BY EMILY BRETH STAFF WRITER

BELGRADE — From the mooing of cattle and squealing of pigs to the hums of irrigators and tractors, something can always be heard on the Anderson farm established in 1889.

This year, the Anderson family — Grant, Noah, Isaac, Sue, John, Erin Krug and Wyatt Krug — welcomed the community to their crop and livestock farm for the Pope County Farm Bureau Breakfast on the Farm.

“The (breakfast) committee has been asking for a couple of years, and we finally agreed,” Grant said.

The committee has been

having monthly meetings at the farm since February, organizing different activities that are being planned.

The event took place Monday, Sept. 2, with breakfast served from 8-11 a.m. and activities going on until noon.

“There is a lot of work the committee puts into it,” Grant said. “They try to make it as painless as possible for the host farm.”

Farm visitors had the opportunity to view a collection of equipment, see how aerial drone sprayers operate, learn about cow and horse hoof care and enjoy a hayride. There was also a play area for the kids and more.

“I think it is good to educate the public,” Grant said.

“Fewer and fewer kids grow up on farms. It’s good to do some education and give back to the community.”

The timing of the event pairs with the beginning of kidney bean harvest sea-

Every year, the Andersons donate a plot of land to the Belgrade-Brooten-Elrosa FFA chapter. The FFA gets all of their

Andersons page 2

September 7, 2024

BY RAE LANZRATH

Published by

Star Publications

Copyright 2024

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6577

Fax: 320-352-5647

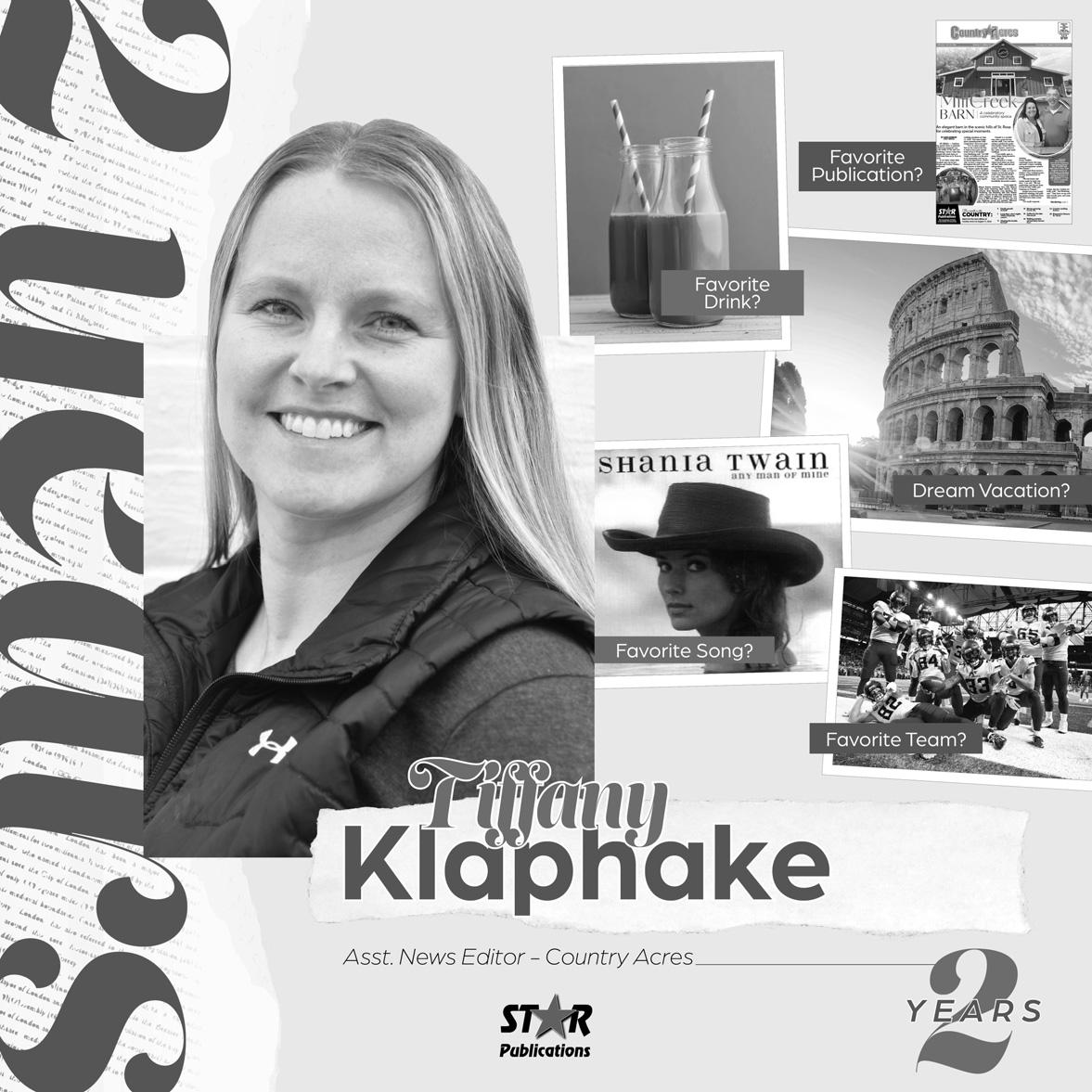

NEWS STAFF

Mark Klaphake, Editor

Mark.k@dairystar.com

Tiffany Klaphake, Assistant Editor tiffany.k@dairystar.com

Sara Eisinger, Writer

sara.e@star-pub.com

Emily Breth, Writer emily.b@star-pub.com

Rae Lanzrath, Writer raeanna.l@star-pubs.com

Carol Moorman, Writer carol@melrosebeacon.com

Natasha Barber, Writer natasha@saukherald.com

Ben Sonnek, Writer ben.s@saukherald.com

Hans Lammeman, Writer hans.l@star-pubs.com

Story ideas send to: annika@star-pub.com

SALES STAFF

Robin Brunette, 320-293-5911 robin@saukherald.com

Missy Traeger, 320-291-9899

missy@saukherald.com

Tim Vos, 320-845-2700 tim@albanyenterprise.com

Mike Schafer, 320-894-7825

mike.s@dairystar.com

Neil Maidl, 320-292-4454

neil.m@star-pub.com

Jaime Ostendorf, 320-309-1988

jaime@star-pub.com

Bob Leukam, 320-260-1248

bob.l@star-pub.com

PRODUCTION STAFF

Amanda Thooft

Nancy Powell

Maddy Peterson

Cheyenne Middendorf

Karen Knoblach

Annika Gunderson

Nadiia Griepentrog

Deadlines: Country Acres will be published the first Saturdays of April, May, June, September, October and November, and the third Saturday of every month. Deadline for news and advertising is the Friday a week before publication.

ISSN: Print 2834-6440 Online 2834-6459

A group of cattle stand around a water tub Sept. 2 at the Anderson farm during the Pope County Breakfast on the Farm near Belgrade. The Andersons have been participating in the Non-Hormone Treated Cattle Program through the U.S. Department of Agriculture since the mid-2000s.

The profit from selling the crop goes back to the chapter to fund future activities.

Other crops on the farm include corn, which takes up half the acres, oats and rye, which are used in the corners the irrigator cannot reach and for a cover crop, and meadow hay in the low ground.

All the corn grown on the farm is utilized as feed. Their feed is ground and mixed in part of an elevator the

Andersons have owned for over a decade. This is located next to Belgrade Grain Inc.

At the elevator, they mix rations to pair with what their cattle and pigs need at different stages of their lives. The Andersons run a farrow-to-finish hog operation.

The family utilizes artificial insemination on all their pigs, breeding to purebred Yorkshire. For the first three weeks, the babies will nurse from their mothers in the

birthing pen, which they are moved to two days before they are born.

From about 3 weeks old until they are 40 pounds, the piglets spend their days in the nursery barn. They are then moved to the finishing barn until they are mature, meaning the first estrous cycle in females and market weight in males.

Most of the hog barns are located on the Andersons’ property. However, they do have a few contract growers within a 30-mile radius of the farm.

All the barns have a way to help the pigs remain cool — from misters that turn on when it gets over 85 degrees to an evaporative cooling system.

When it comes to the cattle, the family has been participating in the Non-Hormone

Treated Cattle Program through the U.S. Department of Agriculture since the mid2000s. All the cattle have a form of identification used to prove the rules and regulations of the NHTC standards are met.

The Andersons buy yearling cattle straight from a ranch in Montana. By eliminating a middleman, they are able to ensure the cattle do not receive any form of hormones. They then bring the heavier ones back to the farm, leaving the lighter half on pasture in North Dakota.

“Come September, the cattle from the feedlot will go to market,” Grant said.

Andersons page 3

Publications bli ti “The newspaper of today is the history of tomorrow.”

Doug

shears sheep in the morning hours Sept. 2 at the Anderson farm near Belgrade.

All the feed the Andersons use is ground and mixed in part of an elevator in Belgrade the Andersons have owned for over a decade.

“We will then bring the pasture cattle home, so we are getting two turns out of the feedlot.”

When it comes time for trucking animals, the family sets biosecurity at the top of their list. Every time a trailer gets unloaded, it is backed into the truck wash station. The trailer is then hosed down and sanitized and left to dry before getting used again.

It was Grant’s late dad, Jim, and uncle, John, who were active in expanding the farm.

“My dad and John are who built the farm to what it is today,” Grant said. “My dad was more of the crop side and John handled the pigs.”

Sue, Grant’s mother, handles the book work and finances, along with helping at the local hardware store of which the family owns 50%.

“We all farm together,” Grant said. “It is all one business, and everyone works together for the good of the whole.”

Everyone found their place on the farm with Grant overseeing crops, Isaac the feed mill and finishing barns, Noah the farrowing barns, and Wyatt the feedlot.

As Grant, his brothers and his cousin, Erin, got more involved in the farm, John continued to handle the logistics of the pigs and cattle. John takes care of the trucking, finds breeding stock and handles relations with farms they sell to.

Corey Theis helps direct cars for parking Sept. 2 at the Anderson farm near Belgrade. The family started experimenting with kidney beans in the ‘80s, and they switched fully from soybeans to kidney beans in the ‘90s.

Koehn raises awareness, funds for FFA

BY TIFFANY KLAPHAKE STAFF WRITER

UPSALA — Not many people can say they have driven across the United States, and even fewer can say they have driven across the country on a tractor. Mark Koehn is about to do just that.

“It’s to promote (the FFA Alumni & Supporters), FFA and agriculture in general,” Koehn said.

Starting Sept. 16, Koehn will embark on a journey from the Minnesota-Canadian border to the Gulf of Mexico on a Farmall M to raise awareness and funds for agricultural education.

“Nobody has done this before,” Koehn said. “Once or twice a year you hear about someone who canoes the Mississippi River or bikes alongside it. I’m just doing it on a tractor.”

Koehn, along with fellow Upsala FFA Alumni & Supporters member, Daryl Larson, will load the tractor onto a fifth-wheel trailer and hook up a camper before driving to the northern border of Minnesota, where Koehn will begin his 2,000-mile journey.

Koehn is a past Upsala FFA member and a current member of the Upsala FFA Alumni & Supporters

chapter. The Upsala FFA Alumni members have helped Koehn plan out his trip and Koehn reached out to the Texas FFA Alumni to help him coordinate the best way to navigate through Texas.

“My final destination is High Island, Texas, which is on Gulf of Mexico and the Texas-Louisiana border, “Koehn said. “I know all the roads I plan on taking, but there is some flexibility.”

By the end of the trip, Koehn will have gone through Minnesota, Iowa, Nebraska, Kansas, Oklahoma, Texas, Arkansas and Louisiana. Because Koehn will be averaging 16 or 17 miles per hour, pulling a camper and taking the long way around to

avoid major cities, the trip by tractor will take a lot longer than it would by car.

“(The trip) should take about a month,” Koehn said. “(In) road miles it is 1,600 miles, but I’m not taking any interstates or highways, so it will be about 2,000 miles for me.”

Leading up to the trip, Koehn did a test run to determine how far he could comfortably travel in a day.

“I was mostly testing fuel economy,” Koehn said. “There is no gas gauge on a 1940 Farmall M. I found out it gets about 7.5 miles per gallon, and I can do about 100 miles on a tank.”

Koehn has his route planned out,

but does not have any designated stops. Since he is pulling a camper, Koehn will only need to pull over into a farmyard or church parking lot and ask if he can park there for the night.

“I will get up each morning, check the oil, check the water, make breakfast, fire it up and take off,” Koehn said.

The trip will have some flexibility in its schedule in case of rain delays. Koehn built a platform to carry a 5-gallon gas can just in case, since he will be traveling alone. Once Koehn arrives at his destina-

Koehn page 6

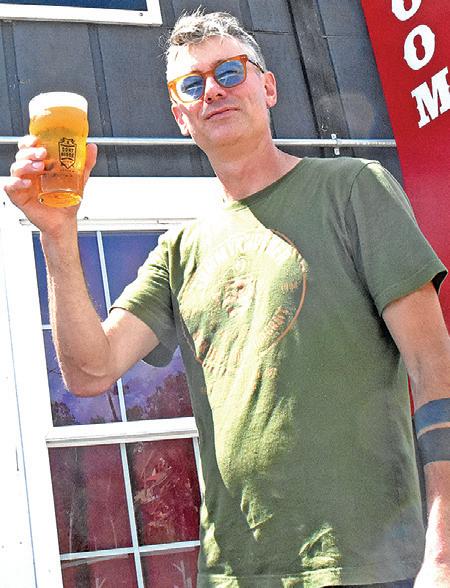

Mark

works on modifications to the tractor Aug. 14 at his home near Upsala. Koehn has added a canopy, cushioned seat,

and a spot to hold an extra gas

A sign hangs on the back of the camper Aug. 14 at Mark Koehn’s home near Upsala. Koehn purchased the camper for the trip and will take it on his solo journey from Minnesota to Texas.

tion, he and his tractor will be taking alternative transportation back to Minnesota.

“When I get there, I am selling the camper,” Koehn said. “Then I am going to line a trucker to haul the tractor back home, and I (will) fly or rent a car back to Minnesota.”

The 1940 Farmall M is a special tractor for Koehn as it belonged to his father.

“When my dad had an auction six years ago, I decided to buy it,” Koehn said. “It needed a lot of work,

but this is the tractor all my children learned to drive. I brought it to the Holdingford agriculture department, and they do an incredible job at restoring tractors.”

In preparation for the trip, Koehn made a few modifications to the tractor, such as adding a canopy and a new, cushioned seat with a seatbelt.

“The tractor is a 1940, and I will be 69 when I do the trip — so there will be 153 years of experience driving down the road,” Koehn said.

The trip has been on Koehn’s mind for 15 years, but he only started planning it last winter.

Koehn page 9

I have always enjoyed attending mass each weekend — well, as long as I can remember, anyway. I look forward to getting dressed up, seeing friends and family and listening to the word of God.

Growing up, I sang in the youth choir, helped with vacation Bible school and was an altar server for many years. As an adult, I participated in Bible studies and other programs.

Jason also values a strong faith. So naturally, we wanted to raise our family in the church. However, having three kids in church — with the oldest being three years old — can be quite distracting.

than I did going into Mass. I got to sit still and concentrate on one thing and one thing only. Like many things, going to church can turn into a mundane task when repeated frequently and when we are not experiencing the process properly.

The two older children are a lot better now than they were a year ago. Their attention span gets slightly longer with each year. About 50% of the time, they can keep themselves occupied for most of Mass by paging through books or playing with a toy they brought. The rest of the time, they are making faces at each other, climbing up and down the kneeler or crawling around in the pew. Our 5-month-old baby usually insists on eating at some point during mass, so Jason is on his own temporarily.

By Tiffany Klaphake

We are able to keep everyone in the pew and quiet, but there is a lot of movement within our pew as we juggle kids, books and shoes that never seem to stay on their feet. Even Jason and I end up shifting around, taking turns holding the kids or sitting between them.

We still plan on continuing to take our children to Mass every weekend, knowing full well they may or may not sit still. However, they will never learn to sit still unless we keep bringing them. We will continue teaching them about the importance of not just going to church but living a faith-filled life.

Not every time, but sometimes after church, as we are walking out, other people thank us for bringing our children to church. While we may have gotten a little annoyed with how the kids were behaving, it brought a smile to someone else’s face, seeing young kids in church. Whether it reminded them of their own kids or grandkids, they were glad to see such young faces in church.

The best way to teach a child what is right and wrong is by living it every day. Taking the time to pray and go to church now might not seem like it is accomplishing much, but in the long run, it will be more than worth it.

to in b to th w g th h

A couple weeks ago, Jason and I were going to go on a date night, so we got a babysitter for the kids, went to church on Saturday evening, then went out. It was so relaxing and meditative. I have gotten so used to only half-way paying attention to the Mass and half-way focusing on my kids. I forgot how fulfilling attending Mass can be.

When Mass was over, I actually felt more alert

While I cannot recall what my brothers or I were like in church when we were little, I’m sure it was very similar to our kids — just as it is a familiar scene to many families with young kids in church. Now that my siblings and I are all grown up, we are all still regular church-goers, and half of us have young kids who we bring to church.

The church, like any organization or group, needs young people involved to help it grow and continue. The church is the most important group we can belong to, and it is important that we pass that understanding onto the next generation.

Emilee Matich

Town: Osakis | Grade: 12

Parents: Patrick and Lynae Matich Osakis FFA Chapter

Tell us about your involvement in FFA. I am currently Osakis FFA’s chapter president. I have been involved in FFA since my seventh-grade year. I have been doing the horse evaluation career development event since I joined FFA. The past two years, I have joined the ag mechanics competition. I also help plan to set up events within the chapter. I was also a Minnesota ambassador at the state convention.

What has FFA taught you so far? Going out of my comfort zone and meeting new people. It has also helped me gain confidence in crowds and talk in front of them. It has helped me grow my leadership skills.

How do you intend to stay involved in agriculture after your FFA career? I plan on being a welder and opening my own mechanics shop with a service truck to help farmers and truck drivers 24 hours, six days a week.

What are you involved in outside of FFA? Band, work, racing pit crew, farming and being a mechanic.

What is one thing people need to know about agriculture? It is a lot more complicated than people think. It has a lot of ins and outs, and it basically is the backbone of our world. It is a good way to learn. A few of my friends and I have been working on a tractor — a John Deere B. It is our supervised agricultural experience project. It has taught us a lot of patience and ways to fix problems we wouldn’t have thought of before. I feel if people got more involved in agricultural things, the world would run much more smoothly as everyone would understand other people and their occupations.

BY RAE LANZRATH STAFF WRITER

WATKINS — Breeding cattle used to involve putting a bull in a pasture of cows and hoping to get good calves; today, breeding cattle can involve test tubes and science. While some producers continue to use the old-fashioned way of breeding, Bruce Schmitz has chosen to use science to his advantage at Back to the Roots farm.

Schmitz uses in vitro fertilization

to breed his purebred Highland cattle. IVF takes unfertilized embryos from a cow, which are then inseminated and placed in a recipient surrogate animal. This is done to get more offspring from high-quality animals.

“We can get 12 embryos from one cow per aspiration, which means we’ll get 6-8 calves from her at the same time instead of one calf per year,” Schmitz said.

Because of this style of breeding, Schmitz can find animals with specific traits and receive embryos or semen

from anywhere in the world. At any given time, Schmitz will have semen from up to 30 bulls in his barn. Semen from these bulls is frozen in liquid nitrogen to preserve it until it’s ready to be used; it’s then thawed and used to inseminate embryos.

Embryos are placed into surrogate cows; these cows carry the calves and care for them as if they were their own offspring. Schmitz is able to place a purebred Highland embryo into a surrogate cow of any breed.

breeding these animals; however, it’s not a foolproof system.

“You can have two calves with

exact same parents, and they couldn’t be more different,” Schmitz said. “It’s the same as humans.”

This type of breeding allows producers to grow their herds faster and focus on more specific traits. There are a lot of numbers and science behind Schmitz page 12

Schmitz weans his calves from their mothers when they reach 600 pounds and sells them. Because of their high-quality genetics, Schmitz’s calves are sold to farms all over the country. The calves coming from the farm are registered animals, meaning most of them will go on to become breeding stock or show animals, and some will become pets.

Highland cattle, originally from the Scottish Highlands, are known for their calm temperament and quality meat, which is why Bruce and his wife, Sam, purchased one Highland cow 8 years ago. Bruce and Sam wanted their three children, Josie, Hunter and Nikki, to have something to do and to have healthy meat to feed their family.

Along with their temperament, Highlands are also known for their horns. Sam found an interest in the horns and uses her artistic abilities to showcase them. Sam paints skulls of cows after they have been butchered to use as art.

“Their horns are just so beautiful,” Sam said.

After purchasing that one Highland cow for his kids, Bruce found a passion for cattle. With no formal education in genetics or animal science, he taught himself everything he knows. In 8 short years, Back to the Roots farm went from a hobby to a top-of-theline breeding operation.

In most cases, registered cattle are not used in production operations because of the high cost that comes with having these genetics. Registered animals are commonly used in breed shows, competing against other animals of the same breed to determine which animal has the most desirable genetics. Animals are judged on traits such as appearance, conformation and body structure.

“Numbers can tell you a lot, but you really don’t know what you have until you get into the show ring,” Schmitz said.

“Scottish Highlands are one of the oldest registered breeds out there,” Bruce said. “That’s where Back to the Roots came from and why we picked Highlands. We’re going back to our roots.”

The American Highland Cattle Association has a national show and sale in Denver, Colorado every year. This show is the biggest Highland cattle competition in the United States — the goal for producers is to get their cattle into this show. Back to the Roots farm has shown animals in this competition multiple times.

Nikki, Bruce’s youngest daughter, shows the cattle in Minnesota, Nebraska and Colorado.

“Being in the show ring gives you a lot of perspective on how you can improve your animals,” Nikki said. “Each judge is different and has different opinions.”

If an animal wins in a show, that animal’s genetics become highly sought-after. Shows such as these are where producers like Bruce find animals with traits they want to introduce into their herds.

Back to the Roots farm is home to 42 cattle, most of which are Highlands. Recently, Bruce has purchased 12 purebred Wagyu calves, which will be used to breed high-quality production animals.

Raising Wagyu is different for Bruce than raising Highlands. Wagyu are being bred for production traits such as muscle mass, udder quality and birthing ease, whereas the Highlands are being bred for show traits. Purebred Wagyu provides excellent flavor and marbling in

its meat, Bruce said, and because of this, the price of Wagyu is much higher than other beef.

Bruce is using the same IVF breeding method in his Wagyu cattle as he does in his Highlands. He imported inseminated Wagyu embryos from Japan, where Wagyu is most popular, and implanted them into local surrogate cows. By doing this, Bruce is able to have purebred Wagyu, whereas most local producers have crossbred Wagyu with other beef breeds.

Back to the Roots farm uses modern science to breed the best quality animals they can. Things may have changed since the days of putting a bull in a pasture, but one thing that will never change is the hope of good calves.

“We’re always watching our cattle (and) figuring out how to be better,” Bruce said.

With the large amounts of rainfall

BY HAILEY HOKANSON | STAFF INTERN

—

Nestled in the heart of Minnesota, there’s a family farm full of almost any vegetable imaginable. The 340acre farm is hidden between back roads and wooded areas, but the name and brand is easily recognizable for those in central Minnesota.

The Thorsons have been calling this land home for more than 50 years, and while the operation has changed, the family’s hard work and dedication stay the same.

“It’s changed and evolved over the

years, but there are still plenty of things to do around here,” said Erik Thorson, current operator of the farm. “There’s a lot of farms around here that have come and gone, but we’re still here.”

The farm first began across the road with Erik’s father, Mike, in 1972 as a traditional crop farm with dairy calves and crops. After a while, they bought the current property and raised 150 sows

Three generations of Thorsons, Christian (from left), Erik and Mike, stand by the Thorson’s produce trailer Aug. 14 at the Thorson farm near Browerville. Mike started the operation in 1972 and has since passed it on to his son, Erik , who gets help from his son, Christian.

farrow to finish while also growing corn and soybeans.

And then the chickens came.

“We wanted to diversify, so we

started raising chickens,” Erik said. “There was a state exemption that allowed you to raise 20,000 chickens on your farm and process them as long as you sold them yourself. So, we processed 20,000 of those for 20 years.”

They sold the chickens at farmers markets, but after a while, they

The Thorson’s produce market awaits customers Aug. 14 at its permanent location in Long Prairie. The Thorsons sell their produce at local farmers markets but also have two farmstand locations — one in Long Prairie and one in Park Rapids.

realized they could be selling something else too — vegetables.

They began by growing squash to sell in the fall alongside the chickens and kept that operation going for a few years until the time came to fully transition the business.

The Thorsons have now been in the vegetable business for 30 years, gradually phasing out the chickens.

“It’s been good for us (to do the vegetables), and since we don’t need to worry about animals anymore, Dad rents out the duration of the farmland to other folks,” Erik said. “So now we

just focus on vegetable production.”

There are 17 acres under cultivation for vegetables, including greenhouses, high tunnels, hoop houses and transplants.

But perhaps the most unique part of the operation is the way they sell their produce. Aside from selling at farmers markets, they also have two farmstand sale locations: Thorson’s Farm Market in Long Prairie and Thorson’s Dorset Stand in Park Rapids.

Thorsons page 16

An employee restocks fresh produce at Thorson’s Farm Market Aug. 14 in Long Prairie. Mike Thorson decided to build the permanent market in Long Prairie more than 15 years ago.

“It’s good people know you’re there every day at a certain time, and they can expect you there,” Erik said. “Since we have a permanent shelter at the Long Prairie location, it doesn’t require a lot of set up, and we know what the locals typically enjoy.”

They opened the permanent location 20 years ago after Mike got tired of traveling to sell his products.

“We were going to the Minneapolis farmers market for many years, and it was just a lot of driv-

ing and going there, so we thought it was better to cultivate and develop the local market,” Mike said. “We’ve always had a nice presence in the area, so that’s why we bought the small land in town and built the market.”

Besides their farmstands, they also sell products weekly at farmers markets in St. Cloud and the Brainerd Lakes area. Sales vary based on location, but the produce is the same regardless of where they are selling from. They use trucks and specialty trail-

Thorsons page 17

(Above, top) Newly planted sprouts begin to peak through the ground Aug. 14 at the Thorson’s farm near Browerville. Produce is consistently planted from the beginning of the growing season in early March until the season ends in October.

(Above, bottom) Heads of lettuce and romaine rest in 50-gallon barrels Aug. 14 on the Thorson farm near Browerville. The family uses scarecrows and fences to keep out hungry deer during the growing season.

BY EMILY BRETH STAFF WRITER

SAUK CENTRE — A variety of critters — from cats and cows to artic foxes — can be found at J2Z Ranch & Exotics under the care of Joe Zimmerman and his mom, Julie Zimmerman.

“We raise a lot of animals for zoos,” Joe said. “We are starting to get into pasture animals like miniature highlanders and emus.”

Joe’s favorite part of raising animals is the wide range they have the opportunity to see.

“If the zoo gets overrun with babies, they will call us to help take care of them,” Joe said. “That is what I like the best. We might not get to keep them, but we get to see a big variety.”

But some animals have made J2Z their permanent home.

“All our adults have come from USDA (U.S. Department of Agriculture) licensed zoos,” Joe said. “We also get calls from the Department

of Natural Resources to take in animals.”

To care for these animals, the Zimmermans have received their licenses from both the Minnesota Department of Natural Resources and USDA.

According to the USDA Animal and Plant Health Inspection Service, the location where exotic animals stay must pass a pre-license inspection. Site owners are given a 60-day period to have their facility meet the qualifications needed for a license. In this time frame, the inspector is allowed up to three visits.

page 20

• 1 package (2 pounds) frozen hash brown potatoes

• 1 can cream of chicken soup

• 1/2 cup margarine or butter, melted

• 1 medium onion, chopped

• 1 cup shredded cheddar cheese

• 1 cup sour cream

• Salt and pepper to taste

Mix all ingredients in a buttered, 9-by-13 pan and bake at 300 degrees for one hour. Serves 10-12 people.

Mix first three ingredients together. Add grapes. Place in 9-by-13 pan.

• 2 cups flour

• 1 1/2 cups quick or old-fashioned oats

• 1/4 cup packed brown sugar

• 1 cup butter or margarine, softened

• 2 cups white chocolate morsels

• 1 8-ounce pack cream cheese, softened

• 1 14-ounce can sweetened condensed milk

• 1/4 cup lemon juice

• 1 teaspoon vanilla

• 1 16-ounce can cranberry sauce

• 2 tablespoons cornstarch

Preheat oven to 350 degrees. Grease 9-by-13 baking pan. Combine flour, oats and brown sugar in a large bowl. Add butter and mix until crumbly. Stir in morsels and reserve 2 1/2 cups of the morsel mixture for topping. With floured fingers, press remaining mixture into prepared pan. Beat cream cheese in large mixing bowl until creamy. Add sweetened condensed milk, lemon juice and vanilla; mix until smooth. Pour over crust. Combine cranberry sauce and cornstarch in medium bowl; spoon over cream cheese mixture and sprinkle reserved morsel mixture over cranberry mixture. Bake 35-40 minutes or until center is set. Cool completely in pan on wire rack. Cover and refrigerate until serving time.

Mix and spread topping over coated grapes. Cover with foil and let refrigerate overnight before serving.

Pour rhubarb, sugar and gelatin in a 9-by-13 pan. Add yellow cake mix, butter and water on top of rhubarb mixture. Bake at 350 degrees for 45-50 minutes.

Mix these two ingredients together; pour over pretzels in a large bowl. Stir well. Pour pretzels in two cake pans; stir every 15-20 minutes until liquid is absorbed, about 1 hour. Put in covered container or zip-close bags.

BY BEN SONNEK STAFF WRITER

NEW LONDON — Throughout his life, Joshua Reed has tended to the earth and the water. He has not stopped doing so with his latest and favorite business, Goat Ridge Brewing, situated next to the clear headwaters of the Middle Fork Crow River in New London. Not only did Reed found the nearly decade-old brewery and taproom with the land in mind, but he is also proud of how it has contributed to the growth and revitalization of his community.

“When I was working for the watershed, I was balancing water quality with the lake systems and helping improve water quality, and you’re dealing with water quantity with the farm,” Reed said. “Whatever the project, one of these groups was (mad) at me, but if you take

the water and turn it into beer, everybody’s happy. I don’t look back at all.”

Reed was raised west of Brooten, where his family still has an Angus ranch. It was through ranching that he picked up a love for nature and conservation.

After graduating from high school and attending college for a time, Reed headed west to Colorado around 1992 to learn snowboarding.

“I got involved in that recreational western mountain culture,” Reed said. “That was the last renaissance of brewing when brew pubs were popping up, and there were a lot of breweries in that part of the country.”

Eventually, Reed moved to Washington where the recreation and brewing

Reed page 26

At 25-35% kernel moisture, we can achieve 100% kernel fracturing. We can grind at a rate of about 2,700 bushels per hour, and we will work around the clock to get the job done! We can also utilize a Dohrect Enject Applicator, which is designed to apply water soluble inoculants in a concentrated form.

from page 25

culture thrived. He lived in Olympia, Washington, for several years. One of his employers did homebrewing out of his garage, so Reed would help him with that. After earning his degrees in natural resource management and geographic information systems in Bellingham, Washington, he moved to Minneapolis and brewed sporadically over the years.

Reed and his wife, Christa, would later move to the New London area and buy her family’s original homestead.

“The old-timers called it Goat Ridge, ‘Geiteryggen’ in Norwegian,” Reed said. “It’s all Scandinavian, Norwegian and Swedish settlers out there. It’s an offshoot of the main glacier ridge that runs through the country. I was homebrewing out there and started growing hops … and sold those to home brewers.”

Reed also volunteered at breweries in the Twin Cities to learn more about the industry. He also worked on native plant management and later as a watershed administrator for the North Fork Crow River, keep-

ing the goal of his own brewery in the back of his mind. Then, in 2011, the Minnesota legislature passed the Surly Bill, allowing breweries in the state to sell alcohol at their establishments, and brewery tap rooms took off in popularity.

Around the same time, New London began a renaissance of its own, growing its arts and business communities. The Reeds had been debating whether to go back to the Pacific Northwest when a property at 17 Central Avenue West came on the market, and Reed saw that as the perfect place to start his own brewery and taproom. The Reeds opened Goat Ridge Brewing to the public in 2015.

“Most people said

(this brewery) would never work in a town of a thousand people,” Reed said. “(However,) craft brewing was starting to take off in the Midwest, so once I decided to do that, I was pretty deliberate about deciding to involve the community and businesses. … Everybody was excited about it, needing a place with beer and so many people around, it kind of became a community center.”

Goat Ridge Brewing does what it can to support other local businesses, including using raw honey from the Glacier Ridge area in some of their products. They also partnered with

Reed page 27

a New London co-op to use Kernza, part of their effort to bring awareness to the perennial grain.

The brewery has hosted art openings for nearby artists and presented area bands and musicians.

When Reed is traveling to beer festivals and other events, he promotes New London and what it has to offer.

“We’re always talking about New London, the arts, the shopping, the river and the fishing,” Reed said. “The more we can bring to town, it complements other businesses, and it all helps us. The big thing from the get-go was to involve the community … and show a lot of people it’s come a long way.”

The community has given back to Goat Ridge Brewing as well. When the brewery was getting started, Bill Gossman, a potter and the mayor of New London at the time, made some ceramic growler-style bottles with wooden carriers, and they were used for a brewery crowdsourcing promotion. Reed still has a carrier with those bottles at the bar.

The Goat Ridge Brewing building has expanded over its near-decade of operation, sometimes incorporating wood and materials from the Goat Ridge Farm. One of their most recent expansions, added in 2019, currently

houses a kitchen with a brick pizza oven that serves pizzas, street tacos, nachos and more.

Goat Ridge Brewing makes a range of brews, including 15-17 beers on tap, as well as seltzers and ciders. Their annual output is usually about 1,500 gallons. Reed prefers making lagers and traditional beers, avoiding gimmicks like putting donuts or cereal in the drinks.

“I’m old-school,” Reed said. “We do a lot of lagers, which a lot of breweries don’t. They take a little more time and are a little more intricate to do. … We have to have a little of everything for people, so we do sours, IPAs (India pale ales) (and) half a dozen flagship beers we always have on tap, and some of those are seasonal.”

When Goat Ridge is not using their own hops, they typically draw from Minnesotan and Midwestern varieties. Depending on the style of beer, though, they will sometimes get hops from New Zealand, Germany

and other locations. Their seasonal beers are typically German.

Overall, Reed has much he loves about Goat Ridge Brewing: the road that took him here, the inspiration he hopes it gives his children, the new people he meets and the repeat customers he welcomes back. He makes a note of how the taproom has no TVs on the walls, further bringing people together around

beer taps, is parked outside Goat Ridge Brewing July 8 in New London. The Goat Ridge name comes from the name of Christa Reed’s family homestead.

beer and conversation.

“We’ve had weddings here, we’ve had funerals here, we’ve had a little of everything here, and it’s kind of a home to people,” Reed said. “There’s a lot of pride in building community. … I threw everything at this place and had to make it work, and it was tough, but it worked.”