WE

WE

WE AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS

In additional to air tools, we offer accessories and abrasives for complete process solutions with the know-how to get the job done right.

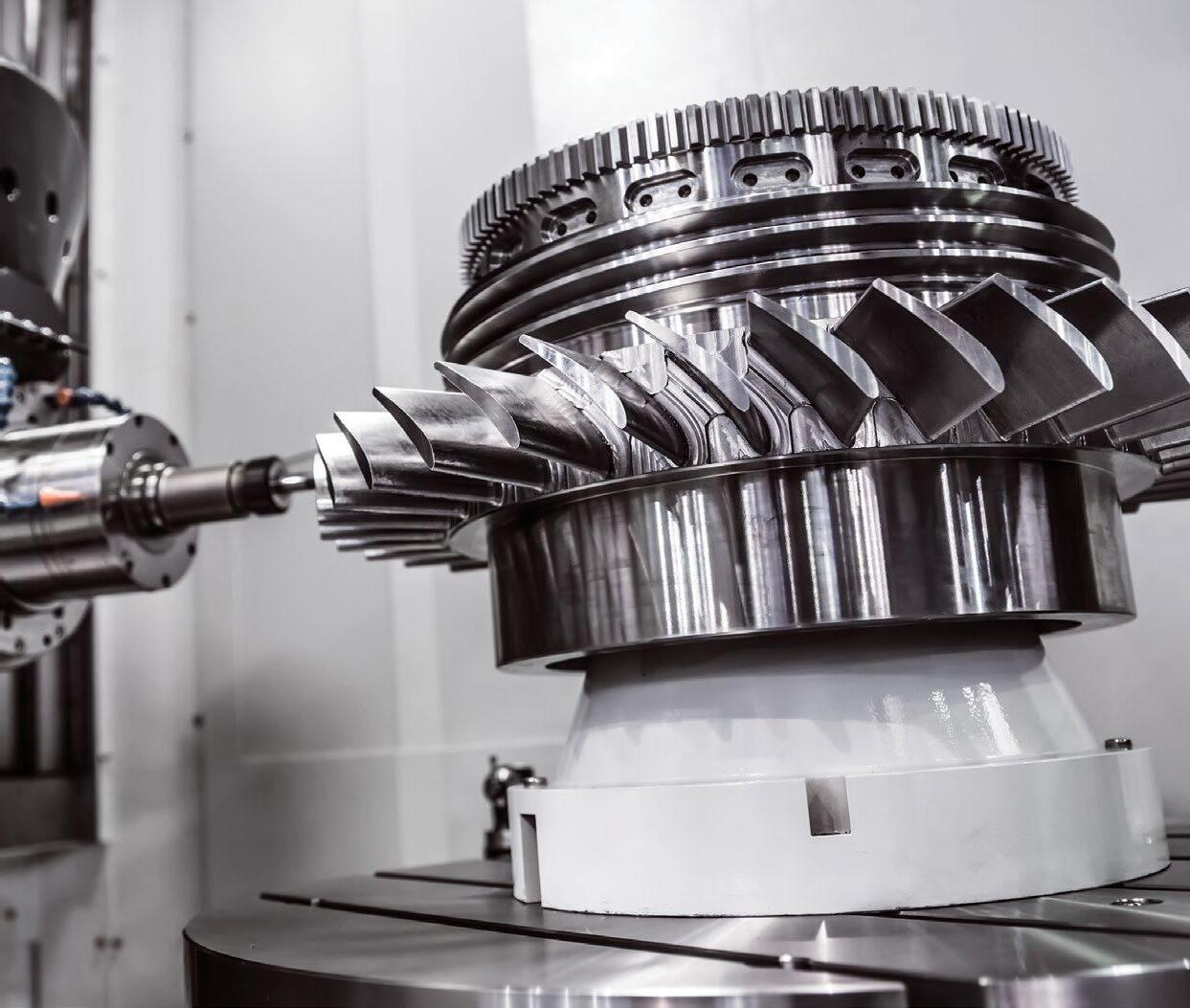

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

William C. Strickland III, Publisher william.strickland@indmacdig.com

800-366-0676 ext. 103 | Fax: 866-826-5918

Trey Bell, Editor-in-Chief trey@indmacdig.com

800-366-0676 ext. 104 | Fax: 866-826-5918

Brian Self, Associate Editor assoc.editor@indmacdig.com

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Adrienne Gallender, Media Adviser agallender@indmacdig.com 888-407-7737

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com source media llc

This digital Quarterly edition has a wide variety of content covering several relevant topics for our readership.

Our Cloudware Software section highlights an article from Network-as-a-Service technology company Lumen. Andy Chabbasol from Lumen shares his thoughts on the Smart Factory connected edge, and Lumen’s offering Secure Access Services Edge, entitled “From the Smart Factory to the Smart Manufacturing Enterprise.” SASE is a new model that blends networking functionality with critical security capabilities.

We further tackle another view of data security in our Integrations section, highlighting Zero Trust Data Security in an article from Nextlabs. We originally discussed zero trust in depth in our March print edition, entitled “Zero Trust in a Big Data World” in which we had some good perspectives from noted cyber security expert and MIT graduate Dr. Daniel Engels. The article in our quarterly edition is a reprint from Nextlabs, who also attended the Siemens Realize LIVE event this quarter, and it provides a hands on perspective of implementing zero trust data security.

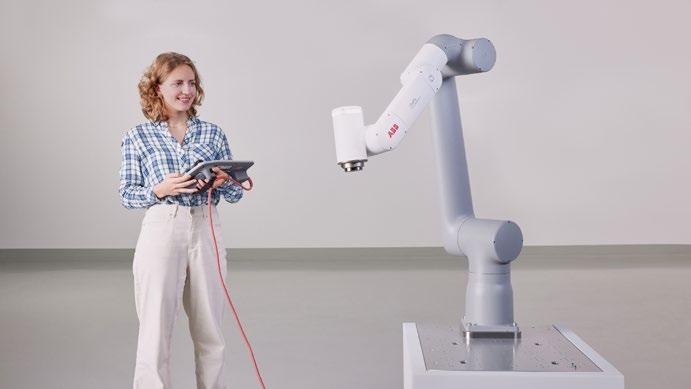

In Machines we profile a new cobot from ABB, which provides a high payload option. Check out the information on the new GoFa Cobots. After that, head over to our Case Study which features coordinate measuring machines from manufacturer LK Metrology. F1 is embracing the machines and the precision engineering benefits. After that, check out our inventory of new products in our Product Showcase section.

Industry news features a story about Cobots and automation in welding that you will find interesting. Specifically, ESAB discusses their Cobot that can enhance welding productivity by 200-400%. You don’t want to miss that read. Over in our Company Profile feature, we profile Tri-Mation and their views on the medical device manufacturing market. It is a complicated space with plenty of traceability requirements that might seem overwhelming, but Tri-Mation provides a path for managing and achieving the requirements.

Something for every angle and for every build out. Second quarter is on the books - look forward to seeing you in August.

Keep building!

With our user-friendly website, users can easily find the type of auction they are looking for, regardless of size or location. The site has the latest technology to make it simple for users to engage with an auction of interest.

Hydraulic Shears: 1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

The future of welding in job shops across the nation has received an innovative boost with the introduction of ESAB's first collaborative robot (cobot) for MIG and pulsed MIG welding applications. The ESAB Cobot, designed to work with steel, stainless steel, and aluminum alloys, stands as a testament to the transformative power of automation and its benefits to the fabrication industry. What sets this cobot apart is not just its capabilities, but its intuitive operation, rapid deployment, and suitability for high-mix, low- to medium-volume applications—all without the need for complex programming.

For fabricators, this technology offers an empowering solution to long-standing industry challenges: improving productivity and addressing worker shortages. However, to fully appreciate the benefits of the ESAB Cobot, one must first grasp the broader context of the problems it solves.

Automation has long been hailed as the future of manufacturing, promising increased efficiency and production rates while reducing costs. However, its adoption in welding, especially in job shops, has been relatively slow. A significant reason for this lag has been the inherent complexities associated with traditional automation systems: high initial costs, a need for specialist programmers, and the lengthy deployment time of robot cells.

The arrival of ESAB's Cobot mitigates these challenges. By leveraging smart technology and intuitive software applications, ESAB empowers operators to teach welding paths using a standard smartphone or tablet and a 'Smart Puck.' This approach simplifies the programming process, making it as easy as creating a song playlist. This simplicity is a radical departure from the intricate programming of other cobots, making the ESAB Cobot a more accessible, user-friendly automation solution. Furthermore, its rapid

deployment time and comparatively low cost also make it an attractive option for small to medium-sized job shops looking to stay competitive.

But, what exactly does this mean for job shops?

First, the cobot presents a unique solution for improving productivity. ESAB's President, Fabrication Technology, Olivier Biebuyck, claims that the cobot can enhance productivity by 200 to 400%. By automating high-mix, low-volume applications, the ESAB Cobot enables job shops to significantly increase the number of parts welded without the need for additional staff. This efficiency translates into higher output and revenue, with the existing workforce freed up to focus on more value-driven tasks.

Moreover, the cobot's ability to improve quality and repeatability addresses another pressing issue in the industry. With the cobot, job shops can maintain a consistent quality of output, a critical factor in client satisfaction and repeat business. It eliminates human error and fatigue, ensuring each weld meets the highest standards, thereby reducing rework and wastage.

In the context of worker shortages, a critical issue facing the welding industry, the cobot also offers a potential solution. It allows businesses to meet increasing production demands without the need to hire additional skilled welders—a notable advantage given the current skills gap in the manufacturing sector.

Furthermore, the ESAB Cobot features a Universal Robots UR10e industrial robot arm and includes ESAB's premiere heavy industrial welding system, the Aristo 500ix pulse power source, providing a reliable and robust solution to job shops. The Siegmund 32- x 48-in. welding table allows the cobot to be moved around the shop with ease, ensuring versatility in its application.

In the era of Industry 4.0, the ESAB Cobot, with its cloud-connected software app, stands out as a smart,

intuitive tool. The app offers real-time support, access to knowledge articles, tutorials, and automated storage of weld sequences. This feature not only streamlines operations but also creates an effective communication channel for resolving issues promptly, thereby minimizing downtime. A basic plan is available for free, but users also have the option to subscribe to a "pro plan," extending chart visibility from seven to 30 days, among other features, enhancing the cobot's usability.

Of course, no solution would be complete without a proven welding platform. The ESAB Cobot has incorporated the tried-and-tested Aristo 500ix power source with a maximum welding output of 500A, and the RobustFeed U82 wire feeder, known for its reliable operation in harsh environments. This robustness, combined with advanced features like stable arc in all transfer modes, reduced spatter with short circuit MIG, and the benefits associated with pulsed MIG, makes the cobot a formidable addition to the welding arsenal of job shops.

The cobot's wire feeder is also unique in its design. With a completely sealed wire feed compartment, it offers unprecedented protection against external contaminants such as grinding dust, preserving wire integrity and further ensuring the quality of welds. Moreover, an internal heater in the wire feed compartment prevents moisture buildup, reducing the risk of defects related to porosity or hydrogen inclusion, and thus minimizing the potential for rework.

The control of these welding functions lies in the hands of the user through the U82 control panel, a core product of ESAB's industrial lineup for nearly two decades. This interface boasts pre-programmed synergic lines, helping fabricators to begin welding faster and reduce change-over time between parts—a critical factor in increasing operational efficiency in high-mix, low-volume environments.

In conclusion, ESAB's introduction of the Cobot into the market marks a significant advancement in welding automation, addressing critical problems in the industry while unlocking new opportunities for job shops nationwide. By simplifying the programming process and making automation more accessible and user-friendly, ESAB has democratized welding automation. The Cobot stands as a symbol of the future of welding, where advanced technology, accessibility, and practicality coalesce into a powerful tool that empowers job shops to operate more efficiently and competitively.

As we move further into the era of Industry 4.0, such advancements are critical for job shops striving to remain competitive in the face of rapidly changing market dynamics. The ESAB Cobot, with its emphasis on simplicity, flexibility, and productivity, represents a substantial step forward, not just for individual job shops, but for the broader welding and fabrication industry as a whole. It offers a clear demonstration of how technology and innovation can effectively address industry challenges, redefine operational norms, and create a brighter future for welding.

Premium features make better parts.

• Closed-loop servo motors for reliable accuracy

• Floating head with Digital Torch Height Control that help make cuts to uneven surfaces like corrugated metal

• Standard breakaway torch holder with collision detection to minimize machine damage if things go wrong

• Minimized run times with fast rapids (1,000 in./min., 400 in./min. cuts) and acceleration (30 in./sec.²)

• Integrated water table mounted on sliding rails, ideal for cutting pipes and larger parts

• The only plasma table built with PathPilot, Tormach’s award-winning CNC controller, and access to PathPilot HUB, Tormach’s browser-based version of PathPilot

Much of subcontractor Driven Engineering's turnover comes from F1, although the cost cap imposed on teams over the past couple of years has reduced it somewhat, leading to a greater focus on aerospace, automotive and general engineering work. Owner Ray Harris has historically machined mainly jigs, fixtures and molds for F1 teams, which were telling him that to break into the supply of parts for race cars, he would have to improve his component inspection procedures and quality reports.

British coordinate measuring machine (CMM) manufacturer LK Metrology was a beneficiary of those conversations, as Mr Harris placed an order for one of the company's AlteraC 10.7.7 CMMs. During its build at the Castle Donington factory, the machine was reduced in height by about 100 mm so that it would fit through

the entrance to Driven Engineering's latest factory unit in Havant and sit comfortably within a new quality room that was being added. As part of the deal, a single licence of PolyWorks Inspector software was supplied, which is swappable between the CMM and an articulated arm bought in 2020 when Mr Harris worked in a previous location in Portsmouth.

He said, "LK seems to be one of the metrology industry's best-kept secrets. I had not come across them before, but our local calibration company and inspection equipment supplier Mech Metrology & Power Tools introduced me. Although LK is a sizeable operation that is celebrating its 60th anniversary this year, with a factory in Derbyshire and a worldwide customer base, it has a smallcompany feel. I got the impression that I would receive good support and back-up, which so far has been the case.

In addition, the CMM is well-built and the software provided is easy to use, including on the portable arm."

The step up to CMM metrology immediately brought in extra F1 work, mainly prismatic machining on three Hermle 5-axis, high-speed machining centres, two of which are fitted with automatic pallet storage and retrieval systems for automated, 24/7 operation. Parts produced are typically for hydraulic manifolds as well as the race car front and rear wings and floor. A lot of titanium is processed, plus stainless steel, aluminium and some engineering plastics. Unlike jigs and fixtures, which have fairly open tolerances, the latest parts have drawing tolerances down to 25 µm true position, which is impossible to check using the portable arm. The CMM on the other hand is able to measure features an order of magnitude smaller, so is easily capable of completing the inspection tasks.

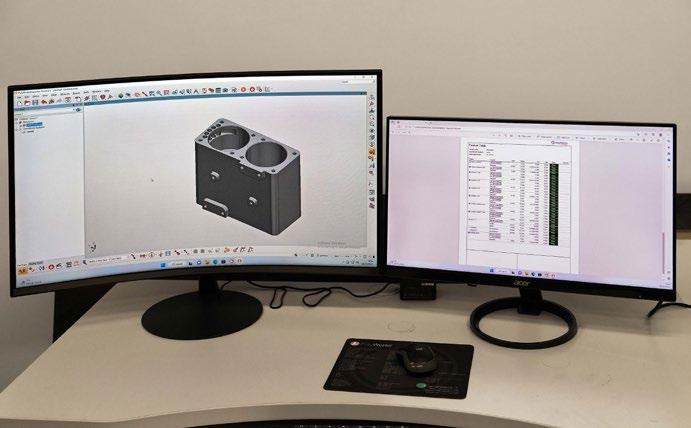

During programming in PolyWorks, Mr Harris simply picks the features and profiles he wants to inspect. The software then automatically sequences the points for the most efficient inspection routine, including all axis movements, head rotations and collision avoidance strategies. He describes the software is particularly easy to use and ideal for someone new to CNC CMM operation. Data is captured both by touch-probing discrete points and tactile scanning using a Renishaw SP25M probe. Vastly more data is generated in a shorter time compared with touch-trigger probing only, enabling faster inspection and hence improved quality control. It also allows more comprehensive reports to be populated with richer information on the accuracy of freeform areas on components as well as dimensions. The PolyWorks software is able to present this data flexibly in a form that the customer prefers and is able to understand easily.

The pre-existing arm was supplied with a touch probe and a laser scanner, but now is used exclusively with the latter sensor for speed

of operation when inspecting, for example, one in five of a batch of 920 aluminium mold tool halves having a complex profile, machined for the aerospace industry. The CMM, on the other hand, was supplied with tactile probing capability only, although it was prepared for laser scanning with a view to adding that capability in the future. Before he invested in the machine, Mr Harris was invited to visit the Castle Donington factory to see a demonstration of an Altera 10.7.7 inspecting one of his components. It was fortuitous, as he was due to race at the Donington Park motorsport circuit nearby, having recently re-entered the sport by driving a GT car in the British Endurance Championship in early 2022. Unfortunately the Donington fixture was cancelled, so to save him the 350 mile round trip, he sent a water system for an F1 car together with the CAD model to the factory by courier and opted to view the demonstration online. LK showed two ways of inspecting the component, first by touch-probing to orientate it on the granite and then laser scanning, and

secondly using an SP25M to probe and touch-scan the part.

Suitably impressed with the latter metrology process, he decided to make the investment in the CMM and PolyWorks, whose ease-of-use is greatly helping his inspection productivity. Programming, due to the level of automation provided by the software, can be carried out in as little as 10 minutes, depending on component complexity and, unlike when using an arm, can be done in advance from the CAD model.

Installation of the CMM has opened up a number of different avenues, as availability of advanced metrology makes new business is easier to win, especially tight-tolerance work. Additionally, Mr Harris has now bought a Ginetta GT race car to hire out for events and intends to start manufacturing a proprietary range of parts for it, such as uprights, bearing supports, axle extensions and drive shafts. The ability to control their quality on the LK CMM to a higher level than would previously have been possible will also enhance this new enterprise.

LK Metrology is renowned for innovative metrology solutions and services. The company’s products, including coordinate measuring machines (CMM), portable measuring arms and metrology software, are used worldwide to control and improve the quality of manufactured components. Its precision technology underpins the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

Established in England in 1963, LK Metrology has an impressive heritage in metrology dating back to the birth of CMM technology. Founded by CMM pioneer Norman Key and his father-in-law Jim Lowther, LK Metrology is credited with many of the CMM industry’s firsts including the first bridge-type design, first OEM to integrate computers, first to use a touch trigger probe, first to develop inspection software, first to use all air bearings and granite guideways, first to use carbon fibre composite spindles, first to use microprocessor-controlled drive systems, first to produce a truly thermally stable CMM and first to produce a high-accuracy horizontal-spindle CMM.

In 2018, LK Metrology was relaunched as an independent CMM manufacturer after several years as a division of Nikon Metrology. Headquartered in the UK, LK's CMM development and production are at the company’s facility in Castle Donington. Sales and support offices are located in the UK, North America, Belgium, France, Germany, Italy and China, supplemented by a worldwide distributor network.

Medical device manufacturers face a clear imperative to automate, yet they also have many unique requirements that can make choosing an automation partner challenging. Manual processes are increasingly difficult to justify in the face of growing demands for manufacturing traceability and the accompanying explosion in the amount of data, among other considerations. Even so, choosing a partner to help in the successful automation of manufacturing processes must be done carefully. Producers need a partner who can help accomplish their revenue objectives while making safe and effective products that comply with all the relevant safety standards.

This article examines some of the special needs of medical device manufacturers and reviews Tri-Mation Industries qualifications to meet those needs.

The increasing focus by health care agencies on early diagnosis and treatment are leading to a rising number of diagnostic, testing, and surgical procedures. In addition, personalized medicine continues to grow, further increasing the need for testing and corresponding medical devices.

Some automation vendors prefer jobs that allow them to concentrate on high volume without regard to flexibility. While Tri-Mation understands the need to ramp up a production process and the benefits that come from the economies of scale, they also have the skill to design systems that can be easily reconfigured. Such flexibility enables a manufacturer to run different medical devices through the same production system, thereby vastly improving the ROI and quickening the pace of benefits from the automation.

The Food and Drug Administration has stringent

requirements for tracing medical devices back to their origin. Data required may include a lot number, production date, sterilization date and certificate number, among other pieces of information. All of this data must be generated and managed, including the labeling of the medical devices as part of the manufacturing process.

Tri-Mation Industries, located in southwest Michigan, has the expertise and experience to meet these requirements.

Medical devices are usually part of life-and-death situations, so there is no tolerance for malfunction or inaccuracy. Especially high-standards for cleanliness are also a standard part of the manufacturing landscape for medical devices, even for something as simple as a tongue depressor.

Founded in 1995, Tri-Mation Industries understands these requirements and knows how to implement systems to comply with these standards. Part of that picture can involve controlling or eliminating direct employee contact with the products being produced.

The suitability for use of a medical device can be affected by numerous factors. And environmental events can

influence how long a manufactured device sustains its fitness for use.

Some of those factors include:

» Storage Conditions - Visible light, air pressure, air-born contamination, humidity, ambient radiation and temperature can all impact the shelf life of a medical device.

» Components - Certain components, such as batteries, may have expiration dates.

» Manufacturing Method - Processes used during manufacturing may affect the storage life of the device.

» Intended Use - The intended use of some medical devices may justify the use of materials that degrade over time.

This is not an exhaustive list, yet it begins to convey the complexity of the automation challenges that must be addressed.

Tri-Mation designs automated assembly systems that integrate handling systems, calibrate components, and improve medical device production capabilities. The advantages to such automated systems include improving both quality and throughput. Working with Tri-Mation Industries enables medical device manufacturers to increase productivity and enhance accuracy and consistency.

Although the complete manufacturing of a product that no human hands need to touch remains an unattained goal at the time of this writing, some production processes can indeed be completely automated. And as technology improves, it is clear that lights-out manufacturing will become a reality in the not-too-distant future. Medical device makers must keep pace with that technology or face the certainty of being left behind.

Tri-Mation Industries was founded in 1995. With over twenty five years of experience, Tri-Mation has deep experience taking on the complex challenge of automating medical device manufacturing processes and possesses a depth of engineering and technological expertise to continue to innovate and improve as technology advances. Their automation systems can produce a wide range of safe and effective products within the strict requirements and regulations of the medical industry. Medical device assembly automation can be integrated as standalone work cells or fully automated assembly lines.

If you are considering automating a medical device production process, reach out to a Tri-Mation sales engineer to share your requirements and start the discussion.

Originally Posted by Nextlabs: view article here, Nextlabs has also created integrations with Siemens© Teamcenter® We covered a bit of this topic in our Talking Shop section from March Edition, “Zero Trust in a Big Data World” in which we discussed with Dr. Daniel Engels the concept of a Zero Trust security strategy: view article here. Nextlabs provides implementation details for their offering.

Organizations adopt Zero Trust security models because traditional security models that rely on a perimeter-based approach are no longer sufficient to protect against the increasing sophistication and frequency of cyber attacks. Zero Trust is designed to address the limitations of traditional security models by assuming that all access attempts are potentially malicious, even if they are from within the organization’s network. The following are the key drivers for organizations adopting Zero Trust:

» Protect against data breaches: Data breaches can have significant financial and reputational consequences for organizations. Zero Trust helps to reduce the risk of data breaches by limiting access to sensitive data and continuously monitoring all access attempts for signs of suspicious activity.

» Secure access: The COVID-19 pandemic has accelerated the adoption of remote work, which has increased the attack surface for organizations. Zero Trust helps to secure remote access by ensuring that all devices and users are verified and authenticated before being granted access to data or other resources.

» Compliance: Many industries are subject to strict regulatory compliance requirements, such as HIPAA, PCI DSS, and GDPR. Zero Trust can help organizations to meet these compliance requirements by ensuring that only authorized users have access to sensitive data.

» Prevention of lateral movement: Once a cyber attacker gains access to a secure network, system, or application, they can move laterally within that resource to find valuable data. Zero Trust can help prevent lateral movement by segmenting a network, system, application, or database into smaller, isolated zones and limiting access to only authorized users and devices.

» Evolving threat landscape: Cyber threats are constantly evolving, and traditional security models may not be able to keep up with the latest threats. Zero Trust is designed to be adaptive and able to evolve with the changing threat landscape, ensuring that organizations are better protected against the latest threats.

By adopting Zero Trust, organizations can better protect their systems, data, and resources from cyber threats. Zero Trust helps organizations to reduce their attack surface,

minimize the impact of a breach, and improve their overall security posture by continuously verifying the identity of users and devices and evaluating the risk profile of access requests.

» Whitepaper: Implementing a Zero Trust Architecture: NIST National Cybersecurity Center of Excellence

» Whitepaper: NextLabs and the Zero Trust Architecture

» Video: The Intersection of ZTA and Data-Centric Security

» Video: What is Zero Trust Data Protection?

» Blog: What is Zero Trust Data Protection?

» Blog: What is Zero Trust Architecture (ZTA)?

» Blog: Zero Trust and Authorization

Zero Trust principles are a set of security concepts that aim to protect an organization’s systems, data, and resources by assuming that all access attempts are potentially malicious, even if they are from within a secure network, resource, or application. The following are the key principles of Zero Trust:

» Continuous monitoring: All access attempts must be continuously monitored for signs of suspicious behavior, and appropriate action must be taken in response to any suspicious activity.

» Contextual awareness: Security policies and access controls must be based on contextual awareness, such as the user’s role, device location, and sensitivity of the data being accessed.

By following these principles, organizations can better protect their systems, data, and resources from cyber threats. Zero Trust principles help organizations to reduce their attack surface, minimize the impact of a breach, and improve their overall security posture by continuously verifying the identity of users and devices and evaluating the risk profile of access requests.

Data-centric security principles are a set of principles that are focused on protecting an organization’s sensitive data at the data level, as opposed to simply relying on traditional perimeter-based security measures. These principles aim to ensure that the organization’s sensitive data is secured at all times, regardless of its location or how it is being accessed. The following are some of the key principles of data-centric security:

» Data Classification: All data must be classified according

» Never trust, always verify: All users, devices, and applications must be verified and authenticated before being granted access to any resources.

» Least privilege access: Access should be granted on a need-to-know basis, and users should only be granted the minimum level of access required to perform their job functions.

» Assume breach: Assume that an attacker has already compromised a secure resource and act accordingly to limit the attacker’s access and ability to move laterally within the network, system, application, or database.

» Micro-segmentation: Segment resources into small, isolated zones to limit the spread of a breach and prevent attackers from moving laterally.

to its sensitivity, and access must be granted on a need-to-know basis.

» Persistent Data Encryption: Sensitive data must be encrypted both in transit and at rest to protect it from unauthorized access.

» Data Obfuscation: Sensitive data must be masked or redacted, or replaced with a token, which can be used for certain processes without exposing the underlying data to unauthorized access.

» Data Segregation: Data should be segmented as fine-grained as possible, so that access to data can be limited to the minimum necessary for each access request.

» Data Authorization and Entitlement: User entitlements to data must be granted on a need-to-know basis and only after the identity of the user and device has been verified and the risk profile of the access request has been evaluated.

» Data Loss Prevention (DLP): Measures must be taken to prevent data loss, such as preventing unauthorized copying, printing, or emailing of sensitive data.

Data-centric security principles help organizations to better protect their sensitive data by focusing on securing the data itself, rather than just the perimeter around it. By following these principles, organizations can reduce their attack surface, minimize the impact of a breach, and improve their overall security posture by continuously verifying the identity of users and devices and evaluating the risk profile of access requests.

Zero Trust and Data Centric security can be complementary approaches to security. Zero Trust can help to limit access to sensitive data, while Data Centric security can help to

protect the data itself. By combining the two approaches, organizations can create a comprehensive security strategy that provides both network-level and data-level protection, helping to improve their overall security posture. A Zero Trust Data Security approach allows organizations to do the following.

» Implement Least Privileged Access and Need-to-Know by defining and enforcing security policies that provide fine-grained data access and authorizations to allow users to view and user all of the data they should be able to access and nothing more.

» Segregate Data for export and regulatory compliance by virtually segmenting shared resources.

» Secure Collaboration with Persistent Data Protection that stays with the data and protects it at rest in databases, in use within applications, and on the move when it is shared.

» Unify Access Control with Attribute-Based Access Control (ABAC), eliminating the need for large numbers of groups or roles and replacing then with a small number of policies where user, data, and environmental attributes are evaluated dynamically at the time of the access request.

» Externalize Access Management and Eliminate Security Silos so that security policies are enforced consistently across the entire organization.

With Zero Trust Data Security, organizations can better protect their sensitive data from cyber threats and ensure that access remains in compliance with security policies. The combination of Zero Trust and Data-Centric Security principles help organizations to reduce their attack surface, minimize the impact of a breach, and improve their overall security posture by continuously verifying the identity of users and devices and evaluating the risk profile of access requests.

The following are some of the common business applications of Zero Trust Data Security.

» Modernization – With Zero Trust Data Security enterprises can keep data secure during system modernization projects by providing centralized authorization for legacy and new applications.

» Segregation of Duties (SoD) and Compliance – Global enterprises often have many different and overlapping regulations that they need to comply with. Zero Trust Data Security allows organizations to enforce segregation of duties to ensure no violations of applicable regulations, including GDPR, SOX, ITAR, FDA, etc while automating controls and the audit process.

» ERP Consolidation – Enterprises are driven to consolidate multiple existing ERP instances into a single global instance for all of the efficiencies this brings. Zero Trust Data Security allows organizations to protect critical data while consolidating those existing ERPs into a single global instance.

» M&A, JVs, Divestitures – Enterprises in the process of mergers, acquisitions, divestitures or joint ventures can keep sensitive data safe while integrating new businesses or splitting off businesses from parent companies. This allows them to comply with M&A, JV, or divestiture agreements while having quicker implementation and lowering the security risk by segregating and partitioning data on existing systems.

» Cybersecurity – Cybersecurity threats are always evolving and organizations must continually adapt their defenses to counter the latest threats. Zero Trust Data Security allows enterprises to reduce cybersecurity risks and implement the best practices as defined in the NIST Cybersecurity Framework. This helps facilitate data and system consolidation and migration to the cloud.

» Trade Secret Protection – There are high costs to enterprises when data breaches result in unauthorized access to trade secrets. Zero Trust Data Security makes sure only the right people have access to the right data and reduces the threat of unauthorized disclosure due to insider or outsider threats.

» Automation – Enterprises can have more consistent enforcement of segregation of duties and internal control policies while cutting implementation and maintenance costs by automating business processes and internal controls.

NextLabs’ Zero Trust Data Centric Security solutions implement Zero Trust and Data Centric security principles using dynamic authorization and Attribute-Based Access Control (ABAC), allowing organizations to determine the level of access to be granted based on attributes such as user identity, device type, location, and time of day. This provides organizations with a flexible and granular way of protecting and controlling access to sensitive data.

NextLabs’ solutions are designed to work seamlessly with existing security infrastructure and are compatible with a wide range of platforms and applications, including cloud-based services and legacy systems. This allows organizations to easily integrate NextLabs’ solutions into their existing security infrastructure and take advantage of Zero Trust principles without having to replace their existing systems.

Zero Trust Data Security Principles are incorporated into all NextLabs product lines, including:

» CloudAz, a unified policy platform that centralizes administration and utilizes the “never trust, always verify” principle, ensuring data is protected at any access point.

» Data Access Enforcer (DAE) helps enterprises protect data access from anywhere, by securing access and protecting critical data stored in databases and data lakes.

» SkyDRM ensures persistent protection of critical files and documents to protect data on the move and at rest.

» Entitlement Management / Externalized Authorization Management which can be used to secure applications, enforce data security controls, and simplify role management.

For more information on NextLabs and Zero Trust, see their Technology page on Zero Trust Architecture (ZTA)

» New GoFa™ variants offer higher payloads, best-in-class reach, and market-leading repeatability

» Cat 3/PLd safety certified for close collaboration with human workers

» Lower barriers to entry even further for first-time users, SMEs and educators with easy programming and rapid deployment

ABB has launched two new variants of its GoFaTM collaborative robot. The GoFa 10 and GoFa 12 open new possibilities for companies to leverage cobot automation for enhanced efficiency. Handling payloads of up to 10 and 12 kilograms with market-leading repeatability, the cobots accomplish an expanded range of tasks in close collaboration with factory workers, addressing skills and labor shortages while improving safety and productivity. Offering straightforward programming and rapid integration into production environments, the new variants lower barriers to entry for first-time users, educators and SMEs.

“Since our YuMi cobot hit the market in 2015, we have built up an unparalleled cobot portfolio meeting growing demand for safe and easy-to-use automation solutions to plug gaps in skilled labor,” said Marc Segura President, ABB Robotics. “Addressing the need for collaborative robots with higher payloads and longer reach, our GoFa 10 and 12 cobots extend the benefits of automation to new industrial applications, even for first time users.”

In addition to their enhanced payloads, the GoFa 10 and GoFa 12 cobots offer class-beating tool center point (TCP) speeds of up to two meters per second with 0.02-millimeter repeatability – a two-fold improvement over comparable solutions. IP67-certified against moisture and dust ingress,

they extend the benefits of fast and accurate collaborative robotics to new industrial applications, automating demanding tasks such as machine tending, welding, parts handling, polishing, and assembly. The GoFa 10’s 1.62-meter reach – 14 percent more than others in its class and enough to cover US pallets – makes it ideal for palletizing applications.

The GoFa 10 and GoFa 12 cobots are straightforward to program, deploy, and use, lowering barriers to automation

for first-time users and SMEs. Set-up is made easy with lead-through programming and ABB’s Wizard easy programming software, allowing even non-specialists to quickly automate their applications by manipulating simple graphical command blocks rather than writing complex programming code.

Pre-installed on the cobots’ ABB’s FlexPendant robot controller, the ABB SafeMove robot safety monitoring app’s cutting-edge safety features, including safe speed limits, standstill monitoring, and orientation supervision, enable close collaboration between robots and factory workers without requiring bulky protective barriers or fencing.

The GoFa 10 and GoFa 12 cobots are powered by ABB’s OmniCoreTM controller. The combination of OmniCore’s class-leading motion control provided by ABB’s TrueMove and QuickMove motion control technologies and GoFa’s intelligent torque and position sensors ensures the smooth movements needed for high precision surface finishing, fastening, assembly, and testing tasks. Energy saving features including power re-generation and brake energy recovery reduce power requirements by up to 20 percent, enhancing sustainability.

Responding to the growing diversification of automation applications, ABB recently launched its ABB Robotics Ecosystem program. Bringing together third-party accessories such as grippers, cameras, and customized software that are compatible with the ABB portfolio, including the new GoFa cobots, the program lets users easily leverage innovation from across the fast-growing ABB Robotics ecosystem.

The GoFa 12 cobot made its tradeshow debut at ABB’s stand at Automatica 2023 (Hall B5, booth 319, June 27th30th) as part of two demonstrations showcasing its use in high precision machine tending and ultra-lean palletizing applications. ABB partner Schunk was also at the show with a GoFa 12 cobot to demonstrate its range of grippers and tools for a polishing application (Hall A5, booth 502).

For more information about GoFa, visit www.abb.com/robotics

ABOUT ABB

ABB (ABBN: SIX Swiss Ex) ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – become more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

https://blog.lumen.com/from-the-smart-factory-to-the-smart-manufacturing-enterprise/

By Andy ChabbasolWhat is a smart factory? The manufacturing industry has been asking that question for several years and largely settled on an answer, and it goes something like this:

A smart factory uses advanced technology, such as the Internet of Things (IoT, sometimes called the Industrial IoT or IIoT), to optimize production processes within a single manufacturing facility. Advanced technology is deployed to gain data about, and increase control of, manufacturing operations to enhance productivity. Vibration or thermal sensors in the equipment? Check. Measurable reductions in unscheduled downtime? Check.

Many consider the smart factory project done once the IoT devices are installed and are producing data and measuring productivity improvements. There is nothing wrong with that answer, and this is the type of smart factory approach that many manufacturers implement today. I also talk with some firms that operate on the old

“if it ain’t broke, don’t fix it” maxim. These companies will acknowledge the potential advantages of how technology enables the smart factory, but they are focused on other issues they think are more strategic in nature, such as supply chain management.

They are just components of the same journey that will eventually be taken. That journey that takes the manufacturer from the smart factory to the smart manufacturing enterprise.

The smart factory approach solves specific challenges in operating the factory: for example, monitoring machine health. These point solutions generally stop at the factory’s doors. In contrast, the smart manufacturing enterprise connects the advanced technologies used in the production process (smart factory) to other parts of the business, such as supply chain management and product development. For

the smart manufacturing enterprise, advanced technologies are building blocks of a larger strategy that weaves together operating technology (OT) with information technology (IT). Rather than viewing the factory as a unique island of operations, manufacturers can see it as part of a larger digital infrastructure.

Let’s look at an example, one that is becoming more common in an age of hybrid workforces: remote access to data. Plant managers and technicians need access to their plant’s operating data, but they may be at home, in a satellite office, in an airport or walking down the street. The data is incredibly valuable to the manufacturer, but also to bad actors looking to steal the data itself or find an avenue to penetrate the enterprise at large. Access to this data must be secured.

Manufacturers often use multiple layers of security to protect their data and their OT systems, which may not have been designed for today’s modern networking and security standards. Within the factory, data is often replicated from OT systems to IT systems as means to lower any potential surface areas of attack.

Secure Access Services Edge (SASE) is a set of integrated technologies that provides a framework for securing remote data access. SASE builds profiles for users, devices and access channels to properly authenticate both the user, the particular data that the user is permitted or restricted to use, and the security of the connection being used. For example, SASE could protect against data breaches that often occur over public Wi-Fi connections, most notably at airports.

SASE can also be configured for devices (such as certain IoT devices) that need access to data from other remote devices. SASE helps isolate components of your network to contain worst-case security scenarios. Those IoT devices expand the attack footprint for attackers and have to be secured. The IoT is already pushing a lot of computing out to the edge. You can secure the smart factory at the edge as well.

The scenarios where IoT is a building block of a smart manufacturing enterprise are limited only by imagination. With the right connections, IoT can help manage the supply chain through inventory tracking, warehouse integration and other automated functions. Some factories have even built digital twins of the factory for long-range management and planning. Digital twins require large amounts of compute and storage capability, but they can’t exist in a vacuum. They need the data coming off the machines to be accurate models of the enterprise’s needs. Likewise, sustainability reporting is an increasingly onerous compliance requirement. Once again, IoT can produce the data, but it needs to be integrated with other systems to process and present it properly.

The smart manufacturing enterprise involves the integration of various systems and technologies, such as IIoT, advanced analytics, and flexible manufacturing

systems, to optimize the entire manufacturing value chain. Smart manufacturing allows for real-time decision-making and optimization throughout the entire manufacturing process, leading to increased efficiency, productivity, and agility.

How integrated is your factory? Let’s map your journey to the smart manufacturing enterprise today.

Lumen is a multinational technology company that empowers organizations to unlock the full potential of their data, quickly adopt game-changing technologies that will revolutionize their business operations, and seamlessly deliver digital innovations that redefine our everyday lives. Opportunities like this need an advanced application delivery architecture—designed specifically to handle the complex, data-intensive workloads of next-gen technology and businesses.

We integrate network assets, cloud connectivity, security solutions and voice and collaboration tools into one platform that enables businesses to leverage their data and adopt next-generation technologies.

Lumen brings together the talent, experience, infrastructure and capabilities of leading technology companies to address the dynamic data needs of next-generation applications.

For more information visit: www.lumen.com

Event offers the latest in abrasive processes, material finishing and robotics, an optional tour of 3M innovation centers, and keynote by 3M chief science advocate and corporate scientist Jayshree Seth

Companies seeking automated material removal and finishing solutions can learn about the latest tools, best practices and proven success stories at the A3 Robotic Grinding & Finishing Conference in Minneapolis, Minnesota, July 25-26. Organized by the Association for Advancing Automation (A3) and presented by 3M, this showcase and conference offers educational sessions and a tabletop expo hall with the latest tools and equipment from companies such as 3M, ATI, FANUC, Fer Robotics, Schunk, PushCorp, Suhner and Universal Robots. Registration is open at https://www.automate.org/events/robotic-grinding-andfinishing-conference

“The automation of grinding and finishing tasks continues to grow in popularity as companies struggle to find and retain skilled employees to do the work,” said Jeff Burnstein, president of A3. “Once they decide to automate, companies discover how increasingly easy and cost-effective these solutions can be to deploy.”

During this two-day event, attendees will get a comprehensive look at the factors, technologies and processes that yield success across all these tasks, with real-world implementation stories showcased in both the conference sessions and the expo hall.

“The technology’s all there, and at an event like this, it really helps system integrators or end-user customers get up to speed faster,” said Carl Doeksen, Global Robotics & Automation Director, Abrasive Systems Division, 3M. “Here,

you can get specific grinding, polishing, sanding, deburring application information, and connect the dots with the right partners.”

The conference opens with a keynote by 3M’s chief science advocate and corporate scientist Jayshree Seth, “The State of Science and the Need for STEM Advocacy,” followed by two days of sessions, including:

» I Wish It Was That Simple –Robotic Grinding, G.A. "Fritz" Carlson III, Acme Manufacturing

» There Is No Silver Bullet: Multiple Tools May Be Needed for One Application, Matthew Dockstader, ATI Industrial Automation

» Optimizing ROI for Robotic Abrasive Processing, Tyler Naatz, 3M

» Keys to Automating Material Removal with a Robot in 2023 and Beyond, Max Falcone, PushCorp, Inc.

» Successful Automation Strategies: Fast, Wide-Scale Implementation for Small or Global Organizations, Jerry Perez, FANUC America Corporation

» How Can Data Improve Manufacturing Processes Such as Surface Finishing? Michael Muldoon, AV&R

» Optimizing Automated Material Removal - Safe, Effective, Repeatable, Henry Kistenmacher, SCHUNK Intec Inc.

» Benefits of Using Torque-Controlled Robots for Grinding, Ran Xu, Flexiv Robotics Inc.

» Physics-Informed Artificial Intelligence for Finishing in High-Mix Manufacturing, Ariyan Kabir, GrayMatter Robotics Inc.

» Using Cobot Programming to Simplify Automated Material Removal, Charles Gales, Weldon Solutions

» Developing Leading Robotic Technology for Manufacturing and Customer-Facing Abrasive Solutions, John Schmidt, 3M

» Abrasive Identification Using Elastomeric Sensing and AI, Kimo Johnson, GelSight, Inc

Why

» “All the industry-leading ecosystem partners—system integrators, robot OEMs, end effector companies — talk about this emerging application: robotic abrasive processing,” Doeksen said. “We’ve done a lot of research, and it isn’t if, but when, it’s going to be a mainstream application like welding or painting or assembly or dispensing.”

Optional tour of 3M’s robot labs provides expert interactions, more networking opportunities.

Attendees can also see real-world projects in action and pose their own questions to experts during an optional tour of two of 3M’s leading innovation centers in St. Paul: the Innovation Center and CAM Center Robot Lab. The 3M tour is limited to the first 120 registrants due to capacity constraints. Buses will be provided.

Registration open for conference and optional 3M tours; visitor and sponsorship spots still available

Show registration is open at https://www.automate. org/events/robotic-grinding-and-finishing-conference. Tabletops booths and sponsorships are still available and can be reserved by contacting Jim Hamilton at jhamilton@automate.org.

A3 hosts a number of industry-leading events, including the Robotic Grinding and Finishing Conference (July 25-26, 2023, Minneapolis, Minnesota); Autonomous Mobile Robots and Logistics 2023 (October 4-5, 2023, Memphis, Tennessee); the International Robot Safety Conference 2023 (October 9-11, Pittsburgh, Pennsylvania); AI & Smart Automation Conference 2023 (October 10-11, 2023, Pittsburgh, Pennsylvania); A3 Business Forum (January 15-17, 2024, Orlando, Florida), and Automate (May 6-9, 2024, Chicago).

Robots at Robotics Summit and Expo 2023

Epson to Offer Live Product Demos of T3-B and T6-B

SCARA Robots for Manufacturing Industries

Epson Robots, the #1 SCARA robot manufacturer in the world, will participate in Robotics Summit and Expo in booth #232. The show is a multifaceted educational forum and expo dedicated to addressing the issues involved with the design, development, manufacture, and delivery of commercial robotics and intelligent systems products and services.

Epson will offer attendees the opportunity to see live demos of its latest automation solutions offering users ease of use, reliability, performance, and overall value. Epson’s live booth demos will include:

T-B Series All-in-One SCARA Robots – The innovative T-B Series All-in-One SCARA robots offer fast, easy and cost-efficient integration, in a space-saving design, and installation in minutes – unlike complex linear-slide systems. With a built-in controller with power for end-of-arm tooling, standard 110 V or 220 V power and no battery required for the encoder, the T-B Series allows for quick

development and simplified maintenance. Offering value without compromise, the T-B Series includes the same intuitive software, powerful features and reliability found in Epson’s high-end robots while helping to keep the total cost of ownership low. The T3-B and T6-B will be shown with Epson’s Vision Guide to demonstrate inspection together with a pick-and-place application.

Advanced Robotic Programming Software – Easy to learn, Epson RC+® Industrial Automation Development Software features a comprehensive suite of advanced tools, such as Vision Guidance, Force Guidance, Conveyor Tracking, Parts Feeding, and more. Additionally, an overview of the popular option LabVIEW will be provided.

Robotics Summit and Expo exhibit will take place on May 10 from 10 a.m. to 5 p.m. EDT and May 11 from 10 a.m. to 3 p.m. EDT. In Boston Convention and Exhibition Centerin Boston, Massachusetts. Epson booth #232

Epson is dedicated to helping both new and experienced automation professionals succeed by providing essential information and education and by delivering the latest robot technologies and innovations to meet their factory automation needs.

For more information, visit www.epsonrobots.com

For more information on the T-B Series SCARA robots, please visit http://epson.com/space-saving-all-in-oneseries-industrial-robots

For more information on Vision Guidance, please https:// epson.com/For-Work/Robots/Integrated-Options/ Epson-Vision-Guide

For more information on RC+ industrial automation software, please visit https://epson.com/robots-industrialautomation-development-software

Cobot offers intuitive operation, fast deployment, suitability for high-mix and low- to mediumvolume applications and the confidence of an ESAB welding system and a Universal Robots arm.

The ESAB Cobot for MIG and pulsed MIG welding enables intuitive operation so that fabricators of all sizes have the freedom to automate high-mix, low-volume applications and improve productivity with their existing workforce.

ESAB has introduced its first cobot, or collaborative robot, for MIG and pulsed MIG welding applications on steel, stainless steel and aluminum alloys. Unlike the complex programming pendants of other cobots, the ESAB Cobot enables operators to teach welding paths using a software app that runs on a standard smart phone or tablet (Apple iOS or Android) and a “Smart Puck” to hand-guide the torch and record its position with the push of a button. Creating a weld sequence is as simple as creating a song playlist. The ESAB Cobot costs a fraction of a pre-engineered robot cell, does not require a programmer and deploys in a matter of hours.

“The ESAB Cobot gives small- and medium-sized fabricators the freedom to automate high-mix, low-volume

says Olivier Biebuyck, President, Fabrication Technology, ESAB Corporation. “With its intuitive operation, we have revolutionized automated welding while addressing the industry’s foremost issues: improving productivity and finding more workers. Using an ESAB Cobot, fabricators can weld more parts without adding staff, improve quality and free their skilled welders to concentrate on other value-driven tasks.”

The ESAB Cobot features a Universal Robots UR10e industrial robot arm. UR is the automation industry’s leading provider of cobots and has an installed base of more than 50,000 cobots. Welding components include ESAB’s

pulse power source, the RobustFeed U82 wire feeder, an air- or water-cooled torch and accessories.

A Siegmund 32- x 48-in. welding table organizes components and enables moving the cobot around a shop. The entire package ships on a pallet typically within two to three weeks of ordering from a distributor. Set up takes a few hours following step-by-step instructions accessed with a QR code. If a user has the skills to set-up an industrial MIG system, they have the skills start automated welding with the ESAB Cobot.

“The ESAB Cobot is a game-changer because it enables fabricators to enjoy the benefits of automation without any of the historical complexity or costs associated with automation, including competitive cobots,” says Dan Colvin, Vice President of Sales – Automated Systems, ESAB. “The ESAB Cobot deploys rapidly to address immediate needs, such as bidding on new projects, reducing delivery time to existing customers and improving repeatability.”

The cloud-connected ESAB software app offers free and fast in-app support from a team of experts that responds to inquiries in two-minutes or less, as well as access to knowledge articles and extensive list of tutorials. The app automatically stores weld sequences, enabling them to be recalled even if they are deleted from a device. Users can add charts to track production data and consumables use, as well as share part programs between cobots.

The software app’s basic plan is free. A “pro plan” extends chart visibility from seven to 30 days and enables users to export chart data. It also enables additional features, such as requiring a password login and attaching photos and files to a part (such as photos showing part location on the table or a PDF of welding procedures).

The ESAB Aristo 500ix power source has a maximum welding output of 500A and offers premium MIG and pulsed MIG welding performance and proven reliability in harsh environments. It features stable arc in all transfer modes, including reduced spatter with short circuit MIG, as well as all the benefits associated with pulsed MIG (little to no spatter, reduced heat input to prevent burn through and preserve mechanical properties, all-position welding, and using the next size larger wire diameter).

The RobustFeed wire feeder has a completely sealed wire feed compartment to protect the internal components and the wire against grinding dust, something no other feeder can claim. To further ensure wire integrity, a heater inside the wire feed compartment prevents moisture and reduces the risk of defects related to porosity or hydrogen inclusion, helping to avoid potential rework.

Users control welding functions with the U82 control panel, a core product of ESAB’s industrial line up for nearly two decades. The U82 offers pre-programmed synergic lines, which enable fabricators to begin welding faster and reduce change-over time between parts.

Flexiv has partnered with renowned Michigan-based system integrator Cardinal to unlock adaptive automation opportunities for Midwestern customers.

Flexiv, a world leader in general-purpose robotics solutions, is excited to announce its new partnership with Cardinal Machine, the machine building and systems integration experts.

As the world’s only manufacturer of adaptive robots, Flexiv will equip Cardinal with the ability to deploy robotic solutions which leverage industry-leading force sensitivity and artificial intelligence. This collaboration will enable jobs that would typically require manual labor, such as sanding, polishing, palletizing, and delicate assembly tasks, to be fully automated.

With over four decades of expertise, Cardinal Machine Company has established itself as one of North America’s leading integration and machine-building businesses. By leveraging cutting-edge software and hardware to create user-friendly, reliable, maintainable, and durable solutions for the most complex manufacturing challenges, they are an ideal integration partner for Flexiv.

“This strategic partnership with Cardinal marks a significant milestone for Flexiv,” said Howard Huang, Flexiv’s Business director for North America. “With the labor shortage showing no signs of abating and manufacturing being a vital part of Michigan’s economy, we hope that Flexiv’s robotic solutions can be used to fill some of the vacancies negatively impacting supply chains. Thanks to Cardinal, we have a real chance to make a positive difference and empower businesses not only to survive but to excel.”

As a Flexiv system integrator, Cardinal will have full access to the Rizon 4, 4s, and 10 robotic arms and the newly released Moonlight parallel robot. Easily integrated into existing production lines or used for standalone applications, Flexiv’s robotic range provides almost limitless possibilities for automating repetitive, laborintensive tasks.

“We are excited and look forward to a successful, long-term partnership with Flexiv,” said Brian Pennington, the President of the Cardinal Machine Company. “Having Flexiv’s adaptive force control technology available to us allows us to provide our customers with complex automation solutions in areas that previously required human intervention. Combining adaptive force control technology with a robot that can work collaboratively with a human operator offers even more potential solutions to complex tasks.”

Merging Flexiv’s robotic expertise with Cardinal’s extensive experience will deliver customers unmatched automation solutions while increasing the productivity, efficiency, flexibility, and competitiveness of businesses within the Great Lake State.

Want to learn more? Please visit: www.flexiv.com.

Since 1989, Actek® Manufacturing & Engineering has established a reputation for providing top-quality products as well as excellent service. Actek hoist rings are ISO 9001:2015 certified, 200% proof-load tested, and come with a certificate.

AGMA is the global network for technical standards, education, and business information for manufacturers, suppliers, and users of mechanical power transmission components. The association includes about 490 of the world’s top gearing companies across more than 32 countries around the world.

Advanced Manufacturing Solutions | Press Brake Safety is a leading industry advocate for press brake operator safety. PBS is the exclusive North American installer of Germany-based Fiessler AKAS® laser safety systems, the most sophisticated press brake safety systems in the world.

The Betenbender Family of American Hydraulic Shears and Hydraulic Press Brakes is made by Betenbender Manufacturing,Inc. in Coggon, Iowa, U.S.A. Now in their fifth decade in business, this Midwestern Company continues to produce, what they believe, is America’s best built Shears and Press Brakes.

Founded over 30yrs ago, Carell's experience in worldwide fabrication machinery & technology solutions continues to provide options that maximize efficiency while matching almost any budget. From small shops to large automated production systems we proudly maintain our goals & commitment to Faster Deliveries, Quality, Performance & Service

AeroGo manufactures innovative load moving equipment, utilizing wheels and hovercraft technology, that move heavy, awkward, or delicate loads in factories. AeroGo works with companies large and small to find a load moving solution that is safe, efficient and cost-effective.

American Technical Publishers (ATP) produces effective training materials for technicians and skilled-trades workers in construction, electrical, mechanical, and maintenance industries. Our high-quality instructional materials are widely used in apprenticeship and industrial training programs.

BEHRINGER SAWS manufactures high-performance bandsawing machines, circular cold saws, and structural fabricating equipment. Our primary goal is to create additional value for our customers by striving to achieve the highest combination of speed, accuracy, and cost-effectiveness.

Since 1951 Burr King grinders, polishers, and mass finishing systems have utilized innovative designs of uncompromising quality. They are industrial grade and intended for use on metals, woods, composites, plastics, rubber, stone, fiberglass and other materials.

The most economical tool for spindle drawbar testing! No batteries or clumsy extension cords, no delicate electronics to adjust or burn out. Clamprite Gages are designed for years of daily use in the shop!

Combilift is a specialist 4 directional forklift & straddle carrier manufacturer producing a wide range of customized handling solutions, all of which are designed for the safe, space-saving, and very productive handling of long and awkward loads. Capacities from 3,200 lbs. to 180,000 lbs.

COXREELS® has remained focused on manufacturing high-quality professional-grade hose, cord, and cable reels since 1923. Offering a full product line serving the industry in every channel and application, COXREELS® designs, builds, and supports their products in America.

Eagle Bending Machines' precision engineered quality is designed to meet the demands for tough, dependable Section Benders for bending pipe, tube, profiles, sections, and ornamental pieces and working day after day with minimum downtime.

A global supplier of high quality machine knives and blades of all types. We can provide the correct replacement blade for your equipment from our large inventory or custom manufacture blades to your specifications.

Fortville Feeders is a manufacturer of Feeding Systems that are engineered to easily integrate into your automation system. Maintenance and changeover friendly. Turnkey capable. Of the highest quality and ability.

Furnace Brokers

International maintains the largest database of available heat treating equipment in the world. Along with equipment sales and buying, Furnace Brokers does appraisals and exports worldwide. Whether buying or selling one piece or an entire plant, call us.

Cosen Saws is a global leader in manufacturing industrial band saws and technologies. Offering cutting solutions for a wide variety of industries and applications, we offer over 70 different models with nearly 200 units in stock and ready to ship from our Charlotte, NC HQ.

Dynabrade has earned a reputation in the innovative design and manufacturing of unique portable pneumatic abrasive power tools, related accessories, and dust collection. Dynabrade tools have been proudly designed, manufactured, and built in the USA since 1969.

Essex Structural Steel has been manufacturing pre-engineered building since 1972. Their buildings are designed for easy erection, energy efficient, designed to exceed local and state codes and are built in the USA by American Workers.

Formdrill helps you produce your own inserts out of the same parts material. Users save money by eliminating the need to buy nuts or threaded inserts. You do not need to weld or install fasteners.

Invented in 1976 in Japan and shipped to millions of satisifed customers all over the world, the Fumoto Valve continues to offer individuals, companies, mechanics and technicians, an easy tool that saves valuable time and resources for routine oil changes.

H&K Equipment provides specialized material handling solutions and exceptional service to our customers wherever and whenever we are needed. We strive to earn our place as the leading authority in our field!

HE&M Saw manufactures more than 70 different models of production band saws for the metalworking industry. Their product line, includes vertical, horizontal, plate and double column saws with capacities ranging from 12” x 12” to 80” x 80” machines.

HYDMECH is a world leader in metal band saw and cold sawing solutions. Their innovative solutions are geared to meet the practical needs of the aerospace, automotive, steel service centers, metal fabrications shops, racing, and other sectors.

Industrial Magnetics, Inc., provides off-the-shelf industrial magnet products. Our ability to provide customerspecific solutions to unique challenges that set us apart from others in the industry. We pride ourselves on quickly providing the best possible magnetic solution for our customer's requirements and without sacrificing quality.

Having been a company solely devoted to the manufacture of gears for 80 years, KHK is world renowned for their brand of gears. KHK USA is a factory direct, full-service distributor of KHK gears to meet your gearing needs.

Lenzkes clamps assist with QMC-Quick Mold Change, QDC-Quick Die Change, SMED-Single-Minute Exchange of Die and other machining/safety issues. Their Free Trial program allows use in real-time working situations (such as Stamping, Milling, and Injection Molding) without obligation to purchase.

At Motion + Power Technology Expo 2023 in Detroit, MI. October 17 - 19. The Motion + Power Technology Expo is a three-day show that connects professionals looking for motion power solutions with manufacturers, suppliers, and buyers.

HMI offers the most versatile C-Frame press or punch of all machines available today. Their frames are designed to have fewer tons-per-square-inch of pressure on their side plates, thus reducing spring back of the frame and reducing tool wear.

Hypneumat, Inc. manufactures an array of automatic drilling units, tapping units and multiple spindle heads under the Hypneumat, Commander and Snow brands. Hypneumat also specializes in contract machining services offering multi-axis turning and vertical machining capabilities.

KEC Incorporated specializes in Tank Turning Rolls, Welding Positioners, Floor Turntables, Sub Arc Manipulators, Head & Tail stocks. We also have a large inventory of Radial drills, bandsaws & other machine tools.

L&L Special Furnace, has a reputation for designing special industrial furnaces, ovens, kilns, quench tanks and heat treating systems. We continually update our product offerings and improve quality.

For more than 45 years, LS Industries has designed & manufactured a diverse product line of custom surface treatments and metal cleaning equipment. We also provide highly responsive service for your equipment.

OnRobot’s cutting-edge robotic tools for lightweight industrial automation empowers end-users to work alongside cobots on applications such as machine tending, quality control, materials handling, packaging, assembly, or surface finishing. Their One System Solution yields unified programming, easy deployment, and zero complexity.

Precision Drive Systems (PDS), a leading global provider of precision motor spindle support and repair based near Charlotte, North Carolina. In addition to better-than-factory repairs and rebuilds, PDS stocks an extensive line of new and rebuilt spindles, gauges, aggregates and variable frequency drives.

Radwell International stocks and sells New and Surplus Industrial Automation, MRO, Pneumatic, Motion, Electronic, Hydraulic, HVAC and Electrical Control Equipment for plant floor and facilities maintenance machinery. Radwell has full component level repair capabilities for Industrial Electronic and Electrical equipment.

Salinger Electric Co., Inc. has been selling quality new and reconditioned electrical equipment and electrical supplies since 1946. We are distributors of Siemens, Eaton, Continental and many others. We have locations in Troy, Romeo and Farmington Hills, MI.

Sprinter Marking manufactures a range of machines models that automatically ink code-mark message on a wide range of porous and non-porous surfaces. While very small in physical size, they are designed for rugged industrial operation.

The original heavy duty Modular Storage Drawer Cabinet that was the norm in the industry until the early 1990s is available only from Stor-Loc®. Their durable Modular Drawer Cabinet comes complete with a unique 55 Year Satisfaction Guarantee.

Sunnen has been a global leader in the manufacturing of bore creation, sizing and finishing equipment, since 1924. The Sunnen product line includes machines for honing, lapping, deep hole drilling and skiving/roller burnishing, plus the tooling, abrasives, cutters and bore gages to finish the job correctly!

Pro-Line has been a leader in workbench manufacturers since 1978. Proline offers a wide selection of workbenches that feature a modular designs and interchangeable accessories. Pro-Line continues to be on the leading edge of modular ergonomics.

Specialists in fine pitch Carbide Gear Hobs, Gear Shaper Cutters, Spur + Helical Master Gears. Our precision line of TRU-VOLUTE gear products are known for reducing setup times, improving gear quality, and producing more parts per regrind. Quality Products Since 1915

Scotchman is the most trusted hydraulic ironworker manufacturer in the USA, and also builds a complete line of Circular Cold Saws: manual to fully automatic, plus distributor of quality Digital Measuring Systems, Band Saws, H-Presses, and Tube & Pipe Notchers/Grinders.

Welcome to Standard-Direct.us, your number one source for industrial fabricated carts, shelf trucks, security trucks, storage cabinets and workbenches and much more. Industrial Shelving systems.

Suhner, we Bring Solutions to help our Customers Create their perfect success-critical Metal workpiece or Metal component. Since 1914, Suhner has offered a variety of solutions with machining & abrasive products, tool holders for machining units, customized flexible drive shafts, and repair services for Machining Spindles.

Sure Tack Systems, a division of Crist Company, Inc. established in 1980 and offers a diverse product line for your hot melt adhesive equipment and application needs. Whether your need is for high-speed extrusion, wide web spray, slot coating or manual product assembly; STS has a hot melt system to fit your individual needs and budget.

Manufacturer of the Sky Hook, a small, portable, ergonomic lifting device designed to provide safe, high quality lifting solutions that can assist in applications involving hard to reach loads up to 500 lbs. Proudly family owned and operated since 1969.

Trilogy Machinery, Inc. is committed to bringing the highest standards of professionalism, integrity and service in order to achieve a reputation as a leader in the metal fabricating machinery industry. Trilogy proudly offer products from Italy, Sweden, Turkey, and Taiwan.

TS3 – The Saw Sales and Service Company – provides all aspects to support your saws - Names you know and trust –Amada, Marvel, Tigerstop, MK Morse, and many more. New machine sales, on-site repairs, applications and replacement parts. TS3 - factory trained or factory authorized in many current and former saw manufacturers.

At Tormach, we are dedicated to providing exceptionally engineered compact CNC mills, lathes, routers, plasma tables, and industrial robots, as well as tooling and related products. We serve customers with best-in-industry technical support and customer service.

Trim-Lok, Inc. manufactures high-quality plastic and rubber extruded trim and seal profiles. From plastic edge trims to sponge rubber seals, our profiles add protection from rough edges while sealing out moisture and debris with a clean, finished look to your application. In-stock profiles and custom engineering is available.

American-owned and operated, US Metal Crafters knows the right supplier transforms your supply chain. Our broad service offering coupled with our commitment to quality & on-time delivery will transform & simplify yours. Laser cutting, stamping, fabrication, assembly, powder coating, tool & die services, and more all under one roof!

BidIndustrial.com

is a Commercial & Industrial Auction Company for industrial machinery & equipment. We specialize in UNRESERVED auctions of heavy equipment & machinery, commercial & industrial inventories.

www.bidindustrial.com | (888) 777-9888

Capital Recovery Group, LLC

CRG is a global private equity firm that creates liquidity through expertise, innovative solutions, and access to worldwide markets by revitalizing idle or marginally productive assets and liquidating surplus.

www.crgllc.com | (860) 623-9060

CNC Exchange

CNC Exchange, Division of Gray Machinery Company, specializes in buying and selling high-quality, pre-owned CNC Swiss-type lathes, turning centers and machining centers and other types of industrial equipment.

www.cncexchange.com/ | (847) 537-7700

Compass Auctions

Compass Auctions provides support, advice & transparent communication throughout the auction process so you can make the most informed decisions. We host monthly industrial machinery & equipment auctions.

www.soldoncompass.com | (423) 702-6180

Denver Breaker & Supply

Denver Breaker and Supply was established in 1984 and has always had a “Customer First” approach of doing business. They provide new and reconditioned electrical equipment and guarantee the finest quality and best prices you can find in the business.

www.denverbreaker.com | (800) 544-7375

BTM Industrial