IN THE Logistics chief Ashley Naughton on how McLaren is changing at a speed fitting for the maker of Earth’s fastest road cars June 2023 | supplychaindigital.com FAST LANE 5PL Providers UST | KEARNEY | UBER FREIGHT | MICROSOFT FEATURING:

A BizClik Event Join the Virtual Event Disrupting Procurement & Supply Chain 28TH JUNE 2023 VIRTUAL CONFERENCE

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Sponsorship Opportunities

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.

▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

The Digital Platform for Suply Chain Leaders

MAGAZINE | WEBSITE | NEWSLETTER + MORE JOIN THE COMMUNITY

Ways to Work With us

Supply Chain magazine is an established and trusted voice with an engaged and highly targeted audience of 550,000 global executives

Digital Magazine

Website

Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

WORK WITH US

The SupplyChain Team

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

PROOFREADER

JESS GIBSON

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN/

SUPPLYCHAIN LEAD DESIGNER ANDY WOOLLACOTT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

JULIA WAINWRIGHT

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION

MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANNA

SALLY MOUSTAFA

JINGXI WANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KAYLEIGH SHOOTER

PROJECT DIRECTORS

MIKE SADR

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

THE COMMUNITY

JOIN

+

AI IS RESHAPING SUPPLY CHAIN

TECH IS ENABLING ORGANISATIONS TO EVOLVE FASTER THAN EVER, AND OFTEN IT’S KNOWING WHERE TO START THAT THE BIGGEST CHALLENGE

AI is taking over the world, or so some press reports would have us believe. It’s certainly playing an increasingly important role in supply chain, allowing companies to optimise and streamline in many ways.

Organisations are evolving faster than ever, and they need to focus on high-impact priorities, which can be tough, when you’re drawing in data, internal processes, and endless administrative tasks.

The number of products claiming to meet this challenge is bewildering, yet a one-size-fits-all fails to cater to the uniqueness of every business. It’s complicated.

But one thing we pride ourselves on here at Supply Chain Digital is drawing clarity from complication. To that end, in this issue we turn to AI guru Dr Adnan Masood, an engineer, researcher, and thought leader with UST.

Masood explains how AI is all about “creating a repeatable approach to processes throughout an organisation”, and “unlocking a company’s human ingenuity”.

Read on for more insight on this and on myriad other aspects of running efficient and clean supply chains.

SUPPLYCHAIN DIGITAL MAGAZINE IS PUBLISHED BY © 2023 | ALL RIGHTS RESERVED supplychaindigital.com 7

FOREWORD

SEAN ASHCROFT

sean.ashcroft@bizclikmedia.com

“AI is about unlocking a company’s human ingenuity”

DR ADNAN MASOOD, CHIEF AI OFFICER & LEAD ARCHITECT, UST GLOBAL

CONTENTS

UP FRONT

014 BIG PICTURE

Bangladesh floods dampen rice supply chain

020 LIFE TIME ACHIEVEMENT

Dr Randhir Thakur: The Intel chief supply chain officer who has made the step up to CEO with one of India’s biggest businesses

024 FIVE MINS WITH Mariel Read, about the point at which technology meets public procurement is where lives can be improved

020

014 126 8 June 2023

024

026 042 052 072 supplychaindigital.com 9 026 MCLAREN Automotive Logistics Director Ashley Naughton on how McLaren is transforming at pace 042 BAE/SUPPECO How supplier relations platform Suppeco helped BAE’s AI Labs 052 BECTON DICKINSON Ensuring a resilient, responsible and agile supply chain 072 SUPPLY CHAIN Digitalisation means customers really are king 126 TOP 1 0 Fifth-party logistics providers JUNE 2 023 FEATURES

Business Design Centre, London

2023

26 - 27 September

GET YOUR PASS SPONSORSHIPS A BizClik Event Join the Event Disrupting Procurement & Supply Chain

Microsoft empowering manufacturing firms to accelerate supply chain innovation 82 June 2023 PRODUCED BY: JAMES BERRY WRITTEN BY: SEAN ASHCROFT 082 096 106 gettyimages1443559562170667a.jpg JUNE 2 023 supplychaindigital.com 11 082 MICROSOFT Yury Gomez – Microsoft’s Process Industries lead – explains why the company’s tech ecosystem is driving change 096 LOGISTICS Tackling the logistics labour issue is no small job 106 SUSTAINABILITY Circular supply chains –good for the planet and profitability 118 TECHNOLOGY How AI is helping deliver smarter supply chains

THE TOP 100 COMPANIES IN SUPPLY CHAIN Discover the companies leading the way, setting the pace and inspiring global business change. COMING SOON Join the community Sponsor opportunities Digital Content for Digital People

BIG PICTURE

14 June 2023

Bangladesh floods dampen rice supply chain

Sylhet, Bangladesh

Bangladesh is one of the most floodprone countries on Earth. Flooding is normal during the monsoon season here, but 2022 was unprecedented.

In July, flooding in the region of Sylhet impacted 7.2 million people, with paddy fields washed away.

Bangladesh is the fourth largest ricegrowing country, producing 7.8% of the world’s total.

This is why the country needs a supply chain that is resilient to extreme weather. Five similarly catastrophic floods since 198 have cost the country a total of $8.4bn.

supplychaindigital.com 15

Dr Randhir Thakur

CEO and MD of Tata Electronics

CEO and MD of Tata Electronics

“As CSCO, it was my job to enable Intel’s product lifecycle, from research and development to high-volume manufacturing”

If one needs any proof that the stock of senior supply chain executives is rising, then Dr Randhir Thakur provides it.

In April this year, Thakur was announced as CEO and MD of Tata Electronics, a company that provides electronic solutions to industries including automotive, defence, aerospace, and healthcare. It is a subsidiary of Tata Sons, one of the largest conglomerates in India.

It is a key appointment, and interesting because Thakur has a supply chain pedigree, which is not a discipline that typically has provided a pathway to CEO status. More usually, it is the CIO or COO who tends to fill that role.

Tim Cook at Apple has long been the exception that proves this rule, but now chief supply chain officers are being seen as executives that carry a good deal of strategic weight. And so it is with Thakur.

Prior to joining Tata, Thakur was President of Intel Foundry Services. This is a business unit within Intel Corporation that was announced in March 2021. It provides chip foundry services, meaning Intel will manufacture chips for other companies. (This was a significant departure for the company, which

historically has produced only chips for use in its own products.)

That in itself was a key strategic appointment, and Thakur put himself in pole position for it thanks to his track record as Intel’s Chief Supply Chain Officer, a position he held for three years and five months.

As Intel CSCO, he was responsible for managing the company’s external ecosystem across technology, design, manufacturing, and product supply chain. “It was my job to enable Intel’s product life cycle, from research and development to high-volume manufacturing,” he says.

His team also managed Intel’s corporate sourcing and procurement, supply chain operations, as well as worldwide planning and logistics.

“In this capacity, I was responsible for Intel’s multi-billion dollar annual spending with external suppliers and partners ecosystem,” he says.

He also oversaw a global team of 4,000 employees including engineers, negotiators, data scientists, analysts, program managers, planners, buyers, solution architects, and product supply chain architects.

Prior to Intel, Thakur held leadership and technical positions at Applied Materials and SanDisk Corp, before which he was with STEAG

LIFETIME ACHIEVEMENT AWARD

supplychaindigital.com 17

The Intel chief supply chain officer who has made the step up to CEO with one of India’s biggest businesses

WATCH NOW

The Future Of Manufacturing

Electronic Systems and Micron Technology. To say his experience is broad is to understate it. In total, Thakur has 40 years’ experience in global manufacturing, research and development, and profitand-loss management, and he has made significant contributions to advancement of advanced semiconductor technologies.

And now Thakur is bringing all that experience to bear at Tata Electronics. Headquartered in Bangalore, its offerings include electric and hybrid vehicle solutions, telematics and infotainment systems, advanced driver-assistance systems, and electronics for aerospace and defence applications.

It also provides engineering and design services, as well as research and development support.

Thakur says of himself: “I have deep expertise in ecosystem leadership, process technology equipment, and with driving mergers and acquisitions, while collaborating closely with ecosystem partners and customers.”

Thakur has a master’s degree in electrical engineering from the University of Saskatchewan, Canada, and a Ph.D. in electrical engineering from the University of Oklahoma.

He was named a Fellow of the Institute of Electrical and Electronics Engineers (IEEE) in 2013. He holds more than 300 patents in the semiconductor field.

Upon joining Tata Group, he said: “I am humbled to be given the

DR RANDHIR THAKUR

TITLE: CEO AND MD

COMPANY: TATA ELECTRONICS

Prior to joining Tata, Thakur was President of Intel Foundry Services, which provides chip foundry services, meaning Intel will manufacture chips for other companies.

Before this he was Intel’s Chief Supply Chain Officer, a position he held for three years and five months.

As Intel CSCO, he was responsible for managing the company’s external ecosystem across technology, design, manufacturing, and product supply chain.

In total, Thakur has 40 years’ experience in global manufacturing has made significant contributions to advancement of advanced semiconductor technologies.

opportunity of a lifetime to work for Tata. I am excited to contribute to building Tata Electronics as an integral and trusted part of the global electronics industry, enabling our customers’ success.

“For semiconductors, as well as precision manufacturing, we intend to deliver innovation, quality, and cost advantage with speed and at scale.”

supplychaindigital.com 19

LIFETIME ACHIEVEMENT AWARD

MARIEL READ

CEO and Co-founder of Pavilion

TELL US A LITTLE OF YOUR CAREER TO DATE

» After starting a career in tech, I joined the San Francisco Mayor’s Office. During my time in public service, I saw an opportunity to use technology to strengthen public procurement – a $2tn industry that touches all Americans. As a public servant, I saw how procurement impacts the speed and quality of all public services. For instance, it was taking the Health and Human Services (HHS) more than 300 days to complete foster care parent applications. My team oversaw the development of technology to massively reduce processing times, and the experience made me wonder how one could unlock the impact of more-efficient procurement at scale? I founded Pavilion to find out.

FIVE MINUTES WITH... 20 June 2023

Mariel Read says, the point at which technology meets public procurement is where lives can be improved

HOW DOES PAVILLION MAKE A DIFFERENCE?

» Pavilion enables public servants to easily find and purchase from contracts that have been solicited by other public entities, expediting procurement for public servants and reducing costs for suppliers.

Technology expedites the release of improvements to public services. When one public entity has de-risked a new supplier, or category of product or service then other public entities should be able to access it quickly.

We enhance the relationship between everyday Americans and their government, regardless of whether they are taxpayers, public sector employees, consumers of public services, or businesses that supply the government.

HOW CAN TECH-ENABLED GOVERNMENT CHANGE LIVES?

» In two main ways. It improves the citizen experience and it addresses significant challenges, such as climate change and cybersecurity.

Yet despite this, many innovative companies are hesitant to sell to the public sector due to slow market scaling. Making procurement more seamless on both sides of the table can help.

Technologies like ours reduce costs, increase efficiency, and encourage diverse business participation – all resulting in better, faster public services.

IS PUBLIC SECTOR PROCUREMENT EVOLVING QUICKLY ENOUGH?

» Procurement is falling short of its potential due to outdated technology. Public servants seeking qualified

“The culture of your business is you on your worst day”

supplychaindigital.com 21

MARIEL REED

TITLE: CO-FOUNDER & CEO

COMPANY: PAVILION

Before founding Pavilion, Mariel Reed joined the San Francisco Mayor’s Office. During her time in public service, she saw an opportunity to use technology to strengthen public procurement. She sais the experience made her wonder how one could unlock the impact of more-efficient procurement at scale? “I founded Pavilion to find out,” she says.

suppliers must resort to 90s techniques: email, phone calls, or visiting individual government websites.

I started Pavilion because it shouldn’t take hours to find information about a government contract or supplier. I’m optimistic that by helping public servants instantly discover and reuse contracts that have been competitively solicited by peer public entities, we can help government agencies keep pace with innovation happening in the private sector.

WHICH COUNTRY LEADS THE WAY IN PUBLIC SECTOR PROCUREMENT?

» Estonia has emerged as a global leader by demonstrating a strong focus on technology, which has significantly impacted its public procurement sector. By digitising and standardising the procurement infrastructure across the country, from posting new opportunities

FIVE MINUTES WITH...

“Estonia has emerged as a global leader in public sector procurement”

22 June 2023

to awarding contracts, Estonia has increased efficiencies, reduced corruption risks, lowered costs, and promoted participation by small and less-incumbent businesses. The system also enables vast amounts of data collection, which allows the government to identify further areas for improvement and optimization.

WHO INSPIRES YOU?

» My grandfather. He came to America as a homeless 15 year-old refugee, and survived only by the generosity of a local synagogue. He spent the rest of his life paying this kindness forward. He fought Jewish persecution by building an organisation out of his Knoxville home that helped dozens of Jewish refugees succeed in America.

BEST ADVICE EVER RECEIVED?

» A fellow founder once shared this gem with me: “Your culture is you on your worst day.”

One of the toughest lessons is that when something in your organisation is wrong you have to look in the mirror. As a founder your behaviour and actions set the tone.

So I’ve tried to focus even more on my own behaviour in order to help the team keep a sense of calm, to assume the best intent and – even on my worst days – to try and remember to be kind and have a sense of humour.

WATCH NOW

Founder Stories from A-Z: Mariel Reed, CEO of Pavilion (fka CoProcure)

Supply chain Transformation in the FAS

26 June 2023

PRODUCED BY: GLEN WHITE

PRODUCED BY: GLEN WHITE

supplychaindigital.com 27 MCLAREN

WRITTEN BY: SEAN ASHCROFT

Automotive Logistics Director Ashley Naughton on how McLaren is transforming at a pace one might expect from the maker of Earth’s fastest road cars

Few companies have the pedigree, history and pure elan of McLaren Automotive, the British manufacturer of luxury, highperformance sports cars and supercars. McLaren was founded in 1963 by Bruce McLaren, a New Zealand-born racing driver, and initially the company designed and built only race cars. In recent years, though, it has shifted its focus to high-performance road cars.

Building McLaren's fast-cardedicated logistics function

Its current lineup includes several models, including the 720S (£227,300/$305,000), and GT (£166,300/$204,990), all of which are midengine sports cars (meaning the engine sits between the axle lines of the front and rear wheels). The company’s latest model is the hybrid-powered Artura (£189,200/$233,000), which was introduced in 2021.

In addition to its road cars, McLaren Automotive also produces racing cars and provides support for various racing teams. McLaren Automotive has been at the forefront of automotive technology, leveraging its experience in F1 to translate this excellence into its road cars. Like other F1 teams (Williams and Mercedes) it is based in

28 June 2023

supplychaindigital.com 29

South East England – in Woking, Surrey, – but has a worldwide network of suppliers.

The Woking facility is a state-of-the-art complex that includes design studios, as well as engineering and production facilities

for McLaren’s road cars, including the GT, Supercars and Ultimate cars.

The centrepiece of the Woking campus is the McLaren Technology Centre (MTC). It’s a stunning, futuristic building designed by famed architect Norman Foster, and is the kind of structure one can picture housing a colony of humans on the Moon, or even Mars.

The MTC houses McLaren’s design and engineering teams, home to advanced simulation and testing facilities, including wind tunnels and a driving simulator. McLaren Production Centre sits adjacent to the MTC and is the focus for its supercar operations.

In addition to its Woking HQ, McLaren has a world-class, state-of-the-art

“We make fast cars and have a fastmoving business, and sometimes that’s a bit of a challenge”

30 June 2023 MCLAREN

ASHLEY NAUGHTON AUTOMOTIVE LOGISTICS DIRECTOR, MCLAREN

McLaren Composite Technology Centre that manufactures its carbon fibre chassis architecture. It is based in Sheffield, in the North of England.

And overseeing all of the logistics holding these operations together is Logistics Director Ashley Naughton, who concedes that the most challenging aspect of the role is – aptly enough, given the dizzying speed of its products – “having to work at pace”.

“We make fast cars and we have a fastmoving business, and sometimes that’s a bit of a challenge,” he adds. But Naughton is battle-hardened on this front, having spent more than a quarter of a century in logistics and supply chain, working largely

ASHLEY NAUGHTON

TITLE: AUTOMOTIVE LOGISTICS

DIRECTOR

COMPANY: MCLAREN

INDUSTRY: AUTOMOTIVE

LOCATION: LONDON UK

Naughton brings over 25 years' global industry experience from aerospace and automotive supply chain.

During his career, highlights include 18 years working for Rolls-Royce PLC holding various operational leadership roles in the UK & USA.

In recent years, Naughton has been focusing on supply chain transformation and digitalisation with some of the UK’s largest automotive

AN INNOVATION, DESIGN AND TRANSFORMATION POWERHOUSE

At Capgemini Invent, we help our clients to embrace innovation and transformation to get the future they want.

By combining strategy, technology, data science, and creative design expertise with an inventive mindset, we partner with our clients to innovate and transform their business, helping them navigate today, while plotting a course for the future. Explore our brands

Capgemini Invent: driving efficiency in McLaren’s supply chain

In today’s volatile climate, Capgemini Invent & McLaren are on a three year path to building a strong and sustainable supply chain to support McLaren’s expansive future.

Capgemini Invent enables CxOs to envision and shape the future of their businesses. It is working all over the world to enable its clients to unleash human energy through technology for a more inclusive and sustainable future.

“We partner with our clients to unlock the value of technology and help them transform their businesses, and support management and stable growth,” says Phil Davies, Capgemini Invent’s Head of Intelligent Industry in the UK.

Davies distils this process into three key stages:

y Using technology to advance the consumer experience

y Accelerating intelligent industry

y Transforming client enterprise efficiencies

Capgemini Invent recently began working with British supercar giant McLaren on

its logistic operations, looking at how it can combine technology, people and processes to drive resilience and sustainability into those operations.

“The world today is much more volatile; supply chains are constantly disrupted,” adds Davies. “We are working with McLaren to implement a strategy to cope and live with that disruption.”

The three main elements of the relationship are:

y Driving efficiency into McLaren’s supply chain

y Supporting McLaren with the transformation of its logistics operation

y Providing a three-year vision

“The three-year vision is really focused on how to create a logistics operation that’s going to thrive in this volatile future,” explains Davies. “Propelling them to unleash the potential of their organisation.

“The aim is to allow them to continue their relentless focus on customer experience and quality whilst building that resilience and visibility they need to cope in today’s volatile world.”

Ashley Naughton, Logistics Director at McLaren, adds: “Capgemini has been an instrumental partner for us. They’ve brought in thought leadership and shared the best industry practices, not only with automotive clients but also other industry sectors, which allows us to learn how other sectors are approaching different problems.”

“I think both McLaren and Capgemini are organisations that really focus on outcomes,” concludes Davies. “So, whilst we’re in the early stages of building the vision, I would say ‘watch this space’ around the next 18 months.”

McLaren: supply chain transformation in the fast lane

in aerospace and automotive, with firsttier suppliers, in either manufacturing or logistics services.

He says the most satisfying aspect of his role at McLaren is “working with our people”.

He adds: “It’s a very passionate organisation, with a rich history in automotive and racing. The innovation and ingenuity of the people is really quite inspiring.

“We also have a very complex product,” he says, “which means we’ve got extremely specialised suppliers, and we are constantly looking to improve the business.”

This, Naughton observes, often means his team has to react super quickly, and concedes this puts pressure on people “to support what the business is trying to achieve”.

Along with logistics chiefs worldwide, Naughton’s ability to support McLaren goals

“Capgemini has been very supportive in helping us to understand the art of the possible”

WATCH NOW

34 June 2023 MCLAREN

ASHLEY NAUGHTON AUTOMOTIVE LOGISTICS DIRECTOR, MCLAREN

has not been made any easier by a multitude of shocks and pressures existing today.

Overcoming obstacles with digitalisation, determination & data

Whether that be raw materials shortages, capacity limitations or cost pressures, it all presents challenges. It’s a situation that makes him more determined than ever to future-proof McLaren’s supply chain.

“It’s about mitigating challenges that are as yet unknown,” he says. “Having information early on in our supply chain is very important. We don’t always know what’s around the corner, so it’s about understanding the risks to our business, and making decisions based on that understanding to safeguard ourselves.”

And what of the longest and most painful supply chain shock of all in the automotive manufacturing world: microprocessor shortages?

“In terms of future-proofing against semiconductor shortages, nothing is going to protect us completely. There is no insurance policy that will give us total availability for all the semiconductors we need.

“That said we have done really well with semi-conductors and were very proactive, early on, as that risk emerged. Securing those commodities gave us the breathing space that others perhaps have struggled with.”

Naughton continues: “Moving forward and thinking about a wider scale of the supply chain, we can better protect ourselves by having early information around these risks,

supplychaindigital.com 35

1963

McLaren was founded in 1963 by Bruce McLaren, a New Zealand-born racing driver

36 June 2023

which are sometimes in the third or fourth tier of the supply chain.

“So building supply chain maps and then ingesting data using technology is a way to become more resilient, so we can deal with those shocks when they occur.”

It is this climate of uncertainty that prompted McLaren to embark upon the digital transformation of its supply chain and logistics operation.

“If you stand still, you’re actually moving backwards,” Naughton says of the digitalisation programme. “Logistics and supply chain are a core part of our business. We design products, we manufacture the vehicles, but we can’t do that without our supply chain partners.”

Naughton adds that McLaren Automotive handbuilds state-of-the-art super cars in a state-of-the-art facility and is constantly looking to innovate. “The same applies for our manufacturing and Logistics operations,” he adds. “I want that same performance. Agile, communicative, and responsive.”

This is why McLaren is investing heavily in improving its supply chain ecosystem.

“Our suppliers are partners in our business and we need their support to be successful. If we don’t invest in that then we’re being negligent,” Naughton says. “Our supply chain is a key enabler for our business. It’s integral to the way that we do business.”

The strategy on digitalisation “comes down to three Cs”, Naughton says.

“It needs to be connected, collaborative and ultimately needs to be cognitive.”

He adds: “It’s about having data that we can use to make decisions much earlier than we do today. This is how we derive resilience, how we optimise and how we discover efficiencies. We need technology to do this, and we’re on that journey.”

Operationally, Naughton says the benefits of digitalisation derive from breaking down

supplychaindigital.com 37 MCLAREN

barriers and silos that “traditionally exist within organisations”.

Such barriers also exist within the supply chain network, Naughton points out, adding that technology can create opportunities for all partners in that ecosystem. “Collaboration and data sharing is quite simple if we adopt Cloud, for example,” he says, adding: “Our inbound operations will hugely benefit from digitalisation and technology, but then that flows into the manufacturing ecosystem, of which I’m part. Similarly, there is also a strong drive for transformation within the manufacturing team and we need to ensure we are synergising.”

Ultimately, he says, the goal of the programme is to transform the business “so our customers get a better quality product and a more reliable service”.

He adds: “At the end of the day, any transformation programme must keep the customer in mind, which is why we’re deeply connected to our customers and how they view our products, as well as how they view the service. Ultimately, we want to be faster, more effective and more trusted, so that we can better deliver on what customers expect.”

Capgemini collaboration is feather in McLaren's cap

Helping McLaren drive the change programme in the right direction is Capgemini, a global leader in consulting, technology services and digital transformation.

“Capgemini has been an important partner for us,” says Naughton. “They’ve brought in thought leadership and have shared industry best practices.”

And not just from the automotive clients with whom Capgemini works, says Naughton “but from other industry sectors”, which he says has been invaluable “because we need

to learn how other sectors are approaching similar and different problems”.

“Capgemini has been important in helping us to understand the art of the possible and to identify those opportunities where technology can help McLaren on its journey.

Naughton admits that there is still much to come “because the company’s logistics transformation is quite embryonic in terms of crystallising what the future looks like”.

He adds that the next phase “will be to begin looking at the specific opportunities and capabilities Capgemini has helped us identify”.

He continues: “We need to consider what’s right for McLaren. We are unique in certain aspects, but we need to adopt standardisation where it makes sense. I am fortunate to have a strong team around me to make the right choices about our future logistics operations. As I said before, it’s about the people. Moving forward, its about understanding the choices we face, and

38 June 2023 MCLAREN

ASHLEY NAUGHTON AUTOMOTIVE LOGISTICS DIRECTOR, MCLAREN

then making decisions based on those options. We’re not quite there yet, but in the coming months we’ll begin making decisions around the processes and technology, then implement what we see as the biggest opportunities.

“Some of those changes will come from our internal team members and some will come from our partners. We have a really strong team here who have already

developed digital capabilities so we will continue to leverage our skills, but there will be things we need support with.”

Sooner rather than later, Naughton hopes – in keeping with the fast pace of life so fitting for a supercar manufacturer.

“I like to operate at pace,” he says. “It’s in my DNA and also in McLaren’s, who like to do the right thing, quickly.”

So that’s the near-term. But what about the longer-term future for McLaren? How does Naughton see this shaping up?

“We will move towards being an insightdriven organisation. Network data is key for this to occur. Through collection of such data, this will enable us to become far more resilient. “The need for sustainability cannot be ignored. The majority of Scope 3 emissions

“We derive resilience from having data we can use to make decisions much earlier than we do today”

supplychaindigital.com 39

come from the supply base, so we have a responsibility to improve how we operate our business. This will be our future.”

From fast cars to fast manufacturing, there's a need for speed in the future

Naughton feels that recent changes at the top of the company will shape McLaren’s performance in the next 12 to 18 months.

Michael Leiters joined as CEO of McLaren Automotive in July 2022.

German-born Leiters has held senior positions at Porsche AG, eventually becoming a Product Line Director there. More recently, he was Chief Technology Officer at Ferrari. So he is certainly someone who knows all about fast-moving manufacturing environments.

“I think we’ve got an exciting future, particularly with Michael Leiters joining the organisation,” says Naughton, adding that “there’s also lots of other positive changes”.

Among which, he says, is “a shift-change in the way we approach things, from design through to delivery of product”.

He adds: “It’s one of the reasons I took the opportunity to join McLaren. I’m passionate about driving change and am lucky enough to have a leadership team that supports the need to transform. “It’s an exciting time to be in operations and supply chain logistics in the automotive business. I believe our future is really bright.”

40 June 2023

supplychaindigital.com 41

BAE LEVERAGES COLLABORATIVE SUPPLIER RELATIONS

How supplier relations platform Suppeco helped BAE Systems Applied Intelligence to tap into valuable relationship data to enrich & strengthen its operations

WRITTEN BY: SEAN ASHCROFT

PHOTOS COURTESY OF: BAE SYSTEMS

WRITTEN BY: SEAN ASHCROFT

PHOTOS COURTESY OF: BAE SYSTEMS

42 June 2023

supplychaindigital.com 43 SUPPECO SPECIAL

“Suppeco appeared on our radar when we were seeking to drive greater value from procurement and supply chain”

44 May 2023

SIMON KING, HEAD OF SUPPLIER MANAGEMENT & OPERATIONS, BAE SYSTEMS APPLIED INTELLIGENCE

uppeco is a collaborative relationship platform that leverages operational relationship data to solve key challenges facing the customersupplier ecosystem.

Central to what Suppeco does is collaborative Supplier Relationship Management (SRM), an approach that is helping deliver notable results for one of its clients, BAE Systems, the UK-based multinational defence, security and aerospace company and Europe’s largest defence contractor.

Suppeco works closely with BAE Systems’ Applied Intelligence, its cyber defence, research, and technology arm.

Applied Intelligence provides a range of services to BAE Systems businesses, third-party companies, and government departments, including R&D, consultancy, specialist manufacturing and technical services.

Its expertise also helps the UK Ministry of Defence, the US Department of Defence, the European Defence Agency, and universities to achieve their goals.

For many years, Applied Intelligence has focused heavily on economic crime, fraud, and the growing threats of cyberattacks.

Simon King, Head of Supplier Management and Operations at BAE Systems Applied Intelligence, says the

Ssupplychaindigital.com 45 SUPPECO SPECIAL

Unlock hidden value in your supply chain

An award-winning collaborative supplier relationship platform

Suppeco leverages the potential in relationships to solve key challenges within the value chain

A practical solution built for the real world

TAKE A TOUR

company realised that, for it to continue delivering its ‘value’ targets, “we would need to innovate together with our suppliers”.

He added that Suppeco “landed on our radar at a time when we were seeking to drive greater value from procurement and supply chain”.

King says BAE wanted to move away from “arms-length relationships” and rebuild its SRM capability “to encourage more transparency and openness”.

To this end, Suppeco worked with BAE to create the Applied Intelligence Collaborative SRM Initiative, built on Suppeco’s Cloud-based platform, which has been available to BAE since early 2020. Initially the project involved four live pilots and 20 BAE Systems suppliers.

Prior to Suppeco, Applied Intelligence used Excel-based collateral for KPI supplier performance management.

“I wanted to get away from managing relationships through spreadsheets and the huge time investment required to create

Simon King

TITLE: HEAD OF SUPPLIER MANAGEMENT & OPERATIONS

COMPANY: BAE SYSTEMS APPLIED INTELLIGENCE

INDUSTRY: AEROSPACE & DEFENCE

King is “a results-driven, experienced procurement professional” with 25 years’ experience of supplier and contract management. He also has 15 years’ experience of category management and strategy, as well as drafting commercial contracts across a range of market sectors.

SUPPECO SPECIAL

Sheldon Mydat

TITLE: FOUNDER & CEO

COMPANY: SUPPECO

INDUSTRY: SUPPLIER RELATIONS

Mydat is an expert in supplier relationship management. Prior to founding Suppeco, he led successful supplier transformation programmes for high-profile organisations such as The Metropolitan Police, Royal Mail Group, and Lloyds Banking Group.

slide decks for periodic governance,” says King.

He adds: “Suppeco demonstrates our commitment to collaborative and transparent relationships with our most important suppliers.”

King says the platform also “requires zero customisation and places no limits on user numbers”.

He also explains that its supplier management information structure follows the principle that every supplier engagement – regardless of what’s being bought or sold – can be split across four main pillars of engagement: Relationship, Commercial, Projects and Service.

“This is what makes the Suppeco environment so effective,” he says. “It brings structure and visibility to aspects of our supplier relationships that were previously intangible.”

Our suppliers also have “extensive access” to the platform, which King says is crucial.

“Suppeco’s rich dashboards give direct visibility of how actively our most important relationships are being managed, and what our challenges and successes are within each one,” he says.

King adds: “the fact that our suppliers are able to see how we operate and that we’re open to criticism drives an immediate stepchange in supplier behaviour.

“They can see that we aren’t just managing their performance on Suppeco, we’re also monitoring our own,” he says. “This has helped in securing supplier engagement and buy-in.”

King explains that in the past, supplier meetings would be monthly or quarterly and that all the information was “historic”.

“It would be compiled by one party or the other,” he says, “so we’d be effectively meeting to talk about what had already happened.”

Now, he says, the company is running performance reviews directly from the

Suppeco platform, and “remotely sharing up-to-date screens, and real-time live data”.

King adds: “Ultimately business is about driving value, increasing profit, and reducing cost. Suppeco is helping us see how all those things are infinitely more achievable by unlocking our supplier relationships.”

Suppeco’s Mydat says that, as with most large organisations that work with multiple suppliers and various levels of complexity, BAE’s applied intelligence “was traditionally focused on driving category spend within their procurement function”.

Suppeco Intro WATCH NOW

“Focusing on cost efficiency ignores the strategic value of supplier relationships”

SHELDON MYDAT, CEO & FOUNDER, SUPPECO

supplychaindigital.com 49 SUPPECO SPECIAL

He states that this fails to leverage the strategic value within supplier relationships, because focusing on cost efficiency and contract performance “puts the emphasis on the numbers and the contracts”.

“This tactical approach leverages a crucial but finite opportunity to drive value. By contrast, the relationship space contains an infinite array of opportunities to collaborate, to create value, promote transparency, innovation, agility and, crucially, to promote growth across the ecosystem and supply chain.”

Mydat explains that the pandemic was “a wake-up call” and has resulted in a “direction of travel” for supply chain technology, towards “more resilient relationship engagement”.

“This is the foundation of Suppeco,” he surmises. “So I was delighted that Simon and his team agreed to trial, and then licence, Suppeco at the beginning of 2021.”

About Suppeco

Supecco was founded in 2017 by Sheldon Mydat, an expert in the field of supplier relationship management (SRM). Prior to founding the company, he led successful supplier transformation programmes for highprofile organisations such as The Metropolitan Police, Royal Mail Group, and Lloyds Banking Group.

In February 2023, Suppeco earned ‘Innovator’ status from International Data Corporation, the global market intelligence firm – earning the accolade for its data-driven live insights that deliver “actionable visibility deep into the supply chain”.

SUPPECO SPECIAL

relationships through spreadsheets”

KING,

OF SUPPLIER

& OPERATIONS,

INTELLIGENCE supplychaindigital.com 51

“I

wanted to get away from managing

SIMON

HEAD

MANAGEMENT

BAE SYSTEMS APPLIED

52 June 2023

ENSURING A RESILIENT, RESPONSIBLE & AGILE SUPPLY CHAIN

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

WRITTEN BY: HELEN ADAMS

PRODUCED BY: MIKE SADR

supplychaindigital.com 53

BECTON DICKINSON

Kevin Nelson, Chief Procurement Officer at BD, on

Kevin Nelson is the Chief Procurement Officer at BD (Becton, Dickinson and Company), a medical technology company based in Franklin Lakes, New Jersey. His responsibilities include overseeing all third-party spend, including direct and indirect.

“I’ve been in the procurement profession for a number of years, starting my career in the high-tech industry and evolving into roles within the biotechnology arena before leading strategic sourcing at C. R. Bard, a medical device company that BD acquired about six years ago,” he says.

BD is one of the world’s largest medical technology companies. Its purpose is ‘advancing the world of health’ by improving medical discovery, diagnostics and the delivery of care.

“Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product,” says Nelson.

Products vary from well-known medical devices such as needles, syringes and blood collection tubes to sophisticated electromechanical devices, diagnostic instruments and reagents.

Mitigating supply chain disruptions

COVID-19 changed the world forever –hybrid working is the new normal, face masks are as common as earrings and you never leave your house without your keys,

how his team mitigates supply chain risks and delivers innovative solutions in an ethical way

54 June 2023 BECTON DICKINSON

A Modern Procurement Platform for Today’s Business

Gainfront’s AI driven technology platform is designed to increase procurement efficiency while solving the unique procurement process challenges that arise from today’s remote and hybrid work environments and increased focus on corporate social responsibility around supplier diversity, ethical compliance, and reducing green house gas emissions

Diversity, ESG & Automation: Gainfront’s modular procurement power

Gainfront’s highly customisable, modular, procure-to-pay powerhouse platform for Diversity, ESG, and collaboration

Gainfront is a platform that meets the procurement needs of today’s business landscape, focusing on mandates related to diversity, supplier diversity, workforce diversity, as well as ESG tracking. Led by Hetal Mehta, CEO of Gainfront, the company provides organisations with an innovative way to achieve compliance to preferred buying while offering powerful workflow automation, which is essential in today’s hybrid work environment.

Diversity, ESG, and Workflow Automation Enabled

Gainfront enables customers to easily configure their workflows, whether in sourcing, finance, or HR, granting them full control over the process through team collaboration and audit trails. As a complete Procure-to-Pay platform, Gainfront fully embraces diversity, ESG, and workflow automation requirements, providing a comprehensive solution for procurement professionals.

The Supplier Discovery Database

Gainfront recognises the pressing need for finding new, diverse, and environmentally conscious suppliers on a global scale. With current supply chain challenges, customers often struggle to identify and source from new suppliers. Gainfront addresses this issue by offering their customers access to a strong and robust global Discovery database. Mehta highlights the importance of this database, stating that it resolves the problem of customers being unable to replace suppliers due to a lack of viable alternatives.

RFX Concierge Service

In the context of today’s hybrid work environment, there is a growing need to find qualified suppliers while managing risk profiles. Gainfront introduces the RFX Concierge service, which allows customers to source suppliers easily by providing preliminary criteria. By leveraging this service, Gainfront identifies qualified suppliers and connects them, significantly reducing customers’ search time by almost 60%.

Enhanced Collaboration

“Gainfront recognises the importance of collaboration in today’s hybrid work environment,” says Mehta. “The company’s horizontal approach to workflow automation provides customers with team collaboration capabilities, allowing for efficient communication and tracking of audit trails. By gathering all decision-making processes in a team-collaboration environment, individuals are held accountable, mitigating the risk of miscommunication or lost information.”

Gainfront’s Partnership with Becton Dickinson (BD) Becton Dickinson (BD) has been a customer of Gainfront for the past three years. Mehta and her team have been instrumental in helping BD manage supplier diversity, spend management, and tracking, thereby assisting them in achieving their BDR goals. Through Gainfront’s database, BD gains access to new suppliers, enabling them to meet their sourcing and diversity goals successfully.

wallet, phone and hand sanitiser. The postpandemic planet changed the procurement process too, especially for those dealing with medical equipment.

“The world has changed and our supply chains need to adapt,” said Nelson. “When we look at the environment, or the world around us right now, we are continuing to see more disruptions every year. We’ve been tracking this, not only within BD, but also within the healthcare and the life sciences industry.”

More frequent disruptions in the supply chain are happening year over year, which include plant shutdowns, supplier shutdowns, supplier insolvency, port strikes, geopolitical tensions and more.

“BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced procurement visibility and agility”

58 June 2023 BECTON DICKINSON

KEVIN NELSON SENIOR VP & CPO, BD

KEVIN NELSON

TITLE: SENIOR VP & CPO

COMPANY: BD

INDUSTRY: MANUFACTURING

LOCATION: NEW JERSEY, US

Kevin Nelson has served as BD’s SVP and Chief Procurement Officer for the past five years focused on applying advanced Procurement strategies to help BD navigate supply chain disruptions and inflationary challenges during the pandemic. Kevin created BD’s Responsible Sourcing Program which strives to develop an ethical, agile supply chain capable of sustaining external pressures.

Prior to B, Kevin was VP of Global Strategic Sourcing C.R. Bard where he introduced an advanced sourcing methodology that delivered solid yearover-year savings as well as additional value through innovative supplier relationship management, revenue generation, reduced backorder and a supplier risk management program.

“All these things result in some sort of disruption to the supply chain,” says Nelson. “We have continued to see that and experience it. That has led us to asking, what do we need to do differently? Because we’re probably not going to get back to this ‘normal’ that everyone’s been waiting for. BD has taken this ‘moment’ to lead a ‘movement’ to create the supply chain of the future, and that all starts with enhanced supply chain visibility and agility.”

This “movement” at BD has resulted in multiple initiatives to evolve procurement strategies to be more resilient, agile and socially responsible.

EXECUTIVE BIO

Kevin received his B.A. from the University of North Dakota and MBA from Boston University. Kevin is a member of the Healthcare Transparency Institute, Strategic Marketplace Initiative, National Minority Supplier Development Committee, Institute for Supply Management and sits on multiple advisory boards in the medical device industry.

Enhanced visibility via AI & ML

“To start building our supply chain of the future, we mapped our product lines to identify which ones are considered critical to healthcare,” Nelson explains. “These are products that the healthcare industry has

deemed essential to care for the patients, and if they aren’t on the market, there’ll be a problem around meeting basic or routine healthcare needs.”

BD identified over a hundred different product lines that are critical to healthcare. Nelson and his team conducted an assessment on every product line, looking at every item in the bills of materials and ensured remediation is in place for the critical high-risk materials.

“A product line may have a few items in the bill of materials, or it may have a few hundred items. We do an assessment on every item in that bill of materials and on every supplier, to see where potential risks are.”

BD creates a composite score that allows them to plot product lines to see which ones are in a high-risk quadrant.

“We’re looking at how we can help a community where our customers are living”

NOW

BD: Ensuring a resilient, responsible and agile supply chain

WATCH

62 June 2023 BECTON DICKINSON

KEVIN NELSON SENIOR VP & CPO, BD

“We can take that back to our business units and work with them to create mitigation plans to dual source, adjust inventory levels, and/or regionally source some of the material or components.”

90%

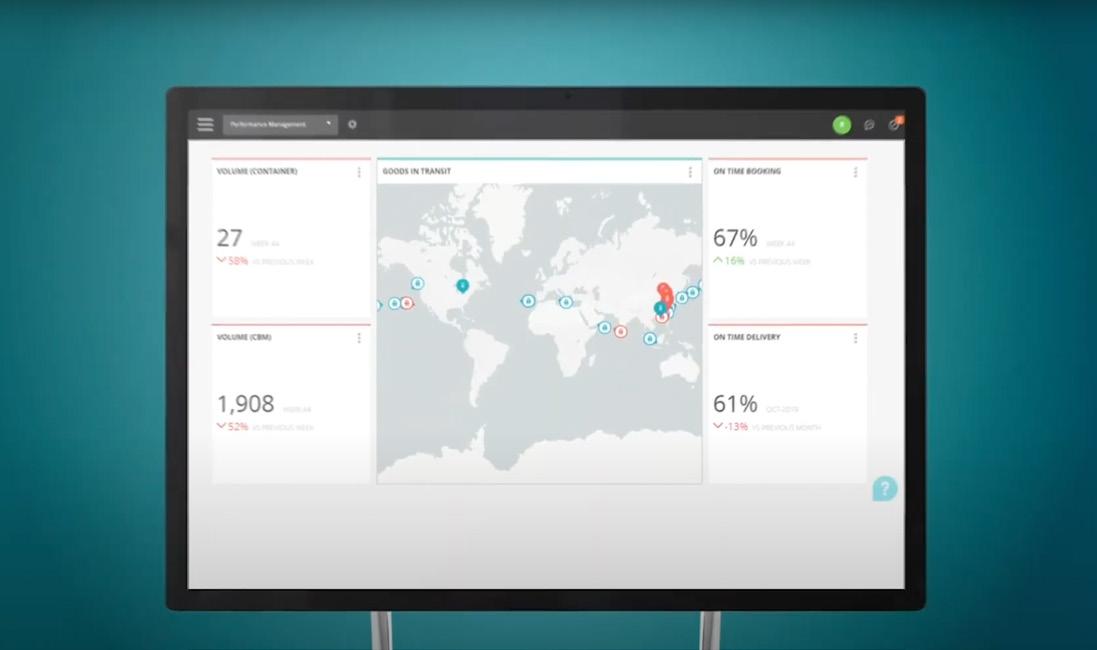

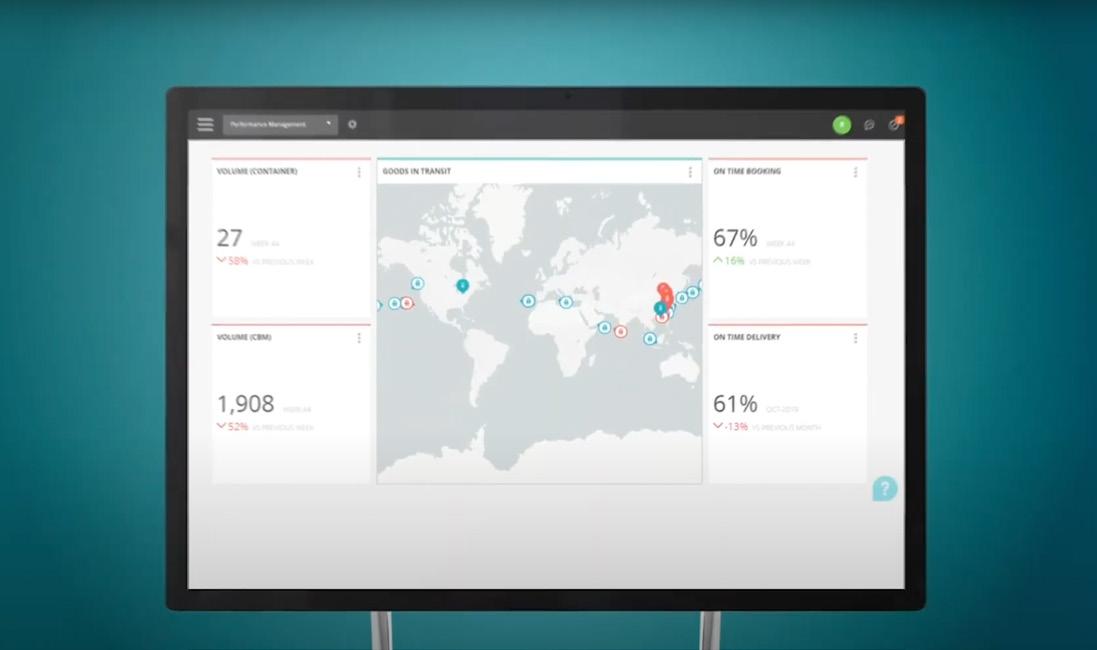

As part of the work to de-risk high-priority products, BD uses discovery technology that employs AI and machine learning ML to map subtier supply chains for critical products and leveraged that visibility to uncover hidden risks in its suppliers’ extended supply chains.

“During COVID-19, 80% of BD’s supply chain disruptions didn’t come from our direct suppliers,” Nelson adds. “They came from our suppliers’ suppliers or even three or four levels down the chain. Unless you have mapped your entire supply chain and employ

very sophisticated technology, it is very hard to know how a disruption at a third or fourth-tier supplier will impact your product.”

An example of the payoff of this work was a recent paper strike in Finland. Because BD mapped the supply chain, the procurement team knew that pulp from Finland was used in medical grade labels the company uses and that there were very few alternate suppliers. BD received early warning signals from the risk intelligence partner along with the visibility to understand the issue early on, work with its partners to find alternate sources and secure inventory of labels well in advance of other companies or industries that would be vying for the same label stock.

supplychaindigital.com 63

Roughly 90% of patients coming into a clinical setting in the United States are going to use a BD product

Fuel breakthroughs

The life sciences industry continues to experience unparalleled innovation as investment and talent flow into the sector and breakthrough discoveries happen at a rapid pace.

Named the 2021 BD Sustainability Supplier of the Year, JLL helps life sciences companies create compelling real estate and facilities strategies that improve efficiency, mitigate risk and deliver a sustainable workplace. Lay the groundwork for rapid growth →

us.jll.com/lifesciences

KEVIN NELSON SENIOR VP & CPO, BD

Creating a socially & environmentally responsible supply chain BD knows its customers want them to provide high-quality products at a fair price and that they expect more than the basics. Improved resiliency, visibility and agility are adding value, but the company is also focusing on sustainable business practices that are environmentally, ethically and socially responsible.

“At BD, we stay true to our values, including doing what is right. We set up the Responsible Sourcing Program to ensure we embed supplier responsibility and sustainability in every purchasing decision we make,” Nelson explains.

This includes partnering with ethical and diverse suppliers, helping protect human rights and working to ensure environmental stewardship.

“Our customers want to understand the bigger picture, too,” Nelson explains. “Are they buying a product from us that is sourced from an ethical and responsible supplier paying fair wages to its workers?”

BD ensures compliance in these areas through ongoing assessments, desktop and face-to-face audits and close partnerships across its supply base. This is all to ensure that suppliers understand exactly what BD

“Unless you have mapped your entire supply chain and employ very sophisticated technology, it is very hard to know how a disruption at a fifth-level supplier will impact your product”

supplychaindigital.com 65 BECTON DICKINSON

66 June 2023

expects when doing business with them, while also making sure risks are anticipated and managed effectively.

Like most companies, Nelson and his team have certainly found some areas of concern in their network that need to improve.

“Instead of moving away from that supplier and letting it be someone else’s problem, we’ve tried to see how we can work with them to identify an area they need to improve in. If they’re able to, that’s great. If not, then we’d have to move away. So far, we’ve been successful in mitigating issues. We’re working to help improve human rights around the world while ensuring important medical products get to those who need them.”

Another focus area of BD’s Responsible Sourcing Program is supplier sustainability. This examines where suppliers are driving reductions in greenhouse gases, diverting waste away from landfills and understanding how much renewable energy they use. The Responsible Sourcing team is also working internally with product stewardship and category management to develop and implement strategies to eliminate materials of concern where possible.

“The partnership is that three-legged stool: our customer, our internal stakeholders and our suppliers”

supplychaindigital.com 67 BECTON DICKINSON

KEVIN NELSON SENIOR VP & CPO, BD

How well do you know your suppliers?

Or even your suppliers’ supplier?

Get clear visibility and unmatched intelligence to make faster, smarter supply chain decisions. Everstream reveals supplier, material, and revenue risk before anyone else. With the world’s most accurate and reliable data, network graphing, and human analysis, Everstream empowers supply chain leaders to build strong, agile, and sustainable supply chains.

Take control of your supply chain with Everstream everstream.ai

everstream.ai/demo

KEVIN NELSON SENIOR VP & CPO, BD

sustainable sterilisation technologies, and addressing materials of concern (MOC).

The third area of focus of the Responsible Sourcing Program is supplier diversity, which has gained a lot of momentum in the US.

“We pivoted our supplier diversity focus from one that historically assessed our spend with small businesses and diverse suppliers, which was more of a reactive approach. Today, we are looking at economic impact in terms of how we’re helping different regions and local economies by using diverse and small businesses that are truly making an impact. We’re looking at how we can help a community where our customers are living,” explains Nelson.

“The Supplier Sustainability pillar includes working alongside our R&D team and business units to identify products, materials and components that are ‘greener’ in nature while also making products that are more effective, efficient and economical,” Nelson explains. “This might be a packaging component that uses less energy to make or is recyclable.”

In 2022, BD launched the Sustainable Medical Technology Institute, a model of practice within the organisation that brings together BD researchers and engineers, as well as quality, regulatory, policy, sourcing and operational expertise, to focus on reducing the environmental impact of the company’s product portfolio in three areas: adopting sustainable product design strategies, developing and deploying

Finally, there’s end-to-end transparency, which is connecting back to the customer and providing enhanced visibility to them. “The key is providing this information proactively and transparently to the customers, to the patients, before it’s a problem, so they have the ability to do something in advance.”

Medical manufacturing partnerships & resilient supply chains

As with any medical manufacturer, BD’s partner ecosystem is vast.

“Partnering with our customers upfront is a key priority for BD. We aim to identify the customer requirements and expectations and build those into our long term strategies and initiatives,” he explains.

From day one, BD’s style has been to collaborate and work with its partners, which was essential during the pandemic.

“We came in working together, wanting to figure out a solution with our supplier partners, as opposed to demanding, ‘Shift this or I’m going to move away from you’.

“Instead of moving away from that supplier, we’ve tried to see how we can work with them to identify how they can improve”

supplychaindigital.com 69 BECTON DICKINSON

70 June 2023

“The partnership is a three-legged stool: our customer, our suppliers and our internal stakeholders that includes business units, Quality and Regulatory, among others.”

This work is further strengthened through strategic collaboration and public-private partnerships with government agencies, including the FDA, HHS, POTUS/White House – and industry collaboratives like Advamed – to address supply chain and sourcing issues that plague the broader healthcare industry.

Being able to incorporate those areas into BD’s strategy has allowed what Nelson sees as a resilient end-to-end supply chain.

The momentum of BD’s procurement supply chain team has been exciting for Nelson and his team.

“We’ve experienced very little turnover in our function, and I think a big reason for that is that people see the movement we are driving and understand we have become extremely vital to BD, our customers and the patients they serve. We are on the frontlines; we are helping shape strategy as we go forward here.”

Nelson views this as an entirely different kind of mindset and even acumen, from a team perspective.

“I think it’s been refreshing for the team to pivot away from historical firefighting or cost-reduction to facing the bigger opportunity we’re trying to address.”

“We have more engineers on the team now doing more,” says Nelson. “Our engineers look at an existing product line and see what we can do to redesign elements that can meet the needs of our customer and patients, reduce our overall risk exposure and benefit BD as well.”

supplychaindigital.com 71 BECTON DICKINSON

Wearable digital devices are among the tech developments helping businesses speed delivery and manage customer expectation

72 June 2023

DIGITALISATION MEANS CUSTOMERS REALLY ARE KING

Supply chain digitisation means that businesses are having to rethink what customers really value, says Venky Arun of Kearney

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

SUPPLY CHAIN

Every part of the supply chain will benefit from digitalisation including quality control

74 June 2023

Sometimes, progress requires out-of-the-box thinking – the ability to seek inspiration from unusual quarters.

A pizza delivery service and the banking sector might seem unlikely use cases to help a business digitally transform its supply chain, yet, interestingly, bestpractice deployment of tech is often transferable from sector to sector.

So much is changing, and so fast, in supply chain that lessons have to be learned wherever one can find them. Predigitalisation supply chains were typically designed to balance costs. In terms of performance, the goal was to give customers similar service levels, with a bias towards the needs of the largest customers.

But technology means businesses now have increased access to data across the supply chain, and with increased data comes better insight, which allows them to provide a bespoke service to customers. In short, supply chain digitisation requires that businesses rethink what customers really value.

Digitalisation helps segment markets

Venky Arun, Partner of Strategic Operations with Kearney, is an expert in this field. He says digitisation “enables companies to further segment its customers across channels and provide customisation on what they truly value”.

Not just this, but he also says technology allows organisations to adjust evolving priorities – such as real-time visibility, customised promotions and growing demands – for sustainable supply chains.

Venky says: “In terms of real-time visibility, customers want to know about status and updates throughout the order to delivery process. The more transparent your supply chain is, the more your company can meet the wants, needs, and expectations of customers.”

He gives as an example the pizza giant, Domino’s, who pioneered real-time order tracking in 2008 when it introduced a feature that let customers know when their pizza order was received, when the pizza was in the oven, and when the order was en route.

“This concept has extended across business-to-business (B2B) and businessto-consumer (B2C) segments in the supply chain,” says Venky.

As well as causing businesses to shift the focus of supply chain away from costsavings and on to customer needs, digital transformation is also changing the nature of supply chain roles – particularly through automation. Businesses are increasingly

“Most firms are working on the what, where and how of digitising their supply chain”

supplychaindigital.com 75 SUPPLY CHAIN

VENKY ARUN, PARTNER OF STRATEGIC OPERATIONS, KEARNEY

having to strike a balance between automation and human expertise, says Venky, who cites collaborative warehouse robots – ‘cobots’ – as an example.

“These are used in areas where humans are also working, and, together, they complete tasks such as sorting, carton loading, case packing, and tray placement.”

Here, he references Unilever’s production plant in Katowice, Poland, which uses cobots “to speed up the palletising process, to optimise work ergonomics and to relieve employees from strenuous tasks”. Another nuanced automation use case that he mentions is the balance between AI-driven chatbots and human feedback.

“Answers to basic questions, such as returns policies for a retailer, can be handled through a chatbot,” he says, “but enquiries that require empathy and personalisation need to be delivered by humans.”

In light of this, Venky suggests Supply chain managers would do well to study the banking sector, which has deployed bestpractice automated customer support.

“For bank relationship-managers, the automation of manual tasks has enabled a more efficient way of working, so they can refocus their time on higher-value engagements that help deepen relationships with their clients.”

“AL and ML help optimise routes, reduce fuel consumption and reduce waste”

VENKY ARUN, PARTNER OF STRATEGIC OPERATIONS, KEARNEY

supplychaindigital.com 77 SUPPLY CHAIN

Cobots, such as this automated picker, are helping warehouses bypass labour shortages

So which organisations does Venky feel are best-practice leaders in supply chain digitisation?

He begins with a rider, saying that digitisation of supply chains “is still in its early stage” and that most companies “are working on improving the what, where, and how they digitise their supply chain”.

PepsiCo ‘digitally mature’

He adds: “There is no one leader in digitisation, but we do see companies that have more mature digital capabilities.”

Such as PepsiCo, which Venky says is using one of its biggest brands – Frito-Lay – to launch new Industry 4.0 initiatives.

“Its Frito-Lay manufacturing plant uses lasers to hit chips and then listen to the sounds coming off the chip to determine

Venky Arun

TITLE: PARTNER OF STRATEGIC OPERATIONS

COMPANY: KEARNEY

INDUSTRY: PROFESSIONAL SERVICES

Arun has been with Kearney for over 10 years. He was previously Vice President and Associate Partner. He was previously an Associate Engineer with Accenture.

texture. Algorithms process the sound and determine the chip texture to automate the quality check for Frito-Lay’s chip processing systems.”

Another example is UPS, which is using an AI-powered GPS tool called ORION (On-road Integrated Optimisation and Navigation) to create the most efficient routes for its fleet.

“Customers, drivers, and vehicles submit data to the machine, which then uses algorithms to create the most optimal routes,” he explains. “Instead of backtracking or getting stuck in traffic, ORION helps drivers make their deliveries on time and in the most efficient manner. The routes can even be changed on-the-go, depending on road conditions and other factors.

Asked what his advice to businesses would be if they could afford to digitalise just one aspect of their supply chain, he returns to the subject of customer-led decision making.

“The customer is at the core of any supply chain. Availability of the right product at the right time is becoming more and more important and that’s an area where digitisation can enable businesses to make more-accurate inventory decisions.

“Digitisation and advanced analytics can help predict consumer habits and forecast seasonal demand to minimise the costs of overstocking excess inventory. When applied to demand forecasting, AL and ML principles create highly accurate predictions of future demand.”

Here, he gives the example of US retail giant Walmart, which is using AI- and ML-based predictions to balance its network “and is placing inventory in the right location, at the right time”.

SUPPLY CHAIN

Frito-Lay uses lasers to gauge texture and determine quality

UPS uses an AI-powered GPS tool to create the most efficient routes for its fleet

supplychaindigital.com 79

McKinsey 5-point formula for digitalisation success

An ongoing McKinsey study into skills requirements shows that companies need inhouse digital supply chain talent to support digitisation efforts.

And to help organisations in their quest to plug the skills gap, McKinsey has published a five-point “capability building formula” based on action taken by businesses who have successfully upskilled their supply chain people. The five points are:

Focus

Focus on the skills that matter –something that is often hindered by a lack of understanding of what ‘good’ looks like, says McKinsey.

Incentivise

Incentivise participation and engagement

Scaleability

Set up the program to scale beyond the initial pilot

Diversify Impact

Use diverse and effective learning methods

Drive for impact on the company’s operating performance

SUPPLY CHAIN

He explains: “Shoppers pack their physical or digital shopping carts. Walmart uses AI to enhance daily supply chain workflows, helping anticipate cycles in demand, especially amid peak or unexpected events in customer traffic.”

Tech is sustainability boon

Staying on the theme of advanced analytics and AI, Venky says such tech is helping in another hugely important area: sustainability.

“AL and ML can help optimise routes, reduce fuel consumption, improve inventory management and reduce overall waste,” he says. “Advanced analytics is also helping companies improve efficiency, as well as enhancing their reputation by allowing them to play a bigger role in preserving the environment.

“For example, since 2015, Amazon has reduced the weight of its outbound packaging by 33%, eliminating 915,000 tonnes of packaging material.

“Once a customer orders a product, an ML solution powered by Amazon SageMaker identifies the type of packaging needed – whether this is paper bags, padded paper mailer – as opposed to defaulting to predefined boxes.”

WATCH NOW

What does it take to transform to a digital supply chain?

“The customer is at the core of any supply chain”

supplychaindigital.com 81

VENKY ARUN, PARTNER OF STRATEGIC OPERATIONS, KEARNEY

Microsoft empowering manufacturing firms to accelerate supply chain innovation

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY: JAMES BERRY

82 June 2023

supplychaindigital.com 83

Helping to spearhead digital transformation programs across the process industry is no small feat, but Microsoft’s industry executive Yury Gomez is the perfect fit for the job.

Gomez – Global Chief Commercial Leader for Process Industries – has a supply chain background, which means that not only is she battle-hardened, but she also has a real-world understanding of what works and what doesn’t when it comes to manufacturing operations.

She has also been tempered by the seismic experience of COVID-19: “Supply chains have always existed. It’s always been the job of demand planners, forecasters, financial planners, and supply chain leaders to make sure products are at hand, and to take care of inventory control, product delivery, and customer satisfaction. But then COVID19 came along and, overnight, none of this worked any more. That was challenging, and I was thrilled to be on my mission to help customers overcome that challenge.”

Gomez began her Microsoft career as Global Executive Director for Pharmaceutical & Life Sciences Manufacturing and Supply Chain Digital Transformation, and had the opportunity to accelerate digital transformations during COVID-19 – a time, she says, “when customers looked to technology companies to help them overcome their supply chain challenges”.

84 June 2023 MICROSOFT

Yury Gomez – Microsoft’s Process Industries lead – explains why the company’s tech ecosystem is driving change

supplychaindigital.com 85

Tubeforging plant frontline workers using Microsoft products to support supply chain operations

Now, she leads digital transformation for all process industries – including the chemicals industry, specialty chemicals, pulp and paper, steel, pharmaceuticals, and the consumer packaged goods space.

Gomez admits that, although most people know Microsoft as the company that created Windows and Xbox, for the past three years, “it has been doing a phenomenal job impacting industry digital transformation”.

Cloud helping Microsoft pioneer transformation projects

“With the advance of cloud computing and technology, we've had the opportunity to

YURY GOMEZ GLOBAL COMMERCIAL LEADER, PROCESS INDUSTRIES, MICROSOFT

86 June 2023

“With advances in cloud computing and technology, we’ve been able to impact how industries think about the digital transformation journey”

impact how industries think about their digital transformation journey,” she adds.

The industry solutions and partner sales organisation of Microsoft is organised by industries. “In manufacturing there are two main kinds of companies: Discrete and Process,” explains Gomez. “For Discrete, you can think of aerospace, for example, but there is also process manufacturing, like chemical companies.”

Her role is to “elevate” customer journeys by “helping them envision how digital transformation can help them accelerate efficiency, increase return on investment, and transform the way they work”.

YURY GOMEZ

TITLE: GLOBAL CHIEF COMMERICIAL LEADER, PROCESS INDUSTRIES

COMPANY: MICROSOFT

LOCATION: UNITED STATES

Yury is the Global Chief Commercial & Strategy Officer

for the Process Manufacturing Industry division at Microsoft. She leads the GTM strategy and sales execution for process industries including chemicals, pharmaceuticals, CPG and others. In her role, she drives end-to-end digital transformation for Fortune 100 companies and many more working with engineering, sales, and partner teams.

Yury has over two decades of industry experience. Prior to joining Microsoft, she worked for Johnson & Johnson, Solvay, and various startups where she had multiple leadership roles leading innovation, manufacturing, E2E supply chain, commercial operations, and

supplychaindigital.com 87 MICROSOFT

The Triple-Double for Logistics . . .

How aThingz and Microsoft are Co-Piloting Global Logistics Transformation.

Supply chain digital twins must continue to evolve in order to drive optimal business outcomes. aThingz and Microsoft are delivering rapid transformation within global logistics organisations by fusing the informational (data), physical, and financial supply chains (the triple threat), and converging planning with execution (the double threat).

This new “Triple-Double” approach helps companies make faster, cost-optimised decisions that solve the most stubborn global logistics problem statements.

Learn more

Autonomous Supply Chain.

aThingz is a unicorn supply chain and logistics solution provider enabling organisations to rapidly take cost out of their logistics spend while helping them be more agile and resilient. Customers reap accelerated value by week 6 with aThingz.

aThingz’s founders are Vijaya Neela, President & CEO and Kannan Ramachandran, Chief AI and Commercial Officer.

Vijaya establishes the supply chain transformation roadmap for customers and leads solution development and delivery engagements. Kannan is focused on aThingz’s AI strategy, managing customer relationships, and leading revenue growth initiatives.

“We are building solutions with an AI component that is a competitive differentiator for our customers. The speed and accuracy of business decisions rely on quality data. Our AI-powered purposebuilt data management solution for Supply Chain and Logistics can identify data anomalies, apply pattern

recognition techniques to standardize, cleanse, and improve the quality of data.”

Logistics management

Vijaya sets the vision for aThingz’s unique approach to global logistics management within the supply chain.

“We establish a customer digital twin model that overlays the physical, financial, and informational supply chain, and analyse historical planning and ongoing execution data to continuously calibrate the effectiveness of the plan. Planning and execution should not be considered two separate entities but should be a closed-loop process for optimal cost savings, efficiencies, and contextual insights.”

aThingz’s partnership with Microsoft

“We’ve been a strategic Microsoft partner for over five years,” says Kannan. “Our solution has been built ground up on their Azure stack using composable microservices. We leverage 100% of what Azure has to offer.”

“We will be co-piloting with Microsoft well into the future” says Kannan. “Our solutions use conversational AI, machine learning, deep learning, intelligent solvers, advanced heuristics, hyper automations, workflows, and alerts. Microsoft’s Azure stack has made it possible for us to drive accelerated innovation and business value for our customers.”

Gomez works with executives at C-Suite level to “better understand their business problems, how they are organised, and their operating models”. She then shares with them what Microsoft is doing in the wider world for other industries and customers.

She says: “I then go deeper into how Microsoft – with our cloud computing technology, our business applications and infrastructure – can help them transform.”

Crucially, she says, it is people who are always at the centre of my conversation with customers because “people are the lifeblood of how companies manufacture, operate and deliver products”. This approach informs Microsoft about the broader culture at the client, and the right journey and roadmap to help customers with a holistic approach to improve their operating processes and impact their workforce to work in new ways.

WATCH NOW 90 June 2023

Microsoft empowering manufacturing firms to accelerate supply chain innovation

“We help transform everything – people, processes, data, and systems,” she explains, “so that these converge into a new journey that will transform how companies can do more with less, and in a more advanced way.”

Visibility is among the main supply chain challenges

So, what are the top supply chain challenges that her customers are facing today?

“The list is enormous,” she says, “but one thing we find most often is that customers need visibility.” This goes back to the effects of the pandemic. The main challenge is endto-end visibility in the value chain ecosystem.