Antique truck goes from pasture relic to the road

Randy Turner and his cousins grew up playing in, around and on top of a 1939 Chevrolet panel truck sitting in his grandparents’ pasture.

With broken out windows, shredded leather seats, interior fabric hanging from the roof, a dented exterior and a seized engine, Turner hauled it out of the pasture and into his furniture refinishing shop.

“I jumped into this thing with both feet, and I didn’t know a thing about it,” Turner said.

The truck sat on its running boards in the field. The wheels, shocks, axles and back end had been removed years before by a handful of young boys. Turner jacked up the front end, put planks under the body and winched it onto a trailer.

“The dirt on the sides, from vegetation decomposing, was 4 or 5 inches higher than the running boards,” Turner said. “Surprisingly, … the body was solid and didn’t have too much rust.”

Even so, Turner was faced with a project he had no experience with.

“I decided I would see if it was worth doing anything with,” he said. “I have no idea why, it just happened.”

Turner relied on the advice of his friends

who were car fanatics and welders. When a friend came to help, Turner worked alongside, helping and learning every step of the way to complete each phase of the work from beginning to end.

Turner knew he was not going to return the vehicle to its original condition and instead focused on keeping the outside as similar to the original as he could. The truck was as a six-cylinder straight stick meant for work and fashioned with a single seat meant solely for the driver.

The half-ton truck was purchased in the late 1950s by Eu-

gene Joarnt, Turner’s stepfather. His dad used the truck to haul milk to the creamery in Gutches Grove in Todd County.

Rumor has it Turner’s uncles used to take the truck out for night drives around the countryside. They would sit on milk stools in the back. One evening, the truck ended up in the ditch alongside a telephone pole, the right side of the truck caved in from the back door to the rear. After that, it was relegated to the pasture.

Over time, sitting in the pasture with the doors splayed open, Turner said

from the pasture in the late 1990s, it was not until his retirement in 2018 that he really had time to put effort into the project.

When Turner first brought the truck to the shop, he took the body off the frame and replaced the running gear, axles and springs.

“I knew I didn’t want to go back to stock,” Turner said. “I’m kind of a cheap guy so I went to a local junkyard and got a front-end and axle from a ‘78 Dodge Diplomat.”

The move gave him power steering and power brakes, and with a little engineering, Turner fit it to the truck. He painted the frame, put the body back on and started to contemplate the dented side.

Turner priced out a professional fix, but it was too costly so he searched for a donor truck he could strip of its sheet metal. He found one at Windy Hill Auto Parts and bought the whole thing, pulling the sheet metal and retrofitting it for his use. After the doors were on, Turner realized the true damage of what was done in decades gone by. The door post was twisted causing a gap in the doors. With

(Right) Randy Turner spent his childhood climbing around this 1939 Chevrolet panel truck. The truck had a dented exterior and a seized engine when he pulled it out of his grandparent’s pasture to restore it.

a little engineering and welding, Turner fixed the problem and filled in the gaps with metal.

Turner was sure to take came from his wife, Pat. Pat said she thought the truck had a gangster-like

look and aptly named it Bugsy. Turner’s friends

“That was probably the biggest setback,” Turner said. “I got advice from a lot of people. I

didn’t listen to it all, but I have a lot of friends who are into cars.”PHOTOS SUBMITTED (Above) Randy Turner stands next to his 1939 Chevrolet panel truck, a truck he pulled out of his grandparent’s pasture and restored.

I jumped into this thing with both feet, and I didn’t know a thing about it

- Randy Turner

from

encouraged him to put advertising on the side, and the phrasing has garnered a few chuckles through the years.

Though Turner rebuilt the truck for his own satisfaction and envisioned taking it for drives through the countryside or running errands around town, he has taken it to car shows with friends.

For Turner, the truck has been a way to try something new and the work has been satisfying.

“The whole project was a learning experience so to speak,” he said. “It means a lot. That was the whole goal, to get it up and running and make it drivable. There aren’t many half-ton panel trucks around that I’ve seen. It’s pretty cool to drive my dad’s truck.”

BY SARAH COLBURN | STAFF WRITER

BY SARAH COLBURN | STAFF WRITER

Cory Schneider spent his childhood taking things apart and putting them back together in hopes he could get them to work again.

Now, as an adult, Schneider owns Schneider Collision and Hydrographics and does the same thing for customers; however, his skill set, knowledge and experience has vastly changed.

“We strive to make it look like it was never repaired, never fixed,” Schneider said. “We use high-quality, top-notch paint. We use all original equipment manufacturer parts. We follow all OEM procedure guidelines the manufacturer tells us to. That way, when we give the vehicle back to the customer, they should feel safe and secure.”

For Schneider, the work is all about taking pride and putting the customer first. Every car that leaves his collision shop is hand washed and given detailing. He and his team specialize in not only repairing cars but also semitrucks.

“There aren’t a lot of shops around here that offer it,” Schneider said.

Schneider began semi work when his friends who drove truck brought their vehicles in asking for help. Initially, he did not have enough space to paint them but eventually rented a place with a tall enough door to bring them inside.

In September, Schneider opened the business at a new shop in Meire Grove which offers plenty of space to work on vehicles of all sizes, including semis.

“Now a lot of people bring them to me,” Schneider said. “They like the work. They like the outcome, and we like to see them go down the road because it’s kind of a show piece for us and it makes the driver look good as well.”

In addition to collision repairs and semitruck collision work and painting, Schneider also offers hydrographics out of the shop. Schneider said he remembers taking apart an Xbox controller and dipping the shell to create a perfect carbon fiber finish.

Today, Schneider uses the process to help customers specialize trim pieces for cars, trucks, four-wheelers and firearms. Schneider has also finished interior outlet covers for a customer, among other things. There are thousands of designs available, and Schneider said there is interest in camouflage and patriotic imagery.

Schneider prepares each piece by sanding and painting. Then, he places the film in a warm water bath, applies a chemical activator and dips the piece into the water. The film then adheres.

“It’s basically wrapped into every orifice of that part, and it stays permanently,” Schnei-

der said. “Anything that is able to be painted and submerged into water, within reason and size, can be hydro-dipped.”

Schneider has used the process to add style to European deer mounts; he wraps the horns and affixes the film to the actual skull. Schneider said customers have wanted the mounts finished out with snow camouflage and one who wanted the look of $100 bills.

“It’s quite a process because every film is different,” Schneider said.

Schneider’s company was founded five years ago, but he has been working in the indus-

try since 2008. He attended St. Cloud Technical and Community College and has experience working with many individuals and insurance companies.

ence. Once

make that

insurance

initial

Schneider Collision and Hydrographics offers custom hydrographics work. He can apply hydrographics to everything from European Mounts to vehicle trim pieces to firearms.

While Midsota Trailer Sales and Service offers a full line of utility and cargo trailers and backs them up with a commitment to service, the company also specializes in customization of trailers.

Whether it is customizing a trailer for a contractor who needs special attachments inside or outside to hold their gear, or an all-terrain vehicle enthusiast looking to add camper components to an enclosed trailer for the ease of a weekend getaway, Midsota Trailer Sales and Service offers solutions.

“If they can dream it, there’s a pretty good chance one of our manufacturers can make something to best suit what they’re looking for,” said Chad Zirbes, retail sales manager and service manager for the company.

When it comes to customizing a trailer, there are a multitude of offerings that can either be ordered as part of a new trailer or retrofitted to an existing trailer.

Zirbes said they offer wall and ceiling in-

sulating, air conditioning units, cabinets, interior lighting, exterior lighting, awnings, benches, outlets, sinks, windows and even beds and bathrooms.

from page 9

Even with the additions, Zirbes said the enclosed trailers with upgrades can cost less than other haulers or campers.

“A lot of people don’t want all the flare,” he said. “They want a trailer they can camp in and rough it a little bit more and not

have that high price tag.”

Where Zirbes is sitting, the demand for the all-terrain vehicle market remains strong. Zirbes said he gets multiple customers a week looking to customize their trailers.

Zirbes said an all-terrain vehicle with a crew cab and two bench seats fits well in a 24-foot to 28foot trailer if a customer is looking to add a full camping setup. However,

customers can go as small as a 16-foot enclosed version as well. The biggest factor is the height of the

their recreational vehicle to be stored in the trailer at night while others park it outside and use the space for sleeping.

On the showroom floor, Zirbes said he and his team work to offer ample inventory with varied interior packages so customers can see exactly what options might be available to fit their needs.

The variety, he said, allows people to pick and

choose from things they can see right in front of them.

The most important thing Zirbes said Midsota Trailer Sales and Service staff does it talk to customers to best understand their wants, needs and expectations.

‘‘

“A lot of people don’t want all the flare. They want a trailer they can camp in and rough it a little bit more and not have that high price tag.”

- Chad Zirbes

The Minnesota State Patrol receives calls daily to remove hazards from the roadway. Those hazards are there due to the improper loading or securing of transport items and trailers.

“It’s going to take a little homework, a little preplanning, a little extra time, … but it’s going to help prevent these unnecessary crashes we see out here,” said Sgt. Jesse Grabow, of the state patrol.

Grabow said he has seen everything, from improperly loaded trailers fishtailing over the road and spilling landscaping pavers to full mattresses blown

off the roofs of cars and run over by other vehicles.

The department has received calls for assistance when hay bales, all-terrain vehicles, boats, pontoons, lawn mowers and skid loaders have been improperly secured to a trailer and landed in the roadway. They also get regular calls for landscaping equipment including rakes, shovels and ladders, branches and firewood being lifted off a trailer or truck by the wind. When it comes to recreational equipment, the most common items flying out of vehicles include coolers, fishing rods and life jackets.

“Often times it’s excuses, ‘Well, I’m just going a short distance,’” Grabow said.

A trailer goes off the road as it enters the highway in the winter of 2021. The driver, on Highway 108 near Pelican Rapids, took the turn too short and the trailer tipped. The hay bales were properly secured to the trailer and stayed in place. While the hazard blocked traffic, nobody was injured.

For some people, that short distance may be half a mile and for others, 60 miles. Either way, Grabow said it is important to follow safety protocols for hauling equipment and gear.

“Hope is not a plan; hope is not a strategy when it comes to securing these things,” Grabow said. “Take the time to do it right. We share the road with other people and things happen.”

Nobody plans to have to brake quickly or make a sudden lane change, Grabow said. And often, those

Ramler Trucking covers the entire Midwest region hauling poultry, cheese, beef and precast cement buildings.

With 50 owner-operators, 15 Ramler Trucking company drivers, 12 broker trucks, more than a dozen office personnel and 14 people working in the accompanying Ramler Truck and Trailer Repair, the company is poised to meet the needs of clients near and far.

“Without truck drivers, the world would definitely be a different place,” said Chelsea Buerman, of Ramler Trucking. “They haul all the necessities of life.”

The company touts an experienced workforce. One owner-operator has been with Ramler Trucking since 1997; the longestrunning company employee has been there since 1992, and the majority of the workforce there has been with the company more than five years. The number of employees with longevity with the company is truly something that sets it apart, she said.

Ramler prides itself on treating its employees well so they in turn can treat the company’s suppliers well. Employees work

with suppliers to transport their goods and receive bonuses for safe driving.

“We appreciate all our employees,” Buerman said. “We wouldn’t be the business we are today without them.”

The company is employee-owned since 2009 which means each employee has shares of the company and Buerman said that gives them ownership and an ongoing sense of loyalty.

“Truck drivers sacrifice a lot of their holidays and family time to deliver products America needs,” she said.

The company’s drivers, dispatchers and mechanics put in extra time to make sure everyone is happy in the end.

“It ties back to the hard work we do … and it makes us unique,” Buerman said.

The hard work comes on and off the road.

The company’s on-site repair center offers 22 repair bays and a whole host of services. The repair center is open to the public and is used by a lot of owner/operators

and companies that need to get their trucks serviced without travelling long distances. Ramler’s offers DOT inspections, trailer washouts to get trucks ready and sanitized for their next load, and semi-truck tire rim polishing. Rim polishing, Buerman said, not only makes a pitted rim look new and shiny again, it allows the driver to more easily assess the structural integrity of the rim.

In addition to servicing owner/operator vehicles and semi-trucks for companies, Ramler can also do repairs for the public including those looking to make repairs to their motorhomes and utility vehicles.

The company was founded in 1954 and is currently led by President Chris Ramler and Vice President Eric Ramler. The Ramler fleet is 20 company-trucks strong and includes refrigerated reefers, tankers, stretch trailers, and flatbed trailers. They work directly with businesses and farmers throughout the Midwest, transporting their goods on schedule and on time.

The company is looking to add drivers, owner operators and company. Ramler Trucking hires people 22 years of age and older who have at least two years driving experience. A class A CDL is required and applicants can apply on the company’s website at www.ramlertrucking.com.

quick maneuvers on the road can cause loads to shift, securements to break and things to fall or fly off trailers and trucks.

“Take the time to make sure you have the proper securements,” Grabow said. “Chains and straps with the proper working load limits.”

Chad Zirbes is the retail sales and service manager for Midsota Trailer Sales and Service. His team gets a lot of questions regarding proper connections, securement systems and vehicle load limits.

“The biggest thing is just learning how to load your trailer,” Zirbes said. “You need to do your research to make sure your securing system is rated for what you’re hauling.”

Additionally, improper loading of a trailer can not only be dangerous going down the road, it can cause additional stress on the vehicle and tow unit.

An improper load can sway back and forth and eventually cause the driver to lose control, Zirbes said.

Midsota Trailer Sales and Service can order trailers with customiza-

People stop to pick up pavers off the road on Highway 59, north of Pelican Rapids in the summer of 2021. The pavers were improperly loaded on a trailer and caused the driver to lose control spilling the load onto the highway. Nobody was injured.

tion to help recreational customers, as well as contractors and others, secure their loads properly. The company also offers the ability to add securement systems to trailers already owned by customers.

There are various ways to secure a load, Zirbes said, and Midsota Trailer Sales and Service can add in D-rings, hooks and tie-down systems. But, it is up to each user to make sure they know how to use them and use

them with the right securement product.

“Every strap, chain and binder has a load rating on it,” Zirbes said. “It will have a working load strength and a breaking strength. Do the research at the manufacturer to make sure four tie-down points together will hold that machine in place. Make sure that worst-case scenario, your load will stay secure.”

Safety page 15

All cargo must be secured from forward (longitudinal) and sideways (lateral) movement.

Midsota Trailer Sales and Service also carries equalizer hitches and anti-sway bars that can assist people in towing. Additionally, its service department can install brake controllers for trailers. At Midsota Trailer Sales and Service, every trailer with a gross vehicle weight of more than 3,000 pounds will have a braking system; if it is a tandem-axle trailer, both axles will have brakes.

When it comes to a truck or vehicle’s towing capacity, Zirbes said clients should research the VIN number on the vehicle to understand that participaular vehicle’s exact towing capacity.

More tips for staying safe when hauling a trailer or load include:

– Lights from the tow vehicle are not adequate for the roadway. Trailers must have working brake lights, hazard lights and turn signals.

– Before hitting the road, do one last walk around to be sure the lights are working and everything is properly hooked to the tow vehicle. Inspect the hitch, hitch pins, safety chains and lights.

– Be sure the trailer tires are properly inflated and in good shape.

– When applicable, make sure the trailer brakes are working. Not all trailers have a separate braking system.

– If anything sticks out past the end of the vehicle, it must be properly marked with a flag to alert other drivers to the unusual size or shape.

rvice ane in de lers ales ross 000 m; if xles clients on paular when le are ailers hazdo he g e ns, are pe ure Not ng ast be ert or

When a motor vehicle carries cargo that is not firmly braced against a front-end structure, or cargo that may shift sideways in transit, the cargo must either be securely blocked or braced against the sides, sideboards, or stakes of the vehicle or be secured by other means to prevent any forward and/or sideways movement.

Tiedown assemblies may consist of chains, cables, steel straps, fiber webbing, and other securement devices and attachment of fastening devices. All tiedowns, cargo securement systems, parts and components used to secure cargo must be in proper working order when used to perform that function with no damaged or weakened components, such as, but not limited to, cracks or cuts that will adversely affect their performance for cargo securement purposes, including reducing the working load limit.

Cargo must be firmly immobilized or secured on or within a vehicle by structures of adequate strength, dunnage or dunnage bags, shoring bars, tiedowns or a combination of these.

The aggregate working load limit of tiedowns used to secure an article or group of articles against movement must be at least one-half times the weight of the article or group of articles. The aggregate working load limit is the sum of:

• One-half the working load limit of each tiedown that goes from an anchor point on the vehicle to an anchor point on an article of cargo;

• One-half the working load limit of each tiedown that is attached to an anchor point on the vehicle, passes through, over, or around the article of cargo, and is then attached to an anchor point on the same side of the vehicle.

• The working load limit for each tiedown that goes from an anchor point on the vehicle, through, over, or around the article of cargo, and then attaches to another anchor point on the other side of the vehicle.

The working load limit (WLL) of a tiedown, associated connector or attachment mechanism is the lowest working load limit of any of its components (including tensioner), or the working load limit of the anchor points to which it is attached, whichever is less.

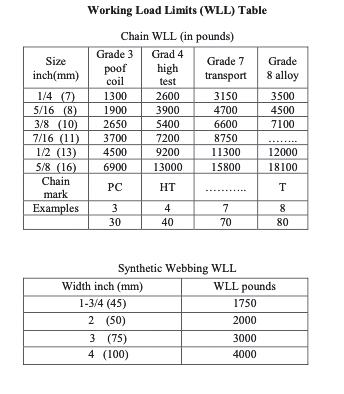

The working load limits of tiedowns may be determined by using either the tiedown manufacturer’s markings or by using the following tables. The working load limits listed in the tables are to be used when the tiedown material is not marked by the manufacturer with the working load limit. Tiedown materials which are marked by the manufacturer with working load limits that differ from the tables, shall be considered to have a working load limit equal to the value for which they are marked.

Welded steel chain which is not marked or labeled to enable identification of its grade or working load limit shall be considered to have a working load limit equal to that for grade 30 proof coil chain.