A unique plural component cartridge spray system for our LVHS series sprayable coating products. U-Spray is a simple application technique with minimal component involvement. The cartridge system is excellent for small project coating applications the perfect solution for field coating repair jobs.

Innovative Solutions for Exceptional Protection and Versatility Learn

NORMAC U-Repair Polyurethane products are designed for quick accurate mixing with long lasting results for conveyor belting and supporting parts. Packaged for easy-on ratio mixing using either our dual cartridge dispensing system or hand mixing can kits.

How

Considering the challenges facing the industry with regard to greenfields exploration, along with the benefits that the country can accrue through this.

Understanding the critical role electro-mechanical engineers play in maintaining the electric motors that ensure a mine can keep critical operations constantly running.

Is it better for mining contractors to rent their heavy equipment, or to rather purchase it outright?

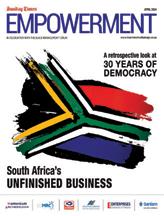

The Minerals Council SA looks back at the enormous changes and exciting developments that have occurred in the sector over the past three decades.

Proper explosive optimisation improves safety, reduces costs and increases productivity through the downstream

value chain.

n today’s economy, it behooves mines to seek ways to improve productivity while at the same time reducing costs. One of the most e ective ways to achieve this, along with additional benefits including improved safety, is through the use of optimal blasting patterns and fragmentation, when utilising explosives.

The importance of proper blasting patterns and optimal fragmentation on a mine’s cost e iciencies and value maximisation should not be underestimated.

One of the key aspects of a successful mining operation is e ective drilling and blasting –something that continues to dominate mine production.

In order to maximise the value of the e ects and reduce the cost of production, the blasting itself requires optimally designed blast patterns to deliver improved rock fragmentation, as this positively impacts downstream processes.

at the end of the exploration tunnel for the mining sector.

While challenges still exist, there remains a strong focus on tapping into SA’s abundance of under-exploited and under-explored potential. A er all, as the JMC points out, the country retains its status as the largest producer of platinum, and one of the largest producers of coal, gold and diamonds.

Among the minerals that demand additional exploration are those related to the green revolution. Clearly, sustainability remains a key focus for mines moving forward, and one of the best ways to achieve this is through the increasing use of renewable energy to power the industry.

Of course, in order to reach this stage, a mine needs to have identified both a mineral and an area to mine – and with South Africa falling behind on greenfield exploration activities, this becomes increasingly less likely.

Fortunately, according to the Junior Mining Council (JMC), e orts by government, the Council for Geoscience, and others o er a light

EDITOR

Rodney Weidemann

Tel: 062 447 7803

Email: rodneyw@samining.co.za

ONLINE EDITOR

Stacey Visser

Email: vissers@businessmediamags.co.za

ART DIRECTOR

Shailendra Bhagwandin

Tel: 011 280 5946

Email: bhagwandinsh@arena.africa

ADVERTISING CONSULTANTS

Ilonka Moolman

Tel: 011 280 3120

Email: moolmani@samining.co.za

Tshepo Monyamane

Tel: 011 280 3110

Email: tshepom@samining.co.za

PRODUCTION COORDINATOR

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

SUB-EDITOR

Andrea Bryce

In this issue, we look at how mines can demonstrate a commitment to following sustainable principles by focusing on reducing their use of fossil fuel-derived energy, by implementing renewable solutions instead. Heavy equipment is equally vital to mining operations, but by its very nature is a costly investment for any mining contractor. We look into the pros and cons of buying such equipment outright, versus choosing to simply rent such machines.

It has also been 30 years since the new South Africa came into being, and in an interview with the Minerals Council South Africa, we consider the many massive changes the local mining industry has undergone, the challenges that have been faced, and the improvements that can be made.

In addition, we take a look at the critical role electro-mechanical engineers play in maintaining the electric motors that ensure a mine can keep critical operations constantly running, as well as the importance of e ective lighting for crushing operations that run on a 24/7 basis, and what this means for safety, e iciency and productivity. We also preview the upcoming Electra Mining Africa exhibition, looking at guest speakers, topics and key areas of discussion.

In our cover story, meanwhile, we celebrate Women’s Month by profiling Pam du Plessis, MD of Invincible Valves. Du Plessis has spent decades proving that women can handle anything the industry throws at them, while avoiding the traditional “big boss” mentality, and instead relying on empathy and emotional intelligence.

BUSINESS MANAGER

Claire Morgan

Tel: 011 280 5783

Email: morganc@sahomeowner.co.za

GENERAL MANAGER MAGAZINES

Jocelyne Bayer

SWITCHBOARD

Tel: 011 280 3000

SUBSCRIPTIONS

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

PRINTING

CTP Printers, Cape Town

PUBLISHER

Arena Holdings (Pty)

1746, Saxonwold, 2132

Motor Engineering (Deutz, Perkins, Detroit & all other engine types)

Parts | Engine Remanufacture

Car, LDV, Truck, Bus & Heavy Duty Vehicle Service & Repairs

Heavy & Diesel Fuel Injections Services (Bosch Accredited)

Field Services (Mining & other Onsite Services)

Vehicle Fire Suppression Services

Andrada Mining has purchased TOMRA XRT sorters as part of its expansion plans at the flagship Uis Mine in Namibia. The sorters feature TOMRA’s latest innovation – the groundbreaking OBTAIN™ software that leverages deep learning to bring singleparticle precision to high-throughput particle sorting.

The open-pit Uis tin mine, representing one of the largest tin reserves in Namibia, is undergoing an expansion, which includes introducing a pre-concentrating circuit of ore sorters, with the aim of increasing tin concentrate from 1 500tpa to 2 600tpa. It has purchased TOMRA COM Tertiary XRT sorters for the ore-sorting pre-concentration circuit in the dry process section of the plant, expecting to increase the tin content of the feed to the wet processing plant by 50%.

A COM Tertiary XRT 1200 will be dedicated to the coarse size fraction. For the small particle sizes, two COM Tertiary XRT Fines sorters are equipped with the high-resolution TS100C ejection module, which delivers high precision in high-capacity applications. The module uses 90% less compressed air to eject the particles, reducing energy consumption dramatically and consequently significantly cutting operating costs while delivering a high-quality product.

These XRT sorters feature TOMRA’s AI-powered OBTAIN™ software, which uses a Neuronal Network to identify the properties of each particle accurately and independently of the sorter’s capacity, achieving unparalleled precision and reliability in detection and ejection.

In addition to enhancing the sorters’ performance, taking capacity, quality and recovery to a new level, OBTAIN™ will provide Andrada Mining with a wealth of detailed and accurate data, which will help them optimise the process with betterinformed decision-making.

While remaining underexplored, South Sudan is considered to hold significant commercial quantities of mineral resources. A nascent gold mining sector in the country offers established producers the opportunity to partner with the government on frontier prospects and leverage their expertise to spearhead mineral exploration, extraction and development activities.

Known gold deposits mainly occur in the central and eastern Equatoria region in South Sudan, which is home to numerous small-scale artisanal mining activities. In these states, gold is mined across the Kawokono area, with reported activity located near the areas of Nyangea, Lauro, Buno, Napotpot and Namurunyan, where gold is extracted by local miners.

Meanwhile, over 50 alluvial sites located near the Luri River – approximately 40km southwest of Juba – have reported gold discoveries, which have been estimated to contain a concentration as high as 4g/m3. Other important alluvial gold concentrations have been reported from the Kinyeti River, the city of Nimule and northeast Karpeto.

Last February, South Sudan’s Ministry of Mining and South Africa’s Department of Mineral Resources and Energy signed an MOU for collaboration in the mining sector, providing for increased cooperation in exploration, knowledge transfer and capacity building. As part of the signing ceremony, South Sudan’s Minister of Mining Martin Abucha called on international investors to participate in the country’s mining industry, inviting private sector players to engage with the ministry in exploring newfound opportunities.

Meanwhile, South Africa’s state-owned African Exploration Mining and Finance Corporation announced last June that it is actively seeking partnerships with South Sudanese mining companies. South Africa’s Council for Geoscience has also expressed interest in geothermal activities in East Africa, with a focus on South Sudan.

These types of collaboration have positioned the South Sudanese government in a space where it is able to explore its own mineral resources and productively develop the sector, potentially providing a significant boost to the nation’s economy.

Engen recently handed over the keys to a new truck to Resegofetse Business Solutions (RBS) that will enhance the 100% black women-owned enterprise’s service capability along the Bafokeng mining belt. RBS, based in Phokeng in North West Province, supplies consumables, cleaning services, and lubricants to mines in the area. Handover of the four-tonne vehicle took place at the Engen Waterkloof Convenience Centre in Rustenburg, with Adnaan Emeran, head of Engen’s commercial and lubricants marketing, saying: “Engen’s support extends beyond mere procurement, o ering a holistic approach aimed at fostering sustainable growth for a company like RBS.”

This collaborative approach has resulted in remarkable growth for RBS, with a 400% increase in business since partnering with Engen, including an annualised average growth rate of 74% in lubricant volumes sold between 2020 and 2022.

UD Trucks Southern Africa (UDTSA) has announced the expansion of its Ultimate Women Programme, in partnership with Commercial Transport Academy (CTA).

The programme was successfully launched in 2022, with its primary objective to drive gender transformation initiatives in the transport industry. UDTSA sponsored two new Kuzer lightmedium duty trucks. A er gaining extensive experience in the year-long programme, CTA was able to support all beneficiaries to secure employment as professional truck drivers, attesting to the continued commitment of UDTSA and CTA to cultivating meaningful change and transformation through empowerment of women in the transport industry.

“Our meaningful partnership with CTA has been nothing short of transformative, in our constant endeavour to empower women in our industry, and our dedication to making a better life for people, the planet, and the logistics sector. We wish the new candidates a fruitful journey in the coming months, and we are confident that they will go on to make a di erence for a brighter future,” says Filip Van den Heede, UD Trucks Southern Africa managing director.

In line with Daimler Truck’s global ambition to o er 100% CO2-neutral trucks and buses by 2050, DTSA has introduced its first fully battery-electric truck range.

Launched at the event was the Mercedes-Benz eActros 300, comprising a 4x2 and 6x2 rigid, along with a truck tractor variant. Also launched was the eActros 400 6x2 rigid and eCanter range. This comprehensive range o ers zero emission during operation and focuses on light and heavy-duty distribution applications for now, until local vehicle weight and length legislation allows the introduction of long-haul application vehicles.

The eActros 300 has three lithium-Ion battery packs with a battery capacity of 336kWh2 and o ers a travel range of up to 330km. The eCanter has six HV battery packs with a battery capacity of 83kWh and a travel range of up to 100km.

Volkswagen Group Africa (VWGA) has appointed Yolanda Cuba as a non-executive director on their board of management.

across various industries, including the

Cuba, who joined the board e ective 1 June 2024, is vice-president for the Southern and East Africa regions for the MTN Group. She has over 20 years’ experience in various African markets and across various industries, including the telecommunications, manufacturing and investment sectors.

University of KwaZulu-Natal, and

A chartered accountant by profession, she holds a Bachelor of Commerce degree in statistics from the University of Cape Town, a Bachelor of Commerce Honours degree in accounting from the University of KwaZulu-Natal, and a Master’s in Commerce degree from the University of University of Pretoria.

Your mining operation is unique. By opting for Joy equipment, our team of experts and engineers will work closely with you to customise its design according to your specific needs and applications. We provide comprehensive support throughout the entire lifecycle of your machine through on-demand field service, remote monitoring and condition monitoring programs. We aim to help you transform and enhance efficiency and responsiveness to changes and challenges within the mining sector.

Talent, determination, and innovation.

This Women’s Day, we celebrate the women who are redefining the mining landscape.

For mines, staying on the right side of the legalities around the Mine Health and Safety Act requires a partner that truly understands this highly specialised area of law.

By Rodney Weidemann

The local mining industry is a significant employer, as a whole, with some 400 000 people working in this particular sector. Despite being a huge contributor to the nation’s overall GDP, it remains an industry marred by occupational health and safety issues.

This despite the fact that in recent years, mining has made significant strides in improving the health and safety of employees at mining sites.

It is with mining safety in mind that the Mine Health and Safety Act, 29 of 1996 (MHSA) was promulgated, notes Tyla Foster, Executive: Mine and Occupational Health and Safety (MOHS) at ENS.

“The MHSA aims to protect the health and safety of all persons at mines and does not merely apply to the health and safety of employees. Employers are obliged to protect, as far as is reasonably practicable, the health and safety of non-employees (such as visitors to a mine) and employees (which includes employees of independent contractors) performing work on or at a mine,” she says.

“This area of law is highly specialised in terms of the number of legal practitioners currently practising in the field of MOHS law. This is because it does not merely entail the application of the law, but also requires an in-depth understanding of all the technical

aspects applicable to mining – such as engineering, geology, rock engineering and seismology.”

There are a number of health and safety obligations that are imposed in terms of the MHSA, adds Foster, to ensure a working environment that is healthy and safe, as far as is reasonably practicable.

“This includes an organisational structure of trained, experienced and competent people, the implementation of a comprehensive risk management system, and the provision of formal and informal (onthe-job) training of employees.”

“It also ensures the provision of standards, procedures and rules, not to mention working place audits and/or site visits, and compliance to standards. Additionally, it focuses on the safe use of machinery, equipment and explosives, and the establishment of a system of medical surveillance, along with emergency preparedness and response.”

ENS is the only law firm in Africa with a dedicated MOHS team, she continues, saying the team currently comprises 15 practitioners, six of whom are women, with a combined experience of over 45 years in advising mining houses and multinationals on compliance with MOHS law.

“ENS’s key di erentiator is its ability and capacity to manage matters from start to

finish, with its MOHS practitioners appearing personally in informal investigations, formal inquiries, inquests and criminal prosecutions, as well as dealing with civil court proceedings and dispute resolution,” she says.

According to Juanita Broom, Executive: Mine and Occupational Health and Safety at ENS, the Mine Health and Safety Inspectorate (MHSI) of the Department of Mineral Resources and Energy (now reconfigured as the Department of Mineral and Petroleum Resources, but has not formally been amended in terms of the MHSA), are the regulators that must enforce compliance with the MHSA, and the regulations binding thereunder.“If an Inspector of Mines (from the MHSI) has reason to believe that a provision of the MHSA (or the regulations binding thereunder) has not been complied with, the regulator has several options available to enforce compliance therewith, one of which is to issue a Notice in terms of Section 54 of the MHSA to halt mining operations in the a ected area of that mine” she says.

“Further options available to an Inspector of Mines to enforce compliance include to issue a Notice in terms of Section 55 of the MHSA or to recommend the imposition of an

Mine and Occupational Health and Safety (MOHS) law requires an in-depth understanding of all the technical aspects applicable to mining - such as engineering, geology, rock engineering and seismology “ “

administrative fine in terms of Section 55A of the MHSA. An administrative fine may be imposed by a Principal Inspector of Mines (from the MHSI) in terms of Section 55B of the MHSA, a er the Principal Inspector of Mines has considered the recommendation of the Inspector of Mines, as well as the written representations made by the employer.”

It is important for employers to prepare comprehensive representation for the Principal Inspector to consider the same before imposing an administrative fine. It is important to note that an administrative fine may only be issued if an employer has failed to comply with the provisions of the MHSA or the regulations binding thereunder.“As a legal practitioner in the field of Mine Health and Safety Law, it is critical to have a proper understanding of the full spectrum of activities associated with mining.”

“ENS ensures that the interests of the persons and/or entities whom we

represent are adequately protected in light of the extensive duties and responsibilities imposed by the provisions of the MHSA and the regulations binding thereunder, as well as the powers entrusted to the MHSI to enforce compliance with such provisions.”

To this end, she notes that staying within the ambit of the law means implementing and maintaining a working environment that is healthy and safe, as far as reasonably practicable. Employers must proactively adopt a holistic approach to health and safety, where a number of measures must form part of a comprehensive health and safety management system.

“In addition, employers are actively engaging in tripartite forums to, among others, remain abreast with any developments in the law and/or industry best practices; share learnings from accidents and/or incidents, which have occurred in the mining industry; and share information on technical advancements

Notable amendments to the MHSA and the regulations include:

■ The implementation of fatigue management system;

■ the selection and provision of personal protective equipment for women in the South African Mining Industry;

■ the Management of Medical Incapacity; and

■ the provision of proximity devices and anti-collision systems or devices to automatically retard or stop diesel-powered trackless mobile machines (TMMs), and to prevent collisions between TMMs and pedestrians or other TMMs.

available to the mining industry. The aforesaid measures assist employers in exercising the necessary due diligence to ensure health and safety at its mining operations.”

“This area of law is unique in that every matter is di erent. It’s complex and is highly specialised. ENS is not only expert in the field of MOHS law, but has also acquired extensive knowledge and understanding of every facet of mining. This enables us to e ectively protect the rights and interests of the persons and/or entities whom we represent. The exposure to the various mining operations spread throughout South Africa is an experience which is unparalleled,” concludes Broom.

As a business leader in the sector for more than a decade, Pam du Plessis of Invincible Valves has eliminated the “big boss” mentality, relying instead on empathy and emotional intelligence.

By Rodney Weidemann

The traditional view of the mining sector is one that suggests there is little room in it for women. But the industry has in fact been slowly transforming for years into a place where women can lead and thrive.

A good example of this is Pam du Plessis, managing director and CEO of Invincible Valves, a position she has held for more than a decade, following a management buyout of the organisation.

Having grown up on the East Rand, she began her career in the IT arena, working for Accpac, a er which she was headhunted by a hospital to serve as its financial controller thanks to her accounting background.

“I actually ended up at Invincible Valves purely by accident, having met one of the owners, who needed some reports written. I went to help them out temporarily, and essentially never le . Although I planned to go, they asked me to stay, and later made me a director of the company. Five years later, we undertook the management buyout and I became CEO,” she says.

Following the passing of her husband, she says the company became her whole world, helping to serve as something of a coping

mechanism. Furthermore, notes Du Plessis, as a woman, she brought a di erent touch to the business.

“While we are now seeing an increasing number of women in these positions, at the time I took over as MD, having a woman in charge did create something of a ‘shock and horror’ reaction from many of the men in the industry. My rather ‘so touch’ approach to business was certainly very new at the time.

I say that if boys can go into hairdressing, why can’t girls become mechanics, boilermakers and more? “ “

“Remember that – being a male-dominated industry – many of the businesses within the sector still adopted the ‘big boss’ mentality, where leaders rule by fear. On the other hand, I brought empathy and emotional intelligence to the table instead. It is my belief that we should work as a genuine team, discuss things and truly work together for the benefit of the business.”

This, she says, came as something of a shock and a rather big change to her employees, adding that now if you had to ask her team, they wouldn’t have it any other way.

“I tend to operate on an ‘open door’ policy, and anyone can come and talk to me about anything, at any time. To this day, I do not even lock Facebook on our internal computers, because I trust our people. I am well aware that life happens, so I give my people leeway to deal with personal issues during work time – as long as their work is up to date,” she says.

“Trust, of course, goes both ways. I can’t expect my team to trust me if I don’t trust them in this way. As long as accountability remains, this system works well and, I believe, makes for happier employees and a much more pleasant working environment.”

Du Plessis points out that even when it comes to retirement, Invincible has a plan for employees coming to the end of their careers. She says this begins at least two years beforehand, with the company starting to reduce their working hours, or the number of days per week they labour, so that they are able to ease into the idea of retiring.

Asked about some of the biggest challenges she has faced since assuming the leadership of the business, Du Plessis says industrial action and the country’s ongoing power issues have been among the largest problems to deal with.

“Our particular industrial area is fairly small and has been heavily hit by load shedding. In recent months, we have taken a hammering in costs, as we have had to use generators under these circumstances, with the attendant exponential growth in running expenses.

“It is the same with strikes, as it is not only the metal industry, but we are also impacted by action in the transport or mining sectors. While there are ways to mitigate this – such as not having branding on vehicles to help protect employees, or using vehicles that don’t look like delivery trucks – industrial action across any one of multiple industries remains a major di iculty for us.”

Another challenge is the rise in imports of cheap parts from the Far East. She suggests that Invincible prides itself on the high-quality equipment the company imports, adding that these are always among the best available. “Nonetheless, in the majority of tenders, these cheap – and generally unreliable – imports undercut us,” says Du Plessis.

“Thus we have begun looking at other options, including exporting as a business. We now export into much of Africa, areas of Europe like Kazakhstan and Russia, as well as the US and Canada. We have a huge agency in Ghana, sta ed by locals who are trained up by our people. Similarly, we have o ices in Lesotho, Zimbabwe and the Democratic Republic of the Congo, also sta ed by locals, thereby helping to upli local communities.”

“Currently, we are in the midst of developing a new valve design, which should be released to the market within the next couple of years. We are also excited about the new factory we have developed nearby. I am a firm believer that any business will eventually stagnate if it doesn’t attempt new things – hence the investment in the new machine shop.”

She is also a big proponent of women empowerment, noting that she was proud to arrive at the factory one day to witness a forkli being serviced by a female mechanic. This was an awesome encapsulation of the principle that women can do anything men can do, she says, adding that it is particularly pleasing to see younger women coming into the field who are not scared to learn a trade.

“In the mining sector, there is a tendency

It is my belief that we should work as a genuine team, discuss things and truly work together for the benefit of the business. “ “

■ Power shortages and blackouts

■ Industrial action and strikes

■ Increasing imports of cheap, lowquality competitor parts

to view much of the industry as being a man’s world, but the reality is that anyone can do anything, if they put their mind to it. Obviously, there are still many young women who are scared of entering such male-dominated industries, but I say that if boys can go into hairdressing, why can’t girls become mechanics, boilermakers and more?

“My advice to young women is to be yourself, because everybody else is taken. Remember that if you can be true to yourself, you can achieve anything. Ask yourself: is this what I want to do, and am I prepared to put in the e ort required to achieve it? If the answer is yes, then the truth is that no matter your gender, you can do it, because your mind is ultimately the most powerful tool you have,” says Du Plessis.

As mining, like other industries, becomes increasingly interconnected, it has become more crucial than ever to monitor and mitigate cybercrime vulnerabilities.

When most people think of cybercrime victims, they imagine an o ice setting with deskbound employees at computers.

However, the reality is that with our increasing dependence on interconnected technologies, no industry sector is immune to cyberattacks – including mining.

In fact, a 2022 survey by EY found that 71% of respondents in the mining sector had seen an increase in the number of disruptive attacks in the year leading up to the survey.

Leading mining companies in Southern Africa are actively implementing digital transformation projects, and the technology used is becoming more complicated. With connected technology used for production and extraction, the threats these companies face are in some ways even more serious than those in o ice-based industries because they impact health and safety.

By Carey van Vlaanderen CEO of ESET Southern Africa

With automated machinery and processes such as self-driving hauling trucks and underground ventilation systems becoming more prevalent, it’s easy to see why a network shutdown could be extremely dangerous.

Cybercrime vulnerabilities must be e ectively monitored and mitigated, otherwise mining organisations and employees are le significantly exposed.

Here are five crucial strategies for the mining industry to safeguard itself against cyberthreats:

With almost 88% of data breaches due to human error, regular employee training and cybersecurity awareness is a crucial element of any cybersecurity strategy.

Employees should be reminded on an ongoing basis of the risks that are out there and the impact these can have on them and the business. Humans are prone to mistakes, but these mistakes, ranging from failure to properly delete data from devices to clicking on links in phishing emails, are also preventable.

As cyberattacks grow in frequency and complexity, all aspects of the mining value chain are vulnerable. From basics such as implementing password managers and using multi-factor authentication to using cutting-edge security technology to withstand an attack on data and intellectual property, every aspect of the business deserves equal attention.

Even the smallest gateway can be used to gain access to sensitive data or intellectual property. Make sure every entry point is protected.

In any industry, the emphasis is on spending the minimum to maximise profits. This unfortunately sometimes means that companies take the risk of installing the minimum cyber protection they hope will be necessary – and that’s a dangerous position to take. Can your business really a ord to go o line for days because your simple anti-virus didn’t do the job? What about the health and safety risks should machinery or operations suddenly come to a halt?

When it comes to cybersecurity, business leaders in the mining industry need to reframe their approach to one of risk management and risk tolerance.

Mining companies o en do comprehensive background checks to verify the credibility of suppliers and ensure compliance. The same should be done to secure against cybercrime.

Machinery provided or maintained by a third party, for example, may allow remote access for maintenance –and a novel attack path for criminals. Ensure that you’re not unintentionally le exposed by gaining a clear understanding of such policies and processes.

With connected technology used for production and extraction, the threats mines face are in some ways even more serious than those in o ice-based industries because they impact health and safety. “ “

The EY survey also found that 55% of mining and metals executives were worried about their ability to manage a threat. Mining companies need to be highly attuned to the constantly evolving threat landscape and adapt their defences accordingly.

If you’re unsure of your ability to stay ahead of new cybersecurity trends, use a trusted partner who does so. ESET, for example, relies on research and development centres worldwide to ensure protection against the latest developments and our enterprise solutions are backed by 30 years’ industry-leading experience. As one of the top 10 mining countries in the world, the mining industry is vital to South Africa’s economy and clearly requires the utmost protection from cyberattacks. Don’t wait until it’s too late – ensure your company is protected from every angle so that it can continue to be a part of this country’s proud mining legacy.

views expressed are the author’s own and do not necessarily reflect

Women in Mining SA recognises the need for gender equality in the industry, and aims to inspire, support, and develop the progression of women in the SA mining sector.

Women in Mining South Africa (WiMSA) stands as a beacon of empowerment and progress in the South African mining industry.

Established in 2010, this non-profit organisation has been tirelessly working to create an inclusive environment where women can thrive and lead in a traditionally male-dominated sector.

WiMSA’s mission is clear: to inspire, support, and develop the progression of women in the SA mining industry. Through a multifaceted approach, the organisation aims to increase female representation, foster professional growth, and advocate for gender equality across all levels of the mining sector.

By Raksha Naidoo Chairperson, Women in Mining South Africa

One of WiMSA’s key initiatives is the creation of networking opportunities. By organising events such as the First Thursday Club and Speed Networking Events, WiMSA provides platforms for women to connect, share experiences, and build valuable professional relationships. These connections o en lead to mentorship opportunities, career advancements, and a stronger sense of community within the industry.

In its commitment to nurturing the next generation of female mining professionals, WiMSA has developed a comprehensive Career Booklet. This online resource showcases the diverse career options available in mining, encouraging young women to consider this dynamic field. By distributing this booklet to schools and at career days, WiMSA is planting the seeds for a more diverse and inclusive future in mining.

WiMSA’s impact extends beyond networking and career guidance. The organisation is actively involved in addressing industry-wide challenges. As part of the Women in Mining Task Team (WiMTT), in collaboration with the Minerals Council South Africa, WiMSA works to improve basic facilities for women in mining operations, including adequate ablution facilities, personal protective equipment, and physical work requirements.

Looking ahead, WiMSA is set to host its inaugural Symposium this year, on 20 and 21 August, at the Randpark Golf Club in Johannesburg. This event, themed Forge Forward: Empowering Women to Lead the Mining Industry, promises to be a transformative experience that will reshape the landscape of the mining sector.

The Symposium is not just another conference; it’s a catalyst for change, designed to ignite passion, foster connections, and equip attendees with the tools they need to thrive in the mining industry. It o ers a unique platform for addressing critical issues that resonate deeply with women’s experiences in mining, such as overcoming impostor syndrome, tackling gender-based violence, navigating career growth, and fostering leadership skills.

Recognising the importance of inclusivity, WiMSA has made a concerted e ort to keep the event a ordable, ensuring that more women can access these valuable resources and connections. This inaugural Symposium represents a significant step in WiMSA’s ongoing

e orts to empower women and shape the future of mining, creating a more diverse, equitable, and innovative industry for all.

Another innovative initiative is the WiM-Chapter Toolkit. This online manual provides information, guidelines, and support for women who want to start their own Women in Mining chapters, further expanding the reach and impact of WiMSA’s mission.

The organisation’s e orts have not gone unnoticed. It proudly celebrates its members who have been recognised on the Women in Mining UK’s 100 Global Inspirational Women in Mining list. These accolades highlight the calibre of talent within WiMSA, and serve as inspiration for aspiring female mining professionals.

To continue its vital work, WiMSA relies on the support of sponsors and partners. The organisation o ers various sponsorship opportunities, from hosting events to funding specific projects or activities. This support is crucial in enabling WiMSA to expand its reach and impact.

WiMSA’s mentoring programme has been a resounding success, providing valuable support and guidance to women in the mining industry. The peer-to-peer mentoring initiative brings together women from diverse mining professions, fostering connections and facilitating knowledge sharing across the sector. This programme has been instrumental in broadening WiMSA’s reach, connecting women from various locations across South Africa through its online platform.

Building on this success, WiMSA is now evolving its approach to create even more inclusive mentoring opportunities. As the organisation looks to the future, it is shi ing its focus towards a series of mentoring-focused workshops. This strategic move aims to make these valuable experiences accessible to a wider audience of women in mining, extending beyond the limitations of a traditional mentoring programme.

Expanding its mentorship initiatives to reach a wider demographic, WiMSA is making substantial progress in fostering female empowerment within the mining industry, paving the way for a more diverse and vibrant sector.

WiMSA’s journey has been one of determination, progress, and hope. By advocating for women’s rights, providing networking and educational opportunities, and fostering a supportive community, WiMSA is not just changing the face of mining in SA – it’s reshaping its future. For women in the mining industry, for those considering a mining career, and for companies looking to diversify their workforce, WiMSA o ers a platform for growth, support, and transformation.

As the mining industry evolves, so too does the role of women in it. With WiMSA leading the charge, the future of women in SA mining looks brighter than ever. For those inspired by this mission, whether as potential members, sponsors, or supporters, the organisation also extends an invite to join it in forging a more inclusive and dynamic mining industry for all.

views expressed are the author’s own and do not necessarily reflect SA Mining’s editorial policy.

While gains have been made in recent years, it is imperative we continue to advance and retain women within Africa’s cutting-edge renewables companies.

Climate change is a growing threat, and it is poised to a ect Africa – and specifically African women – the hardest.

From extreme weather events to diminishing water resources and agricultural disruptions, the impacts of climate change on the continent are far-reaching and severe. Despite contributing minimally to global greenhouse gas emissions, African countries bear a disproportionate burden of the consequences. Furthering the inequality, African women experience the greatest repercussions of climate change due to the unequal burden of food production, water collection and other responsibilities.

Given this disparity, the importance of prioritising women in Africa’s green energy transition cannot be overstated. While they bear the brunt of energy poverty, African women simultaneously play crucial roles in sustainable development. Women’s active involvement in the green energy transition is critical for its success and sustainability.

By Makena Ireri Director of Demand Jobs and Livelihoods

and Ciara Remerscheid Director of Shortlist Futures at the Global Energy Alliance for People and Planet (GEAPP)

Research published in Energy Research & Social Science emphasises that women’s participation in decision-making processes and leadership roles in the energy sector lead to more inclusive solutions. Gender-inclusive approaches lead to more e ective products by ensuring that the unique needs and priorities of women are adequately addressed.

Despite this, women remain severely under-represented across levels of management in Africa’s clean energy sector. International Finance Corporation research shows that women hold only a quarter of leadership and manager roles at renewable energy companies in Sub-Saharan Africa. Not only are women missing out on the responsibilities, salaries and fulfillment of management positions, but this disparity hurts the sector as well.

If more women were empowered to lead in the renewable energy industry, companies could harness their diverse perspectives and innovative ideas to drive a faster transition towards clean and sustainable energy systems improving energy access and climate goals. All this while improving the company’s bottom line.

So what barriers do women face in accessing and advancing in clean energy careers? A report by Shortlist and the Global Energy Alliance for People and Planet (GEAPP) found that social norms and cultural biases, both within companies and in wider communities and families, played a critical role in shaping the

structural barriers observed in hiring, advancement and workplace dynamics.

For example, clean energy companies struggle with hiring and retaining women in field-based sales and technician roles due to perceptions about safety and physical labour. While relocation can provide professionals valued opportunities for growth, it is o en experienced as disruptive for women who are married or have children because it can pull them away from social networks that provide help with childcare and domestic support. There are many actions that companies can take to improve gender equity both in hiring and retention. Overtly encouraging women to apply for jobs advertised remains one of the lowest-cost and easiest ways for companies to attract women to roles. For example, in our programmes, we’ve seen that simply including language like “Women are encouraged to apply” can increase female application rates.

Throughout the hiring process, companies should ensure they have female representation in terms of interviewers, so that women can see themselves at the company, and use unbiased, skills-based assessment to evaluate applicants.

It is critical to not just pay attention to the pipeline of women entering the field, but also the factors leading to retention and advancement. Research shows that to support women employees, companies will need to continue improving workplace features. These include structured training, mentorship and coaching programmes, transparent pathways to promotion, flexible maternity leave policies, and access to female role models.

A recent gender pay equity analysis of clean energy professionals in Sub-Saharan Africa finds that third-party training and placement programmes also play a crucial role in boosting compensation parity between male and female employees, further demonstrating the need for structured support. Several African clean energy companies, including Husk Power, Nuru, Sistema.bio and Sun King, have already made great strides in improving gender equity in their workforces.

The green energy transition presents a unique opportunity to advance gender equality and sustainable development in Africa. By promoting women’s leadership in clean energy companies, projects and decision-making processes, Africa can unlock their full potential as agents of change and accelerate progress towards a more inclusive and resilient energy future. It’s time to harness the power of women to drive the continent’s clean energy revolution forward.

The views expressed are the author’s own and do not necessarily reflect SA Mining’s editorial policy.

A new range of KSB inline pumps have been engineered to excel in air conditioning, heating systems, water supply, heat recovery, industrial re-circulation and cleaning circuits.

Pump manufacturer KSB Pumps and Valves has introduced the latest ETAline range of inline pumps, including the advanced ETAline Pro – for diverse applications such as HVAC, industrial re-circulation and heating systems.

The single stage volute casing pump requires a smaller footprint, while maintaining high outputs as required, particularly in tight industrial applications where space is at a premium. The standard range of dry installed ETAline pumps range in outputs from 1 400 litres per minute (l/min), to 3 000 l/min, making them suitable for a wide range of applications in tight quarters, where performance and reliability are key.

According to KSB’s market area manager Dylan Mitchell, ETAline pumps are engineered to excel in air conditioning, heating systems, water supply, heat recovery, industrial re-circulation and cleaning circuits.

“Key features include a space-saving inline design, allowing for vertical or horizontal installation, making these ideal for environments with limited space such as roofs or attics. Unlike traditional longcoupled pumps, ETAline pumps eliminate unnecessary space requirements, while maintaining exceptional performance,” he says.

Despite their compact design, ETAline pumps boast impressive e iciency, he adds, delivering reliable performance without the need for balancing valves. This e iciency is further enhanced by the integration of a variable speed drive (VSD) in the ETAline Pro model, which delivers unmatched control and energy savings.

“ “

Intelligent features enable users to have greater control over their pumping systems, simplifying operation and maintenance processes from remote locations if required.

“Our ETAline pumps represent the pinnacle of fluid management technology. With an innovative design and advanced features, these pumps o er unparalleled performance, flexibility and e iciency, for a range of applications in industrial pumping solutions.”

In addition to the advanced design of the standard ETAline pumps, the ETAline Pro pump incorporates advanced intelligence features, including a VSD with remote capabilities and a user-friendly flow manager app. These features enable users to have greater control over their pumping systems, simplifying operation and maintenance processes from remote locations if required, notes Mitchell.

“Intelligent settings allow the pumps to adapt to the existing conditions, delivering optimal performance, regardless of demand and flow rates, enabling vastly enhanced e iciencies as a result.

“These pumps are designed for e iciency and longevity from the bottom up, and are notable in that they contribute to sustainable manufacturing practices. This is achieved by reducing material usage and weight, aligning with global e orts to minimise environmental impacts. The carbon-neutral production process for these pumps thus reflects KSB’s commitment to sustainability and corporate responsibility,” he says.

Mining operators are seeing an increased demand for minerals and ores. Operators must now consider the costs of pump maintenance and replacement as well as the cost-benefit of utilizing fewer larger pumps versus several smaller pumps to perform the same work.

The KSB GIW® MDX pump line delivers proven results in the harshest hard rock mining applications.

The Electra Mining Africa exhibition of 2024 offers visitors dozens of interesting presentations, hundreds of live demonstrations of machinery and equipment, and thousands of new products and innovations.

Technology innovation is progressing so rapidly today that it is not always easy for businesses to stay on top of the latest developments, especially in industries like mining. This is why Electra Mining Africa 2024 is such a crucial event, as it o ers not only displays of the latest cutting-edge technologies, but brings together industry trailblazers across the mining, electrical, automation, manufacturing, power and energy sectors.

The largest trade show of its kind in Southern Africa, with over five decades of experience, Electra Mining Africa is set to take place from 2 to 6 September at the Expo Centre in Nasrec, Johannesburg. The event will host more than 850 exhibitors, and includes international contingents from, among others, the UK, US, Canada, Australia, Italy, Germany, Switzerland, Taiwan, India, and China.

According to Charlene Hefer, portfolio director at Specialised Exhibitions, there are several core topics that will be of interest to delegates. On the Monday, she notes, the topic covered will be Sustainability and Innovation.

Among the key speakers for day one will be Brandon Horn, head of Commercial, SolarAfrica; Terry Galvin, VP Recycling Services at Kal Tire’s Mining Tire Group; Irene von Knoblauch-Dreyer, managing director of Flexilube; and Brett Nash, technical director at NovaSolis.

“Presentations here will include one on creating a sustainable future for businesses with solar, battery and wheeling, a discussion around why SA is ready for a thermal

conversion mining tire recycling facility, and a look at how responsible mining practices are necessary to meet growing demands for critical minerals and to support the future needs of the energy transition,” she says.

“With regard to skills development and training, which is Tuesday’s focus, future trends in engineering training – both locally and across Africa – will be outlined, along with the importance of continuous professional development.”

Tuesday’s guest speakers include Dr Sean Douglas Jones, CEO of the Artisan Training Institute; Ramaesela Cillia Molomo-Mphephu, a director at the Centre of Engineering Excellence; Adi Stephan, chief learning and innovation o icer at The Boiler Room. Finally, Anene Britz, of IR Olav Globetrotters, will consider opportunities in the Dutch job market for South African specialists.

Mining and occupational health and safety are the focus on Wednesday, adds Hefer, with presentations covering areas including the challenges in implementing explosives tracking and tracing solutions, the interconnected concepts of safety culture and safety climate, and a focus on advanced positioning technology and digital document compliance management for health and safety.

Key speakers on this day will include Johann Kruger, Simpology Group CEO; Chris Coetzee, director and owner of OHSS Consulting; Steven Je ery, Strategic business development manager, Saryx Engineering

REASONS TO VISIT:

■ Connect with over 650 exhibitors.

■ Meet with leading industry experts.

■ See thousands of innovative products.

■ Attend conferences and workshops.

■ Join free-to-attend seminars.

Group; Katri Mulder, an audiologist at H.A.S.S. Group; and Michael Illsbroux, CEO and co-founder of Epic Blue.

“Thursday is innovation day, covering all that’s new in machinery, products and technology, including integrating autonomous tire inspections and AI to improve safety, uptime and inspection compliance, Industry 4.0 industrial internet of things (IIOT) smart digitisation solutions for the mining Industry, the future of electric motors, and the power of intelligent solutions in transforming mining operations.

“On this day, we will have speakers like Christian Erdelyi, manager: Mining Technology Solutions for Kal Tire Mining Tire Group; Matt Saunders, application

Electra Mining Africa 2024 is a crucial event, as it o ers not only displays of the latest cuttingedge technologies, but brings together industry trailblazers across the mining, electrical, automation, manufacturing, power and energy sectors.

“

development specialist at CSL Silicones Inc; Rob Penney, programme manager at Synertech; and Bernard Mitton, who serves as a business development consultant for WEG Africa.”

Finally, adds Hefer, Friday will be South Africa day, with a focus on local manufacturing, such as on-site machining industry applications and how these help to reduce downtime, a presentation from the South African Institution of Mechanical Engineering, and a look at the challenges the

manufacturing industry faces, and how to overcome these.

“Special guests on the final day include Nkosana Ncaba, managing director at Total Onsite Machining Solutions; Uncel Mhelembe, chief executive o icer at SAIMechE; and Eric Bruggeman, chairman of the South African Capital Equipment Export Council.

“With so many interesting presentations, hundreds of live demonstrations that bring machinery and equipment to life, and thousands of new products and innovations displayed throughout the five exhibition halls and extensive outside exhibit areas, Electra Mining 2024 is undoubtedly where inspiration and innovation meet,” she says.

Focusing on innovation at every stage of a tyre’s life, we’ve developed proven solutions that support customers on their sustainability journey. Promoting a circular economy, our thermal conversion mining tyre recycling solution helps mines solve the challenge of scrap tyres.

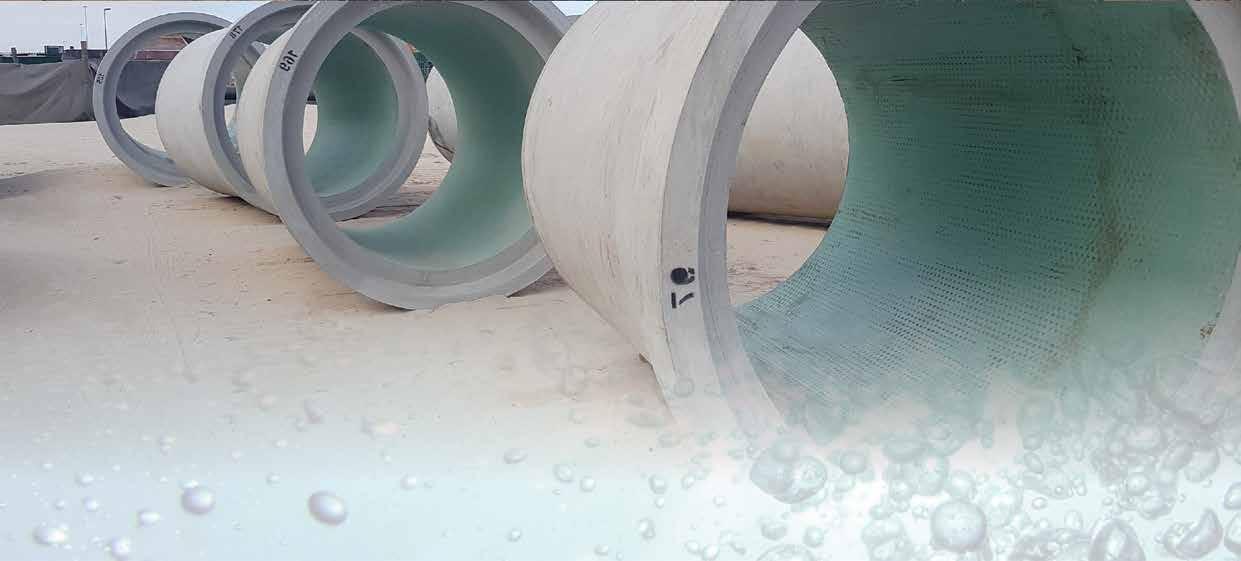

Geomembrane and corrosion protective liners are the optimal choice for various containment applications. They o er excellent impermeability and allow for exceptional durability, high chemical and UV resistance, and superior weldability, while remaining flexible enough to allow for ease of installation, without compromising their integrity.

As a manufacturer of thermoplastic liners, AKS Lining Systems is a competitive global producer, exporting its products to more than 30 countries worldwide. They are used in diverse applications, including mining, environmental conservation, water treatment and general infrastructure.

With a plant situated in Cape Town, AKS Lining Systems is well positioned to o er strong support to the local South African and Southern African Development Community regions.

According to Peter Hardie, technical and international sales manager at AKS Lining Systems, the company’s geomembrane range of products, Geoliner™, are manufactured from HDPE or LLDPE resins which are considered chemically inert.

“Designed specifically for use in chemically aggressive environments, Geoliner™ is manufactured using the ‘flatdie’ process and is supplied in 7m-wide rolls, in lengths of up to 220m per roll, with various surface finishes, such as smooth, textured or mega textured,” he says.

Lining solutions designed specifi cally for use in chemically aggressive environments are used extensively in infrastructure containment projects.

“These finishes can be supplied in combinations that are either single- or double-sided. Our state-of-the-art laboratory ensures that all liners produced meet or exceed international standards such as GRI-GM13, GRI-GM17 and the local standard SANS1526.”

concrete structures, by being cast into the concrete. The mechanical bond into the concrete means the product can be used in a vast range of applications, from mining to sewerage treatment and large outfall sewers. Due to the extremely high wear resistance and abrasion resistance, the AKS™ internal lining in sewer systems is ideally suited for trenchless installation of large diameter pipes.”

The company is ISO 9001:2015-certified, which ensures that management system and quality procedures are maintained and reviewed at the highest possible levels. These systems and procedures follow through right from resin suppliers, shipping and logistics, to finished product, testing and delivery.

Hardie notes that Geoliner™ is used in the construction of environmentally critical facilities like landfill sites, tailings facilities, and ash storage facilities. They are critical components in ensuring that contaminated e luent does not seep into the ground water. When it comes to the crucial matter of conservation of water, Geoliner™ is the highperformance barrier of choice.

In addition to the Geoliner™ range, AKS Lining Systems o ers its flagship product, AKS™ Corrosion Protection Liner. AKS™ (Anchor Knob Sheet) is a liner extruded with a matrix of anchors, he says.

“It is used extensively in acid proofing

For identification, tracking and traceability purposes, Hardie points out that all AKS™ and Geoliner™ rolls are individually labelled and numbered. The in-house manufacturing qualitycontrol system thereby ensures traceability of each roll and its components, right through from incoming resin to in-line production testing, QC testing and final MQC certification.

“With a wealth of experience and knowledge, our sales engineers can deliver technical assistance and custom solutions for clients’ projects. Further, our competent logistical team ensures expert handling and loading of trucks and containers, along with paperwork and all other commercial requirements.

“At AKS, we also o er an open-door policy, inviting customers to inspect and review their product during manufacturing and testing. This in turn assures their peace of mind when materials start arriving on their sites,” he says.

New to the local market, Bell Equipment’s range of updated JCB 3CX backhoe loaders improves safety, effi ciency and productivity.

Bell Equipment’s range of updated JCB 3CX backhoe loaders recently arrived on South African shores, promising to build on the brand’s popularity with new features designed to provide improved comfort, versatility, and productivity, while reducing costs and increasing e iciency.

According to Bell Equipment sales product manager for JCB products, Massyn Jansen van Vuuren, the new model range will replace the existing JCB 3CX Eco, 3DX and 3CX Global product lineup.

“The new cab makeover is the most noticeable change, with the striking new design using high-quality moulded plastics, while the pillars and roof are light grey in colour, to give a lighter and more spacious feel,” he says.

“Most importantly, the new cab places a huge focus on operator safety, comfort, and ease of operation. For example, the loader lever has been simplified to operate like a wheel loader. In addition, there is a proportional switch on the side of the lever to operate the six-in-one bucket, which further reduces the e ort needed to operate the machine.”

He says the new EasyShi transmission, with kick-down, is standard across the range and simplifies gear changing. The kick-down switch is located on the floor, and allows the operator to drop from second to first gear when extra push power is needed for loading or site stripping.

“All cabs are certified for roll-over protection systems (ROPS) and fallingobject protective structures (FOPS), and

the seat rotation area is larger to give the operator more room. This, together with improved cab sealing to keep out water and dust, creates a cleaner and more pleasant workspace. There is also improved visibility to the working area behind the machine.”

Under the bonnet, he notes, the JCB 3CX range benefits from improved e iciency in the hydraulics, thanks to new variable displacement piston pumps that are

standard across all models. The larger pump provides 150lpm, a 39% increase over the previous model.

“This allows the engine speed to be reduced while maintaining productivity, e ectively reducing fuel consumption. Furthermore, the variable flow pump only provides flow on demand and backs o the flow when not required, in order to reduce load on the engine and improve fuel consumption.

“The six-in-one shovel can be used for dozing, loading, digging, grabbing, spreading, and grading, while the optional flip-over forks are ideal for machines that will double up as a forkli for pick-and-place activities around the work site, and to unload vehicles,” he says.

Lighting has also been improved, with six LED work lights instead of halogen lights. Two adjustable LEDs are fitted on the front and four on the rear, of which two can be adjusted. Meanwhile, a battery isolator key has been installed, which allows the operator to isolate the machine’s electrics while carrying out machine maintenance.

“All in all, the new 3CX range has a machine to suit all customer requirements, and we expect these new machines to add real value and strengthen JCB’s position as the world’s leading brand of backhoe loaders. We have a fleet of units that will be used across the country to familiarise customers with the new range and the improvements, meaning that all it takes for customers to experience the machines for themselves is for them to contact their nearest Bell dealer.”

Bell 4x4 Articulated Dump Trucks: reduce tyre scu ng, improve manoeuvrability, and save costs without a ecting productivity.

Bell Water Tankers: feature intelligent cab controls and a variety of options, all fully supported by Bell Equipment, no additional 3rd party support required.

Bell Coal Bins: say goodbye to multiple trips and hello to increased productivity with our low-density coal bins for increased load volume.

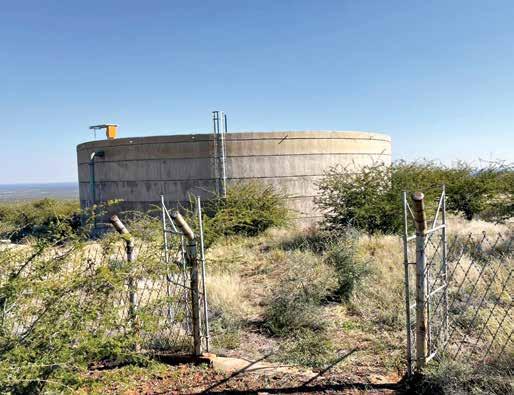

Sustainability is a key focus for mines moving forward, and one of the best ways to achieve this is through the increasing use of renewable energy to power the industry.

By Rodney Weidemann

In the mining sector, although the principles of sustainability di er from those related to energy management, there is an underlying commonality that ties these two subjects together.

Today, the drive for true sustainability is vital, hence the focus on environmental, social and governance (ESG) factors. Those organisations that can best demonstrate to stakeholders how they follow sustainable principles will, a er all, be the ones to obtain the best access to both markets and capital.

According to Wickus Botha, energy and natural resources leader for Africa at EY, one of the best ways to demonstrate a commitment to following sustainable principles is to focus on reducing a mine’s use of fossil fuel-derived energy, and instead implement renewable solutions.

“For those mines that use renewable independent power generation facilities, it is not only about the source of the energy, but also the amount consumed, as this speaks directly to the project’s emissions and carbon footprint,” he says.

“An additional aspect to this is the reliable and predictable supply of power such a facility provides to a mine, enabling it to ensure optimal energy provision for its business activities. So, beyond the need to properly manage emissions and the project’s carbon footprint, such an approach also

means the mine is in a position to ensure the business is resilient, stable and capable of operating e iciently.”

EFFECTIVE STRATEGIC DECISIONS

Furthermore, he adds, such an approach also speaks to capital allocation – taking money invested in the mine and using it for the purposes of private power generation helps to demonstrate an organisation’s commitment to sustainability.

“Government initiatives to allow this level of private generation have been enormously beneficial to heavy industries, especially mines, as it has a orded them the opportunity to make their own strategic decisions around the key issues of emissions, sustainability and allocation of capital. Moreover, this positions mines to intently focus their e orts on reducing their contributions to global fossil fuel emissions.”

This approach is not cheap, however, notes Botha. He points out how even a private house will likely have to expend several hundred thousand rand to go completely o -grid.

“On the other hand, using renewable energy to reduce a home’s dependence on the grid is something that can be achieved at only a small percentage of this cost. The same goes for mines – it is far less pricey to leverage something like a solar plant to

According to the PwC Mine 2024 report, sustainability considerations have been a pivotal element in transaction decisions. In their quest to decarbonise, mining companies are investing in renewable energy projects. Such projects bolster their sustainability profiles and help them gain greater control over one of their most significant operational costs.

With operations in remote areas, companies o en face the prospect of interruption in power supplies even as they strive to decarbonise – hence the increased investments in renewable energy, aimed at increasing their power reliability.

For example, Anglo American entered into a partnership in 2022 with EDF Renewables, to develop a regional renewable energy ecosystem in South Africa, in order to help overcome the challenge of electricity shortages.

Envusa Energy, the jointly owned company they formed, plans to develop at least 500 megawatts of solar and wind capacity. Ultimately, the project is expected to generate 3GW to 5GW of clean energy by 2030, boosting the resilience of South Africa’s electricity network.

reduce dependency than it is to go o -grid completely.

“In the end, mines need to e ectively determine a baseline of their power needs, which will mean they can more easily determine what areas of power consumption can be taken o the grid,” he says.

Mines need to e ectively determine a baseline of their power needs, which will mean they can more easily determine what areas of power consumption can be taken o the grid. – Botha “ “

It is also worth noting, continues Botha, that the biggest challenge government has faced since enabling this legislation has not been around the type of power being generated –for example solar or wind – so much as it has been about the transmission thereof.

“Remember that in order to generate and consume this energy, it still requires the Eskom grid for transmission purposes. The challenge here lies in the fact that the most appropriate areas for solar or wind power plants tend to be far from the mines that wish to consume this energy.

“Thus, it needs to be wheeled across the grid, which creates challenges both in terms of the actual transmission of this power over distance on what is technically an old grid, and also with regard to the model around how to charge for this additional use of the grid.

“Ultimately, the key focus for mines –from an energy point of view – is that they

need stable and reliable power that is delivered e ectively and predictably. Thus, if they seek to use solar as the power source, they would need to supplement this with batteries or maybe wind turbines, in order to ensure security of energy consumption.”

The key considerations then, he says, are for mines to find the right energy mix to deliver this level of stability and security, as this will allow for more e ective operational planning.

“The critical thing for mines to remember is that despite the potential challenges around grid infrastructure, there are ways to reduce costs and drive up their sustainability credentials by introducing renewable energy a little at a time to the mine.

“Something as simple as installing solar panels can help alleviate some of the energy pressure and reduce costs, simply by using these to provide fallback power, instead of using the much more costly diesel generators that are generally used today.

■ An EY report around risks and opportunities for mines indicates that mining companies are also investing in adjacent businesses, particularly those that support or derisk other investments –including infrastructure, energy and technology.

■ It suggests that horizontal integration allows miners to increase scale and investment, by decreasing risk in a non-familiar geography or commodity, driving a value model change to gain competitive advantage.

■ Sustainability is also a big driver of innovation. Beyond renewable energy, these companies are starting to invest in startups – including in energy storage, batteries and hydrogen.

“Once they have a foundation of renewable energy sources, it also becomes much easier to continue improving their renewable energy mix, thus increasing their overall sustainability,” says Botha.

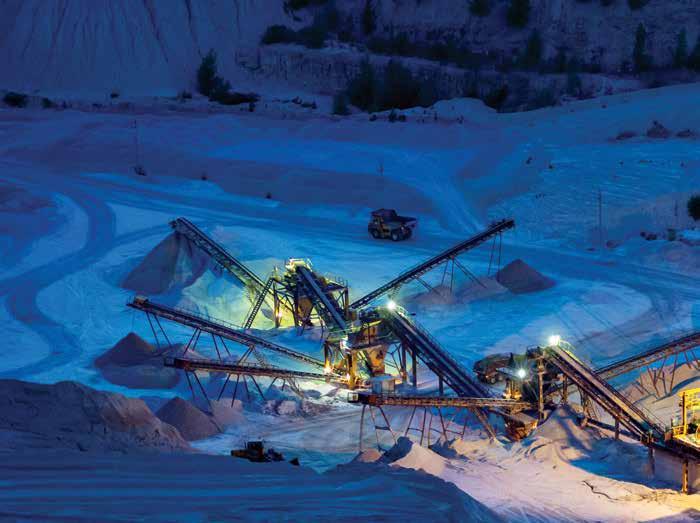

Many crushing operations run on a 24/7 basis, meaning that for the sake of safety, effi ciency and productivity, effective lighting is vital.

By Rodney Weidemann

Crushing and screening operations frequently run on a 24/7 basis, to meet demand and optimise productivity, which is why e ective lighting is such a crucial aspect of these operations.

When it comes to continuous crushing operations, safety, e iciency and productivity are paramount factors, so ensuring sites and machinery are always well lit is vital during night-time work.

According to Francois Marais, sales and marketing director at Pilot Crushtec, adequate illumination allows workers to see clearly, immediately reducing the risk of accidents and improving their ability to operate machinery accurately.

“It also enhances the visibility of hazards, ensuring that workers can identify and avoid potential dangers. Well-lit work areas also contribute to better morale and reduced

fatigue, as workers can perform their tasks more comfortably and confidently,” he says.

The importance of such lighting should not be underestimated, he adds, pointing out that insu icient lighting can lead to numerous challenges and problems in crushing and screening operations.

“Poor lighting can cause workers to misjudge distances, miss hazards, or make errors in operating machinery – leading to accidents and injuries. Workers may work more slowly and less accurately in poorly lit conditions, leading to decreased productivity.

“Poor visibility can further result in equipment damage, due to mishandling, leading to an increase in maintenance and repair costs. Naturally, straining to see in low light conditions can also lead to eye strain and fatigue, further impacting worker performance and safety.”

ENERGY EFFICIENCY AND PORTABILITY

Marais notes that recent advancements in lighting technology have significantly improved conditions for crushing and screening operations. He indicates that the shi to light emitting diodes (LEDs) has been beneficial, as these lights provide bright, consistent light and have a much longer lifespan when compared to traditional bulbs.

“They are also more energy-e icient, reducing operational costs. Smart lighting systems can be programmed to adjust lighting levels, based on the time of day or specific needs, ensuring optimal illumination at all times.

“Portable lighting solutions – such as tower lights – allow for flexible and temporary lighting setups, which are particularly useful in remote or changing work areas.

“Modern lighting solutions are designed

to withstand harsh environmental conditions, including dust, moisture, and vibrations common in mining operations. The particular advantages of these new technologies include better energy e iciency, reduced maintenance needs, improved safety and enhanced productivity,” he says.

It is not only about the light quality, continues Marais. The height of light masts is critical in ensuring that the illumination covers the required area e ectively. Properly positioned lights reduce shadows and provide even lighting across the entire work site.

“If the mast is too low, the lights may not cover enough area, leaving dark spots. If the mast is too high, the intensity may be insu icient. The correct height ensures that all areas are adequately lit, facilitating safer and more e icient operations.

“E ective lighting is a key component of

the zero-harm principle too. It helps prevent accidents and injuries by enhancing visibility where workers can see potential hazards and avoid them, reducing the likelihood of incidents. Adequate lighting enables workers to perform tasks safely and correctly, following standard operating procedures,” he says.

In case of an emergency, well-lit areas allow for faster and more e ective response and evacuation. By minimising the risk of accidents and ensuring a safer work environment, good lighting directly supports the zero harm objective.

We asked what the key factors are that crushing entities should consider when choosing lighting equipment. “Lights that can withstand harsh conditions and have a long operational lifespan reduce the need for frequent replacements and maintenance, while energy-e icient lights can significantly

E ective lighting is a key component of the zero-harm principle too, as it helps prevent accidents and injuries by enhancing visibility on-site. “ “

While it is vital to have su icient lighting for the stationery crushing and screening equipment on a site, this is not the only purpose behind the implementation of such solutions – there are typically also several pieces of yellow metal equipment, such as excavators, trucks and loaders, moving around on the site

Good lighting is therefore a critical element of the industry’s quest for zero harm.

For this reason, the range of lighting solutions are designed to cover everything from entry level, right up to premium applications. On the smaller end, a unit with four 320 LED floodlights will achieve a lighting area up to 5 000m2; at the other end of the scale, a mining unit with six 320 WLED floodlights will light up 7 800m2.

Francois Marais.

reduce operational costs,” he says. “Lastly, portable lighting solutions can be easily moved and adjusted as needed, providing versatility in dynamic work environments.”

The importance of proper blasting patterns and optimal fragmentation on a mine’s cost effi ciencies and value maximisation should not be underestimated.

By Rodney Weidemann

One of the key aspects of a successful mining operation is e ective drilling and blasting – something that continues to dominate mine production. In order to solve this challenge and reduce the cost of production, the blasting itself needs to seek improved optimal fragmentation from a properly designed blasting pattern.

According to Simon Tose, global manager: mining optimisation at AECI Explosives, the primary objective of blasting through good design is to minimise the overall cost, and maximise the value of the e ects.

“This is achieved by converting the in-situ rock mass into a muck pile of appropriate shape, looseness and fragment size distribution for downstream processes,” he says.

“These include loading, hauling – in the case of the waste material – crushing, grinding and mineral processing. This must be achieved while containing overbreak, back damage, flyrock, noise, and vibration.”

Enaex Africa’s CEO, Francisco Baudrand, says poor blast performance in mining is usually a result of geological, geotechnical, operational or technical and environmental issues.

“Problems may be created by the presence of joints and geotechnical structures, or by excessive water in the holes.

Furthermore, hard rock with the inadequate selection of explosives agent may mean there is not enough energy to the blast, while improper blast design, blast sequence and explosives selection are additional challenges,” he says.

ROCK AND A HARD PLACE

“Other potential problems include sub-optimal block preparation drilling practices, leading to short or collapsing holes, inadequate stemming material, and environmental factors – including ground conditions and weather, among others.”

Poor blast performance also reduces productivity, he notes, by causing outcomes such as ine icient fragmentation, which will increase processing costs, accelerates loading equipment wear, and decreases loading equipment productivity, among others.

“It may also lead to sub-optimal muck pile distribution, which will decrease loading equipment productivity; flyrocks, which might damage property, equipment or people; excess of vibrations, which might damage property, equipment and/ or a ect neighbouring communities; or the generation of an oxygen unbalanced detonation, which will create fumes. All of these challenges a ect productivity and costs at di erent magnitudes.”

Tose indicates that improving blast performance depends on the correct modelling of the whole “mine to mill” process, not operating in silos, and understanding that a “saving” in the blast cost does not necessarily translate to value in terms of mineral recovery.

“Using the correct tools to measure and track the fragmentation, understanding the cause of poor performance and redesigning for improvements is key. The combination of explosives, controlling the mean size of the rock fragments, and using electronic detonators to manage the uniformity, gives great flexibility in managing the geology and rock properties to optimise the fragmentation.”

Baudrand agrees, pointing out that an optimum fragmentation will decrease ore processing costs, decrease wear elements and maintenance in loading equipment, and optimise equipment productivity, thereby decreasing mining costs and improving throughput.

BME’s GM for technology, Nishen Hariparsad, suggests that the benefits of achieving optimum fragmentation extend to immediate and long-term economic value to mining customers, and further into tangible gains in both safety and environmental avenues.

Poor blast performance in mining is usually a result of geological, geotechnical, operational or technical and environmental issues. – Baudrand

“A predictable blast, yielding consistent fragmentation and blast outcomes, delivers savings as well as productivity gains. Moreover, blasting is a fundamental step in the mining process, and a quality blast will generate predictable consistency, muck piles, and dilution. This makes everything easier, from digging to crushing, and eliminates pain points throughout the mining value chain,” he says.

“The benefits of optimum fragmentation can also be expanded beyond productivity, cost avoidance and energy savings. It also o ers a benefit that supports and feeds into mining companies’ quest for ‘green’ benefits. For example, in BME’s quest to deliver optimum fragmentation, our choice of controlled explosive emulsions and precision blasting systems also reduce vibrations, control fume emissions and limit the need for autonomous energy inputs.”

These benefits, continues Hariparsad, all talk directly to lowering environmental footprints while further firming up BME’s customers’ commitment and accountability in using “green” practices in the industry. “These are just some of the benefits that achieving optimum fragmentation can deliver.”

Talking to the benefits of good blast design, AECI’s Tose says that suitable controls reduce the impact of overbreak,