See page 12.

See page 12.

Electric vehicles (EVs) have gained significant attention recently as an alternative to fossil fuel-powered vehicles. While there are benefits to adopting EVs, there are some potential drawbacks.

One of the benefits is their lower environmental impact. EVs produce zero emissions, reducing logistics operations' carbon footprint, which is particularly beneficial for companies focused on sustainability and reducing environmental impact. Additionally, EVs can be more efficient than traditional vehicles, saving costs.

There are some potential downsides to relying solely on EVs. One of the biggest challenges is charging infrastructure, which can

limit the range and usability of EVs. EV range can be particularly problematic in the logistics industry, for example, on an island like New Zealand, where vehicles may need to travel long distances or operate on tight schedules. Additionally, EVs can be more expensive to purchase upfront than conventional vehicles, which can be a barrier to adoption. Another potential issue with EVs is their battery life. While battery technology has improved significantly, EVs still need their batteries replaced over time, adding to companies' overall cost of ownership and maintenance. Globally, recent weather events which caused power outages meant that many vehicles were abandoned

on the side of the road or at charging stations.

So while EVs are worth looking into, an in-depth analysis of your business needs must be the first consideration before adopting this technology.

Currently, the primary concerns for businesses are the lack of charging infrastructure, higher upfront costs, battery life, and reliability. These are critical factors to consider when evaluating EVs' feasibility in your business.

tania@reviewmags.com

Amajor food company has announced the recipient of its 2023 grant, supporting research innovative research that has the potential to benefit the horticulture industry significantly.

T&G Global announced the recipient of the 2023 Edward Turner Horticulture Futures Grant, Reuben Panting, a Masters's student at Auckland University.

The postgraduate tertiary student grant, valued at $10,000 NZD, was established to celebrate T&G’s 125th anniversary and is named in honour of company founder Edward Turner.

T&G Global’s Chief Executive, Gareth Edgecombe, stated that the company was

delighted to appoint Reuben as the inaugural recipient of the Edward Turner Horticulture Futures Grant.

“Reuben greatly impressed us with his passion for the horticulture industry and his interest in addressing key issues that threaten the sustainability of fruit varieties,” said Edgecombe.

“Reuben’s commitment to innovation, development and commercialisation in the field of biology fits the intent of the Grant perfectly, and we’re looking forward to seeing him complete his studies and bring his ideas and discoveries into the industry in the future.”

Reuben Panting, 21, originally from Nelson, is

currently undertaking a Master of Science at the University of Auckland, focusing on plant and microbial biotechnology. He completed a Bachelor of Science, Majoring in Biological SciencesBiotechnology pathway

in 2022. These academic studies have led Reuben to develop a strong interest in plant biotechnology, microbiology and how the intersection of these fields can lead to innovation for practical gains.

Read more here

American agricultural technology company Ancient Organics Bioscience, Incorporated, which develops proprietary soil and plant probiotics, announced today the commercial launch of PaleoPower. PaleoPower is the only product known to break down organic glyphosate contamination in the soil.

PaleoPower is a consortium of beneficial microorganisms that degrade glyphosate. Glyphosate is the active ingredient of Roundup and other glyphosate-based herbicides. PaleoPower is a consortium of beneficial microorganisms that degrade glyphosate. In controlled studies, PaleoPower reduced glyphosate levels in the soil

A new matchmaking service will connect primary producers with local organisations looking for ingredients in an effort to create new animal feed products from by-product streams created during food production.

Using a new Bioresource Database developed by partners in the Bioresource Processing Alliance, companies will

by 80 percent in 90 days and 90 percent within 180 days of application.

Scientific studies suggest that glyphosate reduces soil productivity by adversely impacting the microbiome.

Glyphosate has been linked to several human health issues, including cancer. Glyphosate has also been detected in many foods, causing increasing consumer concerns over the quality

and safety of the food supply.

PaleoPower is an essential new tool for farmers to improve their soil quality and productivity and grow healthier food.

It is estimated that more than 200,000 tonnes of food production by-products could be redirected using the database if rolled out nationally.

“The by-products of food production, such as seeds, stalks and low-grade produce, are generally viewed as waste, but can hold value for other uses,” said Dr Richard Edmonds from Plant & Food Research.

be able to identify food production by-products as ingredients for existing or new formulations. This service will allow producers to redirect by-product streams away from landfill or low-value uses, such as compost, while providing opportunities for manufacturers to source nutritious ingredients close to factories, reducing transportation costs.

“Animal feed manufacturers, for example, are often looking for nutritious ingredients for new products and would like to be able to source these locally direct from the producer. Being able to link producers and manufacturers can reduce the amount of waste while supporting the development of new products, a win for both sides.”

The initial pilot version of the Bioresource Database is now live for the Canterbury region. Scientists at Plant & Food Research, who have developed the database and interface, will be contacting organisations over the coming months to join the database (via a survey) as the first step to resource sharing. The database will then use all available data to link potential users with by-product suppliers, including accounting for the transportation and processing costs that often limit the reuse of low-value by-product streams.

The Bioresource Processing Alliance is a collaboration between Plant & Food Research, AgResearch, Scion and Callaghan Innovation, which aims to increase the value of biological by-products from the primary sector.

Chelsea has been refining sugar at its site on the northern shore of Auckland's Waitemata Harbour since 1884. It is one of the first sugar refiners in the world to harness this technology in its production process.

New Zealand Sugar Company (Chelsea Sugar) has made strides towards achieving its carbon emissions goals by completing its Mechanical Vapour Recompression Evaporator (MVR) Project.

The MVR project, which has been fully operational for just six weeks, was co-funded through the Government Investment in Decarbonisation (GIDI)

Fund and enabled Chelsea to recover and reuse energy generally lost through the evaporation process. The new method is 18 times more efficient than singlestep evaporation.

In 2020, in partnership with EECA (Energy Efficiency and Conservation Authority), Chelsea undertook an Energy Transition Accelerator (ETA) study where the MVR

Project was identified as a viable emission abatement solution.

“The results of our ETA study were pivotal in identifying areas where we could make significant strides in our emissions abatement and, in turn, allow the business to set ambitious emission reduction goals,” said Bernard Duignan, CEO of New Zealand Sugar Company.

“Chelsea has been integral to New Zealand’s food and beverage manufacturing sector for over a century. Producing around 205,000 tonnes of product yearly for domestic and export markets. We are very much business with our sights set on the next 100 years and continuing to improve sustainably and relevantly.”

Duignan explained that the MVR Evaporator represented a leap forward in the company’s sustainability goals. The innovation was approximated to reduce its greenhouse gas emissions by more than 30 percent by 2030, to be Net Zero Carbon by 2050. Read more here

produced great Australian seafood. While UK consumers will have access to the greatest seafood in the world, tarifffree.”

The free trade agreement will help to increase the competitiveness of Australian seafood in the UK market and will provide Australian seafood companies with new opportunities to expand their international operations and diversify markets.

“Australian seafood exports to the UK were worth $720,000AUD in the 2020-21 period. The new agreement is expected to significantly boost this figure in the coming years and help to drive growth and diversity within the Australian seafood industry,” said Papacosta.

Seafood Industry Australia (SIA), the national peak-body representing Australia’s commercial seafood industry, has welcomed the recent signing of the free trade agreement between Australia and the United Kingdom.

“The agreement is expected to create a wealth of new opportunities for the Australian seafood industry and strengthen trade ties between our two nations,” said SIA CEO Veronica Papacosta. “Our Great Australian Seafood producers now have access to more than 65 million UK consumers who value our safe, healthy, and sustainably

The agreement will provide a much-needed boost to the Australian seafood industry, and is likely to support the growth and success of the industry for many years to come.

“The Australian seafood industry is committed to working closely with the Australian and UK governments to ensure that the new agreement is implemented smoothly and effectively. With its world-class seafood products and our commitment to sustainability, the Australian seafood industry is well-positioned to take advantage of the opportunities provided by this new agreement and to continue to grow and thrive in the years ahead.”

Driven by innovation, creativity and quality ingredients, our skilled culinary team has its pulse on the latest food trends throughout the world.

Newly Weds Foods NZ provides customers with the food solutions they’re looking for.

Newly Weds Foods (NWFAP) is a joint venture between New Food Coatings LLC and George Weston Foods Asia Pac.

We specialise in Japanese Style Bread Crumbs plus a complete range of marinades, seasonings, batters, breadcrumbs, biscuit crumb and specialised coating systems, to suit every possible application, accompanied by an extensive range of functional ingredients for processed meat products.

Generally recognised worldwide as the premium coating system, our Japanese Style Bread Crumbs are widely used and endorsed by celebrity chefs. The unique process results in

long and delicate slivers of breadcrumb giving a ‘melt in the mouth texture’.

Our extensive food range also includes a delicious mix of wet and dry sauces plus dressings both sweet and savoury.

We are very well known and established within most major food manufacturers and QSR’s both within NZ and internationally https://newlywedsfoods.com/company/ourglobal-view/ [newlywedsfoods.com]

NWFAP is well-established in NZ and a proud supplier to the Industrial and Processing channel to many of New Zealand’s leading food manufacturer’s

We are globally integrated…and locally focused. Our New Zealand business is well supported by the NWF family of 32 facilities

around the world, including seven innovation hubs located in USA, UK, Thailand and Australia with dedicated Chef’s and Technical/ Regulatory support.

We share our global insights into trends in the Retail, Food Service, QSR channels. From plant-based diets to meat, seafood to Supply Chain future challenges, NWFAP are dedicated to supporting our Local customers.

Our NWF NZ facility offers solutions for Gluten Free, Blending (ie batters, Gravy, Powder Stocks, Cake mixes, Bread additives, Donut batters), Curing (Marinades dry and wet), Dry sauce and glazes,. Wet sauce (ie Chili sauces, BBQ sauce, Garlic Aioli), Dressings (ie Mayonnaise, Tartare, Ranch), Japanese Panko crumb and TLC Breadcrumb.

We operate within the highest standards with our BRC “AA” certification.

For any enquiries please reach out to our National Sales team at NZSales@ newlywedsfoods.co.nz

DTS runs responsible jugfor-jug refrigerant swap

LUKE WALKER DTS National Sales & Service ManagerDTS, a New Zealand manufacturer and innovator of advanced refrigeration technologies, is taking the heat out of running cool. The company, well-known as New Zealand’s leading manufacturer of stainless-steel vats, is bent on saving refrigeration users from unpleasant surprises in the short- and long-term by breaking the chain of R404A gas use across New Zealand.

R404A is a common refrigerant in New Zealand. This high-pressure blended gas became a stalwart of dairy and commercial applications from 1995 when CFCs were banned for use in new equipment. Nearly 30 years on, R404A is now considered one of the worst refrigerants in the country for greenhouse gas emissions, and its price is soaring.

Luke Walker, DTS National Sales and Service manager, believes many producers are unaware of the specific refrigerant cooling their systems — until a leak occurs.

“Whether it’s farms, vineyards, horticultural operations, breweries, or butcheries, exactly which refrigerant is running a cooling system is unnecessary information for day-to-day operations. Usually, the only clue is a small sticker on the condenser.”

“People generally become aware of the type of refrigerant after a leak, when a system needs to be re-gassed or topped up, and the bill rolls

in. This is when the type of refrigerant hits home with immediate effect. R404A has a relatively high GWP of 3922 which attracts levies and currently rests at a full retail price just shy of $10,000 per jug.”

DTS is instigating a fast track of R404A removal and offering a jug-for-jug swap out between R404A and R449A as part of its proactive servicing to reduce the nasty surprise at the wallet. R449A is a widely available refrigerant and compatible with most refrigeration systems currently running R404A.

A more environmentally friendly refrigerant, R449A has a GWP of 1397 (one-third of the R404A rating). It is more energy efficient, expending greater cooling capacity — and considerably more affordable.

Luke says the swap-out is a simple step for farmers, growers, and other commercial enterprises.

“We are excited to be able to offer R404AR449A swap as part of our standard proactive “Service-man” contract. R404A is used across multiple market sectors and we have the capability to address this wherever it is being used. There is no equipment upgrade, save a small valve replacement in some circumstances, and there is no introduction of operating hazards.”

The longer-term advantage of replacing the R404A with a lower GWP refrigerant is

lowering impact on the environment.

“We know about 90 percent of refrigerants leak out by the end-of-life of equipment. Rather than accepting that eventual release, DTS is removing the R404A from cooling systems and eliminating its re-use in New Zealand or offshore. The R404A is collected, treated in a high temperature reactor to break the chemical bonds, then transformed into compounds which can be used in various manufacturing processes.”

Luke says collaboration is also an option. “We are open to working with others to help transition primary industries and other sectors with cool storage away from the harmful R404A.”

“DTS has a strong reputation in refrigeration technologies. We want New Zealand producers and those involved in the cool-food chain to know that we are here, we are a highly responsible company and we’re interested in creating solutions that deliver increased efficiency and sustainability of our customers’ businesses.”

DTS is a leading manufacturer of specialty foodgrade stainless steel vats, pharmaceutical tanks, fuel tanks and pressure vessels, with expertise in advanced refrigeration technologies to service the dairy, beverage, and food tech markets.

Contact: Megan Fowlie, Landing Communications m.fowlie15@gmail.com 022 301 0334

Hamburg | Maersk and the German project developer bauwo are building a 20,000-square-metre logistics centre near Hanover to store and handle electric car batteries and components to produce the batteries.

Following the successful launch of a similar facility in Teplice, Czech Republic, in November 2022, the two new halls in Berkhof, directly on the A7 motorway, will further strengthen Maersk's strong position as a logistics partner in the automotive industry. Thanks to the recently granted construction permit, the works on the approx. 50,000 square metre sites have already begun. Completing the highly automated battery warehouse is scheduled for May 2024.

"In addition to Teplice, the battery warehouse in Berkhof will be our second, even larger location in Europe, with which we will meet the growing demand of the automotive industry for logistics solutions for electric car batteries. The new facility is close to the production sites of several car makers and will help e-mobility to grow across Germany and Europe," said Jens-Ole Krenzien Maersk, Managing Director of North Europe Continent"

“Logistics in the automotive industry is one of

the most demanding. Through our control over all important assets along the transport chain from the factory in Asia to the use of the parts in a plant in Europe, we can offer our customers not only tailor-made but, above all, very resilient and flexible logistics solutions,” Krenzien continues.

“The logistics centre in Berkhof will be a central building block for transporting and temporarily storing the batteries as the most important element in e-mobility.”

In addition to storage and repacking, the services offered in the special warehouse include in-depth quality controls and charging of the batteries as well as other value-adding services along automotive supply chains.

Up to 34,000 pallets can be accommodated in the two halls with a clear height of twelve metres. A sophisticated safety system monitors

the batteries. For example, in case of higher temperature or expansion in size, a pallet is evacuated fully, automatically and safely stowed outdoors in a special container where it can be further examined. The warehouse can be tailored to separate compartments dedicated to a customer if needed.

The strong growth of e-mobility in Europe continues, and the demand for specialised battery logistics is increasing. In addition to converting new car production from combustion technology to electric engines, the first generation's handling and recycling of used e-car batteries are now also starting at scale. Specialised companies, including some from Germany, can give these used batteries a second, multi-year life by replacing individual battery cells, but this also requires storage and distribution capacities.

Ultra-agile and highly dependable - perfect for city deliveries with plenty of stops and starts. Our medium duty electric range is built for constant use, supported by a range of services and extra features to keep you on the road.

Volvo Trucks are quietly leading with improved uptime and efficiency - boosting your bottom line.

To learn more visit volvotrucks.co.nz or talk to our team 0800 683 683.

Introducing Volvo Electric Medium Duty TrucksThe world’s food supply chain is one of the most complex logistical networks on earth, and the demand for innovative, sustainable, affordable and efficient transport is growing exponentially. One of the challenges for the supply chain sector is to reduce the environmental and climate impact of goods against a background of increasing demand. And while no single solution can fully address climate change and related issues, heavy vehicle manufacturers are making inroads towards a more sustainable transport future.

When it comes to logistics for the food and beverage industry, choosing the right truck is critical to the success of your operations. Volvo Trucks is a leader in the industry, providing trucks with advanced features that can be tailored specifically to your business needs.

Volvo’s commitment to innovation is evident in its partnership with industry leaders such as Fonterra. A trial of the new Volvo Electric FL is currently underway at New Zealand’s biggest dairy company, working out of The ShedFonterra Brand’s Auckland distribution centre.

Electromobility is just one of the areas in which Volvo Trucks has been leading the way. The company has introduced electric and hybrid trucks to reduce carbon emissions and provide a sustainable alternative to traditional diesel-powered trucks.

Volvo Trucks commitment to electromobility is evident in its introduction of route planning and connected technology tools to support customers in scaling electromobility solutions.

These tools help customers optimise their routes, ensuring Volvo electric trucks are used to their maximum potential.

The Volvo FL Electric is the forerunner of sustainable alternatives from the global truck brand. Paul Illmer, Vice President of Emerging Technology Business Development at Volvo Group Australia, confirmed that Volvo has a battery electric or fuel cell electric alternative for every Internal Combustion Engine (ICE) model on the market, either currently in production or at trial stage.

Paul Illmer also stressed that the truck is only one part of the solution for New Zealand’s transition to sustainable transport. “Tools, expertise and infrastructure are essential to delivering operational peace of mind for New Zealand transport companies as they shift to e-mobility,” said Illmer.

“Selecting the right model and specification for both application and route is critical, as is driver training, specialist after-sales support, and charging infrastructure.”

The company has developed other tools to support logistics companies as they drive down the carbon footprint of their operations,

including an Environmental Footprint Calculator. Volvo is also exploring the use of renewable fuels such as biogas and HVO.

As you would expect, safety is a top priority for Volvo Trucks. The company has introduced a range of state-of-the-art features including a Lane Keeping System, helping to prevent accidents caused by driver fatigue or distraction, and the Electronic Stability Program, reducing the risk of rollovers and loss of traction.

The Volvo Truck range also has a night mode feature, where drivers can instantly switch off all unnecessary dashboard backlights at the press of a button. The result is less glare in the driver’s field of vision and fewer distractions from reflections in the windscreen and side mirrors.

“At Volvo Trucks, we prioritise active safety measures to help to prevent the mistakes that are responsible for around 90 percent of traffic accidents,” said Scott Robinson, National Sales Manager at Volvo Trucks NZ.

“To achieve this, we enhance drivers’ visibility, provide them with a comfortable and focused

driving environment, and equip our trucks with cutting-edge systems and technology that take safety to new heights.”

Volvo Trucks now offers a full range of medium and heavy-duty electric and combustion engine models, that offer both operational and environmental benefits. Through services that help to optimise loads and increase logistical efficiencies, Volvo Trucks supports a reduction of waste in the transport system.

“Volvo Group is committed to offering flexible services and solutions that empower customers to develop their businesses in the smartest possible way. With the shift towards electric equipment, system thinking has become increasingly important. The truck is just one part of a total solution that includes charging infrastructure, battery optimisation, maintenance, financing, and value-adding services.”

For more information and to find out how you can reduce your carbon footprint and improve supply chain efficiency, call 0800 683 683.

Transporting New Zealand has announced its annual conference for 2023. Named A Changing World, the conference will be held at Lower Hutt’s Event Centre from June 28th, concluding with an industry awards dinner on the 29th.

The conference is geared to focus on pressing issues facing the transport industry, in conjunction with providing all those within the industry a vital networking opportunity where the work in achieving increased economic productivity since its last annual conference can be recognised

and celebrated by all.

Tickets for the conference are now available to purchase.

Issues that will be addressed range from the challenges following severe weather events, climate change, and the resilience of the transport industry and network to technological

changes and difficulties in garnering new people into the industry.

As it is an election year, there will also be an opportunity to hear from politicians, including Transport Minister Michael Wood, and transport spokespeople from major political parties.

Keynote speaker Phil O’Reilly, the founder of policy advisory firm Iron Duke, is a New Zealand and global business leader and advocate.

Meanwhile, economist Cameron Bagrie will present a hard-hitting report on the economy and what the industry can expect for the coming year.

More topics will be covered, such as the Green Compact (Transporting New Zealand’s joint initiative to tackle emissions and decarbonisation), the road to success and new trainees, health and safety, fatigue management, and the law.

The conference will conclude with an industry awards dinner on June 29.

The paintwork gleams in blue and silver. There are a few snazzy LED lights but you’ve got to look hard to tell this DAF truck is any different. There’s just one main giveaway: a couple of gas cylinders behind the cab, mounted just forward of the second axles. They contain hydrogen gas and they make this truck unique in New Zealand – for now.

We’re at Teretonga Park in Invercargill for the launch of trucking company HWR’s first dual-fuel truck, which it believes will be a gamechanger for the industry.

I climb up into the cab and once again, there’s nothing radically different. It’s a comfortable, ergonomic cab with all the main controls within easy reach for driver, Hydrogen Project key account manager Craig McKenzie. There’s just one main difference: a control that lets him switch effortlessly from running on pure diesel to a mix of diesel and hydrogen. It’s all done by a precision computercontrolled injection system. The technology is complex but it’s super-simple to use. The only other difference

is a dial that shows how much diesel and how much hydrogen the truck is using: right now, 42 percent hydrogen.

“It feels just like a truck,” says Craig. A very nice one with an automatic gearbox, to be sure, but the available torque feels no different from a conventional pure diesel model. It has the same DAF 12.9-litre six-cylinder inline Paccar engine, which meets the latest Euro 6 emissions standards.

“One of the key success criteria is you don’t notice that the hydrogen is active,” says Gareth Wishart, HWR Group General Manager Innovation. He says the truck can also carry the same payload as a conventional truck at 58 tonnes, with no heavy load displaced. That is

because of where the gas cylinders are mounted. They hold 25kg of hydrogen and 430 litres of diesel. Range is 450 km before the hydrogen tanks need to be refilled, with the truck still able to run on just diesel. (Precise fuel consumption figures will be monitored closely. A British company, which already has dual-fuel trucks in operation, has worked with HWR on the project and is sharing its results.)

A team of HWR experts is overseeing the dual-fuel project. It represents a $15 million investment by the group. Each truck costs about $150,000 to convert it, although costs are likely to come down.

Continued on page 20.

For us it’s all about how do we make a meaningful difference today. This truck does that without payload degradation, without range anxiety, and the ability to lead the industry. The big benefit is it’s zero carbon, using 40 to 50 percent hydrogen.

Wishart says nine more dual-fuel trucks will be deployed in coming months, operating out of Gore, where the first hydrogen fuel station is being built. Allied Petroleum operates 122 Allied Petroleum stations in New Zealand, so there is good potential for growth. “It’s a successful fuel for the heavy vehicle industry. We are deploying it around the country.”

Mike Webster, of Christchurch-based Transport Repairs Ltd, is responsible for converting each truck to run on dual fuel. An advantage is it’s possible to convert pretty much any truck, both older and new. Conversion and ongoing maintenance are also seen as a growth area for training and upskilling mechanics and engineers.

Another interesting aspect is how the hydrogen is produced. Professor Sally Brooker, of the University of Otago, heads up He Honoka Hauwai, the German-NZ Green Hydrogen Centre. She has set up a table demonstrating how hydrogen – the most abundant element in the universe – can be produced using electricity to split hydrogen (H) and oxygen (O2). The hydrogen is used for fuel while the oxygen can be used for other purposes, for example, in hospitals. Once the energy from the hydrogen is expended, it recombines with oxygen to form water (H20) as the only by-product.

She says hydrogen can be transported safely and conveniently, just like any other fuel.

Brooker is pleased that in New Zealand hydrogen is produced using electricity generated from the Manapouri underground power station, making it true green hydrogen. She also sees a big potential for growth in clean energy.

According to HWR, one dualfuel truck running an average of 384km per day can eliminate 200kg of carbon emissions per day. If all New Zealand’s fleet were to transition to dual-fuel, millions of kilograms of carbon emissions would be eliminated each year.

HWR chief executive Anthony Jones says the dual-fuel project will make a significant difference to the road transport industry. “For us it’s all about how do we make a meaningful difference today. This truck does that without payload degradation, without range anxiety, and the ability to lead the industry. The big benefit is it’s zero carbon, using 40 to 50 percent hydrogen.”

Jones says smaller BEVs (battery electric vehicles) may be a good solution around town and for passenger cars, but they are not so practical for heavy long-haul transport. Fuel cell vehicles are another possibility, but they are not widely available so far.

“We’re excited by it. We see it as the only solution for heavy mass at the moment. We’re proud of what part this will play in the industry showing it’s possible to change.”

By David Killick

By David Killick

Extreme weather events such as Cyclone Gabrielle may have disrupted the supply chain for Feijoas, but the fruit has remained in relatively good shape in the face of the last few weeks.

The slow start to the fruits 2023 season is going on an uphill trajectory, with the New Zealand Feijoa Growers Association (NZFGA) manager, Ian Turk, stating the impacts of the Cyclone have been less devastating for the fruit than for other fresh produce.

“The weather has impacted feijoa orchards in the top half of the North Island. However, they appear to have escaped significant damage to both the plantings and the structures,” stated Turk.

Grown commercially from Northland to the top of the South Island, the fruits have a large geographical area within which it grows, which could be attributed to the minor impact on the feijoa following the devastating weather.

The weather appears only to have delayed the supply of feijoas from the Northland area, typically distributed in March. However, now it's expected in April.

“This year NZFGA are estimating harvest volumes of around 1200 tonnes, produced by 120 growers nationwide. That’s a good result following a couple of tough seasons with

challenges ranging from weather disruptions to labour shortages and a global pandemic.”

These delays in supply will maintain a more affordable price point as the seasons change. The most adverse impact of the weather conditions is on the fruit's skin. However, Turk stated that the flavour would not be compromised.

There may be a slight decrease in volume, but the reduction is not significant enough for the industry to expect any lack of supply to meet demand. As a highly perishable fruit, stores must store and display it to maintain its quality and freshness.

Storing feijoas at four degrees Celsius is the optimum after purchasing, and they should not be displayed for at most two or three days out of refrigeration.

As a highly nutritious fruit, Turk shared the reminder that feijoas are a healthy incorporation of a 5+ A Day diet.

“Including just two feijoas in your diet each day through the autumn months will provide 64 percent of the recommended daily vitamin C intake, which has an important role in increasing immunity.” n

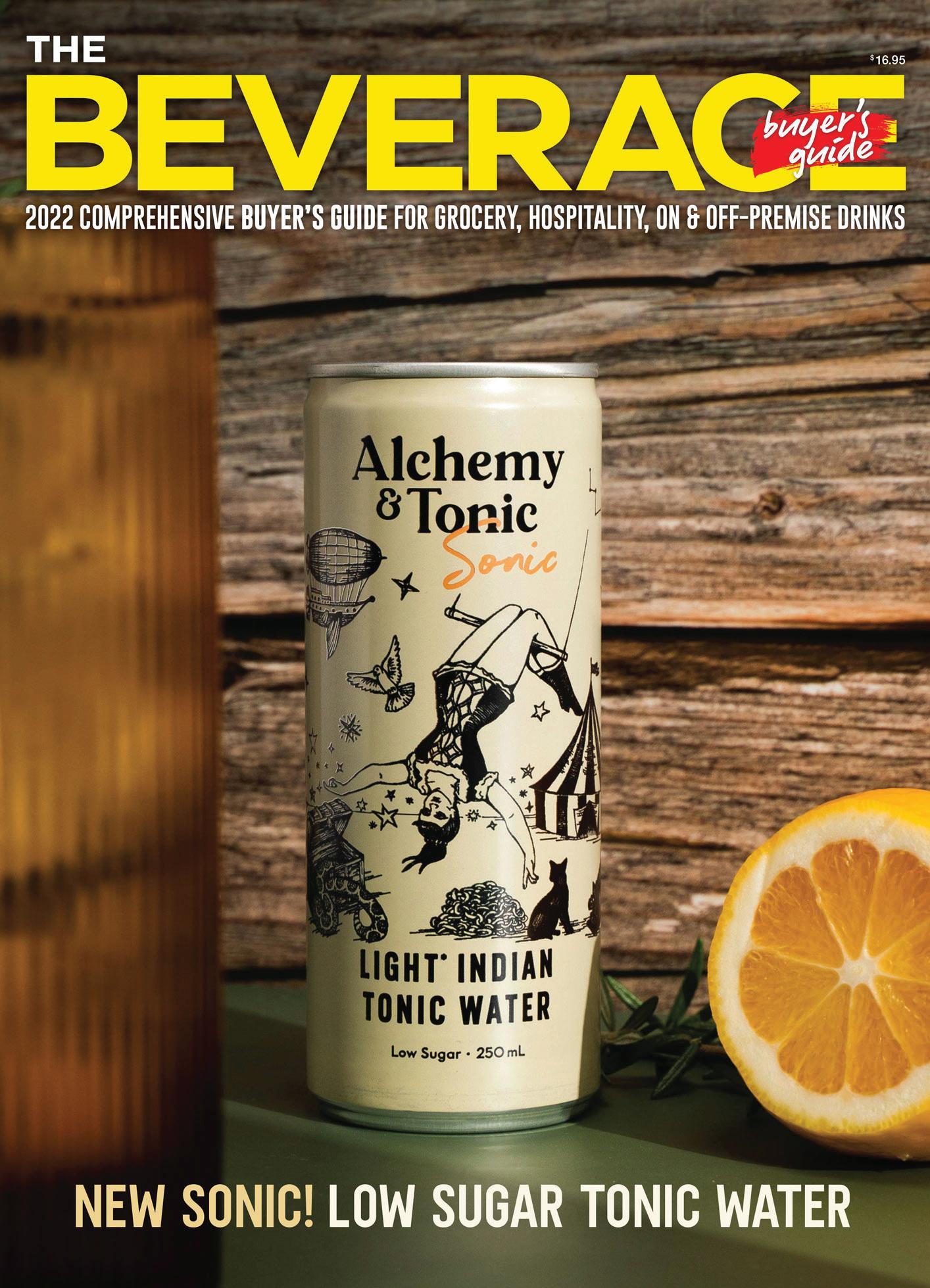

Brand Manager at Alchemy, Sophie Roberts, revealed that with each new product development, the company always explored packaging which would help reduce the company’s overall environmental footprint.

“For Alchemy & Tonic, it was critical that our packaging portrayed the sense of magic that the brand embodies,” revealed Roberts.

However, Roberts also revealed that standing out was essential in the competitive beverage market. Therefore, Alchemy & Tonic translated its charm into its packaging by using unique colours and artwork in playful and unexpected formats, such as the brand’s 250ml cans and new bespoke 600 ml glass bottle, both of which Roberts commented were recyclable.

Roberts shared that at Alchemy & Tonic, there was a talented in-house design team. However, the company worked with a range of talented individuals. With a unilateral desire for distinctive design, the team worked alongside Brave, a renowned and talented local artist known as Kallola Brown.

“The brief was to create a series of characters to bring to life our tonics under the theme of ‘magic’.”

Roberts revealed that Brown self-described that her inspiration for the Alchemy and Tonic illustrations was from a converging of themes, such as transformation, illusion, sorcery and astrology.

Inspiration was drawn heavily from the Victorian Era, a golden age for the mystical arts and characters such as the invisible man, oracles, and contortionists, which captured and cultivated the imagination of many. These features were blended into individual scenes depicted on Alchemy & Tonic’s new range, ensuring each drink had a throughline of magic that made each drink unique.

Design is of utmost importance at Alchemy & Tonic, with Roberts revealing that the brand packaging is designed to tell a story aligned with the consumer desire for quality products that are sustainably packaged with recyclable material also reveals a unique story.

“Design is important to us, and we wanted

our packaging to tell a story. Not only do consumers look for a quality product, but they also want to know it’s made from recyclable materials, is sustainable and looks good not only on the shelf but when they are consuming it.”

Roberts elaborated that the brand’s choice to have its mixers packaged into cans and glass was specific to both materials being the most recyclable packaging options in New Zealand. She shared that over 18 months were spent creating a bottle design that used lightweight

glass, at minimum, 70 percent of which was recycled glass, making it cheaper and more efficient to move around the country. The glass is locally made through Visy, which diverts 521,000 tonnes of glass from a landfill yearly.

“We consciously chose to use paper labels on our bottles instead of plastic-based labels. In addition, all of our outer cartons are made from FSC-approved paper sources, along with a high percentage of recycled cardboard.”

All of these choices by Alchemy & Tonic are deliberate for the company to reduce its carbon footprint.

With the brand’s recent glass bottle launch, Alchemy & Tonic is actively pursuing avenues to create a bottle-swap programme to reuse its bottles. However, this venture is still in its infancy, with the company’s long-term goal of creating a circular economy.

Roberts described the design process as beginning with research into the company’s target audience, garnering knowledge of market opportunity.

“We also look at trends in packaging design and competitors to come up with a look and feel that has shelf standout.”

Pastel colours and magical scenes were utilised in the new range in alignment with the brand’s personality. Alchemy & Tonic’s research process has allowed the company to develop a brand that would stand out in a crowded market and resonate with customers.

Kerry Tomane, the Head of Marketing at Earthwise, shared that convenience was a key driver of laundry market purchasing as consumers see little difference between brands and products. If other brands present additional benefits or convenience, consumers will switch what brand they use products from.

Earthwise’s eco-laundry scoop is a first of its kind, structured as a flat cardboard design. It is incorporated into the dieline of the existing laundry box, where consumers tear along the perforation and self-assemble the scoop in three easy steps printed on it. The scoop has a volume capacity of 30 grams, which measures a standard powder dosage and is 100 percent recyclable.

Tomane described Earthwise’s packaging philosophy as reflective of the Earthwise Group’s pledged support to the New Zealand Packaging Declaration, which has meant that the company has committed to having 100 percent of its recyclable, reusable packaging or compostable by 2025.

“Since October 2018, Earthwise has reused and diverted over 950 Tonnes of plastic from landfills since using at least 75 percent recycled plastic content in bottles.”

The brand’s carton packaging was already 100 percent recyclable, crafted from PEFC board, with the new laundry scoop fitting in perfectly with Earthwise’s existing product and packaging ethos.

The new scoop further demonstrated Earthwise’s commitment to sustainability, national targets, and adherence to sustainable packaging guidelines through its reduction of unnecessary use of plastic. Its 100 percent recyclability has zero increase on the product’s carbon footprint and does not process increases as it requires no additional labour or equipment to create.

Tomane stated that sustainability was a movement, not a trend and that the brand was committed to creating an eco-friendly solution whilst there was consumer demand for a scoop.

“Small changes can still make a tangible benefit to the environment.”

Going on further, Tomane shared that sharing knowledge and collaboration could be incredibly powerful for the industry as a whole to come together to create potential solutions with a unified goal.

Earthwise’s practices differ from traditional scoops provided in laundry powder, which are fully formed as a separate product crafted from plastic or board. The Head of Marketing shared that these traditional scoops required extra packaging and processing steps and could create further waste.

Extra processing has the potential of requiring additional labour or equipment to physically add the scoop into laundry powder boxes, which is a design challenge that Earthwise wanted to address directly.

“The design challenge for us was to create a scoop that was an integral part of the existing unit carton, optimise the use of existing unit carton board sheet and avoid additional cost.”

This required the team to innovate, and by working closely with its packaging supplier, Forbes Packaging, Earthwise was able to come

up with its current solution.

Earthwise has committed itself to look at new projects each year that reduce water, energy consumption, and waste production as an Environmental Choice Certified (ECNZ) company, which is New Zealand’s highest ecofriendly accreditation. Measuring its energy and water consumption is completed annually as part of this certification.

The Head of Marketing exclusively revealed that Earthwise would be removing the resealable bag in its Dish Tablets, a venture that has taken extensive product and packaging trials to achieve.

When discussing the global plastic pollution crisis, Tomane shared that the most significant challenges companies such as Earthwise face in addressing the problem are related to costeffectively achieving scale. Tomane explained that investment is required from numerous companies to increase supply and drive down costs.

“Incorporating recycled content in packaging is a step towards this, but we only moved to this after rigorous testing to ensure the bottle

still did do its job.”

Tomane emphasised that sustainability was a journey, not an end goal. With that central to Earthwise’s philosophy, the company is consistently and continually searching and implementing ways to improve its carbon footprint. Working with and supporting existing regional and national recycling schemes is essential when improving the recycling infrastructure.

Ecostore has recently launched its new 3X Concentrates Laundry Liquid, the new packaging design centred around the brand’s commitment to sustainability and reducing its environmental impact.

The new design contained 55 percent less plastic and water than the brand’s regular laundry liquids. APCO (Australian Packaging Covenant Organisation) approved both pump and bottle, making the new product fully recyclable while maintaining and delivering a powerful performance.

With the new design of the three pumps method, the laundry concentrate makes it easy application without mess. CEO of Ecostore, Pablo Kraus, stated that the new smaller and more convenient bottle saves shelf space at home and in the supermarket all while

providing the same number of washes as the brand’s larger mainstream products.

“Our new design aligns with our brand purpose. A world where safe, sustainable, ethical products are the norm,” shared Kraus.

Kraus stated that Ecostore’s packaging design choices are centred around the company’s planet-before-profit philosophy.

Ecostore’s packaging design choices are aligned with the company’s incentive to prioritise sustainability, safety, and simplicity, which has been an ongoing theme of Ecostore’s intention with its products since 1993.

Kraus revealed that the brand’s plastic bottles

are created with a mix of sugar plastic, a material the company transitioned to in 2014, which he said was before the increased trend of utilising locally sourced plastic. The brand’s new 3X Concentrates Laundry Liquid also reflects this environmental consciousness.

“We are committed to using renewable, recyclable, and refillable packaging for our products whilst eliminating as much unnecessary packaging as possible.”

Certified by the Forest Steward Council, the cardboard packaging of the laundry liquid was created to promote environmentally appropriate, socially beneficial, and economically viable management of the world’s forests.

Kraus shared that the company uses sugar plastic instead of petrochemicals to capture CO2 from the atmosphere rather than release it. Secondly, the Ecostore incorporation of recycled materials creates a circular economy, reducing the need for new plastic.

Ecostore’s combination of plastic made from sugar and recycled materials has enabled the brand to create durable bottles which require less energy and resources for production and minimise the amount of plastic in our environment.

Kraus revealed that Ecostore had saved over 7,676 tonnes of carbon from being released into the atmosphere, the equivalent of driving a car from Cape Reinga to Bluff 14,610 times.

“Our sugar plastic bottles are 100 percent recyclable through kerbside collection and can be remade into new bottles. And whilst recycling is excellent, refilling is an even better option which ecostore offers in many supermarkets and stores across Aotearoa.” Furthermore, Ecostore utilises minimalist designs that are simple, clear, and easy for consumers to understand to reflect the brand’s transparency about what is contained in its products to support consumers in making informed decisions when purchasing.

Kraus shared that Ecostore also provides and encourages consumers to refill their used products, with the company having over 90 refill stations around New Zealand.

Ecostore’s commitment to sustainability and the environment has earned the company certifications from Toitū Net Carbonzero and Enviro-Mark Diamond, which the Kraus stated set the company apart.

In addition to the 3X Concentrates Laundry Liquids’ eco-friendly packaging, design, and easy application, Kraus shared that Ecostore was proud to use gentle plant-based ingredients on fabrics while removing dirt and stains.

“Our formula is free from harsh chemicals like phosphates, synthetic dyes, and optical brighteners, making it a safer and more sustainable choice for customers and the environment.”

As B Corp-certified organisation, Kraus shared that Ecostore was one of the first

companies to go carbon-neutral in Australasia. The company have installed solar panels on the roof of its Auckland manufacturing facility, generating enough energy to power the site and feed surplus electricity back into the grid. The company sources locally wherever possible and uses various techniques to reduce energy usage in its manufacturing process.

Furthermore, the company offsets its carbon emissions by using renewable energy and being involved with native forest programs. As well as this, the company has established its Plastic Return Program, which remakes its empty packaging bottles, reducing the new for new plastic production.

In its first year, the Plastic Return Program collected 4,600 kilograms of plastic, equivalent to around 83,600 500-millilitre dishwashing liquid bottles. Of this plastic, 72 percent has been recycled into new bottles, and the remaining 28 percent will be sorted, cleaned, and reground.

The company’s refill stations have meant that Ecostore has saved the equivalent of 275,693 1-litre containers in 2019 and has continued to expand its refill locations into its global markets.

“We constantly seek new ways to minimise our environmental impact and improve sustainability across all business areas.”

Kraus revealed that the company aims to reach carbon negativity by 2025, which it plans to achieve by reducing its carbon footprint across production and distribution, investing in renewable energy sources, and offsetting any remaining emissions through carbon credits.

The CEO said that Ecostore believed that education about sustainability was imperative to creating a sustainable future and would continue to be a critical part of the company’s mission.

“Businesses have a responsibility to prioritise sustainability. By adopting sustainable practices, businesses have the potential to drive growth and engage with consumers who are looking for companies to take a more proactive stance on environmental issues.”

Kraus emphasised that sustainability was something that both businesses and consumers needed to work together on, as addressing the challenges of environmentalism will create new opportunities for growth and profitability while taking care of the planet.

“We are proud to be leaders in sustainable business practices, and we hope to inspire other companies to join us on this journey.”

With the success of the orchard's ability to become fully electric, Director of Total Utilities, Mike Ette, shared that the challenge moving forward included cost and availability of electricity.

“New Zealand needs to invest a lot more in baseload generation that can supply when the sun is down, and significant expansion of the national and local grids is required,” said Ette.

has continued to search globally to bring new and innovative technologies and solutions to the market to improve its data collection, allowing the company to develop informed sustainability decisions.

The Director stated that the company’s goal for the future was to help as many New Zealand businesses and public sector organisations as possible on their sustainability journey.

MIKE ETTE Director, Total Utilities

MIKE ETTE Director, Total Utilities

Total Utilities recently assisted Forest Lodge in saving money, gaining real-time data visibility, and proving the orchard's 100 percent electricity claims to grant providers. All drive sustainable growth and set an example for food producers worldwide.

Ette explained that Hydro and Geothermal have traditionally been the country’s answers, as wind farms are unreliable as an energy source as generation is sporadic. The Director stated that NIMBY (Not In My Backyard) was the prevailing attitude, as high-heat industrial processes are problematic and cannot be addressed through electrification.

“We have doubts that the economics behind hydrogen for most transport fuel applications will ever add up compared with electrification and batteries.”

Total Utilities are borne from energy procurements, with the business model revolving around the belief that the first step in sustainability derives from optimising consumption.

Ette shared that every unit of energy that is not being consumed daily or weekly, whether that is electricity, natural gas, or diesel, is a saving that is both good for the environment and the bottom line.

“We are data analysts, and we believe that the best decision-making is driven by and verified with data.”

As a Toitu-certified net zero company, Ette emphasises the importance of walking the talk before it advises its customers. Total Utilities

With the success of Forest Lodge becoming fully electric, it has proven that commercial electrification is not only possible but applicable. It supports others within the sector to transition to make similar technological choices and boosts the market opportunity and confidence in electrification throughout the industry.

Furthermore, Ette shared that the positive brand impact has enabled Forest Lodge to differentiate and market its point of difference in sustainability versus its competitors, adding value to its products. Ette stated that Froest Lodge was the embodiment of going up in the value chain.

Global issues such as food miles from markets have placed New Zealand’s agricultural and horticultural heritage at threat moving forward. Forest Lodge’s innovation in this space has served as an example to the industry that commercial success and increased brand value can be simultaneous with improved sustainable practices.

Forest Lodge has not only become fully electric, but the brand has also monitored its usage to understand further what and where the benefits are, which, when understood and utilised, help companies gain financially and sustainably.

We’re excited to announce the Peter Mitchell Memorial Golf Day, where we’ll be teaming up with the Graeme Dingle Foundation to raise funds for Kiwi Can and the amazing Peter Mitchell Scholarship. This scholarship is perfect for anyone looking to further their knowledge and training in FMCG, fashion, and hospitality. Peter Mitchell was an industry legend who received the FGC Lifetime Achievement Award twice, as well as numerous other awards during his lifetime. He was passionate about supporting and nurturing talented individuals in these fields, and this scholarship is a wonderful way to continue his legacy. By joining us for the Peter Mitchell Memorial Golf Day, you’ll be supporting Kiwi Can and helping to create a brighter future for aspiring professionals in these industries. So come join us for a fun day of golf and giving back!

(*rain day 7 August)

237 Alfriston-Ardmore Road

Papakura, Ardmore

We’re hosting an awesome end-of-play auction and we’ve got some great spot prizes lined up too. If you’re keen to join us, it’s just $300 plus GST for an individual player (and we’ll put you in a team if you don’t have one), or $1000 plus GST for a team of four. A great day of golf at a world class course while catching up with industry colleagues - we hope you’ll join us.

Ambrose,