Tania Walters Publisher tania@reviewmags.com

In this issue, we dive into New Zealand's aquaculture industry, updating you on trends, technologies, and future forecasts to reshape this vital sector.

Our aquaculture industry, globally renowned for highquality seafood and sustainable practices, stands at the cusp of transformation. Technological advancements, climate change, and evolving consumer preferences drive this shift. Advanced technologies like automated feeding systems, underwater drones, and sophisticated monitoring tools are revolutionising seafood farming and enhancing efficiency and sustainability.

Thanks to an initiative led by Minister Shane Jones, the industry is set for further acceleration. During a recent visit to Nelson, Jones emphasised the urgent need for swift infrastructure

development, stating, "It takes far too long in New Zealand to deliver essential infrastructure."

The current resource consent process is complicated, costly, and time-consuming. The Resource Management (Extended Duration of Coastal Permits for Marine Farms) Amendment Bill will remove this unnecessary red tape, giving marine farmers greater confidence to invest in improvements, new technology, species, and practices to make them more productive and sustainable. About 1,200 marine farms require one or more resource consents under the Resource Management Act 1991 to operate. About 200 would need to renew their consents by the end of 2024. These farms face costs of at least $20,000 to $100,000 to renew consents when they expire, in a process that takes an average of six months.

"Aquaculture is incredibly important for New Zealand. It provides jobs in the regions and contributes to our export-led recovery. One of my priorities is to remove barriers to the growth of aquaculture," said Jones.

Nelson Mayor Nick Smith welcomed the $1.2 billion Regional Infrastructure Fund, praising its potential to foster industry growth through public-private partnerships. Jones highlighted the fund's inclusive structure, stressing the government's commitment to swift action and economic growth. The future of New Zealand's aquaculture sector appears promising. Experts predict significant growth driven by domestic and international markets. However, adapting

to climate change, regulatory changes, and market fluctuations remain key challenges.

PS: Fisheries New Zealand is inviting feedback on proposed changes to catch limits and other settings across a range of New Zealand's fisheries as part of its regular sustainability reviews. Have your say on catch limits here

14 8 18 27

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES info@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC DESIGNER Raymund Santos

Retail 6, Heards Bldg, 2 Ruskin St, Parnell, Auckland. PO Box 37140 Parnell, Auckland Tel (09) 3040142 Email: edit@reviewmags.com

THE RETAIL CRIME INTELLIGENCE movement has welcomed the public safety technology leader, Axon, as its newest product integration partner and part of Auror’s Connected Ecosystem to keep retailers and their frontline workers safe.

Working together to standardise data and evidence-sharing workflows, Auror has continued to empower retailers and law enforcement to make communities safer.

The Axon/Auror product integration has created an end-to-end solution for secure video and evidence transfer, helping retailers and law enforcement obtain better and faster outcomes.

Many organisations have deployed body-worn cameras to frontline team members to capture incidents and evidence of violence, aggression, and criminal actions. These videos have become important evidence and assist in the investigation process.

Videos captured on Axon body-worn cameras can be exported into the Auror platform and linked to the relevant incident or investigation. Traditionally, evidence and information have been given to law enforcement through manual and physical methods (such as paper, CDs, and USB sticks).

However, with this new integration, law enforcement can export and securely transfer a complete evidence package from Auror Investigate to Axon’s Evidence.com once an investigation is at the hand-off point.

“The focus of this integration is in the US (not New Zealand) where retailers are experiencing rising rates of violence and crime - for example, 10 percent of people are causing up to 91 percent of the violence and harm for some US retailers,” said Vanessa Wills, Director Strategic Communication & Engagement, Auror.

“Footage from body-worn cameras may be voluntarily made available

by retailers to law enforcement when violent or criminal acts are undertaken and witnessed in a retail environment. These incidents include assaults, harassment and other violence.”

Wills explained that using footage through Auror was similar to how CCTV has been used (voluntarily uploaded by retailers as a record of instances of harm in-store), as retailers and law enforcement come together to keep their teams and communities safe.

“Auror does not operate or own any cameras, CCTV, or body-worn equipment in NZ or globally. Instead, it provides the software platform that enables retailers to record and, if they choose, report instances of organised retail crime and violence in their stores efficiently and securely.”

Auror’s platform has robust safeguards and privacy measures and ensures the safe and secure transfer of needed information.

Over the past six months, Auror and Axon have partnered with the Retail Industry Leaders Association (RILA) on the Vibrant Communities Initiative. The collaboration has yielded impactful outcomes for retailers, law enforcement, and the communities.

For example, a repeat offender connected to over $500,000 in loss across more than 70 reported events was recently identified and arrested through collaboration among six retail organisations involved in the Vibrant Communities Initiative.

In conjunction with the Vibrant Communities Initiative, these retailers continue to work with local law enforcement and district attorneys on this case closure.

FISHERIES NEW ZEALAND has sought feedback on proposed measures to mitigate seabird risks from data transmission cables on fishing trawlers. This feedback will significantly affect the decision to allow the use of data transmission cables.

“Data transmission cables attached to trawl nets provide fishers with real-time information about what’s happening under the water, so they can fish more efficiently and reduce their environmental footprint,” said Emma Taylor, Fisheries New

Zealand’s director of fisheries management.

Data transmission cables on trawl vessels were banned in 1992 because of risks posed to seabirds. Birds were often attracted to fish waste being continually discarded from vessels, and while attempting to feed, birds would collide with deployed cables from the stern of vessels.

“In the three decades since the ban on these cables, we have developed a better understanding of how to manage the risks they pose to seabirds. This includes practices to manage fish waste, which attracts seabirds, using devices like tori lines to scare birds away, or bird bafflers that put a barrier between foraging birds and the vessel.”

The proposals to strengthen seabird protection from data transmission cables include changes to improve fish waste management practices, additional seabird scaring devices such as bafflers or tori lines minimising

the portion of cables above the waterline and restrictions on the areas and times of year data transmission cables can be used.

The consultation also sought feedback on amendments to reporting and monitoring requirements should data transmission cables be allowed.

In 2022, Fisheries New Zealand consulted on lifting the ban on data transmission cables.

Feedback from this consultation included that mitigation measures to protect seabirds should be reviewed before a decision on allowing data transmission cables is made.

“If data cables can be introduced with appropriate protections against seabird bycatch in place, the data gathered has the potential to support innovation and new technology to make fishing more efficient and reduce bycatch and harm to protected species.”

The consultation has now been opened and will run until the 9th of August 2024.

FOOD-TECH start-up NewMoo, Ltd. has debuted in the “happy cow” space by using plant molecular farming (PMF) to produce casein proteins for cheese-making.

Caseins comprise about 80 percent of the proteins in dairy milk. This innovative product will allow cheesemakers to deliver the same cheese experience as traditional dairy cheese through a cost-effective, animal-free, and sustainable pathway. Until now, cheese alternatives have struggled to offer consumers the real cheese experience

WALMART has been testing cutting-edge technology that improves how it handles store pricing adjustments. This will ultimately speed up processes and enhance the overall customer experience. Walmart plans to roll out this new technology, digital shelf labels (DSLs), to 2,300 stores by 2026.

This would be a significant change in how in-store employees handle pricing, inventory, order fulfilment, and customer interactions, guaranteeing that customers will have an even more enjoyable shopping experience.

in terms of nutrition and price. The scientists at NewMoo discovered a way to express casein proteins in plant seeds that can grow abundantly through traditional field agriculture.

After harvesting the plants, the NewMoo casein liquid base is produced through a unique development process that yields hormone-free liquid casein naturally free of lactose and cholesterol and replicates dairy cheese’s functionality.

The dairy industry has considered caseins the “holy grail” of milk structure. Developing animalfree caseins through plants instead of cows makes it possible to make almost any dairy product, starting with cheese.

“Our animal-free liquid casein mimics all the functional traits of real milk protein for crafting cheese the traditional way,” said NewMoo cofounder and CEO Daphna Miller.

“This means it can seamlessly replace dairy milk in any dairy cheese manufacturing facility without needing any special equipment or reconfiguring existing equipment. NewMoo’s caseins can form the basis for a cheese that has the exact melting

Walmart stores stock over 120,000 items with their price tags on the shelves. The stores support numerous pricing updates for new products, rollbacks, and markdowns every week.

The digital shelf labels, created by Vusion Group, will enable updating prices on the shelves using a mobile app, reducing the need to

and stretching behaviour as animal dairy cheese and delivers the typical aroma, flavour, and texture that cheese eaters crave. Our animal-free proteins are identical to animal-derived caseins.”

Unlike protein powders, the NewMoo liquid casein is production-ready, helping streamline production and go-to-market. This approach doesn’t require expensive bioreactor machinery to grow proteins compared to current precision fermentation practices. The plant seeds themselves act as bioreactors.

“Our goal is to assist dairy cheese manufacturers in broadening their market scope to include the burgeoning flexitarian demographic,” said co-founder Hod Yanover, Vice President of Food Development for NewMoo.

“We empower cheesemakers to create delectable and nutritious guilt-free products with ease and at no added costs.”

According to Euromonitor data, 42 percent of consumers worldwide identify themselves as flexitarian. The global cheese market is projected to reach USD 220 billion by 2028.

manually change paper tags around the store and giving employees more time to assist customers.

Using DSLs has revolutionised daily tasks, enhancing productivity and minimising walking time. What used to take an associate two days to change can now be done in minutes with the new DSL system.

The “Stock to Light” feature allows an associate to flash an LED light on the shelf tag using their mobile device, signalling the areas that need attention. This feature simplifies the process of identifying shelf locations when restocking shelves.

The “Pick to Light” feature directs associates to the products required for online orders, expediting the picking process and enhancing order accuracy.

Walmart’s transition to digital shelf labels has been a game-changer as it digitises stores and extends digital shelf labels.

AN AUCKLAND INTERNATIONAL

freighting company and manager have been fined over $28,000 for failing to do biosecurity checks and transporting 15 sea containers to unapproved locations for unpacking.

Under the Biosecurity Act, all sea containers arriving in New Zealand must be sent from the port of first arrival to a Ministry for Primary Industries (MPI) Approved Transitional Facility (ATF) for inspection and unpacking.

Auslink International New Zealand Limited and logistics manager Christopher James Manning (68) were sentenced in the Manukau District Court on eight charges each under the Biosecurity Act following a successful prosecution by MPI.

Auslink was fined $16,250, and Mr Manning was fined $12,000. “When imported sea containers are sent to and unpacked at

unapproved locations, they leave the country vulnerable to pests or unwanted organisms that could devastate the environment and people’s livelihoods,” said MPI director of investigations

Gary Orr.

“The rules are there for a reason—to protect our borders from unwanted biosecurity threats.”

Compliance investigators found that between December 2021 and April 2022, Auslink was contracted to complete biosecurity checks at their MPI-approved transitional Facility for 15 sea containers. None of the required biosecurity checks were done in total. In the end, 13 of the 15 sea containers were sent to a grass paddock at a farm that would never be approved as a transitional facility.

Placing sea containers that have not had complete biosecurity checks on the grass risks the

potential for exotic pests that might be present in or on the container to get into New Zealand soil or vegetation. “While we subsequently confirmed that no exotic pests were found in or on the 15 containers, the defendants took an unacceptable risk with New Zealand’s biosecurity.”

THE DEPARTMENT OF AGRICULTURE, Fisheries and Forestry have tested detector technology to identify biosecurity risk material and hitchhiker pests.

Christchurch-based Techmatics NZ has produced the Cyclops-2 prototype. The advanced, new wand-like camera-pole device was trialled in Melbourne to determine whether it fits broader biosecurity operations.

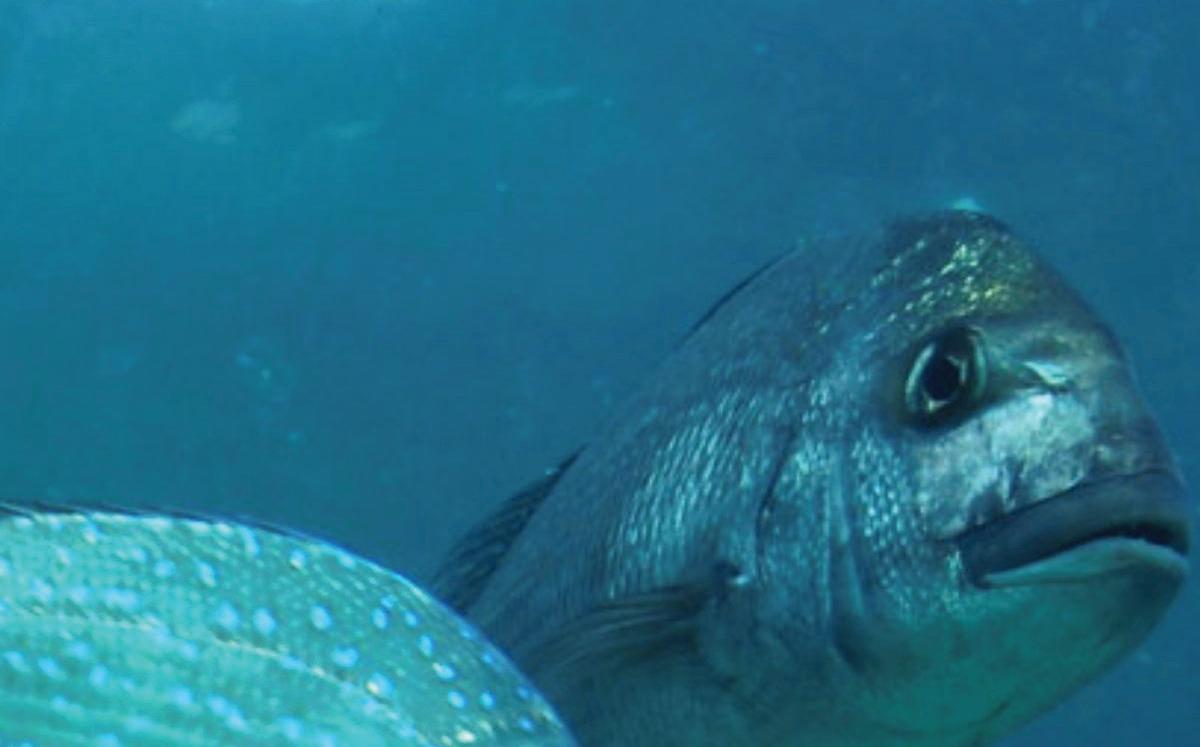

AN IN-DEPTH scientific report has found a mix of complex climate factors that have been likely to cause Milky White Flesh Syndrome.

Fisheries New Zealand’s director of science & information, Simon Lawrence, said that snappers with the condition appeared skinny and had mushy, white flesh rather than their usual translucent, firm flesh and were malnourished.

Early and ongoing tests ruled out exotic diseases and food safety issues, meaning that fish with the syndrome were still safe for people to eat if they chose to.

“The evidence suggests a complex interplay between factors, including extended La Niña weather patterns and warmer waters, causing lower phytoplankton and zooplankton production that provide important food sources at the bottom of the food chain,” said Lawrence.

“This is a complex issue, and it is more likely to be due to the effect of recent weather patterns and natural changes in fish biology throughout the seasons. The prevalence of the syndrome appears to be declining, which supports these theories.

The report found that a lack of food was likely the cause of the syndrome, but there was no evidence to suggest that fishing caused it. Areas in the Gulf where bottom trawling was permitted did not correlate with the areas where the syndrome was most prevalent.

“Overall, we’ve seen more snapper in the Hauraki Gulf for some time. The fishery is abundant, with plenty of younger fish entering the stock, all competing for food. Commercial fishing does not affect snapper’s

Justine Saunders, Deputy Secretary of Biosecurity and Compliance at the Department, said the pilot aimed to make biosecurity officers’ jobs easier and safer.

“If successful, the wand could unlock a digital, efficient and safe way for officers to check hard-to-reach areas, such as the top of shipping containers or underneath large machinery,” said Saunders.

“Currently, inspections are very labour-intensive and involve non-digital equipment. This technology can safeguard the safety and well-being of hardworking officers who serve on the frontlines of our nation’s biosecurity.”

With enhanced digital functionality, these wands could also increase risk detection capabilities and better protect Australia’s agriculture sector from hitchhiker pests. Using readymade, off-the-shelf technology has also been cost-effective for Australia’s biosecurity.

At the Department’s request, Techmatics NZ has enhanced the Cyclops-2 inspection kit with a motorised function for camera tilting, removable batteries for more extended usage and a support harness to steady the wand during inspection sessions.

Innovation pilot projects leveraged government-industry collaboration to better tackle biosecurity challenges in the field. The project will deliver outcomes for the National Biosecurity Strategy to build an effective and efficient future-focused biosecurity system.

primary food sources.”

The National Institute of Water and Atmospheric Research (NIWA) undertook research on behalf of Fisheries New Zealand and collected a range of data, including information from commercial and recreational fishers about affected snapper and where it had been caught.

The syndrome has been most prevalent throughout the inner Hauraki Gulf, near Auckland, and around Doubtless Bay near Northland.

Researchers considered data gathered from fishers and environmental information, such as sea surface temperature, to determine if any changes had occurred before fish with the syndrome were seen.

“We know that individual growth rates of all snapper around New Zealand have declined over the last 15 years as snapper abundance has increased, which could be explained by the mix of factors at play.”

Fisheries New Zealand has received recent reports about snappers with a few similar symptoms on the west coast of North Island. Some initial tests have been undertaken, and no biosecurity concerns have been raised.

AN INDEPENDENT panel has approved resource consent for a multiyear aquaculture trial in Tasman Bay, subject to conditions.

New Zealand Institute for Plant and Food Research Limited applied for resource consent under the COVID-19 Recovery (Fast-track Consenting) Act 2020.

These trials will take place in an open ocean marine farm in Tasman Bay, approximately six kilometres west of Sauvage Point on D’Urville Island, as part of a multi-year research programme trialling new technologies for finfish aquaculture.

The decision comes 143 working days after the application was lodged with the Environmental Protection Authority.

The Environmental Protection Authority has played a crucial role in this process. It provided procedural advice and administrative support to the panel convenor, Judge Laurie Newhook, and the expert consenting panel he appointed.

Wednesday 2nd October 2024

18th September 2024

Wednesday 3rd July - 18th September 2024 2024 AWARDS ANNOUNCED Wednesday 6th November 2024

Wednesday 16th October 2024

By combining a carefully curated mix of European seaweed species with fava bean and pea protein, BETTAF!SH has developed products like TU-NAH and SAL-NOM, which look and taste like the original. These products are 100 percent plant-based, protein-rich, and free from soy and wheat.

This technology was inspired by the urgent need to address overfishing and the environmental damage caused by traditional seafood production. With 43 percent of global fish stocks overfished and aquaculture contributing to environmental pollution, there was a clear need for a sustainable solution.

Additionally, the rising demand for fish and the health risks associated with toxins in seafood highlighted a significant market gap for nutrient-rich, healthier and more sustainable alternatives.

“Our technology aims to provide a solution by offering delicious, plant-based fish alternatives that reduce reliance on overfished species and harmful aquaculture practices,” said Thao Trinh, marketing manager of BETTAF!SH.

“Seaweed is the solution to the many challenges, as it helps our oceans regenerate and increases water’s biodiversity. It has a diverse nutritional and flavour profile and can be a natural income source for fisheries.”

During product development, the team at BETTAF!SH also realised that there was a gap in the ingredient space in terms of

clean-label aroma and flavour enhancers. Since those properties can be found in different seaweed species, extensive R&D was conducted on seaweed to take advantage of this potential and create novel ingredients for the food industry.

“We’re not only a supplier of the most authentic fish alternatives but also want to be a key supplier of seaweed ingredients. Our partners count on us as a reliable and flexible supplier with a pioneering position in seaweed R&D.”

As a small company, BETTAF!SH has been quite flexible and based on personal connections. It has also been open to working with partners on tailor-made seaweed ingredients as long as their visions to protect oceans align.

BETTAF!SH has contributed to sustainability by utilising seaweed since it can be cultivated without land, fresh water, fertiliser, or pesticides. Seaweed cultivation has helped restore marine ecosystems and provide a nutritious food source.

Replacing traditional fish with plantbased alternatives has reduced the pressure on wild fish stocks and environmental damage from aquaculture.

Continued

Continued from page 9.

“Our products also address the inefficiencies of traditional seafood supply chains, offering a scalable and sustainable alternative that can adapt to changing food markets and climate conditions.”

The food processing solution from BETTAF!SH is also highly scalable, as evidenced by its successful launch across over 4,000 supermarkets in Germany in 2021 with ALDI and expansion into Austria and Switzerland.

Through its unique offerings, such as the seaweed mix as a dry, flour-like ingredient and powdered versions of individual species, the versatility has catered to the needs of different production companies, whether they require raw ingredients for food service or prepackaged products for retail.

Quality and safety of BETTAF!SH food

products have been ensured by sourcing seaweed from the pristine fjords of Norway, where it is tested under lab conditions post-harvest. The seaweed is free from heavy metals and contaminants, as it is harvested after six months, preventing bioaccumulation.

The company also partnered with renowned research institutes to continuously improve its processing methods and maintain high quality and safety standards.

“Our fish alternatives TU-NAH and SAL-NOM are prime examples of our sustainable offerings. Thanks to the seaweed, they taste authentically like the ocean without the negative environmental impact on them.”

These products are rich in protein, omega-3 fatty acids, and other essential

nutrients, making them comparable in nutritional value to traditional fish. Consumer feedback has praised the taste and texture, noting the close resemblance to real tuna and salmon.

However, one of the company’s main challenges has been raising awareness and acceptance of seaweed-based products among consumers accustomed to traditional seafood. Therefore, its future goals include expanding the product line to offer a wider variety of plant-based seafood alternatives and developing new seaweedbased ingredients for the food industry.

“We aspire to lead the way in sustainable food innovation, making seaweed a mainstream ingredient in global diets and becoming a key seaweed supplier in the food industry.”

Our products also address the inefficiencies of traditional seafood supply chains, offering a scalable and sustainable alternative that can adapt to changing food markets and climate conditions.

Microalgae protein company Brevel, Ltd. has opened its first commercial plant, covering 27,000 square feet, to produce microalgae protein powder in the global alternative protein space.

The new site located in the desert periphery of Israel facilitates the introduction of Brevel’s new plant protein to the commercial food market by bringing production up to industrial levels.

From the new facility, Brevel can provide a fresh source of protein extracted from uniquely grown microalgae belonging to the chlorella family. It is highly nutritious, possesses a complete amino-acid profile, and is highly cost-effective, with a neutral flavour and colour, leaving a negligible environmental footprint.

Brevel cultivates its microalgae in indoor bioreactors via the fermentation of sugars. The company expects the new facility to start rolling out its first products by the first quarter of 2025.

“Combining light and fermentation to produce microalgae is like putting an electric motor into a Tesla car,” said Brevel’s cofounder and CEO Yonatan Golan.

“It may sound like a very simple straightforward task to achieve but is actually extremely complex. This was the challenge we managed to crack and lies at the core of our technology.”

Until now, fermentation has been confined to dark environments and was instrumental in producing extremely high yields. However, microalgae’s natural makeup of nutrients depends on photosynthesis for their development and growth.

“Our versatile solutions can boost protein content in dairy alternative while mimicking the same sensory experience. We have strategised several joint-venture partnerships in the US, Europe, and Asia. The result will be construction of larger facilities to fulfill growing demands for our sustainable protein in multiple applications.”

As part of its waste-free manufacturing process, Brevel valorises all of the algae’s valuable components, making the oil and fibre byproducts available as clean-label emulsifiers and a source of food enrichment for functional foods and food supplements.

At an inauguration event, visitors enjoyed tastings of a variety of protein-rich plantbased cheeses, demonstrating Brevel’s ability to provide nutritional value without compromising flavour or appearance.

“This new facility is just the beginning for Brevel,” said Ido Golan, CTO and cofounder of Brevel.

“We will make a vital contribution to building a secure, resilient food value chain that will nourish future generations with a new supply line of affordable yet highly nutritious protein.”

Brevel will supply its protein to plant-based food formulators and food manufacturers worldwide, some of whom are strategic partners and investors in the company. Last year, the company netted nearly USD 19 million in seed funding.

Cultivated seafood start-up Forsea Foods Ltd. has put its cell-cultivated freshwater eel unagi creation to the taste test at the chic Tel-Aviv restaurant “a” and welcomed an intimate gathering of 40 guests.

The exclusive group included investors, journalists, key opinion leaders in the food industry, representatives from the Japanese embassy, and various Japanese food companies based in Israel.

Three culinary fish creations were on the menu, including Forsea’s cell-cultivated iteration of unagi kabayaki—grilled fresh eel on a bed of aromatic rice. This traditional Japanese dish was featured as the centrepiece of the menu.

On a mission to save wild eel populations and other threatened species, the company pioneered a new approach to cell-cultivating fish tissues outside their native water habitats by applying organoid technology.

Forsea’s patent-protected method

Continued on page 16.

Continued from page 15.

The feedback from the diners was indeed uplifting. Several remarked that they wouldn’t have guessed that the unagi was cell-cultivated had they not been informed.

involved creating the ideal environment for fish cells to spontaneously assemble into three-dimensional tissue structures with their natural composition of fat, muscle and connective tissue. This method echoed the natural growth process of these tissues in a living fish.

The method bypassed the scaffolding stage and dramatically reduced the dependence on costly growth factors. This made the process highly scalable and raised its commercial viability and price parity with traditionally aqua-farmed eel meat.

Wild eels have experienced severe supply shortages due to overfishing, while aquafarming of eels has remained challenging, and breeding eels in captivity has remained elusive. This shortfall occurred amidst a surge in demand for the Japanese delicacy, not only among the Japanese population but also across Asia, the United States and Europe.

“Forsea’s unique organoid technology has the potential to overcome many of the industry bottlenecks in bringing cultivated meat to the consumer plate,” said Roee Nir, CEO and co-founder of Forsea.

“Since the start of the year, we have significantly improved our cell lines and worked diligently to enhance our recipes. This event was a great opportunity to present our unprecedented achievements to partners and industry stakeholders.”

At the closed dining event, guests enjoyed the first tastings of Forsea’s cultured eel unagi filets.

Celebrated Israeli gourmet chef Yuval Ben Neriah, a specialist in Asian cuisine and owner of the five-elements-inspired restaurant Taizo in Tel Aviv, played a pivotal role in fine-tuning the finished product to capture the authentic flavour and sensory attributes of the Japanese specialty.

“As a chef who spent many years tantalising diners with fine Asian cuisine, this project with Forsea has been particularly exciting as it marks my first venture into future food, the world of cell-cultured seafood, and its resonating sustainability message,” said Ben Neriah, the restaurant’s chef.

“The feedback from the diners was indeed uplifting. Several remarked that they wouldn’t have guessed that the unagi was cell-cultivated had they not been informed.”

Executive chef Katsumi Kusumoto, who started the vegan restaurant SAIDO in Tokyo, also contributed to bringing Forsea’s inaugural unagi product to culinary perfection. Unagi has been Chef Kusumoto’s famous specialty for many years.

Takahashi Seiichiro, Japan’s Deputy Chief of Mission to Israel, congratulated

“While we Japanese have been eating eel for over 5000 years, we understand that cultivating eel is no simple task. Therefore, I believe introducing the first cell-cultured eel results from great comprehensive corporate efforts.”

Aqua Mould Systems (AMS), an aquaculture technology company, has licensed its patented technology to oyster farmers. AMS’ sustainable practices include recycling consumables, setting up farm sites with smaller footprints, and installing hardware that forms an artificial reef. This has benefitted farmers and created a better environment for local fish and other aquatic species, instilling a sense of responsibility and commitment to sustainable practices.

sing our patented technology improves the environmental impact and enhances profitability. The improved prices from the market of differentiated inshell branded shellfish products, produced on our technology, can significantly boost the farmers’ income,” said Shaun Gregory, MD of AMS.

“This potential for increased profitability should make our audience feel optimistic and excited about the business opportunity.”

Gregory created the concept when he realised the potential need to automate the processes in the oyster industry, which was generally a labour-intensive exercise. The lack of automation was due to the inconsistent shapes of shellfish, and it was apparent that the ability to grow a uniformed-shaped oyster would lend itself well to automation.

Due to its uniform shape, the product aligned well with the high-end market. The ability to grow a brand logo into a smooth shell naturally and have an ingrown branded shell gave end consumers excellent flavours, provenance, and a storytelling experience while dining. The uniformity also reduced freight costs and carbon footprint.

“End consumers are becoming more aware of what they consume and have higher expectations. Being flexible in what we produce allows us to create custom oysters and grow further in the high-end seafood market.”

However, Gregory acknowledged that entering foreign markets had been challenging, as there were different legal requirements, tax laws, cultures, etc., and that having a good distributor was an essential step in scaling internationally.

The patented hardware to grow the

shellfish has been produced by tooling, allowing for easy scalability on a global scale. The ability to produce around 50 dozen oysters per lineal metre or 27,000 dozen per 0.5 hectare increased yields in the same water space.

This has also allowed other shellfish companies to easily convert to the AMS regime as the infrastructure to set up the lines is minimal, and extra water space is not necessarily required.

“AMS has a proven growing regime that is mandatory for all licensees to follow; thus, accurate traceability by labelling the actual shellfish ensures quality, safety, and transparency.”

The oyster spat has not been taken from the wild to ensure sustainability. Instead, oysters have been produced in a land-based environment, allowing the selection of family lines more resilient to disease. The taste and nutrient value of oysters depends

on the environment they are grown in and the types of algae and phytoplankton eaten, making each farm unique.

AMS has some innovations developing in the background, including the ability to open an oyster where no skill is required by simply pulling a lever, removing the currently dangerous need to use a knife. Gregory has hoped to implement this in the 2025 season.

The company has also sought investors to assist with developing and growing the business and international licensees to become producers of AMS Qyster, or locally oyster-branded products, serving niches at the top end of the seafood market.

Tora Collective’s Coast to Plate approach has brought the freshest, sustainably caught seafood directly from the pristine waters of New Zealand to the consumer’s table. The organisation has been deeply committed to sustainable fishing practices, ensuring seafood is delicious and ethically sourced.

Catching to order means that Tora Collective only harvests what is required and keeps the time between catch and delivery to the absolute minimum, preserving the quality, freshness and flavour.

“Quality and freshness are at the heart of Tora Collective. Our seafood is caught to order and delivered overnight. It is under the water one day and with our customers the next; this ensures it’s as fresh as possible and removes the need to store fish completely,” said Claire Edwards, co-owner of Tora Collective.

The organisation has also been using eco-friendly packaging as part of its commitment to limiting its impact on Mother Nature, hand-making its homecompostable icepacks using seawater wool to insulate the package and harvest seaweed from the beach cast seaweed to keep the fish cool and cosy in transit sustainably.

“This limits our impact and ensures our catch stays in peak condition and arrives at our customer’s doorstep just as fresh as when it left the coast.”

Sustainability has been the DNA of Tora Collective, from its fishing methods to other practices to protect the marine ecosystem. For example, catching to order ensured minimal impact on the marine ecosystem by harvesting tiny amounts from different locations weekly.

All female crayfish are returned to the water to protect future stocks, and seasonal fishing has been done to protect the breeding cycles. Tora Collective has also increased the minimum size of pāua that it harvests.

“Fishers do not require many practices we have implemented in our business, but we have chosen to implement them to preserve our backyard. We’ve also just

Continued from page 22.

launched a Charitable Trust to preserve the Tora coastline.”

Tora Collective is not just a fishing business or seafood company; it’s a lifestyle and a community. The organisation has engaged with customers through authentic storytelling, sharing its journey and the realities of sustainable fishing.

It has continuously innovated its product offerings, such as the recent addition of a fish market, seaweeds and sea herbs, to meet customer’s needs. Another innovation has been the world’s first home compostable ice pack made with Moana water, which has reflected its commitment to sustainability and reducing waste.

“For our industry, we took a step back in some ways to innovate our business practices by catching to order and going direct from ocean to plate - as the norm for many seafood businesses in Aotearoa relies on land-based holding tanks.”

Edwards added that Tora Collective had closed the loop by being both the fisher and the distributor, living on the coast, and getting seafood from the seafloor to customers’ doors in around 24 hours.

With the seafood industry prices fluctuating all year round, mainly due to the export changes in the export market, Edwards mentioned that the prices were based on the costs and lease price each season. This has ensured a stable price and consistency for customers throughout the year.

Collaborations with New Zealand restaurants, chefs, and festivals, including a partnership with YETI, have also been undertaken to promote seafood and sustainable practices.

While direct collaborations with other fishers and seafood businesses have yet to occur, Tora Collective has been willing to collaborate with those committed to doing the right thing.

Looking ahead, Edwards has been keen to expand the product range into other seafood products, particularly seaweed, and explore new opportunities in eco-food tourism.

“We hope to offer a Tora Collective Experience next summer/autumn, where guests can enjoy the Tora coastline and lifestyle—from adventure to great food.” Continued from page 21.

For our industry, we took a step back in some ways to innovate our business practices by catching to order and going direct from ocean to plate - as the norm for many seafood businesses in Aotearoa relies on land-based holding tanks.

Cell-based seafood maker Wanda Fish, Ltd. has unveiled its first cultivated bluefin tuna toro sashimi. The creation of this prototype addressed the demand for bluefin tuna via a pollution-free, qualityconsistent, and sustainable supply of the highly sought-after fish.

The raw toro specialty has been composed of the fish’s underbelly. It has the highest fat content, with exceptionally high omega-3 levels. This gives it a unique buttery sensation, making it the most tender and desired meat of the fish.

Wanda Fish’s cell-cultivated sashimi has the same sensory features as wild-sourced toro sashimi. The cell-cultivated adaptation of the 3D filet has combined the cellular mass of

muscle and fat created from the Bluefin tuna’s cells, developed with a plant-based matrix. The company also enlisted skilled chefs to bring its sashimi to culinary perfection.

“A key focus in creating our product was achieving the same level of fat marbling as real Bluefin toro sashimi to create the same look and mouthfeel,” said Daphna Heffetz, PhD, co-founder and CEO of Wanda Fish.

“Reaching this milestone demonstrates Wanda Fish’s ability to bring a whole-cut

A key focus in creating our product was achieving the same level of fat marbling as real Bluefin toro sashimi to create the same look and mouthfeel.

DAPHNA HEFFETZ PhD, co-founder and CEO of Wanda Fish.

bluefin tuna toro filet to market without harming the ocean or diminishing the wild fish population. The product is sustainable and free of microplastics, mercury, and other chemical toxins all-too-commonly found in wild catch.”

Malkiel Cohen, VP of R&D for Wanda Fish, said that the prototype was unique in the cultivated food industry, as the product had no cooking or panning.

Cultivated bluefin tuna is one of those rare food products that makes good business sense.

YARON SFADYAH VP of Business Development & Marketing for Wanda Fish.

Continued from page 25.

Bluefin tuna has been considered the pinnacle of tuna species. They are no easy catch, not only because they are one of the ocean’s fastest long-distance swimmers, making them difficult to raise in captivity, but also because they are a prized marine delicacy.

Overfishing and illegal fishing have prompted governments to place caps on fishing activity by implementing strict fishing quotas, contributing to its premium price.

Toro sashimi is a luxury dish served

mostly in high-end restaurants across Japan and in exclusive sushi outlets globally.

A single one-kilo serving can cost USD100 or more.

“Cultivated bluefin tuna is one of those rare food products that makes good business sense,” said Yaron Sfadyah, VP of Business Development & Marketing for Wanda Fish.

“It is in high demand, with limited alternatives that match the taste and texture of the wild fish, and at an ideal

price point and distribution model. Alternative protein companies often contend with high manufacturing costs and the low price of animal-based products. It is a completely different story for cultivated bluefin tuna.”

The start-up will first introduce its tuna in the high-end food service sector, focusing on Japanese cuisine, where sushi and sashimi are traditional features .

Prolific Machines has harnessed light to produce everyday essentials more efficiently, from high-value nutritional proteins and cultivated meat to lifesaving drugs and novel solutions. It has used light as a signal to control cellular behaviour with unprecedented precision and instantly instruct cells on what to do, where to do it, and when to do it.

“Our co-founder and CEO, Deniz Kent, PhD, first had the idea to build and use light for manufacturing while pursuing his PhD in Stem Cell Biology at King’s College,” said Nicki Briggs, spokesperson for Prolific Machines.

“At that time, academics had been using light for research, but he saw an opportunity to use it as a manufacturing tool. Soon after, he brought in the biology and engineering expertise of co-founders Declan Jones and Max Huisman.”

Methods currently used to make bioproducts have been imprecise, inefficient, and expensive to control cells indirectly. Prolific’s first-of-its-kind photomolecular platform has brought together safe and effective tools like light, bioengineering, hardware, and AI to unlock unparalleled control and precision.

The company has also been co-developing the future of biology with innovators across cultivated meat, nutritional and therapeutic

proteins, disease models, tissue engineering, cell and gene therapy, and more.

Its process has been more efficient and offers an alternative to producing natureidentical, functional proteins without reliance on animal systems and commodity agriculture, unlike existing production processes that have relied on inefficient, unscalable systems and tools.

“Thanks to light’s incredible efficiency, we offer a way to create a healthier, more sustainable tomorrow.”

Some examples include nutritional proteins used in supplements and infant formula, antibodies to treat diseases, whole cuts of cultured meat, higher fidelity disease models, and other innovations never before possible.

Using non-ionizing light at relatively low intensities in its process, there is insufficient energy to harm living cells, making it safe to produce food and non-food products.

These products are structured or marbled, like steaks, using light. It has also made it possible to create all cuts of meat that would

have been impossible to make in a scalable manner with existing cultivated production methods.

“Our process is a boon for the cultivated meat industry, which can achieve massive cost, scale, and sterility benefits without recombinant proteins or growth factors.”

The platform has helped elevate its partners’ existing cell lines and product approaches, providing a critical infrastructure layer for biology.

“Think of us as the NVIDIA for biology. We are already co-developing the future of biology with several partners and welcome anyone interested in leveraging our technology to contact our team.”

Prolific Machines has been currently speaking with diverse partners to commercialise its technology. This round of funding will accelerate its platform commercialisation via partnerships, which will be announced in the months ahead.

Global Strength. Local Action.

Put to work our technical ingenuity and industryleading portfolio to create future-forward nutrition solutions with flavours, colours, fibres, plantbased proteins, specialty ingredients and more. We bring more than a century of global expertise to Australia & New Zealand. Your Edge. Our Expertise.

Concept Solutions offers a comprehensive range of flat belt and plastic modular belt conveyors and equipment. These can be specified to suit virtually any configuration, environment or conveyed product.

• Versatile, reliable and economic conveying solutions

• 3D design for realistic product visualisation

• Hygienic design for ease of sanitation

• Plant layout and flow optimisation

• Safety standard compliant design

• Food grade plastic machining and supply

Vacpack is a leading provider of innovative machinery and cardboard base food packaging products to New Zealand, Australia and the Pacific.

Are you looking for eco-friendly packaging that improves the shelf life of your fresh and frozen items? Then, Vacpack’s market leading cardboard base technology is the solution for

you. The systems help reduce plastic by up to 80%, is 100% biodegradable or recyclable and creates an appealing and safe end-product. Call us now to find out more.

or

www.conceptsolutions.co.nz

At DTS, we specialise in stainless steel engineering solutions for the food, beverage and pharmaceutical industries. Our tank design philosophy is to minimise waste and maximise profit, not only during tank fabrication, but also throughout the tank’s operational life and production. • Food & beverage tanks

• Insulated hazardous pressure vessels

• Hot water recovery / 2205 duplex

• Laser-welded dimple pads / thermal control

• Clean in place and agitation

• Walkways, ladders and handrails

In the food industry, temperature measurements are part of the daily routine. The quality of food products can only be tested and guaranteed by precise measurements. The Testo range of measuring instruments, available from NZ authorized distributor Eurotec Ltd, a member of Carel Group, can carry out spot-check measurements in seconds.

Whether in the transport and storage of foods, in restaurants or in large kitchens, wherever temperature needs to be recorded, Testo measures up and helps you keep compliant. Testo enables you to guarantee optimal performance in key areas of your business.

Food industry instrumentation for incoming goods: Every item that enters your premises should undergo rigorous checks in order to ensure its quality and safety. Whether that be your weekly delivery of fresh fish, or the daily top up of your fruit and vegetable stocks, food can spend a long time in transit from the wholesaler before it arrives at your door. The testo 831 infrared thermometer is perfect for

dealing with incoming goods, as it allows you to carry out quick and precise temperature measurements of whole pallets of food and smaller individual products from a distance.

Monitor the cold chain and ensure food safety Perishable foods are sensitive to changes in temperature. While fruit and vegetables ripen quickly and barely make it to the supermarket if they are stored and transported in conditions that are too warm, bacteria can multiply in meat and dairy products when heated. These, in turn, can cause serious illnesses. Therefore there must never be any gaps in the cold chain, but this can only be ensured through continuous monitoring. The testo 184 series

of Cool Chain Temperature Loggers can measure the temperature and humidity of your goods while in transit. With up to 150 days of battery life, you’ll be able to keep track of goods over long stretches, measure and analyse temperature and humidity data - arming you with information to implement changes when needed backed by data.

info@easirecycling.co.nz www.easirecycling.co.nz

Freephone: 0800 342 3177

Protect your brand solutions that enhance food safety and weight compliance for processing lines.

LEARN MORE ABOUT OUR EQUIPMENT ONLINE

EXBERRY® Colours are the ideal and future-proof solution for food and drink applications matching the recent plant-based, vegan and vegetarian trends.

HRS Heat Exchangers operates at the forefront of

Pasteurisation

Sterilisation

Aseptic Filling

Direct Steam Injection

Evaporation

CIP Kitchens

Process Skids

Juice Crushing and Remelting

NZMS Scientific offers specialised solutions to help ensure your products meet the standards you and your customers expect.

Give us a call today to talk about:

• Pathogen testing

• Allergen testing

• Hygiene testing

• Sterility testing

SCANZ is a multi-discipline supply company and manufacturers agent, specialising in technology and equipment for the food industry. It’s primary focus is within three market segments, namely fish (including aquaculture), meat and the dairy industry. High Pressure Processing takes Scanz into other areas, as does a recent involvement in industrial waste water treatment.

SCANZ

a Custom Blends

a Flavours: Sweet, Savoury, Smoke

a Caramel Colours

a Yeast Extracts

a Proteins: Plant & Animal

a Starches: Native & Modified

a Minerals

a Dehydrated Vegetables

a Carrageenan & Gums

a Preservatives

a Clean Label Ingredients

For 125 years we’ve been a trusted ingredient partner for iconic vanilla. With a range of bulk and customised solutions for industrial, along with deep manufacturing experience, we can help you find your next flavour solution. Our food industry passion, dedicated technical team and global commitments to sustainable and ethical sourcing can help you achieve your business goals.

BULK FORMATS & CUSTOMISED SOLUTIONS:

Extracts

Pastes

Dried vanilla derivatives

CUSTOMISABLE CLAIMS:

Certified organic

Certified vanilla provenance

Urgent Couriers are specialists in temperature -controlled deliveries of chilled small goods.

Fast, reliable, guaranteed sameday services live tracked from despatch all the way to your customer’s door. We provide techforward and innovative solutions to make your life easier.

With over 40 years operating experience in New Zealand, TC Transcontinental Packaging New Zealand (TC NZ) is a leading manufacturer of flexible packaging to the FMCG, horticulture, retail and manufacturing markets

TC NZ is both a reputable manufacturer and trader, supplying all forms of flexible packaging made from traditional plastic films recycled blended films, laminated barrier substrates. TC NZ employs over 90 people in New Zealand with centres in Auckland and Christchurch, home to an ultra-modern food grade packaging manufacturing plant, and supported by our global TC Transcontinental research and technology platform from North America.

TC Transcontinental Packaging brings a distinctive blend of science, technology, and art together to create flexible packaging that preserves our customers’ products and accentuates their brands on the store shelf. Our expertise, resources and conversion technology helps us create packaging that gives our customers a competitive advantage. We utilise a widevariety of printing techniques, laminations and converting styles including pouches that help enhance your brand.

We invest in state of the art technology to offer and invest in a sustainable future and are delighted to be recognised for our high quality packaging that we supply to our customers. Globally TC Transcontinental Packaging is committed to a circular approach to plastic. As global signatories to the Ellen MacArthur Foundation, we are working towards our 2025 goal where 100% of our plastic packaging will be reusable, recyclable or compostable, and 10% of our plastic output to be made from recycled plastic waste.

At the 2022 Pride in Print Awards, TC NZ were awarded Gold Sustainability Award in the Flexible Packaging Category for our significant volumes used into industrial, refuse and hygiene packaging. TC NZ are meeting customer requirements by extruding and converting recycled resins of in-house, postindustrial waste, and post-consumer recycled content , Green PE (PE derived from renewable resources such as waste sugar cane), and has the ability to manufacture flexible packaging with other