Third-party logistics providers

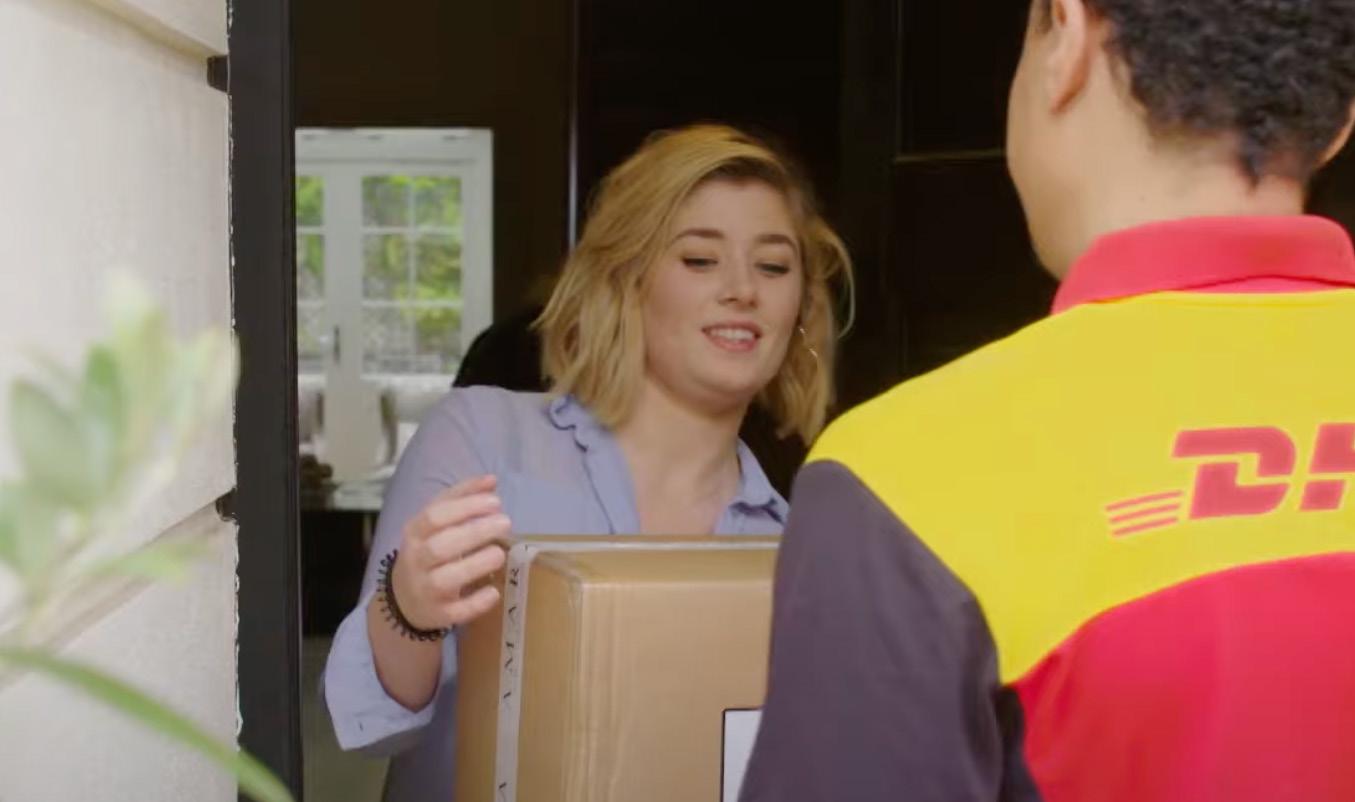

Gfk

Helping the helper transform

Supply & climate change

Mitigating the risk of extreme weather

NHS England

Building a commercial community through the NHS Central Commercial Function

Sanofi French healthcare giant’s CSCO

Arnaud

Dourlens on building a resilient value chain

Strategy, sourcing and supply chain resilience of global pharma

more

more

more

Learn

Learn more Learn

Learn

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

PROOFREADER

JESS GIBSON

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN

ANDY WOOLLACOTT

LEAD DESIGNER

JUSTIN SMITH

The SupplyChain Team

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANA

SALLY MOUSTA

JINGXI ANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KAYLEIGH SHOOTER

PROJECT DIRECTORS

MIKE SADR

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

THE COMMUNITY

JOIN

Supply chain visionary lights the way

In the late 70s, Dr Wolfgang Partsch gave us supply chain management, and his thinking is more relevant today than ever

Every industry has an elite group of thinkers – visionaries who have shaped the working worlds of generations of professionals.

In supply chain, one of those thinkers is Wolfgang Partsch, who in the late 1970s created the concept of supply chain management.

This issue includes an interview with Dr Partsch. Five decades ago, the Austrian-born doctor of physics had a vision for how companies can best make, move and deliver goods around the world.

“My vision was to break up information silos,” he says. “The goal was to help businesses see from one end to the other, operationally, with no interruption of information.”

Sound familiar? Today, supply chain professionals call it ‘having end-to-end supply chain visibility’.

Fifty years on, everything – and yet nothing – has changed in supply chain. This is precisely why people like Dr Partsch are visionaries: they are able to see, and articulate, simple, timeless truths about the world around us.

His story makes for fascinating reading, as do his views on today’s supply chain challenges, many of which are explored throughout this issue.

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

SUPPLYCHAIN DIGITAL MAGAZINE IS PUBLISHED BY © 2023 | ALL RIGHTS RESERVED supplychaindigital.com 5 FOREWORD

“Visionaries like Wolfgang Partsch are able to see, and articulate, simple, timeless truths about the world around us”

Our Regular Upfront Section: 10 Big Picture 12 The Brief 14 Timeline: ESG investment in supply chain 16 Trailblazer: Dr Wolfgang Partsch 20 Five Mins With: George Kochanowski Sanofi The arrival of the ‘haute couture’ supply chain 26 Supply Chain Supply visibility shows clear and present dangers 42 CONTENTS

iQuantum A modern procurement platform for today’s business 72 NHS England Building a commercial community through the NHS Central commercial function 50 Tech & AI Blockchain strengthening links in supply chain 106 Logistics Reshoring takes hold in face of supply chain pressures 64 Gfk Helping the helper transform 94 Sustainability Climate change is ill wind threatening supply? 84 Top 10 Third-party logistics providers 114

supplychaindigital.com 9

BIG PICTURE

54 million avocados, for guacamole (675 truckloads)

Food & drink supply chains in US brace for Super Bowl Arizona, United States

Early February marks one of the most watched single sporting events in the world: SuperBowl.

The 2023 event will be held at State Farm Stadium, Glendale, Arizona.

Consumption of food and drink in the US on SuperBowl day goes through the roof. People consume an estimated: 1.2 billion chicken wings (1,590 truckloads); 50 million cases of beer (27,778 truckloads); 28 million lbs of potato chips (350 truckloads); and 54 million avocados, for guacamole (675 truckloads).

10 February 2023

28 million lbs of potato chips (350 truckloads)

1.2 billion chicken wings (1,590 truckloads)

supplychaindigital.com 11

THE BRIEF

BY THE NUMBERS

Planned large-scale hydrogen power schemes, by country

Source: McKinsey

READ MORE

314 Europe

154 Asia & China

READ MORE

103 North America

54 Oceania

EDITOR'S CHOICE

COUPA & IVALUA ISSUE ADVICE ON NEW GERMAN ESG LAW

Coupa, Ivalua & Inverto say new law demanding strict ESG auditing in supply chains forces global business to comply if they want to keep German customers.

READ MORE

2023 PREDICTIONS FOR LOGISTICS, SUPPLY CHAIN & PROCUREMENT

Danone, Proxima, FourKites, Endava & Globality share their 2023 predictions for supply chain, logistics, procurement and digital transformation.

READ MORE

READ MORE

“There is no single provider on the market who competes with us pin-to-pin”

Hetal Mehta Chief Executive Officer, iQuantum

“It’s my job to get the drug to the patient on time, whatever the situation ”

Arnaud Dourlens Head of Clinical Supply Chain Operations , Sanofi

“Standardising and stabilising processes is far more important than the actual systems that are used”

Suki Becker

VP Procurement and Real Estate, GfK

12 February 2023

Efficio finds CPO

ESG-disconnect with procurement teams

Controlling costs is a higher priority for executives -- including chief procurement officers -- than driving sustainability initiatives, new research suggests.

A report called Bridging the Gap, from procurement and supply chain consultancy, Efficio, suggests that more than nine in ten (93%) of business leaders believe revenue maximisation is ‘important’ or ‘very important’ to their business strategy, compared to the 66% who say the same of implementing net zero plans, such as controlling Scope 3 emissions in the supply chain.

Efficio says the findings bring into even sharper focus the key role procurement leaders must begin to play if board-level plans on sustainability and ESG are to be translated into meaningful action.

The report highlights a disconnect between chief procurement officers (CPOs) and procurement teams, with CPOs fixated by “compliance-based metrics rather than core ESG issues”. It also says too many CPOs fail to act upon sustainability opportunities flagged by team members who are involved in the daily management of goods and services.

WOMEN IN LOGISTICS

Stockholm Ports appoint Magdalena Bosson as its new CEO, while US logistics CEO Techa Pacitto wins a prestigious industry award given to women making a lasting impact in the business community. She won for 'thinking differently about supply chain'

AUTONOMOUS HAULAGE

Uber Freight is to deploy Volvo’s autonomous transport solution on the Uber Freight network on select routes, starting in Texas. The partnership marks Uber Freight’s first commercial collaboration with an autonomous fleet.

SEA FREIGHT RATES

Rates for shipping containers from Asia to the US are falling towards pre-pandemic levels and may still have further to drop, while long shipping delays are increasingly disappearing from the market, according to analysts.

BOARD-LEVEL ESG ACTION

Controlling costs is a higher priority for executives -- including chief procurement officers -- than driving sustainability initiatives, suggests research from the world's largest procurement and supply chain consultancy, Efficio.

W I N N E R S

FEB 23

L O S E R S

supplychaindigital.com 13

ESG INVESTMENT IN SUPPLY CHAIN

Not so long ago, ESG was a ‘nice to have’ in supply chain. No longer. Now consumers demand end-to-end ESG compliance across an organisation. Here is how investment in ESG initiatives evolved.

TIMELINE

14 February 2023

1960s

The dawn of sustainable investment

The 1960s sees the beginning of ‘socially responsible investing’. Organisations begin to exclude stocks or entire industries from their portfolio should their operations not be seen as ‘socially responsible’.

2005 ESG is born

The term Environment, Sustainability & Governance (ESG) is coined by the UN Global Compact in 2005 in a study called Who Cares Wins, which urges the financial industry to better integrate ESG issues in securities brokerage.

2013

The rise of ESG investment

ESG investment begins to drastically increase, following heightened interest in the correlation between corporate sustainability and positive financial results.

2015 The Paris Agreement

In 2015, the Paris Agreement – a legally binding international treaty on climate change – is signed by most leading countries. This encourages investors to begin targeting companies with ESGcompliant supply chains.

2018

GRI standards

GRI Standards allow organisations to publicly report the impacts of their activities in a transparent way to stakeholders. Launched in 2000, they begin to see serious ESG traction around 2018.

supplychaindigital.com 15

Dr Wolfgang Partsch

The Austrian physicist who is the father of modern supply chain management

In

the late 1970s,

physicist Dr Wolfgang Partsch used science as the basis for his revolutionary concept of supply chain management

In the November issue of Supply Chain we featured British logistician and business consultant, Keith Oliver, as our ‘trailblazer’,and presented him as the person who coined the term ‘supply chain’. On publication, the article generated strong interest online, especially on LinkedIn.

Many people commented on the piece, with most saying the same thing: Keith Oliver may have been responsible for introducing the term ‘supply chain’ into popular culture, but he was not the one who gave it to the world.

That honour, we were told, should go to Wolfgang Partsch, whose LinkedIn profile describes him as the ‘Inventor of Supply Chain Management’.

Following feedback on LinkedIn we amended the Keith Oliver article, adding the following paragraph:

“It should be pointed out that Oliver was part of a team that created the concept of 'supply chain management'. The first project the team was involved in ran from 1980-82 in Switzerland, under the management of business analyst Wolfgang Partsch. The term first appeared in print in 1982, in the German business magazine, Wirtschaftswoche.”

TRAILBLAZER

Dr Partsch himself contacted us, grateful for the amendment, but added that we still didn’t have anything like the full story of how ‘supply chain management’ was born. And so we fixed up an interview, and Dr Partsch told us, in captivating detail, how he helped change the face of supply chain forever.

Partsch was born in Vienna, and went on to gain a PhD in Physics from the city’s university. For four years in the early 1970s he was a software engineer, before becoming a logistics consultant with Kearney, in 1975. Three years on, he joined Booz.Allen & Hamilton, where as a Senior Associate he began formulating the

concept of supply chain management, with Keith Oliver part of the same team.

“Keith was a consultant,” says Partsch. ‘I was younger, and a mere associate. Although supply chain management was my concept, Keith was the one who presented it to clients and so he ended up getting all the glory,” he adds, grinning.”That’s just the way it is.”

Partsch’s vision for how companies can best make, move and deliver goods around the world may have been formulated over 50 years ago, but with so much disruption and uncertainty today, they have never held more sway.

supplychaindigital.com 17

“MY IDEAS AROUND SUPPLY CAME FROM EARTHQUAKES, WHICH YOU CAN MEASURE FROM THOUSANDS OF MILES AWAY”

18 February 2023

“BY THE EARLY 1980s, HE HAD FORMULATED

TRAILBLAZER

A COHERENT SUPPLY STRATEGY THAT WAS FIT TO BE PRESENTED TO BOARDROOMS”

“My vision was to break up information silos,” he says.

Sound familiar?

He adds: “The goal was to help businesses see from one end to the other, operationally, with no interruption of information.”

Or, in today’s terminology, end-to-end supply chain visibility.

Partsch’s revolutionary thinking was based not on business thinking, but natural science.

“It really struck me how, with earthquakes, you can measure shockwaves from thousands of miles away. My vision was of something similar for supply, whereby something like purchasing has an effect on sales and production at the other side of the chain,” he explains.

Partsch’s thinking here was crystallised by a seminal 1961 book called Industrial Dynamics, by Jay Forrester.

“Forrester was an industrial engineer, and it’s a very mathematical book, but I am a physicist, and so I understood his ideas.”

It was in the late 1970s that Partsch’s vision for the future of supply began to take shape, and by the early 1980s, he had formulated a coherent supply strategy that was fit to be presented to boardrooms.

It was on a journey to a Swiss client that Partsch and his team chanced upon a name for his concept, and all thanks to a snowstorm..

“We were driving to a client through heavy snow,” he recounts. “We had to get the snowchains out to put on the wheels, and that’s when someone got the idea of using the idea of a chain to describe our strategy of managing supply, because chains have many links that form something whole.”

Now, 40 years on, Dr Partsch’s thinking has helped hundreds of companies – including Pierre Cardin, Red Bull, Nestlé, Siemens, IBM, and Ferrari – save billions of dollars, by streamlining their supply chains, and making them run more efficiently.

supplychaindigital.com 19

GEORGE KOCHANOWSKI

Empty shipping containers clog ports, slowing supply chains and pumping out carbon. George Kochanowski, CEO of Staxxon may just have a solution…

Q. TELL US A LITTLE OF YOUR PROFESSIONAL BACKGROUND?

» I received a bachelor’s degree in Chemical Engineering from the Polytechnic Institute of Brooklyn. Some graduate studies in Business at Northwestern University.

As the inventor of all-plastic retro-reflective traffic signage, I received Plastic Product of the Year in 1998. As Manager of Process Control for GE Plastics, I received a leadership award for state-of-the-art computer control systems and networks at GE’s Alabama facility.

I’ve held senior corporate leadership positions with public and private companies, ranging from electromagnetics to advanced composite materials.

Q. WHAT DOES STAXXON DO?

» We design foldable intermodal shipping containers that exceed ISO and CSC standards and the systems needed to fold them standing upright in bundles, safely and quickly. We are in the process of developing a network of fabricators in Europe and North America to produce our assemblies.

Q. WHAT CAUSES ‘EMPTY RUNNING’?

» Empty containers clog roads and ship terminals, causing port congestion and leaving little space to unload ships. This then forces many ships to wait offshore, wasting resources and slowing the supply chain to a crawl. The problem disappears only as the ships sail away.

.

Q. HOW SERIOUS IS THE EMPTYRUNNING PROBLEM?

» Unfortunately, due to global importexport imbalances, the ‘empties’ – when delivered to terminals – cause port congestion.

This has a domino effect, as they need to be stored on their chassis, temporarily, at off-terminal storage facilities reducing chassis availability. (A chassis is a trailer or undercarriage used to transport ocean containers by road.) This then starves exporters both of empties and. The empties are at the wrong place and at the wrong time. The environmental price is steep for each move, as each non-productive activity is handled by fossil-fueled equipment.

As we move into the post-pandemic era, where there will be less commerce, port productivity should increase. But at a price, as the cost of labour and fuel have risen by double digits, sparking global inflation. More than ever empties are more expensive to reposition; it costs more to move nothing around.

Q. ARE SHIPPING CONTAINERS OUTDATED?

» The intermodal shipping container is 70 years old. Over the years it has been refined but ownership costs have increased. For example, example, this year, the annual

FIVE MINUTES WITH... 20 February 2023

operating prices have ranged between $25,000 to $40,000 to reposition an empty container. Those costs are primarily labour-, fuel-, and land-use, and all are increasing at the rate of inflation.

Q. HOW DOES YOUR SOLUTION HELP?

» For 50 years, the repositioning of empty containers has had a negative financial effect and a severe environmental impact.

During this time, the only method of folding was a technology whereby the end walls collapsed onto the floor. Unfortunately, the cost of ownership was too high, and many of the design limitations were not overcome. In the end, collapsible units drew little interest.

Staxxon approaches the problem differently. A Staxxon box folds like an accordion. We always keep the box upright even when folded. This offers the capability to stack the bundled sets anywhere on the ship.

Plus, you don’t have to wait for a set number of collapsed containers to be nested to meet required ISO dimensional standards, saving space at ports, reducing the need for offterminal temporary storage, and freeing up numerous chassis.

With the number of moves now minimised, there is a significant reduction in the use of fossil fueled vehicles and pollution.

The goal of the Staxxon container is to create a ROI while reducing the environmental impact.

Q. WHO INSPIRES YOU?

» Early in my career, I had the benefit of working for GE Plastics when Jack Welch was running GE, and years later, I ran an advanced composites company for Dr Walt Robb, who was Welch’s close advisor and confidant when Robb was at GE. Although not without faults, these two were always inspiring to be around.

22 February 2023

FIVE MINUTES WITH...

supplychaindigital.com 23

0 0 0 0 1 1 A BizClik Brand

supplychaindigital.com 25 10 0 0 0 1 LEADERS2022 • LE A D SRE 2202 • SREDAEL2202 • EL A D ERS2022 • Creating Digital Communities OUT NOW Read now Don’t miss this Issue! The most influential people in Supply Chain

WRITTEN BY: HELEN ADAMS

PRODUCED BY: CRAIG KILLINGBACK

26 February 2023

The

The arrival of the ‘haute couture’ supply chain

supplychaindigital.com 27 SANOFI

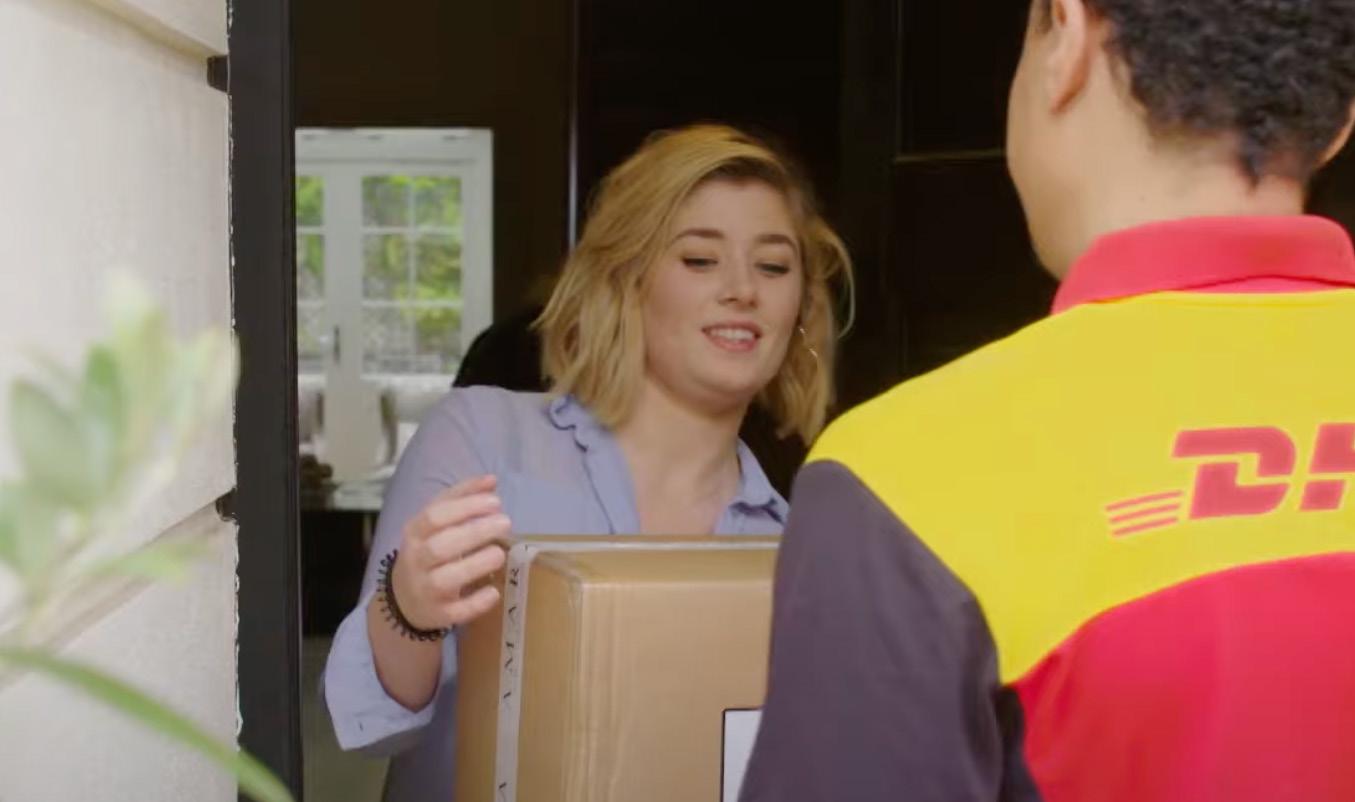

Arnaud Dourlens, Head of Clinical Supply Chain Operations at Sanofi, on building a resilient supply chain and creating efficient clinical trials

Sanofi is a one-of-a-kind pharmaceutical company for the modern age. Self-described as ‘pushing the frontiers of science’ and ‘chasing the miracles of science to improve peoples’ lives’, the 100,000-plus employee company delivers ‘life-changing treatments and life-saving vaccines’ to patients around the globe, in more than 100 countries.

The man in charge of the entire strategic sourcing and shipping process for the pharma company is Arnaud Dourlens, Head of Clinical Supply Chain Operations, who also oversees worldwide trial supply.

At heart, though, Dourlens is an engineer. He began his career in the FMCG (fastmoving consumer goods) industry, working for giants Procter & Gamble. Later, he moved into the luxury sector – the domain of beauty powerhouses such as perfume and cosmetics’ leader Christian Dior.

“For more than 10 years, I worked across operations, the supply chain, new product launches, and industrialisation – first in the makeup area and then in every cosmetic area, meaning makeup, fragrances and skincare,” outlines Dourlens.

In 2017, he switched to Sanofi as Production Director and embraced the pharmaceutical environment. During this period, Dourlens was based at the Compiègne site, in Northern France.

28 February 2023 SANOFI

supplychaindigital.com 29

Arnaud Dourlens, Head of Clinical Supply Chain Operations at Sanofi

“It’s quite a strategic site here,” says Dourlens. “I led the team on the road of site improvement and transformation to be fit for the future.”

Dourlens joined Sanofi because he was passionate about the pharmaceutical field and had experience in demanding, highadded-value environments.

“I was proud to have worked in the luxury sector, making it possible for people to be even more beautiful than they are, thanks to makeup and cosmetics,” says Dourlens. “But being a part of a journey where you are allowing patients to access treatment, to

change the life of some people on a daily basis and improve their wellbeing may be a bit less trendy, but it’s so important.”

Dourlens joined the pharma’s Clinical Supply Chain Operations in Montpellier in 2020, during the COVID-19 pandemic, in this period of chaos, it was up to Dourlens to ensure the business continuity.

“That was not easy,” says Dourlens. “As Global Head of Clinical Supply Chain, I'm heading the world supply chain of Sanofi’s clinical development – overseeing more than 300 clinical studies, making sure that we are delivering their investigational

“More than ever, the level of uncertainty we have in the worldwide clinical supply chain is just incredible”

30 February 2023 SANOFI

ARNAUD DOURLENS HEAD OF CLINICAL SUPPLY CHAIN OPERATIONS, SANOFI

treatments to all the clinical patients, either at home or at hospital.”

Clinical trial supply chains – a source of value

Dourlens believes that the clinical trial supply chain can be a source of value for patients and the healthcare sector.

“When a patient is suffering from a disease, he or she is in a tough situation and clinical trials are an option of care for him or her,” explains Dourlens.

Behind the clinical trial, there are a lot of activities that are happening around

EXECUTIVE BIO

ARNAUD DOURLENS

TITLE: HEAD OF CLINICAL SUPPLY

CHAIN OPERATIONS

COMPANY: SANOFI

INDUSTRY: HEALTHCARE

LOCATION: GLOBAL

Arnaud Dourlens is an "Arts et Métiers" engineer. He began his industrial career in the FMCG sector where he held growing responsibilities. Then he joined the LVMH group where he reorganised new product launches and industrial investments in the Make-up segment .

Arnaud joined Sanofi in 2017 as Production Director of a major production site (>€2.5bn turnover). He has been a key player in the development of the continuous improvement mindset and in the transformation of the site through IT projects, investments and activity growth.

Since 2020, he has been the global head of Sanofi Clinical Supply Chain Operations, managing worldwide clinical supply teams involved in more than 300 clinical studies.

supplychaindigital.com 31

40% Average drug waste reduction

30% Average supply cost savings

2-6 Months reduction in time to market

100% Patient service level

ambitious clinical development through optimal supply chain planning

Enable

N-SIDE Suite is a game changer in clinical supply chain

N-SIDE Life Sciences VP Sébastien Coppe explains how leveraging data & AI can streamline clinical plans, accelerate trials, mitigate risks and curb waste

N-SIDE combines deep clinical supply chain expertise with advanced mathematics, packaged into solutions to optimise the entire clinical trial supply chain by taking a global view and making data-driven decisions at every step.

“N-SIDE has been building extensive expertise over the past 20 years in empowering supply chain management in clinical development through advanced analytics and AI,” says Sébastien Coppe, N-SIDE Life Sciences VP.

Pharma companies of all sizes use the N-SIDE Suite, an intelligent SaaS solution, to avoid supply chain bottlenecks, minimise waste, control costs, reduce time-to-market, speed up the initiation of new trials, manage production plans, monitor supply chain strategy for ongoing trials, and support commercial launches. Pharmaceutical and healthcare company Sanofi started a strategic partnership with N-SIDE five years ago to digitalise their clinical supply chain.

This has led to impressive outcomes for their supply chain efficiency.

The N-SIDE Suite consists of the Supply App, for risk-based clinical supply optimisation; the Production App, for building and maintaining an optimal manufacturing strategy; and a comprehensive slate of BI dashboards and expert services.

The N-SIDE Supply App helps pharma companies optimise their supply chains throughout the trial lifecycle. It allows them to make data-driven decisions about issues including overage, packaging, sourcing, IRT setup, and depot shipments, in a smart and interconnected way. With more than 12,000 trials optimised, N-SIDE’s Supply App can be used to design and optimise any trial of any size and complexity.

“Globally, when you consider what happened during and after the Covid pandemic, we’ve seen a lot of good changes backed up by AI technology, leading to really faster clinical development activity,” says Coppe.

GET IN TOUCH TODAY

www.n-side.com

The arrival of the ‘haute couture’ supply chain

defining a protocol, defining the way in which the study will be carried out, and the way that the data will be managed.

“The main thing that the patient will see when they are included in a Sanofi clinical trial will be the treatment. The patient will see the investigator, the physician and the hospital staff who will take care of them, but no one from Sanofi,” said Dourlens.

Yet, the treatment that the patients will get – when they receive a box of drugs or vaccine designed to either save or vastly improve their life – comes from Sanofi. It’s Dourlens’ team’s job to get the drug to the

patient on time, whatever the situation.

“We have been experimenting with our supply chain for years, during both the COVID-19 pandemic and Russia’s invasion of Ukraine,” says Dourlens. “We were still able to continue to supply almost everywhere during the pandemic.”

So, how did managing the COVID-19 clinical supply chain compare to supporting it after Russia’s invasion of Ukraine?

“Many patients have been in a terrible situation due to the war, but even more so when expecting a life-saving drug that it isn’t possible to receive.”

34 February 2023 SANOFI

Sanofi is creating value in its patientcentric care by thinking about the patient in these types of extraordinary circumstances, devising ways to overcome situations such as war or pandemics.

Part of this is the company delivering drugs to patients’ homes, alongside a nurse where necessary: “Sometimes a patient is very far away from the clinical site, so a nurse's visit with the medicine allows easier access to the clinical trial.”

This reduces the burden of the trial on the patient, something Sanofi is very proud to facilitate. But it’s the supply chain itself that’s

responsible for making this easier for both the nurse and the patient.

“By reducing the number of trips back and forth to the hospital, we’re supporting healthcare staff and patients. But it is down to the patients to make sure that they are taking their medicine on time.”

If we think about value, we have also to discuss a bit about trial design. “When you have a clinical trial, you’re able to influence the trial design to make sure that you limit the risk of shortage and wastage,” explains Dourlens, who, in his role, has the job of optimising the capacity in supplying the trial.

supplychaindigital.com 35

The healthcare sector is aware that it is moving into an era where the cost of drugs and products is high, due to supply chain complexity, in addition to the development of drugs. The clinical supply chain has the ability to influence the way Sanofi performs the trials – something Dourlens’ team is working on each day.

“We know that, in the near future, trial design is going to be more and more complex,” he says. “We will be adjusting the design in the course of the trial, depending on the results; it's what we call adaptive trial design.”

Sanofi’s supply chain must have the agility and flexibility to follow the changes it hopes to enact, though there are analytics tools on-hand to improve productivity, resilience and sustainability.

“To have an important impact and run successful, innovative therapies, we must avoid bottlenecks linked to drug supply and we must then guarantee that the treatment is available to the patient as quickly as possible,” says Dourlens.

“We’re not getting drugs that are similar for everybody; this is a tailor-made supply chain. I like to say that it’s an haute-couture

“The world has changed over the past two years –in the supply chain, in the clinical supply chain, and across the pharmaceutical supply chain”

36 February 2023 SANOFI

ARNAUD DOURLENS HEAD OF CLINICAL SUPPLY CHAIN OPERATIONS, SANOFI

supply chain. This is where digital healthcare is really able to provide the required end-toend traceability.”

Whatever the production is – internal or external – and whatever the geography level, digital is helping to make sure Sanofi is tracking all drugs everywhere in the world, at each step of the process.

Global cost optimisation & resilience strategies

Clinical trials are happening in quite a complex landscape, because each country has its own specific regulations. Depending on the design of the trial, Dourlens’ team may have different requirements to meet, such as importation and exportation rules. The number of changes, from a regulatory perspective, in the worldwide environment is huge.

“To make a long story short, regulatory complexity and varied trial design is a big challenge. Digital healthcare is a great help in making sure that we are within these constraints in the right way,” says Dourlens.

€40bn turnover per year

100K+ number of employees

60+ sites across the world

supplychaindigital.com 37

ARNAUD DOURLENS HEAD OF CLINICAL SUPPLY CHAIN OPERATIONS, SANOFI

From an integration and cost-optimisation viewpoint, digital healthcare is also important. Today, nobody is able to run a full supplier clinical trial end-to-end without any partners. Therefore, a smooth and efficient integration becomes a must.

“When we start speaking of partners, we start speaking of making interfaces, and

when we speak about interfaces, we speak about exchanging data. The level of platform integration thanks to digital development is also key. If you have a nice digital ecosystem internally, but you don't have the proper level of connection with all the players that are contributing across your value chain, you’re not fully leveraging the efficiency of your digital system,” he says.

To perform in the global clinical supply chain, there are some core activities that are part of the internal expertise of Sanofi: optimising the design of the trial from a supply perspective, the logistics setup, packaging design, and, ultimately, the needs of the patient.

There are, however, some other areas where Sanofi relies on partners due to their greater expertise and experience with a

“When a patient has a disease, they’re in a tough situation. Clinical trials are an option of care for them”

supplychaindigital.com 39 SANOFI

range of customers. Put simply, these partners are able to offer services that are complementary to internal ones.

One of these integral partners is Thermo Fisher Scientific, with whom Sanofi has worked for a number of years – though a partnership devoted to the US market was only agreed two years ago, which specifically focuses on the subcontracting of packaging labelling and distribution activities for certain studies.

“We are relying on them mainly to supply everything that is manufactured in the US and then distributed worldwide for studies,” says Dourlens. “We're reaching a level of maturity and interaction between the teams in terms of development that is really high.

“

By reducing the number of trips back and forth to the hospital, we’re supporting healthcare staff and patients”

ARNAUD DOURLENS HEAD OF CLINICAL SUPPLY CHAIN OPERATIONS, SANOFI

40 February 2023 SANOFI

Thermo Fisher Scientific has been helping us in our journey to make sure that we deliver the drug at the right time – any time – but also, that we're doing it at the right cost with the right level of optimisation.”

Any partnership requires trust because it is a vital ingredient, but for the healthcare supply chain, it is absolutely crucial.

“In a partnership, nothing happens without trust,” says Dourlens. “The second ingredient is to make sure you have a partnership based on a common interest: in a good partnership, there cannot be somebody who is winning and somebody who is losing.”

Over the next year at Sanofi, Dourlens highly expects the world to change again.

“More than ever, the level of uncertainty we have in the worldwide clinical supply chain is just incredible,” he says. “The world has changed over the past two years –in the supply chain, in the clinical supply chain and across the pharmaceutical supply chain.”

Here, the level of flexibility and agility is essential to be able to adapt for the supply chain. Yet, as the world has changed, Sanofi has also grown more resilient – so much so that managing a complex supply chain is Dourlens’ 2023 goal.

supplychaindigital.com 41

SUPPLY VISIBILITY SHOWS CLEAR AND PRESENT DANGERS

What supply chain bosses really need is a crystal ball, but the next best thing is supply chain visibility. Here, Ryan Closser of FourKites explains why

WRITTEN BY: SEAN ASHCROFT

What every supply chain chief really needs in today’s tumultuous world is an in-house Nostradamus – someone able to peer into the future and headoff yet more disruption, from whatever catastrophes the future has in store for already beleaguered supply chains.

But seers blessed with supernatural insight are rather thin on the ground, at least in B2B circles; I was unable to find even a single one on LinkedIn. And so it is that businesses have to make do with the nextbest-thing to make supply chains more resilient: visibility.

Having a clear, end-to-end picture of one’s supply chain at any given moment in time is the goal. As the past two years of conveyorbelt shocks to supply chains has shown us, visibility has never been more important.

Yet knowing what is needed and achieving it are two very different things.

42 February 2023

VISIBILITY AND DANGERS

supplychaindigital.com 43 SUPPLY CHAIN

www.prenax.com 1 2 page ADVERT OCTOBER.indd 1 04/07/2022 10:43:44

RYAN CLOSSER DIRECTOR PROJECT MANAGEMENT & NETWORK COLLABORATION, FOURKITES

A recent CIPS & Deloitte report into procurement and supply chain resilience shows that rather than being visible, the supply chains of most public- and privatesector organisations are positively opaque. The thrust of the report was that organisations are failing to measure the environmental impact of their supply chains

– mainly because they can’t see it – but its findings are symptomatic of a wider trend among organisations that lack supply chain visibility.

Report shows just 13% of firms have supply chain visibility

The report found that just 13% can map their entire supply chain network, and that up to 22% have no visibility beyond their immediate suppliers.

So, with this in mind, we asked a supply chain visibility expert to walk us through the business benefits of the ‘Nostradamus effect’ and why it is vital that organisations are at least ready for the future – even if they can’t see it.

Ryan Closser is Director of Project Management & Network Collaboration at

“ SUPPLY CHAINS ARE STILL CATCHING UP TO THE MODERN TECHNOLOGICAL AGE. LACK OF REAL - TIME DATA HAS HELD THEM BACK”

supplychaindigital.com 45 SUPPLY CHAIN

“ A TRANSPARENT SUPPLY CHAIN SHOWS

FourKites, which connects global end-toend supply chains through real-time visibility technology to help shippers, carriers, and 3PLs work better together.

Closser says: “In many ways, supply chains are still catching up to the modern technological age, as the lack of real-time data and cross-company collaboration has consistently held back their advancement and evolution.

“For example, if your inbound freight terms aren’t collected, you likely have no visibility into what’s coming into your facilities. This lack of visibility can lead to production delays and downstream stockouts at the point of sale.”

He adds: “A transparent supply chain enables you to see everything, including whether shipments are in transit, in the warehouse or distribution centre, and where they will be later. Extending visibility into every corner of your supply network unlocks business value through a variety of benefits.”

Here, Closser runs us through some of the most valuable benefits.

Better strategic planning

Few companies directly manage their entire supply chain, from raw materials to shipping finished products. By mapping the entire lifecycle and knowing where everything is at all times, companies can better plan for all possible scenarios.

This connection that exists between planning and reliable transit times allows us to be prepared for any change in volume and to attend to the urgency we may have in production changes.

Monitoring and benchmarking execution Visibility doesn’t just aid planning; it’s critical for measuring the performance of your plan, to ensure that you can gauge the effectiveness of any changes you make in the future.

WHETHER SHIPMENTS ARE IN TRANSIT, IN THE WAREHOUSE OR DISTRIBUTION CENTRE, AND WHERE THEY WILL BE LATER”

RYAN CLOSSER DIRECTOR PROJECT MANAGEMENT & NETWORK COLLABORATION, FOURKITES

46 February 2023

This gives operating teams more data to monitor operations in their region or site, meaning they can have more productive conversations with providers, as well as being able to drive improvements.

Reduce shipping fees

With hundreds of disparate systems used by carriers and freight forwarders, updates about milestones or ETAs can often come too late or be inaccurate, causing delays or excessive dwell

Vendorful leveraging data to bring visibility

Speaking at Procurement & Supply Chain LIVE: The Risk & Resilience Conference, Peter Bonney, CEO of Vendorful, spoke of the importance of supplier visibility: “We provide our customers with the customerrelationship management software experience that sales teams have been used to for a long time.

“Sales teams have long been able to access data about customers and prospects, and we're providing that kind of functionality to customers, making it easy for them to manage those supplier relationships as well as reduce the amount of time they need to spend on manual tasks such as keeping compliance data up to date.

“How deep does Vendorful visibility go? That depends on the level of data that we're given access to. We'll draw-in data from a customer's enterprise resource planning and unlock insights that traditionally have not been visible to people in procurement.

“I think the thing that's interesting is we're finding most organisations have better data than they realise. It's usually locked away in different places and inaccessible to the people who want and need it. We hear stories about how, when procurement people need data, they have to email somebody to get it. The data is there and of decent quality, it's just not visible. We're unlocking that for our customers.”

supplychaindigital.com 47 SUPPLY CHAIN

time and, therefore, added demurrage and detention fees.

Visibility allows the underlying logistical issues causing the delays to be directly addressed. You cannot address what you cannot measure.

Improve lead times

Rather than constantly reacting to delays and exceptions, supply chain professionals

should regularly examine their network design to identify optimal patterns within their flow of inventory. Such optimisation is useless unless you’re accounting for 100% of your network.

Better supplier collaboration

With deep visibility and data you can answer critical questions about your supplier base. Questions such as: How

48 February 2023 SUPPLY CHAIN

many suppliers make the most sense?

Are my suppliers collaborative?

Being a preferred supplier is a big deal for many organisations because it helps them grow.

Increased customer and partner satisfaction

Imagine being able to proactively communicate to customers or address an issue before it becomes a problem. When

employees have real-time insight into every shipment, everywhere – regardless of who owns the container or warehouse it’s in – they can.

The better you can collaborate and integrate with your carriers, the more effective you'll be at delivering on your customers expectations, which is, in the end, what it's all about.

Increase productivity

Happy customers means happy employees. No one wants the mind-numbing task of manually tracking and tracing each shipment, and even less desirable is doing so after being yelled at by an angry customer.

The ability to track details at stockkeeping-unit (SKU) level – across both managed and unmanaged freight – with network visibility can enhance warehouse and labour productivity.

Optimise reverse logistics

Returned items are likely a black hole in your network – this means that 15% of your inventory is unaccounted for. Where a specific part or a SKU order with a vendor might take weeks, you could already have it in a bulk load somewhere within your network.

By gaining full visibility, you can improve command over inventory and, on top of that, reduce the credit cycle by knowing when shipments change custody.

Strengthen your sustainability strategy

The thing about Scope 3 emissions is that many of the largest sources are the ones over which a business has littleto-no direct control. But investing in greater visibility helps you spot where inefficiencies are occurring so that you can influence a better outcome and hit your sustainability targets.

“ EXTENDING VISIBILITY INTO EVERY CORNER OF YOUR SUPPLY NETWORK UNLOCKS BUSINESS VALUE THROUGH A VARIETY OF BENEFITS”

supplychaindigital.com 49

RYAN CLOSSER DIRECTOR PROJECT MANAGEMENT & NETWORK COLLABORATION, FOURKITES

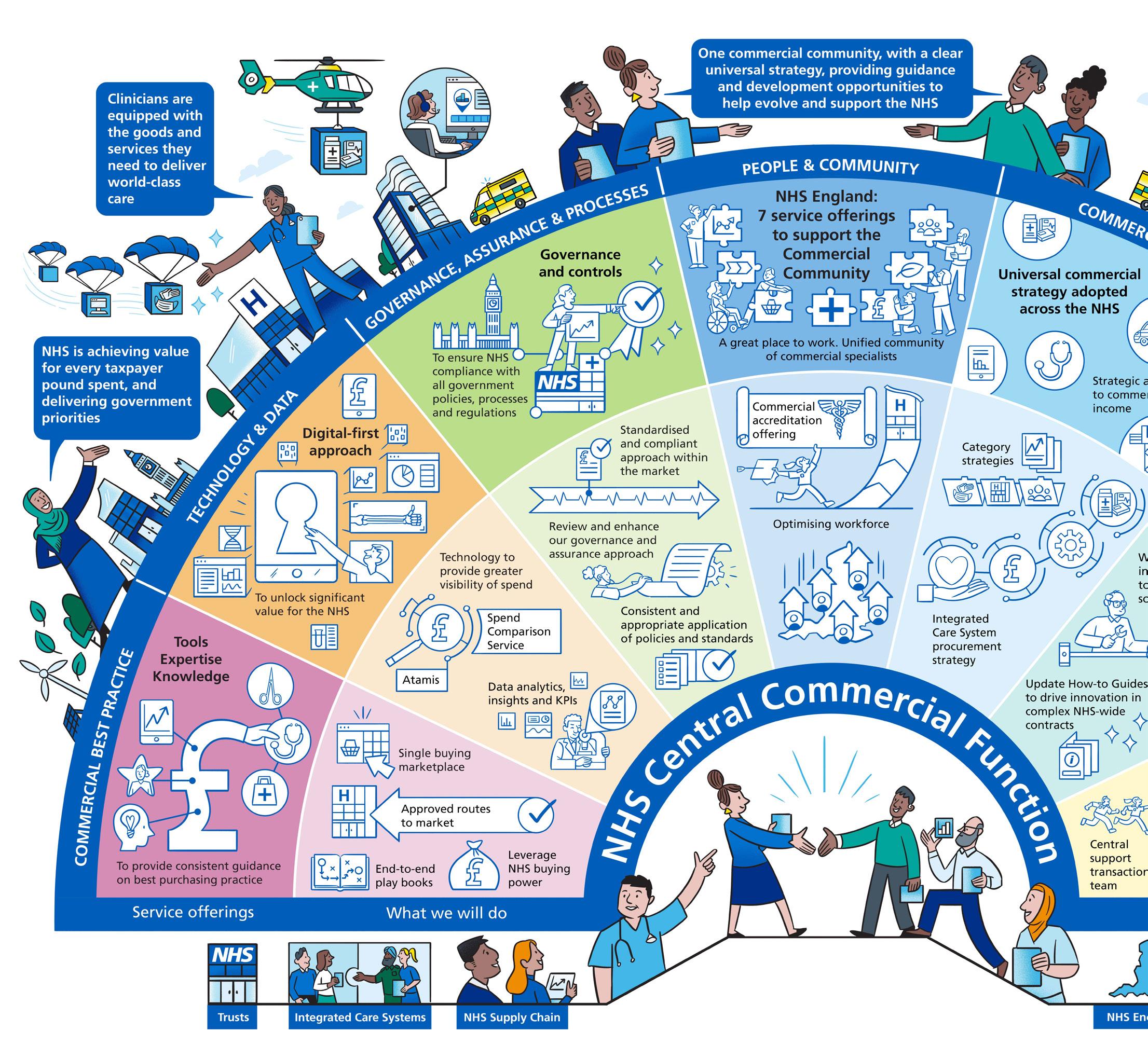

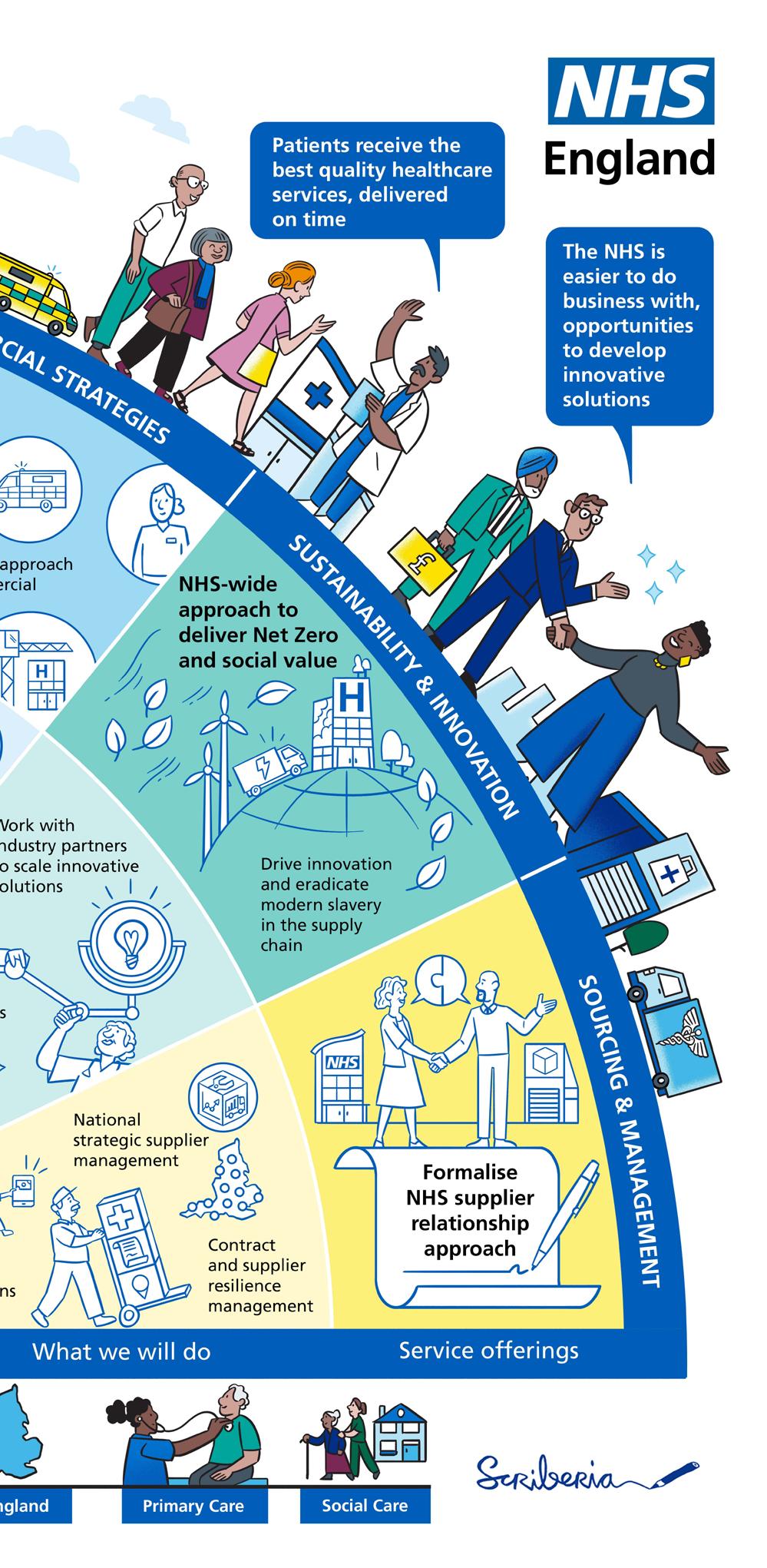

Building a Commercial Community through the NHS Central Commercial Function

50 February February20232023

AD FEATURE WRITTEN BY: ILKHAN OZSEVIM

PRODUCED BY: GLEN WHITE

supplychaindigital.com 51

People often say that they fall into procurement. I didn't ‘fall’ into procurement; I made a very definite choice that this was the career path that I wanted to follow.”

These are the words of Jacqui Rock. Rock is NHS England’s Chief Commercial Officer and is spearheading one of the most significant reforms NHS procurement has seen since its inception. It’s a task of gargantuan proportions, but she has the expertise, the vision and the sheer tenacity to get it done through the NHS Central Commercial Function.

The Challenges and Opportunities

Rock points out that the private sector is very much profit-oriented, “especially in financial services, as you can imagine”.

“In the public sector though, we're extremely conscious of taxpayers’ money and of how we spend that money towards the provision of services.”

Beyond these key orientations, she notes that different sectors have different agendas, giving the example of the military (having worked in major programmes across the full military estate for the Army, Navy, Royal Air Force and Joint Forces Command), whose agenda is about protecting the realm.

With the NHS, the agenda is about providing the UK’s population with one of the best health services in the world, and Rock points out that these agendas come with their own particular challenges.

“Over the top of all of those sets of challenges, though, there are also those that we as commercial professionals constantly face – whether that be the challenge of supplier resilience, the supply chain and the availability of goods, the costs of inflation, or our supplier relationships.

“Every sector or industry has challenges that we, as commercial procurement professionals, need to know how to handle.

“The NHS is in a very challenging time right now. We’re in the midst of a difficult winter and COVID-19 is still with us. Then we have the significant impact of the cost-of-living crisis, higher inflation, increasing energy prices and the overall pressure that not only the NHS and our people are feeling, but also pressures that are being felt across the entire country.

The way that I'd like to summarise that is by pointing to Amanda Pritchard, our Chief Executive, who, at the NHS ConfedExpo in June 2022, laid out the priorities for the NHS under ‘the four Rs’.”

Jacqui Rock, NHS England’s Chief Commercial Officer, launched the NHS Central Commercial Function to reform NHS commercial practice through Collaboration, Communication & Partnership – here’s how

52 February 2023 NHS ENGLAND

an image caption supplychaindigital.com 53

Recovery, Resilience, Reform and Respect

“First we have ‘Recovery’,” she says. “NHS staff are moving heaven and earth right now to deliver the Elective Recovery Plan, which is one of our biggest challenges. But this is also the most ambitious catch-up programmes in health service history.”

Where appropriate, and where patients are willing to be transferred, NHS England is implementing programmes to realise those transfers, enabling access to healthcare –not just between hospitals or trusts, but between regions – and is also strongly focused on spreading innovation in recovery and best practice across the entire country.

The second ‘R’ is ‘Reform’, and there are silver linings to dark clouds. “The pandemic supercharged the NHS with innovation,” says Rock. “We started using new drugs, new technologies and new ways of working to treat those with the virus, and to care or all of the millions that had numerous other conditions.”

COMMERCIAL SPEND

The NHS commercial spend is in excess of £30bn per year. It's the largest spend in government

54 February 2023 NHS ENGLAND

JACQUI ROCK

TITLE: CHIEF COMMERCIAL OFFICER, NHS ENGLAND

INDUSTRY: HEALTHCARE

LOCATION: UNITED KINGDOM

Jacqui was previously Chief Commercial Officer, Head of Corporate Services and Transition Director at the UK Health Security Agency. As a member of the NHS Test and Trace Executive Team, she was a driving force behind dynamic and rapid innovation and technology development in the supply chain. Jacqui was formerly director for the Defence Infrastructure Organisation at the Ministry of Defence and was a member of the Cabinet Office Commercial Function. She joined the UK government after 30 years in the financial services industry where she held multiple executive positions in companies including Credit Suisse, JP Morgan, Barclays and Bank of America Merrill Lynch.

The pandemic also emphasised the importance of collaboration between different NHS organisations in the service of patients. Rock emphasises this by noting that traditional barriers were really broken down.

The third ‘R’ stands for ‘Resilience’.

“At NHS England, we're now producing a Workforce Plan, which is going to look at people, skills and training – not just for what we need now, but for what we’ll need in the next five-to-ten years – and look out to the longer term.

“And then, finally, I'll touch on ‘Respect’. Healthcare is about experience, and it's about outcomes – which is why respect is absolutely vital.

“We respect our patients, which means making sure that they are informed and ensuring that they and their families are treated with dignity.

“And, of course, we respect the British taxpayer, which really, also from a commercial perspective, is critically important.

“We’re making sure that we’re spending public money really wisely, and, with all of these challenges, I constantly remind myself of the great public support for having a National Health Service.”

Rock is right. She refers to the recently published Ipsos MORI poll from April 2020, “which showed that 62% of the public feel that the NHS was the thing that made them the most proud to be British”.

NHS England: A Singular Vision

How could one not be proud of this role? Rock’s position is one of great responsibility, and, equally, one that’s a great point of pride – and should be.

Jacqui Rock took on her role as NHS England’s Chief Commercial Officer on 1st of January 2022, and she feels that one of the most gratifying things about working in the NHS has been the people.

This is fitting for a National Health Service whose ultimate goal concerns the wellbeing of people, and in fact, begins with people, is

56 February 2023

carried by people, and ends with people. A truly British and essentially democratic institution –and Rock is instinctively aware of this.

“Regardless of the pressures everybody is under, regardless of the challenges the NHS is facing, as I go around the hospitals, everybody is on mission. Everybody shares the same vision. Everybody wants to do the absolute best they can, even under the most difficult circumstances.

“And, for me, that's been absolutely gratifying. To work in an organisation that actually employs more than 1.2 million people, where everybody has the same drive and the same mission, is incredible.

Carter, Boardman and The Government Procurement Bill

Rock touches on The Carter Review that also took place in 2015, which concerned operational productivity in the NHS.

“It was a real key moment in the journey of NHS procurement,” she says. “The findings in the review changed the way we were recommended to work, and they informed our future ambitions.

Another significant event that occurred in this timeline was the Boardman review of government procurement in the wake of the COVID-19 pandemic, which was published in 2021.

Similar to the Carter Review, the Boardman Review looked at how the NHS works across spending taxpayers’ money and provided some significant recommendations for the future.

Some of its key findings concerned transforming supply chain resilience, integrated roles for commercial and procurement expertise within strategy formation, and, most importantly, procurement strategy as being central to policy making when the NHS are spending government money.

Rock says: “When it comes to procurement – and this also applies to the NHS – this is something I am dedicated to, and very much focused on enhancing and fixing. We have gathered and leveraged all of the lessons and reviews that have taken place to ensure that we deliver on the recommendations through the NHS Central Commercial Function.

“Going forward, in 2023, we've got the launch of the Procurement Bill, which is currently going through Parliament. The intention of the Bill will be to reform the UK's public procurement regime to streamline new procedures, and is intended to save time for public bodies and suppliers, allowing us to promote commercial outcomes and deliver more value for the money.

“The new Procurement Bill is fundamental to the NHS Central Commercial Function, which we’re rolling out so we can ensure that

“People often say that they fall into procurement. I didn't 'fall' into procurement. I made a very definite choice that this was the career path that I wanted to follow”

supplychaindigital.com 57 NHS ENGLAND

JACQUI ROCK CHIEF COMMERCIAL OFFICER, NHS ENGLAND

the NHS is ready and able to procure and leverage the market.”

The NHS Central Commercial Function

In July 2022, Jacqui Rock launched the next evolution of the commercial service offer for the NHS - the Central Commercial Function (CCF), which aims to build a world class commercial community in the NHS. This will help unlock significant commercial opportunities for the NHS including leveraging NHS buying power where appropriate, delivering value for money for the taxpayer, ensuring clinicians have the right products and services they need at the right time, and tackling some of our commercial challenges such as supplier resilience.”

“This wasn’t something that we at NHS England have done alone. After spending months visiting trusts and seeing all the amazing commercial activity that’s taking place across the NHS, we've engaged closely with commercial teams right across the NHS, and have ensured that their feedback was incorporated into the development of the NHS Central Commercial Function.

Our collective ambition is a modern, effective, and efficient procurement function in the NHS that is among the best in the world, one that truly delivers taxpayer value, supports innovation, stimulates growth, and most importantly, delivers the highest quality of patient care.’’

58 February 2023

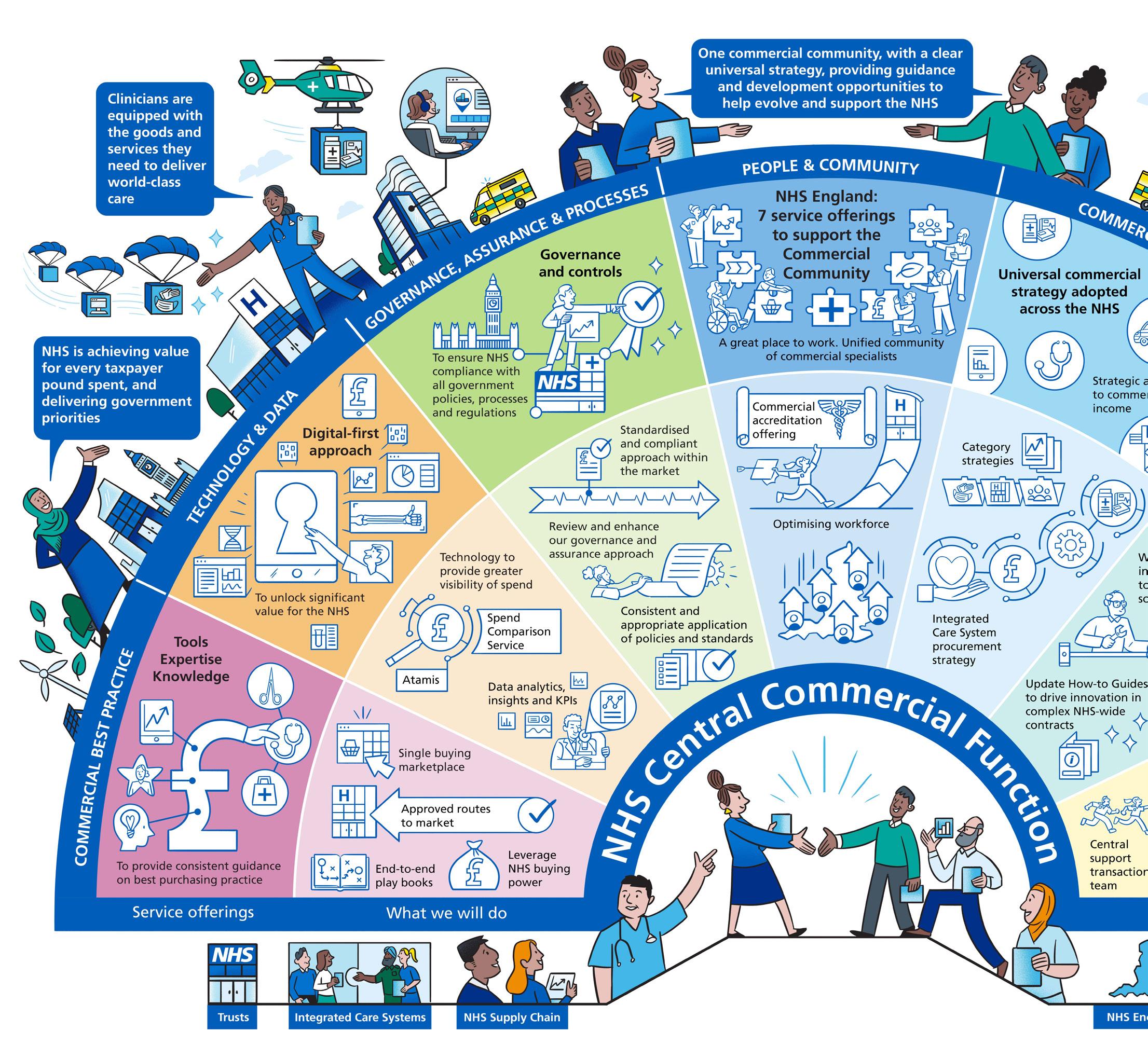

An overview of the NHS Central Commercial Function's 7 service offerings

Since the launch, Rock and her team have developed a robust programme plan and have governance in place. They’ve really been focusing on putting NHS commercial and procurement teams at the forefront of change, and raising their profile with many of their suppliers.

The 7 service offerings of the NHS Central Commercial Function

The NHS Central Commercial Function is comprised of 7 service offerings, which are already delivering across the system.

1. Commercial Best Practice – Enabling the NHS commercial community to access tools, expertise and cutting edge knowledge to deliver purchasing activities at every level of the NHS.

2. Governance, Assurance & Processes – Endorsed, standardised and complianceassured routes to market that wield NHS influence and promote innovation to deliver government priorities.

3. Technology and Data – Developing and adopting technology that provides the NHS with insight into procurement value and savings opportunities and outcomes. This will help to leverage, rationalise and shape the market.

4. Commercial Strategies – Creating a universal strategy across the NHS with clear commercial activities and routes to market that facilitates ease of doing business.

5. Sustainability & Innovation – Developing an NHS-wide approach to delivering net zero and social value, driving innovation and eradicating modern slavery in the supply chain, enabling stakeholder engagement and application.

6. Sourcing and Management – Developing a strategic partnership approach that leverages the NHS buying power, shapes the market, drives innovation and resilience in the NHS.

7. People and Community – Embedding a unified community of procurement and commercial specialists who strive to deliver and uphold the NHS Commercial Strategy ensuring best value for money.

supplychaindigital.com 59 NHS ENGLAND

Using a universal ecommerce system

A key deliverable of the Central Commercial Function was introduced just weeks after its launch – and that was the universal rollout of the ecommerce system: Atamis.

NHS England made Atamis available to all health and family organisations, following funding from Crown Commercial Services and working in partnership with the Department of Health and Social Care in July 2022.

It is being used by a range of different organisations across the health family, namely (1) NHS Providers, (2) NHS Integrated Care Boards, (3) NHS CSUs, (4) national bodies (e.g. NHS England, UKHSA) and (5) the Department of Health and Social Care.

Rock says: “So far, 131 health family organisations have onboarded to the platform and nearly 29,000 suppliers have registered on the platform in order to respond to opportunities and manage their contracts with the NHS.”

“The key point of using a universal e-commerce system is that, by the end of the financial year we will have a really detailed view of commercial spend. We will know where we are spending, where the variance exists, and where we are getting better value for money.

“We will have a very good view of our supplier footprint across 220 trusts and thousands of primary care providers, so it's a really key initiative.

“We've got to be data-driven, because, ultimately, service provision is all about the data. Up to this point, it's been very hard to pull data together and actually have that overall NHS view – and this is going to enable us to do that.”

NHS organisations are already seeing the benefits. The London Ambulance Service (LAS) were one of the first to

“The real value of the NHS commercial team is in collaboration. It’s about bringing everybody across 4,000+ procurement and supply chain professionals together, so that we can agree on category strategies and move forward with a single vision”

60 February 2023 NHS ENGLAND

JACQUI ROCK CHIEF COMMERCIAL OFFICER, NHS ENGLAND

onboard. Operating across London out of 70 ambulance stations, LAS has an annual addressable non-pay expenditure of around £150mn and over 340 active contracts valuing over £296mn.

Using a universal e-commerce system has allowed them complete visibility of their pipeline of procurement activity which means that the team can be more proactive with resource planning and plan upcoming procurements in a transparent and consistent manner.

Shaping the Market: Eliminating Waste and Redundant Contracts

One of Jacqui Rock’s key commitments is to implement a strategic supplier management programme to help the NHS to shape and leverage the market.

Rock says: “We should be leveraging the market. We should be able to drive innovation through our suppliers. We must focus on greater resiliency in our supply chain. We want to focus on eliminating waste, and one of the things that I found really enlightening when I came in here, is that we’ve got multiple contracts with the same supplier for the same thing, but with lots of variation.

“This is something that we need to work on collaboratively and in partnership with our big strategic suppliers to discover how we can just simply buy better in the NHS.

“So we've been spending a lot of time listening to suppliers and our key stakeholder Strategic Supplier Relationship Management teams to understand how this presently works and how we can align our strategies to make it as easy as possible to supply to the NHS.”

supplychaindigital.com 61

“Every challenges procurement

62 February 2023

NHS England's Sustainability Roadmap

In October 2020, the National Health Service published a report called the Greener NHS Report, which announced that the NHS will be net-zero by 2040 and, for its carbon footprint plus, by 2045.

Over 60% of the total NHS Carbon Footprint sits within its supply chain and these include emissions from freight, the manufacturing of goods, catering, business services and construction.

“Our net-zero procurement plans are aligned with government policy,” says Rock. “From April 23rd, the NHS will adopt the government’s ‘Taking Account of Carbon Reduction’ plans PPN, which will require all suppliers of contracts valued over £5mn to publish a carbon reduction plan for their direct missions.

“We have also adopted the government social value model, which ensures that a minimum of 10% waiting on net zero and social value, is included in all tenders; The NHS Central Commercial Function team have been producing detailed guidance to support trusts with this.

“It's a new area for many of the trusts and certainly many of our suppliers, so we've

been ensuring we can deliver that support right the way through this process.”

The Mission: Collaboration, Communication and Partnership

The reason that Rock set up the NHS Central Commercial Function was to take a good hard look at how they buy across the NHS, so that taxpayer money is being spent in the most efficient way. Their commercial spend is in excess of £30bn per year. It's the largest spend in government, and they are spending in a very federated way because the NHS isn't just one organisation. The NHS is already one of the most efficient health services in the world, spending 2p in the pound on administration, compared to 5p in Germany and 6p in France, but Jacqui Rock says that there are opportunities to go further.

“We want to make sure that NHS bodies and trusts have the autonomy to run their hospitals and their clinical pathways.

“But the real value of the commercial team is in collaboration: it’s about bringing everybody across 4,000+ procurement and supply chain professionals together, so that we can agree on category strategies and move forward with a single vision.

“What I am really doing is getting people to work together as commercial professionals.

“It’s about collaboration, it's about community, it's about partnership.

“Our buyers are very gifted – they know what they're doing – but they will be supercharged in their effectiveness once brought out of their silos and enabled to see the bigger picture, for a better, stronger and much more effective NHS.”

“Every sector or industry has challenges that we as commercial procurement professionals need to know how to handle”

supplychaindigital.com 63 NHS ENGLAND

JACQUI ROCK CHIEF COMMERCIAL OFFICER, NHS ENGLAND

RESHORING TAKES HOLD IN FACE OF SUPPLY CHAIN PRESSURES

WRITTEN BY: SEAN ASHCROFT

WRITTEN BY: SEAN ASHCROFT

64 February 2023

The shape of supply seems to be changing in every conceivable way. It’s becoming less chainlike and more network-based, as businesses seek the sophistication needed to thrive in an uncertain world. Supply chains themselves are also shrinking, with organisations beginning to move away from the cheap-labour strategies that have fuelled the manufacturing boom and rapid industrialisation in South East Asia for the past 40 years.

But those days seem to be drawing to a close, because supply chains that span the globe are too vulnerable to disruption in today’s volatile, uncertain world. Increasingly, firms are looking to reshore and nearshore both manufacturing and sourcing to reduce their exposure to risk.

A recent Reuters Events whitepaper shows just how strong the reshoring trend has become. Produced in conjunction with A.P. Moller-Maersk, the giant Danish shipping company, the paper – called ‘ A generational shift in sourcing strategy’ –is a global deep-dive into near-sourcing, nearshoring and reshoring in the postpandemic world.

It looks at how companies across the world are looking to rebalance their supply chains, reduce risk, increase visibility and improve sustainability.

The paper shows that the countries with the two largest manufacturing workforces,

supplychaindigital.com 65

LOGISTICS

Disruption, uncertainty and inflation are driving businesses to reshore and nearshore manufacturing and retail operations, but at what cost?

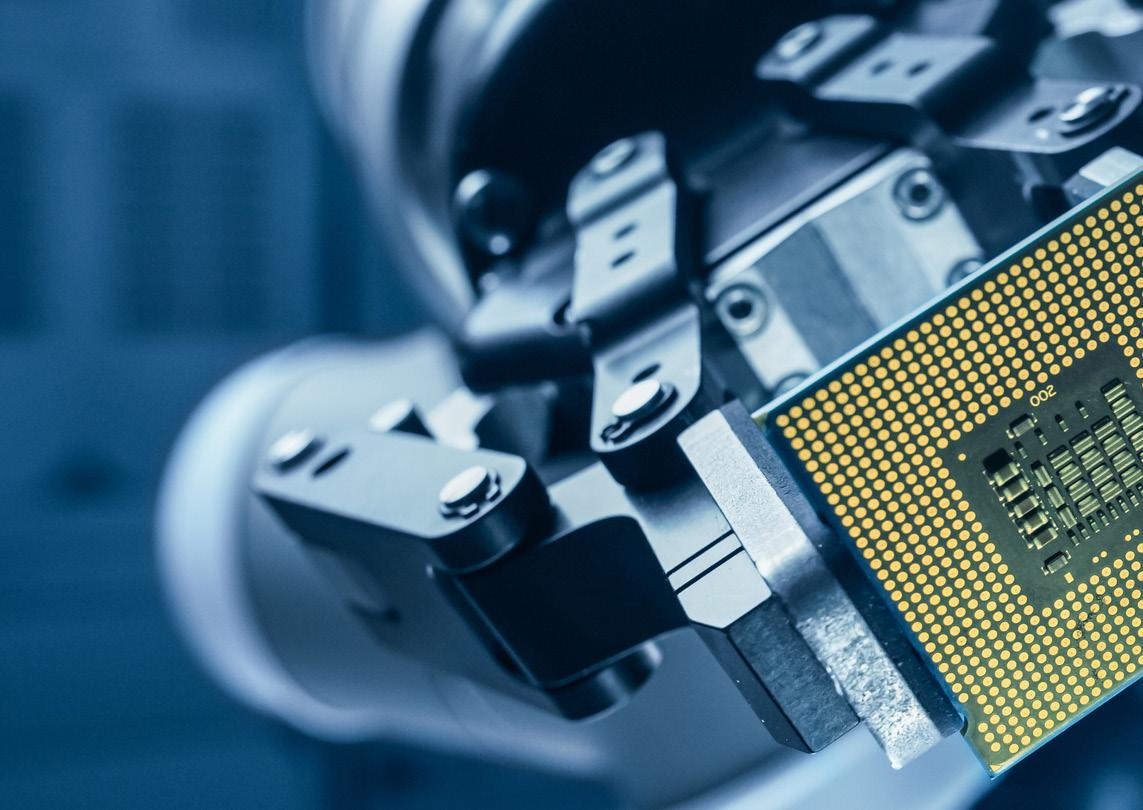

There has been more reshoring and nearshoring around the manufacture of semiconductors than any other product, because of the longstanding and ongoing chip shortages

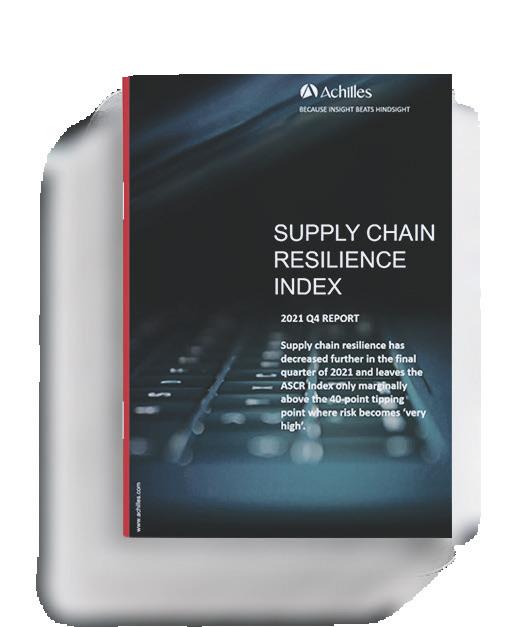

Inform your supply chain resilience planning with our time-measured report series

Ensuring the agility and resilience of your business and supply chain starts with identifying the risks.

Download our report to start your resilience planning today.

Download ASCRI Report

Because

Hindsight

Insight Beats

Germany and Poland, are the most attractive sourcing and reshoring locations.

But the authors also add that there’s a “broad-based commitment” among businesses to source more from within both East and West Europe to reduce the distance to end-market and meet the increasing need to draw on pools of skilled labour.

In the foreword to the paper, Mikkel Søndergaard Rasmussen, Regional Head of Logistics and Services, Europe A.P. MollerMaersk recounts the chaos and disruption of the past two years, including the pandemic and war in Ukraine.

“Global markets have been fragmented and this has left supply chains exposed,” he says,

adding: “Little wonder, then, that companies hold supply chain resilience in increasingly high regard, because the ability to deliver products reliably and on time is increasingly important to their customer-value propositions.”

Rasmussen observes that this has seen sourcing strategies “come under the microscope for many” as the bid for resilience gathers pace. He says: “Resilience doesn’t come without its costs but when set up correctly, logistics can be seen as a business enabler and potential source of competitive advantage, instead of being a financial hindrance.”

This, he continues, means adopting “a less fragmented logistics supplier base and a more integrated, holistic approach across the entire supply chain, together with a trusted logistics partner accountable for outcomes”.

MIKKEL SØNDERGAARD RASMUSSEN, EGIONAL HEAD OF LOGISTICS & SERVICES, EUROPE, A.P. MOLLER-MAERSK

supplychaindigital.com 67 LOGISTICS

“Global markets have been fragmented and this has left supply chains exposed”

REAL - ESTATE DATA CONFIRMS STRONG RESHORING TREND

Data from European commercial property company BNP Paribas Real Estate reveals that the industrial and logistics leasing market has been met with a surge of activity from manufacturing occupiers as they seek to ‘reshore’ activity back to Britain, following the impact of Brexit and ongoing supply chain disruption. It shows that, in 2022, take-up of units of 100,000sqft and above has increased by 53% on 2021 levels. Logistics providers were the most active sector, with a 35% year-onyear increase.

Vanessa Hale, Head of Research and Insights at BNP Paribas Real Estate, said: “There are a number of driving factors behind reshoring, including inflation, Brexit, the pandemic, the Ukraine war and the blockage of the Suez canal, all of which have massively impacted supply chains and overheads.

“As businesses fight harder for space, activity will continue to put pressure on chronically short supply levels.

“Acute supply-demand imbalances of suitable facilities are likely to continue, especially as rising construction costs weigh heavily on future development pipelines.”

Two-thirds of firms say disruption had changed sourcing policies

Some key figures quoted in the paper:

• 67% of global retailers and manufacturers say that global supply chain disruptions have changed where they source materials and components from.

• 58% of those who have shifted sourcing say that further relocation

• remains a high priority, or the top priority, for their business.

• 76% do not expect supply chains to normalise in the next 12 months, following Q3 2022.

• 37% plan to change manufacturing locations.

68 February 2023

The paper says that among the factors fuelling plans to nearshore and reshore manufacturing and sourcing are disruptions to raw materials (70%), shipping (68%), and components or finished goods (63%).

The top five reasons given by businesses looking to shorten their supply chain are: to increase flexibility (65%); to limit reliance on single-sources of materials (57%); to limit operational risk (56%); to reduce transit time (48%); and to increase control over operations (45%).

The paper also looks at how supply chain structure is changing in industry verticals in the face of disruption and uncertainty. It reveals:

The electronics and technology, and automotive, aerospace and machinery sectors have been the most active in changing sourcing locations as a result of disruption.

The electronics and technology sector has been the most disrupted by delays in components.

The fast-moving consumer goods and food & beverage sectors have been the most disrupted by lack of shipping capacity and labour shortages.

The chemicals and chemical products sector has been the most disrupted by delays in raw materials, inflation and delays in shipping.

Turning its focus to regions, the paper reveals that North American supply chains are the most internationally focused, containing the smallest number of supply chains saying they source only in their home region.

North American respondents are, as such, more likely to face labour and factory capacity shortages than in Europe or Asia-Pacific.

Asia-Pacific, meanwhile, has been hardest hit by shipping complications, the paper reveals, which reflects ongoing COVID shutdowns in the region, especially in China.

MIKKEL SØNDERGAARD RASMUSSEN, EGIONAL HEAD OF LOGISTICS & SERVICES, EUROPE, A.P. MOLLER-MAERSK

supplychaindigital.com 69 LOGISTICS

“Logistics can become a business enabler and a source of competitive advantage”

Future supply chains ‘will look very different’

The paper concludes: “Future supply chain logistics will undoubtedly look different from today’s offerings, as supply chains start to move closer to the end consumer, with fewer intermediate parts traded over long distances.”

It continues: “While it is still unclear how pervasive nearshoring will be, heightened uncertainty has already impacted supply chain decisions in some sectors.

“Multi-sourcing and changes in inventory management will become more widespread and will need to be supported by new and more holistic logistics offerings, to manage complexity and cost.”

The paper also says that integrated logistics and fulfilment strategies “will be in even

sharper focus in order to meet consumer demand for flexibility, speed and reliability across a widening range of delivery channels”.

In conclusion, the paper says that outcome-based, long-term logistics partnerships are needed “to deliver seamless, cost-effective and resilient supply chain solutions based on widely accepted ESG standards”.

Cost is driving retail towards reshoring strategies

But it is not just industrial manufacturing that’s seeing fundamental changes to supply chain strategies; retail supply chains are also shortening as brands look to cut costs.

In a recent study conducted by global e-commerce fulfilment platform ShipBob, it was found that 40% of British brands are

70 February 2023

LOGISTICS

planning to manufacture domestically in response to the cost of shipping to the US rising by 30% in just twelve months. The findings were drawn from a survey of 750 UK brands.

While cross-border commerce has traditionally been the engine for rapid ecommerce growth, rising shipping costs are causing many smaller UK brands to prioritise operations closer to home, the ShipBob study shows, and it’s a similar story across much of Europe and North America.

When asked to name measures that would best drive business growth over the next 12 months, 38% said moving manufacturing operations from overseas to the UK to avoid import challenges and rapidly rising freight costs.

Enda Breslin, ShipBob EMEA General Manager, warned that spiralling

shipping costs are “strangling the growth of the UK’s e-commerce entrepreneurship sector”.

He added: “While it’s understandable many will look to protect their bottom line by focusing inside British borders, it means brands won’t scale as fast as they should.”

Breslin went on to say that small brands should still “look to expand ambitiously” but that they should seek to do so “in a resilient way”, such as by making use of their ecosystem of ecommerce partners.

“Choosing fulfilment partnerships carefully will help small brands position themselves closer to their overseas customers, and level the playing field with local competitors when it comes to shipping speed and cost.”

supplychaindigital.com 71 LOGISTICS

A modern procurement platform for today’s business

72 February 2023

supplychaindigital.com 73

PRODUCED BY: MIKE SADR

IQUANTUM

WRITTEN BY: ILKHAN OZSEVIM

iQuantum is a global technology platform that uses AI & ML to enable innovation and procurement focusing on supplier diversity and ESG

Hetal Mehta is the founder and CEO of iQuantum Inc., a modular, modern procurement platform. As the leader of iQuantum’s woman and minority owned business, Hetal works closely with all internal teams, customers, partners, and the iQuantum Advisory Board of industry champions and practitioners.

Hetal Mehta’s journey into the industry

For many years, Mehta worked as a developer and consultant to procurement teams. Through that experience she recognised the need for a more sophisticated and user-friendly procurement solution, “one that does all the efficient and effective consolidations, automation and workflows – but also helps guide alignment between buying decisions and larger strategic corporate goals like increased diversity,” she says.

“My in-depth experience and understanding of supplier diversity led me to realise that customers struggle with finding appropriate suppliers and are prone to continuing business with existing ones – even if that is not ideal.

“With iQuantum our goal is to leverage machine learning and AI to provide a modern procurement platform with access to the largest global supplier database that includes diverse and sustainable supplier options. This helps customers build a more resilient and robust supply chain.”

iQuantum’s unique selling point

iQuantum Inc. is a modern Source-to-Pay platform designed to meet today’s procurement needs for Supplier Relationship Management, Diversity and ESG Sustainability tracking and reporting. They provide the tools and transparency to align spend decisions to strategic corporate goals.

74 February 2023

IQUANTUM

supplychaindigital.com 75

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

Mehta says: “There is no single provider on the market who competes with us pinto-pin.” iQuantum is the only SaaS platform to provide:

• Complete Supplier discovery to Pay on one platform WITH modern ESG and full diverse supplier management.

• New supplier discovery from a database of millions of global suppliers to increase supply chain resilience and support new product introduction (NPI) sourcing

• Integrated supplier communication and collaboration with in-built Chat and conversation storage for future reference and context

• Modern approach to complete strategic sourcing for indirect, direct and new product introduction with internal team collaboration

• Rich contracts, procurement, and spend management analytics

• Integrated Tier 1 & Tier 2 Diversity and ESG Sustainability reporting and benchmarks

76 February 2023

“Prioritising diversity in your employees and your supplier base as a part of ESG is integral to the growth and future trajectory of the company – employees, leadership, investors, stakeholders, and customers seek brands that are improving their profiles”

• Government and Customer reporting along with Subject Matter Expertise by fine-tuning their diverse spend tracking and achieve the elite Billion Dollar Roundtable or BDR

• Diverse and small supplier visibility to iQuantum’s Fortune 500 customer base, including support for supplier marketing of their products and catalogues

• Modular licensing approach and enterprise interoperability to accommodate each customer’s needs, budgets, and existing system investments

• Single code base for quick implementation, easy maintenance, and simple configuration with a sophisticated, userfriendly user experience

• Access to global database of suppliers including diverse/non-diverse and green suppliers for procurement to add to supply chain and achieve savings

• Better alignment, reduced risk, and increased compliance across procurement, finance, and corporate legal

HETAL MEHTA

TITLE: CHIEF EXECUTIVE OFFICER

LOCATION: IQUANTUM

Hetal holds a BS in Electrical Engineering, and, prior to founding iQuantum, she logged more than 15 years of IT consulting experience with financial firms on Wall Street. Her technical background combined with her sharp domain expertise has been instrumental in building iQuantum; engaging industry-leading customers, attracting and mentoring top engineering talent, and delivering top-class business results, she has driven iQuantum’s growth over the years. Hetal Mehta has been recipient of Steve Awards and Women of the

IQUANTUM

HETAL MEHTA CHIEF EXECUTIVE OFFICER, IQUANTUM

The importance of diversity in procurement and supply chain and the role of iQuantum McKinsey reported that working with diverse suppliers leads to an 8.5% in cost savings, which is more than the 3 - 7 % savings most procurement organisations realise.

“Prioritising diversity in your employees and your supplier base as a part of ESG is integral to the growth and future trajectory of the company – employees, leadership, investors, stakeholders, and customers seek brands that are improving their profiles,” says Mehta.

Qualified diverse suppliers bring savings and better service to customers. Procurement leaders have recognised this, and are looking at ways to increase their diverse supplier base (increasingly Tier 1 and Tier 2 diversity reporting is becoming a mandate across different industry verticals).

78 February 2023 IQUANTUM

“Every purchase made needs to be aligned to strategic corporate goals and help to move the needle. Increased government regulation and consumer scrutiny of corporate brand spending has increased the need for a new procurement approach”

She says: “We see these two tiers in Manufacturing, and in Law firms it typically comes from customers setting goals to win RFPs, while for the Healthcare and Pharmaceutical industry the stimulus comes from the government and encourages organisations to negotiate diversity goals and to report them annually.”