works with many kinds of power steering pumps or fluid supply.

GEAR PUMPS… Eaton Series 26 gear pumps with 13-tooth gears minimizes flow ripple to reduce noise and vibration. Bearing lubrication system uses inlet oil rather than high pressure oil, improving volumetric efficiency and power output. The 13 available displacements and many mounting configurations provide for an easy retrofit. Other series available.

INDUSTRIA L MACHINERY DIGEST COM IMD | 33 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

WWW.MACMHYDRAULIC.COM 7355 N. Lawndale Ave., PO Box 6, Skokie, IL 60076 PHONE: 847-676-2910 FAX: 847-676-0365 CHAR-LYNN HYDRAULIC PRODUCTS

LOW SPEED HIGH-TORQUE

autonomy in operations. Additionally, the 80-volt NexSys® iON battery and NexSys®+ Outdoor charger were featured as solutions for electrifying outdoor equipment, reducing emissions, and conserving water, marking a step towards sustainable industrial practices. These innovations reflect EnerSys®'s commitment to addressing customer needs with advanced, efficient power solutions.

Grizzly Industrial Introduces High-Performance

Sanders and Bandsaw

Grizzly Industrial announced two additions to its product line: the G0967 20" Variable-Speed Disc Sander and the G0970 14" Vertical Metal-Cutting Bandsaw. The G0967 sander, ideal for both wood and metal projects, features a large disc, variable speed, and a robust 2 HP motor. The G0970

bandsaw, designed for precision metal cutting, offers a 6" cutting height and features geared for slow-speed operation essential for metalwork. Both tools are designed to enhance workshop efficiency and precision, with the bandsaw priced at $1,695 and the sander at $1,995, providing professional-grade equipment for a wide range of applications.

Kassow Robots Launches KR Pulse Ecosystem for Enhanced Cobot Integration

Kassow Robots introduced the KR Pulse ecosystem, designed to facilitate the integration of cobots with end-of-arm tools and software solutions. Aimed at simplifying cobot deployment, KR Pulse underscores Kassow Robots' commitment to flexible automation. The ecosystem

includes components, application kits, and engineering tools, enabling a plug-and-play functionality for seamless integration. This innovation reflects Kassow Robots' strategy to support end customers and systems integrators in implementing cobot solutions more efficiently, reinforcing the company's position in the automation industry.

KUKA Defines the Future of Supply Chain Solutions at MODEX 2024

At MODEX 2024, KUKA Robotics, alongside Hyperion Automation, demonstrated the capabilities of the KMP 1500P autonomous mobile robots (AMRs) and the KR 210 QUANTEC-2 robot in optimizing supply chain logistics. The KMP 1500P, designed for intricate logistic environments, enhances material transport with its autonomous pathfinding and robust carrying capacity. The KR 210 robot, equipped with advanced safety and operational features like AIRSKIN® and digital motion modes, showcases flexibility in depalletizing and palletizing tasks. These demonstrations highlight KUKA's commitment to advancing industrial automation and material handling efficiency.

KUKA Robotics Elevates Precision in Automated Handling at MODEX 2024

KUKA Robotics showcased its advanced KR 10 R1440-2 CYBERTECH nano robot at MODEX 2024, Atlanta, in collaboration with Mech-Mind. This demonstration spotlighted the robot's bin picking capabilities, enhanced by

34 | IMDQ | Q1 2024

Grizzly Industrial Introduces High-Performance Sanders and Bandsaw

Kassow Robots Launches KR Pulse Ecosystem for Enhanced Cobot Integration

3D vision and AI technologies. With a 10 kg payload and exceptional precision of 0.04 mm repeatability, the KR 10 is designed for handling small, irregularly shaped parts. Its compact, lightweight design and flexible installation options make it ideal for confined workspaces. Featuring IP65 and IP67 ratings for robust protection and the versatile KR C4 smallsize-2 control system, this setup exemplifies KUKA's commitment to optimizing automated materials handling with speed and precision.

Mazak Strengthens Industry 4.0 with Cybersecurity Innovation

Mazak has partnered with the Cybersecurity Manufacturing Innovation Institute (CyManII) to enhance digital connectivity and cybersecurity in manufacturing. As a collaborative partner, Mazak brings its expertise in advanced data protection to the forefront, working alongside top U.S. research institutions and manufacturers. Key to Mazak's cybersecurity measures is its SmartBox technology, which isolates connected machines for secure data collection. This partnership underscores Mazak's leadership in developing secure, innovative technologies for Industry 4.0, promising significant advancements in manufacturing security and digital infrastructure.

Norstat Introduces Durable and Versatile Industrial Connectors

Norstat's extensive range of industrial connectors enhances machinery and automation systems' efficiency and reliability. Offering DIN Valve Connectors, Circular M8, M12, M23, and 7/8" versions, along with Specialty Connectors, Norstat ensures compatibility with various applications. Features include LED status indication, different forms and materials, and protection ratings up to IP67/IP69. Additionally, Norstat's MBX PRO SERIES enclosures and PICO-02 Pressure and Vacuum Sensor showcase robust design for demanding environments, emphasizing the brand's commitment to high-quality, durable automation components.

Lumina: Enhancing Worker Safety with Wearable LED Technology

Norstat presents Lumina, a wearable safety device designed for maximum visibility in low-light conditions. Ideal for first responders and maintenance workers, Lumina's

12 LED lights offer 360° illumination. With user-friendly controls for color change and "Torch mode," Lumina's magnetic attachment ensures easy application on any clothing. Featuring a durable, water-resistant design, and a long-lasting battery, Lumina stands as a reliable solution for ensuring worker safety and visibility in challenging environments.

INDUSTRIA L MACHINERY DIGEST COM IMD | 35

C-FRAME PRESSES HYDRAULIC MACHINES OF IOWA A Division of Betenbender Mfg. Inc Phone: 319.435.2378 | Fax: 319.435.2262 www.betenbender.com • Heavy Gauge Steel Design • Press Bed bolted on, not welded, to prevent distortion. • Large press bed to accommodate a variety of tooling other than just punching. • Pump, motor, valve and reservoir are all easily accessible for maintenance. • Large rectangular tubes used at base of machine to give safe, instant portability. WE CAN BUILD A CUSTOM MACHINE FOR YOU!

OMRON Launches Integrated Autonomous Mobile Robot Solutions

OMRON introduces its new MD-650 and MD-900 autonomous mobile robots (AMRs) with lifter and roller modules from ROEQ. Tailored for efficient material transfer, these AMRs feature advanced safety and reliability, showcasing OMRON's commitment to enhancing automation projects. The lifter module enables precise cargo handling, while the roller module facilitates seamless transfers to conveyor stations, highlighting OMRON's synergy with ROEQ in providing comprehensive, out-ofthe-box automation solutions.

Platinum Tooling Now Offers Rineck Shrink Fit Tooling in the US and Mexico