Encouraging

The key to future-proofing mining in Africa includes looking at the intersection of gender diversity, innovation, and the future sustainability of the industry. In contrast to 1994, which paved the way for the introduction of some key pieces of legislation, the mining industry has made some significant gains towards gender equity.

Notwithstanding these wins, there are still many barriers women face in entering and advancing in mining. One of the biggest is the deeply entrenched gender stereotypes that paint mining as a male-dominated field, both in terms of physical demands and societal expectations.

Many women are discouraged from pursuing careers in mining due to perceptions that they lack the physical strength or aptitude for the work.

According to Ntsiki Adonisi, head of natural resources and environment at ENS, breaking down these stereotypes is crucial, which is why gender sensitivity and awareness training should be implemented across the industry, to shi perceptions of what women can achieve in mining.

Educational programmes that highlight successful women in mining can also inspire future generations to enter the field.

“As the global movement for women’s equality continues to gain momentum, there are also many pregnant and nursing female employees within male-dominated industries like mining, who still face significant economic hardship,” says Adonisi.

“While Section 26 of the Basic Conditions of Employment Act (BCEA) o ers some protection for these employees, concerning

gaps in the legislation continue to leave many without financial support during critical stages of pregnancy and post-natal care.”

In the mining industry, the risks associated with hazardous work environments compound the challenges for pregnant employees. Section 26 mandates that employers must ensure that pregnant or nursing women are not exposed to dangerous working conditions, she says.

Where this is not possible, they must o er alternative, suitable work. If an employer cannot o er suitable alternative employment, they are not entitled to remuneration until they commence maternity leave.

The earliest a pregnant employee may take maternity leave is four weeks before they give birth. Once an employee is on maternity leave, they are entitled to maternity leave benefits from the Unemployment Insurance Fund.

PROGRESS

“The mining industry, like many others, has made strides towards gender equality, but there is still much to be done to ensure that women working in high-risk environments are adequately protected.

“As the industry looks to future-proof itself with innovations and sustainability initiatives, it must also address the glaring gaps in its support systems for all women, including pregnant and nursing employees,” says Balindile Shezi, employment executive at law firm ENS.

“Despite this, it’s worth noting that over the past decade, the role of women in mining has evolved significantly, with more women entering the industry and taking on leadership roles, as recognition of the value of diversity and inclusion has spurred positive change.”

One of the most notable areas of progress Shezi points to is the promotion of gender diversity within senior leadership and decisionmaking roles. More women are now heading mining companies, serving as executives, and taking up roles in boardrooms.

Increasingly, they are also playing a more prominent role in technical fields, ranging from geology and engineering to health and safety management.

“In terms of ‘future-proofing’ the mining sector, there is a growing emphasis on attracting and retaining women by creating an inclusive and supportive work environment.

“This includes the introduction of gendersensitive policies, mentoring programmes, and initiatives aimed at developing women’s skills in technical and leadership capacities,” she says.

“The future of mining lies in innovation, sustainability, and adaptability. As mining companies shi towards more sustainable and technologically advanced practices, there is more room for women to bring fresh perspectives and contribute to the sector’s future growth.”

Progress in areas such as automation, data science, and green mining initiatives is opening up new opportunities for women in mining. Furthermore, increasing corporate responsibility and the drive for greater community engagement means that more women are assuming leadership roles in driving these transformations.

Diversity is equally important in the legal arena, says Adonisi, noting that it is important to bring a variety of legal expertise to the table when assisting a mining client with a challenge.

This is because the mining industry operates within a complex environment comprising legal, regulatory, environmental, and social considerations.

A multidisciplinary team ensures that all facets of the challenge are addressed, making it easier to develop holistic and practical solutions.

“Mining challenges o en involve overlapping areas such as corporate law, environmental compliance, labour regulations, tax implications, and community relations. A team with diverse legal expertise can comprehensively analyse these interrelated issues, ensuring that no critical aspect is overlooked.

“A well-rounded legal team helps clients make informed decisions by presenting integrated advice that accounts for all potential implications whether that involves legal, financial, or reputational risk. This avoids the need for back-and-forth consultations with multiple external experts, saving time and resources.”

Adonisi and her team indicate that the ENS team has extensive experience in handling a wide range of mining and minerals transactions across Africa. This includes exploration, mergers and acquisitions, mine development, mineral royalty, mining regulation, project finance, resource finance, and restructuring, alongside expertise in mine health and safety.

“Our value lies in our comprehensive understanding of both the technical aspects of mining – such as geology and engineering – and the commercial, regulatory, and geopolitical factors that shape the industry. This combined knowledge enables us to provide well-rounded and informed legal

guidance to our clients.”

Beyond solving immediate challenges, she says, a multidisciplinary approach helps clients future-proof their operations.

“For example, tax lawyers can optimise financial strategies, while environmental lawyers can ensure sustainability practices align with global standards, thereby enhancing the company’s long-term viability,” says Adonisi.

In summary, ENS believes that a multidisciplinary team enhances e iciency, creativity, and foresight in addressing mining challenges. By leveraging diverse legal expertise, the client benefits from wellrounded, e ective solutions that address both immediate issues and long-term goals.

“As is the nature of the mining industry, there are still significant health and safety risks, and this is particularly true for women working in hazardous environments,” says Shezi.

Ensuring that the workplace is safe for women – including providing adequate maternity leave and pre-birth UIF benefits, addressing issues like sexual harassment, and implementing gender-sensitive policies – will be vital for both workforce retention and productivity, she says.

“Women in mining also o en face barriers to accessing training and career development opportunities. Ensuring equal access to skills development, mentorship, and leadership programmes will help close the gender gap and foster a more inclusive and capable workforce.”

Another key aspect of future-proofing mining involves adopting green technologies, improving environmental stewardship, and

One of the biggest barriers remains the deeply entrenched gender stereotypes that paint mining as a male-dominated field, both in terms of physical demands and societal expectations. – Shezi “ “

The future of mining lies in innovation, sustainability, and adaptability. As mining companies shi towards more sustainable and technologically advanced practices.

reducing the sector’s carbon footprint, all while ensuring that women play an active role in these e orts. This is especially vital as the pressure to adopt more sustainable practices grows.

“With constantly evolving regulatory frameworks, mining companies need to stay ahead of ESG, labour, and gender-related legislation. Ensuring compliance with policies that promote gender equality and environmental sustainability, while navigating political and economic uncertainties, will be a key issue for the mining sector moving forward,” says Shezi.

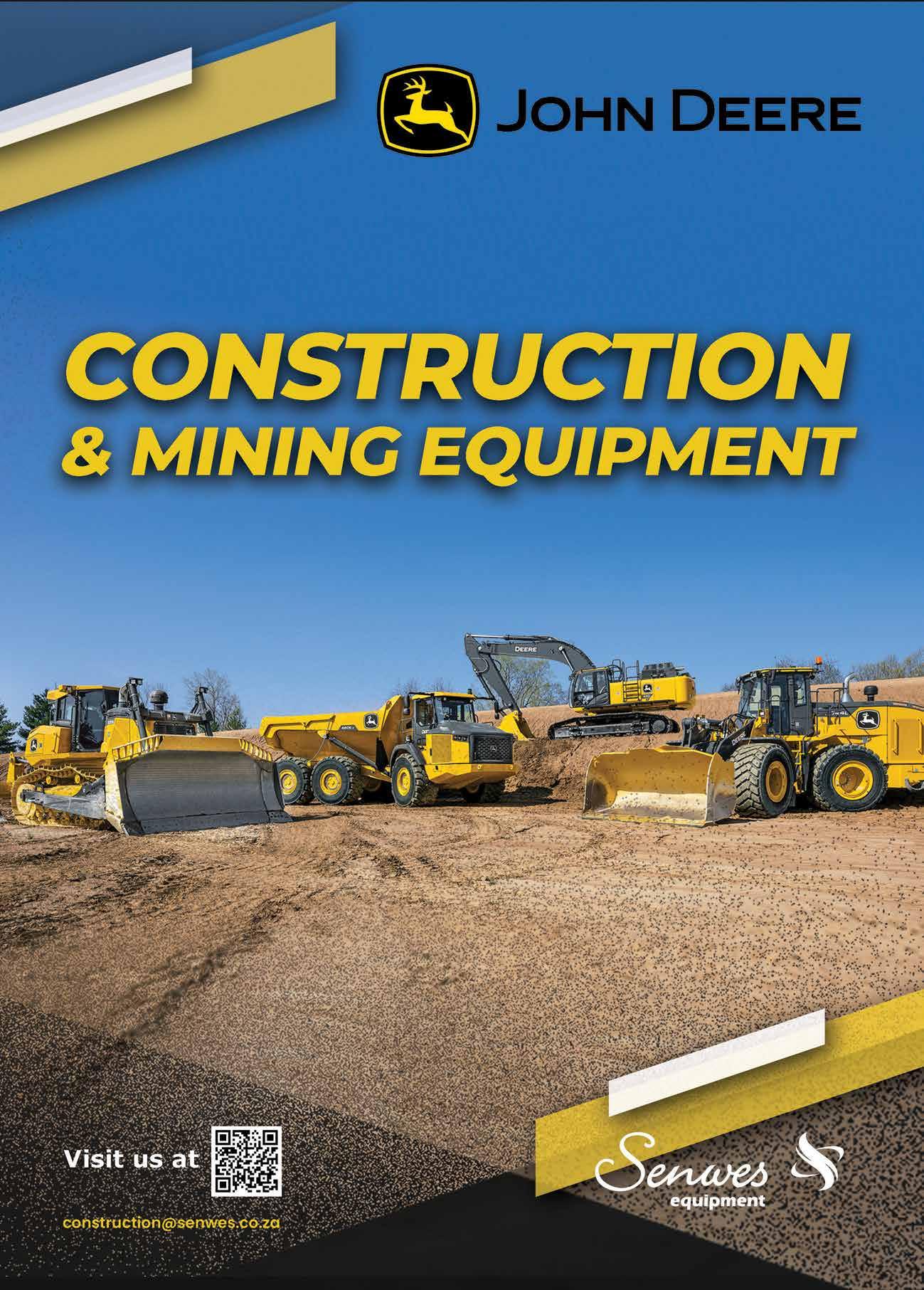

Mining for tomorrow, where innovation drives sustainability

While not yet promulgated, the Climate Change Act will have a major impact on the mining sector. It is thus best the sector begins preparing for this.

Platinum group metals (PGMs) are closely associated with commodities like gold, but unlike the latter, the green energy transition o ers hope for the future for PGMs.

Considering the impact AIIM’s recently announced partnership to spearhead SA’s rail sector revival and reshape passenger and freight transport will have.

How do explosives suppliers ensure the safety of their product during the storage, handling and application phases?

Prefabricated solutions can help mines achieve their environmental, health, and safety goals, while streamlining operations and improving profitability.

Law suggests that

www.linkedin.com/company/samining/

businessmediamags.co.za/mining/sa-mining/subscribe/ www.samining.co.za or www.businessmediamags.co.za

https://issuu.com/sundaytimesza/docs/2024_calendar_a2

www.facebook.com/businessmediaMAGS/company/samining/ twitter.com/BMMagazines www.instagram.com/business_media_mags/

The impact of climate change is driving additional changes: to legislation, to the platinum sector, and even to construction techniques in the mining industry.

Rodney Weidemann

he devastating wildfires that have caused so much destruction in Los Angeles are just the latest example of the increasing impact of climate change. Recognising the need to put in place laws to help combat this global challenge, the South African government has prepared the Climate Change Act.

This piece of legislation is considered to be pivotal, designed as it is to define, manage, monitor, and implement the country’s response to climate change. Although signed into law in July 2024, the act is yet to be promulgated, and so will only come into operation at a later date.

climate-resilient economy in the context

Nonetheless, it is a law designed to support South Africa’s transition to a low-carbon, climate-resilient economy in the context of sustainable development. To this end, it is expected to have a major impact on the mining sector, which will play a crucial role in the country’s broader transition to a lowcarbon economy.

Speaking to players across the logistics spectrum, we find out what impacts this plan to transform and modernise the country’s critical rail and logistics infrastructure will have on mining and logistics, economic recovery and long-term growth.

Gold was the mainstay of the South African economy for many decades, but it has continued to shrink in size and value, to the point where it could now be described as a “sunset industry”. Recognising this, SA Mining asked whether platinum group metals face a similar decline.

The good news is that Anglo American Platinum and other platinum miners are firmly of the opinion that the green energy transition and the metals that are key to this – including platinum – o er hope for the future of this segment of the industry.

Headline A proud division of Arena Holdings (Pty) Ltd, Hill on Empire, 16 Empire Road (cnr Hillside Road), Parktown, Johannesburg, 2193 PO Box 12500, Mill Street, Cape Town, 8010 www.businessmediamags.co.za

EDITOR

Rodney Weidemann

Tel: 062 447 7803

Email: rodneyw@samining.co.za

ONLINE EDITOR

Stacey Visser

Email: vissers@businessmediamags.co.za

ART DIRECTOR

Shailendra Bhagwandin

Tel: 011 280 5946

Email: bhagwandinsh@arena.africa

ADVERTISING CONSULTANTS

Ilonka Moolman

Tel: 011 280 3120

Email: moolmani@samining.co.za

Tshepo Monyamane

Tel: 011 280 3110

Email: tshepom@samining.co.za

PRODUCTION COORDINATOR

Neesha Klaaste

Tel: 011 280 5063

Explosives remain an integral part of mining activity, as they enable the extraction of minerals from rock formations that would have been inaccessible through conventional methods.

Email: neeshak@sahomeowner.co.za

SUB-EDITOR

On the subject of transformative processes, we take a look at the partnership announced by African Infrastructure Investment Managers, which aims to spearhead SA’s rail sector revival and reshape passenger and freight transport.

However, the dangers posed by these products should not be underestimated, which is why we talk to the manufacturers in order to consider the methods used by these explosives suppliers to ensure the safety of their product during the storage, handling and application phases.

As the global mining industry faces the twin challenges of needing to adopt sustainable practices to meet zero-emissions targets and constantly improving health and safety standards, an unexpected solution has arisen: prefabricated solutions. Using these can help mines achieve their environmental, health, and safety goals, while at the same time streamlining operations and improving profitability.

Finally, in our cover story, NSDV Law suggests that while challenges inevitably remain, 2025 is shaping up to be a very good year for the sector. This positive outlook is driven by amendments to mining law, improvements in digital technologies, and South Africa’s large share of the green minerals required to drive the just energy transition.

Andrea Bryce

BUSINESS MANAGER

Lodewyk van der Walt

Email: lodewykv@picasso.co.za

GENERAL MANAGER MAGAZINES Jocelyne Bayer

SWITCHBOARD

Tel: 011 280 3000

SUBSCRIPTIONS

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

PRINTING

CTP Printers, Cape Town

PUBLISHER

Arena Holdings (Pty) Ltd, PO Box 1746, Saxonwold, 2132

Motor Engineering (Deutz, Perkins, Detroit & all other engine types)

Parts | Engine Remanufacture

Car, LDV, Truck, Bus & Heavy Duty Vehicle Service & Repairs

Diesel Fuel Injections Services (Bosch Accredited)

Field Services (Mining & other Onsite Services)

The Critical Minerals Africa Group (CMAG), an organisation dedicated to advancing responsible sourcing and sustainable development of Africa’s critical mineral resources, has announced a strategic partnership with APO Group. The latter is a Pan-African communications consultancy, aiming to raise the global prominence of Africa’s critical minerals sector.

The partnership will leverage APO Group’s public relations and strategic communications expertise and CMAG’s leadership in the sector to showcase Africa’s role in the global supply chain for essential resources, and to elevate the global profile of Africa’s critical mineral sector.

Sub-Saharan Africa is estimated to hold approximately 40% of the world’s proven critical mineral reserves. Minerals like cobalt, lithium, and rare earth elements are essential for the global energy transition and advanced technologies. As demand for these resources rises, CMAG is committed to placing Africa at the centre of international discussions on critical minerals and associated supply chains while ensuring that the continent’s mineral wealth benefits local economies.

“This partnership with APO Group marks a key step in our mission to position Africa as a leader in critical minerals,” says Veronica Bolton Smith, CEO of CMAG. “By combining our expertise, we will amplify Africa’s voice in global conversations, influence policy and supply chain discussions, and unlock the full potential of Africa’s critical minerals.”

Zimbabwe’s government is taking action to support a more responsible artisanal gold mining sector, launching a US$23.7-million project to reduce mercury across mine sites in the country.

A toxic chemical used to extract gold from ore, mercury damages the lungs, skin, and eyes. The chemical can travel far from where it is released, polluting the air, water, and soil. Furthermore, it bio-accumulates up the food chain. In Zimbabwe, over 300 000 people work in artisanal gold mining, with the sector contributing to more than 40% of the country’s mineral exports. Across the country, 96% of artisanal gold mine sites use mercury, with miners o en forgoing protective equipment and risking exposure to toxic fumes. Zimbabwe’s artisanal gold mining activities result in more than 24 tonnes of mercury being released annually.

The African Development Bank Group board of directors has approved a $150-million senior loan to Mauritanian state-owned iron ore firm Société Nationale Industrielle et Minière (SNIM) to increase its logistics capacity and strengthen the country’s mining sector.

The approval, granted on 29 November, is part of SNIM’s $467m logistics expansion programme, which aims to double the transport capacity of its iron ore railway by 2030.

The investment will enable the company to produce higher valueadded products, such as iron ore pellets, and includes plans to construct a 12MW photovoltaic solar power plant as part of

The five-year planetGOLD Zimbabwe project is financially supported by the Global Environment Facility and implemented by the United Nations Environment Programme. The project is executed by the international non-profit organisation IMPACT in close coordination with the government of Zimbabwe.

The project will work together with local communities to reduce the use of mercury in artisanal and small-scale gold mining – the world’s largest source of anthropogenic emissions of mercury pollution – while improving the health and lives of local mining communities. The Zimbabwe project is part of a global programme implemented in 25 countries.

decarbonising e orts. The initiative also underscores the African Development Bank Group’s commitment to fostering sustainable economic growth and promoting inclusive development in Mauritania. The project includes climate resilience measures.

“This programme is a crucial forerunner of SNIM’s future growth as a producer of high-quality iron ore and will facilitate its downstream integration,” says Solomon Quaynor, the bank group’s vice president for Private Sector, Infrastructure and Industrialisation. “It also represents a significant step forward for Mauritania’s mining sector and will help establish a true regional industrial hub in the medium term.”

The current rate of decarbonisation is too slow to meet science-based targets. As the mining industry looks towards a new year, it needs to urgently commit to an intensified pursuit of decarbonisation targets, suggests Gerhard Bolt, principal with dss+.

Mining accounts for 4%-7% of direct global greenhouse gas emissions. When scope 3 downstream emissions are included, this rises to 28%, or 19 440 megatonnes of carbon dioxide equivalent, which is second only to agriculture/land use/waste at 30% of global emissions.

The research done by dss+ shows that little is changing, with roughly the same amount being emitted per tonne of mineral output every year. This holds especially true for deep gold and platinum mines that are experiencing reduction in ore grades and increasing demand for ventilation and cooling services – technological advances proving insu icient to o set an increase emissions intensity.

“Based on our analysis of 52 mining companies, we found that the average annual rate of emission reductions was approximately 2% between 2018 and 2021. The current 2% annual reduction rate would result in a 40% gap to 2030 targets.

“The current decarbonisation rate aligns to a future of more than 2°C of warming, far above the target of 1.5°C future set out by the Paris Agreement and associated science-based targets,” says Bolt.

“To achieve such reductions, the decarbonisation rate must increase to 4.5% per annum across the mining industry, and be extended to include scope 3 emissions.”

Over the past two years, Seriti Green has embarked on an ambitious journey to diversify South Africa’s energy mix, recognising the growing need for secure, a ordable and sustainable power.

The company currently has 23 renewable energy projects underway in various stages of development that will have a significant impact on the country’s energy sector. Its flagship Ummbila Emoyeni wind farm in Mpumalanga – currently under construction – will be South Africa’s first wind farm in that province, and symbolises innovation, leadership and progress in action.

Mike Teke, chairperson of Seriti Green and Group CEO of Seriti Resources, says: “As someone deeply connected to Mpumalanga and its people, I have seen first-hand the need for a Just energy transition. This is not only about sustainable energy; it’s about creating a future that is inclusive and prosperous for our communities.”

The construction of the first wind farm in Mpumalanga is a milestone the company is immensely proud of, but this is just the beginning, he says. “The project will pave the way for 4GW of renewable energy capacity by 2027, contributing to national energy security while empowering local communities.”

Circular Energy is proud to announce its partnership with Bradshaw LeRoux, a disability inclusion specialists organisation, to forge a disability-positive workplace. Together, they aim to action meaningful change in the workplace.

“I’ve found that the disability inclusion model does not speak to the individual abilities of people. The medical understanding of disability doesn’t recognise that most of the disabling barriers come from our environments, our attitudes, and the world that we live in,” says Lesa Bradshaw, founder of Bradshaw LeRoux.

Circular Energy is excited to begin work that will seek to diminish barriers for people with disabilities in the workplace, she says – the di erent types of barriers being attitudinal, environmental, and organisational.

“Attitudinal barriers refer to perceptions and stereotypes of people with disabilities, while environmental barriers speak to infrastructure that people with disabilities have to work and live in. Lastly, organisational barriers highlight what we include or forget to include in our policies, thus promoting ableism in the workplace,” she says. In order to create a disability-confident workplace, these barriers must be removed to enable people with disabilities to thrive.

As part of its commitment to advancing meaningful inclusion, Circular Energy will financially support 10 learners living with disabilities to obtain an NQF Level 4 Further Education and Training Certificate: Environmental Practice.

Although challenges remain, NSDV Law suggests that amendments to the legislation, improvement in technology and SA’s large share of green minerals hint at a very positive 2025.

As we move into 2025, it is worth recognising that a potentially bright future is built on the foundation of the Mineral and Petroleum Resources Development Act (MPRDA).

This Act became e ective legislation 20 years ago, and brought the South African mining industry into the 21st century. It removed the ownership of minerals from a private structure, as it had been under the previous law, and placed all of the country’s mineral wealth and ore bodies in the care of the State.

This meant that all citizens of the country could apply for specific mineral rights, where they believed they could optimally mine these.

According to Lili Nupen, co-founder and director of mining and environmental law at NSDV Law, there have been some huge developments since this Act came into e ect.

“For one thing, the rise of numerous junior miners and smaller empowerment players applying for mining rights and permits means that it is no longer only the majors that can a ord to mine in SA. Instead, many successful smaller organisations are now also able to exploit the mineral wealth of the country, thereby helping to grow the SA economy,” she says.

“Looking ahead, we expect to see a lot more movement in terms of larger mining companies selling what they consider less profitable operations to these junior players, that are

flexible enough to be able to mine certain ore bodies more e ectively.”

Nupen says more recently there has been a growing interest in the country’s mining sector, particularly with regard to critical

We expect to see a lot more movement in terms of larger mining companies selling what they consider less profitable operations to juniors with the flexibility to mine certain ore bodies more e ectively. “ “

or green minerals. South Africa has a major share of these minerals, and with the rising demand for them globally, this has played into the local industry’s hands.

“There has certainly been a significant

increase in due diligence requests made by international mining entities seeking to play in this space, by investing in operations related to the mining of these green minerals.

“It is also worth noting that we are increasingly seeing the integration of renewable energy projects within the mining space, which also has a positive impact on the SA economy. This is because mines that implement self-generation solutions are able to (in many instances) wheel the excess power produced back into the grid, reducing loadshedding and boosting the economy.”

That is not to suggest there aren’t challenges, she suggests, pointing to the increasing deterioration of critical infrastructure such as railways and power stations as a major issue.

“Both our ports and rail infrastructure have been poorly maintained for a long time, although there is hope that the government of national unity (GNU) will lead to more accountability with regard to these stateowned enterprises, as GNU partners put pressure on the ruling party in this regard.”

There are, a er all, a lot more checks and balances in the GNU, she says – so there is more accountability, which means things will hopefully get done more e ectively.

While the DMRE is still in the process of sorting out its new cadastre system, NSDV notes that there is some phenomenal work being done by the Council for Geoscience.

SA is an attractive destination from a green minerals perspective, and the GNU has recognised the potential this o ers to bring in foreign investment. “ “

“This will positively impact the mining value chain too, as more accountability from all players will only improve the sector.”

She notes that NSDV Law has already seen positive impacts, with the company receiving a number of water-use licences for its clients in recent months from the Department of Water and Sanitation, as well as environmental authorisations and general feedback from the Department of Mineral and Petroleum Resources.

She says there has been an increase in both collaboration and openness from these departments, which is a pleasant change from the o en “radio silence” mining companies are used to.

“The GNU is certainly leading to improvements – we have already seen advances in the transport, minerals, water and environmental spaces within government. Of course, it is not all rosy, as many challenges remain, like fluctuating commodity prices, labour and community issues, wage disputes, leading to unhappiness among both workers and the communities that surround the mines,” says Nupen.

“There is also a lot of frustration for mining companies with regards to di erent interpretations of the MPRDA from various departments and their o icials. While I believe our legislative regime is actually quite brilliant, the di ering interpretations of the law continue to create challenges for the mining sector.”

Of course, she continues, the ongoing global energy transition is forcing the rest of the world to look more closely at SA (and Africa), which holds a large percentage of many of the critical minerals needed to facilitate this transition. This increased demand for “green” minerals a ords the local industry many opportunities to grow.

“SA is thus an attractive destination, from a green minerals perspective, and the GNU has recognised the potential this o ers to bring in foreign investment. We also anticipate that it will ensure that the proposed amendments to the MPRDA occur, which will only make SA a more attractive destination for foreign investment.”

One thing to note, she says, is that there is always talk of streamlining licence and permitting requirements.

“We now have the opportunity to do so through these proposed amendments, while also considering social and labour requirements around community upli ment and skills development.

“We also anticipate a greater focus on local beneficiation, driven by increased spend and focus on research and development. This can only boost job creation, while creating a new revenue stream for the mines – a genuine win-win scenario,” she says.

She suggests that NSDV Law has a positive outlook for the future, as SA is in what she refers to as a genuine “sweet spot”.

The council has made enormous strides in respect of exploration and the mapping out of where the various minerals bodies are found across SA, collating and collecting as much information around these as possible, which will make populating the cadastre system with data that much simpler, when it comes online.

“Not only do we have a major share of the green minerals that are in demand, but our laws are being amended – which will, ideally, open the industry up to greater foreign investment – and we have the promise of a new cadastre system to be implemented in June this year.

“In addition, the increasing investments in renewable energy generation are not just boosting mining operations, but also improving the national energy crisis, by wheeling the excess generation into the Eskom grid.”

She is not one to view the industry with rose-tinted spectacles, she says, but all of the above-mentioned changes demonstrate that there is huge and positive movement in the industry.

“I am really hopeful that 2025 will see even greater impacts in the mining space, particularly in the junior mining sector, where a growing number of these players can add value to industry through the creation of a mid-tier mining space that will further boost job creation and the economy,” says Nupen.

While not yet promulgated, the Climate Change Act

will have a major impact on the mining sector. It is thus best the sector begins preparing for this.

By Rodney Weidemann

South Africa’s Climate Change Act is considered to be pivotal legislation, designed to define, manage, monitor, and implement the country’s response to climate change. Although signed into law in July 2024, the act will only come into operation on a future date yet to be announced.

The main purpose of the act is to support South Africa’s transition to a low-carbon, climate-resilient economy in the context of sustainable development. To this end, it is expected to have a major impact on the mining sector, which will play a crucial role in the country’s broader transition to a lowcarbon economy.

SA Mining spoke to several law firms that work closely with the industry, to clarify the impact this act – when promulgated by President Cyril Ramaphosa – will have on the mining sector.

KEY MECHANISMS

Asked about the key mechanisms aimed at reducing the risks of climate change impacts that mining organisations should be aware of, Mandy Hattingh and Minnette Le Roux, from environmental law firm NSDV Law, note that there are several.

“The new act underlines that mining

companies must comply with mechanisms aimed at mitigating and adapting to climate change. There are several key proposals under that act that will impact on mines,” says Le Roux.

“With regard to national greenhouse gas (GHG) emission reduction targets, the act imposes sector-specific emissions caps that align with the national trajectory. These targets promote the reduction of emissions, without compromising the contribution to GDP made by energy-intensive industries. It should be noted that the sector-specific emission reduction targets, including those applicable to the mining sector, are still to be established.”

A second area of impact is that of carbon budgets. Here, mining companies must comply with carbon budgets that prescribe limits on GHG emissions over a specified period. Noncompliance may lead to financial penalties under the Carbon Tax Act, 2019.

Hattingh adds that GHG mitigation plans are another mechanism applicable to mines, explaining that mining companies must develop, submit, and implement GHG mitigation plans to demonstrate how they intend to reduce GHG emissions. These should focus on energy e iciency, renewable energy integration, and innovative low-carbon technologies.

“Reporting obligations will also have an impact, as mines will be expected to report GHG

emissions annually, in line with the National Greenhouse Gas Inventory requirements,” she says.

“Lastly, adaptation measures will need to be implemented, as the act emphasises climate risk assessments and strategies to ensure infrastructure resilience, water security, and workforce safety.”

In addition to and as a result of these mechanisms in the act, Mikaella Bodeux and Catherine Warburton of Warburton Attorneys, a specialist mining, environmental and climate change law firm, say there are several key areas of impact on the mining industry as a result of the GHG emission reduction trajectory towards net zero and beyond.

“First and foremost, mining companies will need to reduce GHG emissions from their own mining operations in order to align with this trajectory,” suggests Bodeux.

“The national GHG emission reduction trajectory will require a shi away from the use of fossil fuels andenergy security maybe impacted during the transition to renewables, which will impact the mining sector, as well as South Africa as a whole.”

Warburton says this issue is obviously compounded by historical supply issues from

Some of South Africa’s largest mining houses have their roots in the coal industry, and many will have to diversify their mining portfolios or otherwise look at shi ing to mining other commodities. – Warburton “ “

Eskom. Nonetheless, this challenge has already led to many mining houses investing in private renewable energy sources to ensure stability and cost reduction, indicating they view the transition to renewables as an opportunity, rather than as a threat.

“A pivotal issue will be the impact on the coal industry and the knock-on e ects of the need to phase down the use of fossil fuels in order to meet carbon reduction targets. Some of South Africa’s largest mining houses have their roots in the coal industry, and many will have to further diversify their mining portfolios or otherwise look at shi ing to mining other commodities as some have already done,” she continues.

“There will likely be an associated increase in demand and opportunities for mining for PGMS and other minerals such as lithium and copper, which play a critical role in the renewable energy and battery storage sectors. We are therefore likely to see a shi in dominant commodities as a result of the need to reduce carbon emissions.”

Law firm ENS points out that a person to whom a carbon budget has been allocated must prepare and submit a GHG mitigation

plan to the minister for approval. Lawyers for ENS note that such a plan must firstly describe the mitigation measures that the person to whom a carbon budget is allocated proposes to implement in order to remain within their allocated carbon budget.

Secondly, they must comply with the content requirements of such plans as may be prescribed by the minister responsible for environmental a airs, including requirements pertaining to processes, procedures and reporting.

Ntsiki Adonisi, head of ENS’s Natural Resources and Environment practice, suggests that a person to whom a carbon budget has been allocated is faced with several tasks.

“They must be aligned with the national GHG trajectory; they must implement the approved GHG Mitigation Plan and monitor annual implementation of the plan in accordance with the prescribed methodology; and they must also evaluate progress on the allocated carbon budget,” she says.

“The person is also required to annually report on the progress against the allocated carbon budget to the minister, and in the event that such reporting indicates that the person has failed, is failing or will fail to comply with the allocated carbon budget,

Warburton Attorneys highlights three key sections of the act that mining companies should be made aware of, in light of the consequences of noncompliance with these provisions:

■ Section 23 of the act allows for the minister responsible for environmental a airs and climate change to request that an entity submit an Adaptation Information and Synthesis Adaptation Report. Should an entity fail to provide this report, or provide false or misleading information in this report, this is considered an o ence under the act.

■ A failure to submit a carbon budget where required in terms of section 27 of the act is an o ence. Notably, there is currently no penalty in the act for non-compliance with a carbon budget or failure to implement a mitigation plan and the dra regulations may provide for this. The department responsible for environmental a airs and climate change has indicated that the Carbon Tax Act will be amended in due course to provide for penalties in this regard.

■ The minister is also empowered in terms of section 28 of the act to prescribe thresholds for the use of synthetic GHGs. If these thresholds are exceeded, or if an entity fails to comply with any measures that facilitate the phase-down or phase-out of synthetic GHGs, this is considered an o ence under the act.

■ O ences under the act are punishable by way of a fine of not more than R5-million or imprisonment for a period not exceeding five years for first time convictions. For second or subsequent convictions, this escalates to a fine of not more than R10m, or to imprisonment for a period not exceeding 10 years or to both a fine and imprisonment. Some critics point out that these penalties are wholly insu icient while proponents from a ected industries counter that these penalties are unfair, bearing in mind that they are liable to pay carbon taxes on their emissions as well.

must provide a description of measures they will implement in order to remain within the allocated carbon budget.”

This, she says, will mean mining companies will have to ensure their operations are aligned with the above,

which may have economic-related consequences – in the form of an increase in operational costs – arising from this regulatory transition risk.

It must also be recognised, says Adonisi, that climate change is a global problem, and that on an international scale, governments, political and economic unions are taking action to combat climate change. For example, the European Union’s Carbon Border Adjustment Mechanism (CBAM), which contemplates the imposition of a carbon tax on imports, will impact commodities such as steel and iron ore, among others.

“The CBAM will have a direct impact on South African mining companies whose portfolios include the abovementioned commodities. According to a working paper of the South African Presidential Climate Commission, the introduction of the CBAM will increase the costs of South African exports in European markets, reducing their competitiveness, and thus the likely value of future exports.

“Nonetheless, although compliance with the Climate Change Act may lead to an increase in operational costs, it also o ers mining companies the opportunity to gain a competitive edge,” she says.

It is important to remember that, although the Climate Change Act has been published, it is not yet in e ect, as the president has not yet proclaimed its commencement, notes NSDV’s Le Roux.

“On commencement, the Climate Change Act will be included in the list of specific environmental management acts under section 1 of the National Environmental Management Act, 1998. This means that every application for an environmental authorisation needs to include applicable provision for the adherence to requirements that are prescribed in the Climate Change Act, relevant to the listed or specified activity in question.”

Furthermore, she says, environmental

management inspectors will also have authority to investigate any transgression under the Climate Change Act.

“It is therefore recommended that mining companies start considering the ‘dra guideline for consideration of climate change implications in applications for Environmental Authorisations, Atmospheric Emission Licences and Waste Management Licences’,” says Le Roux.

“The Climate Change Act provides a framework for mining companies to futureproof their operations while contributing to South Africa’s climate goals. By embracing the act’s requirements, the mining sector could lead in the transition to a low-carbon economy, securing long-term viability and resilience.”

- Heavy duty engineering design - 38 meter long - 1350 wide conveyor (3180 ton/hour)

- Comes with 2 x 75kw - 525 Volt motors with gearboxes and transformer. - Can be disassembled completely. ONLY R1 180 000 Excl

Your mining operation is unique. By opting for Joy equipment, our team of experts and engineers will work closely with you to customise its design according to your specific needs and applications. We provide comprehensive support throughout the entire lifecycle of your machine through on-demand field service, remote monitoring and condition monitoring programs. We aim to help you transform and enhance efficiency and responsiveness to changes and challenges within the mining sector.

Platinum group metals are closely associated with commodities like gold, but unlike the latter, the green energy transition offers hope for the future for PGMs.

By Rodney Weidemann

At last year’s Mining Indaba, Craig Miller, Anglo American Platinum CEO, asked the tough question: do platinum group metals (PGMs) have a long-term future, or will PGMs follow gold as the next sunset mining sector in South Africa?

According to Miller, in order to understand if PGMs have a long-term future, it is necessary first to look at the current state of the market. He notes that PGMs have applications in electronics, artificial intelligence (AI), chemicals, jewellery, and even the medical industry, where they are used in pacemakers.

“Despite these numerous and varied applications, the industry has certainly faced significant headwinds in the past year, and it is expected to continue to do so for the foreseeable future.

“Prices declined by some 35% in 2023 – driven by global economic uncertainties, such as inflationary pressures and regional wars. These factors impacted the industry in many ways, but the sector has been here before, and each time it has emerged stronger and more resilient. I have no doubt it will do so again,” he says.

IMPORTANCE TO THE ENERGY TRANSITION

There are some early signs of recovery already, notes Miller, pointing to the fact that the automotive industry accounts for around two-thirds of PGM demand, due to its need for catalytic converters – and these are once again gaining in traction.

He also highlights a 5% increase year on year in jewellery demand, adding that the World Jewellery Confederation expects this to increase by some 7% in 2025.

Sylvania Platinum CEO Jaco Prinsloo says PGMs are classified as strategic minerals by South Africa’s key commercial and diplomatic partners, including China, the European Union, Russia, and the United States.

“These metals are vital to various industries, such as automotive catalytic converters, petrochemical processes, optical instruments, the glass industry, and medical devices. Platinum is also used in jewellery and has a minor role as an investment asset,” he says.

“It is worth noting that South Africa possesses approximately 70% of the world’s platinum and 40% of its palladium reserves, providing the country with a significant advantage in global markets.”

Prinsloo suggests that the current lower

price environment in the PGM sector is a challenge for all PGM producers, but that Sylvania strongly believes that this is a temporary situation.

Andries Rossouw, PwC’s Africa Energy, Utilities and Resources leader, agrees that the demand for PGMs is very much linked to the energy transition, in particular in the mobility sector and the hydrogen economy.

“Given the uncertainty of the pace of the transition, mining companies have been reluctant to over-invest in capacity. The current depressed PGM price environment has exacerbated this lack of investment, and this, in turn, does mean that the South African production profile will decrease over time,” he says.

“South Africa’s dominant reserves and resources position for PGMs also means that the country will continue to be a key PGM supplier, globally. In the end, the world needs PGMs, and, thanks to its premier PGM position, South Africa will have to deliver into that demand.”

Rossouw adds that PGMs are metals with unique characteristics, which are likely – in the long run – to play a key role in the global economy, with South Africa continuing to play a key role in their supply to the rest of the globe.

Several local companies are at the forefront of PGM beneficiation.

– Miller “ “

PGMs will play an increasingly central role in the JET, and we expect them to be recognised on the critical minerals list.

Miller notes that the energy transition will likely be more complex than expected, though in the longer term, he feels the picture is much brighter. A er all, PGMs have a unique role to play in the just energy transition (JET), and this is where the real future lies.

“PGMs will play an increasingly central role in the JET, and we expect them to be recognised on the critical minerals list. It is clear that decarbonising the automotive sector is something we must all support as responsible citizens, particularly as road transport decarbonisation is not progressing as rapidly as expected.”

He adds that electric vehicle growth is something that poses a longer-term threat to PGMs, because these cars do not use catalytic converters.

“However, although hybrids were seen as transitional technologies, these cars are proving more resilient than expected, which is good news for the PGMs industry. Moreover, we are of the view that platinumenabled hydrogen-powered vehicles will be a new form of transport that will boost the sector.”

Amplats has partnered with BMW and Sasol to launch the first trial of a pilot fleet

of BMW iX5 hydrogen-powered fuel cell vehicles (FCV). Meanwhile, Toyota is also testing an FCV model, while Honda has one under production in the US.

“Furthermore, in China there are several models of FCV in production or under development.

“Looking beyond automobiles, governments are also investing heavily in green hydrogen projects and infrastructure. The EU has set ambitious targets for hydrogen production, and PGMs are a vital component of the electrolysers that ultimately produce the hydrogen,” he says.

Prinsloo agrees that the increasing focus on and anticipated growth of the hydrogen economy should lead to demand for platinum growing as we move forward, with the metal expected to play a key role in growing clean energy supply into the future.

“Green hydrogen is produced via electrolysis, using renewable energy sources for power, and is a key technology for decarbonising heavy industries and everyday activities,” he points out.

“PGMs are integral to the e iciency and e ectiveness of proton exchange membrane (PEM) electrolysers, which are well suited

Anglo American Platinum and Impala Platinum are notable examples, having developed sophisticated refining processes that convert raw PGMs into various industrial and consumer products. These companies have invested significantly in technologies and processes to enable the local processing of PGMs into higher-value products.

to using intermittent renewable energy sources like solar power.

“Platinum and iridium are critical components in PEM electrolysers, where they act as catalysts to produce hydrogen. This hydrogen can then be used in various applications, including in FCVs.”

Rossouw adds that PGMs are also key in emission control. Although their application is evident in the mobility sector, there is also a growing demand for industrial emission control and other green applications for PGMs.

“Hydrogen is seen as a key method of greening traditional industrial processes, such as replacing coal as a reductant in steel manufacturing. It also o ers excellent storage solutions for both stationary and mobility solutions,” he says.

“South Africa is an excellent refiner of

PGMs to the pure metal stage, and as new uses for PGMs are discovered, the country should consider the best ways of maximising value from its PGMs, where it can do so on a competitive basis.”

Sylvania notes further that the adoption of PEM electrolysers and FCEVs has the potential to significantly reduce CO2 emissions, contributing materially to the United Nations’ targeted CO2 reductions by 2030.

“PGMs are indispensable to the decarbonisation and energy transition e orts. Their role in reducing vehicle emissions, producing green hydrogen, and powering fuel cells underscores their importance in achieving a sustainable and environmentally friendly future.

“As the world moves towards cleaner energy solutions, the demand for PGMs is set to rise, highlighting their critical role in the global green economy,” says Prinsloo.

“From Sylvania’s perspective, we believe that there is still a strong future for PGMs and that we would be able to continue adding value to our stakeholders by focusing on low-risk, low-cost, cash-generative businesses and maintain our position at the bottom end of the PGM industry cost curve.”

Prinsloo points to Sylvania Platinum’s recent joint venture (JV) with Limberg Mining Company, a subsidiary of ChromTech Holdings, which underscores its strong confidence in the future of the PGM and chrome sectors in South Africa.

“This strategic partnership, known as the Thaba JV, is set to process PGM and chrome ores from historical tailings dumps and current mining areas at the Limberg chrome mine, located in the northern part of the western limb of the Bushveld Complex.”

Amplats’ Miller also believes in the future of PGMs, suggesting that with strong partnerships and intense focus, the company – and the metal – will continue to play a vital role in the global economy for decades to come.

“I believe the answer to the question of ‘Do we have a future?’ is a resounding yes. We are investing in the technologies of tomorrow and seeking new applications and markets for these metals.

“Moreover, we are at the forefront of global innovation in respect of the JET, and are well placed to help build a cleaner, greener and more promising future. Amplats thus remains committed to ensuring these metals play a vital role in tomorrow’s future,” he says.

Rossouw holds a similar opinion, indicating that PGMs are unique metals that

PGMs are crucial to the national economy. Between 2013 and 2023, they generated over R1.5-trillion in export earnings, more than double the revenue from coal, gold, or iron ore exports. Before 2019, PGMs accounted for 8% of total merchandise exports. Since the pandemic, this figure has risen to 13%.

the world needs for a cleaner greener future.

“As the main resource holder, South Africa will continue to play a key role in the supply of PGMs. However, the country’s ability to remain the dominant supplier will ultimately depend on its ability to create an enabling environment for its miners, and for industrialists to maximise the value of these special metals,” he says.

Focusing on innovation at every stage of a tyre’s life, we’ve developed proven solutions that support customers on their sustainability journey. Promoting a circular economy, our thermal conversion mining tyre recycling solution helps mines solve the challenge of scrap tyres.

Working closely with China as it seeks to meet the needs of the sustainable transition could be the key to securing the future of the metals and mining sector.

Around 90% of the metal-based items used globally are currently made in China. The country is ingrained at the very epicentre of the metals industry and, for the foreseeable future, will continue to be an invaluable source for domestic and international markets.

China’s vast experience and knowledge of the industry and its evolving markets have allowed it to build resilience and adaptability in this o en unpredictable sector. It has, for example, become fully integrated across the entire supply chain, from mining and smelting to finished products. China also holds a dominant position in future-facing commodities that are essential for the global energy transition.

As such, explains Richard Horrocks-Taylor, global head of Metals & Mining at Standard Chartered, it is now actively at the forefront of developing the technologies and products that drive today’s demand for metals and minerals. China is a key player in the electric vehicle (EV) sector, as well as in renewable energies development, including solar panels and wind turbines.

“With its ingenuity, forward-looking strategies and unique skill sets around the development of new mines, China will be crucial as the industry seeks to address a pressing challenge in the mining sector: building enough projects quickly enough to satisfy demand.

“The International Energy Forum (IEF) estimates that to electrify the global electrical fleet of vehicles by 2050, at least 35 new copper mines will be needed to meet the demand of this essential metal for the green transition,” he says.

“Currently, much uncertainty surrounds how this is going to be achieved, but China’s engineering prowess could be a part of the solution. Its ability to innovate and deliver projects on time and within budget has made collaboration with Chinese groups attractive to many international players, particularly during the construction phase of new mines.”

“ “

Many geographies welcome Chinese investment and the technological and production capabilities it brings – particularly in renewable energy and the battery materials supply chain.

Horrocks-Taylor suggests that realising the future mining landscape that is required cannot be accomplished without a joint e ort – a cross-continental community that brings together the strengths and specialisms of multiple parties, both from China and from countries elsewhere.

“Of course, the geopolitical strains

between China and the West endure, with some Western governments seeking to prevent Chinese acquisition of assets in key commodities – particularly those linked to the energy transition – on the basis of protecting national strategic interests.”

Many geographies, however, welcome Chinese investment and the technological and production capabilities it brings, he says – particularly in renewable energy and the battery materials supply chain.

“As an industry, we are facing the monumental challenge of both transitioning away from fossil fuels and meeting growing global metal demand for future-facing commodities. Successfully achieving this will require greater dialogue and partnership between China and the rest of the world.

“The success that such collaborations can bring has already been evidenced by the joint venture Simandou project in Guinea, between Chinese players and Rio Tinto, and it is a united approach that will position us to deliver the commodities that will help us transition. With its leading position in Asia, the Middle East and Africa, Standard Chartered is uniquely positioned at the juncture between China and the rest of the world to help connect buyers and create value for all stakeholders.”

Ultimately, he says, the industry’s future success is dependent on a mindset shi , gradually transitioning perspectives and potentially misconceptions, and accepting the potential for China to bring real value to the table.

“By breaking existing barriers, opening a channel for dialogue and being receptive to the possibility of collaboration, the stage can be set for the new mining era,” he says.

[[Let’s talk about what’s working

We don't have all the answers, but we're here on the ground working to make real world impact where it matters.

Let's keep talking at sc.com/letstalk

A digital health and safety solution centralises information and boosts compliance, improving the overall performance of a mine.

The digitisation of a mine’s health and safety function provides enormous benefits, o ering enhanced operational e iciencies, while ensuring sustainability and addressing the demand for transparency. In addition, it allows for the automation of processes, thereby minimising downtime and reducing costs.

It is for these reasons that Saryx Engineering Group has launched a cloudbased solution that provides a transparent, collaborative workflow platform, one that is accessible on any device, from anywhere and at any time. Known as HSEC Online®, the solution was originally designed with the health, safety, environment and community (HSEC) compliance of its own organisation in mind.

According to Ingrid Osborne, Saryx Engineering co-founder and CEO, it allows for the management of vast amounts of compliance and safety data – fostering collaboration between all relevant stakeholders, thereby improving the overall performance of the mine.

“As an electronic solution, it is able to centralise all the HSEC documents, which makes it easy to access, update and verify information in real time. Furthermore, it ensures your compliance records are accurate and auditable, in turn promoting transparency and reducing a mine’s risk of non-compliance, while also enabling a chain

of accountability for both the mine and the contractor,” she says.

There are multiple reasons why a digital solution is better than a physical safety file, including the fact that all the information is centralised, making accessibility simple. Furthermore, because it provides automated alerts regarding documents that are set to expire, it improves e iciencies.

In addition, Osborne notes that it is more cost-e ective, as it reduces the resources required from the contractor’s perspective, and enables multiple contractors to be processed through a single resource.

“Also, it improves accuracy by minimising the human error associated with manual files, while its digital nature means it is highly scalable, as the system can accommodate growing data needs without the physical storage constraints.”

Ultimately, she says, it improves the entire HSEC process. “We always like to say that if you want real-time safety, you need access to real-time data.”

Speaking to the obvious security concerns around a digital solution, Osborne notes that Saryx has focused on four key elements in this regard. First is encryption, to secure data during both transmission and storage. Second, access control, which prevents non-authorised users from viewing sensitive information.

Audit trails are third. These are to track all users for compliance and determine

exactly who is using the system, when they are doing so, and whether they are allowed to do so. And last, data retention policies. All of these ensure HSEC Online® is complaint with all relevant international security standards.

“We have also focused a lot of attention on training and support, o ering a dedicated training centre, as well as a 24/7 support desk. In addition, Saryx o ers weekly training that a ords users the opportunity to focus on specific modules or aspects of the solution,” she says. “We also look at the number of support calls we receive on a specific topic, and develop what we call ‘power hour’ lessons on these topics, helping to train users on these targeted areas, while also reducing the pressure on our call centre.”

HSEC Online® is a product that delivers intuitive user interfaces, so ware that is designed to minimise the learning curve, role-based training for administrators, and specific training for both contractors or endusers, says Osborne.

“I have no doubt that the future of HSEC compliance lies in the digital space. Mines – with their strong focus on safety – want proactive risk management, insight into issues before they escalate, and a way to reduce ine iciencies and human error.

“HSEC Online® o ers them a powerful and connected tool that will significantly boost health and safety in what is a tough and dangerous industry,” she says.

•

•

•

• Proactively

•

Digital workfl ow solutions can assist mines to increase operational effi ciencies, improve security and compliance, boost health and safety, and optimise visibility and control.

In industries like mining, logistics, and commodities, e icient operations are essential to maintain secure access, compliance, and asset protection. These industries typically face operational challenges that include access control, truck scheduling, gate timing (between sites and within sites), seal management, safe loading, and route validation.

It should be clear then, adds Mark Lilje, a director at Nimbus Solutions, that operational delays, the , and noncompliance with regulations can disrupt workflows, increase costs, and jeopardise a company’s reputation.

“To this end, the Nimbus Solutions Commodities-Workflow Solution empowers companies with full control and visibility over the movement of goods, vehicles, and personnel. It further ensures monitoring and optimisation from loading to delivery, thereby reducing delays and enhancing security for a seamless workflow,” he says.

“Generally, the solution is deployed at the mine – the point where the product is dispatched from – and is usually also applicable at the port or siding, where the product is o loaded. As part of the visibility it delivers, the solution is equally e ective for mines in respect of issues like access control and visitor management.”

Lilje explains that the solution is provided in the form of a Platform-as-a-Service solution. This mobile and web application seamlessly integrates with mobile scanners, boom gates, weigh bridges, and radio frequency identification (RFID) readers, he adds, e ectively streamlining a mine’s operations.

“It also integrates seamlessly with existing systems to provide real-time monitoring, secure access, and operational e iciency across sites. For example, transporters/ trucks and drivers are pre-cleared and scheduled to allow access; real-time validation takes place at the point of entry; and integration with the weighbridge and camera systems means that every step of the process is date-, time- and location-stamped, allowing for analysis of durations associated with any individual, vehicle, or location.

“When coordinating truck schedules, ensuring secure access, or maintaining compliance with health and safety standards, ine iciencies can lead to costly delays, security breaches, and compliance risks. Nimbus o ers a comprehensive suite of services that address these challenges, helping mines to run more smoothly, safely, and e iciently.”

He notes that the number of vehicles allowed on-site may be controlled and

■ Operational e iciency: Automate vehicle and truck scheduling, gate timing, and cycle durations to eliminate delays and optimise resources.

■ Security and compliance: Real-time seal management, RFID integration, and enterprise resource planning systems like SAP protect your assets and prevent unauthorised access.

■ Health and safety: Ensure vehicles and personnel meet compliance standards with integrated medical certifications and safety protocols.

■ Visibility and control: Gain realtime monitoring of access points, vehicle movements, and deliveries to reduce errors and allow quick intervention.

the reporting currently includes extensive standard reports, while additional reports may be configured on demand. Furthermore, real-time alerts are sent to responsible individuals to attend to situations requiring their level of authority.

“Obviously, every site or operation faces its own unique risk and safety challenges that need to be catered for. The Nimbus Solution includes a large set of standard tasks or procedures, but is also thoroughly customisable. This means that, by design, it is still able to meet the varied needs and demands of a wide range of customers within the mining and logistics spaces,” says Lilje.

Operational delays, theft, and non-compliance can severely disrupt workflows and elevate costs in mining. Nimbus Solutions delivers a comprehensive Platformas-a-Solution (PaaS) that optimises your logistics and supply chain, from vehicle entry to final delivery. By integrating with weighbridges, Radiofrequency identification (RFID) readers, and boom gates, Nimbus helps mining companies gain full visibility and control over the movement of goods, vehicles, and personnel, ensuring efficiency, safety, and compliance.

Maximise efficiency and safeguard your mining operations with Nimbus Solutionsstreamline vehicle access, monitor routes in real-time, and eliminate costly delays.

Operational efficiency: Eliminate manual errors with automated access and scheduling, reducing delays and improving resource allocation.

Enhanced security: Real-time seal management and automated vehicle validation ensure safe, tamper-proof deliveries.

Compliance and safety: Automated systems ensure compliance with safety regulations and operational standards, protecting both personnel and assets.

Cost optimisation: Real-time data insights allow you to make informed decisions, reducing operational costs and preventing delays.

As the world shi s towards cleaner energy sources, Namibia and South Africa provide favourable conditions, and are well situated on one of the world’s central shipping routes to transport the commodity to all corners of the globe.

Two key projects are already in advanced stages of development in Namibia, with the Hyphen Hydrogen Energy and Daures projects well underway and gearing to transform Southern Africa into a vital supplier of hydrogen, to meet the energy demands of developed nations.

Global pumping solutions provider KSB has identified the vast potential of these types of projects in the region, and through its KSB Pumps and Valves subsidiaries in Namibia and South Africa, is investing heavily in bringing the right skills to the region.

This type of specialised planning is essential to ensure the success of the hydrogen economy. The process of creating green hydrogen is complex, as is the generation of renewable electricity to split water molecules into oxygen and hydrogen through electrolysis.

According to KSB business strategist Ulrich Stahl, the important enabler function of hydrogen is that it makes the transport of renewable energy over long distances possible. Furthermore, transporting hydrogen as a gas or in liquid condition is challenging.

“Being a light gas it is di icult to contain and requires compressing and cryogenic freezing to convert it to liquid form. This

With abundant sunshine and wind, Southern Africa is perfectly positioned to become a global powerhouse in green hydrogen production.

is prohibitively di icult and has led to techniques where it is converted to ammonia, which is a compound of nitrogen and hydrogen.

“The addition of nitrogen to create ammonia makes it easier to store and transport than pure hydrogen. Once shipped to its destination, it can be converted back into hydrogen, making it a practical and scalable solution for fulfilling global energy needs,” he says.

KSB Pumps and Valves Namibia managing director DeWet van Wyk adds that with its local manufacturing ability and access to global supply chains, KSB is well poised to support the scale of the hydrogen economy where entire regions need to be transformed.

“KSB is planning for the full cycles of equipment and services needed, as the scale of these hydrogen projects requires extensive infrastructure, both for the hydrogen production process, and for supporting the influx of workers and services needed to sustain the operations,” he notes.

“For hydrogen production, advanced electrolyser plants need to be built to separate hydrogen from water, using renewable energy. Our technology will play a crucial role in supplying the specialised pumps needed to handle the ultra-pure water in electrolysers, as well as those needed for pressurising hydrogen and convert it to ammonia to facilitate transport.”

KSB’s pumps ensure the ultra-pure water used in electrolysis remains contaminant-

free, which is crucial for maintaining the integrity of the electrolysers. Additionally, KSB pressurises the hydrogen, making it easier and cheaper to transport it as ammonia.

Beyond the technical infrastructure, he adds, these projects will require significant investment in population amenities. The remote location of the hydrogen projects, particularly in sparsely populated areas like Lüderitz and the Northern Cape, necessitates the development of entire support ecosystems.

Housing for thousands of workers will need to be built along with critical services such as wastewater treatment, food supply chains, schools and healthcare facilities among others.

KSB believes that with international collaboration, government support and private-sector investment, the green hydrogen projects in Namibia and South Africa hold enormous promise, says Ulrich.

“Southern Africa’s ability to produce and export clean green hydrogen positions the region as a strategic destination for global investment. The infrastructure needed to support these projects will also provide much-needed economic growth.”

Mining operators are seeing an increased demand for minerals and ores. Operators must now consider the costs of pump maintenance and replacement as well as the cost-benefit of utilizing fewer larger pumps versus several smaller pumps to perform the same work.

The KSB GIW® MDX pump line delivers proven results in the harshest hard rock mining applications.

Through substantial investment in research and technology, Sasol is developing efficient energy solutions for the present while also pioneering renewable and sustainable options for the future.

Proudly South African fuel brand, Sasol, is renowned for its ability to enable and advance cutting edge technologies, as well as develop high-quality products for the benefit of its customers. As the company moves into 2025, it is focusing on the business of today, by optimising the use of current fossil feedstocks.

“This involves improving e iciency in existing processes to lower energy consumption and emissions, and innovating and commercialising new sustainable products to o er customers access to alternative lower carbon footprint product options,” says Dumisani Bengu, Sasol Senior Vice President for Energy Marketing & Sales.

Sasol currently o ers SASOL TURBODIESEL ULS 10ppm, which uses the company’s innovative, advanced additive technology with a sulphur content of less than 10 parts per million. The fuel formula includes revolutionary additives to clean and protect engines, enabling them to run with less harmful exhaust emissions and improved fuel e iciency.

This fuel allows fleets and drivers

to transition to modern diesel engine technology, thus contributing to reduced carbon dioxide emissions and a cleaner environment. The diesel also conforms to

“ “

Sasol, as the energy transition partner of choice for the mining industry, aims to make fuel management services that are smarter, simpler, and more e ective. We will enable our mining customers to meet their energy transition goals while minimising any performance impacts.

international standards for diesel, which is critical in ensuring fit-for-purpose operation of modern, as well as older technology vehicles.

Another o ering by Sasol is the SASOL TECHNO OIL. This product comprises a complete range of lubricants designed to complement Sasol’s ultra-low sulphur diesel and can be used for any mining equipment’s lubrication requirements.

These lubricants are engineered to provide optimal care for equipment and vehicles, saving owners’ money, prolonging the engine lifespan and enhancing reliability, while delivering improved performance and enhanced fuel e iciency.

Sasol is also advancing its more sustainable product portfolio, with Renewable Diesel, Sustainable Aviation Fuel and Renewable Energy. Bengu explains that the company is building its business of the future by exploring lower carbon feedstock alternatives. “This includes slowly transitioning to renewable and low-carbon raw materials, to decarbonise our own operations and supply chain,” he explains.

Sasol’s Business Building team is evaluating alternative feedstock solutions to produce lower carbon fuels such as bio-diesel and sustainable aviation fuels, chemicals, green hydrogen, green ammonia, renewable energy, and other low carbon emission products.

“ “

Sasol’s first large-scale renewable energy project, Msenge Emoyeni Wind Farm, reached commercial operations in October 2024. The 69MW wind farm comprises 16 turbines and is already supplying electrons wheeled through the national grid to its Sasolburg Operations in the Free State.

Since 2021, Sasol has become South Africa’s largest private sector buyer of renewable energy. With renewable energy being a cornerstone of Sasol’s strategy, the company currently has 688 MW of RE projects under construction with Air Liquide.

These comprise: a Free State based 97,5 MW solar project; the Impofu cluster, consisting of three onshore wind projects totaling 330 MW of wind renewable energy; and Paarde Valley PV2 Solar PV Farm and the Mulilo De Aar 2 South Wind Farm, adding 120 MW and 140 MW respectively. The renewables procured by Sasol to date are expected to inject R18-20 billion of capital investment into SA economy.

Further, Sasol’s first large-scale renewable energy project, Msenge Emoyeni Wind Farm, reached commercial operations in October 2024. Located in Bedford, Eastern Cape, the 69MW wind farm comprises 16 turbines and is already supplying electrons wheeled through the national grid to Sasol’s Sasolburg operations in the Free State.

“Our focus is on providing customers with the energy solutions they need today, while actively transitioning to the energy solutions

of tomorrow. This journey is built on close collaboration with our customers, drawing inspiration from their evolving product needs,” elaborates Christian Herrmann, Sasol Executive Vice President for Energy and Chemicals Marketing & Sales: Southern Africa.

Sasol has a comprehensive list of highquality, high-performance products to optimise customers’ total cost of ownership, and help them keep their mining operations running e iciently.

“Sasol, as the energy transition partner of choice for the mining industry, aims to make fuel management services that are smarter, simpler, and more e ective. We will enable our mining customers to meet their energy transition goals while minimising any performance impacts,” adds Bengu.

Reiterating Sasol’s commitment to driving innovation for a better world by fostering strong partnerships within the mining sector, Herrmann says: Our customer-centric approach is at the centre of everything we do, collaborating closely to tackle their most complex challenges, and establishing Sasol as their partner of choice.”

By working together, Sasol unlocks innovative solutions that empowers its partners to achieve their sustainability and low-carbon goals in their own energy transition journeys. Among its most important partnerships are:

■ The Za ra joint venture with Topsoe in the Netherlands to advance the development of Sustainable Aviation Fuels.

■ Sasol Chemicals’ participation in the German-South African CAREO-SENE partnership, which is striving to produce catalysts that can be used in the Fischer-Tropsch process to produce sustainable aviation fuels.

■ Sasol’s Dyno Nobel’s Track and Trace initiative, which enables all stakeholders to have full traceability throughout the supply chain, reducing the and misuse of explosives, while optimising inventory management.

3-6 February 2025

CTICC, Cape Town

Mining Indaba: Creating opportunities for African miners and laying the groundwork for a greener, more inclusive future.

• Implementing innovative technological solutions for enhanced operational efficiency.

• Developing new standards for sustainable and innovative mining practices.

• Increasing resource efficiency and minimising waste.

• Contributing to productivity and health safety while reducing the environmental impact.

For more information contact: marketing@miningindaba.com

Mines need to stay on top of technological advancements, as these are the key to improved effi ciencies, reduced costs and increased safety.

The technology space is an everchanging environment, so like other industries, mining has to adapt to the latest technologies in order to remain relevant and competitive in the global market space.

This is why Industry 4.0 is so crucial to the mining space – it not only keeps the sector at the forefront of technological evolution, but also o ers it tools to help it maintain a competitive edge.

In the current global economy, the key to remaining competitive is for mines to ensure they keep their productivity as high as possible, and their costs as low as they can.

According to Sabine Dall’Omo, Siemens SubSaharan Africa CEO, the best way to achieve this is through automation, which is driven by Industry 4.0 solutions.