ACCELERATING SUPPLY CHAIN INNOVATION

YURY GOMEZ – Microsoft’s industries lead –on how its tech ecosystem is driving change

YURY GOMEZ – Microsoft’s industries lead –on how its tech ecosystem is driving change

26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

Supply Chain magazine is an established and trusted voice with an engaged and highly targeted audience of 550,000 global executives

Digital Magazine

Website

Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

WORK WITH US

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN/

SUPPLYCHAIN LEAD DESIGNER

ANDY WOOLLACOTT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

JULIA WAINWRIGHT

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION

MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANNA

SALLY MOUSTAFA

JINGXI WANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KATHRYN WEBB

PROJECT DIRECTORS

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

FOR SUPPLY CHAIN EXECS IN THE PHARMACEUTICAL INDUSTRY, LIFE COULD BARELY BE ANY MORE CHALLENGING

Supply chain is a complicated business at the best of times, and that’s when everything is going swimmingly. Throw in a pandemic, war, inflation, a labour shortage and looming recession, and it becomes a monumental challenge.

But then, even on top of all this, some sectors take supply chain complexity to a whole new level. Such as the pharmaceutical industry.

As well as the usual litany of supply challenges, pharma has a cold chain element for vaccines and other temperature-controlled medicines, plus medicine is just about the most regulated sector there is.

Then there’s the added pressure of how catastrophic any delays might prove, with the medicines being shipped critical for either ensuring patients maintain their health or keeping them alive.

In this issue, we explore the demands of pharma supply chains, and how senior managers facedown the daily challenges they face. Their skill and expertise is a reminder of just how wide-ranging and demanding the world of supply is.

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

“Some sectors take supply chain complexity to a whole new level –such as the pharmaceutical industry”

26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

084 BRIDGESTONE Bridgestone’s Head of Procurement, Lars Bettermann, reveals the secrets behind its procurement transformation, sustainability commitments and its future

102 SUSTAINABILITY Oracle guiding customers on their sustainability journey

114 SANOFI & MARKEN Transform the pharma supply chain

gettyimages1443559562170667a.jpg

132 TECHNOLOGY Managed data is the currency of success Gregor Stühler talks about how businesses can leverage data to gain competitive advantage

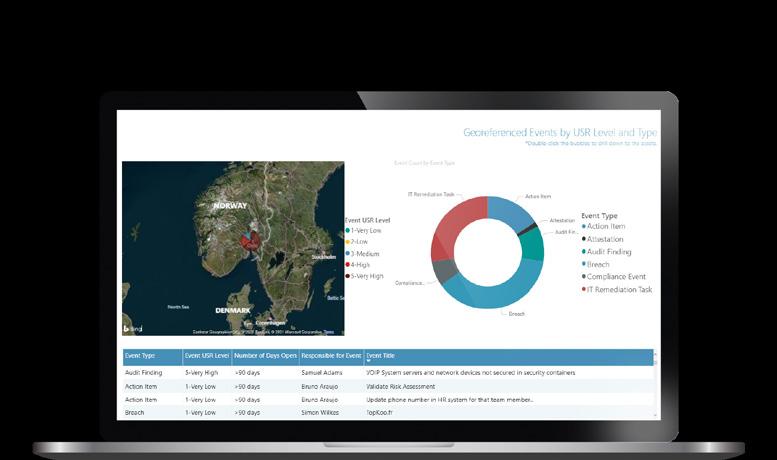

ProcessUnity supports small companies just getting started with vendor risk and large enterprises with the most complex program requirements.

With ProcessUnity Vendor Risk Management, customers quickly streamline their third-party risk management processes and ensure their results will stand up to regulatory scrutiny.

Why do companies choose ProcessUnity Vendor Risk Management for Third-Party Risk Management?

When you combine the strength of our platform with the quality of our people and our time-tested methodologies, we are wellpositioned to help you achieve your program goals quickly.

We are known for our fast deployment times and implementations that lower your costs while also being able to change over time as regulations or requirements change. Request

TOP-RATED PLATFORM

Proven Agility

“No-Code” platform can handle any program regardless of maturity or complexity

Easy Administration

Simple configurations so clients can make changes when needed

End-User Configuration

Dynamic platform that 100% adapts to specific program requirements

Integration

Capable of integrating with enterprise systems and incorporating external content

UNPARALLELED EXPERTISE

Subject-Matter Experts

In-house GRC experts incorporating best practices on behalf of clients

End-to-End

Program designed to support both procurement and information security teams

Customer Success

Product and implementations are based on success with hundreds of clients

Flexible Deployments

Out-of-the-box, best practice solutions or specifically configured platform features

CUSTOMER VALUE

Time to Value

Access to world-class GRC programs faster – usually measured in weeks

Future Proof

As client programs mature, the platform adapts to the evolving requirements

Program Success

Gain full transparency of risks while freeing time for more value-added work

Lower Costs

Decreased total cost of ownership and gain better results with the same resources

Working together with our experts and partner ecosystem, we can help your organisation to meet your program demands today and prepare you with confidence for any future changes and challenges across your vendor landscape.

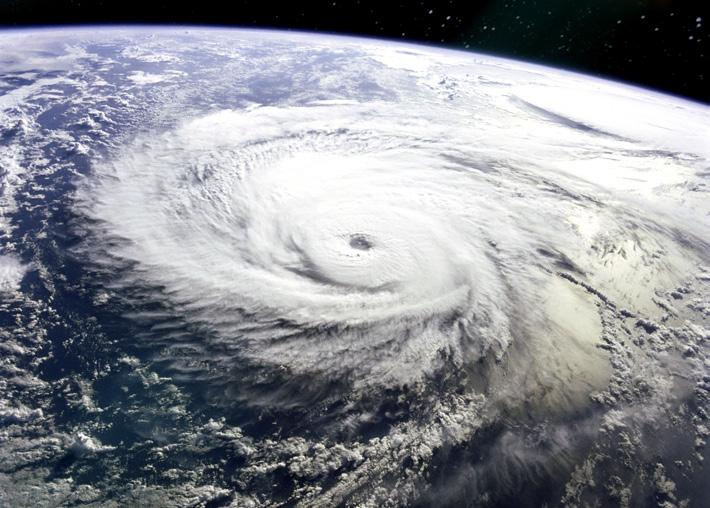

July is the month that marks the beginning of peak typhoon season. A typhoon is a tropical cyclone that forms in the Northwest Pacific Ocean near Asia (hurricanes form in the Atlantic Ocean and the Northeast Pacific Ocean).

In July 2021, China was devastated by Typhoon In-Fa, which closed two Shanghai airports and saw almost one million people evacuated from the city.

In 2019, Typhoon Hagibis hit Japan, Russia and Alaska, causing 100 deaths and costing an estimated $17bn.

Much of that economic damage is due to ravaged infrastructure bringing supply chain to its knees.

Çağlayan Arkan leads global industrial metaverse sales at Microsoft. If you are unsure what it is, exactly, that Arkan is selling, then join the club; I had to look it up, which is a fair guide to just how cutting-edge his role is.

For the record, the metaverse is a massively scaled and interoperable network of real-time rendered 3D virtual worlds that can be experienced individually by an unlimited number of users.

The industrial metaverse blends the digital and physical worlds through engineering, manufacturing, and field service. Though still in its early stages, the vision is for it to enable real-time collaboration, connectivity, and spatiallyaware context within industrial environments And Microsoft is in the vanguard of this, with Arkan key to its efforts.

“My team and I have a deep understanding of the unique challenges and opportunities that companies face in this rapidly evolving landscape,” he says. “Our ability to bring the power of immersive experiences into the world of work has the potential to empower millions across the globe and our commitment to supporting our customers along this journey is unwavering.”

This bleeding-edge role is one Arkan has held for just two months. Prior to that, he was Microsoft’s VP Global Strategy & Sales Lead, Manufacturing & Supply Chain. There, he led the company’s manufacturing and supply chain business globally, helping manufacturers run complex global supply chains.

In that role, Arkan said it was his job to “help all customers rethink

Çağlayan Arkan, Microsoft’s Industrial Metaverse Global Sales Leader, has been at the forefront of supply chain and manufacturing innovation for 20 years

“I’m so fortunate to be doing what I’m doing, because we’re at an historical point”BY 2030

how they operate and rethink their workforce”. This included everything from supply chain, security, data and cultural shifts.

Arkan has a deep experience of manufacturing, and says he is inspired by the role Microsoft plays within the partner ecosystem.

“I’m so fortunate to be doing what I’m doing, because it’s a historical point,” he says of his work in this area, which has included stints at Microsoft as VP, Global Lead, Manufacturing Industry, as well as Global Lead, Manufacturing and Resources Industry. In his career he has worked across Turkey – though is now based in Bellevue, Washington – and has had a hand in manufacturing from all sides. After undertaking internships and projects on factory floors, he went on to gain an MBA in Industrial Engineering.

“I had over a decade of entrepreneurial time, owned a bunch of companies with partners, walked away from that and joined Siemens. That was me coming back to automation, energy, manufacturing and high tech.”

But, now, Arkan is a part of Microsoft’s transformation.

“Microsoft has one of the most ambitious and broadest mission statements, and that really is very attractive for people like me, that are

all about leading with their vision and helping others,” he says. “Technology has changed both personal lives and how businesses operate. It’s part of Microsoft’s mission, in terms of, ‘we democratise technology and now, we’re going to democratise digital transformation’.

“Being part of that, being able to influence something that is so impactful – I don’t know how life gets any better.”

Arkan has spent half a lifetime travelling the globe, talking to customers from all industries and verticals. Not all leaders understand what Microsoft technology has to offer, he says. It has been his life’s work to help such people grasp the importance of what’s on offer.

“If everyone knew what technology had to offer we would already have a sustainable world, with sustainable operations and supply chains,” he points out. “We would have moved our workforce to the digital age and reskilled them.”

It is part of his job at Microsoft to create awareness and inform everyone, from individual users to large enterprises, about how to become a digital entity.

“My role is to meet them where they are, go through their journeys and move them towards their own ‘art of possible’, however they define it,” Arkan says.

MCKINSEY RESEARCH SUGGESTS THAT THE METAVERSE COULD REACH A VALUE OF UP TO $5bn

“If everyone knew what technology had to offer, we would already have a sustainable world”

Cağlayan Arkan presents Art of Possible: Advancing digital transformation at scale across industries

» For over a decade, I’ve worked with customers in the manufacturing and logistics space to help them use technology to develop simple solutions to complex problems.

» Nexer Group is a global tech company delivering services in strategy, technology and communication. On a high level, we provide design, software development, and implementation expertise on digitisation, engineering, and research and development projects.

In the US, we’re focused on helping manufacturing and distribution clients use enterprise resource planning (ERP) solutions to streamline their supply chains.

These custom, connected software solutions help businesses eliminate bottlenecks, improve cash flows, and make better business decisions with real-time data.

As we help manufacturers and distributors stay on top of recent advances in technology, they’re able to positively impact almost every aspect of their supply chains.

» Generative AI is an emerging technology that promises to impact a variety of industries, and the supply chain space is no different.

Through conversational chatbots or ERP-connected headsets, warehouse users can tap into complex datasets and quickly make decisions based on up-to-the-minute information – all

with the ease of a conversation with a coworker. Generative AI has the potential to create safer workspaces, streamline order flow, and accelerate the order picking process.

The result? Fewer disastrous bottlenecks that ripple through the supply chain and happier customers, suppliers, and employees.

“These days, it seems like everyone wants in on the generative AI action”

DAN GIANGIULIO

TITLE: CSENIOR DIRECTOR, SOLUTION DELIVERYO

COMPANY: NEXER ENTERPRISE APPLICATIONS

Guingiulio is a senior solution architect who is committed to providing exceptional quality to his customers in the ERP space. He says: “I refuse to cut corners and have a knack for thinking outside of the box to develop simple solutions to complex problems.

“My primary focus is manufacturing and distribution logistics. I have a proven track record as both a technical architect, and a subject matter expert.”

» Generative AI will positively impact the supply chain in a number of ways:

n VOICE PICKING

AI technology can enable employees to communicate with their computer systems via audio. By asking conversational questions via a headset microphone, workers can learn information on inventory levels, supplier constraints, and order status without fumbling with confirmation codes or clumsy command-based language.

n PREDICTIVE MAINTENANCE

A generative AI assistant can keep tabs on equipment monitoring sensors, giving alerts on when breakdowns will occur. Further, it can give repair recommendations, generate easy-tounderstand charts showing equipment status, and even help contact technicians to schedule any larger repairs.

“Generative AI has the potential to create safer workspaces”

Generative AI can help relieve pressure on operational managers as they navigate supply chain issues and mounting customer frustrations. By flagging product movement trends, creating heatmaps, and monitoring for broader supply chain disruptions, the AI can serve as a personal copilot.

» These days, it seems like everyone wants in on the generative AI action: from spell-check tools and research universities to luxury fashion brands. But some larger tech players, like Microsoft, boarded the generative AI train early. The company first incorporated the technology into a commercially-available product in May 2021.

Microsoft is an advocate for generative AI in the supply chain space. Specifically, Copilot in the Microsoft Supply Chain centre helps supply chain managers

navigate the frequent disruptions and limitations that have plagued the space over the last few years.

» To ‘take the leap’. This advice was given to me shortly before embarking on our entrepreneurial journey. It has encouraged me to embrace risk, step out of my comfort zone, and pursue new opportunities. Through these opportunities, I have experienced significant personal growth, overcoming many of the fears and doubts that I held previously.

» Satya Nadella. He has been a transformational leader at Microsoft, shifting the company’s focus toward cloud computing and embracing a growth mindset. His expansion into areas such as AI exemplifies his ability to identify emerging trends, set a clear vision, and execute strategic initiatives.

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

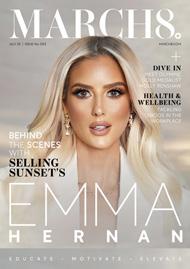

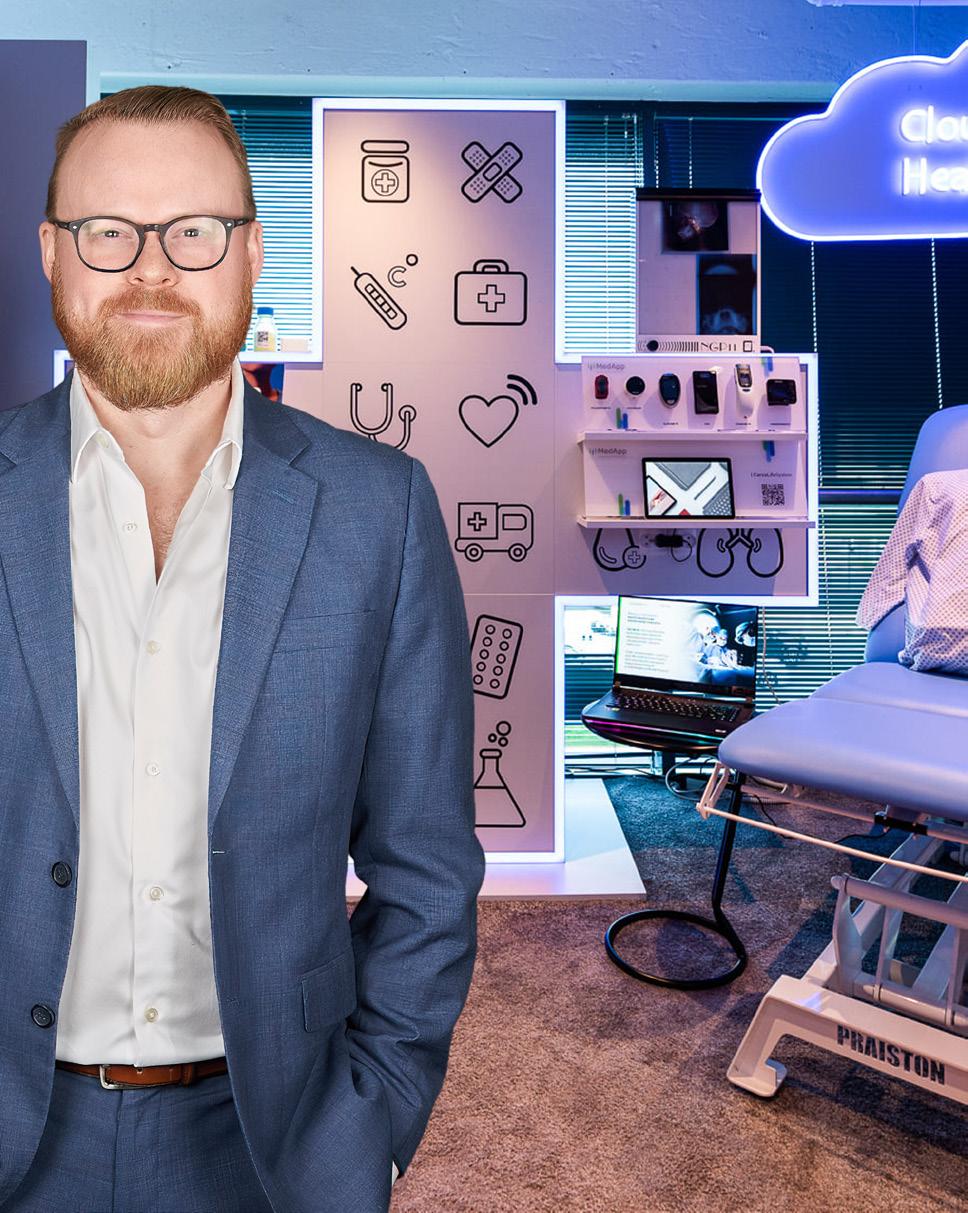

Helping to spearhead digital transformation programs across the process industry is no small feat, but Microsoft’s industry executive Yury Gomez is the perfect fit for the job.

Gomez – Global Chief Commercial Leader for Process Industries – has a supply chain background, which means that not only is she battle-hardened, but she also has a real-world understanding of what works and what doesn’t when it comes to manufacturing operations.

She has also been tempered by the seismic experience of COVID-19: “Supply chains have always existed. It’s always been the job of demand planners, forecasters, financial planners, and supply chain leaders to make sure products are at hand, and to take care of inventory control, product delivery, and customer satisfaction. But then COVID19 came along and, overnight, none of this worked any more. That was challenging, and I was thrilled to be on my mission to help customers overcome that challenge.”

Gomez began her Microsoft career as Global Executive Director for Pharmaceutical & Life Sciences Manufacturing and Supply Chain Digital Transformation, and had the opportunity to accelerate digital transformations during COVID-19 – a time, she says, “when customers looked to technology companies to help them overcome their supply chain challenges”.

Yury Gomez – Microsoft’s Process Industries lead – explains why the company’s tech ecosystem is driving change

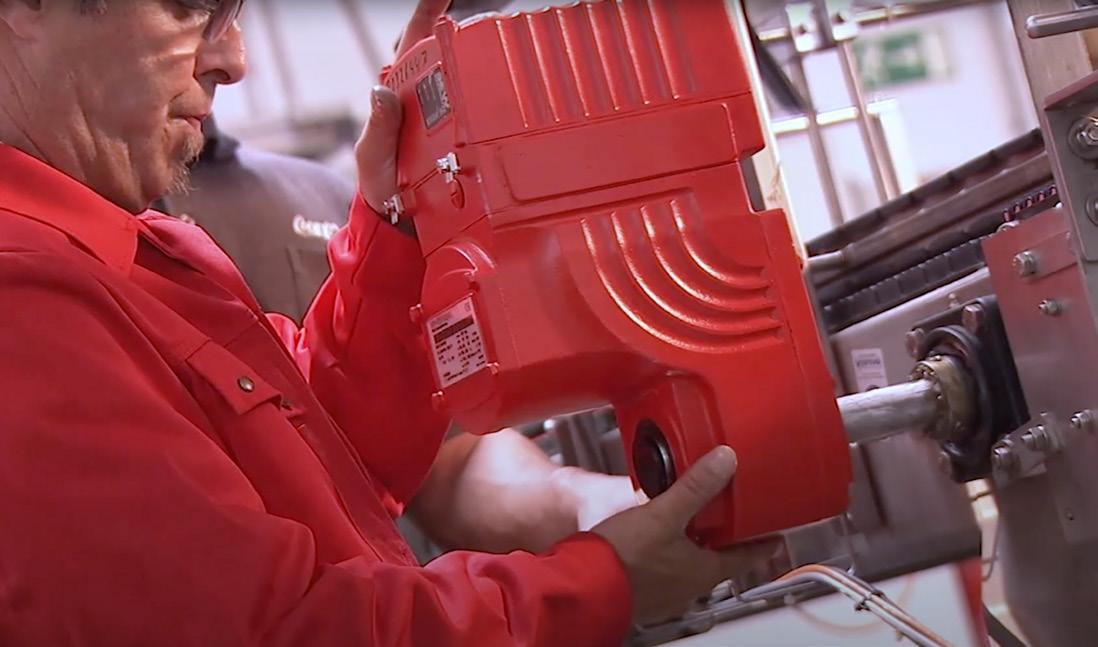

Tubeforging plant frontline workers using Microsoft products to support supply chain operations

Tubeforging plant frontline workers using Microsoft products to support supply chain operations

Now, she leads digital transformation for all process industries – including the chemicals industry, specialty chemicals, pulp and paper, steel, pharmaceuticals, and the consumer packaged goods space.

Gomez admits that, although most people know Microsoft as the company that created Windows and Xbox, for the past three years, “it has been doing a phenomenal job impacting industry digital transformation”.

Cloud helping Microsoft pioneer transformation projects

“With the advance of cloud computing and technology, we've had the opportunity to

YURY GOMEZ GLOBAL COMMERCIAL LEADER, PROCESS INDUSTRIES, MICROSOFT

“With advances in cloud computing and technology, we’ve been able to impact how industries think about the digital transformation journey”

impact how industries think about their digital transformation journey,” she adds.

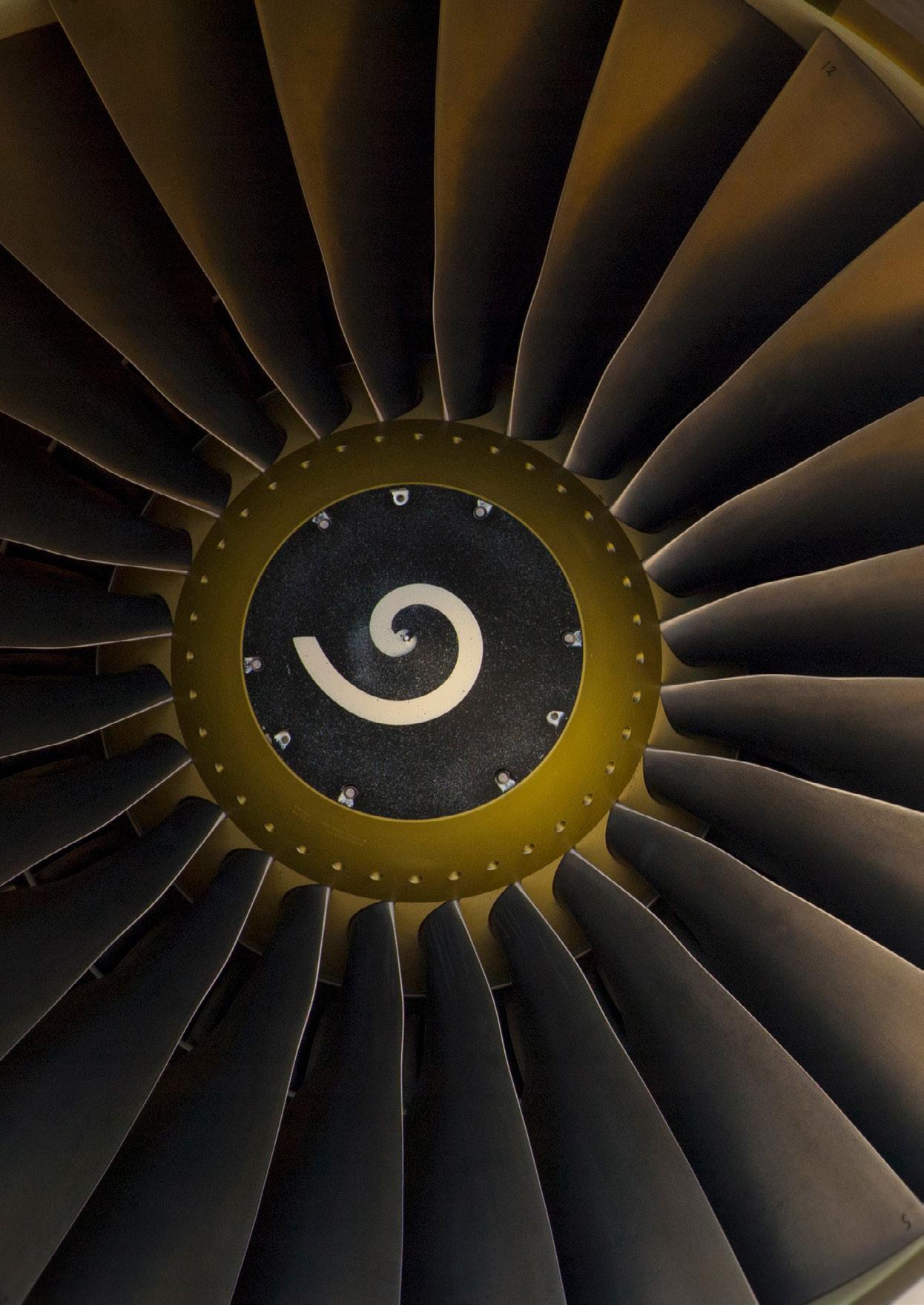

The industry solutions and partner sales organisation of Microsoft is organised by industries. “In manufacturing there are two main kinds of companies: Discrete and Process,” explains Gomez. “For Discrete, you can think of aerospace, for example, but there is also process manufacturing, like chemical companies.”

Her role is to “elevate” customer journeys by “helping them envision how digital transformation can help them accelerate efficiency, increase return on investment, and transform the way they work”.

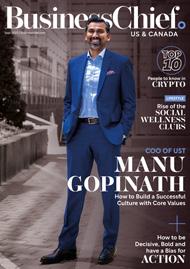

TITLE: GLOBAL CHIEF COMMERICIAL LEADER, PROCESS INDUSTRIES

COMPANY: MICROSOFT

LOCATION: UNITED STATES

Yury is the Global Chief Commercial & Strategy Officer

for the Process Manufacturing Industry division at Microsoft. She leads the GTM strategy and sales execution for process industries including chemicals, pharmaceuticals, CPG and others. In her role, she drives end-to-end digital transformation for Fortune 100 companies and many more working with engineering, sales, and partner teams.

Yury has over two decades of industry experience. Prior to joining Microsoft, she worked for Johnson & Johnson, Solvay, and various startups where she had multiple leadership roles leading innovation, manufacturing, E2E supply chain, commercial operations, and

Supply chain digital twins must continue to evolve in order to drive optimal business outcomes. aThingz and Microsoft are delivering rapid transformation within global logistics organisations by fusing the informational (data), physical, and financial supply chains (the triple threat), and converging planning with execution (the double threat).

This new “Triple-Double” approach helps companies make faster, cost-optimised decisions that solve the most stubborn global logistics problem statements.

Learn more

aThingz is a unicorn supply chain and logistics solution provider enabling organisations to rapidly take cost out of their logistics spend while helping them be more agile and resilient. Customers reap accelerated value by week 6 with aThingz.

aThingz’s founders are Vijaya Neela, President & CEO and Kannan Ramachandran, Chief AI and Commercial Officer.

Vijaya establishes the supply chain transformation roadmap for customers and leads solution development and delivery engagements. Kannan is focused on aThingz’s AI strategy, managing customer relationships, and leading revenue growth initiatives.

“We are building solutions with an AI component that is a competitive differentiator for our customers. The speed and accuracy of business decisions rely on quality data. Our AI-powered purposebuilt data management solution for Supply Chain and Logistics can identify data anomalies, apply pattern

recognition techniques to standardize, cleanse, and improve the quality of data.”

Vijaya sets the vision for aThingz’s unique approach to global logistics management within the supply chain.

“We establish a customer digital twin model that overlays the physical, financial, and informational supply chain, and analyse historical planning and ongoing execution data to continuously calibrate the effectiveness of the plan. Planning and execution should not be considered two separate entities but should be a closed-loop process for optimal cost savings, efficiencies, and contextual insights.”

“We’ve been a strategic Microsoft partner for over five years,” says Kannan. “Our solution has been built ground up on their Azure stack using composable microservices. We leverage 100% of what Azure has to offer.”

“We will be co-piloting with Microsoft well into the future” says Kannan. “Our solutions use conversational AI, machine learning, deep learning, intelligent solvers, advanced heuristics, hyper automations, workflows, and alerts. Microsoft’s Azure stack has made it possible for us to drive accelerated innovation and business value for our customers.”

Gomez works with executives at C-Suite level to “better understand their business problems, how they are organised, and their operating models”. She then shares with them what Microsoft is doing in the wider world for other industries and customers.

She says: “I then go deeper into how Microsoft – with our cloud computing technology, our business applications and infrastructure – can help them transform.”

Crucially, she says, it is people who are always at the centre of my conversation with customers because “people are the lifeblood of how companies manufacture, operate and deliver products”. This approach informs Microsoft about the broader culture at the client, and the right journey and roadmap to help customers with a holistic approach to improve their operating processes and impact their workforce to work in new ways.

Microsoft empowering manufacturing firms to accelerate supply chain innovation

“We help transform everything – people, processes, data, and systems,” she explains, “so that these converge into a new journey that will transform how companies can do more with less, and in a more advanced way.”

So, what are the top supply chain challenges that her customers are facing today?

“The list is enormous,” she says, “but one thing we find most often is that customers need visibility.” This goes back to the effects of the pandemic. The main challenge is endto-end visibility in the value chain ecosystem.

“So visibility to multi-tier suppliers – not only tier one, but also tiers two and three. Also, visibility on customer data, how quickly inventory is turning over, and how the production systems are looking.”

This need for visibility has, according to Gomez, been heightened not only by the pandemic but also the knowledge that “market dynamics can impact supply at any time”.

“Take the Suez Canal blockage, or the Ukrainian war – the latter of which is causing a significant energy crisis impacting how companies operate and the manufacturing volumes they can sustain to maximise energy use.”

Despite difficulties, Gomez feels that, although the world is slowly returning to prepandemic just-in-time inventory models, today’s businesses want advanced digital tools to manage supply chain uncertainties.

Digital cloud-native technologies such as AI, analytics, blockchain, and IoT are helping customers build resilience and more visibility. Hence why end-to-end supply chain ecosystem visibility has become supremely important, she says “to improve production, planning, logistics, and cost efficiencies”.

Another challenge is how organisations can secure their supply chain “all the way to customers”, which she says makes logistics visibility and optimisation vitally important if companies are to achieve operational and financial goals.

Supply problems are in a constant state of flux Gomez and her colleagues at Microsoft seek to bring order to a disordered world, but she concedes that the challenges shape-shift from month to month, and that technology

also needs to change fast also to meet the needs of the evolving industry market.

“The pandemic is largely over but we’re continuing to see labour shortages that are impacting manufacturing industries, and manufacturing is a big piece of enabling the supply chain,” she says.

“People are also retiring younger, and there’s a lack of skilled people who know and understand digital technologies. Businesses have to operate faster to have competitive advantage, so all this is a challenge that’s added into the existing complexity.”

Gomez also references the rampant inflation occurring around the globe: “This is putting a lot of pressure on companies to digitise even faster to reduce their operating costs.

“So, a customer that has already started on the digital transformation journey and is getting close to a higher maturity stage – and that has visibility around suppliers, customers, and manufacturing production – is suddenly hit by spiralling inflation. It can sometimes feel like it’s difficult to keep up, especially if you are trying to do this on your own.”

She adds: “Taxes are also rising, and debt is increasing, and companies need to pass this down to consumers or customers. But to what degree? How far can they go before customers seek out a competitor, whose prices are lower?”

These are the kind of fluctuating dynamics that Microsoft is helping businesses tackle, mainly through its cloud solutions.

AI-enabled cloud products mark out Microsoft as unique for industry digitalisation

Its AI-enabled cloud products mark out Microsoft as unique. They demonstrate the company’s commitment to industryspecific standards and communities, such as the Open Manufacturing Platform, the OPC Foundation, and the Digital Twins Consortium.

Coupled with this is its innovative partner ecosystem, featuring composable and extensible solutions that seamlessly connect people, assets, workflows, and business processes.

“Our technology is giving businesses more intelligence and visibility than ever before, while making operations more adaptable,” she says.

Data is, it seems, the key driving force – both in the need for such solutions and the way in which they operate, as Gomez says: “We realise that though companies have a lot of data, it's siloed so they can't make much sense out of it. So we give them the infrastructure and technology they need to unify this data, helping them gain advanced insight into their supply chain to make better decisions.”

Referencing Microsoft’s partner ecosystems, Gomez says the company “leverages partners to help industry”,

adding: “Every customer wants to prioritise certain aspects of their supply chain, and we have partners that play very well to all these various needs – whether it’s end-to-end or for specific functions of the supply chain.

“We partner with ecosystem companies to bring the operational efficiency and agility that companies are looking for. Most importantly, we recognise customers’ need to simplify the way they work with vendors while ensuring a secure platform that’s flexible and extensible. We built Microsoft Supply Chain Center because we recognise this security and flexibility is very important.”

Gomez describes Microsoft as “the most trusted, secure cloud provider that provides the infrastructure and connectivity to partner solutions”, adding that the very nature of the platform is to recognise that “no one partner has everything a customer needs and so it provides a platform to enable an ecosystem of solutions”.

This ecosystem is helping Microsoft modernise supply chains, which by nature are complex, and involve many operational steps and activities, whether it’s manufacturing, procurement or logistics.

“There are many partners we work with to address the various challenges in supply chain,” says Gomez, “and we bring them together to light up the digital transformation of the supply chain.”

She adds: “Partners are the lifeblood of how we execute transformation. They have deep knowledge of the industry and know what, exactly, is the right solution. And then we, Microsoft, bring our secure and intelligent infrastructure technology

to enable our partner to deliver a solution that is secure and that leverages the best cloud-based digital capabilities and latest solutions to enable customers to become more agile and resilient.”

Businesses, she says, have discovered that operational and supply chain resilience is the key to their competitive advantage; to help them build this resilience, “I encourage customers to work with us to advance their digital journey”.

“The start point is always what they are doing today,” says Gomez. “What's your current state? What are your top operational problems? What is your digital maturity? Then we bring them the digital solutions and roadmaps to help them orchestrate, so they can better plan and optimise to improve their supply chain visibility, execution and logistics models.”

“Most importantly,” she adds, “we deliver all of this in a secure manner, meaning customers can really embrace digital transformation.”

This is where Gomez’s supply chain experience stands her in good stead.

She says: “Before Microsoft, I was part of industry myself. I was a leader of supply chain, and so I understood that supply chain people often don't know how to get started on digital transformations.

“To build resilience, supply chain leaders have to understand how digital capabilities can enhance each step of the supply chain operational process. It’s about working with partners and getting a dynamic going. I think that’s how companies can start their journey toward building a more resilient supply chain.”

LOCAL

Pharmaceutical supply chains are shortening in response to the need for greater resilience, as global uncertainty and instability hold sway

WRITTENBY: SEAN ASHCROFT

Supply chain is a complicated discipline that typically requires highly-trained engineers to oversee the entire process, but pharmaceutical (pharma) supply chains take complexity to another level.

As well as the usual litany of supply challenges, pharma has a cold chain element for vaccines and other temperaturecontrolled medicines, and, because the field of medicine is just about the most regulated sector there is, it also faces the perils of frequent product recalls and compliance issues.

Then, of course, there’s the added pressure of how catastrophic any delays might prove, with the medicines being

shipped critical for either ensuring patients maintain their health or keeping them alive.

Pharma supply chains begin with the sourcing of raw materials – chemicals and ingredients – used to manufacture drugs. The manufacturing process involves several stages: formulation, quality control, packaging and labelling. Once the drugs are ready, they are shipped to warehouses or distribution centres, from where they are distributed to healthcare providers, pharmacies, and hospitals.

The supply chain is also responsible for ensuring products are stored at the right temperature and humidity, and with tracking shipments to prevent counterfeiting and diversion.

“The ultimate goal is to give patients access to the right drug at the right time”

OLAF ZWEIG LIFE SCIENCES PARTNER EY-PARTHENON

The pandemic showed us just how important – and fragile – the pharma supply chain can be. To address these and other challenges, pharma companies are adopting digital technologies such as blockchain, artificial intelligence, and the Internet of Things (IoT) to enhance transparency, traceability, and efficiency in their supply chains.

But in many regards, it is not the ‘how’ of pharma supply chains that is a defining area of change, but the ‘where’, because in the wake of geopolitical instability (RussiaUkraine and China-Taiwan, for example)

“Ggggggg”– and ongoing post-pandemic supply shocks – pharma companies are moving away from globalisation, and towards regional hubs, which help deliver greater levels of flexibility and resilience.

The changing face of pharma supply chain is explored at length by EY, in its paper, Pharma Supply Chains of the Future, one of whose co-authors is Olaf Zweig, a Life Sciences Partner at EY-Parthenon, EY’s global strategy consulting arm.

Zweig says that, regardless of market conditions, those connected to pharma supply chains – whether it’s supply chain managers, policymakers or vendors – must never lose sight of the ultimate goal: to

give patients access to the right drug at the right time.

With this overarching principle in place, Zweig adds that pharma firms looking to regionalise supply must understand that any such strategy will involve costs and benefits, and that the challenge is “to find the optimal balance in each regional context”.

He adds: “While the industry can expect to see some moves toward localisation, these moves are likely to be combined with other new approaches.

“The practical implications of localisation depend on what steps of the supply chain

EY-Parthenon:

UPS uses an AI-powered GPS tool to create the most efficient routes for its fleet

are considered. At the simplest level localisation could just denote companies ensuring local stockpiles of finished goods inventory.”

Zweig explains that the different steps of the pharma manufacturing process entail different levels of investment in order to localise: “A pharma company could relatively easily localise secondary

Packaging. This would entail building a local GMP-approved, licensed site, or outsourcing the same to a local contract development and manufacturing organisation.”

(GMP stands for Good Manufacturing Practice and describes the minimum

TITLE: LIFE SCIENCES PARTNER

COMPANY: EY-PARTHENON

INDUSTRY: LIFE SCIENCES

Zweig leads the health sciences and wellness sector of EY-Parthenon in Europe.

He helps companies to transform within a changing and increasingly digitised health ecosystem. His experience covers strategybased transformation and improvement programmes, supply chain management and resilience.

A better future starts with strategy realised

“Collaboration and cooperation between pharma and stakeholders is key to building resilient and sustainable supply chains”

OLAF ZWEIG LIFE SCIENCES PARTNER EY-PARTHENON

standard a medicine manufacturer must meet in their production processes.)

Zweig adds that such an approach would also require infrastructure to receive and store the primary packaged product from the previous stages of the supply chain. “Carrying out the on-site secondary packaging would need basic additional raw materials, such as cardboard, adhesives and printer cartridges, plus manual labour supplied locally, and the presence of a quality organisation and maintenance team.”

If companies seek to localise earlier stages of the manufacturing process, Zweig states that complexity levels then rise correspondingly, “with increased needs for complex raw materials, skilled labour and higher capital outlay to build sites for highertechnology manufacturing”.

In terms of localising at the earliest stage of pharma supply chains – or API (Active Pharmaceutical Ingredient) manufacturing, which is the biologically active component of a drug product – Zweig says it is “the most significant challenge”.

In its paper, EY concludes that although localising API manufacturing will result in far greater agility, there would be negative impacts on other important supply chain metrics, such as reliability, time to innovate, risk exposure and efficiency.

Zweig says that focusing on the lower-cost, lower-complexity option of localising finished goods rather than the manufacturing process itself “will likely improve the reliability of product supply because more of the product would be locally stockpiled for distribution”. But he also goes on to warn that “this process would

A collective of 19 EU member states have called for the bloc to reduce its dependency on China for medicine supplies.

The countries – including France, Belgium, Spain and the Netherlands – have signed a newly-published paper titled, ‘Improving the security of medicines supply in Europe’, which warns that the EU is too “dependent” on China.

Not only did the paper conclude that Europe’s drug production is too dependent on China, but it urged ministers to compile a list of critical medicines that should be monitored to shore up their supply, production and value chains.

The paper said: “The EU is becoming increasingly dependent on imports from a few manufacturers and regions for its medicines supply, adding a [new] security dimension. In 2019, 40% of all active pharmaceutical ingredients were sourced from China.”

It noted “almost all” active pharmaceutical ingredient producers are now dependent on China for intermediate inputs.

It said: “As a result, Europe, and the world, depends on a few manufacturers for a large bulk of their medicine supply”. The paper’s release coincided with wider supply concerns, as the EU has been forced to confront severe medicine shortages over the past few months.

Essential medicines – such as antibiotics, thrombolytics and insulin –have all been in short supply, as well as antipyretics and painkillers.

be unlikely to significantly enhance any of the other aspects of resilience”. In practice, the merits of localisation must be assessed “relative to alternative options that exist for bolstering pharma supply resilience”.

Such measures might include industrylevel initiatives, such as a procurement clearing house or joint warehouses, company-level measures like multiple sourcing of raw materials, or government-level steps, such as shortening regulatory processing timelines.

company, by the broader industry working collaboratively or by policymakers and regulatory bodies interacting with pharma and having a stake in the future of its supply chain operations.”

“Multiple plausible approaches exist,” says Zweig. “Initiatives can be led by an individual pharma

Wearable digital devices are among the tech developments helping businesses speed delivery and manage customer expectation

He concludes: “Greater collaboration and cooperation between pharma and its stakeholders will be key to successfully building resilient and sustainable supply chains for the future, and delivering the outcomes sought by patients and by all parties in the ecosystem that serve them. But it’s important to say there is no single nor simple path forward from this point.”

“Initiatives can be led by pharma companies, by the broader industry, or by policymakers and regulatory bodies”

OLAF ZWEIG LIFE SCIENCES PARTNER EY-PARTHENON

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

PRODUCED BY: JAMES BERRY

Supply chain is a complicated industry that typically requires highly trained engineers to oversee, but pharmaceutical (pharma) supply chains take complexity to another level.

As well as the usual litany of supply challenges, pharma has distinct requirements on the handling of materials like a cold chain element, and also faces the perils of product recalls and compliance issues, because the field of medicine is just about the most regulated sector there is.

And then of course there’s the added pressure of how catastrophic any delays might prove, because the medicines being shipped are critical for ensuring patients have access to the medicines they need to maintain their health, or even keep them alive.

While there is a variety of permutations, the most prevalent today is the small molecule pharma supply chain. This chemical-based drug will typically begin with the sourcing of raw materials – active pharmaceutical ingredients – used to manufacture drugs. The manufacturing process involves several stages: formulation, quality control, packaging and labelling. Once the drugs are ready, they are shipped to warehouses or distribution centres, from where they are distributed to healthcare providers, pharmacies and hospitals.

For other forms, like biologics or vaccines, the supply chain is required to keep these volatile medicines stored at the right temperature and humidity, with tracking shipments to prevent counterfeiting and diversion.

To address such challenges, pharma companies are adopting digital technologies such as cloud, blockchain, artificial intelligence and the Internet of Things (IoT) to enhance transparency, traceability and efficiency in their supply chains.

One company that is helping pharma firms digitally transform operations is Microsoft,

“My role is about being a trusted business advisor to empower our top global customers with expertise and proven practices to accelerate their digital strategy”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

and at the forefront of its offerings is Mike J. Walker, Executive Director, Strategy, Health & Life Sciences.

In his role, Walker is the strategy leader for Microsoft’s supply chain and manufacturing point of view on pharmaceuticals, med-tech and biopharmaceuticals.

“My role is about being a trusted business advisor to empower our top global customers with expertise and proven practices to accelerate their digital strategy,” he says. “Ensuring that these conversations are business-led with a keen understanding of the pharma business along with the external market risks. As with all industries, technology is always part of that conversation, but the key is to ensure that

TITLE: EXECUTIVE DIRECTOR, GLOBAL HEALTH & LIFE SCIENCES STRATEGY

LOCATION: UNITED STATES

Mike J. Walker is an entrepreneur, futurist, digital strategist, podcast host, global keynote speaker and a best-selling author with a specialty in helping business executives stay relevant in the digital economy.

Walker brings paradigm-shifting digital transformation by leveraging leading innovation practices through experiences with Fortune 500 leaders around the globe.

He has found success in driving pragmatic approaches to large scale problems, an ability to break down large complex challenges into something manageable, along with an insatiable need to bring teams together.

Currently at Microsoft, Walker leads a team focused on life science supply chains and manufacturing.

He acts as a trusted advisor to executives, helping them with some of their toughest challenges. This includes how pharma organisations digitally transform using digital ecosystems, digital twins, AI, IoT and blockchain.

How cloud-based supply chain management specialist Kinaxis is helping pharma navigate transformation, in partnership with Microsoft.

Microsoft’s Azure ecosystem is helping businesses modernise supply chains worldwide, and Kinaxis is at the heart of this important process. Kinaxis provides cloud-based supply chain management (SCM) software called RapidResponse, built on prescriptive AI and automation. This provides organisations with supply visibility and resilience. Supply chains are by nature complex, and involve many operational steps and activities – whether this is manufacturing, procurement or logistics.

Using RapidResponse, planners can create disruption scenarios – such as severe weather events, material shortages or major surges in demand – and use this to make informed decisions, with business outcomes, customer needs and sustainability in mind.

Giovanni Pizzoferrato is Kinaxis CTO and helps define the technology strategy of its customers globally. “We are an amazing global team of engineers and experts,” he says. We are grounded in a ‘people matter’ culture built over nearly 40 years.” It’s a culture Kinaxis brings to its customers through Microsoft Azure,

the cloud computing platform that facilitates access, management and development of applications and services through global data centres. Kinaxis is a Microsoft Independent Software Vendor partner, and co-sells RapidResponse through the Azure Marketplace, where businesses seek out Azure-optimised software solutions.

“We work closely with Microsoft’s industry verticals teams, and interoperate with the MS Supply Chain Frameworks and Cloud Solutions,” explains Pizzoferrato. In terms of pharma supply chains, Kinaxis helps some of the world’s leading pharma companies manage supply chain complexities that are unique to areas like biotechnology, cell and gene therapy, medical devices and over-thecounter medicines. “The regulatory environment is very complex in pharma,” says Pizzoferrato, “so our software uses embedded, attribute-based planning specifically for this challenge.”

He adds that “expiry management” is another critical part of the pharma landscape. “Planners use RapidResponse to get a clear view of what’s on-shelf, what’s about to expire, what the demand patterns look like and what supply plans will meet consumers’ future needs.”

those technology conversations are focused on how strategically relevant they are to your businesses long-term goals. Once we know that, we can have a conversation on how to maximise the value potential of those technologies. That is what really matters for my client’s executive teams.”

Typically, Walker partners with “decisionmakers” – C-suiters both on the business and technical sides of pharma organisations.

The most challenging aspect of the role, he says, is “the pace and the sheer amount of change happening”. He adds: “When you peel back the onion you find each has subtly different business drivers, different cultures, different personalities and leadership styles. It requires you to employ a level of emotional intelligence to your approach. ‘This is the right answer’ is something that never flies.

Microsoft helping pharma supply chains navigate change

‘I am like a counsellor, only without the couch’

“Instead, provide the executive with a framework to work within and let them drive the conversations based on the guided journey and lots of questions. I am there to shepherd them through proven practices, almost like a counsellor, only without the couch.”

Another challenge stems from the nature of the pharma industry itself.

Walker says: “What most needs changing in pharma supply chains is the legacy mindset and a culture of risk aversion. These organisations fall into the trap of thinking they can’t do something because they’ve always done it that way. With this mindset they don’t ask the right questions.”

Questions, he says, such as: How do we create this experience within the bounds of the rules? Will the market dynamics change that would make this a viable solution? What is the level of risk tolerance we are willing to take? How can we partner with the regulatory bodies to influence change?

On the latter point, Walker says that, in his experience, regulatory bodies like the FDA are “very willing to hear you out if you've got a compelling approach to solving industry challenges”.

As for barriers to digital transformation, Walker says that here things are playing out just as they have in other sectors.

“I see lots of barriers other industries have gone through and have overcome,” he says. “It just takes time. The nice part of having a cross-industry background is I've seen how other supply chain organisations have dealt with this level of change.”

This is why Walker likes to take biopharma clients to visit Microsoft customers in other fields, such as consumer goods. He has also taken them on visits to brewing giant ABinBev Anheuser-Busch.

“Brewing beer is very similar to what a biologics organisation does,” he explains, “so showing them what is possible in a less complex environment is a worthwhile thing to do.”

Technology obsolescence is another hurdle, 65% of manufacturing environments run outdated operating systems, he says.

“Even though the intent is to update technology and software, if you’ve got manufacturing equipment running Windows XP on devices supporting your biologics

manufacturing lines, you can’t just shut it down and replace it because that could impact the entire batch worth millions of dollars.”

He adds that from a strategy perspective the challenge is “to not only fix the current problem, but to create an evergreen model that prevents obsolesce from happening to begin with”.

Of course, some of the barriers to transformation in pharma differ to other sectors, particularly around regulation. The FDA’s Drug Supply Chain Security Act (DSCSA), a single federal framework for tracing prescription medications through the supply chain, is challenging the pharmaceutical sector to reach data transaction targets by November 2023.

“We need visibility across the entire value chain, and you can't do that in a sequential, linear, compartmentalised way”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

“There is much less scrutiny on manufacturing a beer versus a vaccine,” says Walker. “Medicine is treated very differently not only from a supply chain perspective but also from a manufacturing and a sourcing perspective.”

Pharma regulatory environment is unique

He adds: “The entire supply chain looks a little bit different, and the regulatory environment is unique. In an automotive company's supply chain, for example, they don't necessarily have to tell a regulatory body the specific specs of the machines that they will use to make that product.“

And of course, like all businesses across all sectors, pharma organisations are getting

hit from all sides. There’s a rising need to be more sustainable, materials cost more, increased energy costs – especially in Europe – which drives the impetus to do more with less cost. They're also getting hit from a geopolitical perspective, like the war in Ukraine but also, says Walker, economically from a global trade and tax perspective.

“In China for example, there is an increase in operating costs of doing business in China, especially for manufacturers with aspects like minimum wage increasing between 30% and 65% in recent years. Tax rates are also higher across the board due to a unified corporate tax, and with China’s new cybersecurity and privacy regulations, they

have the potential to transform how pharma companies conduct business in China. The most pressing question I hear from pharma executives is, should we stay or should we go.”

Walker also points out that the pharma industry is being disrupted by smaller biotech firms, along with tech-savvy companies. He likens what’s happening here to how Uber and Lyft have changed the taxi business.

“It’s the same in the pharma industry, where you've got countless small biopharmas that, from an R&D perspective, are pumping out way more patents than the traditional players.

“A lot of that has to do with their ability to be nimble and they also leverage technology at its fullest. With the bigger organisations you've got a big ship to turn, and you've got a lot of moving pieces.”

Technology is a conversation for later in the relationship

Technology is vital, but Walker says it is “always a conversation I have later in the relationship”. But it is very much a conversation that needs to be had, because many supply chains as they stand are simply ill-suited to being digitally transformed.

“Supply chains can be very linear,” he says. “The connections between the ecosystem of partners can be brittle and fragile, and there is a growing need to make sure supply chains are modular, dynamic and provide transparency across the entire value chain –and you can't do that in a sequential, linear, compartmentalised way with technology.”

He adds: “You have to do it in a way now that is much more decentralised than what it was before. There's a significant amount of processes around reconciliation of data that is introduced because of that.”

“

Many of my customers are regional ecosystem hubs that serve specific markets”

MIKE J. WALKER EXECUTIVE DIRECTOR GLOBAL HEALTH & LIFE SCIENCES STRATEGY, MICROSOFT

Walker observes that this requires “an ecosystem approach” – supported by a common “data fabric” that allows organisations to digitise their supply chains in a meaningful way.

On this note, Walker has partnered with Kinaxis, a ‘visionary leader in supply chain’ solutions, according to analyst firm, Gartner.

Walker believes that leveraging the power of the Microsoft Azure cloud platform together with Kinaxis' solutions will provide pharma organisations with an agile and autonomous supply chain platform,

which are essential in today's rapidly changing business environment.

He says: “This combination of capabilities enables a digital ecosystem platform for pharma supply chains that uses advanced analytics and artificial intelligence to analyse data from across the supply chain, including suppliers, customers, and internal systems.

“It can also integrate with other systems, such as ERPs, MES, CRMs, and logistics systems, to provide a comprehensive view of the entire supply chain.

Walker recounts a past conversation he had with a pharma company.

“They were talking about how one of their key priorities is to digitise all instances of paper use,” he says. “On the surface

“But I asked if this meant putting scanners into their factories at each process-step to make sure that all paper was scanned, and then entered into a document management system.

“Then I asked if they wanted instead to solve the root problem, which was fundamentally how to reinvent the business process and how data is handled.” This, he says, requires a rethink of the organisations’ relationship with data

Walker says he knows of pharma organisations that are leveraging digital twins for an end-to-end view of their supply chain. But does this tick all the boxes that need to be ticked, even? Probably not, he feels.

“When you look at these digital twins there's different levels and types. You have layers of digital twins that coexist within an organisation. Some represent the asset itself. Some represent the people and the interaction. Some represent the process, and others represent the facility or the

Walker says that what is needed, and often lacking, is a strategy around creating “a common data platform that is able to create digital threads to connect all of this data”, and “a full genealogy of everything that was involved in the creation of all these layers of digital twins”.

What makes Microsoft unique is our commitment to industry specific standards

and communities, such as the Open Manufacturing Platform, the OPC Foundation, the Digital Twins Consortium and our innovative partner ecosystem, coupled with composable and extensible solutions that seamlessly connect people, assets, workflows and businesses processes. Our technology is giving businesses more intelligence and visibility than ever before and making operations more adaptable.

Looking at the bigger geopolitical picture, Walker says pharma companies are changing the shape of their businesses, by stepping away from globalisation.

“I've heard from four very senior executives in the pharma supply chain that globalisation as an approach is dead,” he says. “Now it's more about de-globalisation and modularity. Many of my customers are creating an ecosystem of ecosystems strategy whereby they are regional ecosystem hubs that serve specific markets. However, each one of these is still loosely connected and provides a level of autonomy but also flexibility.”

Walker references McDonalds here because “they solved this problem in the fifties with the franchise model”.

He adds: “Why make every one of your factories unique and bespoke when you can create a franchise model that provides speed, modularity, and flexibility through a common set of methods and standards? For example, maybe it would be possible to take an oral solid dose drug and make the manufacturing and supply chain 90% standard across all applicable factories.

“This also gives you a level of nimbleness and agility in the marketplace that you won't have in linear supply chains with bespoke factories.”

Last-mile logistics is facing generational change as well as huge challenges like rising costs and labour shortages, but technology is helping ease the burden

WRITTEN BY: SEAN ASHCROFT

The COVID-19-sparked ecommerce boom has shown few signs of fading, and the omnichannel retail model is an increasingly important part of many businesses’ logistics solutions. With omnichannel, come new logistics challenges and opportunities. It has made logistics more complex, because the last mile now involves multiple sales channels, such as online platforms, physical stores, and mobile apps.

Logistics providers must handle diverse order types, fulfilment methods, and delivery options. Retailers need excellent inventory visibility across multiple channels, as well as flexible micro-fulfilment solutions to ensure goods can be delivered in good time, often on a postcode-by-postcode basis.

Adaptability and flexibility are the watchwords of last mile, because it’s about being as physically close to as many

customers as humanly possible. It’s a challenging, dynamic landscape, and that’s before retailers have even factored in rising operational costs.

Advanced tech – such as AI, machine learning and IoT – plays a vital role here, helping to optimise delivery routes, manage real-time tracking and to enable efficient resource allocation.

“Automation, AI, and other leading technologies can make all the difference, and I am seeing the benefits with our clients,” says Capgemini Global Retail Lead Lindsey Mazza.

She adds that Industry 4.0 technologies in product and supply chain planning processes not only maximise the use of labour, and help companies meet sustainability objectives, but also help ensure that last-mile consumer fulfilment can support optimised costs.

She adds: “For example, analytics can be used to reduce inventory, identify underperforming areas, and recommend solutions to increase efficiency.

“Using real-time data and intelligent integrated planning, consumer products companies and retailers can customise the right assortment mix, and have the right inventory for each store or channel.”

“Analytics can reduce inventory, identify underperforming areas and help find efficiencies”

LINDSEY MAZZA, GLOBAL RETAIL LEAD, CAPGEMINIThe global last-mile delivery market is projected to reach $288.9bn

by 2031

She also says that autonomous vehicle delivery, although early in development, “could transform the last-mile delivery cost model”. Much-needed urban warehouse capacity is in short supply, as is the labour needed to staff them – but automation is helping ease both issues, says Honeywell.

The ecommerce boom that began during the pandemic is now less a boom and more like the ‘new normal’ for logistics.

But cost inflation is just one of the ‘new normal’ challenges facing retailers and logistics companies. Another is the sky-high demand for warehousing and micofulfilment centres to store and ship goods.

This has led to an acute shortage of available warehouse space in urban areas.

To address this issue, companies are looking at storage options that include

Lindsey MazzaTITLE: GLOBAL RETAIL LEAD

COMPANY: CAPGEMINI

INDUSTRY: PROFESSIONAL SERVICES

“I’m here to solve problems,” Mazza says of herself. “My passion is collaborating to create innovative solutions to the challenges that keep retailers up at night. If there is a better way, we’ll find it together.”

“Autonomous vehicle delivery could transform the last-mile delivery cost model”

LINDSEY MAZZA, GLOBAL RETAIL LEAD, CAPGEMINI

Keith Fisher

TITLE: PRESIDENT, WAREHOUSE AUTOMATION

COMPANY: HONEYWELL INDUSTRY: IT

Honeywell IT solutions can be found across all industries. It has 110,000 employees worldwide, including 19,000 engineers and scientists. Prior to his current post, Fisher spent 19 years with Honeywell Aerospace.

shared warehousing, or they are outsourcing logistics to third-party providers (3PLs).

There is also increasing pressure on governments to help businesses react to new consumption trends, by investing in infrastructure to support the growth of logistics and warehousing industries.

These are serious operational and infrastructure problems, but there is another, much more immediate and pressing, warehouse problem: labour shortages.

Keith Fisher is President of Warehouse Automation for Honeywell, the US multinational business that specialises in aerospace, building technologies, performance materials and technologies, as well as safety and productivity solutions

Fisher says the labour shortage is the most pressing challenge being faced by warehouse operators, especially across

“Automated sorting equipment is enabling companies to offset labour shortages”

KEITH FISHER, PRESIDENT OF WAREHOUSE AUTOMATION, HONEYWELL

Europe: “Across the continent, the past 12 months have seen a decrease in workforce availability across all industries, with the warehousing and logistics sector being one of the most at-risk.”

In the UK alone, 86% of organisations are experiencing staff shortages in warehousing, according to The Chartered Institute of Logistics and Transport. Like Mazza, Fisher says a saving grace for warehouse operations has been automation: “Not only is automation meeting the growing demand for faster order fulfilment, driven by consumer expectations amid the rise of e-commerce, but it is also being used to gaps caused by labour shortfalls.”

Fisher cites “intelligent automated sortation equipment” as an example.

“This is enabling many companies to offset labour shortages,” he says. “Sortation

Businesses that allow tough market conditions to impact their supply chains face losing customers, who are no longer listening to excuses, warns BDO.

BDO is an international network of public accounting, tax, consulting and business advisory firms that form the fifth-largest accounting network in the world.

It recently published its 2023 Manufacturing CFO Outlook Survey, in which it reveals that supply chain visibility is a priority for 42% of manufacturing Chief Finance Officers (CFOs).

The MD of BDO’s Supply Chain Advisory practice, RJ Romano, told Supply Chain Digital: “The message is clear; supply chain performance is pivotal for manufacturers this year.

“Customers aren’t listening to excuses about disruption anymore. They want to see improvements, and it’s on manufacturers to deliver them.

“Going from shortages to surpluses is difficult to navigate. Having clear visibility throughout the supply chain, especially from a planning and forecasting perspective, is key.”

technology boosts efficiency by combining items from multiple locations, to improve order processing time and accuracy.

He says it also “quickly directs products to proper staging and shipping lanes”. Fisher also says that autonomous mobile robots (AMRs) are emerging as another invaluable asset for warehouse operators.

He says: “AMRs can easily be integrated into existing operations to transport products efficiently through the warehouse on non-linear paths. This cuts reliance on staff to push loaded carts or drive or forklifts, freeing up capacity for other tasks.”

Fisher believes this collaborative approach to automation tech is the gold standard when it comes both to easing warehouse labour issues, and the pressing need for lightning quick last-mile logistics.

The global micro-fulfilment market was worth $3.53bn in 2022 and is expected to to hit $113.84bn by 2032

“It is the ideal way to use these emerging technologies. It reduces repetitive tasks that are not the most effective use of people’s time.”

So, although last-mile logistics is an increasingly testing area for companies, they can at least draw upon ever-improving technology to help them meet these challenges.

“Autonomous mobile robots are emerging as an invaluable asset for warehouse operators”

KEITH FISHER, PRESIDENT OF WAREHOUSE AUTOMATION, HONEYWELL

The Global Supply Chain Awards 2024 will be celebrating the very best in Procurement & Supply Chain with the following categories:

Procurement Transformation Award

–Digital Supply Chain Award

–Global Logistics Award

–Supplier Diversity Award

–

Supply Chain Innovation Award –

Supply Chain Sustainability Award –Procurement Technology Award –

Procurement Consultancy Award –Future Leader Award –Executive of the Year Award

–Project of the Year Award –

Lifetime Achievement Award

Bridgestone, a global leader in tyres and sustainable mobility solutions, was founded in 1931 by Shojiro Ishibashi. The company’s name is a direct translation of the Japanese word ‘Ishibashi’ into English. Its main mission is to serve society with superior quality. Bridgestone takes pride in delivering a wide range of best-in-class tyres and solutions that cater to the evolving mobility needs of its such as data-driven services, telematics, sensor devices, and tyre management systems. These solutions enhance productivity, cost efficiency, and sustainability. By equipping fleets with data intelligence and sensor technology, Bridgestone enables them to maintain their vehicles and provide optimal service. This combination of tyre manufacturing and mobility solutions defines Bridgestone as a mobility-driven solution company.

Lars Bettermann is the CPO for Bridgestone EMIA, overseeing procurement operations in Europe, the Middle East, Africa and India. He leads a team of around 150 procurement professionals to drive the company’s procurement activities into the future.

Lars Bettermann’s professional journey in procurement began approximately 25 years ago when he joined Ford Motor Company. Prior to that

LARS BETTERMANN CPO EMIA, BRIDGESTONE

“Proximity to stakeholders ensures that the procurement team comprehends their needs and can effectively serve them”

he says, he never imagined procurement to be such an interesting place to be.

“My time at Ford became a transformative experience, allowing me to fill my toolbox with the most essential procurement skills.” Lars Bettermann gained expertise in supplier negotiations, establishing long-term agreements, and understanding the critical interdependencies within the value chain, spending several years at Ford; building a strong foundation for his work in procurement.

In his current role, he now has full responsibility for all procurement activities in the EMIA region.

LARS BETTERMANN CPO EMIA, BRIDGESTONE

“In the value deliver chain, a crucial role is played by close partnership with suppliers, moving from a cost factor to a strategic long-term collaboration”

TITLE: CPO EMIA

COMPANY: BRIDGESTONE

Lars Bettermann is a procurement expert, having 25+ years of professional experience in procurement relevant subjects and project scope. He holds a university degree in business administration. His know-how is based on the operational fundament he built up in the automotive sector enhanced with the methodical and strategic application in strategic sourcing project, being a strategy consultant for more than a decade. Today he is heading procurement at Bridgestone EMIA as a CPO, holding responsibility for all source-to-pay activities across the company.

Over the course of its nearly hundredyear history, Bridgestone has witnessed significant changes and advancements. Its fundamental product - the tyre - has undergone remarkable developments to become more performant, efficient, safe and sustainable over time.

More than 5 years ago, the company embarked on a transformation into a mobility solutions company to ensure it captures business opportunities arising from data and digital transformation offering efficiency and convenience .

By diversifying into mobility solutions, Bridgestone has positioned itself for the future, offering a balanced mix of products and services to meet evolving market needs.

When Lars Bettermann joined Bridgestone two and a half years ago, he identified an opportunity to further leverage the value that procurement could bring to the organisation.

At that time, the procurement department primarily focused on raw materials procurement. Lars Bettermann initiated a transformation journey to enhance the procurement function, which is still ongoing.

The transformation efforts encompassed several key aspects:

Firstly, there was a strong emphasis on upskilling the existing raw materials team. Significant investments were made in providing additional training and equipping the team with the necessary tools and resources to drive even more value in their procurement activities.

Secondly, a new procurement department was established to cater to CapEx (Capital Expenditure) and Bridgestone’s indirect procurement needs; focusing on equipping the company’s plants with all the machinery they need in manufacturing their tyres, as well as understanding the needs of the business in the headquarter and the sales offices.

Lars Bettermann’s vision was to have a team that closely understands the requirements of internal stakeholders. He says, “Proximity to stakeholders

ensures that the procurement team comprehends their needs and can effectively serve them.”

Thirdly, Bridgestone entered into a strategic partnership with Accenture for managing indirect procurement categories.

Lars Bettermann says this decision was driven by the desire to achieve operational efficiency from the outset and to tap into Accenture’s expertise in areas that are not Bridgestone’s core competency. “The partnership with Accenture enabled Bridgestone to benefit from specialised knowledge and industry insights in categories such as travel, IT, spare parts and logistics.”

LARS BETTERMANN CPO EMIA, BRIDGESTONE

“Rooted in the visionary mindset of founder Shojiro Ishibashi, our E8 commitment recognises the importance of businesses in contributing to societal wellbeing”

This approach allowed Bridgestone to optimise the utilisation of resources and ensure access to the best market offerings in those areas. Lars Bettermann points out that the success of this transformation relies on the unified commitment of the entire team, regardless of whether they are from Accenture or Bridgestone.

“The shared goal is to prioritise stakeholder relevance, maintain close collaboration, and deliver the best value from a procurement perspective,” he says. These three components continue to drive the team’s day-to-day activities as they progress on their transformation journey.

Lars Bettermann says the primary objective of a procurement professional is to effectively manage all the company’s spends in the market. “This involves ensuring that all demands are driven through the appropriate procurement channels and avoiding ad hoc purchasing outside of the established processes.”

Recognising the need for a centralised and user-friendly platform, Bridgestone launched its procurement portal, known as B-Store, on January 1st, 2022.

The B-Store portal serves as a single access point for all employee demands.

“B-Store’s purpose is to guide users to the proper channels based on their specific needs,” says Lars Bettermann. “For instance, if an employee requires travel-related services, they can access the portal, click on the travel button, and swiftly be directed to the dedicated travel portal. Similarly, employees seeking spare parts or office equipment can easily locate the relevant catalogues or submit their demands for processing and assistance from the shared service centres.”

The implementation of the procurement portal was crucial for the day-to-day success of Bridgestone’s procurement activities. Lars Bettermann likens the portal to a supermarket that needs to be well-stocked and attractive to employees - encouraging them to use it as their go-to resource.

The B-Store is powered by SAP’s widely-recognised Ariba tool. Lars Bettermann says that the key challenge however, lies in effectively implementing and making the tool work for the organisation’s specific needs.

“Throughout the year 2022, Bridgestone focused on ensuring the functionality and user-friendliness of the B-Store. They initiated a hands-on approach by guiding employees through the portal, both at manufacturing facilities and in various offices, including the headquarters and the more than 20 regional sales offices,” he says.

“By providing the necessary support and guidance, Bridgestone aimed to familiarise employees with the B-Store and facilitate their ability to find and fulfil their procurement requirements. Now, after 17 months since its launch, we consider the buying platform to be a success. While we have not yet achieved 100% adoption, the usage rates have significantly increased, demonstrating positive progress.

The continuous growth in numbers and positive feedback we are seeing, reaffirm that we are on the right track, and we remain committed to further enhancing its effectiveness and adoption rate.”

The Bridgestone E8 Commitment was established in early 2022 as Bridgestone’s global corporate commitment. It represents the company’s dedication to delivering value to society, customers and future generations. “Rooted in the company’s mission to serve society with superior quality, our E8 commitment recognises the importance of businesses in contributing to a sustainable future,” says Lars Bettermann.

The E8 Commitment encompasses eight focal points that serve as guiding principles for Bridgestone’s strategic priorities, decision-making, and actions worldwide. These focal points are:

• Energy

• Ecology

• Efficiency

• Extension

• Economy

• Emotion

• Ease

• Empowerment

They provide a comprehensive framework for the company’s sustainability efforts, ensuring alignment and coherence across all regions and aspects of Bridgestone’s operations. The E8 Commitment is seen as a powerful expression of Bridgestone’s commitment to conducting business in a sustainable manner. It establishes clear goals and targets for the company to strive towards, facilitating its progress towards a more sustainable and responsible future.

People, planet and procurement-diversified Lars Bettermann’s goals involve supporting the company’s sustainability targets for being 50% CO2 reduction neutral by 2030, and 100% by 2050 with 100% sustained material. This can only be reached by establishing the right partnerships and ecosystem. Another key aspect is the creation and management of a cohesive team of procurement professionals who can effectively communicate and work together.

Lars Bettermann recognises the value of diversity within the team, highlighting that individuals bring different backgrounds,

cultures and experiences. As a leader, he believes in harnessing the strengths of these diverse components to achieve success. Effective communication plays a crucial role in motivating the team and meeting daily challenges.

Bridgestone’s approach to partnerships

Bridgestone relies on a wide range of partners for success. Rather than listing all 20,000 suppliers, he focuses on the concept of partnership itself. “To ensure a sustainable future,” he says, “Bridgestone requires partners in specific core categories and key raw materials necessary for tyre production.

1931 Bridgestone was founded by Shojiro Ishibashi. The company’s name is a direct translation of ‘Ishibashi’ into English

“There are three critical ingredients for tyre manufacturing: steel cord, synthetic rubber, and carbon black. Bridgestone recognises the importance of

“B-Store’s purpose is to guide users to the proper channels based on their specific needs”

these materials in achieving its sustainability goals, particularly in implementing circular economy practices. By maximising the use of tyres and extracting valuable components for recycling, Bridgestone aims to create a circular flow that supports the production of new tyres. Considering these core categories, the partners especially in steel cord, synthetic rubber, and carbon black become vital for Bridgestone’s success.”

He suggests that failure to secure reliable partners in these areas would hinder the company’s ability to achieve its targets. “However,” he says, “it’s essential to acknowledge the significance of all partners, including those involved in all other raw materials but also in machinery, marketing, IT, consulting, logistics and others.”

It is the entire ecosystem of partners that contribute to building

LARS BETTERMANN CPO EMIA, BRIDGESTONE

“The goal is to prioritise stakeholder relevance, maintain close collaboration, and deliver the best value from a procurement perspective”

the necessary foundation and ecosystem for Bridgestone’s operations.

Lars Bettermann says in the next 12 to 18 months, Bridgestone will be focused on several key priorities. “Firstly, we need to prepare ourselves to meet our 2030 targets for sustained materials. This entails establishing the right partnerships, driving innovation, and developing the optimal mix of raw materials to continue building premium tyres.

“Additionally, we have encountered challenges due to global crises like the Russian-Ukrainian war.

“The impact of these crises on our supply base has been significant. In 2022, we dedicated substantial effort to de-source materials and seek alternative