8 minute read

Structural Engineers’ Role On Building Sustainability

BUILDINGS ARE BUILT-UP MASS. AND THIS MASS CONTAINS VALUABLE RESOURCES THAT ARE BECOMING INCREASINGLY SCARCE AND ARE RESPONSIBLE FOR MANY CO 2 EMISSIONS. STRUCTURAL ENGINEERS IN PARTICULAR CAN MASSIVELY REDUCE MATERIAL CONSUMPTION.

STRUCTURAL ENGINEERS AND THEIR ROLE IN THE CONSTRUCTION PROCESS:

Advertisement

They are popularly known as structural engineers, although structural engineering is not the only part of their work. They are also responsible for ensuring that the building is given a welldesigned, economical and appropriate supporting structure and, of course, that it is sustainable in the end. They deal with everything that forms the skeleton of the structure, the bones that are usually not visible. They exchange with the architects or the building services planners. The role they play in detail naturally depends on than a sports arena. However, for integrative and thus optimal planning, they should be there from the start, i.e. already in the interdisciplinary planning competition. Unfortunately, this is often not the case in reality.

The primary task carried out by engineers involves calculating the loads and stresses that will be generated in a building and then providing a solution that will enable the structure to withstand the loads and stresses. The key part that is often overlooked by most engineers is doing this in an economical way. Most buildings end up structurally sound and overdesigned which makes them expensive to build and increase the carbon footprint.

Engineers are responsible for selection of suitable construction material. Materials are a core driver of sustainability. A sustainable built environment would also require more ambitious and updated building codes in order to limit energy consumption, reduce pollution and protect natural areas. The use of contemporary materials like timber and steel boxes (containers) have taken off all over the world, with ourselves still to catch up to this highly sustainable idea. The construction of steel framed buildings should be examined, as this system offers speed of construction and savings in cost over mere traditional construction methods. However the system must be designed to resist the high force winds and to be resistant to corrosion. Reusable materials should top the list of construction materials if things are to be turned around.

Project supervision and management is another of the facets that resources depleting, it has become of utmost importance to ensure that construction crews limit waste and reuse as much as is possible. Sustainability is focused on eliminating waste, and supervision to ensure little waste is produced, goes a long way in preserving natural resources.

It is the role of the engineers when managing a project to educate the client and encourage the use of modern improved construction methods. One area we can look at is the use of premix concrete versus site-mixed concrete. Apart from the fact that premix is cheaper, it also supports a key sustainability principle, water conservation. Premix concrete uses only enough water as required to achieve certain strength. However, on site, it’s drastically different. The crew mixing concrete tends to add more water than required to make it easier to mix, this means that water is being wasted at the same time, the strength of the mixture is reduced.

WHY STRUCTURAL ENGINEERS SHOULD TAKE THEIR ROLE SERIOUSLY TO ENHANCE SUSTAINABILITY:

For a long time, the discussion about sustainability in construction was primarily centred on saving energy. The big issue of today and tomorrow, however, is also on the consumption of resources and the associated CO 2 emissions. Considering that between 80 or 90 percent of the resources are in the shell construction, i.e. in the foundation, supports, walls, etc., the structural engineers is presented with many options for working in terms of sustainability. necessary knowledge and appropriate advice.

Recently we visited a site just to have a look at the reinforcement steel that had gone into the building.

Upon inspection, and later, calculations, we concluded that the building structural engineering terms, is when the structural designer provides more steel than really is necessary. The building does not collapse; it’s like using a Toyota Hilux D4D to carry a 2 litre Water container for a distance of 2m. It works, but it’s unnecessarily expensive.

This, unfortunately happens when clients select an incompetent they will put more steel than is required to ensure they are absolved of any structural failure liabilities. In some instances, they want to hurry to the next job, the engineer will put more steel than is required project quicker and move on.

Over the years, we’ve had a look at many projects that have been designed by fellow engineers, and it is true, that many are overdesigned. Apart from the detrimental environmental effects, clients’ pockets have suffered unnecessarily.

DOES THAT MEAN OUR BUILDINGS ARE SUPER HEAVYWEIGHTS?

The majority yes. A few numbers make it clear to us what masses we are talking about when building. Let’s take a normal two-story residential building. A concrete deck that is 20 centimetres thick weighs 500 kilograms per square meter. In addition, it is estimated that around 50 percent are used for columns, walls and other components. A normal residential building already weighs several hundred tons. Now think about the enormous effects that it has if we can save a few centimetres per floor or wall.

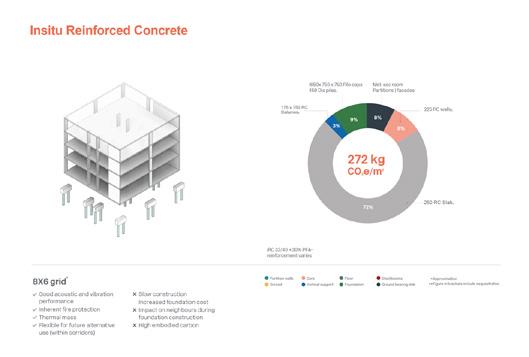

A quick example of lightweight construction that comes to mind is use of ribbed slabs, which is a common method of construction in our neighbouring country, South Africa. This method of doing concrete When bricks were made they were initially made without holes, but someone realised that a lot of the weight in bricks was redundant and holes were introduced. The weight reduction of a building built using was also successfully applied to steel. Why then do we stick to solid construction elements? We did a study on a low rise student accommodation in Mutare to appreciate how much carbon that can be saved. We compared a four storey cross laminated timber (CLT) block with a too often default option – a concrete framed option with stud partition walls to form living spaces within.

When cross laminated timber (CLT) is used, the embodied carbon of low rise student accommodation can be reduced by up to two-thirds when compared to concrete; based on the study we conducted. The reason behind the result is because like all good building materials, the CLT (cross laminated timber) lends itself so beautifully to the application.

Where in other schemes additional partition walls are needed (which adds to the carbon), student accommodation is naturally segmented, lending itself perfectly to a CLT (cross laminated timber) frame using the shear walls as partitions.

Figure 1: Embodied carbon on a typical cross laminated timber (CLT) block The concrete frame option came in with 272 kgC02e/m2 compared to just 87kgC02e/m2 for the CLT frame in terms of embodied carbon. Figure 2: Embodied carbon on a typical insitu reinforced concrete block

minutes, a rating which is easily met by the CLT (cross laminated timber) with simple plasterboard covering on the walls and minimal thickness screed topping on the floor slabs. This screed also serves to dampen any vibrational issues which might arise. The lightness of the timber frame compared to the other solutions also means a less carbon intensive foundation can be used. Where the concrete frame needed a heavier foundation, the lightness of the CLT (cross laminated timber) meant only ground beams were needed – a saving not only in embodied carbon, but cost as well. By knowing how to design in timber, the use of this material can embodied carbon building.

IS BUILDING AS LIGHT AS POSSIBLE THE ANSWER OR SOMETIMES ITS WORTH ANOTHER TON?

Of course, easy to build is an obvious way to save resources. We of optimization to save materials. In practice, the utilization of components is often only 80 percent, although 100 percent would be acceptable in the truest sense of the word. With simple optimization studies, we could certainly easily achieve material savings of 10-20 percent. Structural engineers could do a lot more educational work here. But of course these studies cost time and money and are not (yet) included in their range of services. Too great caution and ignorance therefore lead to unnecessary material consumption.

The rise of factory-made and site-assembled buildings is certainly welcome. The precision is much higher. On site, 100mm can easily become 120mm multiply this over 4 floors you have a redundant 80mm of concrete.

In a controlled environment it becomes much easier to optimise design. Human error, especially a tired crew on Friday afternoon, is

OTHER OPTIONS AVAILABLE IN ADDITION TO WEIGHT REDUCTION IN TERMS OF RESOURCE CONSERVATION:

There is great potential in reuse at the material, component and building level. We must therefore also consider other alternatives and steer them in the right direction. With conventional building materials, for example, steel can be easily recycled. And when it comes to concrete, you can use recycled concrete, because the quality is in no way inferior to normal concrete.

With a view to the reuse of components, there are already valuable research approaches that can be made reference to.

1. Rodney Chishakwe is a Director of KCVisart Design Studio, an engineering consultancy keen on designing sustainable buildings.

For a further discussion on the topic you can email chishakwer@gmail.com 2. Innocent Mhandu is a sustainable building design consultant with GreenA Sustainability Pte Ltd, a provider of consulting services on integral approach in building design.

For a further discussion on the topic you can email innocent@greenaconsultants.com or enquiry@greenaconsultants.com