Bjoern Kirchner shines a light on Henkel’s remarkable supply chain transformation Henkel’s new May 2023 | supplychaindigital.com Logistics in the Fast Lane Innovation the watchword at space-age McLaren Reshaping Pharma Supply Chains Microsoft’s Mike J. Walker on the unique challenge of pharmaceutical supply Fail to Plan, Plan to Fail The importance of demand planning SUPPLY CHAIN CUSTOMER-FIRST Supply chain schools NETSTOCK | ROLAND BERGER | UBER FREIGHT FEATURING:

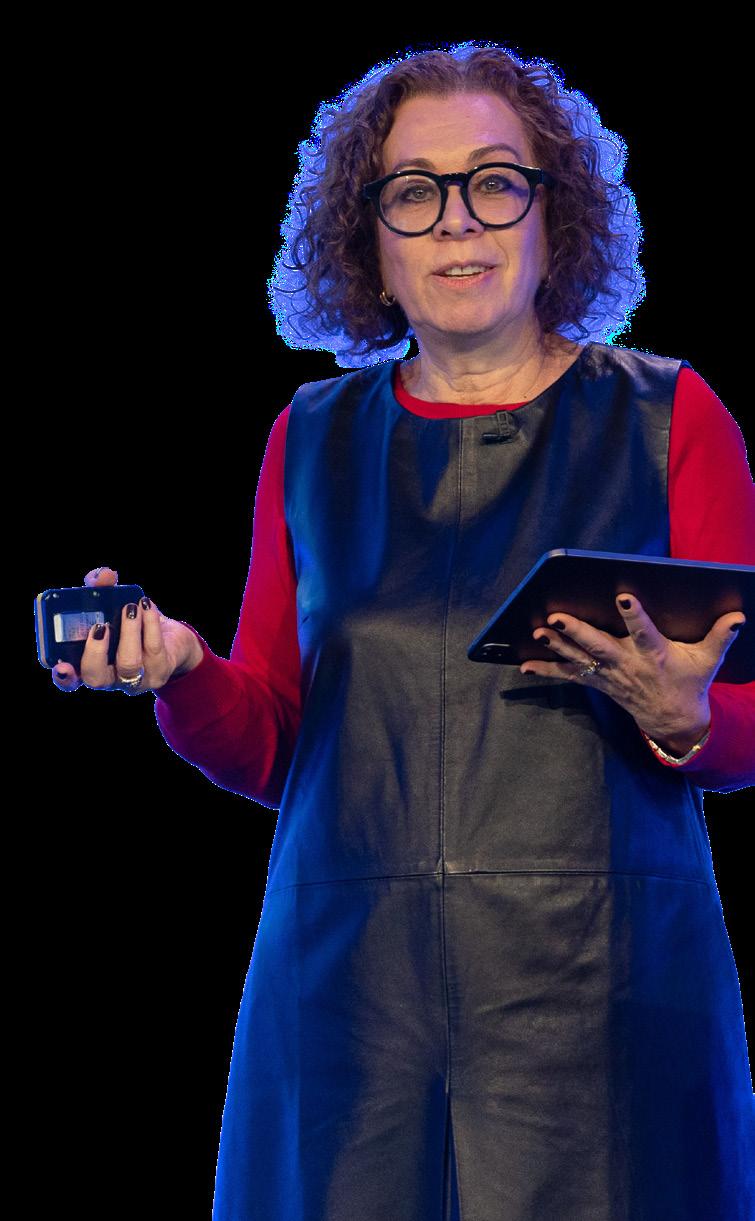

A BizClik Event Join the Virtual Event Disrupting Procurement & Supply Chain 28TH JUNE 2023 VIRTUAL CONFERENCE

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Sponsorship Opportunities

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.

▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

bizclikmedia.com

Ways to Work With us

We produce Digital Content for Digital People across 20+ Global Brands, reaching over 15M Executives

Digital Magazines

Websites

Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

Work with us

The SupplyChain Team

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

PROOFREADER

JESS GIBSON

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN/

SUPPLYCHAIN LEAD DESIGNER

ANDY WOOLLACOTT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANNA

SALLY MOUSTAFA

JINGXI WANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KAYLEIGH SHOOTER

PROJECT DIRECTORS

MIKE SADR

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

THE COMMUNITY

JOIN

+

DEMAND PLANNERS ARE THE MIRACLE WORKERS OF SUPPLY CHAIN

WHAT SUPPLY CHAIN CHIEFS REALLY NEED ARE CLAIRVOYANTS, BUT THE NEXT BEST THING IS A GOOD DEMAND PLANNER

A running joke among supply chain professionals is that, in today’s uncertain and volatile world, what they really need is the services of a clairvoyant armed with a crystal ball.

Instead, they have to settle for the next best thing: an old-fashioned, non-mystical demand-planning professional.

Demand planning has never been more important. Post-pandemic supply disruption, war in Ukraine, rampant inflation, and workforce volatility. The seismic challenges just keep rolling in.

That’s why, in this issue, we explore the role of demand planners – the people who optimise inventory levels, reduce out-of-stock instances, and improve customer service levels, while minimising costs and inefficiencies.

‘Miracle worker’ might be a better job title, given the difficulties most of them face on a day-to-day basis. But supply chain is full of miracle workers, and we do our best to give as many as possible their moment in the sun.

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

SUPPLYCHAIN DIGITAL MAGAZINE IS PUBLISHED BY © 2023 | ALL RIGHTS RESERVED supplychaindigital.com 7

“Miracle worker might be a better job title for demand planners, given the challenges most face on a daily basis”

FOREWORD

CONTENTS

UP FRONT

014 BIG PICTURE Roll out the red carpet – for supply chain A-listers

020 LIFE TIME ACHIEVEMENT

Anna Spinelli: Deutsche Post DHL is a world-leading logistics company, founded in 2002 when Deutsche Post AG acquired DHL

024 FIVE MINS WITH Michelle Knight on how she helps businesses mitigate risk by providing visibility on the ever-changing supply chain ESG regulations landscape

020 024 014 160 8 April 2023

055 SUPPLY CHAIN

Fail to plan, plan to fail: the critical crystal ball of demand planning

076 LOGISTICS

Turbulence on journey to net zero air cargo

104 SUSTAINABILITY

Sustainable sourcing a net zero necessity

132 TECHNOLOGY

Uber freight looks to an autonomous future

160 TOP 1 0

Supply chain schools in the US

055

104 132 supplychaindigital.com 9

076

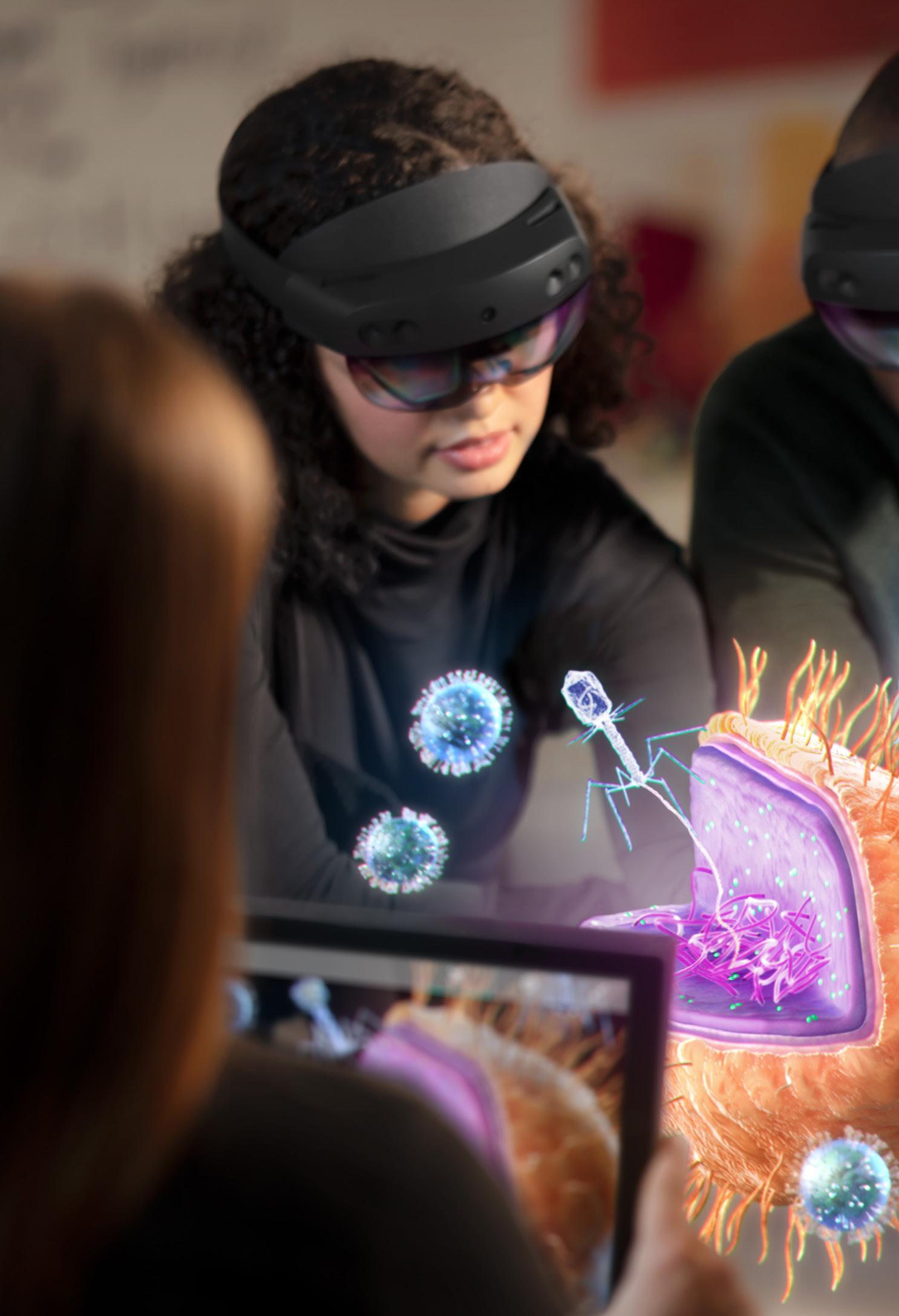

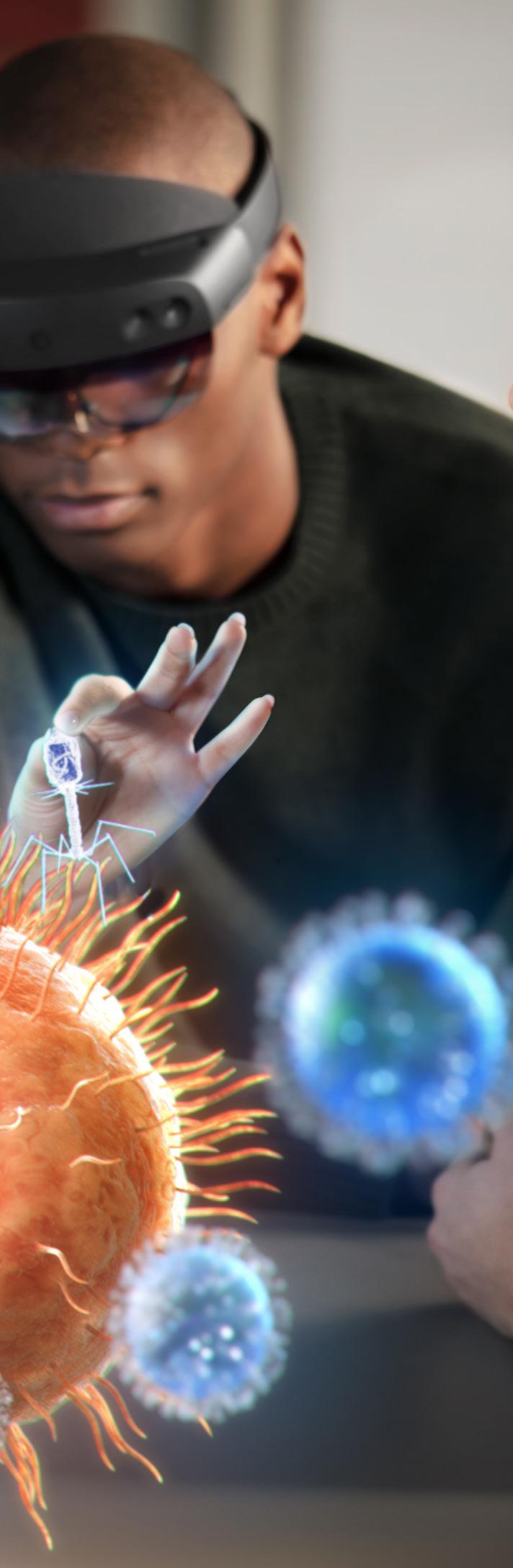

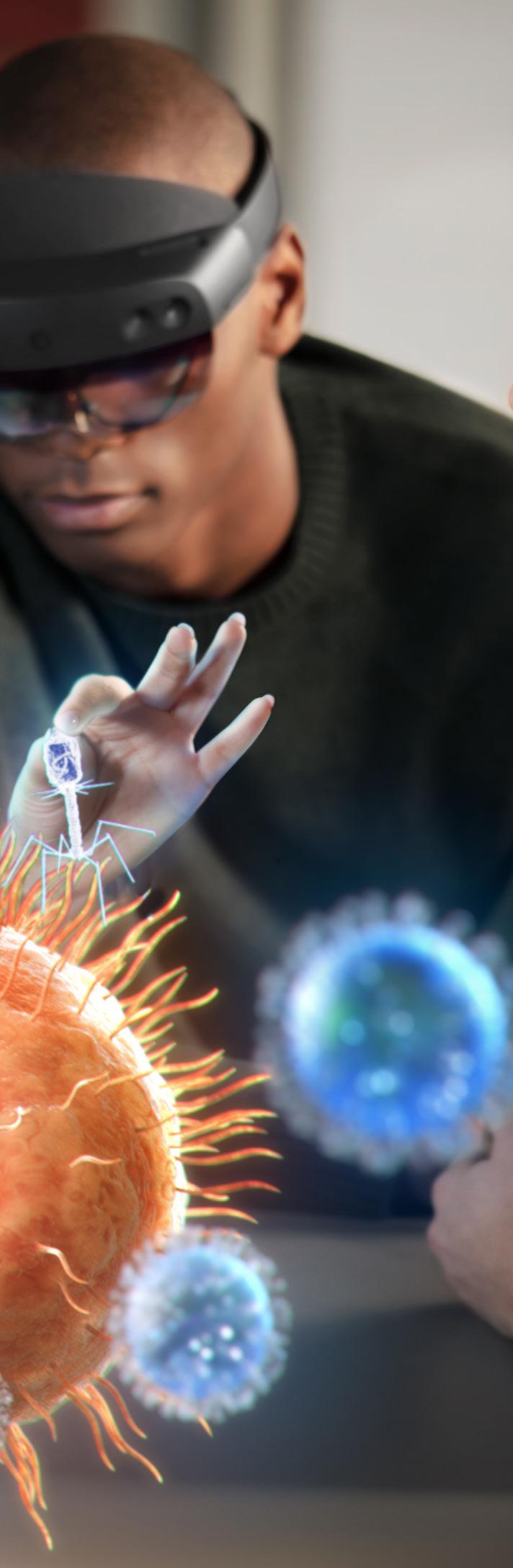

MAY 2 023

FEATURES

Business Design Centre, London

2023

26 - 27 September

GET YOUR PASS SPONSORSHIPS A BizClik Event Join the Event Disrupting Procurement & Supply Chain

026 060 088 116 144 MAY 2 023 COMPANY

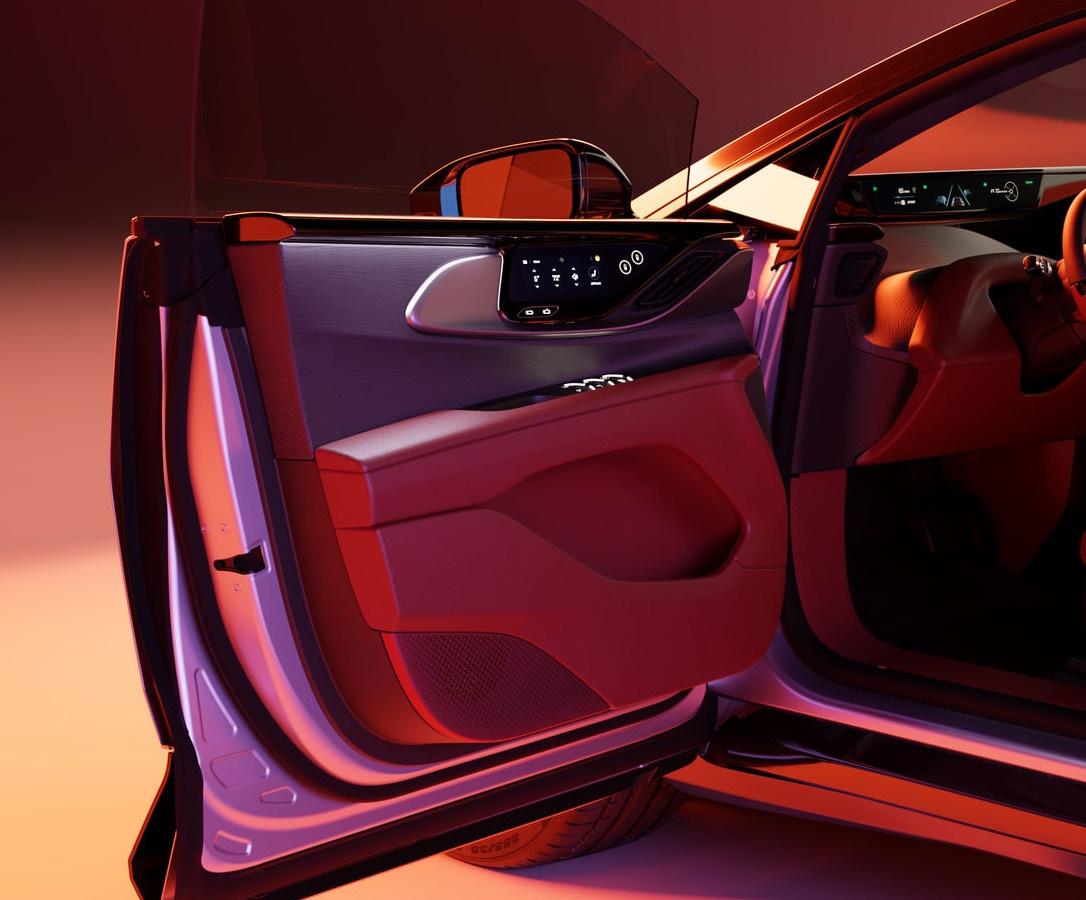

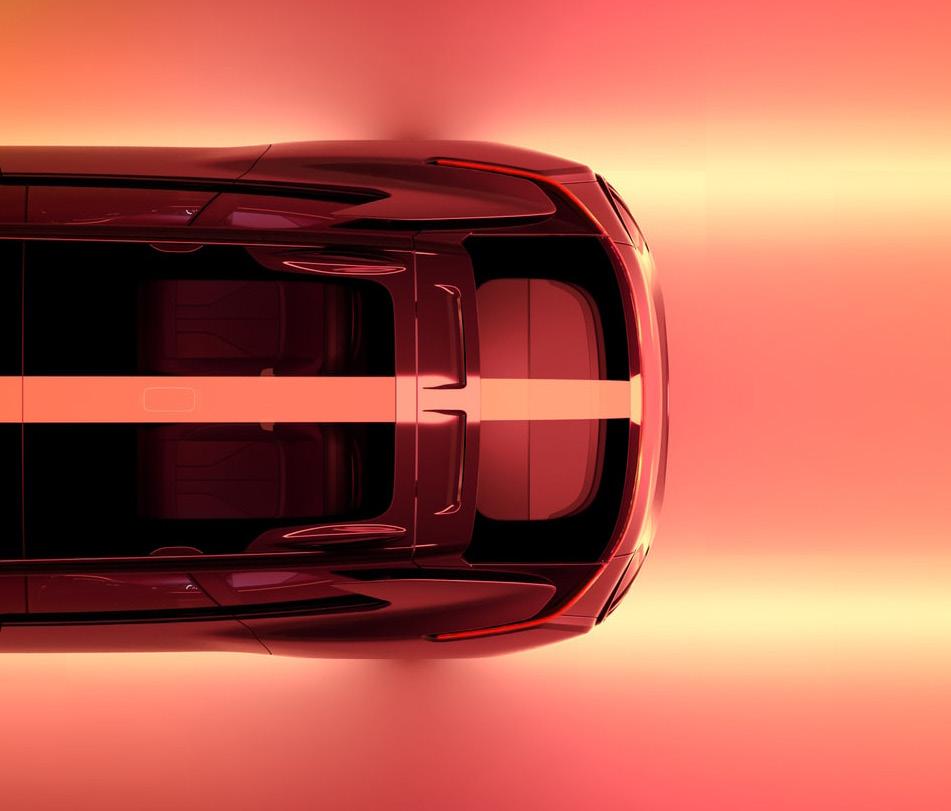

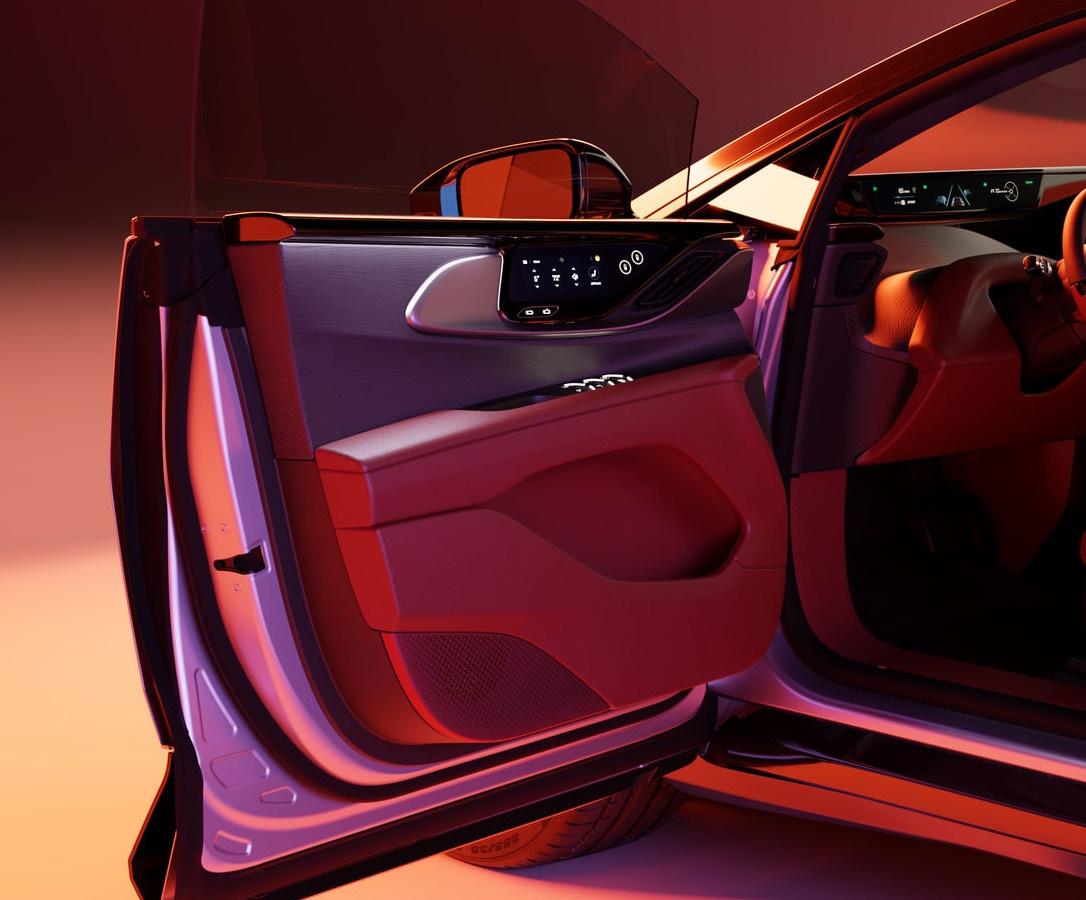

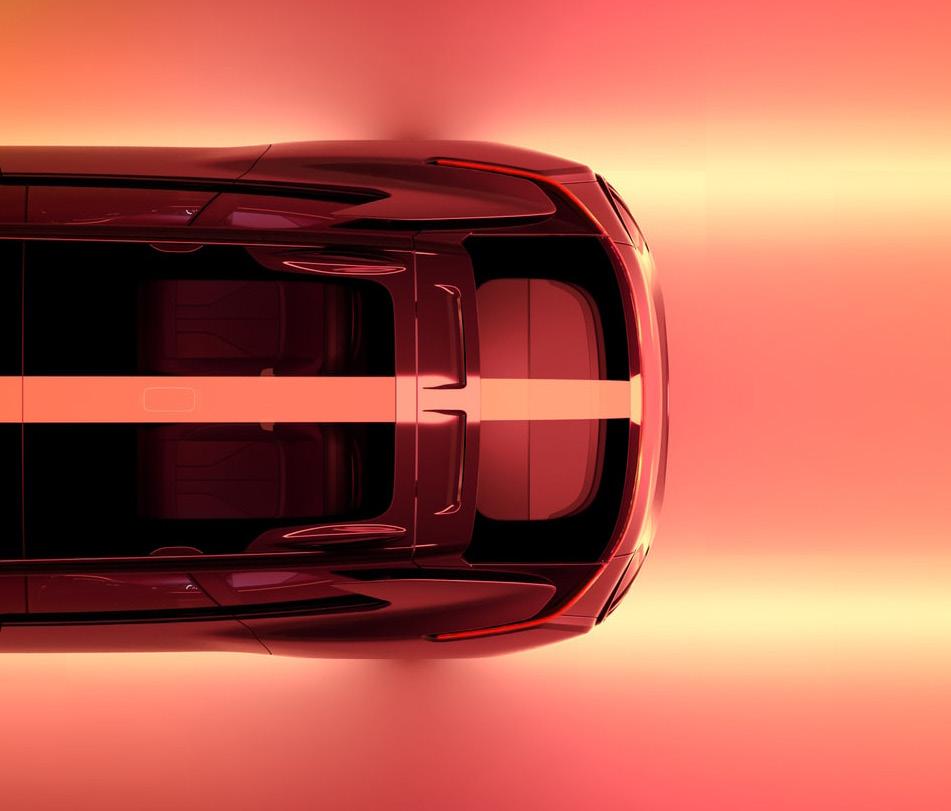

026 HENKEL Henkel’s secret to success: Amazing customer experience 060 META Meta EMEA: Connecting communities through supplier diversity 088 UNITED UROLOGY GROUP Safeguarding health through supply chain 116 MICROSOFT Mike J. Walker at Microsoft empowers pharma supply chain innovations 144 MCLAREN Supply chain transformation in the fast lane 172 FARADAY FUTURE The leader in luxury electric vehicles supplychaindigital.com 11

REPORTS

A BizClik Event Join the Virtual Event Disrupting Procurement & Supply Chain 28TH JUNE 2023 VIRTUAL CONFERENCE

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Sponsorship Opportunities

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.

▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

BIG PICTURE

Roll out the red carpet – for supply chain A-listers

Cannes, France

Every year since 1946, the world has gathered in the tranquil French town of Cannes to enjoy the Cannes Film Festival. It’s one of the biggest media events in the world, as 4,500 film industry professionals – including an A-Z list of Hollywood icons – attend screenings and social events.

The procurement and logistical challenges around organising the festival are onerous, and include providing for:

n 80,000 festival goers

n 4,000 journalists

n 230,000 visitors (triple its usual population).

n 1,000 people working on the Festival.

Oh, and someone also needs to procure 180 metres of red carpet – every single day.

14 May 2023

supplychaindigital.com 15

“There is a sense of urgency that behaviour around sustainability must be part of your company’s strategy”

Anna Spinelli

Deutsche Post DHL is a world-leading logistics company, founded in 2002 when Deutsche Post AG acquired DHL

Anna Spinelli is a strategic thinker with a practical mind. In her 20-year career – as an experienced executive leading multicultural and diverse organisations – she has had to be.

Spinelli has a proven track record of driving transformation while enhancing performance sustainably. She says she is “passionate about developing meaningful supplier relationships and engagements, building a competitive ecosystem”.

Constantly looking for ways to enhance a company’s success beyond functional and personal boundaries, Spinelli began her career at Fiat Chrysler Automobiles.

Over the past two decades, she has climbed the corporate ladder, working for organisations in the automotive, consumer goods, telecommunications and logistics industries.

Such companies include Opel AG, General Motors, BMW and Phillips, before joining Deutsche Post DHL in 2020 as Chief Procurement Officer.

In March 2022, Deutsche Post DHL announced one of Spinelli’s

proudest moments since she began working for the logistics company: the signing of two of its largest Sustainable Aviation Fuel deals, with BP and Neste.

Working with her cross-functional procurement team, Spinelli contributes fully to the company’s sustainability roadmap, working to boost the company’s decarbonisation efforts. Spinelli’s peers on LinkedIn describe her as a “natural born leader”, with both “astonishing technical skills and interpersonal skills”.

Spinelli’s many skill sets include: purchasing, supply management, global sourcing, supplier development and supply chain management. In our recently published Top 100 Women in Procurement 2023, Spinelli sits in 21st place, and in the fast-changing world of procurement, she was named the single most influential woman in our 2022 list.

Sustainability in supply chain and procurement

It can be clearly seen from her career that Spinelli is a firm believer and advocate for sustainability.

LIFETIME ACHIEVEMENT AWARD supplychaindigital.com 17

LIFETIME ACHIEVEMENT AWARD DHL x Coldplay Working together for a more sustainable world tour WATCH NOW

Spinelli speaks eloquently about the value sustainability has in procurement, and also highlights the correlation between sustainability and long-term value creation among partners, and how building resilience to be more decisive in procurement can accelerate the value stream in business strategies.

“As such, procurement stands to benefit from the supply chain increasing its transparency and supporting sustainable and ethical sourcing strategies,” she says.

Spinelli adds: “Concerning Sustainability there is a sense of

ANNA SPINELLI

TITLE: CHIEF PROCUREMENT

OFFICER & HEAD OF MOBILITY

COMPANY: DHL FREIGHT

YEAR JOINED: 2020 (AS CPO)

EDUCATION: UNIVERSITÀ DEGLI

STUDI DI UDINE AND LICEO SCIENTIFICO

SKILLS: PURCHASING, SUPPLY MANAGEMENT, SUPPLIER DEVELOPMENT, STRATEGIC SOURCING

urgency. The expected actions and behaviours need to be part of your company’s strategy, which means where you put focus needs to be meaningful and fit to the company’s purpose – in our case, ‘connecting people improving lives’. Communication is therefore absolutely key and setting meaningful targets can also create focus on the critical topics.”

She is also a graduate from the Università degli Studi di Udine – with a degree in Management Engineering – and is fluent in four languages: English, German, Italian and Spanish.

supplychaindigital.com 19

MICHELLE KNIGHT

Michelle Knight on how she helps businesses mitigate risk by providing visibility on the ever-changing supply chain ESG regulations landscape

MICHELLE KNIGHT

TITLE: CHIEF PARTNERSHIP & STRATEGY OFFICER

COMPANY: ETHIXBASE360

WHAT IS YOUR PROFESSIONAL BACKGROUND?

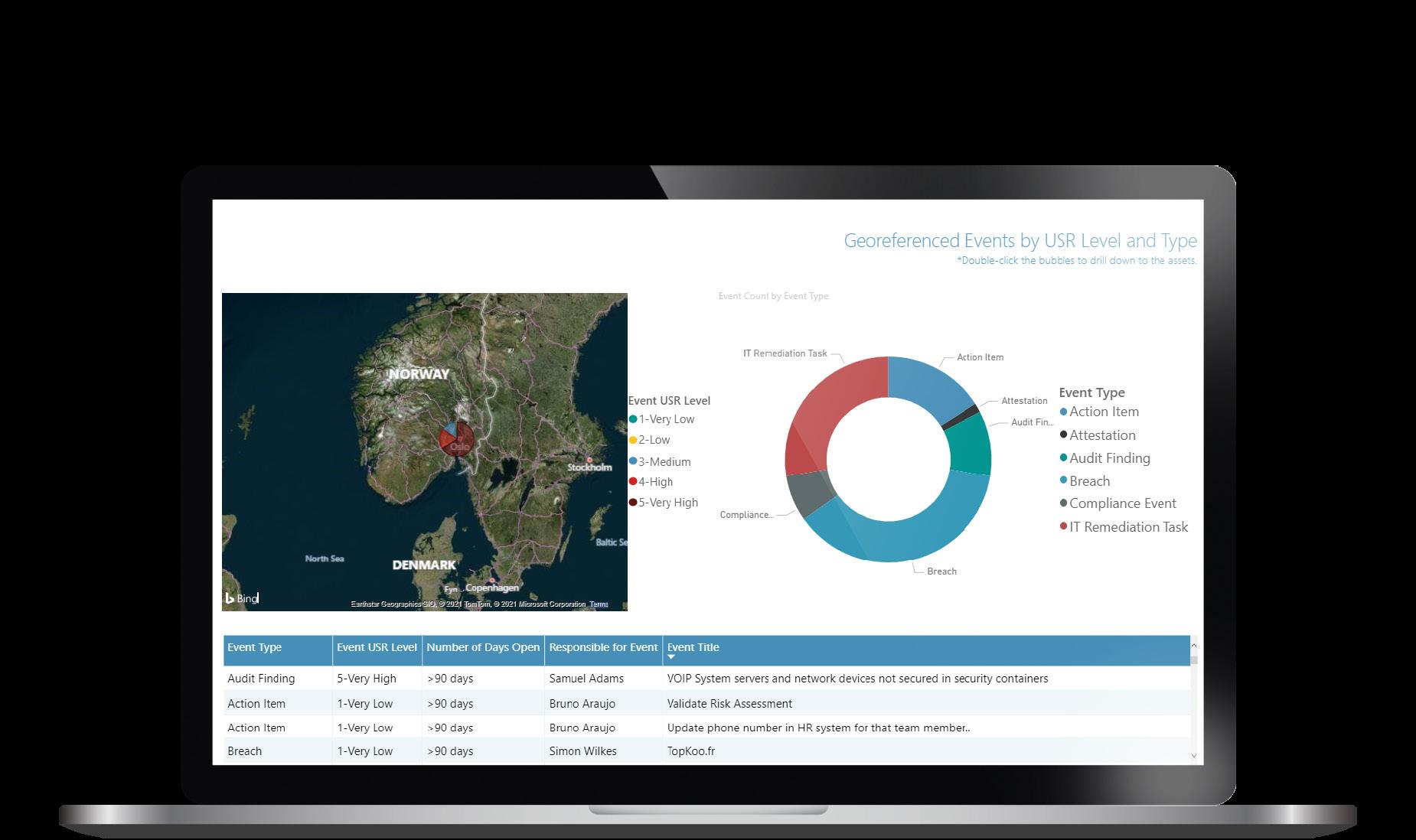

Michelle Knight says of Ethixbase360: “We help organisations elevate, build, maintain and monitor sustainability in their supply chain.”

Knight provides clients with “a deep and broad view of supply chain risk”, including: anti-corruption, human rights, and labour & environment.

“We access complex data sets from millions of open sources to give clients transparency into their third-party supply chain,” she says.

» I have worked in the risk and compliance industry for over 25 years, in global roles with large risk-management organisations and boutique compliance companies in Hong Kong, Singapore, Sydney and London.

WHAT IS ETHIXBASE360, AND WHAT’S YOUR ROLE THERE?

» Ethixbase360 is a global leader in third-party risk and compliance technology. We offer a comprehensive end-to-end risk management solution for managing third party risk.

I oversee the research function at Ethixbase360, as well as looking into partnership opportunities and working on strategic accounts.

EXECUTIVE BIO

FIVE MINUTES WITH... 20 May 2023

BIGGEST ESG CHALLENGES FACING SUPPLY CHAINS?

» New regulations and reporting standards are placing demands on companies for more-credible corporate disclosures, which are linked to the risk of potential fines for non-compliance of existing or incoming ESG legislation.

This is coupled with an increasing customer awareness of sustainability themes, high expectations from new and existing employees to work for and with ethical companies, and the need to demonstrate solid ESG credentials in stakeholder management and investment raising.

More and more companies are being asked to measure and report on their supply chain sustainability metrics.

HOW DO YOU HELP FIRMS OVERCOME THESE CHALLENGES?

» By increasing end-to-end supply chain transparency, and by exploring

risk with all third parties, by interrogating that risk and by collaborating with third parties to elevate standards and protect businesses.

Originally, we focused on governance and anti-bribery risks but our platform and approach has developed handin-hand with our clients and their third parties off the back of their real-world needs, which is why we focus on risks across the ESG spectrum.

HOW DOES THE GERMAN SUPPLY CHAIN ACT CHANGE THINGS?

» This came into effect at the beginning of the year and affects all companies doing business in Germany, as well as their direct and indirect suppliers.

Companies with more than 3,000 employees must comply with the Law, with firms of over 1,000 employees being included from early 2024.

It applies to the entire value chain and specifies how companies must

“More and more companies are being asked to measure and report on their supply chain sustainability metrics”

supplychaindigital.com 21

perform due diligence on human rights and the environment, including analysing possible risks, taking measures to prevent and mitigate any violations, setting up grievance mechanisms, and reporting on relevant activities.

Compliance will require additional resources for companies that are affected, but those complying with similar laws in other countries have a head start, especially if they have automated due diligence and risk management processes.

Businesses still relying on manual or homegrown risk-management systems can expect a steep learning curve.

HOW DO YOU HELP FIRMS ADAPT TO NEW SUPPLY CHAIN LEGISLATION?

» Staying on top of ESG regulations is already very important for organisations, and it will become even more important over time. The new German supply chain law is part of a wider movement that’s likely to bring more ESG regulations. For example, the EU Supply Chain Directive, once approved, will mandate extensive due diligence requirements. Ethixbase360 helps by automating manual processes and providing a single platform for risk assessment, risk ratings, and other risk management workflows. It allows clients to replicate existing

FIVE MINUTES WITH...

22 May 2023

processes and workflows, for an easier transition from manual to automated systems. It also performs risk assessments on third parties, applying a company’s own risk criteria, thresholds and weighting.

WHO INSPIRES YOU?

» I continue to be inspired by my family, my friends and my colleagues who have all contributed to where I am today.

I have also been very fortunate to have lived in a number of different countries, both as a child and an adult. As a result I have experienced different cultures and learned to be resilient. I have grown from all these experiences.

We are Ethixbase WATCH NOW

“Staying on top of ESG regulations is already very important for organisations, and will become even more important over time”

supplychaindigital.com 23

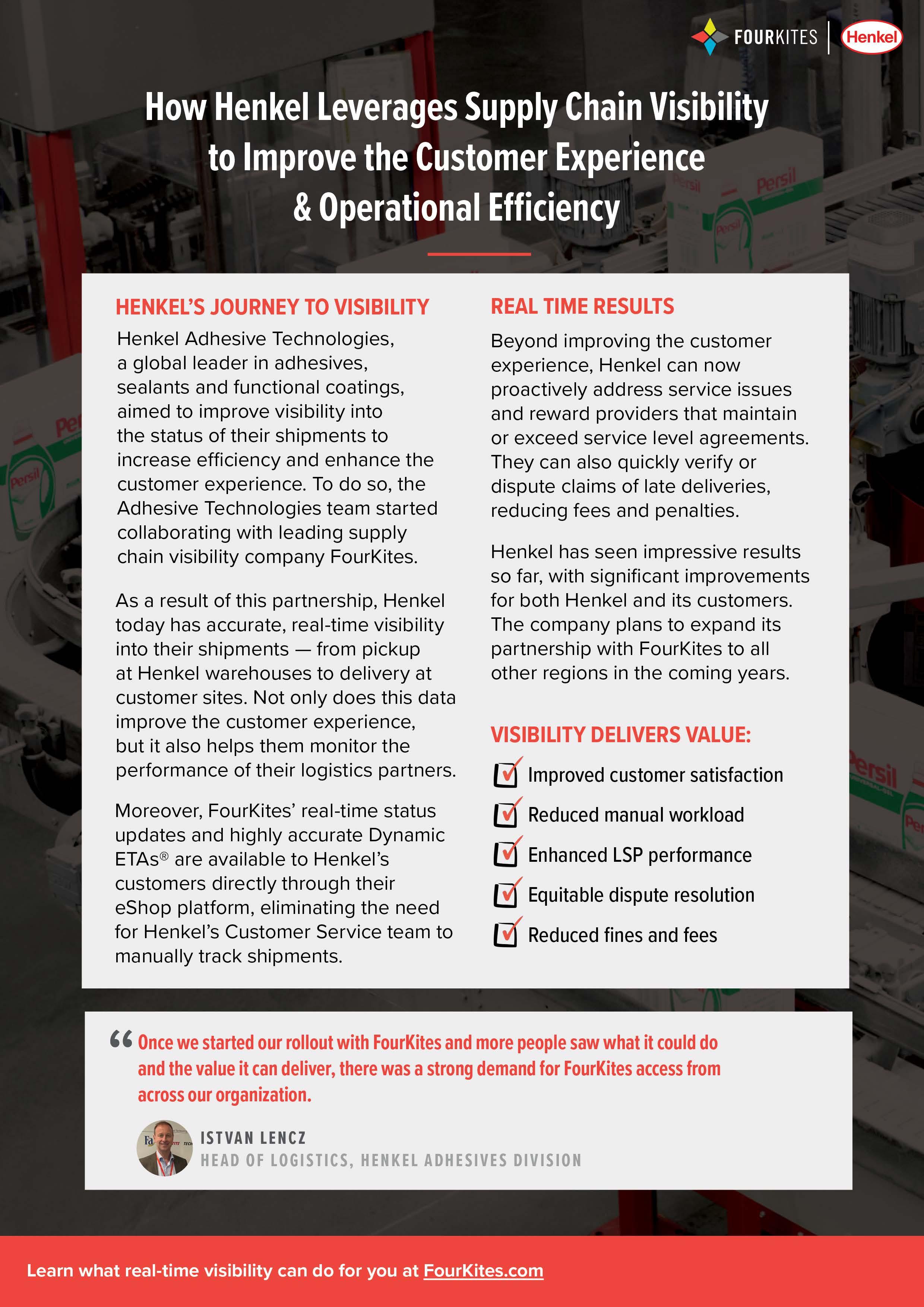

HENKEL’S SECRET TO SUCCESS:

AMAZING CUSTOMER EXPERIENCE

WRITTEN BY: ILKHAN OZSEVIM

PRODUCED BY: CRAIG KILLINGBACK

26 May 2023

customercentric Supply Chain (SC) transformation

It all began with a vision. Henkel, the German multinational chemical and consumer goods company, many of whose goods you surely consume and have done since your childhood, saw that the world was changing. Henkel recognised that they needed to transform, and to be able to do this, they completely reimagined the supply chain.

Unravelling this vision, is Bjoern Neal Kirchner, the Global Head of Supply Chain for adhesive technologies. The goal was to create an amazing customer experience as a competitive edge.

Kirchner explains: “The vision behind the customer-centric Supply Chain (SC) transformation programme emphasised the potential for supply chains to contribute to the top line, in addition to the traditional bottom line.”

“While most supply chains focus on improving cost positions, inventory and working capital – in other words, KPIs established on traditionally internal data –Henkel believes that supply chains can also improve how customers engage with the company itself,” says Kirchner.

“By optimising the many touchpoints that customers have with Henkel throughout the entire supply chain interaction, such as ordering, logistics and planning, Henkel aims to provide a unique customer experience that can set it apart from its competitors.” This is a creative and visionary approach.

28 May 2023 HENKEL

Henkel’s

programme is nothing short of remarkable; Bjoern Kirchner shows us how they did it

Inspiration Center Düsseldorf: The state-of-the-art building comprises 30 labs and 4 technology centres for more than 650 Henkel employees

supplychaindigital.com 29

BJOERN KIRCHNER

TITLE: GLOBAL HEAD OF SUPPLY CHAIN FOR ADHESIVE TECHNOLOGIES

COMPANY: HENKEL

Bjoern Neal Kirchner is the Global head of supply chain for adhesive technologies at Henkel.

He is an experienced economist who has studied in both Munich and London. After completing his studies, he opted to travel to China where he was awarded a scholarship to study the Chinese language and immerse himself in the country’s culture. It was during this time that he began his career in logistics, as he sought to better understand China’s supply chain landscape. He secured a position at a logistics company, where he became captivated by the real-world challenges faced by businesses and their employees. From there, he continued to grow within the supply chain industry, holding various positions in different locations, including China, Hong Kong, Switzerland and Germany.

view

When asked how Henkel approaches establishing an amazing customer experience as a competitive edge, Kirchner explains that the company had to effectively relearn its perspective on customers.

The North Star

Instead of building on its own perception of what is good or effective and then executing on them, Kirchner says that Henkel engaged with customers on an entirely different level.

“So, we identified the values that were important to them in their engagement with us,” he says. “And through this process of value mapping, we identified areas where we may have not been delivering up to our customers’ expectations – in areas such as reliability, speed and innovation. Then, based on these findings, we implemented new programmes to improve the customer experience in all of these areas.”

So what is the guiding light in Henkel’s reimagining of the supply chain – or even more correctly – the value chain? Kirchner says: “We knew that we needed a North Star, and we needed it to guide the transformation and ensure that we were getting better at creating amazing experiences for our customers. This North Star was forged out of our customers’ values.”

As an execution-driven operational team, Kirchner says that Henkel are accustomed to having numbers guide them – making it difficult for something like the customer experience to be effectively measured.

“However, we needed an indicator,” he says, “an indicator that shows us whether we are making progress for our customers, and this is where the North Star shines.

“It is also crucial that, as an indicator, the North Star be connected to the overall

“Digital capability should overcome a purely functionalist view of supply chains”

BJOERN NEAL KIRCHNER

€11.242mn 2022 sales (Adhesive Technologies) supplychaindigital.com 31 HENKEL

GLOBAL HEAD OF SUPPLY CHAIN FOR ADHESIVE TECHNOLOGIES, HENKEL

Henkel and CAMELOT: A longstanding, trustful relationship

Bastian Kunze, Partner for Supply and Operations at CAMELOT Group, explains how his company became one of Henkel’s most trusted partners

LEARN MORE

Within any partner ecosystem, trust between organisations is absolutely paramount.

For more than a decade, it’s that exact trust that has enabled Henkel and CAMELOT Group to form a strong and fruitful relationship. CAMELOT has enjoyed 25 years of successful supply chain consulting, leveraging industry expertise in life science, chemicals, consumer goods and industrial manufacturing.

Explaining the firm’s core mission, Bastian Kunze, Partner for Supply and Operations at CAMELOT, says: “We connect people, processes, and technology to enable our global customers during their supply chain transformation journey.

“We are able to do that because we combine management consulting capabilities with enterprise application know-how and digital innovation.”

Trustful relationship at heart of supply chain projects

CAMELOT’S partnership with Henkel began with a supply chain process and solution implementation using SAP APO technology.

Several more projects followed in the ensuing years, mostly in the area of demand, supply and production planning – but always with the aim of innovating Henkel’s supply chain processes.

“We have had to tackle various challenges,” Kunze adds. “These were things like improving the inventory situation or helping Henkel to bring their demand process to the next level. But everything is based on a long-term, trustful relationship. That was always the foundation.”

Recently, the partners tackled a complex supply and inventory project, which saw CAMELOT implement the DDMRP (demanddriven material requirements planning) concept and the innovative Supply Chain Avatar DDMRP module by Elixum. This further improved and positioned inventory throughout Henkel’s entire supply chain network.

Elixum: Home of the Supply Chain Avatar

Elixum is a global software company that was born out of the CAMELOT Group and, in Kunze’s words, ushered in a “new era of operations and supply chain management”.

Its flagship product, the Supply Chain Avatar, is a cloud-based software suite enabling organisations like Henkel to build and plan resilient, sustainable supply chains by combining the best of two worlds. One element of this is next-generation, advanced planning and scheduling functionalities; the other is AI-driven, cognitive decision support during that process.

“With the in-built Hypertrust Platform,” Kunze explains, “the Supply Chain Avatar solutions can be implemented and deployed on any system infrastructure out there in the market.”

Success breeds trust

One thing that clearly helps to build trust between partners is success – and that’s exactly what CAMELOT has consistently achieved. The firm’s proven, market-leading supply chain process experience, combined with deep technology knowledge and global delivery capabilities, has continued to make the difference for Henkel and similar clients.

With its latest project, CAMELOT has increased the visibility of Henkel’s inventory status and projection, using increased automation that facilitates faster decision-making.

Kunze concludes: “We were able to position the inventory in the Henkel network at the right place, with the right quantity, with an overall effect of lower inventories – achieving a greater supply chain resilience.”

LEARN MORE

IN SUPPLY CHAIN PLANNING THE NEW WOW GET YOUR PERSONAL DEMO Orchestrate your supply chain at a new level with Elixum’s intelligent planning software. For insight-based decisions. For resilient operations in turbulent times. For sustainable success and growth. A CAMELOT GROUP COMPANY WWW.ELIXUM.COM https://elixum.com/ https:// elixum.com/ x.io x.io x.io x.i o x.i o x.i o

strategy of the company, which in our case is to create an amazing customer experience with our technologies. By doing so, we ensure that we are always aligned with our overarching goal, and that every step we take is working towards achieving that goal.”

Kirchner says that it’s important to put this indicator in place to ensure that momentum is not lost as progress is made. “Additionally,” he says, “ the truth is that people need encouragement, and seeing the North Star KPI rising is a clear sign that progress is being made towards the company’s vision. To achieve this, we reviewed our current service KPI and brought in the perfect order measurement.

The perfect order

The difference between the perfect order measurement and other internal data is that with the perfect order, Henkel is able to cast its net much wider, capturing data points from the customer’s perspective as well. By doing so, they are able to take into account the actual time of arrival; what the customer requested initially; and what Henkel have promised to deliver. “By measuring progress against these external data points, we can be sure that our customers will feel the difference,” Kirchner says.

supplychaindigital.com 35

HENKEL

Fixing a kitchen worktop with Pattex

Reimagining the customer-supply chain relationship – 360 degrees Henkel has a philosophy that “digital capability should overcome a purely functionalist view of supply chains”. Kirchner says: “Traditionally, supply chains are viewed as a linear chain of events that transform raw materials into finished goods, with the customer only at the end of the chain.

“However, Henkel believes that new technologies can enable a 360-degree view of the customer, putting the customer at the centre of all functions that interact with them.”

This approach requires a different set of technologies to ensure that everyone in the company has the same view of the customer experience. “For example,” he says, “service cloud technology allows for customer service interactions to be tracked and followed up on, providing insights into customer satisfaction levels.”

Digital capability, in this example, is an enabler to drive towards a new customer experience.

“The vision behind the customercentric Supply Chain (SC) transformation programme emphasised the potential for supply chains to contribute to the top line, in addition to the traditional bottom line”

36 May 2023 HENKEL

BJOERN NEAL KIRCHNER GLOBAL HEAD OF SUPPLY CHAIN FOR ADHESIVE TECHNOLOGIES, HENKEL

14% of global market

Across all 60 segments (Adhesive Technologies)

Bjoern Neal Kirchner

Bjoern Neal Kirchner

Flo Group is the leading OTM implementing specialist from Europe and the developer of new software solutions to optimise logistic processes.

A team of experts in IT, supply chain and logistics solutions worldwide. Every day they implement, develop, integrate, and connect software to solve any supply chain and logistic challenge.

Discover our Services 〉〉

Flo Group delivers OTM with excellence in client-centricity

As the leading OTM implementation partner, Flo Group’s CEO Michiel Keijzer shares how its expert consultants deliver customer-centric strategy and outcome

With circa 250 consultants globally, Flo Group is the market leader for Oracle Transportation Management System (TMS) implementation. With core teams in Europe, India, and South America, Flo is home to many senior experts with more than 15 years of experience driving knowledge around the Oracle product, which is helping support small and large scale businesses.

Built on a people-centric culture, Flo enables its consultants to develop and grow with echoing effects across its team and client base, delivering excellence and a like-minded approach to transport management.

To achieve this, Flo Group’s CEO, Michiel Keijzer, explained how Flo has created

a templated approach upon which its consultants can build to support businesses operating globally.

“The template can subsequently have functionality and locations added to ensure the solution meets local needs where required,” says Keijzer. “We do encourage our clients to keep localisations to a minimum for ease of solution ownership going forward.”

In the early stage of Oracle TMS rollout, Flo is heavily involved in the process to ensure a successful execution, where consultants are able to get clients on board with the solution for their own specific use cases.

“Our consultants will develop the core solution

and then support the global deployment for each regional roll out,” says Keijzer. “During the roll-out stage, we will work with the clients’ own teams as they become more familiar with the solution. After each ‘go live’ during a deployment, we will hand over to the Flo support team that offers 24/7/365 live solution support and is thereby able to support any timezone.”

This client-centric approach inherently puts Flo in a great position to meet and exceed customer expectations, which has been critical to its success and a leading component of its journey to Oracle Transport Management (OTM) stewardship.

“Henkel believes in the outside-in approach to supply chains, taking in the views and the voices of the customer, as well as data points from outside the company, to design and improve its supply chain performance towards customers”

BJOERN NEAL KIRCHNER GLOBAL HEAD OF SUPPLY CHAIN FOR ADHESIVE TECHNOLOGIES, HENKEL

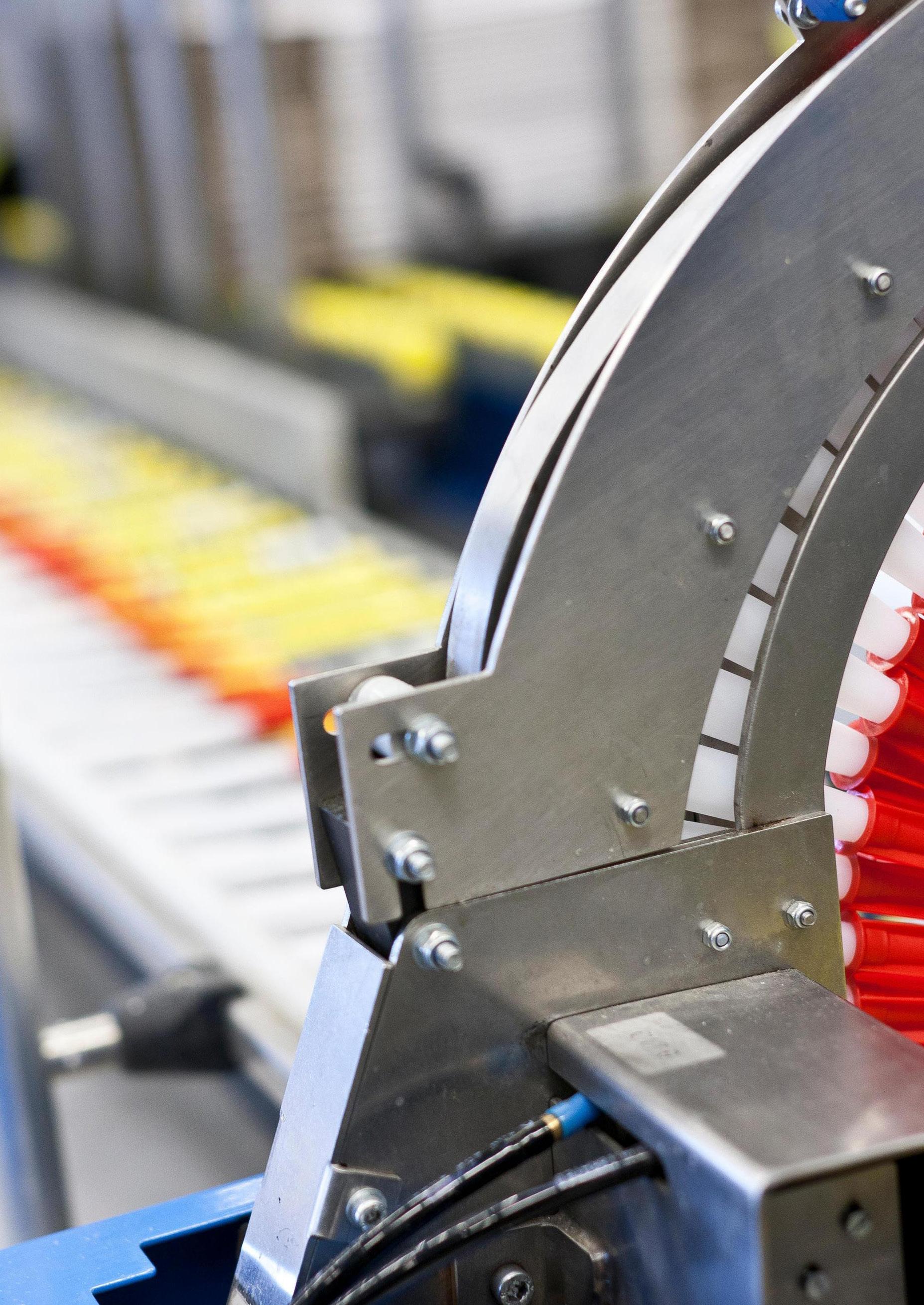

Adhesives production at the site in Düsseldorf

Rechanneling data: from inside-out to outside-in

Kirchner discussed the difference between the inside-out and outside-in approach to supply chains, and where Henkel stands on this.

Kirchner says: “As the term ‘supply chain’ indicates, it is, in essence, a chain of events. We can visualise this as two opposing streams. The first consists of the material flow, which exists from the procuring of raw materials, to producing intermediaries, on to finished goods, and finally out to delivering those goods to customers.

“Then there is the information flow –and this streams in the opposite direction, from the demand of the customer, on to production and procurement.”

The traditional inside-out approach is where a company accesses the information it has inside of its company, and constructs its reality around that. Kircher expresses that as a company matures in the supply chain, they enhance their perception of their needs, and this is where digital capabilities come into play. “You begin to understand that you need to extend your visibility to the data you receive on both ends of your value chain.” Kirchner says: “In contrast, the outside-in approach acknowledges that a company is part of a much larger value stream that includes suppliers, distributors, customers and consumers.

“By taking these perspectives into account, we are able to make decisions that are better aligned with the overall value stream. Henkel believes in the outside-in approach, taking in the views and the voices of the customer, as well as data points from outside the company, to design and improve its supply chain performance towards customers.”

supplychaindigital.com 41 HENKEL

Building the value chains of tomorrow

As a leading value chain consulting and technology company, Bluecrux transforms today’s supply chains into smart, efficient and fully integrated value chains. As a community, that is built on the intersection which they call “the Cutting X”: where problem meets purpose, and expertise meets technology. Where supply chains evolve, and value chains are forged.

Transforming supply chains into the value chains of tomorrow

with purpose. Like no other player in the market, we offer a unique value proposition. One where expertise and technology converges.” Bluecrux focuses on distinct industry verticals, backed by the belief that specialised knowledge is crucial. It focuses on these main clusters:

Schoenmakers.

Founded in 2011, Bluecrux uses an ecosystem approach transforming the value chains of tomorrow. “The time of either providing advice or providing technology solutions is behind us,” says Managing Partner Anouk Schoenmakers: “We work with our customers to go from the initial ideation towards actual implementation and real results, combining consulting services with state-of-the-art technology.”

Across Bluecrux’s diverse customer base, it sees the same elements creating the rising complexity companies need to deal with nowadays:

1. The increasing speed at which business decisions need to be taken.

2. The growing uncertainty that businesses are facing.

3. The digitisation of technological progress that is needed.

4. The looming market disruption behind every corner.

“And while our answer to our customers’ complexities is always different, the elements that make up our offering are typically the same,” says Schoenmakers. “We connect a deep understanding of the problem with solutions

1. Pharma

2. MedTech

3. Healthcare

4. CPG

5. Specialty chemicals

6. Industrial manufacturing

“In our focus industries, we have the ability to help our customers to transform their entire value chain end to end,” says Schoenmakers. “At the heart of Bluecrux is the belief that innovation is born of collaboration. This requires a community approach, building a movement that is called The Cutting X. Where supply chains evolve and value chains are forged.”

Bluecrux’s transformational, collaborative, customer-centric approach is essential to Henkel: “No longer looking from an inside-out perspective, pushing one size fits all standards across the supply chain. Instead, we look through the customer’s lens.” Schoenmakers says: “We share the belief with Henkel that supply chains should no longer be linear, functional and siloed. Hence, we started a transformation journey together, to deliver real customer centricity.”

The key to overcoming complexity and unlocking supply chain value is the convergence of business and technology, says Bluecrux’s Anouk

more

Learn

From vision to reality: crafting the customer CX program

According to Bjoern Kirchner, the first step of building a customer centric Supply Chain (SC) transformation programme at Henkel was to engage directly with customers and ask them about their experience. This was the ‘going broad’ approach.

However, with over 150,000 customers, it was not realistic to cover them all, so Henkel selected customer representatives and engaged deeply with them, performing value mapping and workshops to build a perception of what customers actually thought of the company: ‘going deep’.

The second phase was about creating ideas to fulfil different customer needs, such as innovation capability, quality, reliability and speed. Henkel then gathered teams across all functions to generate ideas on how to improve the customer experience, redesigning crucial touchpoints, such as

shipment experience, track and trace, sampling and complaints processes.

Kirchner says: “We structured the CX programme into three areas, including the differentiators, which were the redesign of crucial touchpoints with customers, the fundamentals, which were the subsystems to enable getting those data points, and the efficiencies, which was about bringing new technology to capture a different efficiencylayers, such as process mining and optical character reading.”

He admits that the transformation was a complex undertaking given the size of the company, but it was powerful for both sides of the equation, and could partially fund new initiatives while continuing to contribute to the bottom line.

supplychaindigital.com 45

HENKEL

Products on display, Düsseldorf

46 May 2023

(INSET): TCA: Application of thermally conductive adhesives for batteries of e-cars

(MAIN): Dragon Plant: Henkel is operating the biggest adhesive production facility near Shanghai, China

HENKEL

Henkel’s partner ecosystem Such an undertaking could not be executed without the right partner ecosystem. Just some of the partners involved with Henkel’s projects include Bluecrux, VMware, Camelot Consulting, and Flo Group.

“When looking for a partner to help with our vision of repositioning the supply chain, we needed someone who had experience not only in customer-centricity, but also in supply chain planning. Bluecrux, with its deep supply chain knowledge and customer centricity track record, was a great partner for us to work with,” he says.

Kirchner also talked about their partnership with Camelot Consulting, which helps them with their material master data governance process and quality control. “The other area of our partnership with Camelot is in planning capabilities, where they are implementing demand-driven MRP to drive customer-centricity and outside-in supply planning.”

Flo Group is another one of Henkel’s key partners, and they work together in the logistics arena. Specifically, Flo Group was Henkel’s implementation partner for OTM (Oracle Transportation

supplychaindigital.com 47

13.2% Organic sales development (Adhesive Technologies)

“Henkel believes in the outside-in approach to supply chains, taking in the views and the voices of the customer, as well as data points from outside the company, to design and improve its supply chain performance towards customers”

BJOERN NEAL KIRCHNER GLOBAL HEAD OF SUPPLY CHAIN FOR ADHESIVE TECHNOLOGIES, HENKEL

Management). Kirchner says: “Flo Group’s expertise in implementation is crucial to our undertakings”.

Then there is Salesforce. Kirchner expresses that they are currently implementing Salesforce’s main application – the service cloud – in their customer service and technical teams. “We have been impressed with how professionally Salesforce has been running the program and are happy to learn from them. I believe it was a wise decision to work with a best-in-class company like Salesforce, and to listen carefully to their advice.”

Last, but not least, in Henkel’s pantheon of key partners is Fourkites. Henkel sees T&T capability as a basic customer requirement to shape customer experience. Fourkites is Henkel’s strategic partner to deliver visibility and transparency in logistics services. In the past few years, Henkel managed to cover a significant part of the deliveries with Fourkites’ T&T platform, and there is an ambitious plan to continue the roll out of T&T in the coming year.

The greatest challenges and lessons

Kirchner describes the biggest challenge in their current role as balancing the urgent needs of their supply chain team with the important task of transforming and maturing their capabilities in terms of systems, processes, mindset and people. Henkel needs to make sure that the performance and transformation sides of their teams work in-sync, and don’t develop things independently.

On a slightly philosophical conclusion – but one that has obviously served him well, as can be seen in his overseeing Henkel’s customer-centric Supply Chain (SC) transformation programme – Kirchner tells me that the best advice he has ever received is “to figure out how fast you can be in implementing change – and then go a bit slower – to make sure that people have enough time to absorb and digest it all”. And that’s how you turn visions into realities.

supplychaindigital.com 49 HENKEL

50 May 2023

FAIL TO PLAN, PLAN TO FAIL: THE CRITICAL CRYSTAL BALL OF DEMAND PLANNING

The pandemic, ongoing supply chain disruption and volatile politics means the role of supply chain demand planners has never been more important

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

supplychaindigital.com 51 SUPPLY CHAIN

A 52 May 2023 SUPPLY CHAIN

running joke among supply chain professionals is that, in today’s uncertain and volatile world, what they really need is not a welter of technology, but the services of a clairvoyant armed with a crystal ball. But in the absence of such help, the next best thing is an old-fashioned, non-mystical demand-planning professional.

The importance of demand planning has been elevated by ongoing postpandemic supply disruption, happening against a backdrop of war in Ukraine, rampant inflation, workforce volatility and the looming spectre of recession But what is supply chain demand planning, exactly? This is the process of predicting customer demand for products or services and determining the amount and timing of inventory needed to fulfil that demand.

The goal is to optimise inventory levels, reduce out-of-stock instances and improve customer service levels, while minimising costs and inefficiencies.

It is a skill that is built on data analysis around customer-demand patterns, market trends, sales forecasts, and historical sales data.

This information is used to build a demand plan, which outlines the expected demand for products or services over a specific time period.

Once the demand plan is in place, supply chain professionals can use it to determine the amount and timing of inventory needed to fulfil that demand. This can involve working with suppliers to ensure timely delivery of raw materials or finished goods, managing warehouse inventory levels, and coordinating production schedules to meet demand.

Effective supply chain demand planning is critical for businesses that want to stay competitive and meet customer needs while minimising costs and inefficiencies.

By accurately predicting demand and optimising inventory levels, companies can improve customer satisfaction, increase revenue, and reduce waste and inventory carrying costs.

Here, we speak to Jefferson Barr, Chief Marketing Officer at supply chain planning specialist, Netstock. Barr gives his views on how the pandemic and technology has changed the discipline, but also how key elements of it remain unaltered.

A

“Knowing your customer is an enormous benefit to demand planning”

supplychaindigital.com 53

JEFFERSON BARR, CHIEF MARKETING OFFICER, NETSTOCK

How does customer-understanding help demand planning?

The purpose of demand planning is to generate a future plan that the organisation thinks reflects consumption by their customers, so knowing your customer is an enormous benefit. The use of statistical forecasting methods should be adopted in order to use the historical customer consumption data.

This enables organisations to derive patterns and trends and provide future projections of what could be consumed. Demand planning is after all a process of planand-review, and the more customer insight you have to add to the mix, the more accurate your forecasts will become.

We have also found that ‘what-if’ demand planning provides huge benefits to our customers, especially in light of all the recent supply chain disruptions.

What-if scenarios allow them to see the net effect of various actions. For example, what if they adjust lead times from 90 to 180 days for a particular channel? This would allow them to see how much more inventory they would need to order, and what the financial impact of these changes would be.

“Volatility within the supply chain is the new norm, which makes demand planners more crucial than ever”

JEFFERSON BARR, CHIEF MARKETING OFFICER, NETSTOCK

supplychaindigital.com 55 SUPPLY CHAIN

How important is a deep understanding of one’s suppliers?

Very. We have seen where our clients went through a process of identifying underperforming suppliers, surfacing the past results, and finding that those suppliers were completely unaware of what was happening in the organisation. This is often the case when you deal with hundreds, or even thousands, of suppliers. Better collaboration leads to a leaner stock-holding, and the ability to jointly plan around supply chain disruptions.

Jefferson Barr

TITLE: CHIEF MARKETING OFFICER

COMPANY: NETSTOCK

INDUSTRY: DEMAND PLANNING

LOCATION: NEW YORK

An experienced sales and marketing executive, expert in SaaS, B2B, high-tech and enterprise software solutions. He says of himself: “I’m proficient in developing and executing strategic sales and marketing programs focused on driving revenue, generating demand, building market awareness, and consistently achieving business goals.

Pre-digital, what did demand planning look like?

Demand planning is a process, and as with any process you have a list of steps that needs to be followed for it to work. With all the sophisticated planning tools available today, this process is sped up so that demand planners can review past results at scale and identify exceptions much faster than the old “line-by-line” paper-based review process.

What

elements of pre-digital demand planning remain important?

Most definitely the internal collaboration between different stakeholders in the organisation. Demand planning is an inputheavy, people driven process and there are also various units of measurement within the organisation.

Unfortunately, that will not be replaced by any planning tools in the near future, as people are connected to the real world and their judgement is a key input to the demand planning process. But a word of caution here: technology will only help you do ‘bad things’ quicker if you don’t have proper processes and procedures in place.

How different was demand planning, pre-pandemic?

The work-from-home movement obviously resulted in far more remote planningsessions. We have seen that remote planning-teams often spend more time huddling around the issue at hand and less time on inter-relationship tension, which we all know exists in a highly stressful environment like a demand planning review meeting. In many cases, the ‘newnormal’ way of remote demand planning has improved the flow of insight and quality of planning.

Retailers ‘don’t plan around supply chain kinks’

Last year, many multinational retailers faced an unprecedented glut of inventory, most notably Nike. Part of the problem is that retailers are adept at planning for recession, but are not so great at doing so for kinks in the supply chain. The average recession is 10 to 12 months long, and retail CEOs are planning for economic uncertainty; they’re planning for this economic risk factor.

“But they are less likely to plan for supply chain imbalances, and take proactive steps to de-risk their supply chains.

Alla Valente, Senior Analyst at global market research firm, Forrester, agrees

retailers need “to do a better job at planning for the correct levels of demand”.

“If retailers want to restore supply chain to its former healthy state they need to consider unplanned events,” she said. “For example, how much longer will the war in Ukraine last?

“And what about climate chaos in certain parts of the world? How might this impact suppliers in high-risk areas?

“Then there’s record inflation. How much further is it going to peak, and how is that going to impact companies that are suppliers or maybe suppliers of your suppliers?”

supplychaindigital.com 57 SUPPLY CHAIN

Netstock demo overview WATCH NOW SUPPLY CHAIN

How valuable are demand planners in times of uncertainty?

Demand planners are becoming way more valuable to organisations that have complex supply and demand chains that need to be planned.

What the pandemic proved is how fragile the supply chain really is. We have witnessed how a seemingly obscure disruption in supply and demand can bring the whole house of cards tumbling down. Volatility within the supply chain is the new norm, which makes demand planners more crucial than ever to supply chain management.

What does best-practice demand planning entail?

Demand planning teams should be connected to other stakeholders and foster collaboration within the business. Within organisations, teams have different roles, incentives, and views on supply chain excellence. Visualising supply chain issues through collaborative planning helps organisations improve alignment and drive reliability in business results and basic business strategies such as:

n What are the goals of the various divisions in the organisation?

n What service level do we want to offer our customers?

n Are we driving towards service level or market growth?

These goals all have different outcomes, and organisations need better planning collaboration to to collectively achieve these goals.

And to successfully implement collaborative planning programs that drive supply chain excellence, companies must be clear on the role of the forecast and the inventory plan.

Grocery demand planning is high-wire act

Within retail, one segment is set apart from the others: grocery. Demand planning for perishable goods is a different ball game. But the consumer packaged goods companies supplying a given retailer with products only see what the grocers are ordering. They have no idea what customers are buying, or when.

And this is where lags can occur. If a significant order is made based on inventory and then it’s shipped, it can become disconnected from the actual consumer demand signals. This can cause imbalances in the supply chain, including out-of-stock in one region and overloaded inventory in another.

The right data and analytics tools can help identify customer behaviour, as well as track the quantity and quality of produce coming in, and also produce that is going to waste.

“Collaboration leads to a leaner stock-holding and the ability to jointly plan around supply chain disruptions”

JEFFERSON BARR, CHIEF MARKETING OFFICER, NETSTOCK

supplychaindigital.com 59

60 May 2023

META EMEA: CONNECTING COMMUNITIES THROUGH SUPPLIER DIVERSITY

AD FEATURE

WRITTEN BY:

ILKHAN OZSEVIM

AD FEATURE

PRODUCED BY:

GLEN WHITE

supplychaindigital.com 61

META

Krystle Sands, Head of Supplier Diversity for the EMEA region on Meta’s global mission to foster opportunities for diverse-owned companies

Meta’s mission is to give people the power to build community and to bring the world closer together.

According to Krystle Sands, Meta’s Head of Supplier Diversity for the EMEA region, this holds true for her team’s work as well. “When it comes to supplier diversity, Meta’s goal is to create opportunities for diverse-owned companies to do business with Meta, and the people and communities that Meta connects.”

This principle of ’connection’, acts as a sort of subtle double-entendre in Meta’s vision, since it simultaneously means bringing people together; and also empowering them to network through its technologies.

Supplier diversity at Meta is one of ambitious proportions, but it has already exceeded expectations both in terms of its reach and its impact.

In 2020, the company announced their public commitment to invest a minimum of US$1bn with diverse-owned suppliers and US$300mn with black-owned businesses.

“We surpassed that goal in 2021, with an amazing recorded spend of US$1.4bn globally with diverse-owned companies, and US$306mn with specifically blackowned businesses in the United States. And we’ve been focusing on continued progress, says Sands.”

62 May 2023 META

2004

Year founded (then Facebook) 2021 Facebook became Meta Platforms, Inc

$116bn Revenue (USD)

10K+

Number of Employees

CEO Mark Zuckerberg

Such a level of growth and expansion is nothing short of incredible, and it speaks to both to how foundational DEI is at the company, as well as the unmistakable explosion in demand for such projects.

And as the demand accelerates, adept companies will move with the zeitgeist accordingly. But only the most visionary will have the wherewithal to actively stimulate that demand.

In keeping with this axiom, Sands says that Meta’s Global Supplier Diversity work has evolved quite dramatically over the last few years. Originally launched in 2016,

“Meta’s mission is to give people the power to build community and to bring the world closer together”

64 May 2023 META

KRYSTLE SANDS HEAD OF SUPPLIER DIVERSITY FOR THE EMEA REGION, META

it has expanded across countries and regions ever since.

“In 2020, we launched our efforts in APAC, EMEA and LATAM, and the real focus was on making as big an impact for diverseowned businesses as possible,” she says.

Sands knows that one of the main reasons that Meta has been so impactful is because of the way that the company communicates concerning supplier diversity within the business.

“Everyone at Meta is a buyer,” she says. “We want Meta employees to be intentional in the way that they spend their budgets,

$1bn

In 2020, Meta announced their public commitment to invest a minimum of US$1bn with diverse-owned companies and US$300mn with black-owned businesses

$1.4bn

In 2021, Meta recorded a US$1.4bn spend with diverse-owned companies and a US$306mn with U.S. black-owned businesses, exceeding its annual goal

and I think that’s a big part of the reason why we’ve been one of the fastest growing supplier diversity programs in the whole world.”

Last year, Meta was inducted into the Billion Dollar Round Table (BDR). “It was an incredible achievement for the team globally, but we’ve still got more to do, and much more of an impact to make,” she says.

As an organisation with such weight, Meta is perfectly oriented to have a serious impact in supplier diversity on a global scale, and we can already see its influence.

Supplier diversity is the branch of DEI that particularly focuses on the economic aspect of the grand project; recognising that economic empowerment is closely tied to, and indivisible from social empowerment. In the end, it all goes back to first principles.

“Opportunities shouldn’t be based on historical systemic biases and supplier diversity really challenges that,” says Sands. “For me, that’s why it’s so important to hold companies to account in terms of how they spend their money; and consequently how they affect broader

supplychaindigital.com 65

society in the creation of generational wealth and socioeconomic change.”

There are still many people that labour under the false impression that only the largest players, and the largest suppliers in the world are really capable of bringing about any kind of meaningful change; and so ’why then should the small players even play?’

Krystle Sands is not one of those people. She illuminates the situation for the fatalist and disaffected by saying: “Diverse suppliers have an enormous impact on their communities. They employ people; they pay rent; they bring massive value to our economies – economies which are primarily made up of small and diverse-owned businesses that exist to really drive us forward through their innovation, entrepreneurship –and the diverse perspectives that they bring.”

From this angle, supplier diversity is grass-roots, and it is in this recognition that Meta shines.

“Diverse suppliers have an enormous impact on their communities. They employ people; they pay rent; they bring massive value to our economies”

KRYSTLE SANDS HEAD OF SUPPLIER DIVERSITY FOR THE EMEA REGION, META

66 May 2023 META

Meta’s S2P and supplier diversity journey

Meta’s source-to-pay organisation has been on an impressive transformational journey over the past few years. When Sands came aboard back in 2019, she joined a small global team who were set to expand. Since then, the team has expanded out on an international scale. They’ve grown in their tooling, their processes and their capability, all within a very short timeframe.

“We’re able to do this by building connections, by driving stakeholder engagement and by building an intuitive buying experience – all while streamlining our processes,” says Sands. “We’ve aligned our performance measures to north stars that embody source-to-pay’s commitment to our stakeholders. Supplier diversity sits within one of those North Stars and shines as part of our community pillar.”

“Opportunities shouldn’t be based on historical systemic biases and supplier diversity really challenges that business norm”

68 May 2023 META

KRYSTLE SANDS HEAD OF SUPPLIER DIVERSITY FOR THE EMEA REGION, META

2016

Meta’s supplier diversity initiative was originally launched in 2016, and has expanded globally ever since.

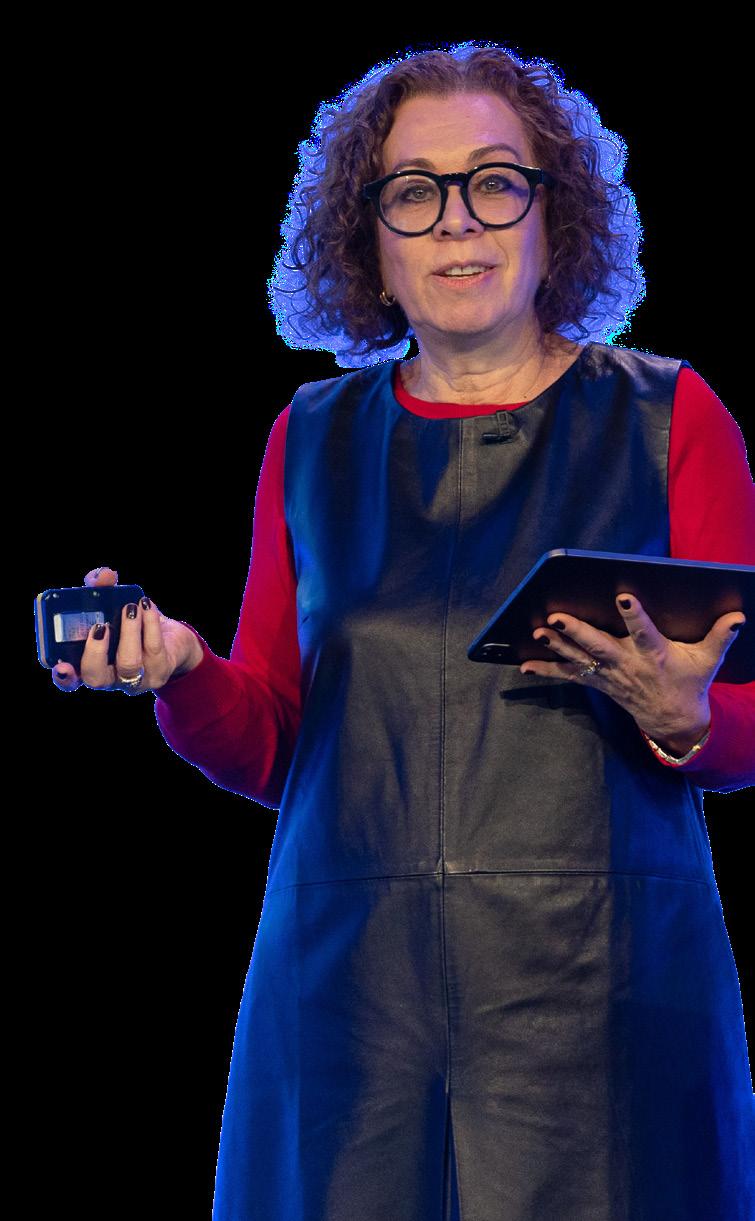

Krystle Sands at the MSDUK 2022 Kowledge Forum

Krystle Sands at the MSDUK 2022 Kowledge Forum

supplychaindigital.com 69

2020

In 2020, Meta expanded its supplier diversity efforts in APAC, EMEA,and LATAM, and the focus was on making as big an impact for diverse-owned businesses as possible

70 May 2023

From European to global supplier diversity partnerships

To have a truly inclusive supply chain, Sands says that Meta needs to partner with suppliers that are not just based in the United Kingdom or the United States. There is another kind of ’united’ that Meta has in mind.

“Our supply chain needs to be where our customers are, and our stakeholders need to represent the communities that we work with. For this reason, collaborating with our advocacy partners to expand supplier diversity outside of the US and UK is a core priority for us.

“Further, we’ve been partnering with a number of organisations and two of the big partners that we are really focused on for 2023 are the European Supplier Diversity Project and the Global Supplier Diversity Alliance.”

“Our supply chain needs to be where our customers are, and our stakeholders need to represent the communities that we work with”

supplychaindigital.com 71 META

KRYSTLE SANDS HEAD OF SUPPLIER DIVERSITY FOR THE EMEA REGION, META

Supplier Diversity: European, Global

The European Supplier Diversity Project started as a way to help ethnic minority businesses in Europe to do business with corporates like Meta. Their objective is to expand certification to six new markets in Europe, and Meta is a founding member of that programme.

“The Global Supplier Diversity Alliance on the other hand, will act as a governing body laying out a framework for country and regional supplier diversity initiatives. They will be investing in world class research into the business case for supplier diversity at country and regional levels, and will support other advocacy bodies to grow their certification programmes.”

Through the web of these programmes, and fittingly, the interconnectivity that they represent, we can see the network of Meta’s supplier diversity initiatives steadily expanding across the globe.

Orienting Meta’s supplier-diversity initiatives Sands says that for 2023, Meta will continue to provide opportunities and increase spend with diverse-owned businesses. “We’ll be looking at our tooling and using data-driven decision making to build on them to ensure that stakeholders can make well-informed buying decisions.

“We’ll also be prioritising our external corporate relationships to share best practices and collaborate as part of a wider community.”

“Diverse suppliers have an enormous impact on their communities. They employ people; they pay rent; they bring massive value to our economies”

72 May 2023 META

KRYSTLE SANDS HEAD OF SUPPLIER DIVERSITY FOR THE EMEA REGION, META

Just as Meta is aiming to connect and forge communities between diverse suppliers, we feel that Meta remaining connected to other companies and developing wider corporate communities is an inevitable part of the process.

Supplier Readiness and Champions Sands says: “Two of the internal programmes that I’m really excited about in particular for this year are our Supplier Readiness Programme and our Champions Programme.

“The Supplier Readiness Programme will look at how we can support diverse businesses in becoming ready to work with companies like Meta, through the training, information and guidance we can provide so that they can be successful.

“The Champions program is a broader program looking internally at how we can increase advocacy and adoption of supplier diversity by our employees, and really create a community of champions to support the cause.”

supplychaindigital.com 73

META

Stronger, together

I ask Sands about her visions and hopes as head of supplier diversity for the EMEA region, and she doesn’t flinch.

“I hope to see more cross collaboration with corporates and advocacy partners.

“We can create a lot of positive change by sharing best practices and helping other companies to start their own supplier diversity journeys.”

Meta’s supplier diversity initiative seeks to further expand into Europe over the next few years.

“When we look at supplier diversity,” she says, “the UK is behind the US, but actually, Europe lags behind the UK.

“With the work that MSDUK are doing in the European Supplier Diversity Project; and that which WeConnect International are doing in broadening their scope, we’ll see more European companies start to create their own supplier diversity programmes which will be incredibly impactful.

“I hope to see more transparency around how we’re measuring supplier diversity; what we are measuring; how we’re measuring, and what the standards are by which we’re measuring supplier diversity and success.”

If credibility is to be achieved, and real change is to be brought about in the world,

quantifiable KPIs must be ushered in. More hope, less faith.

Sands predicts that there will be a fundamental change in the way that the economic impact from supplier diversity is measured, and in conclusion, asserts the formula that sits in essential poise at the human heart of supplier diversity as a principle – she says: “We can go further and faster, if we go together.”

supplychaindigital.com 75

TURBULENCE ON JOURNEY TO NET ZERO AIR CARGO

Two senior aero industry experts from Roland Berger explain why a joinedup supply chain is crucial if technology is to help the air cargo industry meet sustainability goals

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

76 May 2023

supplychaindigital.com 77 LOGISTICS

f the aviation sector is to be carbon neutral by 2050 – its declared goal – then it must embrace new technologies, and fast. It knows this.

The aviation industry recognises the need for greater sustainability. According to a recent survey of industry suppliers by international management consultancy Roland Berger – in conjunction with aerospace associations in Germany (BDLI) and France (GIFAS), 64% of respondents “are working to develop sustainable parts and systems”.

A number of solutions are close to certification while other, more radical innovations, remain in the testing phase. The will to be more sustainable is there, if not always the means, and this is a problem. It is not the only problem.

Global air freight 'been growing for years'

The global air freight industry has been experiencing significant growth for decades, driven by globalisation and the demand for faster and more reliable shipping options. Major players include DHL, FedEx and UPS, and airlines such as Emirates, Cathay Pacific, and Lufthansa Cargo. Other players in the industry include freight forwarders, ground handlers, and customs brokers. According to the International Air Transport Association (IATA), global air freight volumes grew by 4.4% in 2021, despite the challenges

78 May 2023 LOGISTICS

“ Sustainable aviation fuelsn are a transitional aidn rather than a gamen changing solution”n

supplychaindigital.com 79

MANFRED HADER, SENIOR PARTNER, ROLAND BERGER

posed by the COVID-19 pandemic. Growth is being driven by factors such as the rise of e-commerce, an expansion of global trade, and rising demand for time sensitive and high-value goods.

Being a growth industry adds further complexity to the drive for greater sustainability, and as if this wasn’t enough, there is yet another issue creating turbulence on air freight’s flight path to net zero: lack of supply chain support.

Roland Berger has produced a paper exploring this very issue, in which it says greater supplier involvement is critical if green aviation is to become a reality.

The paper is written by two of Roland Berger’s top sustainable aviation experts: Senior Partner Manfred Hader, who heads up global aerospace and defence operations, and Stephan Baur, Principal, who is an expert in aerostructures and interiors.

Manfred Hader

TITLE: SENIOR PARTNER

COMPANY: ROLAND BERGER

INDUSTRY: PROFESSIONAL SERVICES

LOCATION: GERMANY

Hader heads Roland Berger’s Global Aerospace & Defense Practice and operates out of the firm’s Hamburg office. He focuses on consulting large international companies and institutions in the fields of aerospace & defence.

“

Airframe and enginen OEMs are currentlyn following differentn tech roadmaps.n We need a moren unified approach”n

LOGISTICS

MANFRED HADER, SENIOR PARTNER, ROLAND BERGER

Supply chain 'lacks market coordination'

Hader and Bauer say that there is “a lack of market coordination along the supply chain”, and that this is preventing progress on sustainable aviation technologies.

To improve things, they say, original equipment manufacturers (OEMs) “need to clearly communicate technology roadmaps with suppliers”, adding that governments “must also commit to increased funding and clearer policies”.

The Roland Berger consultants say that, of all aviation industry suppliers, systems suppliers are making the most progress, because “they are concentrating on electrification of onboard systems and other weightor energy-saving solutions to

improve energy efficiency”.

Bauer adds that aerostructure and interiors suppliers are also focusing on reducing weight, as well as improving recycling loops for materials. Yet it is propulsion suppliers that have the biggest impact on aircraft sustainability.

The majority, says Hader, “are currently focusing much of their efforts on sustainable aviation fuels (SAF) in combination with more advanced conventional engines”.

Three quarters of respondents to Roland Berger survey say these two things are their first or second priorities, while a quarter say hybrid propulsion is a main priority and just 16% say hydrogen. “Electric propulsion, which is mostly

In 2022, air cargo revenues reached a record US$204bn more than double the figure for 2020 82 May 2023

suited to shorter flights and would therefore cover just a small percentage of industry emissions, is even less of a priority,” says Hader.

But, says Hader, sustainable aviation fuels are not enough “They are a transitional aid rather than a game-changing solution,” he explains. “They’re designated mainly to make today’s aircraft more sustainable for the next two decades”.

He says SAFs use scarce supplies of green electricity with a lot less efficiency, and adds that the aviation industry’s goal of covering 2% of flights with SAFs by 2030 “is not enough to achieve broad market adoption of SAF by 2050. The technology is still in its infancy,” he says, adding that “providing all air traffic with SAFs by 2050 is a ship that has already sailed”.

Stephan Baur

TITLE: PARTNER

COMPANY: ROLAND BERGER

INDUSTRY: PROFESSIONAL SERVICES

LOCATION: GERMANY

Baur joined Roland Berger in 2011 as a Principal in our Industrial Products & Services team. He is an expert in aerospace and in particular aerostructures and interiors..

LOGISTICS

Decarbonising airfreight

A case study in sustainable air freight

Green air cargo key focus for the industry

Sustainability was the focus for the most recent World Cargo Symposium, an event run by the International Air Transport Association (IATA), the air industry trade association that supports aviation with global standards for safety, security, efficiency and sustainability.

In 2022, air cargo revenues reached a record US$204bn, more than double the figure for 2020. It accounted for around 40% of total airline revenues in 2022.

The event focused on how the industry can capitalise on resilience to build a more sustainable future.

Identifying new ways to attract and retain talent was also a focus of many of the sessions.

Returning to the subject of sustainableaviation technology, Hader says this “is moving much too slowly, and the industry knows it”.

The reasons for this vary, he says. More than a quarter (28%) of survey respondents cite the absence of a clear roadmap from OEMs; 21% feel a lack of investment is most to blame, while 18%). Say limited human resources are to blame.

Unfortunately, say Hader and Baur, supplier struggles are just the tip of the iceberg – that the entire aerospace sector is currently falling short in driving the industry towards greater sustainability.

“Market participants are highly dependent on each other to develop new technologies, and the required investments to reshape the industry are huge,” says Hader. “If the industry cannot act together, development stalls for everyone.”

For suppliers, it seems that a lack of external guidance and overemphasis on

WATCH NOW 84 May 2023 LOGISTICS

International Air Transport Association (IATA), says global air freight volumes grew by 4.4% in 2021

supplychaindigital.com 85

SAFs is limiting technological development.

Airframe and engine OEMs, meanwhile, are currently following different technological roadmaps, points out Baur. “This is despite the need for a more unified approach,” he adds.

And to compound the problem, they say governments are struggling to provide clear, internationally aligned guidance.

“Without direct demand or clear roadmaps, infrastructure providers have little incentive to invest in sustainable infrastructure such as hydrogen fueling capacities,” explains Hader.

So, what needs to be done? Hader and Baur say OEMs must take a leading role and – in conjunction with governments and authorities – decide which specific technologies to pursue.

“Then they must communicate detailed technological roadmaps quickly and clearly across the entire sector,” says Hader, “and with a specific focus on their suppliers”.

He says this “would help to intensify R&D efforts throughout the supply chain and drive faster technological development, as well as allowing a more effective allocation of funding.”

He adds: “In turn, this would enable a clear, international infrastructure roadmap for areas such as refuelling once technologies are ready.”

In conclusion, the pair warn that, although 2050 might seem some way off, the long timelines in the aviation industry mean it must act now to stand a realistic chance of hitting its targets.

“Suppliers are willing and able to take on a more active role in improving sustainability, but the onus is on OEMs to involve them more effectively,” Hader says.

86 May 2023

LOGISTICS

“Aerostructure and interiors suppliers n are focused on reducing weight and n improving recycling loops for materials”n

supplychaindigital.com 87

STEPHAN BAUR, PRINCIPAL, ROLAND BERGER

SAFEGUARDING HEALTH THROUGH SUPPLY CHAIN

88 May 2023

supplychaindigital.com 89

PRODUCED BY: MIKE SADR

WRITTEN BY: SEAN ASHCROFT

United Urology Group (UUG) is a US-based national network of 1,500 urology healthcarefocused employees. It has affiliate practices in Arizona, Colorado, Delaware, Maryland, and Tennessee.

Founded in 2016 and with its HQ in Maryland, it supports 220 providers in 95 locations across five states, making it one of the largest urology networks in the US.

At heart, UUG is a management services organisation (MSO), providing administrative and support services to urology practices across the United States. This support includes revenue cycle management, financial management, human resources, marketing, and strategic planning.

David Forbes is VP of Supply Chain Management for UUG and is responsible for its source-to-pay programme, strategic sourcing, procurement, and accounts payable. He also provides consulting services in inventory management for UUG clinics.

The support Forbes and his team provide includes everything from human resources and sourcing services to IT.

He says: “I source contracts for my practices. I aggregate everybody's spend and negotiate the best possible agreements with the right trading partners at the right level.”

90 May 2023 UNITED UROLOGY GROUP

Why supply chain is a point of difference for US-based healthcare management services organisation, United Urology Group

Forbes also offers procurement support, or “day-to-day blocking and tackling” as he describes it. Accounts payable is another of his areas, and his team also ‘owns’ the company’s source-to-pay solution that serves its physician practices.

UUG’s network of practices are known for their integrated urologic care programs, a patient-first approach, clinical excellence, and innovative treatments for

a wide range of urologic conditions, from the most common to the most complex cases.

“We aim to support our affiliated practices in providing high-quality, patient-centred care,” he says, “and to support our affiliated practices in delivering care in an efficient and effective manner.”

UUG’s supply chain organisation is vital to this goal, says Forbes, who explains that it helps the

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

92 May 2023 UNITED UROLOGY GROUP

“We aim to provide high-quality, patientcentred care”

company deliver on its Quadruple Aim strategy, comprising:

• Clinical efficacy

• Patient experience

• Clinician experience

• Cost takeout

“These are four metrics our practices look to base decisions on, whether small or major,” says Forbes.

He adds: “Clinical efficacy is about whether or not a decision made by our affiliated practices improve patient outcomes. Clinician experience refers to the experience

DAVID FORBES

TITLE: VP SUPPLY CHAIN MANAGEMENT

COMPANY: UNITED UROLOGY GROUP

INDUSTRY: HEALTHCARE

David Forbes is a seasoned supply chain professional with almost two decades of experience. Currently serving as the VP of Supply Chain Management for United Urology Group, his team is responsible for providing end-toend source-to-pay support to over 220 urologists and advanced practice practitioners. David's extensive experience includes working with the Healthcare Industry Distributors Association to develop healthcare trading partner data communication standards, building value analysis and sourcing departments for a hospital-based system, and serving as a strategic sourcing consultant with The Advisory Board Company. He holds a B.S. in Business from Miami University and an MBA from Loyola University Maryland.

EXECUTIVE BIO

“Shortages and back orders are the toughest part of the job. In the healthcare industry, we've never seen it as bad as it is right now”

94 May 2023

DAVID FORBES VP SUPPLY CHAIN MANAGEMENT, UNITED UROLOGY GROUP

Safeguarding health through supply chain

of physicians, nurses, and medical assistants when using the product or service.”

Patient experience, he explains, concerns factors such as patient comfort and recovery each of which “are key considerations in cost takeout”.

Forbes cites as an example the purchase of a simple piece of urological equipment, such as a catheter.

“Cost takeout is about what we can do to prune unnecessary costs from healthcare, but it is not always about monetary cost. I might be able to negotiate a fantastic deal on the latest foley catheter, say, but if this product is going to cause urinary tract infections, or if it’s difficult to insert or remove, then it doesn't make sense to do it.”

Supply chain, he says, helps UUG deliver on its Quadruple Aim metrics.

“The obvious one is cost takeout, and the rest are impacted through the clinical integration of my department with our physician practices.”

220

Number of providers UUG has for its urology practices

95