Bearhug Pallet

Wraps Pg 8

Effective Cleaning - in - Place (CIP) kitchens Pg 20

Finland Grocery

Chain Opens

MFC Pg 34

Bearhug Pallet

Wraps Pg 8

Effective Cleaning - in - Place (CIP) kitchens Pg 20

Finland Grocery

Chain Opens

MFC Pg 34

Tania Walters Publisher tania@reviewmags.com

In this issue of F+B Tech, we examine the role of automation in the cold storage and food logistics industry.

e-commerce, has brought about new distribution challenges. Globally, energy concerns continue to rise, and along with labour shortages, the challenges to operational efficiency are increasing. The industry is increasingly looking toward innovative automated solutions to overcome these hurdles. These technologies are not just about cutting costs; they’re about creating smarter,

safer, and more sustainable environments for the storage and movement of food products.

Automation is revolutionising the industry by minimising energy consumption, enhancing operational efficiency, and ensuring the safety of workers. From automated guided vehicles and automated storage/retrieval systems to advanced smart controls and safety systems, these innovations are setting new standards in the industry.

Technology is paving the way for a more resilient, competitive, and sustainable future in the frozen and chilled food sector, setting the stage for a new era in food logistics.

With consumer preferences for fresh and frozen products on the rise, demand for cold storage warehousing is an essential part of . This increased consumer demand, combined with the expansion of global supply chains, and the surge in 18 10 24 30

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES info@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC DESIGNER Raymund Santos

Retail 6, Heards Bldg, 2 Ruskin St, Parnell, Auckland. PO Box 37140 Parnell, Auckland Tel (09) 3040142 Email: edit@reviewmags.com

USA | Berry Global Group, Inc., a global leader in sustainable packaging, partnered with Abel & Cole, a pioneer in sustainable food delivery, to supply bottles for its Club Zero Refillable Milk delivery service.

Made with widely recyclable PP, the new bottles produce fewer greenhouse gas emissions than heavier glass bottles, challenging the conventional use of glass bottles for home milk delivery. Research conducted by Abel & Cole suggested that reusing the Club Zero Refillable Milk bottles just four times reduced the carbon footprint of their single-use milk bottles by half compared to heavier glass bottles, which would take over 15 returns to reach similar emissions savings.

At the same time, the concept saved 450,000 single-use plastic milk bottles from landfills or incineration per year, equivalent to 23 tonnes of plastic.

“When it comes to packaging materials, plastic is often seen as the enemy,” said Hugo Lynch, Sustainability Lead at Abel & Cole.

“But we challenged ourselves to ask if it was better to use glass, heavier and more energyintensive to make, or to go against the grain.”

The bottle design was optimised to support Abel & Cole’s eight-stage cleaning process, eliminating the drying stage and reducing the risk of bacterial contamination. When returned, bottles underwent an eight-stage washing process, ensuring thorough cleaning before being conveyed to the cleanroom for refilling.

To facilitate superior cleaning with minimal risk, the new bottles were designed without a handle, reducing ‘trap points’ where bacteria might gather and allowing for easy drainage.

Read more here

electricity together.

Pet

CINCINNATI | ProAmpac, a leader in flexible packaging and material science, announced the launch of its innovative ProActive Recyclable Fresh Tray FT-1000.

This patent-pending polypropylene-based tray has been classified as plastic #5 and approved for curbside recycling. It has introduced the food service and grocery markets to an easily recyclable lightweight foam tray.

"ProActive Recyclable Fresh Tray FT-1000 offers grocery and food retail markets a robust, sustainable packaging solution that aligns seamlessly with their operational needs," said Pascal Labrie, vice president and general manager for ProAmpac’s tray business.

"By adopting the FT-1000, these sectors can meet their sustainability goals without compromising performance or customer satisfaction. This tray is a significant step forward in our commitment to supporting the food industry's environmental initiatives and advancing recyclable packaging choices."

Read more here

Pavegen. The company has developed innovative flooring technology to harness pets' natural energy and raise awareness about the power of renewable electricity.

Each step taken by pets and their owners will produce about three joules of electricity.

"At Purina, we've always looked to pets for inspiration to drive our actions, and now, inspired by their boundless energy, they're helping us demonstrate the power of renewable electricity," said Tiffany Gildehaus, senior manager of environmental sustainability at Purina.

"The Pet Power activation is a small symbol of the importance

of renewable electricity to Purina's sustainability strategy."

Turning the movement of people and their pets into renewable electricity is a firstof-its-kind use of the Pavegen technology, aligning with Purina's ongoing efforts and commitment to creating a more sustainable planet for pets and the people who love them.

Ninety-five percent of Purina's electricity comes from solar and wind power investments to help make the food that powers pets. Purina will achieve 100 percent renewable electricity by 2025 across its factory network and corporate offices.

Read more here

UK | Sainsbury’s has become the first retailer in the world to invest in new AI veterinary technology to measure and enhance positive animal welfare on dairy farms, revolutionising the approach to cattle care.

In partnership with Vet Vision AI, a new spinout company from the University of Nottingham, Sainsbury’s has been trialling new technology designed to spot when cows are happy and healthy and why. The cows are monitored through low-cost, portable cameras that vets can use on multiple farms.

The AI works by recognising patterns in behaviour, analysing video footage, and turning it into real-time, accurate data. In addition to monitoring

behaviour, the AI offers farmers suggestions on further improving the animals’ lifestyles.

Examples include housing improvements for better comfort and animal engagement and providing enrichment such as cow brushes, similar to a back scratcher, to reduce stress.

The ability to monitor cows around the clock has enabled more informed decisionmaking. Farmers will have unique insights into cow welfare that they may not have been able to identify with standard vet visits.

Continuous behaviour analysis also allowed for a ‘test and learn’ approach to the suggested welfare tactics. Constant monitoring can also identify diseases early, preventing vets from having to treat them later.

Beyond the benefits for the animal, the tech has promoted a step forward in farming

Maintaining food safety and quality is crucial in today's interconnected world. With global supply chains becoming increasingly complex, the food and beverage industry is turning to innovative technologies to enhance food safety and compliance. Food safety is vital due to the severe health risks of contaminated food. The World Health Organisation estimates that nearly 600 million people fall ill each year from foodborne illnesses, leading to 420,000 deaths. This highlights the urgent

efficiency, as a healthy cow means a more productive cow.

Thirty of Sainsbury’s Dairy Development Group farms have aimed to roll out the technology next year. The SDDG was founded in 2007 to provide more support to farmers.

“Investing in British farming and continuously improving animal health and welfare are key priorities for us, and this

innovative new technology will mean we can help both farmer and animal,” said Dr Matt Turner, Vet and Agriculture Manager at Sainsbury’s.

“Our dairy farmers who are using the technology are already seeing real benefits, and we look forward to expanding it to our wider network of dairy development group farms soon.”

Read more here

Verdant Bloom Ltd (parent company of Urchinomics Group) and NYK signed a share purchase agreement, marking the beginning of an exciting new partnership aimed at environmental restoration and sustainability.

Kelp forests, essential for marine biodiversity and carbon sequestration, are under threat due to an explosion in Sea Urchin populations. Urchinomics is addressing this by transforming barren urchin populations into a sustainable delicacy, while simultaneously restoring vital kelp beds.

Urchinomics’ Innovative Solution

need for robust safety measures throughout the supply chain.

Blockchain technology is revolutionising food traceability by providing an immutable ledger of transactions. This ensures every step in the food supply chain is recorded and verifiable, allowing for rapid identification and isolation of contamination sources. Walmart, for example, has reduced the time needed to trace leafy greens from seven days to just 2.2 seconds using blockchain. Read more here

Urchinomics collects and feeds sea urchins from affected areas, turning them into high-quality products. Profits are reinvested into further restoration projects, creating a sustainable cycle that benefits the environment and local economies. This approach has earned global recognition, including endorsement by the United Nations Ocean Decade for Sustainable Development. Read more here

| Authentic plant-based alternatives with reduced fat content. Wheat-based solutions for fat replication offer processing and nutritional benefits.

In the food industry, there are many reasons to replace animal fats with plant-based alternatives, be it to replicate meat products or provide hybrid offerings with an optimised label. Ingredients specialist Loryma supports manufacturers with wheatbased solutions that promise top-quality characteristics. They imitate animal fats that perfectly replicate the originals in terms of texture and processing properties. Wheat-based stabilisers, starches and clean label compounds, meanwhile, enable manufacturers to create melt-in-the-mouth

or stable, sliceable textures. They also improve the appearance and sensory properties of products such as juicy poultry sausage, mouthwatering vegan salami pizza or crispy plantbased chorizo.

Consumer demand for plant-based, healthconscious yet tasty convenience products continues unabated. However, plant-based fats do not always behave like their animal-based counterparts when it comes to production and preparation. Here, manufacturers face several challenges: Meat analogs, meat products or hybrids should have an authentic texture and sensory appeal, and convince with a low fat content and short, natural ingredient list.

Read more here

USA | Northwell Health, New York’s most extensive health system, and Instacart, North America's leading grocery technology company, announced a partnership through the Instacart Health initiative.

The partnership has leveraged Instacart’s platform and products to expand access to nutritious food, inspire sustainable healthy choices, and scale food as health programs to reach diverse Northwell communities.

“Raising health is more than Northwell's care in our hospitals and doctors’ offices. It’s also about how we raise the people in our communities and how we raise our expectations of what health can be, which is why Northwell contributes more than $2 billion in community benefit annually,” said Debbie Salas-Lopez, MD, MPH senior vice president

of Northwell’s Office of Community Wellness and Population Health.

“The collaboration with Instacart is part of our comprehensive community health effort and will provide tools and resources to access nutritious foods for our staff, patients and communities.”

Through the partnership, Northwell will use Instacart Health tools to support unique programs that address social determinants of health, including access to healthy food and transportation.

“We believe that Food is Health. And it’s important to us to meet the needs of our communities, which is why we pursued an Instacart partnership,” said Michael Dowling, CEO of Northwell.

The first program to launch has integrated Instacart Health tools into Northwell’s Center for Maternal Health Maternal Outcomes and Morbidity Collaborative (MOMS) so that moms-to-be who are food insecure have improved access to fresh and nutritious food.

Read more here

SOUTH ASIA | Unilever has agreed to sell its water purification business, Pureit, to A. O. Smith, a leading global water technology company.

Pureit offered various water purification solutions in India, Bangladesh, Sri Lanka, Vietnam, and Mexico, among other countries.

“The sale of Pureit marks another milestone on our journey to evolve our portfolio towards higher-growth spaces,

in line with our Growth Action Plan,” said Eduardo Campanella, President of Unilever Home Care.

“Pureit provides essential water purification solutions to millions of loyal consumers, and I am confident the brand will thrive further under the ownership of A. O. Smith.”

Kevin J. Wheeler, A. O. Smith’s chairman and chief executive officer, believed that adding Pureit would strengthen

the company's leadership position as a global supplier of premium water treatment products and double its market penetration in South Asia.

“The acquisition will also support our corporate strategy by enhancing our premium product portfolio and distribution capabilities,” said Wheeler.

Pureit’s culture of innovation, strong brand recognition and dedication to customer service will be an excellent addition to

the region's premium brand positioning and broad product portfolio.

The transaction is subject to customary closing conditions, and Unilever will continue to manage the business until the transaction is completed.

BRUSSELS, OSLO | PepsiCo Europe and Yara announced a long-term European partnership to provide farmers with crop nutrition programs to help decarbonise the food value chain.

As part of the partnership, which spans multiple countries, participating PepsiCo Europe farmers will be equipped with best-in-class crop nutrition product advice and precision farming digital tools. This will allow them to

increase nutrient use efficiency (NUE), boost yields, and reduce their crops' carbon footprint. Yara, Europe's leading crop nutrition company, will supply PepsiCo with the products and services.

Yara will deliver up to 165,000 tons of fertiliser annually to PepsiCo, covering around 25 percent of their crop fertiliser needs in Europe by 2030. These fertilisers will be mostly Yara Climate Choice fertilisers, which include low-

NEW YORK | Upshop and Invafresh have announced their merger, marking a significant milestone in the food retail industry. Together, they aim to address significant food sector challenges: availability, affordability, and waste.

The merger of Upshop and Invafresh is set to transform the landscape of food retail technology. The combined Upshop organisation has offered the first global retail enterprise operating platform built for the complexities of food.

The platform will be used by over 400 retailers in 35 countries, operating in over 50,000 stores and affecting millions of associates and shoppers daily.

Retailers have been facing increasing pressure to meet heightened operational and service expectations from suppliers, associates, and shoppers alike. The challenge of introducing more affordable, healthy options into stores has been compounded by issues with technology that associates have struggled to adopt.

A unified Upshop platform addresses these challenges with a

The partnership has aimed to upgrade to Yara Climate Choice fertilisers over time as production scales up and technologies mature so that all 165,000 p.a. tons are Yara Climate Choice fertilisers by 2030.

The collaboration underlines the companies’ commitment to building a more sustainable food system aligned with the European Union’s climate targets. At the same time, it will support farmers through transition costs to ensure their livelihoods are not adversely impacted.

carbon footprint fertilisers produced from either renewable ammonia (Herøya, Norway) or low-carbon ammonia via carbon capture and storage (CCS), currently under construction in Yara Sluiskil.

The mix will also include Yara’s standard premium nitrate-based mineral fertilisers produced using natural gas. Thanks to catalyst technology, these fertilisers have a carbon footprint of around 50 percent lower than most non-EU fertilisers.

“This partnership with Yara aligns with our end-to-end transformation known as PepsiCo Positive (pep+) and will be critical as we transition towards the net-zero food system of the future. Targeting Scope 3 emissions is central to our pep+ agenda, but it can be one of the most challenging areas to influence directly,” said Archana Jagannathan, Chief Sustainability Officer at PepsiCo Europe.

“Providing our farmers with fertilisers with a lower carbon footprint and supporting them to improve crop nutrition end-to-end will allow us to make a significant step towards achieving net zero by 2040.”

Read more here

single app, empowering associates to efficiently “win their day” and deliver the best experience for shoppers.

“We do not settle for better; we strive for the best from our platform, our people, and our partnerships with food retailers,” said Shamus Hines, the CEO.

“Our technology's impact on retailers’ supply chains means millions of families will have access to the freshest and healthiest food daily.”

Read more here

Bearhug was launched in January 2023 to transport goods anywhere in a supply chain using reusable pallet wraps, typically used only internally.

Since then, the company has established the world’s first pooling model for reusable pallet wraps.

“After working as a truck driver for five years, I witnessed significant amounts of plastic waste at my workplace and warehouses across New South Wales. The standard practice of using 40m of plastic every time a pallet is moved globally prompted me to launch Bearhug,” said Tom Field, founder of Bearhug Pallet Wraps.

“We offer reusable pallet wraps, keg wraps, and pallet bands. Our system requires companies that receive pallets to accept their suppliers using reusable wraps on their deliveries, before we collect them and arrange return. They’re also suitable for internal use when purchased outright.”

The wraps are affordable, tested to be more secure than plastic, quicker to apply, and far more sustainable when used effectively.

However, Field has observed a general lack of motivation amongst wholesalers and distribution centres to accept their suppliers’ use of reusable-wrapped pallets

on deliveries into their warehouses, even though it would reduce their waste and incur no cost. This has been mainly because these companies do not purchase plastic and, therefore, do not feel responsible.

“By accepting inbound reusable-wrapped pallets, they would assist all their suppliers in eliminating waste.”

Slowly but surely, companies have begun to consider not only their emissions but also those of their suppliers and distributors, as scope three emissions reporting has now been mandated.

Companies have also shown more concern for their waste materials and recognised their inherent value, as evidenced by initiatives such as APCO.

“We hope these two trends will converge, increasing collaboration across the value chain to reduce waste.”

For example, Field would like to see more companies that send plastic-wrapped pallets to a single distributor to establish

a return system for reusable pallet wraps between the two parties.

Recently, Bearhug joined the ANZPAC plastics pact, which has helped expand its reach to New Zealand and Pacific Islands businesses seeking to reduce their pallet wrap waste.

Field added that Bearhug can have the most significant impact by having a niche focus and educating its customers about the advantages of its solution relative to others to promote sustainability effectively.

“We use only what is necessary and nothing more. For most of our deliveries, we roll wraps within other wraps, and the only packaging used is a small amount of tape to secure the labels and string to tighten the outermost wrap around the others.”

With its products being suitable for almost every type of load for the millions of pallets shipped daily, Field’s overall goal is to increase the number of businesses willing to receive reusable-wrapped pallets from their suppliers.

We offer reusable pallet wraps, keg wraps, and pallet bands. Our system requires companies that receive pallets to accept their suppliers using reusable wraps on their deliveries, before we collect them and arrange return. They’re also suitable for internal use when purchased outright.

Auckland-based Opo Bio has aspired to emerge as the foremost provider of ingredients for the growing biomanufacturing sector. The technology originated within an academic setting, with the primary objective of extending the global reach of the research and addressing the challenges inherent in the emerging biomanufacturing field.

We have achieved significant technical milestones in establishing scalable livestock cell lines, a testament to our commitment and progress in the biomanufacturing sector.

Opo Bio supplies cells to the cultivated meat industry for a large-scale cell culture. The mission has been to enable cultivated meat producers to create affordable products. These research products will increase global scientific knowledge and standardisation across the field.

The starting cells affect the entire cultivation process, so Opo Bio has focused on cell line development and building a supply chain for the cultivated meat industry.

With a surge in product launches and regulatory approvals anticipated over the next five years, Opo Bio has geared up for an exciting phase of growth and development, fostering a climate conducive to consumer feedback.

“We have achieved significant technical milestones in establishing scalable livestock cell lines, a testament to our commitment and progress in the biomanufacturing sector,” said Olivia Ogilvie, CEO of Opo Bio.

“Our laboratory strives to minimise waste by adopting bulk procurement and integrating reusable consumables. We acknowledge the inherent waste reduction challenges in a tissue culture lab.”

Ogilvie added that the company has actively sought collaborations with specialists across various technical domains, including media manufacturing, growth factors, and foundational research. It has also extended its support to academic research initiatives that address fundamental inquiries within biomanufacturing.

“We encourage individuals to identify their focus areas and technical specialisation, paving the way towards becoming leaders in their chosen markets.”

The potential for optimising cell lines to enhance efficiency spans numerous domains. Ogilvie said that Opo Bio was in the nascent stages of developing cell lines as an industry, with much ground yet to cover in the next ten years.

Lotus Foods partners with small family farmers to preserve local biodiversity and grow rice more sustainably. These farmers use climate-friendly and womenfriendly cultivation methods to promote organic and regenerative Systems of Rice Intensification (SRI) rice cultivation practices, also called “More Crop Per Drop.”

These practices not only help restore natural resources but also significantly slow climate change, inspiring hope for a healthier planet.

The company has supported various initiatives in the communities where its rice is grown by improving incomes and the resilience of rural communities through Fair Trade premiums. They aim to make healthy rice-based products accessible and advocate for a more equitable food system.

Another aim has been to transition two product lines to recyclable, post-consumer recycled, or biodegradable materials by 2025.

“Regarding packaging sustainability, while our packaging is currently not recyclable, we are working towards making it either compostable or recyclable,” said co-founders Ken Lee and Caryl Levine.

“At the same time, we have made efforts to reduce the thickness of our rice and ramen bags, such as reducing the packaging for ramen singles by 25 percent and rice retail bags by 18 percent. We also sell our branded rice in bulk to retailers with bulk sections to minimise packaging.”

The co-founders added that their farming partners used regenerative farming methods. One of its partners, PraTithi Organic Foods in India, has been a leading champion of organic farming.

“Farmers producing heirloom Basmati rice for Lotus Foods qualified for Regenerative Organic Certified Gold. These farmers also supply our White Quick Cook Rice, another prized heirloom rice called Kalijira.”

Another partner, Bloom Agro in Central Java, supplied traditional Indonesian whole-grain red and brown rice by

working with young entrepreneurial farmers called Wono Agung.

This certified organic rice was the first to qualify for Fair for Life, the most demanding Fair Trade certification. In addition to fair pricing, it encompassed many other social and environmental concerns, including water use and gender equity.

Cambodian Organic Farm Enterprise (COFE) grew from pioneering work by the Cambodian NGO CEDAC to improve farmers’ food security and health by showing farmers how to grow more rice without toxic agrochemicals using SRI.

When formerly food-deficit farmers began producing surplus rice, CEDAC organised them into organic cooperatives to sell their traditional jasmine. Lotus Foods was COFE’s first international buyer and has continued to source organic and Fair-Trade jasmine rice from them.

Over the last two years, Lotus Foods has laid the groundwork for a robust innovation pipeline by capturing and leveraging consumer and market insights and expanding its supplier network to bring new items to consumers’ kitchens in 2025.

“While we’ve accomplished a lot, we’re committed to an even more significant impact in the future. We will continue to advocate for regenerative agriculture and climate causes.”

In terms of future innovation and expansion, Lotus Foods aims to double the amount of rice it buys from farmers using regenerative/SRI methods by 2025 and expand its rice noodle supply chain across Asia by refining sourcing standards to better account for local growing conditions and practices.

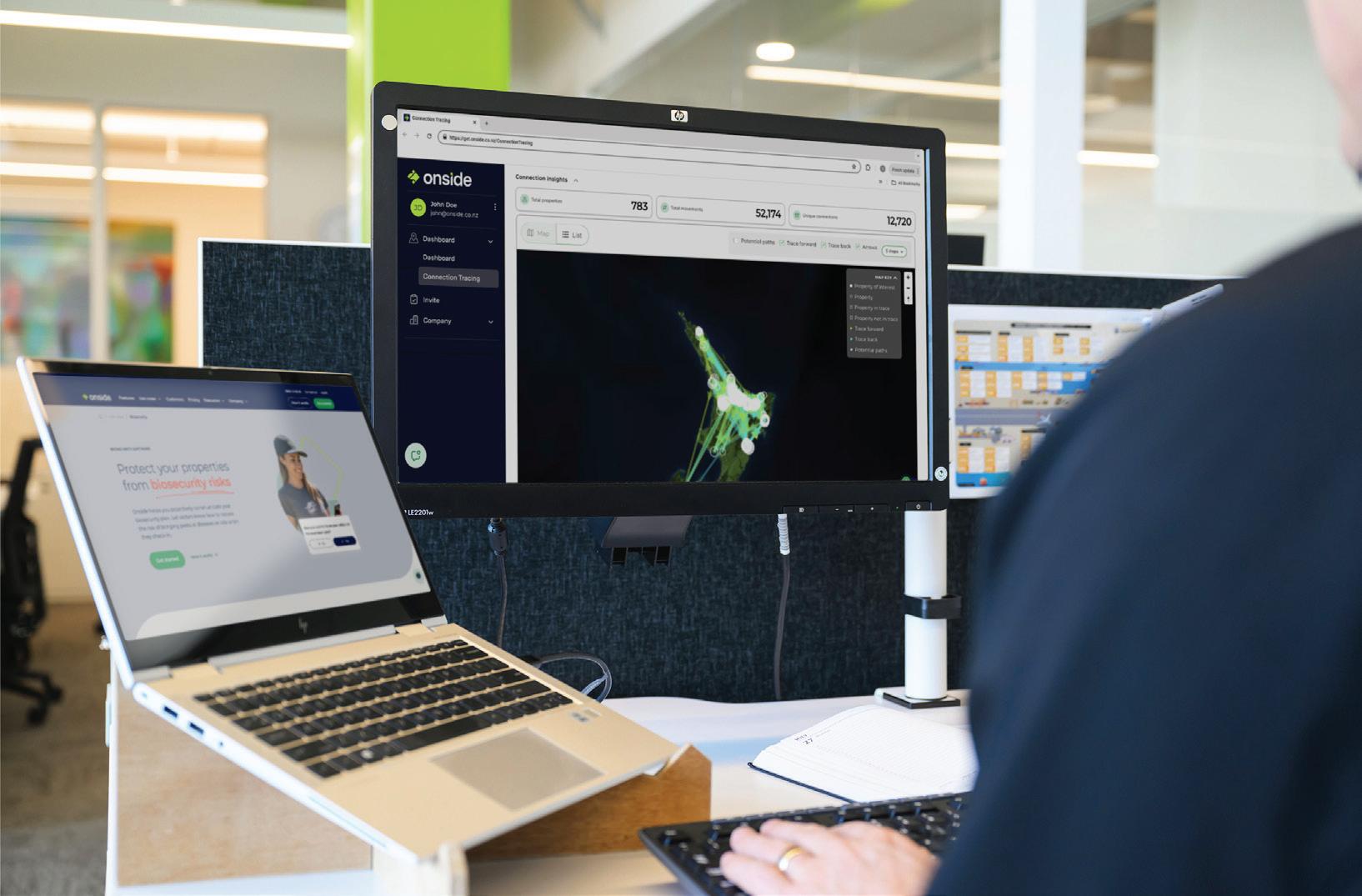

This new technology is intended to transform security practices and help the primary industries better prepare for and prevent biosecurity incursions.

Onside’s mobile app for rural risk management has mapped more than 16,000 rural properties and logged over 2.6 million movements across New Zealand and Australia.

When contractors and visitors check in to rural properties, movement data, including plant material, people, machinery, and equipment, is collected to facilitate the management of health, safety, and biosecurity risks, helping farmers and growers stay compliant.

In the last six months, Onside’s new biosecurity tracing software, Onside Intelligence, has identified at least 1,000 check-in movements that presented a heightened risk of spreading a biosecurity threat.

Onside’s technology has used data from various sources to create an intricate

map of rural interactions and potential disease pathways to support biosecurity management activity. This has made it easier and faster to detect and respond to outbreaks of pests and diseases.

“As a country, we face the growing risk that an increasingly diverse set of pests and diseases will cross our borders and impact our all-important primary sector. Time matters in a biosecurity response, and fast access to accurate traceability data is critical for preparing and responding efficiently to a biosecurity incursion,” said Ryan Higgs, CEO of Onside.

MPI’s investment in Onside technology has been instrumental in getting it into the hands of industry partners working hard to protect farmers and growers.

With additional support from MPI, they have set up a dedicated science group comprising some of the top minds in

biosecurity to tackle the ever-evolving challenges presented by global biosecurity risks.

“Biosecurity is crucial for safeguarding our primary sector and economic security. It’s great to see the development of this tool and industry uptake growing for Onside,” said Biosecurity New Zealand deputy directorgeneral Stuart Anderson, MPI.

The Onside and MPI partnership was established in 2022 to fast-track the development and adoption of Onside’s biosecurity app through a $9m multi-year project co-invested in by the Ministry for Primary Industries Sustainable Food and Fibre Futures fund (SFF Futures).

Biosecurity New Zealand, Kiwifruit Vine Health, New Zealand Winegrowers, NZ Pork, Aquaculture New Zealand, and New Zealand Avocado have become the first industry partners to utilise the technology

to enhance their biosecurity readiness and response and quickly carry out traceability exercises.

Adoption rates of Onside Intelligence in the kiwifruit and viticulture industry have grown beyond 30 percent as growers continue to understand the benefits of digital traceability to protect their industry and livelihoods. Adoption has increased to over 80 percent in some industries, like salmon.

One of the first industries to deploy Onside Intelligence was New Zealand Winegrowers, the country’s grape and wine sector organisation, which sought to test the system to improve traceability in the $2.3bn viticulture sector.

“From a production perspective, many grapes must be of the right quality for exportquality wine. An incursion of a new pest or

Continued on page 16.

Continued from page 15.

disease, like BMSB or Pierce’s disease, could affect grape quality and quantity, posing a significant challenge for our growers,” said Sophie Badland, Biosecurity Manager, New Zealand Winegrowers.

“Having a traceability system like Onside Intelligence potentially saves primary industries and the government a lot of time and money in the event of a response. By having movement data readily accessible, we can get ahead of any new damaging pests and diseases, which gives us the best chance of eradication.”

Kiwifruit Vine Health (KVH), a biosecurity organisation dedicated to protecting New Zealand kiwifruit growers from pest and disease threats, was also one of

the first to implement Onside’s technology to help protect the $4 billion kiwifruit sector from future incursions.

The kiwifruit industry faced its first big biosecurity challenge just over a decade ago when the bacterial canker Psa spread across orchards and growing regions in the North Island. The Psa response cost the industry an estimated $1 billion in production and profitability, with added social and psychological stresses.

“This is an important project for KVH as we help ensure industry preparedness for biosecurity to protect orchards, businesses, and livelihoods. Onside is adding great value to growers by improving day-to-day best biosecurity practices in a simple, innovative

way,” said Leanne Stewart, CEO of Kiwifruit Vine Health.

The industry partners already deployed Onside’s technology as part of the Government Industry Agreement for Biosecurity Readiness and Response (GIA), a formal partnership between the Ministry for Primary Industries (MPI) and 23 industry organisations.

The SFF Futures partnership has also invested $100,000 in a dedicated science program to ensure Onside’s traceability platform remains world-class and meets the ever-evolving challenges presented by global biosecurity risks.

This includes the development of specialised network algorithms that provide

Having a traceability system like Onside Intelligence potentially saves primary industries and the government a lot of time and money in the event of a response. By having movement data readily accessible, we can get ahead of any new damaging pests and diseases, which gives us the best chance of eradication.

insights into where incursions might show up and how to respond most impactfully.

Higgs also mentioned that Onside has leveraged some of the world’s leading scientists to support technology development that provides insights to improve the efficiency of readiness and response.

Dairy products display a wide range of physical and quality characteristics, from simple fluid milk through to creams and yoghurt, to more solid products such as curds, ice cream, cheese, and milk powder.

MATT HALE

Dairy processing also presents a range of heat transfer challenges, including heating, cooling, pasteurisation, and ultra-heat treatment (UHT).

The two most important considerations when choosing a heat exchanger are the nature of the product and how you want to process it. For example, pasteurising homogenised liquid milk is much simpler than cooling a viscous product like yoghurt or curds.

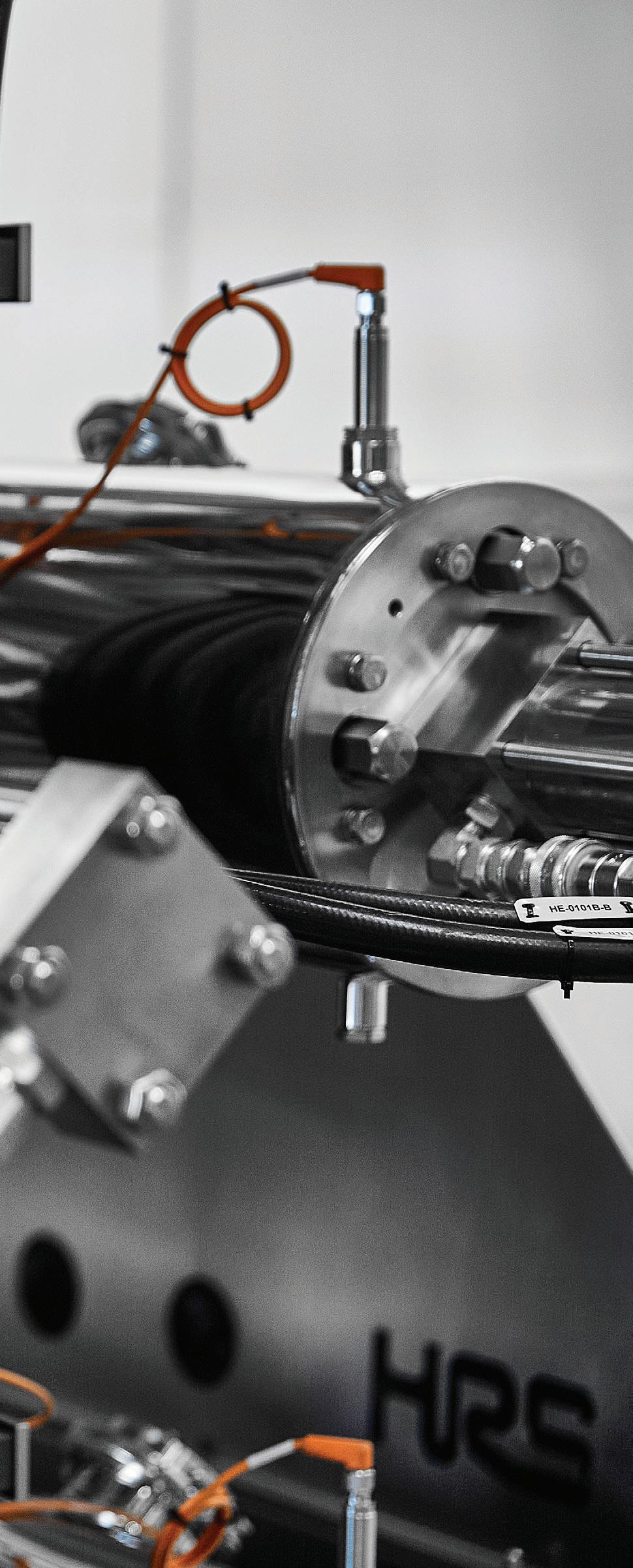

If you over-work cream you end up with butter, which is why a number of dairy producers have chosen HRS tubular heat exchangers. These increase heat transfer, meaning less area is required, resulting in a shorter, more compact design and associated cost savings. Corrugated tube heat exchangers also have lower pumping requirements than other tube-type heat exchangers, contributing to a long operational life and reduced maintenance. Different dairy products have different

requirements. One challenge is handling product gently while ensuring adequate levels of heat transfer. Product viscosity is another, as highly viscous (thick) products can lead to fouling of the heat exchanger surface, which reduces operational efficiency.

Using tubular heat exchangers can provide numerous benefits for viscous dairy products. The main advantage is the gentle handling which maintains the key viscosity characteristics of the product, such as texture and mouthfeel.

Even tubular heat exchangers may be unsuitable for some applications. For example, the patented HRS Unicus Series reciprocating scraped surface heat exchanger can reduce pressure, preventing product shearing, while the oscillating cleaning system is much gentler than a rotary scraped surface heat exchanger.

Located in Melbourne, HRS Heat Exchangers is part of the EIL Group (Exchanger Industries Limited) which operates at the forefront of thermal technology. HRS offers innovative heat transfer solutions worldwide across a diverse range of industries. With more than 40 years’ experience in the food and drink sector, specialising in the design and manufacture of an extensive range of turnkey systems and components, incorporating our corrugated tubular, and scraped surface heat exchanger technology, HRS products are compliant with global design and industry standards. HRS has a network of offices throughout the world: Australia, Canada, New Zealand, UK, Spain, USA, Malaysia, and India; with manufacturing plants in India, Spain, and Canada.

Email: info@anz.hrs-he.com Tel: +64 9 889 6045

Most equipment today, particularly that which contains pipework, enclosed spaces, and small apertures, is cleaned in situ without the need for dismantling or opening, and with minimal operator intervention – a technique which is known as Cleaning-in-Place (CIP).

As well as ensuring that production equipment is hygienically clean and suitable for use, CIP also plays a number of other important roles. CIP systems should ensure that no cleaning fluids or contaminants remain in the equipment – ensuring food safety, and by reducing the effort and downtime required for cleaning, they also ensure production cycles are efficient and cost-effective.

Because of the automated or semiautomated nature of CIP systems, they provide improved control of the cleaning parameters to ensure consistent results, as well as automatic record keeping for traceability and due diligence purposes. Furthermore, being automatic reduces the need for human contact with potentially

harmful cleaning agents or other chemicals.

HRS offers two types of CIP (and SIP) kitchen. The first are those which are integrated into other systems, such as HRS pasteurisers and sterilisers, as well as our Aseptic Block Series and aseptic fillers, for example. The second is the HRS series of stand-alone CIP and SIP kitchens. These are available with single (ST) or multiple tanks, which are heated with an HRS K Series heat exchanger. Fully skid-mounted and modular design enables for quick and easy site installation, and the fully automated systems are supplied with a programmable logic controller (PLC) system, which can operate on its own, or be integrated into the factory’s main control system.

Located in Melbourne, HRS Heat Exchangers is part of the EIL Group (Exchanger Industries Limited) which operates at the forefront of thermal technology. HRS offers innovative heat transfer solutions worldwide across a diverse range of industries. With more than 40 years’ experience in the food and drink sector, specialising in the design and manufacture of an extensive range of turnkey systems and components, incorporating our corrugated tubular, and scraped surface heat exchanger technology, HRS products are compliant with global design and industry standards. HRS has a network of offices throughout the world: Australia, Canada, New Zealand, UK, Spain, USA, Malaysia, and India; with manufacturing plants in India, Spain, and Canada.

Email: info@anz.hrs-he.com Tel: +64 9 889 6045

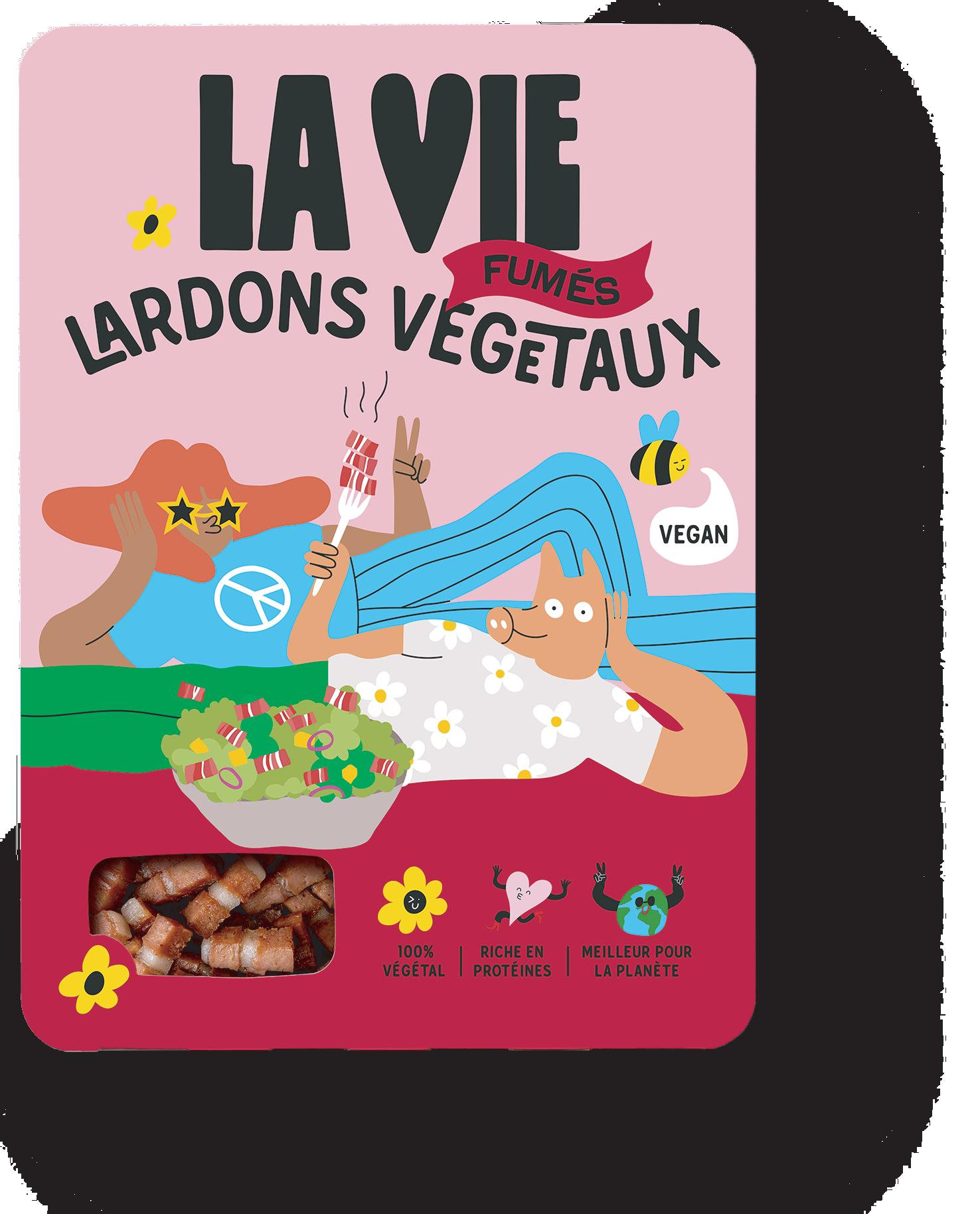

Can you provide an overview of your company’s food innovation?

NICOLAS SCHWEITZER CEO & Co-Founder

At La Vie, we’ve created very unique plant-based ham and bacon. The products systematically won in consumer panels over meat despite having a very short and clean ingredient list.

What inspired this innovative development, and what market gap does it aim to address?

Most people wants to reduce their meat consumption, be it for their health, the environment or the animals. The challenge is that meat is just so good, so deeply rooted in our habits that it is too hard for most people to reduce their meat consumption significantly.

In what significant ways does your company’s solution contribute to making food production more efficient and sustainable globally, particularly in the

face of rapidly changing food markets and climate change?

An independent agency’s Life Cycle Analysis of all products revealed that our ham emits 84% less carbon than pork and our bacon -77%. This is mostly due to bioconversion: a pig needs 9.4kg of feed to generate 1kg of edible pork, which is grossly inefficient.

What are the company’s goals and aspirations for further innovation and expansion in the food processing industry?

In foodservice, we want to extend our partnerships with Burger King and Pizza Hut (already quite developed in Europe).

In the prepackaged meals sector, we seek sandwich/pizza manufacturers eager to offer innovative, delicious plant-based/vegetarian with our bacon, bacon bits or ham.

Food importing is a critical aspect of New Zealand’s food supply chain, ensuring consumers can enjoy a diverse range of products at their table. New Zealand Food Safety – Haumaru Kai Aotearoa (NZFS) are responsible for supporting food importers to ensure food, which is imported into New Zealand, is safe and suitable for everyone, everywhere. NZFS is part of the Ministry for Primary Industries – Manatū Ahu Matua (MPI).

“Importers are bringing a wide variety of products for kiwis to enjoy,” said NZFS’ Deputy Director-General Vincent Arbuckle.

“As the amount and diversity of food being imported continues to grow every

year, the food safety system needs to keep pace with these changes. Importers are responsible for ensuring the food they import, and sell is safe and suitable.”

What is the food import environment like in New Zealand?

Thanks to growing innovation, different food demands in New Zealand, and complex international supply chains, the local and international food environment is rapidly changing.

The number of New Zealand food importing businesses that NZFS regulates has grown significantly over recent years, and currently is 3,800. The value of food imports to New Zealand was $9.1 billion in 2023.

The number of countries New Zealand

businesses import food from has grown from 63 in 2003, to more than 140. Increased types and origins of foods create new risks that NZFS assist food importers to identify and manage. NZFS set rules for importers to meet their food safety requirements.

Meeting standards as food importers

It’s important for food manufacturers, suppliers, and retailers, to know and follow the Food Act 2014. NZFS has information on the MPI website outlining the requirements for food importers, including compliance with the necessary documentation, compliance standards, and risk management strategies to ensure imported food products are safe and suitable for consumption.

Revised Importing Food Notice

Published

In April, New Zealand Food Safety published the revised Food Notice Requirements for Registered Food Importers and Imported Food for Sale, which came into effect on the 1st of August 2024.

This amendment includes new rules for importing frozen berries, as well as a minor change to importing canned bovine meat products from the European Union (EU) and United Kingdom (UK).

Now, frozen berries are considered a High Regulatory Interest (HRI) food. Clearance is only required for ready-to-eat frozen berries and specified frozen berry products. Frozen berries intended for further processing will not require food safety clearance.

In addition, the new notice allows food safety clearance of canned bovine meat products from the EU or UK with evidence of an EU or UK identification mark. More information is available on MPI’s website. Keep on top of food importing rules, changes, and safety requirements.

By staying informed and proactive, food importers can help keep kiwis safe from the supermarket to the local fish and chip shop. Keep up to date with Food Importer News, sent quarterly by NZFS.

Importers can also contact info@mpi. govt.nz.

The 12th annual KiwiNet Research Commercialisation Awards have honoured 18 finalists who transform scientific discoveries into new technologies, businesses and real-world solutions.

The KiwiNet Awards have continued celebrating tech heroes across New Zealand. These professionals and innovations, emerging from outstanding research within New Zealand’s universities, Crown Research Institutes and other research organisations, have driven significant economic and societal benefits.

Five food tech innovators and innovations have been in the spotlight this year as 2024 KiwiNet Research Commercialisation Awards finalists across four award categories.

These include the following:

• Momentum Student Entrepreneur finalist: Emma Arvidson – Teiny/ Te Whare Wānanga o Waitaha | University of Canterbury: High protein oat milk

powder with impact

• Sprout Agritech Breakthrough Innovator Award finalists: Dr Arup Nag –ANDFOODS/ Riddet Institute/ Te Kunenga ki Pūrehuroa Massey University: Innovating tomorrow’s food today and Emily McIsaac - Daisy Lab/ Te Kunenga ki Pūrehuroa Massey University: Making dairy proteins - without the cows

• BNZ Researcher Entrepreneur Award finalist: Professor Harjinder Singh - Riddet Institute, Te Kunenga ki Pūrehuroa Massey University: Research entrepreneurship icon and food science leader

• PwC Breakthrough Project Award finalist: ANDFOODS - Riddet Institute/ Te Kunenga ki Pūrehuroa Massey University/ Massey Ventures: Breakthrough dairy alternatives taking the world by storm

“The KiwiNet Awards highlight the powerful economic impact of research commercialisation and showcase the collective strength of our science and innovation sector. Our 2024 finalists are exceptional,” said KiwiNet CEO Dr James Hutchinson.

“From tackling climate change to improving health outcomes, they’re solving problems that matter for New Zealand and the world. This year, we’re excited to introduce the Commercialisation Rising Star category, shining a light on emerging commercialisation professionals shaping the future of our sector. Together, we’re creating lasting benefits for our communities, economy and environment.”

The 2024 KiwiNet Awards judging panel was comprised of Cather Simpson – CEO of Orbis Diagnostics and Partner at Pacific

Channel; Greg Sitters – Managing Partner at Matū Group; Guy Royal – Director of Tuia Group; Suse Reynolds – Angel Investor; and Olivia Ogilvie – CEO and co-founder of Opo Bio.

Simpson said the judges were impressed by the depth and breadth of the entrants from across the innovation ecosystem, who demonstrated enormous expertise.

“We’re seeing both emerging talent and more senior researchers joining with skilled commercialisation people to create highperforming teams with a drive to solve real-world problems,” said Simpson.

“The extraordinary talent the KiwiNet Awards continue to uncover shows we’re creating a vibrant research commercialisation ecosystem that enables people to make a difference and shape a better future for us all.”

Nic Blakeley, Deputy Secretary of Labour, Science, and Enterprise at the Ministry of Business, Innovation, and Employment, also added that commercialising research was vital to ensuring more people access new knowledge and technological advancements.

MBIE, PwC NZ, Sprout Agritech, BNZ, KCA, Campus Plus, and AJ Park, as well as Return On Science, Momentum, and Matū, the sponsors of the Momentum Student Entrepreneur, have supported the 2024 KiwiNet Awards.

KiwiNet Awards winners for 2024 will be announced this October.

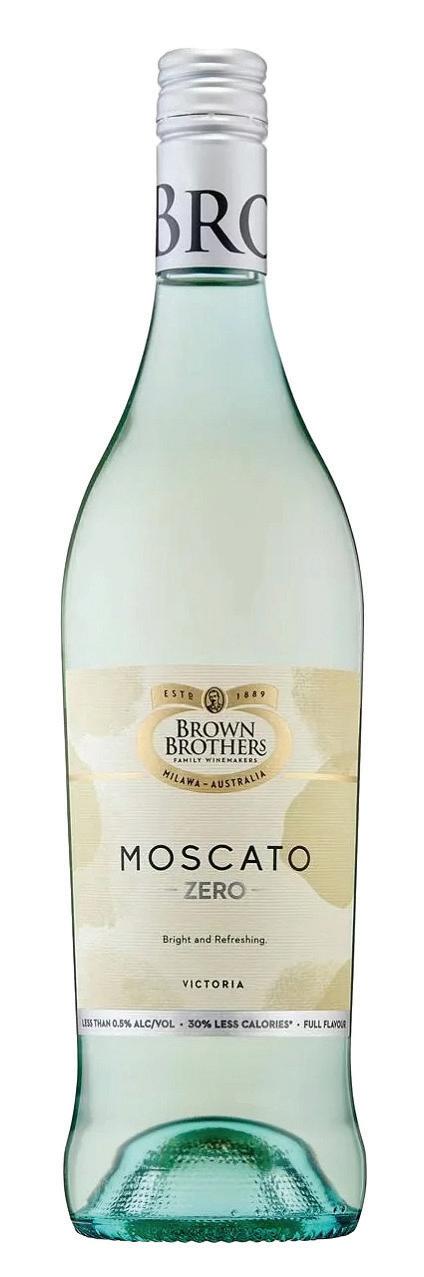

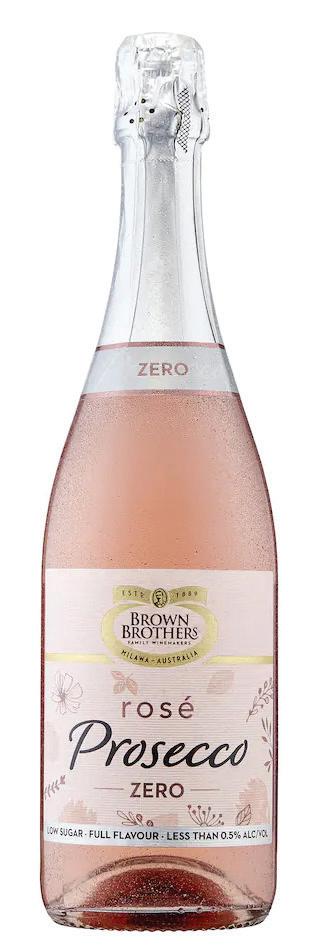

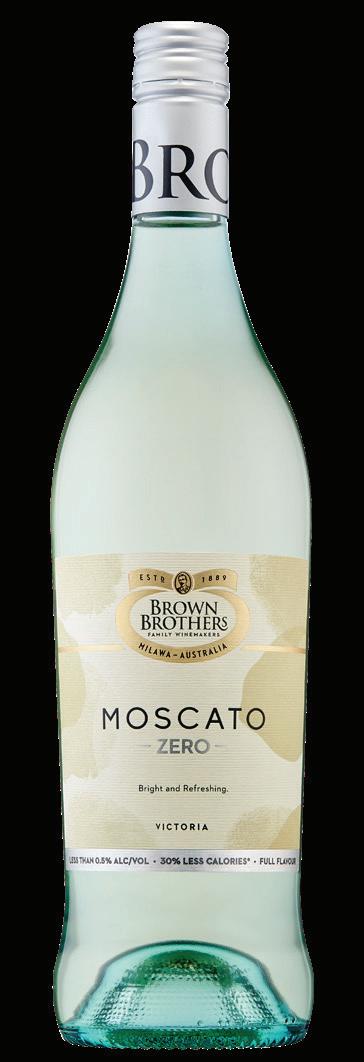

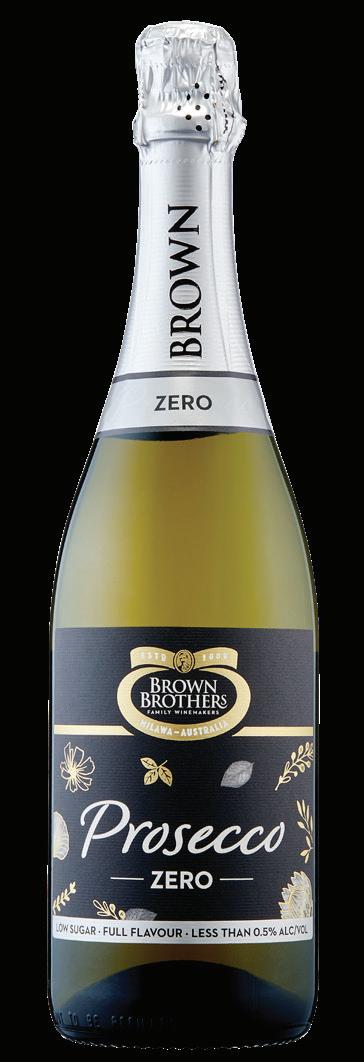

A range of refreshing and delicious wines created via innovative spinning cone technology

With the demand for nonalcoholic wines and other drinks continuing to grow, many people are either abstaining from alcohol or lessening their alcohol consumption to lead healthier lives.

Brown Brothers, home to some of Australia’s favourite wines for more than 135 years, created its range of alcohol-free Zero wines to embrace this growing trend, allowing wine lovers to enjoy great tasting wines that truly deliver on flavour without the alcohol.

All the wines within the Brown Brothers Zero range - Brown Brothers Moscato Zero, Brown Brothers Prosecco Rosé Zero, and Brown Brothers Prosecco Zero - have been made using a unique spinning cone technology to remove the alcohol but leave them tasting as good as their full-strength counterparts.

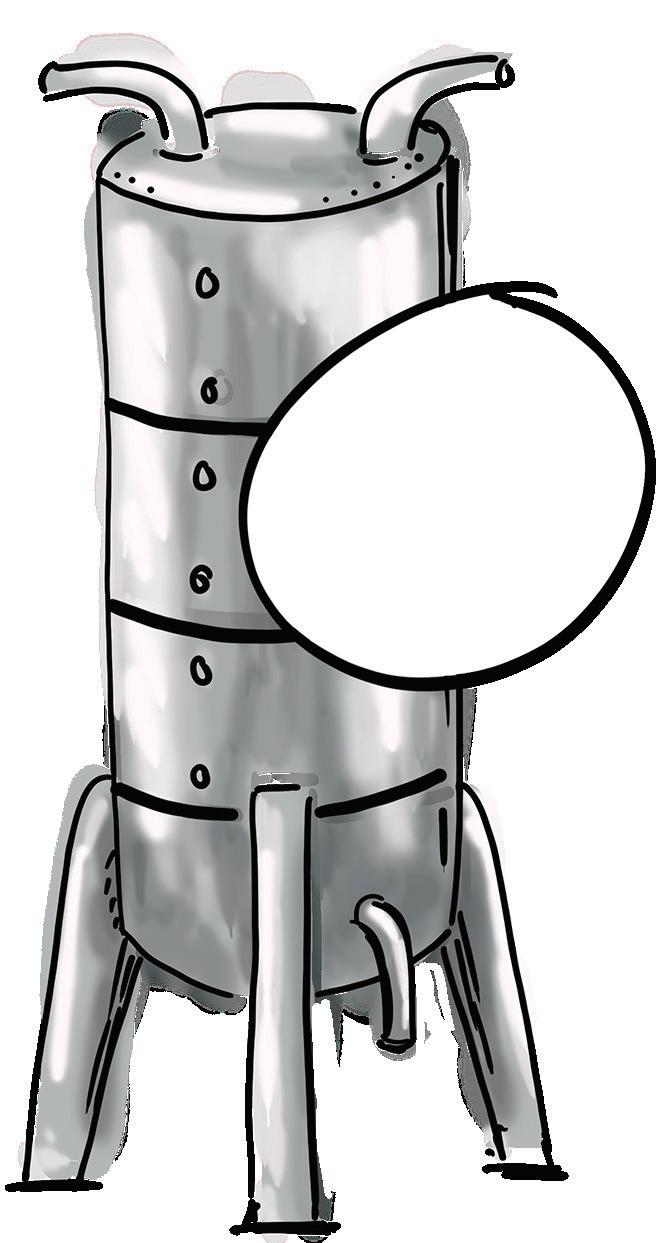

Spinning cone technology is an advanced form of distillation that is the gold standard to produce no and low-alcohol wines. During the distillation process, rapidly spinning cones inside a vacuum column create a vapour-thin film of wine to reduce the

alcohol content to less than 0.5 by volume. This gentle process doesn’t subject the wine to high temperatures or pressures (the wine only reaches temperatures around 35-45°C for 25 seconds), which can damage the delicate aromas and flavours that are key for preserving the integrity of the wine.

Historically, the no alcohol category has been a been a selection of products that varied greatly in taste and quality. Producers were dressing up fruit juices and tea-infused products to look like wine beverages. The wine based no alcohol available was variable in quality and usually tucked away in a dark corner of a store and hardly given any attention. Nowadays the no alcohol sections of liquor retail outlets are substantial and filled with beer, sprits and wine based products. This is a reflection of the growth in category and also the lift in quality of what is available. The quality of the base wine used to make a zero-alcohol product is vital in the quality of the final wine. At Brown Brothers we use the base wine for our Zero products that also go on to make the full alcohol expressions. This is vital in ensuring there is no compromise in the quality of our Zero

range and delivers an almost identical taste sensation to our full alcohol wines. A lot of consumers think that the no alcohol wines should be less expensive. When you think of our situation of taking the same wine and then putting it through several extra winemaking steps it actually costs more to make the Zero range than it does the full alcohol expression.

In the first phase of the de-acoholisation

Wine is passed through the Spinning cone at 30 degrees Celsius. The distilled alcohol from this Phase is held separate as the “aroma strip”

process, the wine is passed through the spinning cone at 30 degrees Celsius. The distilled alcohol from this phase is held separate as the ‘aroma strip’. This aroma strip sits at approximately 50% alcohol by volume and if full of flavour. In the second phase, the remaining alcohol is removed at 40 degrees Celsius. As we already have our aroma strip, we can remove the remaining alcohol at a faster rate, all be it at a temperature that still does not affect the final product. In the final blending phase, the aroma strip and dealcoholised wine are blended together to just below 0.5% alcohol. The dealcoholized wine

Remaining alcohol is removed at 40 degrees Celsius.

Aroma strip and de-alcoholised wine blended together to 0.5% alcohol

added to

is then ready for bottling. There is a lot of research going on in this space at the moment and one of the key ones is whether we can do a second distillation of the aroma strip without losing the flavour. If so, it would allow us to add more of the aroma strip back and still be under the 0.5% alcohol.

Fourth-generation family member and Brown Brothers winemaker Katherine Brown says that many consumers are yet to find ‘the one’ when it comes to a nonalcoholic wine they love, which is one of the reasons why they were inspired to create the

Brown Brothers Zero range.

“Non-alcoholic alternatives have been on the market for a few years now and despite winemakers bringing new or improved wines to market year after year, many consumers are still disappointed with the lack of flavour and range currently available, saying nonalcoholic alternatives are still overall inferior to their alcohol equivalents.

We are proud to say that Brown Brothers Moscato, Prosecco, and Prosecco Rosé drinkers will be hard-pressed to tell the difference between Brown Brothers Zero range and their alcoholic counterparts.”

Transform cookies, macarons, and other confections into edible works of art, all while streamlining your decorating process.

Eddie® The Edible Ink Printer from Primera makes this a reality for bakeries, pastry chefs, culinary departments at schools, caterers, restaurants, cafes, and even cottage bakers.

Unleash Your Creativity with Personalized Designs

Eddie® empowers you to personalize confections with logos, photos, and intricate graphics printed directly onto the cookies, macarons, fondant, marshmallows, candy or other treats. This opens a world of creative possibilities:

Custom Cookies for Every Occasion: Design unforgettable cookies for weddings, anniversaries, birthdays, graduations, or any special event.

Branded Baked Goods: Create logo cookies for corporate events, galas, or product launches, leaving a lasting impression on your guests.

Themed Treats: Match your cookies to any party theme

Edible Art: Create stunning artistic designs that are not only delicious but visually captivating.

The options are truly endless, allowing you to personalize your confections and elevate them from ordinary treats to extraordinary edible creations.

Efficiency Meets Quality: Print Hundreds

of Cookies per Hour

Beyond the creative potential, Eddie® offers a significant advantage in terms of production efficiency. Capable of printing up to 360 cookies per hour, Eddie® allows you to decorate confections in a fraction of the time it would take using traditional methods. This translates to increased output, allowing you to take on larger orders such as corporate logo orders and grow your business.

However, speed doesn’t come at the expense of quality. Eddie® utilizes highresolution edible inks to produce vibrant, detailed prints that maintain a sharp and professional look. This ensures that your confections will not only be personalized but also visually stunning.

The Perfect Finishing Touch: Combine Printing with Traditional Techniques

The beauty of Eddie® is that it seamlessly integrates with your existing decorating methods. After printing your design directly onto the confection, you can still add frosted embellishments or other decorative touches for an extra layer of detail and personalization. This allows you to combine the efficiency of printing with the artistry of traditional decorating techniques.

Peace of Mind with Certifications for Safety and Quality

Eddie® is built with safety and quality in mind. It is NSF® Certified, meeting the strict standards required for commercial kitchen appliances. This ensures that Eddie® is safe for use in professional baking environments. Additionally, Eddie® and its edible ink cartridge is cGMP certified, meaning they are manufactured according to strict quality control regulations.

With Eddie®, you can have peace of mind knowing that you are using a product that is not only innovative but also meets the highest standards for safety and quality.

In conclusion, Eddie® The Edible Ink Printer is a revolutionary tool that empowers bakers and pastry chefs to create personalized confections with exceptional efficiency. From custom cookies for special occasions to logoed treats for corporate events, Eddie® opens a world of creative possibilities while streamlining your production process. With its commitment to safety and quality, Eddie® is the perfect solution for anyone looking to take their confections to the next level.

Learn More, How to Buy

Available now from Primera Technology at www.primera.com or through Primera Asia Pacific, Melbourne Sales and Support Office, sales@primera.com.au or store.primera.com.au.

CMA CGM AIR CARGO announced the delivery of its third Boeing 777-200F, inaugurating a new transpacific route connecting Asia to North America.

This milestone represented a significant step in CMA CGM AIR CARGO’s global expansion strategy. It aligned with the CMA CGM Group’s ambition to offer its clients comprehensive solutions.

The delivery of this new B777-200F, operated by Atlas Air, will play a key role in expanding the CMA CGM AIR

CARGO network on a strategic route, serving airports like Hong Kong, Chicago, and Seoul.

The first commercial flight took place towards the end of August, connecting Hong Kong (HKG) to Chicago (ORD) with a technical stop in Anchorage (ANC). On the westbound leg, the aircraft operates from Chicago (ORD) to Hong Kong

(HKG), via Seoul (ICN).

A second B777-200F will be received in the fourth quarter of 2024 and deployed on a transpacific route connecting mainland China to North America. With the deployment of these two Boeing aircraft, CMA CGM AIR CARGO customers will benefit from a total of seven frequencies per week on the transpacific.

In 2025, a third aircraft will strengthen its fleet by extending its reach and available capacity for its customers.

“We are very proud to extend CMA CGM AIR CARGO’s reach to the United States, a strategic country for the Group. This opening comes with the delivery of a third B777 Freighter,’ said Damien Mazaudier, CEO of CMA CGM AIR CARGO.

“This efficient long-range aircraft will allow us to serve our customers on new routes across the Pacific and respond to dynamic market conditions. This new asset also plays a key role in contributing to greater sustainability in airfreight, which is in line with the CMA CGM Group’s ambitions.”

Since 2022, 2 Boeing 777-200F aircraft operated by CMA CGM AIR CARGO, based at the Paris-Charles de Gaulle (CDG) hub, have been serving routes between Europe and Greater China, with five flights per week to Hong Kong and four flights per week to Shanghai.

The B777-200F is the world’s most extensive, longest-range, and most capable twin-engine freighter. Known for its high reliability, fuel efficiency, and lower maintenance and operating costs, this aircraft boasts a range of 9,200 km and can carry a maximum payload of 103 tonnes, delivering the most economical trip cost of all large freighters.

Launching this new route between Chicago and Hong Kong was a strategic milestone in developing CMA CGM AIR CARGO.

JEDDAH | A.P. MollerMaersk and the General Ports Authority of Saudi Arabia ‘Mawani’ announced the opening of the largest Logistics Park for Maersk in the Middle East at Jeddah Islamic Port.

The Saudi ports sector has witnessed significant unprecedented leaps in terms of high operational performance efficiency, achieving records in international indicators, growing maritime navigation lines and increasing maritime connectivity.

The Maersk Logistics Park at Jeddah Islamic Port will contribute to service and development by supporting economic activity in the Kingdom, providing highly efficient logistics services to support the movement of trade and exports to foreign markets, and enhancing the work of supply chains and logistics.

His Excellency Omar bin Talal Hariri,

President of the General Authority of Port, said the Maersk Logistics Park represented a significant milestone for Maersk and was a testament to its commitment to enabling global trade in the Kingdom of Saudi Arabia, which sits strategically at the crossroads of three continents.

“I am proud that our Logistics Park in Jeddah has become a living example of our integrated logistics strategy, supporting our customers with resilient logistics while implementing the right initiatives to take our decarbonisation journey forward.”

Vincent Clerc, CEO of A.P. MollerMaersk, added that this strategic partnership with Maersk has consolidated logistics

operations into one hub, which will help reduce energy consumption and CO2 emissions. This will move Unilever closer to its sustainability ambition of achieving Net Zero emissions across the value chain by 2039.

“We will continue to harness the power of our brands, people, and partners through collaborative actions that will positively impact societies and the planet,” said Clerc.

“As we witness how this collaboration with Maersk contributes to the logistics ambition of Saudi Vision 2030, Unilever remains committed to the Kingdom and will continue to invest in its growth and empowering local and diverse talent.”

The Maersk Logistics Park has been extended over an area of 225,000 square metres with the provision for multi-modal connectivity between ocean, land and air transport, warehousing solutions catering for B2B and e-commerce requirements, temperature-controlled warehousing, custom-bonded setup, dedicatedly designed for a wide range of industries and verticals, including FMCG, Frozen Food, Automotive, Retail & Lifestyle, Petrochemicals, Electronics, Pharmaceuticals etc.

Its distribution solutions will include firstand last-mile deliveries, customs clearances, visibility solutions and a control tower.

Maersk has implemented several initiatives to reach Net Zero greenhouse gas emissions by 2040 as part of its decarbonisation ambitions. The facility will draw up to 70 percent of its electricity from 32,000 solar panels installed over 64,000 sq. m. on the rooftop. It will use electric equipment and trucks within the facility, optimise low electricity-consumption LED lighting with light sensors, etc.

Maersk Logistics Park was built at the Jeddah Islamic Port. It has an advanced infrastructure with berths capable of accommodating new generations of giant ships and modern, automated, environmentally friendly equipment that improves its operations, competitiveness, and capacity.

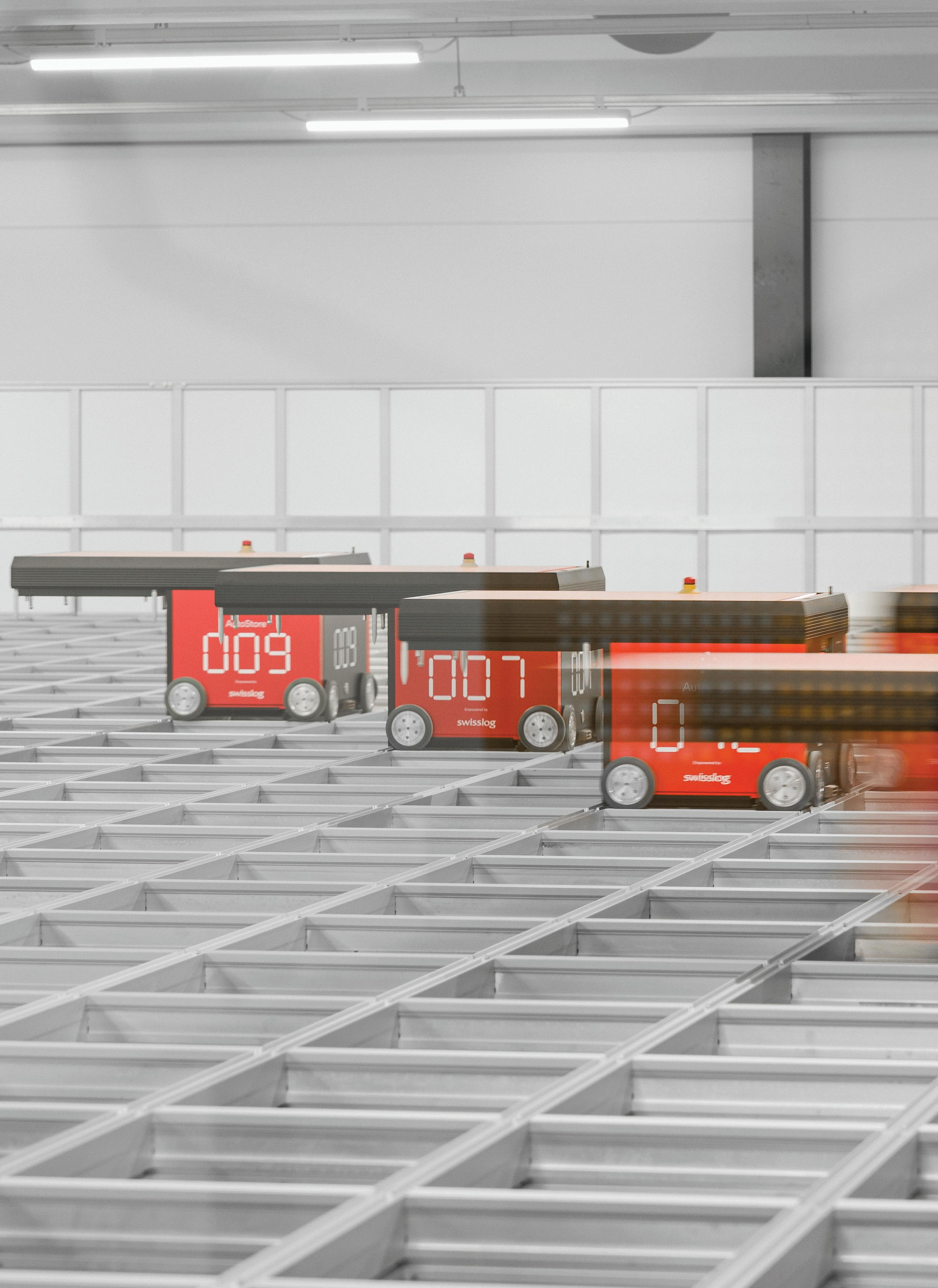

Pirkanmaa Cooperative Society (Pirkanmaan Osuuskauppa) opened the first micro-fulfilment centre (MFC) online grocery shopping in August 2024.

Robots make the collection process more efficient and faster by rapidly bringing the products to the warehouse staff. However, employees will continue to ensure the quality of the products and pack the order for pick-up.

Pirkanmaan Osuuskauppa is a regional cooperative of the Finnish S Group. The centre, developed in cooperation with Swisslog and built from scratch next to the Prisma hypermarket, has been entirely based on automation principles.

“The centre utilises the Prisma hypermarket’s infrastructure. Products from the basic selection will be collected from the warehouse with the assistance of robots, and the order will be supplemented, if necessary, with products from the adjacent Prisma hypermarket, such as fresh food, bakery items, frozen products, and daily consumer goods,” said Ville Jylhä, COO of the Pirkanmaa Cooperative Society.

“Robots make the collection process more efficient and faster by rapidly bringing the products to the warehouse staff. However, employees will continue to ensure the quality of the products and pack the order for pick-up.”

The centre will serve customers in the Pirkanmaa Region, where there has been Continued on page 36.

The new centre will enable us to double our online grocery sales capacity compared with last year.

Continued from page 35.

an increasing demand for online grocery shopping. Sales grew by 27 percent last year compared to the previous year, and in the first half of 2024, they increased by almost 30 percent. The centre will mean more order time slots for customers and faster deliveries.

“The new centre will enable us to double our online grocery sales capacity compared with last year. In recent years, across the S Group, we have systematically invested in developing online grocery shopping to meet customers’ needs. I believe there will be demand for at least two new MFCs in the region shortly. Buying food online is undoubtedly a simple way to make daily life easier.”

Swisslog, a pioneer in market-proven e-grocery and automated order fulfilment solutions, has delivered Pirkanmaa Cooperative Society’s automation solution.

Tero Mäki, Sales Manager, Swisslog, was happy that Pirkanmaa Osuuskauppa chose Swisslog as its first MFC partner. He said work had gone according to plan and looked forward to the continued operation of this innovative and efficient facility.

The new MFC is 1,400 m² and consists of 40 AutoStore robots, employing around 50 people in various roles. This solution will make e-grocery deliveries faster, more precise, and more efficient.

Concept Solutions offers a comprehensive range of flat belt and plastic modular belt conveyors and equipment. These can be specified to suit virtually any configuration, environment or conveyed product.

• Versatile, reliable and economic conveying solutions

• 3D design for realistic product visualisation

• Hygienic design for ease of sanitation

• Plant layout and flow optimisation

• Safety standard compliant design

• Food grade plastic machining and supply

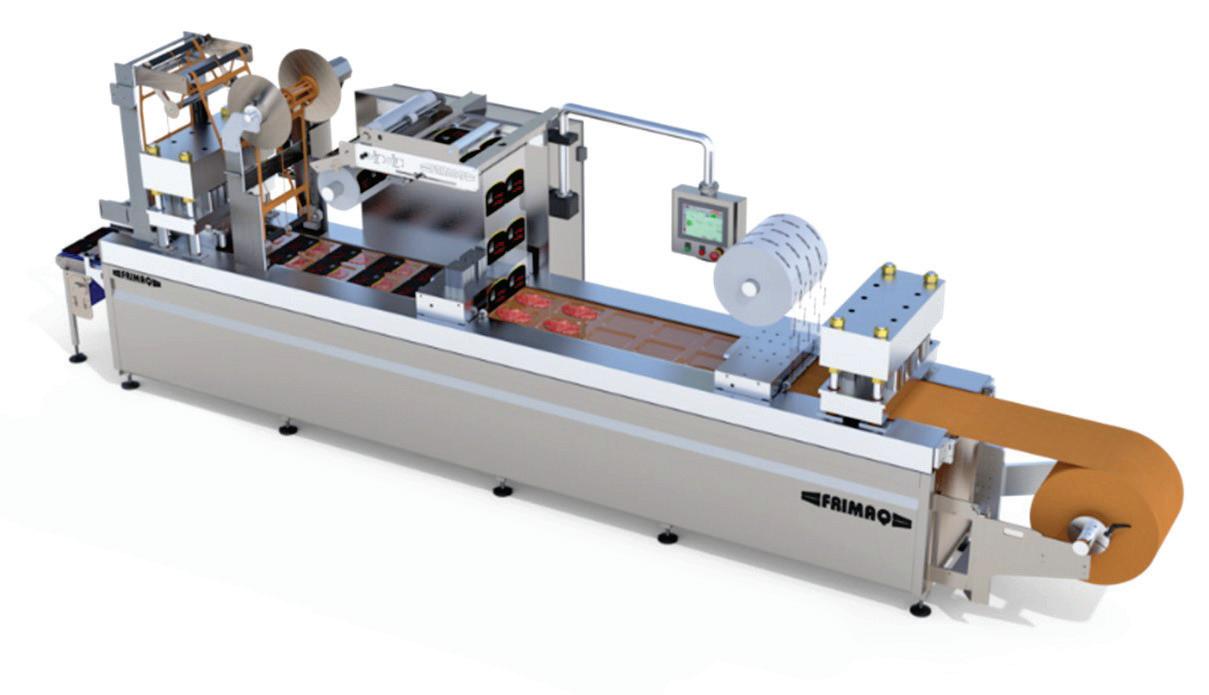

Vacpack is a leading provider of innovative machinery and cardboard base food packaging products to New Zealand, Australia and the Pacific.

Are you looking for eco-friendly packaging that improves the shelf life of your fresh and frozen items? Then, Vacpack’s market leading cardboard base technology is the solution for

you. The systems help reduce plastic by up to 80%, is 100% biodegradable or recyclable and creates an appealing and safe end-product. Call us now to find out more.

or

www.conceptsolutions.co.nz

At DTS, we specialise in stainless steel engineering solutions for the food, beverage and pharmaceutical industries. Our tank design philosophy is to minimise waste and maximise profit, not only during tank fabrication, but also throughout the tank’s operational life and production. • Food & beverage tanks

• Insulated hazardous pressure vessels

• Hot water recovery / 2205 duplex

• Laser-welded dimple pads / thermal control

• Clean in place and agitation

• Walkways, ladders and handrails

In the food industry, temperature measurements are part of the daily routine. The quality of food products can only be tested and guaranteed by precise measurements. The Testo range of measuring instruments, available from NZ authorized distributor Eurotec Ltd, a member of Carel Group, can carry out spot-check measurements in seconds.

Whether in the transport and storage of foods, in restaurants or in large kitchens, wherever temperature needs to be recorded, Testo measures up and helps you keep compliant. Testo enables you to guarantee optimal performance in key areas of your business.

Food industry instrumentation for incoming goods: Every item that enters your premises should undergo rigorous checks in order to ensure its quality and safety. Whether that be your weekly delivery of fresh fish, or the daily top up of your fruit and vegetable stocks, food can spend a long time in transit from the wholesaler before it arrives at your door. The testo 831 infrared thermometer is perfect for

dealing with incoming goods, as it allows you to carry out quick and precise temperature measurements of whole pallets of food and smaller individual products from a distance.

Monitor the cold chain and ensure food safety Perishable foods are sensitive to changes in temperature. While fruit and vegetables ripen quickly and barely make it to the supermarket if they are stored and transported in conditions that are too warm, bacteria can multiply in meat and dairy products when heated. These, in turn, can cause serious illnesses. Therefore there must never be any gaps in the cold chain, but this can only be ensured through continuous monitoring. The testo 184 series

of Cool Chain Temperature Loggers can measure the temperature and humidity of your goods while in transit. With up to 150 days of battery life, you’ll be able to keep track of goods over long stretches, measure and analyse temperature and humidity data - arming you with information to implement changes when needed backed by data.

info@easirecycling.co.nz www.easirecycling.co.nz

Freephone: 0800 342 3177

Protect your brand solutions that enhance food safety and weight compliance for processing lines.

LEARN MORE ABOUT OUR EQUIPMENT ONLINE

EXBERRY® Colours are the ideal and future-proof solution for food and drink applications matching the recent plant-based, vegan and vegetarian trends.

HRS Heat Exchangers operates at the forefront of thermal technology,

Pasteurisation

Sterilisation

Aseptic Filling

Direct Steam Injection

Evaporation

CIP Kitchens

Process Skids

Juice Crushing and Remelting

NZMS Scientific offers specialised solutions to help ensure your products meet the standards you and your customers expect.

Give us a call today to talk about:

• Pathogen testing

• Allergen testing

• Hygiene testing

• Sterility testing

SCANZ is a multi-discipline supply company and manufacturers agent, specialising in technology and equipment for the food industry. It’s primary focus is within three market segments, namely fish (including aquaculture), meat and the dairy industry. High Pressure Processing takes Scanz into other areas, as does a recent involvement in industrial waste water treatment.

SCANZ

a Custom Blends

a Flavours: Sweet, Savoury, Smoke

a Caramel Colours

a Yeast Extracts

a Proteins: Plant & Animal

a Starches: Native & Modified

a Minerals

a Dehydrated Vegetables

a Carrageenan & Gums

a Preservatives

a Clean Label Ingredients

For 125 years we’ve been a trusted ingredient partner for iconic vanilla. With a range of bulk and customised solutions for industrial, along with deep manufacturing experience, we can help you find your next flavour solution. Our food industry passion, dedicated technical team and global commitments to sustainable and ethical sourcing can help you achieve your business goals.

BULK FORMATS & CUSTOMISED SOLUTIONS:

Extracts

Pastes

Dried vanilla derivatives

CUSTOMISABLE CLAIMS:

Certified organic

Certified vanilla provenance

Urgent Couriers are specialists in temperature -controlled deliveries of chilled small goods.

Fast, reliable, guaranteed sameday services live tracked from despatch all the way to your customer’s door. We provide techforward and innovative solutions to make your life easier.

With over 40 years operating experience in New Zealand, TC Transcontinental Packaging New Zealand (TC NZ) is a leading manufacturer of flexible packaging to the FMCG, horticulture, retail and manufacturing markets

TC NZ is both a reputable manufacturer and trader, supplying all forms of flexible packaging made from traditional plastic films recycled blended films, laminated barrier substrates. TC NZ employs over 90 people in New Zealand with centres in Auckland and Christchurch, home to an ultra-modern food grade packaging manufacturing plant, and supported by our global TC Transcontinental research and technology platform from North America.

TC Transcontinental Packaging brings a distinctive blend of science, technology, and art together to create flexible packaging that preserves our customers’ products and accentuates their brands on the store shelf. Our expertise, resources and conversion technology helps us create packaging that gives our customers a competitive advantage. We utilise a widevariety of printing techniques, laminations and converting styles including pouches that help enhance your brand.

We invest in state of the art technology to offer and invest in a sustainable future and are delighted to be recognised for our high quality packaging that we supply to our customers. Globally TC Transcontinental Packaging is committed to a circular approach to plastic. As global signatories to the Ellen MacArthur Foundation, we are working towards our 2025 goal where 100% of our plastic packaging will be reusable, recyclable or compostable, and 10% of our plastic output to be made from recycled plastic waste.

At the 2022 Pride in Print Awards, TC NZ were awarded Gold Sustainability Award in the Flexible Packaging Category for our significant volumes used into industrial, refuse and hygiene packaging. TC NZ are meeting customer requirements by extruding and converting recycled resins of in-house, postindustrial waste, and post-consumer recycled content , Green PE (PE derived from renewable resources such as waste sugar cane), and has the ability to manufacture flexible packaging with other