27 minute read

Biden Versus Trump on Reshoring: A Review, and a Critique

Biden Versus Trump on Reshoring:

A Review, and a Critique

By Harry Moser

Since 2010, companies have brought over 700,000 manufacturing jobs to the U.S., the sum of reshoring by U.S. companies and FDI (foreign direct investment) by foreign companies. This surge is responsible for about half of the 1.4 million manufacturing employment increase from the March 2009 Great Recession valley to the December 2019 pre-COVID-19 peak. At a given level of U.S. goods consumption, the only ways to increase manufacturing are to export more or import less, i.e., reshore/FDI. Importing less is far easier due to the economic advantages of selling locally.

Balancing the goods trade deficit will increase U.S. manufacturing by 40 percent, or 5 million jobs, President Joe Biden’s goal. Reaching this goal in even 20 years will require increasing the rate of annual reshoring/FDI from the Obama and Trump averages of 56,000 and 144,000, respectively, to about 450,000. President Biden’s humanitarian and ecological goals will all be much more affordable if this rate of reshoring occurs.

The purpose of this article is to learn from the Trump experience and offer guidance to President Biden.

Trump in Review

President Trump started strong on reshoring. The number of reshoring and FDI jobs announced coming to the U.S. surged from 75,000 in 2015 to 115,000 in 2016 and 193,000 in 2017. Major driving factors included reductions in corporate tax rates and regulations, and a generally business-friendly environment. The annual rate then fell off to 154,000 in 2018 and 117,000 in 2019, driven by business uncertainty over the unpredictability of tariffs and other trade war actions. Reshoring picked up in 2020 because of COVID-19, with many PPE investments and increased corporate understanding of risk mitigation through shorter supply chains.

President Trump’s haranguing companies to reshore or not offshore did not

work. Patchwork, unpredictable tariffs were ineffective. Imposing tariffs on steel products put U.S. manufacturing, other than steel producers, at a competitive disadvantage. Placing tariffs on China caused work to shift to other southeast Asian countries. Tariffs that are uniform across all countries, all products, and time probably would be much more successful.

At the macro level, the U.S. nonpetroleum goods trade deficit grew from $679 billion in 2016 to $854 billion in 2019, clearly not a successful result. The Broad Dollar Index averaged 10 percent to 15 percent higher than during the Obama terms, a strong headwind against reshoring and trade balance. But President Trump took no action to reduce the value of the USD. U.S. manufacturing employment did better, increasing from 12.4 million as of 12/31/16 to 12.9 million as of 12/31/19, a strong result, especially late in a recovery.

Conclusion

President Trump successfully alerted the nation to the dangers of a huge and growing trade deficit and China’s economic threat. He failed to attack the root cause of the problem, uncompetitive U.S. manufacturing costs because of an overvalued dollar and inadequate skilled workforce. He did not have an effective industrial policy. He therefore failed to make meaningful progress in overcoming the trade deficit and China’s economic threat.

Critique of Biden’s Reshoring Plans

President Biden brings new plans and hopes. Some are well founded; others will not achieve desired goals. Below, we itemize Biden’s plans on various issues, shown in bold type, followed by our critique and suggestions for improvement. Our critique and suggestions are based solely on the plans’ ability to achieve a strong start toward balancing the goods trade deficit, reshoring the 5 million manufacturing jobs that Biden has promised. Such a balance will require an approximately 20 percent reduction in U.S. manufacturing costs versus offshore and increasing our skilled workforce’s quantity by 20 percent and its skills to the German level.

Biden Plans That Will Accelerate Reshoring Add 5 million manufacturing jobs.

Reshoring Initiative’s take: We agree. Five million has long been the Reshoring Initiative’s goal to balance the U.S. $800 billion/year goods trade deficit.

Buy American for government pur-

chases: Increase the difference in price required to justify foreign sourcing and use Manufacturing Extension Partnership Programs (MEPs) for scouting to find domestic sources.

RI take: It’s a good idea to include the use of MEPs. However, changing the metric from price to TCO (Total Cost of Ownership) might double the amount of work reshored without raising the government’s total cost.

Directly drive reshoring by Made

in America tax credit: Use subsidies, federal matching, and tax incentives to

make American products more competitive and incentivize companies to reshore and expand here.

RI take: OK, but this plan is complicated and will be a boon for the lawyers and accountants needed to qualify companies for the incentives. Too often, U.S. manufacturing costs are 20 percent above Europe’s and 40 percent above China’s. A much more efficient approach would lower the USD 20 percent to 30 percent and making huge investments in skilled workforce to cut those price gaps.

Ten percent offshoring tax penalty on overseas production sold in the U.S.

RI take: OK, but this plan does not appear to apply to products purchased from other companies abroad. We recommend a change from a profit tax to a tariff, which then will also apply to purchased products and to products imported by non-U.S. companies. The impact on consumers will be the same.

Public health effort of $400 Billion for vaccinations, testing, PPE, etc.

RI take: Good. This will make it easier to staff U.S. manufacturing.

Strengthen the Affordable Care Act.

RI take: Good. Put more emphasis on reducing the cost of medical care, which raises the cost of U.S. manufacturing. Cutting the U.S. cost to the German level would cut U.S. goods prices about 4 percent and reshore about 400,000 jobs.

$50 billion to apprenticeship and other training programs.

RI take: Agree. Most of the dollars should be in the form of apprenticeship grants or loans, not funding to bureaucratic programs. The training should prioritize the manufacturing skills the country needs more than the skills that a trainee wants to acquire. Change the government message to show that the career opportunities and income with an apprenticeship are as good as those with a university degree. The required recruitment will not occur if free university education is an alternative.

Made in America product labeling:

Crack down on false claims.

RI take: Agree 100 percent.

Tax companies that are parking income in tax havens offshore.

RI take: Agree. The key is to improve the system by which income is ascribed to different countries. Income needs to be taxed where products are made and sold, not where assets such as trademarks and other IP are stored.

China and steel tariffs staying for

now: Steel tariffs on allies likely to come off sooner.

RI take: Agree, but it would be better to replace tariffs with a VAT (value added tax) on all imports as almost all other countries do.

8

Your source for the best in close tolerance strip and edged products.

strip: cold rolled high carbon/pre-tempered spring steels, coated, low carbon stainless, copper based alloys and aluminum ultra-narrow width, close-tolerance slitting edging: round, square, semi-round, deburred, custom, etc. oscillate (traverse) and ribbon wound coils ISO 9001: 2015 certified 43 years servicing the industry

tel. 847.537.2881 toolkinginc.com Wheeling (Chicago), Illinois 60090 USA

Biden Plans That Will Hinder Reshoring:

Strong U.S. dollar: Treasury Secretary Yellen: “The United States doesn’t seek a weaker currency to gain competitive advantage” Eliminating the USD’s approximately 20 percent overvaluation would drive 1 to 2 million manufacturing jobs to the U.S. Announce a gradual reduction in the value of the USD. Either buy other currencies or apply a Market Access Charge to foreign funds stored here in the form of USD.

Raise minimum wage to $15/hr.:

This will make some work not reshorable and will reduce the motivation for low-paid service workers to seek more highly compensated manufacturing careers and for workers to obtain the training now needed to earn a $15 wage. It will increase automation. The Congressional Budget Office projects a 1.3 million job loss. As an alternative, we suggest massive expenditures to provide manufacturing skills training via apprenticeships, certificates and community colleges. Motivate many high school students to choose tech skills training instead of liberal arts university degrees.

Raise the corporate tax rate from 21

percent to 28 percent:This will decrease the ROI on U.S. capital investment, shifting investment offshore and will make inversions—moving headquarters offshore—look appealing again. It would be better to maintain the 21 percent rate or cut it further. Instead, raise the rate on individuals who make more than $1 million/year to recover the lost tax revenue. Companies are much more flexible in their plant location decisions than are individual taxpayers in their citizenship. Repeal right-to-work laws: The 27 states that have right to work laws were responsible for 69 percent of the reshoring from 2010 to 2019. Do we want more jobs or fewer, but more union jobs?

Lower eligibility for Medicare to 60:

This will cause more workers to retire early, increasing the forecast shortage of 2 million mfg. workers. Instead, gradually raise eligibility to 70.

Make college free for low-income

families ($125,000 or less): Will shift more smart students from skills training and engineering to liberal arts degrees. We have severe skills shortages, and 30 percent of all university degree holders are in jobs that do not need a degree. Instead, offer free tuition for degrees in short supply (e.g., engineering and manufacturing) and apprenticeship loans to make apprenticeships affordable to companies and apprentices.

Do nothing about products out-

sourced offshore: Biden’s plans all seem to deal with companies’ owned factories offshore. Most of the imports, especially from China, are produced by foreign OEMs or contract manufacturers. Solution: Make U.S. contract manufacturers more competitive via currency, skilled workforce, low tax rates or a VAT.

Conclusion

President Biden has the right objective: Add 5 million manufacturing jobs. He believes the objective is achievable. “Biden believes that American workers can outcompete anyone, but their government needs to fight for them.”* The Biden plan does not, however, include the elements to make his belief real by reducing U.S. costs by 20 percent versus offshore and assuring universal use of Total Cost of Ownership. Competitiveness requires a lower USD and motivating many more students to choose a manufacturing apprenticeship or engineering degree instead of a liberal arts degree. Unless he takes these actions, Biden will repeat Trump’s failure.

The Reshoring Initiative is available to provide data and analysis to refine the Biden plan. n

Harry Moser is the president of the Reshoring Initiative. For more information on the organization and the total cost of ownership (TCO), visit www.reshorenow.org.

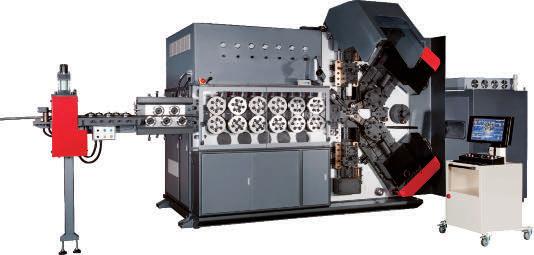

WAFIOS Machinery Corp.

Five Questions provides an opportunity for SMI associate members to tell the spring industry about the products and services they offer. In this edition, we talk with Bob Ackermann, vice president of engineering, WAFIOS Machinery Corp.

1|Can you tell us about the history of WAFIOS? WAFIOS has been in business for more than 125 years and had its beginnings in 1893 when Ernst Wagner begin producing fence machines. This grew to include springmaking equipment with the introduction of the first 2-finger spring coiler in 1912. Later years brought expansion into tube bending, wire forming, chain, cold forming, wire straightening and thread rolling.

WAFIOS offers a broad line of machine types, with many well outside the traditional springmaking arena. While many of these other products do not relate to springmakers, the broad expertise in wire forming allows knowledge acquired in other areas to be applied to springmaking.

2|What types of machinery do you offer to springmakers? Bob Ackermann WAFIOS has a wide range of products and offers springmakers machines that will manufacture compression, extension, torsion and other bent spring forms. We also offer equipment for grinding and testing of springs.

3|This issue of Springs revolves around advances in springmaking. What advances has WAFIOS been a part of over the last decade? WAFIOS continually improves its machines. Over the past decade, WAFIOS has dramatically increased the speed of the spring coilers, added high performance camera systems for inspection, and developed the IQ series of add-in features to improve production and quality.

We recently introduced the new “plus” series in our flagship FUL series coilers. This new model incorporates the latest control systems and offers the option to increase performance by using newer water-cooled drives and systems, to allow wire feed speed up to 500 meter/min. This includes a payoff incorporating a CNC axis to ensure the wire is delivered to the machine with constant tension.

We have continued to improve our camera technology, so that even at these speeds, measurements can be made to ensure quality.

Another area of development is the IoT gateway and smart factory initiative. We are developing enhancements to our machines to allow easy monitoring and maintenance of machines, allowing customers to keep their machines running optimally and with less supervision.

4|Why did you establish the WAFIOS Midwest Technical Center just outside of Chicago? We wanted to provide a centrally located and easily accessible location, to showcase our machines. The Chicago area provides both of these, and allows us to have customers easily travel from both coasts and Canada to see the latest innovations, work and train on actual machines and attend in-house “mini” shows that display the latest machines from the entire line of WAFIOS technologies.

5|Can you tell us about a recent challenge that you were able to solve for a customer? The movement in the auto industry toward e-mobility will result in a paradigm shift in components required for automobiles in the future. As the internal combustion engine is replaced by electric motors, the parts required will change. WAFIOS has been watching this trend and has been developing new machinery to address this.

A good example is the development of a “hair pin” forming machine for the stators of electric motors. We have retooled the FMU series of torsion spring machines, to allow production of these wireforms. This machine is very similar and familiar to existing customers and will allow easy transition into these new markets.

We are also working on adapting our other machines to allow production of buss bars and fasteners for the automobile and battery industries. n

WAFIOS Machinery Corp. 2700 Northeast Industrial Road Branford, CT 06405 203-871-2072 BobA@wafios.us www.wafios.us

Springmaker Spotlight

©iStockphoto.com/tweety

Leadership Lessons from COVID-19

By Gary McCoy, Managing Editor

Normally in this space we profile a spring manufacturing company in our industry. It’s an opportunity to tell the unique story about how and when the business started and the growth that has occurred. With COVID-19 having a crippling effect on our industry, it has been a challenge to put these articles together. The sentiment has often been, “I’d like to do help you, but I just don’t have the time right now since we have several people out with COVID and we are trying to keep our customers happy.”

In light of that, this edition of Springmaker Spotlight focuses on the pandemic, which has forced everyone to change how they do business. While everyone is still producing springs, wireforms and stampings for their customers, they have had to put together procedures to ensure the safety of their workforce. What was once unheard of is now commonplace, such as workers wearing masks, having their temperature checked on a regular basis and being socially distanced from their colleagues.

Leadership has always been important when a crisis occurs, be it a fire, a market collapse, a customer setback or a pandemic. Considering that, I asked a few springmakers to answer the question: “How has the COVID-19 pandemic influenced your approach to work and leadership?”

Firmer on Rules

When this first started to hit everyone in March 2020, we were fortunate that we did not have any cases impact our employees until the end of October. From October through the end of November, we had 21 positive cases out of 155 employees. One of the 21 people died.

From the beginning, we have had staggered lunches and breaks, adjusted the start times for second shift to minimize the overlap of employees, purchased temperature monitoring devices and allowed employees to come and go through two main doors, closing off the other doors from outside access. I also have eliminated my weekly updates with all employees, reducing this down to just the supervisors and facilitators weekly.

This is the hard information on changes. As far as my approach, it has caused me to be firmer on rules and

requirements. A lot of people do not want to wear masks, but it is not an option here. It has also caused us to increase the level of inventory we carry to ensure we can meet customer expectations.

Chris Witham, President, Motion Dynamics Corporation, Fruitport, Michigan

A New Set of Leadership Skills

It has been an interesting year for all of us. “We are all in this together” is the least correct statement I hear. Since each state is making up its own rules, it makes it very difficult for us to find common ground. And, with ever-changing rules and suggestions that are masked as rules, it takes the team time to figure out the correct moves on a weekly, if not daily, basis. So, when it comes to the working environment we must find a way to allow people to stay safe, but also allow them to have the freedom they wish for and need. You can put up absolute rules, but that can conflict with the culture of our business and team. It can conflict with the core values of the company.

My job has changed to making sense of new rules and sorting out what can work and what can be harmful. Within our own state, the rules are different for each type of manufacturing. It depends on who has the most influence with our politicians. It has nothing to do with it being safe or helpful.

In leading our team we have had to look at so many issues that we have never thought of in our space. Some of these are helpful because we have to consider so many variables. With a diverse workforce, there is so much to consider. The age of people seems to set the fear level set up by the media and our government. You would think the older people would have more fear, but the younger ones are equally fearful. It seems the more people watch the “news,” the more fear they feel and the more distrust they amplify.

How do you use all of this? We have pushed our marketing plan to its highest To be a leader right now takes a new skill set that many of us have never had to use. We are running a business and navigating a political and world reality that is new and everchanging. We have to be strong and sensitive and intuitive and open to complete this new challenge. We must be stronger and smarter than we ever imagined.

level. Now is the time to get back our customers who have moved to foreign companies. We have to be there for our customers who have been forced to close. Once they reopen, we have to work with them to solve their issues of catching up with their production.We have to know that this could be a short-term “fix,” but we work to make their businesses come back to life. For the companies that have closed for good, we are working to help find new vendors to take on the old products.

As far as raw materials and supply chains, we are all working harder than ever to find materials for our customers’ products. With so many mills and other suppliers working to capacity to keep up, it is going to be a hard road ahead to fill the needs of our customers. And with rising prices, it will take a new level of education for us and our customers as to what is the new reality.

To be a leader right now takes a new skill set that many of us have never had to use. We are running a business and navigating a political and world reality that is new and ever-changing. We have to be strong and sensitive and intuitive and open to complete this new challenge. It is said it takes 21 days to form a new habit. We have been at this for far too many 21-day periods. Now we have to figure out what new habits are real and useful, and what is dangerous and controlling. This isn’t over yet. Whatever it is we are moving toward is still a mystery. We must be stronger and smarter than we ever imagined.

Scott Rankin, President, Vulcan Spring, Telford, Pennsylvania

Rethinking the Way We Do Things

To say the COVID-19 pandemic has made operating a business very challenging may be the understatement of the year. More than 40 years of experience could not have prepared us for what was coming. Considered by our government to be an essential service, manufacturers such as ourselves had to quickly adapt in March 2020 to protect employees while continuing production. This certainly presented new management challenges every day, as we were scrambling to keep up with public health advice.

Some of our largest customers in the automotive industry shut down for 12 weeks, so we quickly went to a four-day workweek to avoid layoffs. Eventually we were approved for the formal work

sharing program so our employees could collect EI on their days off. We were fortunate that nobody became ill and that the protocols we had put into place seemed to be working. We had to manage through several key employees having to stay home and self-quarantine when they came into contact with family members who returned from overseas or who did test positive. Every day we have to exercise caution and monitor our employees’ health while encouraging anyone who can work from home to do so.

Thanks to our information technology department, we were able to quickly adapt to work at home [beginning] in March 2020, and this has continued and is even more important during the “second” wave. We have really had to think about the way we do things and ensure that our employees are practicing safe distancing, wearing masks and reporting to us if they don’t feel well. We developed a COVID19 policy which allows employees 50 percent of their salary if they need to stay home due to COVID-19. We believe this is going to be an ongoing challenge until everyone is vaccinated, and that could take 10 months or longer.

Chris Wharin, Owner, Bohne Spring Industries Ltd., Toronto, Ontario, Canada

Keeping Positive and Resilient

When the COVID shutdowns started in March 2020, the most immediate impact was reviewing our daily activities to implement social distancing. Our daily meetings had to be canceled. In their place, we used all means possible to communicate — postings, public address (PA) announcements and — most importantly — face-to-face communication. Our team leads were key to making everything work. They really took over production and gave great feedback. Their leadership has been most important.

Since November 2020, our region’s COVID case load has been very high. While we have been able to avoid transmission in our facility, we have lost more than three production days in total due to infections and quarantining. Key employees being out really highlights training needs. We are reviewing each employee’s training to identify opportunities and gaps. Our employees have been willing to work in a variety of areas to do whatever it takes to keep parts going to suppliers.

Finally, our team has kept a positive attitude and been resilient every day. It truly takes us all to be successful — their hard work every day is appreciated.

Rick Eitel, Chief Executive Officer/President, Duer/ Carolina Coil, Greer, South Carolina

INTRODUCING

Spring Testing REVOLUTIONIZED

The Authority on Accuracy.

NEW

Available with Basic or Advanced Software

Innovative Spring Testing Solutions

Starrett offers a complete line of innovative force solutions for spring testing. In addition, a new, affordable high volume production testing solution is available in basic software (S1) and advanced (S2).

MADE IN AMERICA

For more information visit starrett.com/springs

PRECISION TOOLS/GAGES

SPRING TESTING

spring inspection

Creating a Post-COVID Business Plan

What will your business look like once COVID-19 has passed? That question is the premise of a recent Harvard Business Review article by Dev Patnaik, Michelle Loret de Mola, and Brady Bates. The article summary states: “To plan for a post-pandemic world, businesses must understand what your stakeholders’ behaviors will look like after the pandemic. Some behaviors will return to their pre-crisis state; others will be transformed; and others will disappear entirely. Drawing on research into habit formation, technology adoption and behavioral economics, the authors offer a framework to help companies make reasonable predictions on what happens next.” It’s an article you might want to circulate and discuss with your leadership team. Visit https://hbr.org/2021/01/creating-a-post-covid-business-plan

Concern, Confusion and Contemplation

My approach to COVID-19 was confusion, concern and contemplation.

When the shutdowns began, my initial response was confusion. Are we essential? Are we not essential? Employees want to stay home, should they? Are we all going to die if we come to work? It didn’t take long to be told by multiple customers that we were essential, but there were still questions about whether the city, state and federal government and our employees felt the same way.

My concern came from my responsibility for protecting and considering my employee’s health versus trying to keep the business running and not sacrificing our customer’s need for parts. After getting past the initial knee-jerk reaction, we were able to accomplish both well. Initially we didn’t mandate masks, we just monitored temperatures daily, stayed as distanced as possible, restricted visitors, etc. This worked well for many months. We had our first positive case in December 2020 and it was not contracted at work. We had our second case in January 2021 and it was also not contracted at work. It was then that we decided that the two cases were too many and we mandated masks. We have several employees with major underlying conditions, so keeping everyone as safe as possible is my No. 1 concern.

My contemplation was a result of all of the above. Your customers need, expect and, in some cases, make you feel it is required that you continue to service whatever their needs are, but in the long run, it is your people that matter most. My approach to leadership during this whole thing has just been to do my best to make wise decisions for my employees first and my customers second. Some of those decisions have been the hardest I have ever made. I say this because the information we were given almost changed daily, so you always questioned whether your leadership was right or wrong. I know one thing, I’m ready for it to be over!

Phil Jones, President, Industrial Spring Corporation, North Kansas City, Missouri

Communicate Your Story

We have been mindful of the basics, making sure that we continue to communicate our “story” to our employees, customers and suppliers. Relationship management is paramount.

We’ve always communicated well with all these groups, but since COVID we have doubled down on this.

Prior to COVID we had quarterly, all-employee meetings to go over where we are as a company and where we are headed. Since COVID came on the scene, we have held more meetings with employees, simply to reassure them that we are paying attention to their concerns and looking out for them.

We’ve always had a clean workplace, but now it is even better post-COVID. We’ve invested a lot of money to help provide a safe workplace, emphasizing hygiene.

Tim Bianco, President and CEO, Iowa Spring Manufacturing and Sales, Adel, Iowa

Respond, Evaluate, Get Ahead

Tough question, when there are no “How to Conduct Business during Pandemics for Dummies” books laying around. We have relied on discussions between our leadership team and trusted business advisors to plan for and manage difficult times. By talking through what we believe may be the best practice for the current situation, we came to a couple of bullet points that act as a very broad guideline on work and leadership.

Respond: Grip the current situation with understanding and acceptance. Aim to make good decisions that bring steadiness and stability.

Evaluate: What decisions are working, what haven’t we thought of that needs addressed, do we need to go in another direction or maintain our current heading?

Get ahead: Did taking the necessary steps halt the impact of crisis?

With luck and sound decisions, the pandemic may bring opportunity that you hope creates further value, rather than maintaining status quo.

Chris Fazio, President, Diamond Wire Spring Company, Glenshaw, Pennsylvania

Communication is Critical

Located in western Pennsylvania, Ace Wire Spring & Form Co., Inc. felt the impact of the pandemic early in 2020. Our governor declared a state of emergency on March 6, followed by school closures on March 16, and then a business closure/ stay-at-home order effective March 19.

The business closure news had quickly spread through the manufacturing sector. After all, teleworking in our industry is as rare as a unicorn. We think we are essential, and we were fortunate that many of our customers agreed and made their thoughts known. We received emails right away stating unequivocally that “you are an essential supplier to us and we need you need to stay in operation.”

We quickly scrambled to obtain masks, and we made the decision to stay open and support our customers and protect our employees. We quickly received a Cybersecurity & Infrastructure Security Agency letter designating us as essential. We made the announcement to all employees that we would stay open, and we authored and distributed “essential worker letters” for employees to carry.

As head of our company’s COVID-19 team, I reinforced that communication with employees is always important, and it became critical during the heights of the pandemic, critical to maintaining a

workforce and critical in assuring that management is paying attention. Critical to morale. Employees were confused. What were they supposed to do? Bits and pieces of information swirled through the plant floor. Some employees wanted to go home, some out of fear of being infected, some because they had children at home, and some, just because. Balancing the need for manpower with empathy for employees and their families was, and remains, one of the biggest challenges of this period.

Leadership requires a team. A team whose trust comes through communications and actions that display sound reasoning, perseverance, flexibility, and compassion.

Since the epidemic began, commercials, banners, and posters began appearing with phrases like “we’re all in this together” and “we’ll get through this together.” These became popular and optimistic phrases during difficult times.

With the focus on lessons learned regarding work and leadership, after some thought it came back to the realization that teamwork, combined with proper leadership, leads to success, not just during a pandemic but throughout life in general.

The implied/intended message is that yes, we are all in this (the pandemic) together. And that we have been in this (life in general) together for a long time. The formula for success hasn’t changed.

Brian Durkin, Quality Manager, Ace Wire Spring & Form, McKees Rocks, Pennsylvania

Springs is always interested in what readers have to say about important industry topics. Let us know how COVID-19 has influenced your approach to work and leadership. Send your comments to gmccoy@fairwaycommunications.com. n