5 minute read

NEWS

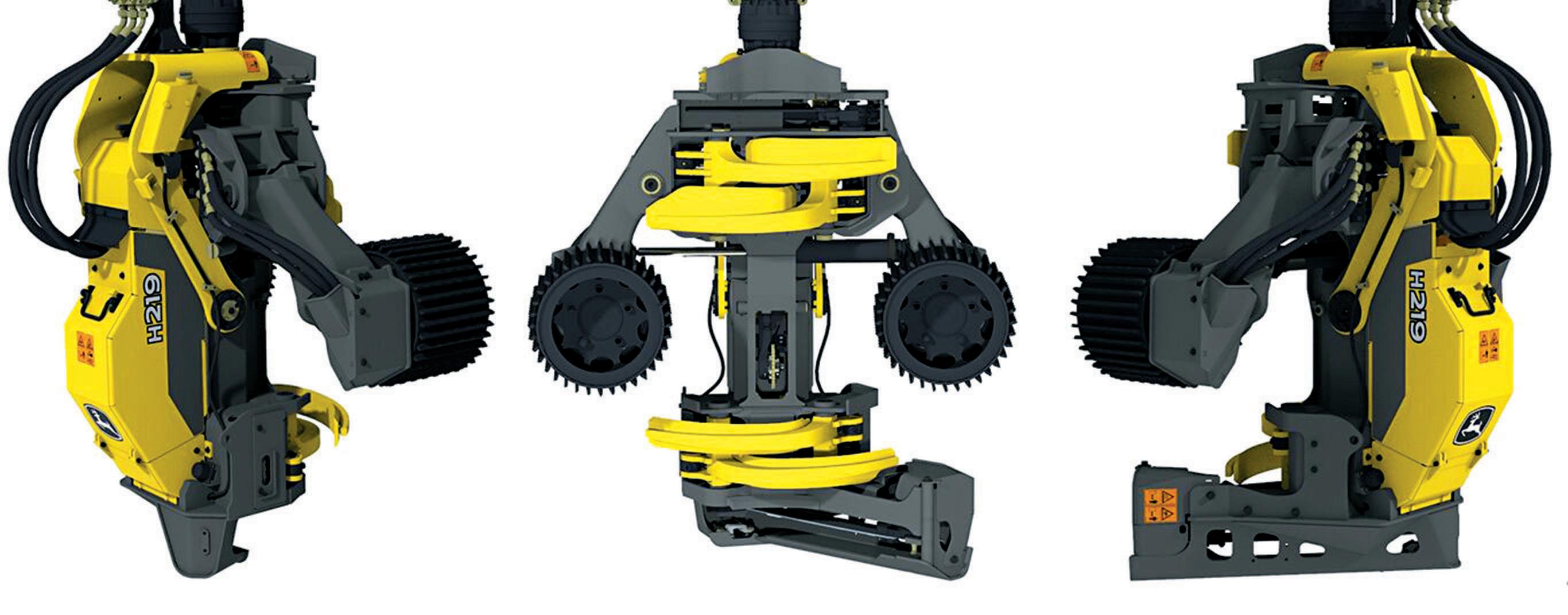

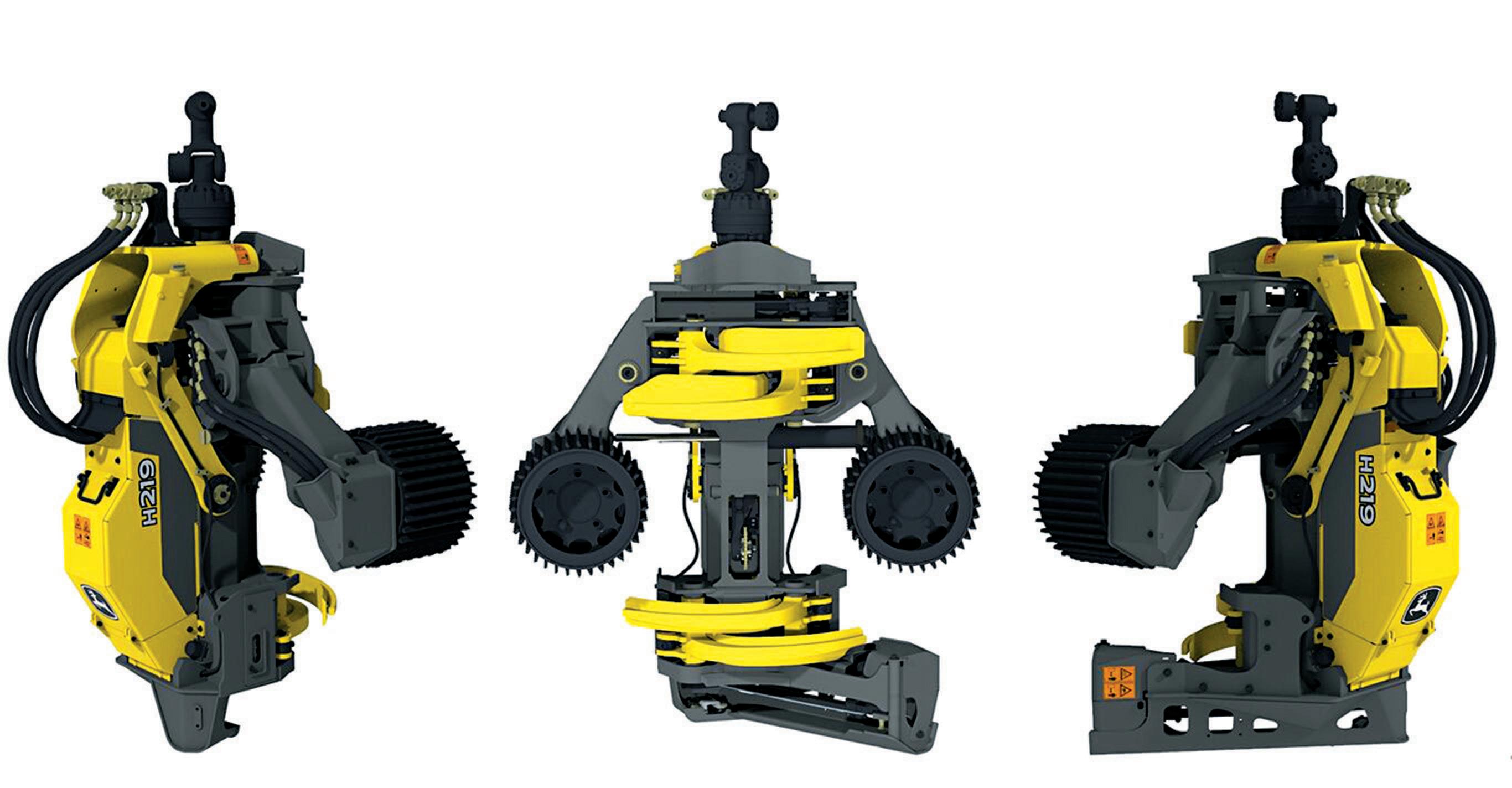

JOHN DEERE H219 HARVESTER HEAD

Advertisement

John Deere has revealed a new two-wheeldrive H219 harvester head with dualspeed feed motors, ideal for use with large harvesters and big timber. Better routing of the feed motor hoses and the hose protection increases the durability of the hoses, while the feed motor’s hose connections outside the valve cover enable easy replacement of hoses. John Deere says the new, hinged valve covers improve serviceability, too.

Furthermore, the serviceability of the length measuring equipment has been increased, and the area around the equipment is better protected. The structure and the strength of the lengthmeasuring equipment have been improved as well, says John Deere, enabling use of the required pressure force of the measuring roller with all types of trees. A new measuring roller option has also been developed for trees with thick bark.

The John Deere H219 is built for use with large wheeled and tracked harvesters, and is ideal for debarking big eucalyptus trees. All John Deere harvester heads now feature have a new SuperCut 100S saw with next-generation chain tensioning unit, automatic chain tensioning, and mechanical bar locking give it added efficiency and reliability.

BKT FORESTRY TYRES KONRAD THINNING HARVESTER The Konrad Thinning Harvester KDH40-1 with Woody WH40-1 BKT has developed a new range of head is a cost-effective solution for first thinning work in specialised tyres for forestry machinery. forests, reckons the Austrian manufacturer. Based on a Wacker The Forestech tyre (pictured left) is Neuson ET90 tracked excavator, the KDH features an suitable for forwarders and features a optimised main boom and tilt device for the upper carriage, robust hitch and reinforced shoulder keeping it level on steep slopes. Options available include a rib to resist punctures. The FS 216 tyre hydraulic winch, for forwarders and skidders resists ‘Power-Boost-Hydrauliccuts and tears, features an enhanced Accumulator’ and tread pattern for improved traction, climbing support bars and is offered with a steel belt or aramid mounted on the tracks. fibre structure. Powering the KDH is The self-cleaning TR 678 tyre is aimed at a turbocharged, 55kW loggers and is equipped with steel belts Deutz engine, and with improving damage and puncture resistance. It also has a high load an optimised main arm capacity. The final tyre, the F 240, is designed for transporting and telescopic extension trucks and is said to offer great longevity, traction, manoeuvrability the harvester can reach and self-cleaning properties. as far as 9.3m.

HYDROGEN FUELLED JCB EXCAVATOR

JCB has developed the industry’s first hydrogen powered excavator. Based on the 20-tonne 220X and tested at JCB’s quarry proving grounds for more than 12 months, the working prototype features a hydrogen fuel cell, within which hydrogen reacts with oxygen to create the energy needed to run electric motors. The only emission from the exhaust is water.

JCB Chairman Lord Bamford said, “The development of the first hydrogen fuelled excavator is very exciting as we strive towards a zero carbon world. In the coming months, JCB will continue to develop and refine this technology with advanced testing of our prototype machine and we will continue to be at the forefront of technologies designed to build a zero carbon future.”

A reliable partner for your timber and forestry needs

With over 50 years’ experience in the UK’s material handling and earthmoving market, Liebherr-Great Britain is the first port of call for operators wanting a professional, reliable and productive solution to their timber handling and forestry requirements.

Liebherr manufactures a wide range of tele-handlers, wheeled loaders, wheeled and crawler material handlers, excavators and dozers for use in the initial harvesting stage through to the loading of finished products and residues.

Our range of equipment can be supplied in standard material handling specification or designed to suit your application, and comes with full support from the manufacturer.

Liebherr-Great Britain Limited Normandy Lane Stratton Business Park Biggleswade, Bedfordshire SG18 8QB Tel.: 01767 602100 www.liebherr.com

SIN CITY’S SHOW- STOPPERS

This year’s CONEXPO-CON/AGG show, staged from March 10th to 14th in Las Vegas, USA featured an enormous range of fantastic site clearance and forest machines from dedicated manufacturers, as Eoghan Daly reports

BANDIT INDUSTRIES

Above: French manufacturer Plaissance brought along its Vario-Trac 350B wheeled carrier with mulching head.

Below: 480B is Tigercat’s largest purpose-built mulcher, shown here with Tigercat’s 4061 mulching head. Left: The CONEXPO event covers 2.7m square feet and attracts more than 2,000 exhibitors every three years.

TIGERCAT

In advance of construction work on any project, a degree of site clearance is always necessary. Effective clearance of trees and scrub leads to a more efficient project start-up, and a range of dedicated contractors serve the sector in this regard. While a host of large manufacturers already provide the UK and Irish markets with equipment for clearance work, it is always interesting to see what smaller producers have come up with to overcome challenging situations. Many of the machines in Las Vegas for CONEXPO-CON/AGG 2020 showed great potential for use outside the USA in forestry clearance applications, and their high end durability really shone through.

As well as purpose built self-propelled mulchers, a large contingent of shredding and grinding plants were exhibited at the show. While many were presented by world-renowned manufacturers, others were shown by smaller producers of niche products. When it comes to horizontal-feed grinders, the machine’s ability to handle both longer and shorter material makes them particularly flexible when processing site clearance material, and reduces the need for advanced size reduction in most situations.

Other American trends included the manufacturing of dedicated forestry specification machines by a large number of excavator manufacturers. These machines