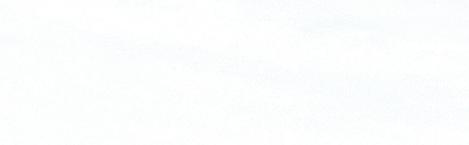

A semi-trailer serves as the cheese processing facility at Little Red Dairy near Theilman. The Millers purchased the trailer from a family who decided to stop processing cheese on their own farm.

A semi-trailer serves as the cheese processing facility at Little Red Dairy near Theilman. The Millers purchased the trailer from a family who decided to stop processing cheese on their own farm.

THEILMAN – The Miller family wheeled an ongoing adventure onto their property in 2018. A semi-trailer stands monumental as their on-farm creamery where they specialize in making cheese curds for local

establishments and customers.

The semi-trailer is armed with anything a person would need to make cheese. Alan Miller said it is called “cheese on wheels” by a company in Wisconsin.

“It’s probably one of the most unique things about our farm,” Miller said. “It was a more affordable way for us to start making cheese on our farm.”

Miller milks 250 cows and farms 500 acres of cropland with his father, Bill Miller.

while raising their four children – Eva, Karl, Cade and Rhett. Eva’s silhouette serves as the logo for the business with her distinct red locks playing into the name.

“It was Eva’s first birthday when we made our first official batch of cheese curds,” Miller said. “That was about four and a half years ago.”

The idea to start processing their milk for cheese started on Alan and Emily’s honeymoon to Alaska in 2016. During their trip they visited one of two Alaskan dairy farms.

Cows eat a TMR ration at the Millers’ dairy farm near Theilman. The Millers are milking 250 cows and farming 500 acres with the help of a few employees.

Alan and his wife, Emily, run Little Red Dairy, an onfarm cheese business,

Due to Alaska not having any creameries, the farms have their own processing facilities. The Millers’ honeymoon trip inspired their on-farm creamery, and Alan got to work learning about cheese with the “Complete Idiot’s Guide to Cheesemaking.” He started in the kitchen of their home until he felt comfortable expanding that new-found skill.

“We thought of building a facility to start making cheese, but we would have gone broke,” Miller said. “The semi-trailer was purchased from a family that had done what we were about to start doing, and (the trailer) continues to serve us well to this day. Before we take a step to a permanent facility, we would like to pay down

what it costed us to get up and running as well as transition further into the family farm.”

The creamery was a way for the Millers to diversify their farm, adding value to the cattle they had in the barn.

Millers page 2

NEWS STAFF

Mark Klaphake, Editor, mark.k@dairystar.com

Grace Jeurissen, Editor, grace.j@star-pub.com

Amy Kyllo, Writer, amy.k@star-pub.com

Tiffany Klaphake, Writer, tiffany.k@dairystar.com

Jan Lefebvre, Writer, jan.l@star-pub.com

Ben Sonnek, Writer, ben.s@saukherald.com

Sarah Colburn, Staff Writer

Story ideas send to: grace.j@star-pub.com, mark.k@dairystar.com

SALES STAFF

Laura Seljan, 507-350-2217, laura.s@dairystar.com

Julia Mullenbach, 507-438-7739, julia.m@star-pub.com

Missy Traeger, 320-291-9899, missy@saukherald.com

Tim Vos, 320-492-6987, tim.v@star-pub.com

Mike Schafer, 320-894-7825, mike.s@dairystar.com

Warren Stone, 320-249-9182, warren@star-pub.com

Jaime Ostendorf, 320-309-1988, Jaime@star-pub.com

Bob Leukam, 320-260-1248, bob.l@star-pub.com

PRODUCTION STAFF

Pat Turner | Amanda Thooft | Nancy Powell

Maddy Peterson | Cheyenne Carlson

Karen Knoblach | Annika Gunderson

ISSN

Any milk not used for their creamery is shipped to Plainview Milk Products.

Miller uses a stainless steel tote to transport milk from the bulk tank to the trailer. From there the milk is added to the pasteurizer. They can then start making curds. Miller said the cheese curds were their starting point being the cash turnaround time was quicker than with block cheese.

Little Red Dairy makes nine flavors of cheese curds and does block cheddar cheese for their cheese boxes. They also work with a local meat processor to make summer sausage, pepper sticks and brats that can also be sold to accompany the cheese.

Deadlines:

Country Acres will be published the first and third Saturday of every month. Deadline for news and advertising is the Thursday before publication.

“Committed to being the eyes and ears of our communities.”

They have participated in fundraising for the local FFA chapters; FFA members sold their cheese boxes. Miller said this was a great way for the creamery to get their name to different potential customers in the area as well as support a great youth organization.

ST ROne of the challenges the Millers found once starting to make cheese was getting their name out to customers. They packed up their products

every week to attend local farmers markets. From there, their name grew, and today their cheese is included on the menus at a number of local restaurants and on the shelves of several grocery stores.

On average the Mill-

ers are processing 1,000 lbs. of cheese each week.

“I have a lot of respect for other people direct marketing their farm products,” Miller said. “I think any time we can spend an extra dollar for a local prod-

uct from an area farmer, the better that is for our communities. There is a lot of work and passion that goes into making, growing and marketing products.”

Millers page 3

Millers from page 2

Miller has a full schedule; he often gets up early to start the cheese making process, which usually takes place Tuesday and Friday of each week. Once milking time rolls around, a full-time employee takes his spot in the creamery and he heads to the barn to tend to free stall cleaning, feeding, among other farm tasks.

“I like the cows; they are my favorite part of the farm,” Miller said. “With my schedule now, I don’t get to do much milking, but I’ve always enjoyed that part of dairy farming.”

There are three farm employees that are assets to the success of the Mill-

er’s farm. Though farming changes with the seasons, Miller said he can count on his help to keep the farm moving forward. Cows on the farm are milked twice a day in a double-8 herringbone parlor. Once they are finished in the parlor, the cows have access to free stalls with mattresses and sawdust and a 24-hour buffet of TMR

feed that is pushed up several times a day.

Though they don’t milk the largest number of cows in the county, the Millers like their herd size. For them, bigger isn’t necessarily better. Miller said their philosophy is to do the best with what they have. They like to focus on cow comfort and high-quality milk.

Miller owns half of the herd of cows currently, and as his dad transitions out, he will purchase the other half of the herd. The family works together to accomplish everything from barn chores and field work to packaging cheese.

“I’m hoping the cheese making can help solidify the farm’s future,” Miller said. “I want my kids to grow up here and be involved in agriculture if they choose.”

They started small, and as the business grows, they will grow with it. For now, the Millers are making the best of their farm’s milk by making a product many of their customers have come to love.

I’m not saying this for certain, but maybe somewhere down the family tree my great-great-great-grandma was hexed by a witch and it miraculously skipped several generations until it landed on me.

I don’t have scientific proof to show that I’m the reason central Minnesota gets snow every two weeks, but it certainly seems like the weather follows me from home and rests on the streets of Sauk Centre every other Tuesday night into Wednesday morning when I need to travel there as part of my job at Country Acres.

I would like to preface that my first suspicion of the weather phenomenon was in 2021. While most of central Minnesota was dryer than a bone in the peak summer months, our farm was graciously swept with steady rains and a bumper crop year for hay making. Looking back at last summer, while my place of residence was Sauk Centre, nearly every two weeks or so Sauk Centre saw lush rains and even several areas with flash flood warnings. During that time our family farm saw a cloud cover the sun a few afternoons but never any rains worth bragging about.

This winter, however, we’ve received more snow than I’ve seen for at least 6 years.

Here is where the phenomenon lies: every two weeks I venture two hours north to lovely Sauk Centre for putting together Country Acres in the office.

I love to visit and brainstorm with co-workers during the day and a half I’m in the office, but somehow it seems, every

time I’m in the office, a snowstorm weasels its way magically into the weather forecast for the day.

These aren’t small snow storms either. In fact, the week of March 1, I was in the office Tuesday but needed to head home that evening to cover milking for my parents on Wednesday. Before I left Tuesday, several people mentioned that once again there was a storm in the forecast when I was visiting town.

I guess I have to leave my mark on the town somehow.

Sure enough, Wednesday morning one of the production team was stuck in Alexandria due to a large snowstorm system sweeping across the I-94 interstate area. We luckily were able to lay out the paper despite that challenge, but thoughts of my strange weather connection made me feel a bit guilty.

If I really am a harbinger of poor winter weather, I apologize to those of you who were stuck in drifts, ditches and driveways. On the other hand, many school children are lucky for the number of late starts and snow days I brought with me.

I like to take a positive approach to these situations and say we will have plenty of moisture once spring planting starts. With that being said, a wet spring means we may have found a way to make the pontoon tax deductible.

Nonetheless, wherever I go, the weather seems to follow. Hopefully, my presence on the farm this summer will bring flourishing corn and thick alfalfa stands.

MONDAY 8:00 am Overnight market cows/bulls 10:00 am Fed cattle, followed by day-delivered market cows & bulls

1:00 pm Dairy cattle, stock cows & breeding bulls followed by feeder cattle

4:00 pm Baby calves, arena 2

TUESDAY 8:00 am Sheep and goats 11:00 am Feeder pigs

WEDNESDAY 10:00 am Hog/Sow/Boar Auction

2:00 pm Fed cattle, followed by market cows and bulls

THURSDAY 10:00 am Special feeder cattle auctions, September - April

FRIDAY Closed Office open 8:00 am – Noon

YARD HOURS

Sunday Noon – 10pm

Monday 6am – 10pm

Tuesday 6am – 10pm

Wednesday 6am – 4pm (Open until 10pm, preceding special Thursday sales ONLY)

Thursday 6am – 4pm

Friday 6am – Noon

Saturday By Appointment

from page 6

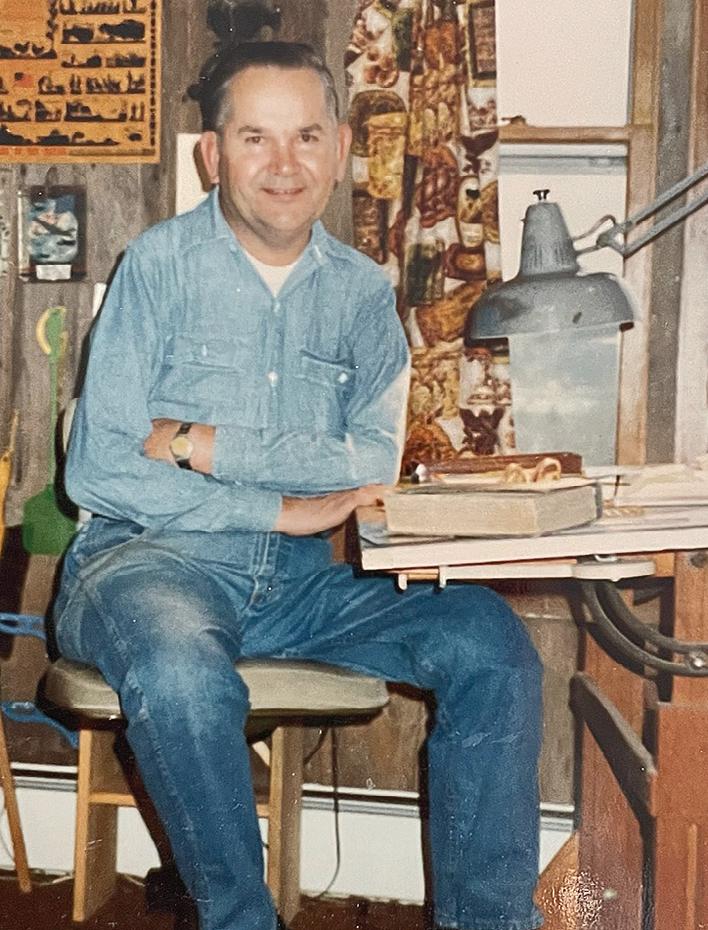

Bernard spent time in an iron lung. In the manuscript of his unpublished book, “Life – One Step at a Time,” he described the iron lung as “the big green monster.” He was in

the hospital for nearly a year.

While in the hospital, Bernard got lessons and assistance in oil painting from Dr. Lay

and Mrs. John Shellito, according to Belva Du Mez Bernard in her book, “Research History of Pleasant Grove Township.”

Belva Du Mez said the disease that changed his life also uncovered incredible talent.

“He has a pre-eminent artistic aptitude that might never have been realized had not polio changed his life’s career,” she said.

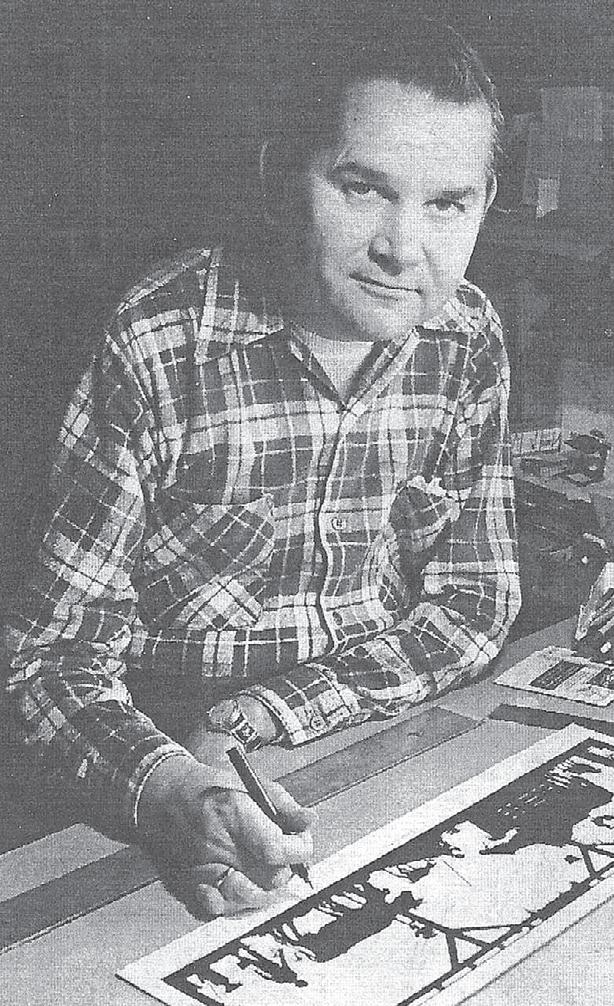

Bernard himself recalls his report card from his last year in grade school in Cynthia Lueck Sowden’s 2006 article “Harvey Bernard: Shadows of the Past.”

“I had straight Cs in behavior and straight As in art,” Bernard said. “After I got polio, all I could do was sit and draw.”

His full-time career in art did not develop until the middle of his life. In 1956, Dave Griggs gave him a job at Ability Building Center putting form lines onto index cards. Bernard describes his work in the manuscript for his book.

Bernard page 9

“It was as close to artwork as we could get,” he said. While at ABC, Bernard was enrolled in a correspondence art class which helped him develop as an artist.

In the late 1960s, Bernard and Griggs started a new business together called Hiawatha Graphics which was a silk-screening business. Bernard remained at Hiawatha until the 1970s when his art became his livelihood.

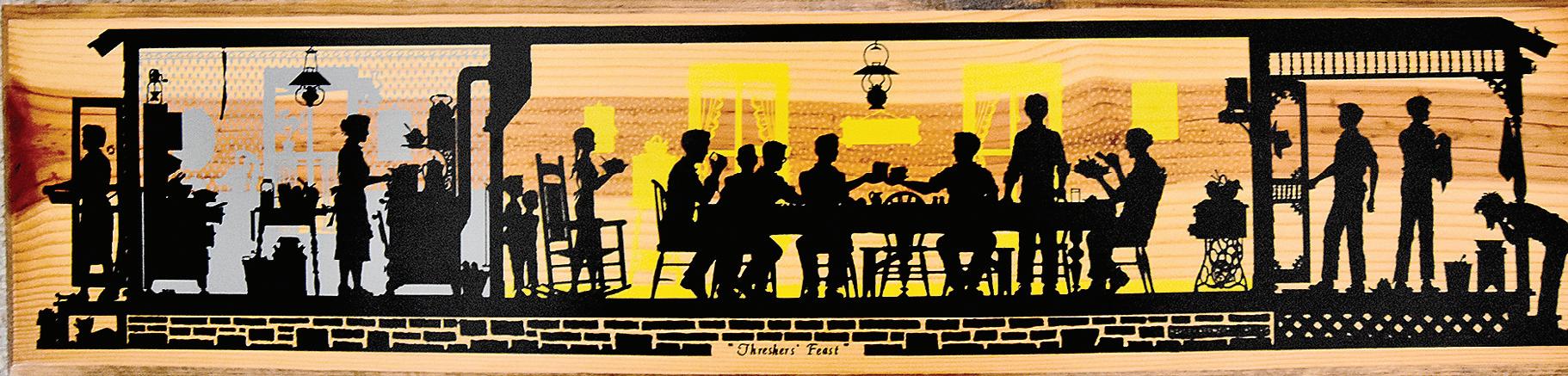

One of the pieces that launched his career was “Steam and Chaff,” a wooden plaque with a silkscreened threshing scene on it. According to Sowden’s article, Bernard entered an oil painting and this plaque at the University of Minnesota’s southeastern art show at the Apache Mall in Rochester where both pieces placed, and Bernard sold 14 wooden plaques within one hour.

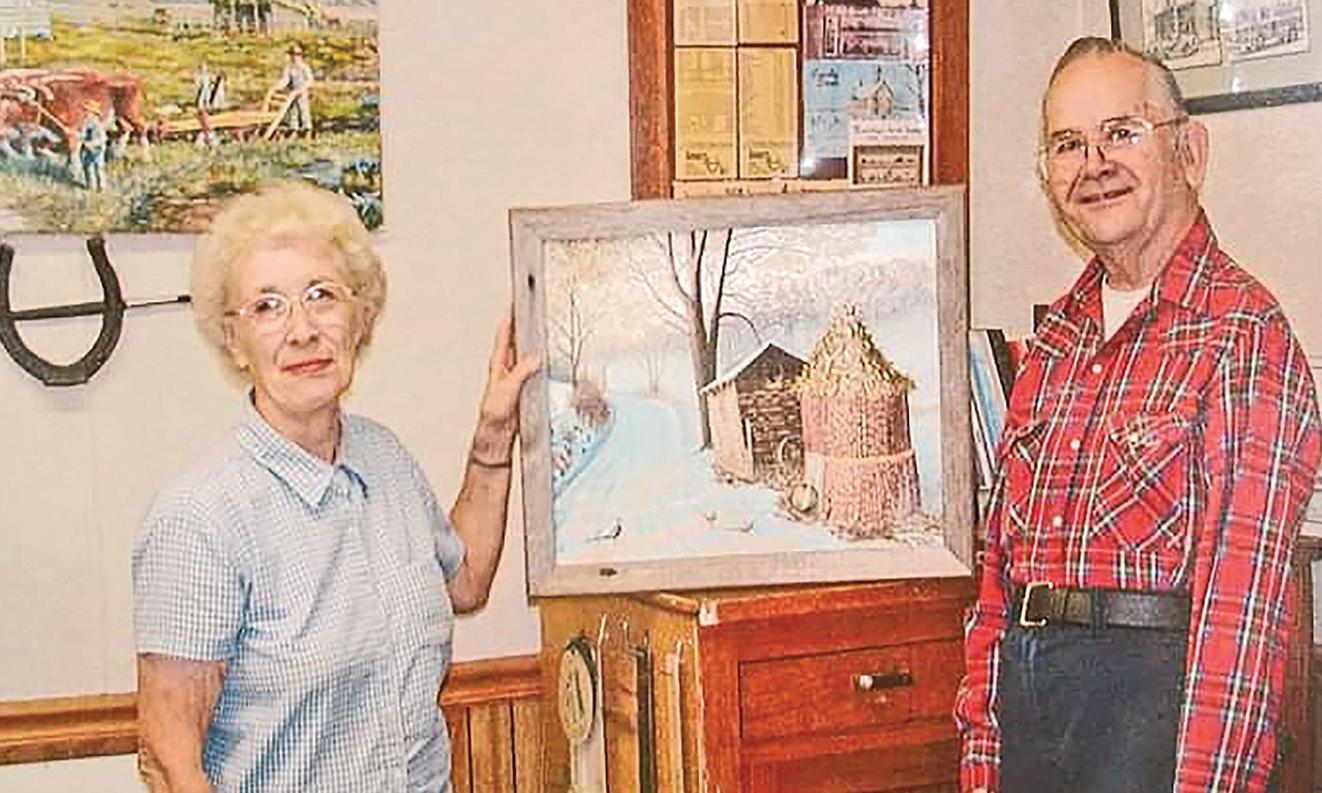

Bernard and Doris sold the majority of his artwork at steam or threshing shows, going to more and more shows as his work gained popularity. They attended shows from the 1960s to 2006. They traveled to Montana, South Dakota, Iowa, Wisconsin, Arkansas and the Ozarks. Even with many miles to travel, they always took the scenic route. They even had a booth at the Minnesota State Fair for many years. The best show they attended was Midwest Old Threshers Reunion in Mount Pleasant, Iowa, which they attended from the mid 1970s until 2006.

Bernard’s children – Harvey, Donna and Darla – went on the road with them. Harvey and Donna were in their teens, and Darla was about 6 years old for the first shows.

“It was like a little mini vacation for me because I was just a little kid,” Darla said.

Donna said storing the money that came in was something they had to do at these shows before the dawn of electronic payments.

“He used to tell me I’d have to take all the cash and stuff it in my boots, because it was like cash and checks,” Donna said. “There (were) no credit cards at that point yet.”

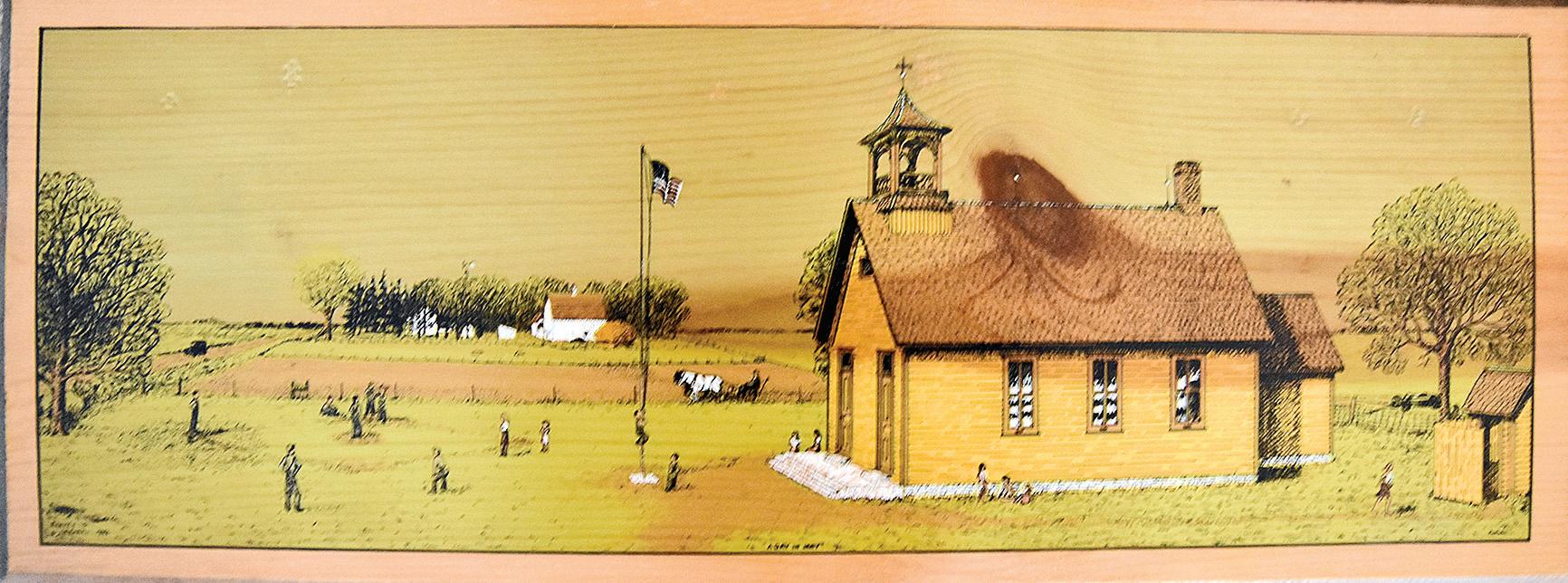

In 1981, Bernard moved the Bernard country school house that he had attended out of Pleasant Grove Township and over to his home near Chatfield where he turned it into his Country Art gallery. In the busiest years of his business, there would be tour busses that stopped. Even Bud Grant, former head coach for the Minnesota Vikings, stopped.

His artwork, though it depicts a different rural time and place, has a timeless quality that echoes today. The tagline of his Country Art gallery, “Where art and memories mix,” is a fitting description of his art. The school house stands today but is no longer a gallery.

One of his popular pieces, a pen and ink entitled “Forenoon Fisherman” done in 1985, shows a barn

scene with a little boy shing in a stream that goes underneath a stone bridge. This bridge, located on a farm near Highway 52 and County Road 7 in Olmsted County, stands today although the barn is no longer in existence.

Darla said many of those who enjoyed her father’s art never realized he created with a disability.

“They didn’t know he had only partial use of one arm,” Darla said. “When they find out the story behind it, then the artwork means even more to them.”

In spite of polio changing the trajectory of his life, Bernard never felt sorry for himself. For his daughters, their father is an inspiration of perseverance and grit.

“To me, Dad didn’t have a disability,” Darla said. “He made the best of what he had.”

Both daughters were inspired by their dad to go into their professions. Donna is a nurse, and Darla works as a special education teacher.

Bernard stopped production of his work in 2003 but continued to sell inventory for the next several years. The family held an auction to sell the remaining inventory after their parents’ death, although Donna and Darla have extra prints stored in their homes.

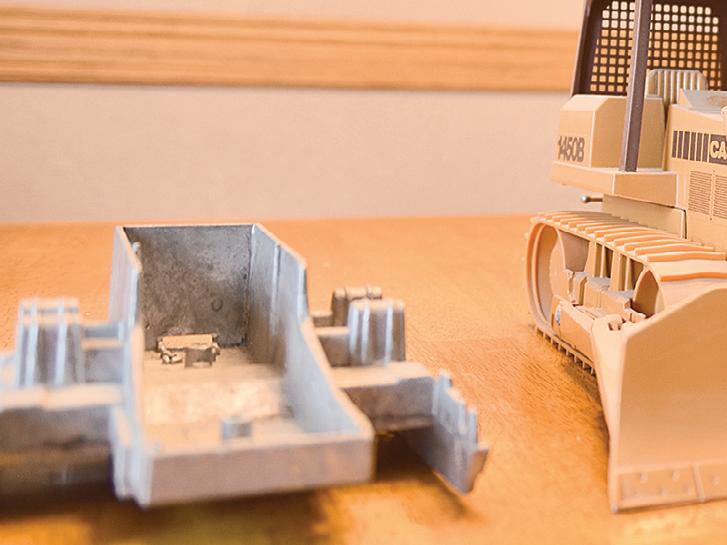

KENYON – Mike and Penny Priebe stand united in their enjoyment and mastery of their crafts. Mike is a former mold maker of replica toy farm equipment who became an organic crop farmer, and Penny is a former intensive care unit nurse who is an avid quilter.

The Priebes live and farm near Kenyon. Mike and Penny both grew up on farms; Mike is from Iowa, and Penny was raised in Kansas.

Though their jobs and hobbies are quite different, they share common threads. Each tie into Mike’s and Penny’s backgrounds, each brings them joy, and finally, each provides them a challenge to excel in.

Penny learned sewing from her mom who taught her when she was preschool age.

“I learned to sew sitting on a Sears and Roebuck catalog because I wasn’t tall enough to sit up to see the machine,” Penny said.

Penny started quilting

as an adult. This past year, she quilted $3,000 in cloth and supplies. Penny does not have a specific favorite pattern but instead loves trying all types of patterns.

Penny has been donating most of her quilting projects to charity for the last 15 years. She gives them to organizations like the Ronald McDonald House Charities and the American Cancer Society.

Penny has a simple reason for why she quilts.

“I just like to do it,” she said.

Mike said overcoming difficulty and working toward excellence are the traits he sees in Penny’s quilting.

“There’s a challenge there,” he said. “I know that. It’s written all over her. … How good a job she can do and how well she could match the colors.”

Penny owns four sewing machines. Her favorite machine is a Singer 221 Featherweight from the 1950s.

Priebes page 11

from page 10

She said it makes the best stitch of any machine today. The Singer is all mechanical. Penny said this means she can fix almost any problem by cleaning, using a screwdriver or oil, or putting in a new needle.

Penny has gained mastery over her craft. She said she has been quilting long enough that when she looks at new quilts, she usually can understand how they were made.

Penny networks with quilters at quilt retreats once or twice a year. She said these events give quilters the opportunity to get help and share ideas.

Penny taught her children to sew, although none of them quilt.

Mike, who is semi-retired, has been farming organically since 1997. He has farmed with his son, Brent, since 2008. Brent farms part time in addition to working as a construction foreman.

The Priebes raise corn, soybean, oat and alfalfa in a four-year rotation on two farms. For Mike, his biggest farming success has come from having excellent crop production using an organic method.

“I have proved to a lot of people that you can raise real good crops and you can keep them clean

without spray and without commercial fertilizer,” Mike said. “A lot of people laughed at me when we started doing this.”

Mike and Penny have noticed an interesting phenomenon when it comes to wildlife pressure on their organic crops. Mike said a neighboring conventional corn field is separated by only a few feet, and he has witnessed his corn cobs being eaten by wildlife while the neighboring corn field was left alone.

Mike and Brent are second- and third-generation organic farmers, respectively. Mike said his father was one of the first organic farmers in Iowa. Mike is ready to pass on the farming legacy to a fourth generation in his grandchildren, if they so choose.

“I have two grandsons coming up,” he said. “My goal is if they are interested, … I’ll be here to help them and guide them a little bit. If they’re not interested, well then that’s OK too.”

For Mike, farming has always been a core part of his identity.

“I’ve had the farm in my blood since day No. 1,” he said.

Like his wife with quilting, Mike enjoys his farming craft and the challenge of striving for excellence.

“I love it,” he said. “I just like to see how good a job I can do.”

Before farming, Mike was a toymaker, making the molds for replica tractors and machinery.

Mike went into making molds after working in a die casting shop operating a mold. There, he observed mold makers and realized he was interested in the trade. Penny was supportive, and they decided to send Mike through school.

Mike went to college for tool and die at the then

Hawkeye Institute of Technology in Waterloo, Iowa.

Mike made toy replica molds for about 24 years. His first mold was a John Deere combine. He said that mold took around 700 hours to complete. The hours spent on a mold vary, with some projects taking less than 200 hours.

The mold makers received patterns as well as blueprints of the machine to work with in creating the

mold. He would take photos of the actual machine if he could find one to help add detail.

Once complete and in production, the molds could make two castings per minute. A mold used continuously can create around half a million parts over its lifetime. If the mold is not used continuously, they can make half of that number in their lifetime because of the stress the mold

goes through from starting and stopping.

The molds are made from steel and are filled with aluminum to create the parts. The molds are filled at around 3,500 pounds of pressure.

One of the most difficult parts of making a mold is that everything has to be done backward.

Priebes page 12

50 Center Ave. S. • Elgin, MN • 507-876-2122

beckimplementinc@gmail.com

First Southeast Bank in Harmony and Canton is seeking a detail oriented team member for a full-time customer service representative position.

The qualified candidate will contribute to the success and growth of First Southeast Bank by providing support in both the deposit and loan operations, processing support, file maintenance, teller responsibilities and assistance to lending staff. The position would be M-F and include every third Saturday 8:15 a.m.-12:15 p.m. Applicant must possess excellent organizational and communications skills along with being accountable, self-motivated, and professional, with the ability to adapt. Experience in Banking with strong computer knowledge preferred. First Southeast Bank offers an exceptional benefit package and a competitive wage.

Please apply at: First Southeast Bank, 3 Main Ave North, PO Box 429, Harmony MN 55939

Attention: Debra A. Dowe Skaalen, Director of Human Resources

firstsoutheastbank.com

“I got where I could not write on paper,” Mike said. “I didn’t know the difference between forward and backward because I did so much stuff in reverse on the molds.”

Mike became an expert mold maker.

“Toward the end, … if I couldn’t do it, we didn’t get the job,” he said.

One piece that Mike helped make has a special story. The John Deere 3010 had an intentional error added to it by Ertl af-

CZMarch18-1B-JM

ter he made it. The tractor looks like a gas replica on one side and like a diesel replica on the other side.

Mike said this error was added to make it a collector’s item.

“I called them on it, and they said, ‘Yep, that’s what we want,’ which I thought was really neat,”

Mike said.

Mike liked making the molds, because the job touched on his background growing up on a farm.

“I think most of it was

just a desire to do it,” he said. “I enjoyed it.”

Mike has a collection of 25-30 toy tractors and equipment in his home. Most of the pieces come from molds that he had a part in making.

So from quilting to constructing to farming, Mike and Penny have threaded a life through perseverance and creativity with an eye on excellence at every turn.

BY AMY KYLLO STAFF WRITER

BY AMY KYLLO STAFF WRITER

HASTINGS – The year is 1993, and Janet Bremer is wrapping up a third-grade tour of her dairy farm with question-and-answer time. A boy raises his hand and wants to know what her husband’s real job is. The question bothered her, as she had just spent the entire tour sharing what dairy farmers do all day every day. From that question, Bremer’s commitment to sharing her farm’s story was born.

For more than a decade, Bremer has been sharing her farm through social media. Bremer uses the handle @My-

BarnyardView to post on Facebook, Instagram, Twitter, YouTube and her blog.

Bremer and her husband, John, have a 100cow dairy farm near Hastings. They raise all of their own feed on 260 acres. Their farm is uniquely located across from a golf course and is a mere 25 minutes from downtown St. Paul.

A strong advocate for agriculture, Bremer said social media is important because it reaches the next generation in a place they go for information and entertainment.

“We need to get the message out to the (Generation Z) population,” Bremer said. “They don’t

read a newspaper; they don’t sit down and watch the news necessarily, but they’ll hop onto social media. … That’s why I think social media is such a perfect platform.”

Bremer said she works to develop a positive rapport for farmers through social media.

“One of the reasons we do this is to inform our followers on what we do on the farm and gain that trust,” Bremer said. “I would like to believe that it’s going to improve what people think of with farming.”

Bremer page 14

Bremer has had Facebook, Twitter, her blog and YouTube since 2012, and Instagram since 2014. Her Facebook account is her most popular channel, with over 4,500 followers. Facebook and Instagram are the channels she is most active on. She posts on Facebook at least five days a week. On YouTube, she has well over 100 videos, with her most popular video accumulating over 23,000 views.

Bremer got started as a content creator through several conferences put on by Midwest Dairy in 2012 to help train farmers to use social media and blogging. Because of her success with social media, she has been asked to return to several training events to mentor new social media content creators.

Bremer’s posts include regular photos of the

farm whether it is a new calf, maybe a photo of her in the combine at harvest season or just day-to-day

farm life. She also shares glimpses of her family life, humorous cartoons for “Teehee Tuesdays” and a religious post on Sundays.

One of Bremer’s favorite social media projects is story time. Each story time video features Bremer reading a picture book that ties into agriculture. At the end of the videos, she includes an agriculture-related activity or talks about something the Bremers do on their farm that connects to the storybook. Bremer made the goal in 2020 to make 100 story times, and she reached 105.

The story times were popular, many receiving hundreds and some even thousands of views on her YouTube page. Bremer’s videos are also linked as an educator’s resource on the Midwest Dairy website.

Bremer said part of her success on social media has come from being relatable.

“I don’t just talk about

dairy farming,” she said. “I share a lot about my family, and I think that gets people to realize that we’re also community members. They’ve got something in common with us.”

Bremer’s favorite part of social media is the conversations. She said she works to create posts where people are encouraged to comment and interact. Bremer also appreciates how social media has helped record and save the story of her life.

“I can go back and look at those posts, and it’s almost like a journal of our family and our farm,” she said.

In the future, Bremer has hopes to include more videos on her platforms.

“That’s what gets the most reactions,” she said. “People don’t want lengthy things. They want to see something quick and move on. I think a lot of times we can tell our story in those quick little snippets.”

Bremer uses her morning routine to keep consistent on posting. Each day, Bremer takes time after breakfast to check her email and maybe create and schedule a few posts. Another aspect that has helped her stay consistent is having set features each week like her “Teehee Tuesdays” cartoons. She said the most challenging part of posting is coming up with ideas for content.

Bremer’s farm can be seen off of social media as well. They welcome tours on their farm every year including YMCA camps. In the winter, they have a special holiday light display called Bremer Farm Lights throughout the month of December. With the light display, they host Santa on the Farm, which is a drive-thru, holiday, dairy experience. These events introduce more people to the farm and

help to bring more exposure to the @MyBarnyardView social media channels where attendees can continue to connect with the Bremers’ farm.

Outside of social media and the dairy farm, Bremer is active on her church and township board and is the Minnesota dairy princess coordinator, working with Princess Kay of the Milky Way. Bremer brings dairy’s

story with her wherever she goes, even providing milk and cookies for her church for June Dairy Month. From social media to events, Bremer has kept her commitment to telling her farm’s story. Followers of @MyBarnyardView experience a dairy farmer’s real job as Bremer continues her journey of impacting agriculture one post at a time.

Online Only · Tuesday, March 21st, 2023

BIDDING OPENS 03/10/23 @ 10:00 A.M. AND STARTS CLOSING 03/21/23 @ 10:00 A.M. Up to date listing & photos: www.hamiltonauctioncompany.com

Location: Hamilton Auction Co. off Interstate 90 at Dexter, MN exit #193 then 1/4 mile east on Hwy 16 (130 State Hwy 16)

TRACTORS: Case IH 5250 Maxxum, 1994 John Deere 7700, Siemans 4 cyl. Detroit w/ 7 ½ ft Tiller PLANTERS/SEED TENDERS: 1999 John Deere 1770, 2012 Yield Pro 4025A Great Plains 16 Row/Twin Row, Kinze 3000 6-Row, 2002 John Deere 1780 16/31 Row, 2003 John Deere 1760, Case IH 5100 Grain Drill, 350 Bushel Gravity Box w/Self-Powered Seed Vac, Unverferth 3750 Seed Tender, Gravity Box w/Seed Tender/ Vac FARM MACHINERY: Highline XL6084 Rock Picker, Ag Systems 8500 Anhydrous Bar, John Deere 520 Hi-Speed Stalk Chopper 20ft, Gehl 1065 Chopper w/Hay Head, 2 Row Corn Head for Gehl Chopper, Delta Harrow Drag, Tandem Axel Fertilizer Spreader, John Deere 235 Disc, 250-Bushel Gravity Box w/Bruch Seed Auger, John Deere 260 Loader, MD Products 38ft Head Mover Trl, Pair of Demco Side Quest Saddle Tanks TILLAGE: 2011 Case IH TM200 60ft Field Cult., Case IH 4800 32ft Vibra Shank Field Cult., Case IH 32ft 4800 Field Cult.,, DMI Tiger Mate 1 40ft Field Cult., DMI Tiger Mate 2 Field Cult., Glencoe 12 Row Field Cult., John Deere 980 30ft Field Cult., John Deere 2210 Field Cult., 1998 Wil-Rich Excel Series 39ft Field Cult., John Deere 724 Soil Finisher 14ft w/5 Bar Harrow, John Deere 2700 7 Shank Ripper, Rite-Way 2130 40ft Pull-Type Rolling Harrow SPRAYERS: L&D 1000-gal Sprayer w/60ft Boom, Top Air TA1200 Sprayer w/80ft Booms, Demco 400 3pt Sprayer TRAILERS: (2) 2012 Trail King RGN’s, 2011 Timpte 42ft Hopper Bottom, 2020 Midsota TB-22 22ft Tilt Bed, 2022 Load Trail 20ft Tri-Axle Trailer w/Large Ramps, 2021 Midsota 24ft Tilt Bed 24ft w/10,000lbs Axles, 2023 Midsota 36ft Gooseneck, 2011 Mauer 38ft Grain Trailer, 2003 4-Star Livestock Gooseneck, 1994 S&S Duraline Stock 16ft Stock Trailer, 2016 PJ 20ft Tilt Deck, 1993 Ravens 48ft Aluminum Flat Deck, 2011 Towmaster 20ft Trailer, 1991 Haulmark 10ftx6ft Enclosed SEMIS: 2013 Kenworth T800 Quad Axle Semi, 2006 Sterling Day Cab, CONSTRUCTION: 2020 Rayco RG165 Stump Grinder, John Deere 244H Payloader, 2017 JCB 8018 CTS Mini Excavator LIVESTOCK/HAY EQUIPMENT: 2009 New Holland BB940 Big Square Baler, Gehl 12ft Hydro Swing Discbine Model 2412, New Holland 316 Small Square Baler w/Belt Thrower, New Holland 1411 Discbine, John Deere 535 Round Baler, John Deere 500 Round Baler, 6-8 Bale Wagon, Gehl 418 Hay Rake, John Deere 3pt Hay Rake, H&S 235 Manure Spreader FARM AUGERS/BELT CONVEYORS: Peck 10”x36ft Auger, Brandt 1535 Field Loader Portable Belt Conveyor, Batco 1535 Belt Conveyor, Feterl 8”x66ft Auger VEHICLES: 2006 GMC Cab & Chassis Truck w/137” Wheelbase, 1996 Dodge Ram, 2004 Thunderbird Convertible, 1993 Chevy Ext. Cab, 2003 Chevy Service Truck, 2010 Ford Econoline Van, 2004 GMC Pickup, 2000 Ford F-350 RECREATIONAL: 2012 John Deere 825i Gator, 2012 Kawasaki 250F Dirt Bike, 2006 Yamaha YZ450F Dirt Bike, 2003 Kawasaki Prairie 650 4-Wheeler, 2001 Artic Cat ZR800 Snowmobile LAWN & GARDEN: Smithco Sweepster 848 Lawn Sweeper, Bush Hog TVM50 Yard Dethatcher/Slitter, 2013 John Deere X750 Riding Lawn Mower, John Deere (Non-Running) GX345 Lawn Mower w/48” Edge Deck w/mulcher ATTACHMENTS: Extension Forks, Rotary Cultivator, Heavy Grass Grapples, Skid Steer Auger w/3 Bits, Tree Shear, 86” Hyd. Snowplow, Brush Cutter, Trenchers, Skid Steer Auger Drive & Bit Attachment, Tiller, Concrete Mixer w/ In-Cab Controller, Wolverine Pallet Fork Extensions, Wolverine Pallet Fork Hyd. Adjustable MISC.: Grand Meadow’s Construction Class Storage Shed, (2) 40ft 4-side-door Container, 8ft Container, 9ft Container, Portable Toilet w/double stools, (2) Golden Mountain Storage Shelters, 20ft Bi-Parting Iron Gates, Safety Cones, Electric Winch, Lincoln SP170 Wire Feed Welder, Greatbear Pressure Washer

130 State Hwy. 16 Dexter, MN 55926 (507) 584-0133

AUCTIONEERS: Andrew Hamilton, Bill Hilton; Sales Associates: Jeff Thorsen, Bob Grass; CLERK: Hamilton Auction Co.

It has been our privilege to provide you with a complimentary subscription to Country Acres South. We hope you enjoy receiving our paper in your mailbox as much as we enjoy bringing it to you.

Country Acres will continue to be FREE for anyone owning 15 acres or more in our coverage area.

To continue your FREE subscription, please fill out the form below and mail it to: Star Publications, 522 Sinclair Lewis Avenue, Sauk Centre, MN 56378, email it to circulation@star-pub.com or use the QR Code below. Please include your address, phone number and number of acres you own in the email.

If we do not receive a request from you by March 31, 2023 you will not receive Country Acres starting with the April 1, 2023 edition.

If at any time you have suggestions or comments for the paper, we want to hear them. Please email Mark, Amy or Grace with your ideas. After all, your stories are what makes this paper successful!

This may seem like a small request, but it’s the little things that need the most attention. Thank you for helping us out. We greatly appreciate your time and effort to do this.

Sincerely,

General Manager 320-352-6577

❑ Yes, I would like to continue to receive Country Acres.

❑ Yes, I own 15 acres or more in:

Do you or someone you know have an interesting story?

What features would you like to see included in the paper that are currently omitted?

Comments