With disruption continuing apace, ESG compliance now mission critical, and inflation squeezing everyone, collaboration has never been more important in supply.

Today’s world is so riven with uncertainty it has become part of the ‘new normal’ for businesses. Normal or not, market conditions are hostile, and organisations must find ways to move things around the globe – not just in a timely fashion but also in ways that are sustainable.

Fail to do either and they run the risk of losing or alienating customers.

The demands being made of supply chains are vastly different to pre-pandemic times, so it ought not be a surprise that the ways businesses are meeting these demands have also changed.

In short, supply is becoming more collaborative. Competitors in vertical markets are beginning to share logistical resources because it’s cheaper that way, and helps offset spiralling cost inflation.

Businesses looking to meet net zero goals are working closely with suppliers, to educate and empower them to be more sustainable.

And companies are also beginning to talk about how one day they will share data with one another, so they can work smarter around all aspects of supply – from designing sustainability into products to optimising supplier contract negotiations.

Supply is more about networks than chains these days. Who knows, eventually, we might have to change the name of this magazine.

SEAN ASHCROFT sean.ashcroft@bizclikmedia.com

“Businesses looking to meet net zero goals are working closely with suppliers, to educate and empower them to be more sustainable”

Minnesota, US Thanksgiving is a cherished American institution that began life as a harvest festival. Today it sees families across the US gather on the fourth Thursday of every November to celebrate, and to drink and eat – mainly turkey.

Minnesota has long been the turkey capital of the US and –some would argue – the world. Every year Minnesota turkey farmers raise 40-42 million birds.

Its 600 turkey farms and stakeholders generate an estimated $1bn in economic activity for Minnesota, and provide around 26,000 jobs.

Source: McKinsey

Source: McKinsey

Plastic has gone from being a revolutionary material that was invented with good intentions to an unsustainable single-use function of consumerism, with global supply chains driving consumption.

In 1869, the first synthetic polymer was created. John Wesley Hyatt responded to a New York firm’s offer of US$10,000 for an alternative to ivory, which at the time meant that around 20,000 elephants each year were being slaughtered.

The birth of fast food – driven by firms such as McDonalds – and the rise of plastics manufacturing in turn gave rise to a takeaway culture that saw people use plastic cutlery on a global scale. It was the start of unsustainable waste that continues to plague the world today.

Like all plastic, plastic bags begin life as fossil fuels and end up as non-decomposable waste in landfills and the ocean. But in the 1970s, supermarket chains bought them in their billions, and only recently introduced ‘bags for life’ as a replacement.

While plastic was developed with good intentions, the case against it increased. In the 90s researchers found that 60-80% of plastic in the ocean would not go away. While it proved more convenient for businesses and consumers, plastic was adversely affecting life under the sea— another problem that can be seen today.

The world begins to see that single-use plastics have no place in the circular economy. Plastics organisations such as the British Plastics Federation begint to work with stakeholder to achieve a circular plastics economy, and reduce leakage of plastic waste into the environment.

From the late 2010s to the present, exciting new alternative packaging concepts begin to emerge, such as biodegradable bottles, liquid packaging solutions, and alternative materials, such as starch-based polymers. The fast-food sector makes the switch to cardboard and paper packaging during the spike in food delivery during COVID-19.

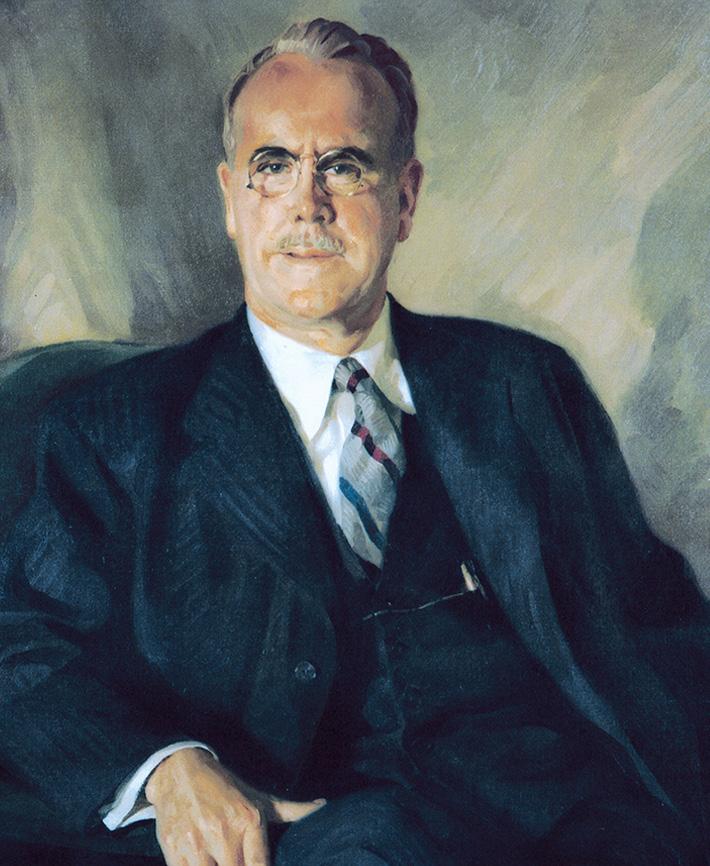

British logistician and business consultant Keith Oliver is a trailblazer in the truest sense of the word, being the very man who first coined the term ‘supply chain’.

Keith Oliver was educated in the UK at Monmouth School and Birmingham University. He was a Methods Analyst at the West Midlands Gas Board before joining consultancy firm Booz Allen Hamilton.

It was while there, in the late 1970s, that Oliver began formulating his revolutionary ideas while working with clients including SKF, Heineken, Hoechst, CadburySchweppes, and Philips.

His key ideas around the subject are said to have gelled during an engagement with Philips, the Dutch consumer electronics manufacturer.

During this time, Oliver first developed his vision for tearing down the functional silos that separated production, marketing, distribution, sales, and finance – to generate a reduction in inventory and a simultaneous improvement in customer service.

Looking for a catchy phrase to describe the concept, Oliver’s colleagues suggested the term ‘integrated inventory management’.

But Oliver was not convinced. On June 4, 1982, he forever changed how we would refer to the business of moving goods around the world. In an interview with Arnold Kransdorff in the Financial Times, Oliver discussed his new business concept, which he dubbed ‘supply chain management’.

He defined it thus: “Supply chain management (SCM) is the process of

planning, implementing, and controlling the operations of the supply chain, with the purpose to satisfy customer requirements as efficiently as possible. It spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point-of-origin to pointof-consumption.”

The term could have easily disappeared into the history of business jargon. Instead, SCM rapidly passed into the public domain – a sure sign the concept resonated with executives wrestling with the endless challenges of procurement, logistics, operations, sales, and marketing activities that fall within its realm.

Oliver went on to serve Booz Allen for 41 years, and, down the decades, undertook boardroom-level assignments across all manner of businesses, focusing on supply chain strategy and management control.

As a consultant, he was able to offer laser-sharp guidance on all aspects of industry supply chains, from material procurement and purchasing through the manufacturing processes, as well as distribution and the marketplace interfaces of demand capture and customer service.

Towards the end of his career, Oliver’s focus turned to how service businesses could find real-world applications for the supply chain.

In an article headline, ‘ When will supply chain management grow up ?’, Tim Laseter – a supply chain professional now with the University of Virginia – explored the origins and evolution of Oliver’s SCM concept.

He wrote: “Both the term and the discipline it describes have evolved considerably during the past two decades. Indeed, by today’s standards, the original scope of SCM appears quite narrow.

“Initially, it applied only within the boundaries of a single company. The challenge was simply getting production, sales, finance, marketing, and distribution operating in concert to focus on the movement and availability of finished goods.

“It’s hard to believe that management’s perspective could have been so limited.”

Laseter added: “SCM began to look outside the company’s four walls and the first place attention alighted, naturally, was on customers.”

But he goes on to point out that, since the late 1990s, many leading companies have placed greater emphasis on cost reduction and innovation at the supplier end of the chain.

“With this evolution, SCM’s scope has expanded well beyond the movement of materials,” Laster writes. “Now, the term ‘supply chain management’ encompasses such concepts as strategic sourcing and supplier involvement in product development.”

The term has, however, evolved and Oliver’s place in the pantheon of noted supply chain figures is secure.

“ON JUNE 4, 1982, OLIVER FOREVER CHANGED HOW WE’D REFER TO THE BUSINESS OF MOVING GOODS AROUND THE WORLD”

» In the late 80s, I got into electronics, and in 1991 I founded Partstat. From there, it’s been an exercise in adapting our company and the services we provide to meet the growing demands of our customers.

In 2012, we identified an opportunity to heighten our value to customers by harnessing and reviewing data from a large scale. This insight guided the development of our big data warehouse that gives us real-time inventory positions of all the major authorised distributors and component manufacturers.

» Intel’s CEO said he felt the chip shortage will go into 2024, but that’s a bit optimistic in my opinion. Rising inflation and interest rates have put constraints on the semiconductor industry as it tries to work through the critical labour shortage and ramp up production.

There are also geopolitical issues at play. Taiwan makes a huge amount of the world’s chips, but if China makes its move it will worsen the chip shortage.

» Any sector that’s electronic and dependent on semiconductors has been hard hit.

On the OEM level, companies that use many different semiconductors but not a high volume of any of them have been severely impacted. In the queue, they’re behind companies requiring high volumes of chips.

» Having experienced similar inventory challenges in the past, we’ve learned that, when there’s a disruption or technology change, OEMs tend to double and triple orders from multiple suppliers. But, when OEMs receive the inventory, they cancel the other supplier orders and this creates issues, including potentially an abundance of inventory in the marketplace.

Manufacturers are aware of this and are carefully measuring how they upscale production, knowing that past forecasting has been an issue. One way OEMs can gain a stronger position with chip manufacturers

are

on computer chips – and

specialist semiconductor storage facility is one solution

is by making a financial commitment to the manufacturer over a specific period of time, for a specific volume of inventory.

» Semiconductors cannot be stored in ambient storage facilities. A high percentage of third-party logistic companies have storage areas that aren’t air-conditioned or humidity controlled. The careful handling of semiconductors is a significant challenge for such companies. For them, it’s primarily about the footprint on the storage facility floor, and shipping inner and outer box quantities.

Semiconductors are delivered inside vacuum-sealed packaging, which means warehousing facilities need a special environment and experienced, trained employees to open the packages, remove the quantities the manufacturer requires, ship them according to their specifications to protect them, and then repackage them for future delivery.

It’s a more sophisticated fulfilment and warehousing environment than what is available in most storage facilities today, so upgrades are needed to handle the chips properly.

The Partstat environment and warehouse staff are equipped to handle and store semiconductors and electrical components appropriately. Our facility in Florida is airconditioned and it’s a humidity-controlled environment. Plus, we have a semiconductor vault designed for irreplaceable or obsolete components. It has a 1,000lb door, and is fireproof and hurricane proof.

» Semiconductors cannot be stored in ambient storage facilities. A high percentage of third-party

logistic companies have storage areas that aren’t air-conditioned or humidity controlled. The careful handling of semiconductors is a significant challenge for such companies. For them, it’s primarily about the footprint

» SInnovators and disruptors such as Steve Jobs and Elon Musk. We didn’t know we needed the iPhone until it was developed, and now it’s a necessity for many of us.

WRITTEN BY: HELEN ADAMS

PRODUCED BY: CRAIG KILLINGBACK

WRITTEN BY: HELEN ADAMS

PRODUCED BY: CRAIG KILLINGBACK

TotalEnergies is a multi-national energy company, founded in 1924 in France. Previously known as Total, in 2021 the Company rebranded as TotalEnergies –in line with its transformation into a broad energy company and a world-class player in the energy transition, including through its own carbon neutrality commitments. TotalEnergies has activities in more than 130 countries worldwide.

TotalEnergies is one of Europe’s largest producers of bitumen and its affiliate, TotalEnergies Marketing UK, has been a market leader in UK bitumen supply for decades, including through the supply of pioneering bitumen products manufactured in its Preston production site. Bitumen is the black viscous substance used to construct roads.

Garr Chau is the Supply Chain Manager for TotalEnergies Marketing UK, a role he landed through a graduate scheme.

“My role involves overseeing a team of planners and the supply of bitumen and additives to our supply locations, imported via ship, rail and road, in addition to road deliveries of bitumen products to our customers from those supply locations.”

TotalEnergies is transforming into a broad energy company and has committed to the Paris Agreement and the United Nations Sustainable Development Goals.

TotalEnergies’ Head of Bitumen Supply Chain Garr Chau , and Market Development Manager, Rick Ashton , talk sustainability solutions

“We have an ambition and that is to help with the world's energy transition, to reinvent the production and use of energy and to reach Net Zero by 2050 together with society,” says Chau.

TotalEnergies has set objectives to reduce its emissions.

The first step is to reduce Scope 1 and 2 CO2 emissions from TotalEnergies’ worldwide operations.

“We've set ourselves measurable short, medium, and long-term goals - so, by the year 2030, we've committed to reducing Scope 1 and 2 emissions at our own facilities by over 40% versus 2015 levels,” explains Chau.

In addition to decarbonisation, the company seeks to achieve this through improving efficiency across all operations, as well as achieving zero routine flaring at refineries, cutting methane emissions leaks in its gas operations and also by investing significantly in carbon capture and storage capacity as well as natural carbon sinks.

TotalEnergies has also set a 2030 target to reduce its global Scope 3 emissions - i.e. those from the energy products used by its customers - to below 2015 levels.

“The way we can influence this is to work with society - our customers, suppliers, partners and public authorities. We have

“ The impacts of climate change are irrefutable”

GARR CHAU HEAD OF SUPPLY CHAIN, TOTALENERGIES MARKETING UK LTD.

to transform the way that we all use energy so that we can be sustainable.”

“We are changing our energy mix as a company, hence why we are transforming from being an oil & gas company into an integrated and broad energy company. We are reducing the carbon intensity of petroleum products sold by more than 30%, whilst we also plan to produce and sell 30% more energy products, especially through growth in electricity and liquefied natural gas (LNG). LNG, in particular, is a very important fuel in the transition, as the lowest carbon fossil fuel,” says Chau.

The UK has recently witnessed extreme weather events, first with the heatwaves and then with resulting scenes of flash floodingexamples of how our climate is changing.

“The impacts of climate change are irrefutable,” says Chau. “The general public expects governments and large companies, like TotalEnergies, to act on this. In Europe, around 80% of greenhouse gas emissions come from energy production and consumption, so energy producers have a vital role to play.”

TITLE: HEAD OF SUPPLY CHAIN INDUSTRY: OIL & ENERGY LOCATION: PRESTON, UK

Garr Chau is currently the Head of the Bitumen Supply Chain for TotalEnergies Marketing UK Ltd, where he’s responsible for: primary supply via ship and rail import; stock management and quality control of the 3 terminal locations; and ensuring the safe and cost efficient distribution of finished products to TotalEnergies’ bitumen, PMB and emulsion customers.

Year founded 250+

Number of employees

During his 17-year career at TotalEnergies, Garr has (amongst other roles) served as: a Chemical Engineer at the Lindsey Oil Refinery, responsible for energy optimisation of the combined heat and power (CHP) unit, steam methane reformer (SMR) unit, fired heaters and boilers; Operations Manager of the long distance pipeline and aviation assets; JV Director of the HOSL terminal operation; responsible for safety and mitigating the environmental impact of the bitumen business.

Garr earned both a PhD and MEng in Process Engineering from University College London

Are you looking for an agile, flexible logistics partner with highest quality and safety standards? Do you appreciate expertise that moves you forward? The HOYER Group is one of the world’s leading logistics services providers in handling and transporting liquid products. We are the first point of contact for the chemicals, petroleum products, gas and foodstuffs industries. By road, rail and sea – with our extensive global network we will find the optimum solution for you. We maintain our leading market

position in the petroleum products sector through outstanding safety, environmental and customer service performance. Driving achievement in logistics is part of our DNA. With our sophisticated full-service logistics (from remote stock management to completion of the transport delivery) we make our customers’ business easier and more successful. Together we break new ground in a customised way

MORE

LOCATION: PRESTON, UK

I started in the sector in 1989 in an aggregates and asphalt testing laboratory with Hanson covering quarrying and asphalt operations. I studied construction materials technology with Bath College, then quarrying and asphalt technology with Doncaster College. I joined Aggregate Industries as a Technical Manager, managing on-site asphalt testing, laboratories, and various R&D projects before joining TotalEnergies as Market Development Manager in 2011. My role involves marketing communications, technical liaison, market development and representing TotalEnergies at international conferences and seminars. I’m a member of the Chartered Institute of Highways and Transportation, Institute of Quarrying, and a Branch Chairman of the Institute of Asphalt Technology. Also, the Asphalt Industry Alliance PR Committee liaising with ‘The All-Party Parliamentary Group for Better Roads’ and have assisted BSI working groups in the writing and publication of the current UK Asphalt standards.

Sustainable solutions for customers According to Rick Ashton , Market Development Manager at TotalEnergies Marketing UK, offering customers a range of sustainable solutions is essential in modern

One such solution is the increased adoption of low temperature bitumen that can be used in warm

“The focus at the moment is lowering the temperature of asphalt,” Ashton explains.

“Conventional asphalt is mixed at around 180°C and that takes a lot of energy. If we can lower the manufacturing temperature by chemically

modifying the liquid bitumen, we can reduce the energy demands by up to 30%.”

Representing TotalEnergies, Ashton is also working alongside industry bodies towards net-zero carbon goals and contributing to CO2 reduction in the UK.

“The All-Party Parliamentary Group for Better Roads put together a report for all the local authorities in the country on how to support this.

“The report claims if all asphalt production in Great Britain for 2017 had been switched to warm mix asphalt, it would have saved at least 61,000 tonnes of CO2 – the equivalent of cutting almost 300 million miles of car journeys. (Citation: Working for better roads Warm Mix Asphalt: reducing carbon emissions and improving efficiencies)

“When you mix the materials 30°C lower, it means products are cooler to install. This allows faster roadworks as the asphalt can cool to a point where it won’t be too soft to traffic causing deformation. You use less energy to heat the product, because a big part of the energy used in asphalt production

“ The focus at the moment is lowering the temperature of asphalt”

RICK ASHTON MARKET DEVELOPMENT MANAGER, TOTALENERGIES MARKETING UK LTD.

is to get the product to a workable state. Our low temperature ECO2 bitumen, for example, allows the same workability at 140°C - or 40°C cooler.”

Ashton says that this will support road workers, too. “It's a safer environment for them because they're not walking or driving through steam when there's live traffic going past just on the other side of the traffic cones.”

The TotalEnergies team conducted trials to measure the typical cooling times of asphalt. For a traditional hot mixture, a layer can typically be 100mm thick and it will take

TotalEnergies has committed to reducing its Scope 1 and 2 emissions by over

TotalEnergies is reducing the carbon intensity of petroleum products sold by more than

of greenhouse gas emissions come from energy production and consumption

two hours in normal ambient temperatures before traffic can run on the asphalt. Lowering the temperature by 40°C can halve this cooling time.

“Our customers may only have a five-hour slot where they can get in there and actually do the roadworks on a local urban road,” explains Ashton. “If they can add an hour's surfacing into that slot or get the road open an hour quicker, it's a 20% efficiency benefit.”

National Highways, who manage the motorway and trunk road networks, also estimate that an increase in shift outputs of 20% could be provided by using this technology on its network, saving up to £70mn a year. ( Citation – Report, The AllParty Parliamentary Group on Highways: Working for better roads Warm Mix Asphalt: reducing carbon emissions and improving efficiencies. )

“Society needs to focus on ways to reduce energy consumption and it’s the case with prolonged road works and wasted energy if using conventional hot mix asphalt. We know our low temperature energy saving ECO2 products stop this waste.”

Asphalt is the most recycled material globally and, like its hot mix equivalents, TotalEnergies ECO2 is also 100% recyclable back into asphalts in the future, giving further embodied CO2 reduction benefits, helping to prevent waste and conserving natural resources as less aggregate needs to be quarried.

Styrelf® is one of TotalEnergies’ premium products. The name comes from adding a cross-linked polymer into bitumen, called styrene.

“It’s historically been used in high profile sites like at the Monaco Grand Prix

Circuit and the Mersey Gateway Bridge. We perform a huge amount of research and development, both here in the UK and in Europe, and the last 30 years have seen continuous improvement for these products,” explains Ashton.

A new grade in development, Styrelf® Long Life, aims to delay the onset of roadworks. Historically, highways engineers have to predict how long a road will last before potholes begin to form and a road needs to be repaired.

“It’s oxidation that makes the surface more brittle, and eventually it cracks. As it cracks, water gets into the cracks, they get bigger - then you've got a pothole, which somebody needs to repair. To do that, you’re going to have to cause disruption.”

TotalEnergies is working with local authorities and those responsible for maintaining roads on this matter. To get things moving, Ashton is involved in a number of industry bodies such as being a branch Chairman of The Institute of Asphalt Technology (IAT).

“

we can lower the manufacturing temperature by chemically modifying the liquid bitumen, we can reduce the energy demands by up to 30%”

RICK ASHTON MARKET DEVELOPMENT MANAGER, TOTALENERGIES MARKETING UK LTD.

Then there’s a group called the Asphalt Industry Alliance (AIA) whose purpose is to promote the benefits of asphalt. This is a joint venture between the Minerals Product Association and Eurobitume UK, the two principal bodies that represent the suppliers of the raw materials used to produce asphalt, as well as asphalt producers and laying contractors. This then feeds into central government via the All-Party Parliamentary Group for Better Roads.

TotalEnergies has a partnership with transportation and supply chain company Hoyer Gas & Petrol Logistics Limited, which provides services to the company in the form of planning, safe loading, road transport and delivery of bitumen products to its UK customers.

“TotalEnergies was Hoyer’s first client for bitumen transportation in the UK,” says Chau.

“I'm proud to say that a lot of expertise, experience and procedures have been developed in collaboration between TotalEnergies and Hoyer.”

Chau states that Hoyer understands the vital ingredients for a successful partnership.

“It's strong and good quality communication that can only come through trust and mutual respect. That communication needs to be strong on all levels of management and day-to-day operations. If that communication breaks down on any one level, then things can quickly go awry”.

The next 12 months will continue to be interesting for the supply of bitumen into the UK.

In the wake of the Russian invasion of Ukraine, the government announced that the UK would sanction crudes and petroleum

products of Russian origin from the end of this year.

“What that means for the bitumen world is quite significant because Russia has been important for bitumen in Europe. So this presents some challenges for the industry and supply chains need to evolve and adapt.”

TotalEnergies is moving with the times and transforming its bitumen supply chain across the UK. In the future, it is expected that more bitumen will need to be imported into the UK, potentially from further afield.

“We're extending our partnership with Navigator Terminals, a very large independent bulk liquids storage provider. We are expanding through a new position in Teesside in addition to an existing facility we have with them in London, for importation of bitumen by sea."

The combined storage of the positions will give TotalEnergies significantly more storage capacity.

In a testament to TotalEnergies’ longterm commitment to its bitumen customers, these assets will ensure TotalEnergies’ bitumen supply into the UK is truly national and resilient.

Today’s world is so riven with uncertainty that it has become part of the ‘new normal’ for businesses.

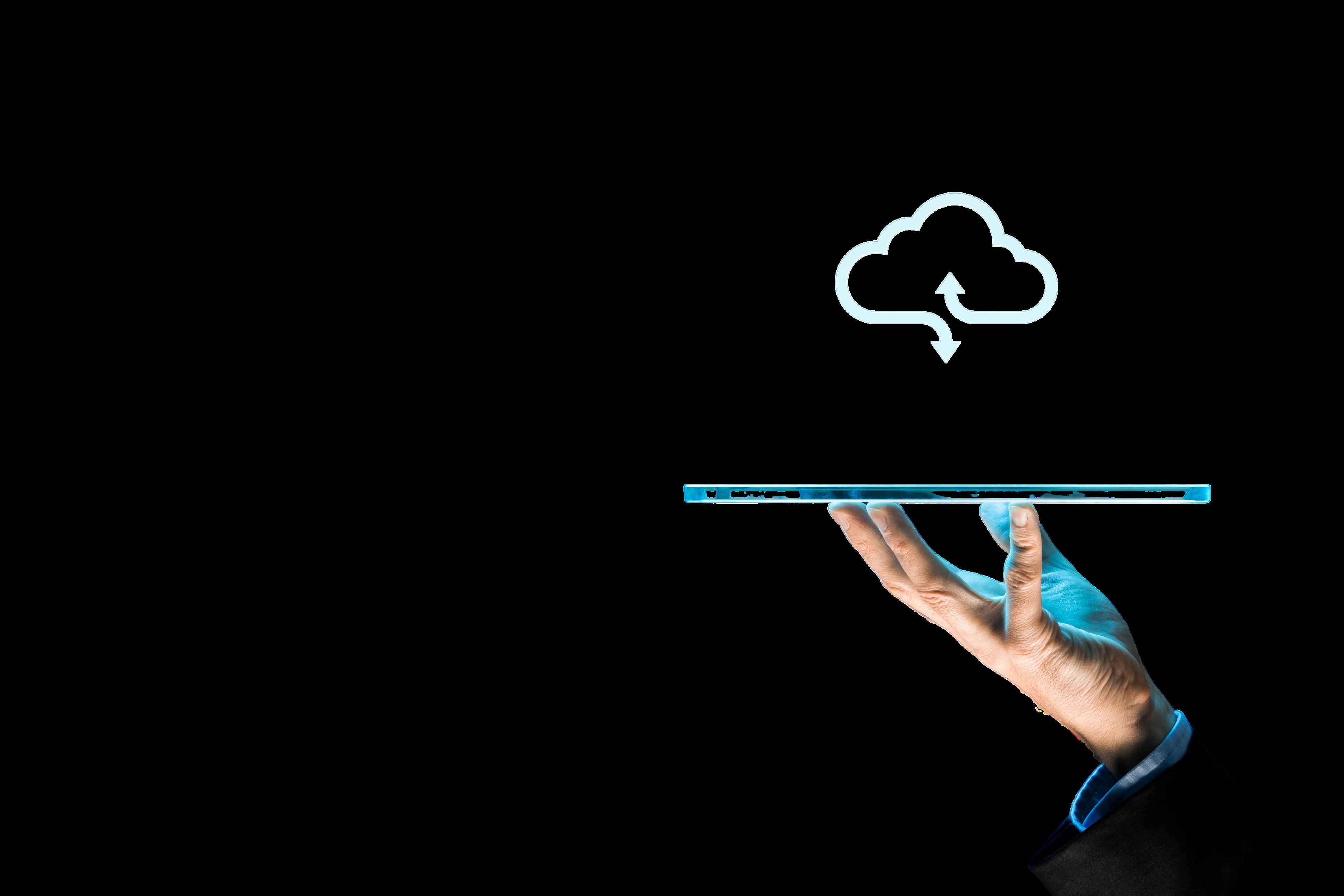

As such, organisations that want to thrive, not just survive, know how crucial it is that they are plumbed into supplier and partner ecosystems.

Speaking to Supply Chain Digital magazine in March 2022, Maria Rey-Marston – Global Supply Chain Innovation at Accenture – coined the term ‘Demand Response Network’. She said that, far from being linear, supply is now “a network of suppliers, plants, and transportation companies, as well as intelligent locations for placing products”.

Such networks are greater than the sum of the participating businesses. They enable organisations to collaborate with trading partners to streamline processes, create value in real time, and solve problems quickly, as they arise.

Helena Jochberger is Global Lead Manufacturing at CGI, the global IT and business consulting firm. She says that one area in which strong supplier ecosystems can help businesses is by offsetting the effects of inflation caused by supply disruption.

“With increasing uncertainty, the question of real-time scenario planning and multicriteria risk management becomes more relevant. This is the point where data-driven ecosystems can provide significant support.”

Supply ecosystems – networks of suppliers, plants and transportation companies, driven by data visibility – are the future for organisations who seek resilience

Supplier networks can help offset inflation, says CGI But she says that, in order to share data, those in the ecosystem need:

• Clear contractual frameworks with defined rights and duties.

• To have trust in sharing their data

• Data Standards in place.

“With the help of privacy enhancing technologies manufacturers can share data without disclosing intellectual property,” Jochberger says. “If organised in the right way, data driven supplier ecosystems can help mitigate inflation by assuring supply in manufacturers’ value chain.

Another area in which robust supplier networks and ecosystems pay dividends, says Jochberger, is in mitigating disruption.

Data ecosystems mitigate against disruption “Data ecosystems support real-time supply in the manufacturing value chain. If one supplier is unable to deliver a part, they will know because of predictive forecasting, and another supplier will take over,” says Jochberger.

Sustainability is another goal with which collaborative networks can help.

“Sustainability targets have become a business imperative, as financial institutions will no longer finance companies that are not adhering to ESG compliance,” she continues. “Data-driven supplier ecosystems create transparency on emissions and wastage along the value chain, and because of this manufacturers will be able to reduce both.”

Another supply chain professional in no doubt as to the importance of collaborative

“DATA ECOSYSTEMS SUPPORT REAL-TIME SUPPLY IN THE MANUFACTURING VALUE CHAIN”HELENA JOCHBERGER GLOBAL LEAD MANUFACTURING, CGI

supply ecosystems is Tony Harris, Senior VP and Head of Marketing & Solutions with SAP Business Network, which enables organisations to collaborate with supply chain trading partners, including suppliers, logistics and services providers, asset operators, and maintenance contractors.

Supplier ecosystems can reduce business costs

“We’ve seen the effect of recent disruptions on supply chains, exposing their fragility. Because a business network can provide visibility across the supply chain, companies can anticipate issues that may arise,” explains Harris. “This allows them to adapt and react quickly, avoiding unnecessary

costs due, for example, to shipment delays.” Harris echoes Jochberger’s point about business networks enhancing resilience through greater visibility. “Companies can reduce costs through their ability to identify and work with the most efficient and lowcost logistics supplier for order fulfilment. This enables businesses to reroute shipments through a logistics business network, ensuring deliveries are handled quickly to meet customer expectations.

“Such networks make a company visible to new suppliers, and this larger supply base can lead to new relationships, which helps drive down purchase prices – further enhancing profitability and bringing new customer channels to light.”

“SUPPLIER ECOSYSTEMS CREATE TRANSPARENCY ON EMISSIONS AND WASTAGE ALONG THE VALUE CHAIN”

Here, Helena Jochberger, Global Lead

Manufacturing at CGI, outlines ways technology underpins supplier ecosystems.

Empowered by the IoT and underlying networks (5G, IoT, WiFi), this is the first and most important aspect of becoming data-driven in the supply chain. Without the capture and provision of data and the downstream storage in the respective data lakes, transparency is not possible.

Once the data has been collected, cleared, and contextualised, the deep analytical work can begin: designing and training the right algorithms in place.

In recent years, large hyperscale platform suppliers have significantly democratised the way predictions can be made. This means that a lot of use cases are already available out of selfservice and enable manufacturers on their path to become data-driven.

Paper-based processes hinder the supplier system, dampening responsiveness.

Embracing automation processes creates frictionless ways of operating across the supply chain, helping ensure a company remains a partner that people enjoy doing business with.

In times of increased convergence between information and operational technology, it is of utmost importance to secure both the shopfloor and the supply value chains. If not secured properly, the damage caused by a security breach again can disrupt supply demands significantly. Manufacturers can develop cyber strategies that go beyond their boundaries and support safe interactions with the entire supply chain.Factory cloud

Factory clouds coming from the global hyperscaler platform providers helps assure continuity, resilience and scalability f or businesses.

Factory clouds coming from the global hyperscaler platform providers helps assure continuity, resilience and scalability for businesses.

Harris identifies other ways in which such networks can help:

• Boosting customer satisfaction – “One of the most important elements of running a successful business is having happy, referenceable customers,” he says. “When organisations collaborate in real time and work in parallel, the customer benefits. Customer service is enhanced because

the customer receives the value as the businesses in the network focus on their needs. This allows them to understand and satisfy customers' needs, solve fulfilment challenges in real time, and over-deliver on expectations.

• Choosing aligned suppliers – On this, Harris says: “A business network provides transparency that allows companies to

“EVERY TRANSACTION HAS TWO SIDES, WHICH IS WHY NETWORKS CAN QUICKLY EXPAND”

TONY HARRIS SENIOR VP AND HEAD OF MARKETING & SOLUTIONS, SAP BUSINESS NETWORK

choose suppliers who best align to the company’s values, processes, and their customers’ expectations. For example, from a logistical perspective, it may be more beneficial and less risky to work with a local raw material supplier. Also, selecting suppliers who prioritise sustainability can help businesses achieve their environmental, social, and governmental (ESG) goals.

• Increasing revenue – “Relying on a business network can help a company move beyond its local market to become part of a global network that continues to grow as more companies join,” he says. “Business networks are multipliers for buyers, sellers, shippers, carriers, and even asset utilisation and maintenance. “This helps companies expand into new global markets, find new customers, uncover new opportunities, and secure the suppliers needed to support these new business models. And with a global network of suppliers, businesses can be assured of supply during times of disruption, reducing stock-outs and revenue loss.”

• Increased connections – Harris states that “every transaction has two sides, whether this is the buyer and seller or shipper and carrier”. This, he explains, is why networks can quickly expand: “When a buyer uses a carrier, that carrier becomes known to the seller, which can then become a new source for both businesses. As these two businesses transact more with others, the carrier may work for even more of their connections. This network effect is an excellent means for companies to broaden their customer base and trading partnerships.”

• Predicting risks and identifying opportunitie s – “Which of us wouldn’t like to predict their own future to prepare for whatever comes our way?” he asks. He adds that, in the context of business continuity and resilience, this ability should be no pipe dream. “The ability to address risk across the supply chain is mission critical,” he points out.

BY: MIKE SADR &

BY: NEIL PERRY

Scott Schwartz: Chief Procurement Officer & Head of Sustaining Engineering, Royal Philips

Scott Schwartz: Chief Procurement Officer & Head of Sustaining Engineering, Royal Philips

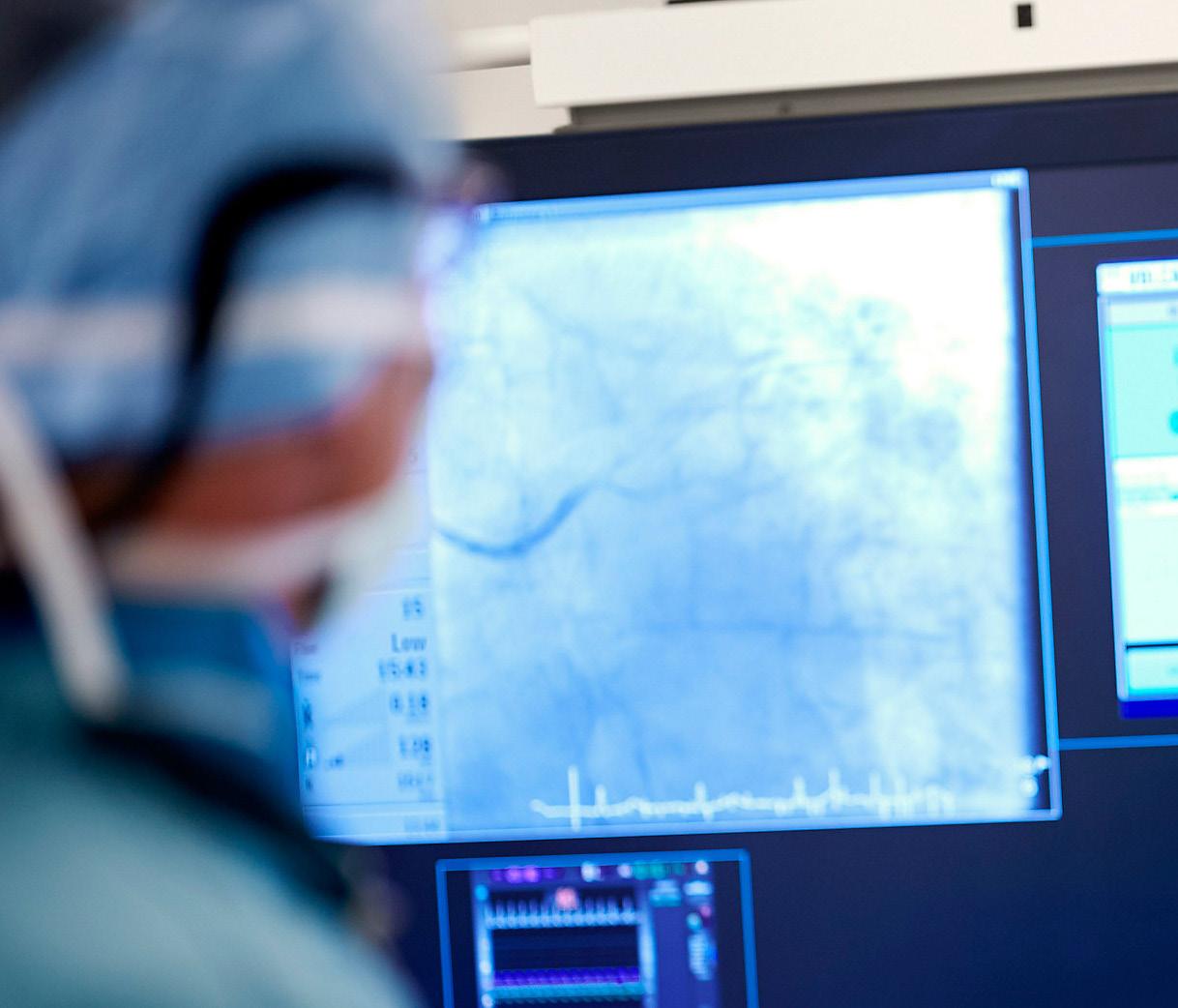

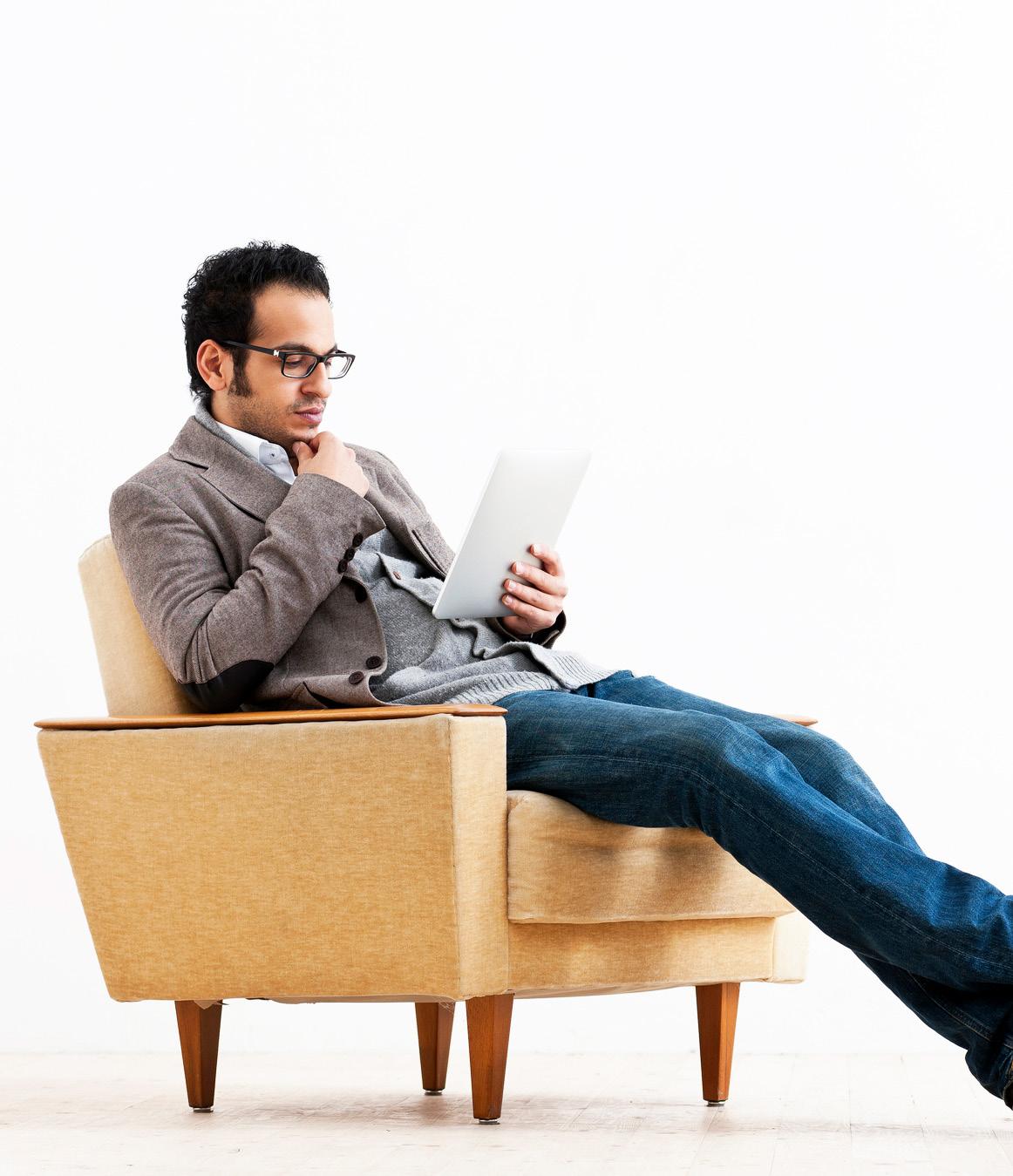

There can be few better opportunities to learn about your products and your customers than seeing them in action in the hospital or clinic. Scott Schwartz from Philips recently had that opportunity at a hospital appointment, where he saw the global health technology company’s ultrasound systems being used first hand. As Chief Procurement Officer and Head of Sustaining Engineering at Royal Philips, he knows all too well how important their products are to people all over the world.

“The beauty of what we do here is that we make products and solutions which have a direct connection to our family and friends. Our products help them and other people around the globe improve or save their lives. That’s really inspiring and has motivated me throughout my career in medtech,” says Scott, who has been recently appointed

as Chief Procurement Officer at Philips, in addition to his Sustaining Engineering Lead responsibility. “We help improve the workflows in hospitals, lower the cost of care and have a direct impact on society. That greatly contributes to my job satisfaction: it's all about helping people and improving their life and wellbeing. At some point of our life, we are exposed to our own products either ourselves or our family members, friends or colleagues are. That makes our task very real and puts a face to it.”

This purpose-driven motivation is what Scott also likes to drive into his own team. He was able to build a purpose-driven, high-performance team that understands the impact Philips’ products and solutions have on the end user. Driving strategic ideation into a strong rigour in execution is a valuable mantra for success.

“The key here is that, first, you have really talented, creative people that are always curious to dig deeper, to dig for more – and I think that's the culture that we are trying to create here, that rigour, that depth, that curiosity to find more,” he says. “That is the foundation of trying to find these improvement ideas.”

As Chief Procurement Officer and Head of Sustaining Engineering at Philips, Scott Schwartz highlights how an end-to-end approach to strategic ideation and drive into execution together with strategic partners helps Philips to fulfil its purpose: to improve people’s health and wellbeing through meaningful innovation, to lower the cost of care and improve the patient/customer experience.

Scott is very clear on the importance of talent in his own team, but for him, the team doesn’t end at the walls of Philips. He recognised in past company experiences how important it is to team up with strategic partners in the value chain to do things first time right and avoid higher costs in later product lifecycle stages. It is therefore important for Philips to share their purpose as well with their strategic suppliers and connect them to the outcomes desired for the customers and patients.

“I think it's really valuable to hear different users talk about your products,” he says. “A lot of times, what you believe they're going to say is not actually what they end up saying. For me, it was really insightful to talk to the technician because you are thinking they are going to talk a lot about the actual diagnostics, the clarity of the imagery and the quickness of the machine, which are things we are driving

at the company. But instead, a lot of times you end up hearing about the basic ergonomics and usability of the machine. It's important to see that there is more to the overall satisfaction of the customer than just the traditional features you are driving.”

Scott explains that having the customer’s point-of-view helps in ensuring that they are providing market-leading technology that makes a tangible difference to the lives of both patients as well as the healthcare professionals using the equipment.

“We're making these products to help people; real people and real faces are using our products. So that purpose, that responsibility, is constantly reinforced in the organisation and I'm trying to continually implement this outside-in view in the organisation. We want everybody thinking outside-in. What does this product do, and as I understand what it does, how do I improve that?”

Scott Schwartz

Scott Schwartz is currently the Chief Procurement Officer and Head of Sustaining Engineering. He is responsible for the execution of the E2E Procurement & Supplier Management strategies from New Product Development to Life Cycle Management to support key business strategies across all business groups of Royal Philips. The Procurement & Engineering team have a strong engagement in Advanced Development & New Product Development connecting the supplier ecosystem to drive innovation, productivity and quality. In addition, he is responsible for the sustaining engineering team for the Supply Chain & Operations group driving continuous improvement on the marketed products. The Procurement & Engineering team links the Commodity Strategies to the Business Strategies creating local impact and global leverage. Scott joined Philips in 2014 as the Head of Procurement Engineering for the Philips Healthcare businesses.

Prior to Philips, Scott worked for Boston Scientific for 18 years where he held leadership roles in Product Development, Process Development, General Management and Procurement. Prior to Boston Scientific, Scott started his career at 3M Company as a product/ process development engineer.

Scott has a BS in Mechanical Engineering from MIT, a MS in Mechanical Engineering (Statistics Minor) from University of Minnesota, and a MBA from the Carlson School at the University of Minnesota.

We understand medical customers. Since 1999, Kimball Electronics has served the medical market, manufacturing millions of medical devices, medical electronic assemblies, and complex full medical devices. By leveraging our focused medical core competencies, decades of experience, and customer-aligned global footprint, we’re ‘Creating Quality for Life’.

Learn more about how Kimball Electronics is ‘Creating Quality for Life’ for our medical industry customers. Learn more

Kimball Electronics used the pandemic to bring its global facilities closer together to build life-saving equipment around the world for the new normal.

The electronics manufacturing company, Kimball Electronics, is expanding, despite the global supply chain crisis, and the new normal. Steve Korn, the President of Global EMS Operations, is ready.

“I’m responsible for all the manufacturing of those facilities, as well as our global supply chain and an IT team, as well as a finance team that supports those operations.”

There are a lot of people reporting to Korn and he knows each of them is a vital employee. “Our people are critical to us and that’s what separates us from our competitors,” says Korn. “We spend time making sure that we have the best work environment we can have.”

Kimball Electronics manufactures electronics for products across several markets, including automotive, industrial, medical, and public safety.

“It’s really exciting working across those different industries,” says Korn. “The number one thing for us is in each one of those industries, we manufacture very reliable products. If you’re going to a

hospital and you have an AED device or a monitoring device or a ventilator, the last thing you would want is for it not to work.”

As Kimball Electronics manufactures for the medical and public safety markets, the company has adapted over the pandemic.

“I think a couple things changed us, such as supporting our medical customers,” says Korn. “We did a lot of work for Phillips in building ventilators and building BIPAP equipment, it really helped us focus more into the medical space and public safety.”

Over the pandemic, Korn has had the time to develop professional skills. “I have continued to improve my communication skills — for how to develop communicating virtually and in writing.” Virtually or officebased, Kimball Electronics is ready for the new normal.

The sector comes with a degree of public responsibility, and, as someone who has worked in medtech for the vast majority of their career, Scott says it is something with which you foster a deep connection.

“I wouldn't go anywhere else or to any other sector because the beauty of what we do here is that we make products and solutions which have a direct connection to our family and friends.” Scott’s route to Philips has taken him across different business roles since completing a mechanical engineering degree at MIT. The first career step was to 3M Company

“We want everybody thinking outside-in. What does this product do, and, as I understand what it does, how do I improve that?”

after graduating. He completed a Master’s degree in mechanical engineering and an MBA at the University of Minnesota. Scott says that his goal was always to be a leader of technical people, so he needed to be sure his technical capability was strong to have credibility in an engineering environment, but also having the MBA to bring a broader business view to the table. He then spent eighteen years at Boston Scientific working across product development and supplier engineering, providing him a wide scope of experience to manage products from endto-end during their development.

Scott believes the structure at Philips

Procurement and Sustaining Engineering is one of their key strengths, as it allows them to have more of an end-to-end overview of products, from inception to delivery. As well as the traditional procurement responsibilities that fall under his responsibility, there is also an engineering arm connected directly to procurement, which allows them to drive the overall strategy through partnerships with their supplier base.

“It’s a unique combination compared to most other procurement organisations that you would typically see,” he says. “We are also heavily involved in new product

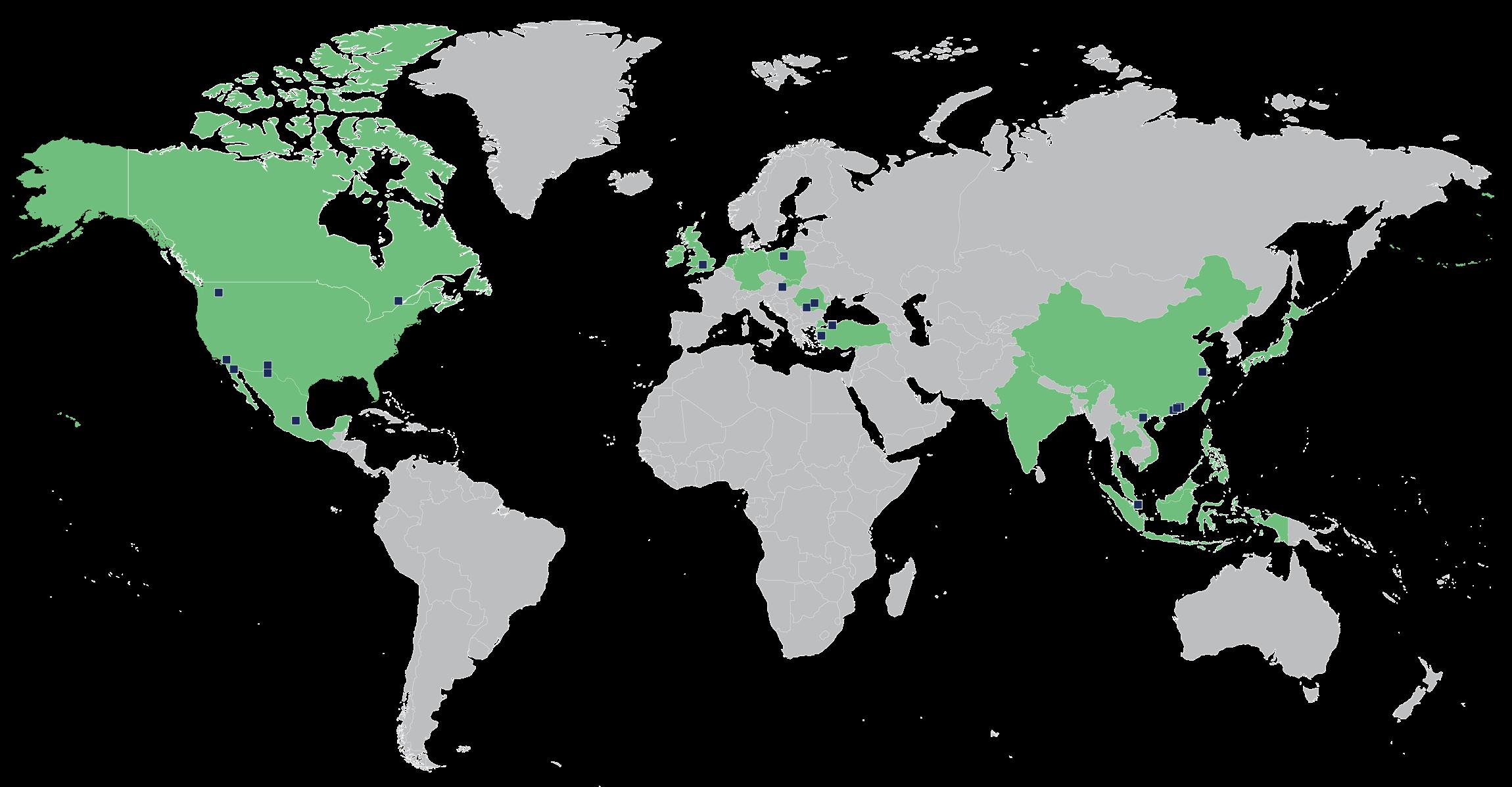

Made up of 8,000 people, in 19 factories, across three continents, “Volex’s global footprint is unparalleled in our industry,” says Paul Bullock, COO Europe, Volex.

Since 2004, Volex has been supplying Philips with its services. “We started providing cables for their defibrillator products,” says Bullock. “Over the last 18 years, that relationship has grown to be a global strategic partnership, underpinned by three pillars: exceptional quality, global footprint, and scale.”

“We have seven factories right now that are approved to the ISO 13485 medical standard, and recently, with Philips’ promotion and support, our Tijuana, Mexico factory was able to achieve MedAccred accreditation, becoming the first cable and wire harness accredited supplier in the whole of Mexico, which was a fantastic achievement,” says Bullock.

Committed to reducing lead times, increasing their market reach, and getting closer to the end customer, local supply and regionalisation of supply chains is becoming increasingly important for Philips.

“Soon we will be supplying Philips from eight locations, with the addition of India.

Volex will be investing in a new factory in the Pune region, close to Philips, supporting the company’s localisation efforts for their supply chain and facilitating their growth plans for the region,” says Bullock.

The scale of Volex affords its customers like Philips to have the confidence that they are working with a global supplier with a worldwide partner ecosystem and global experience. “Volex currently supplies Philips with over 2,200 part numbers, that contain 6,000 raw materials into 20 different Philips locations, which is a huge portfolio of parts with a huge amount of complexity,” says Bullock.

“We manage that expansive portfolio by engaging closely with Philips at a local, regional, and global level through our factory teams, and the executive team, to give Philips the confidence in the quality delivery and service that they’re getting at multiple touch points.” adds Bullock.

“As Philips continues to develop its lifesaving products, Volex will be there as a trusted global integrated manufacturing partner,” concluded Bullock.

development – which I think is common with other procurement organisations – but we are doing it at an even more technical level, partnering with the R&D organisation and getting involved very early in that new product innovation cycle.”

This set up allows Philips to accelerate the strategic execution and drive strategic initiatives from the Procurement perspective, whether that is supply base mobilisation, innovation, cost down and quality up activities. Projects focused on quality, productivity, resilience, or innovation can be driven with great speed in partnership with the supply base. This makes supplier performance management truly end to

SCOTT SCHWARTZ CHIEF PROCUREMENT OFFICER & HEAD OF SUSTAINING ENGINEERING, ROYAL PHILIPSend. It is much faster and more efficient to have the needed resources in one team. By having the internal team joining forces with strategic suppliers, Scott aims to foster a culture of collaborative disruption to drive into fast, customer-oriented outcomes.

Scott has been at Philips through a time of transformation, as it pivoted further into a health technology company, which now is one of the world’s largest health technology companies. It has been a long journey for a company that started in 1891 with its namesake, Frederik Philips and his son Gerard, producing electrical lighting products in an Eindhoven factory before diversifying into home appliances.

“It is key to have these smaller sets of suppliers that are more strategic as we interact with them”

At USI, we deliver global projects within local supports. We bring up the possibility of miniaturiza�on and provide diverse solu�ons from wireless communica�on to medical devices. Most importantly, we share the same values with you.

“When I first arrived at Philips, it was basically a conglomerate with a healthcare technology business, the heritage lighting business, personal health and a domestic appliances business. Over those eight years, we've actually transformed pretty impressively in such a short time into a truly health technology company – so, spinning off our lighting business, divesting our domestic appliance business and then creating one of the largest health technology companies in the world.”

“The industry needs to transform from working on hardware alone to driving cost reductions, simplicity in workflow, and improved outcomes for patients. To achieve those ambitious goals, you have to bundle technologies, bring hardware and software together to create solutions that truly solve problems. This requires the procurement organisation to transform as well. It is not about hardware alone anymore. It is about bringing in suppliers that help with the innovation on those solutions which is easier to say but not so easy to be done. Driving innovation on hardware is a little bit more concrete than driving ideation on a solution

that is not easy to conceptualise and requires a lot of pieces to be put together, and that is the challenge we face: how do you bundle solutions that truly improve outcomes, reduce costs and improve the workflow in clinics and hospitals?”

A vital part of that transformation has been the relationship Philips has with their partners and suppliers, which Scott and his colleagues are leveraging to deliver more solutions that improve outcomes, reduce costs, and optimise workflows in clinics and hospitals.

SCOTT SCHWARTZ CHIEF PROCUREMENT OFFICER & HEAD OF SUSTAINING ENGINEERING, ROYAL PHILIPS

SCOTT SCHWARTZ CHIEF PROCUREMENT OFFICER & HEAD OF SUSTAINING ENGINEERING, ROYAL PHILIPS

“Having a strong partnership with our suppliers is crucial, allowing us to connect the suppliers to our problems, thus connecting the supplier innovation capabilities to our problems, to actually leverage a much broader ecosystem to identify these step-up improvements.”

“The culture that we are trying to create here is that rigour, that depth, that curiosity to find more”

By using an early engagement approach with their suppliers, Scott believes it gives them the best possible chance of delivering solutions and step-up improvements to their products, and, with his role having a larger overview of development, it can bring the best out of those partnerships.

“Everybody thinks that every procurement leader says, ‘We are going to leverage the supplier ecosystem and bring the suppliers closer to our activity’. It’s easy to talk about the concept, but it's very hard to do in practice. We have done some of the structural things, like consolidating our supply base to strategic suppliers that have strategies and visions lined up with Philips’

strategy and vision. I think that it is key to have these smaller sets of suppliers that are more strategic as we interact with them.”

It is this culture of trusted collaborations embedded in these partnerships that allows a stronger bond between the two for the benefit of both parties, and, ultimately, for the customers and patients who use the technology. Scott is confident that the company’s top strategic partners feel listened to and empowered to play an active role in the process of product development.

“That's the key – that it’s a two-way street,” he says. “They are partners and so we have confidence in them, but it's also our responsibility to treat them like strategic

“What is really inspiring about this whole industry is that we are helping people”

partners and give them benefits for being our strategic partners. Whether that is access to our new product development opportunities or focusing on other creative innovations that we are working on, we want them to feel part of Philips.”

Scott also says that they strive to make sure there is a flow of communication and innovation coming from their suppliers for productivity, quality, performance, and resilience. That is the benefit of connecting a strong procurement organisation with a sustaining engineering capability to drive execution.

All those ideas permeate through product development cycle to the consulting

rooms, clinics and wards of hospitals and clinics around the world. It was following his appointment that Scott got to witness the benefits of that approach first hand and see staff interacting with their innovations.

‘It was just very insightful to talk to the technician and ask him about Philips and our products – that is what it's all about. Not only the connectivity to the personal experience you have with our products, but also seeing that our products are perceived as delivering on their high-quality premise. And that's satisfying as well.”

In a world of increasing risk and uncertainty, the expertise of 3PLs is increasingly important to organisations, as is their transformation savvy

In the past few years, businesses have been rocked by unforeseen supply chain disruptions, across industries ranging from pharmaceuticals and consumer goods to electronics and automotive. The global pandemic has cost the world economy an estimated $11 trillion, and in 2021, a giant container ship ran aground in the Suez Canal, blocking the world’s busiest trade corridor for six days and disrupting

$40bn of trade. And now, of course, we have war in Ukraine, along with the disruption to trade and spiralling fuel inflation that has caused.

Supply chains often have to navigate chaos, confusion and disruption on a global scale, and the ways they are seeking to do so include new and innovative approaches. One is using third- and fourth-party logistics providers to help them.

Third-party logistics (3PL) companies provide services and expertise across the supply chain as a whole, including monitoring, communications and customs formalities; fourth-party logistics (4PL) companies offer digital integration solutions over and above the resources offered by 3PLs.

Because

Because

One person who thinks such companies have a major role in helping businesses navigate disruption and uncertainty is Ashley Naughton, who is Group Director of Logistics with McLaren Automotive.

3PLs ‘have crucial role to play in future supply chains’

We spoke with Naughton at Procurement & Supply Chain LIVE earlier in the year, when he was UK Director of Supply Chain Transformation with Capgemini,

a role in which he helped some of the most prestigious brands in the UK on their transformation journey towards a sustainable supply chain.

At the time, Naughton said: “I think thirdand fourth-party logistics providers have a critical role to play, because they are often able to see disruptions early, particularly with regards to logistics routes.

“A lot of disruption that we've seen over the past couple of years has come through logistics issues. The Suez canal issue, for example, is a classic example of where transportation was severely affected. 3PLs and 4PLs are often best placed to analyse how such disruptive events might impact a company’s ability to deliver product and goods on time. In turn, this enables an organisation to assess how that impacts their own customers.

“LOGISTICS COMPANIES ARE AN IMPORTANT RESOURCE BECAUSE THEY’RE UNDERGOING THEIR OWN DIGITAL TRANSFORMATIONS”ASHLEY NAUGHTON GROUP DIRECTOR, LOGISTICS, MCLAREN AUTOMOTIVE

“So availability and access to logisticsroutes data is really an area where I see they can add a lot of value.”

Of course, for the outsourced logistics providers, having been forewarned also means being forearmed – with the technology that makes supply chain visibility possible. This is expertise that Naughton believes businesses would do well to tap into.

“Logistics organisations are of course a key part of the value chain,” he says now, “and, as such, I think organisations need to work more carefully on collaboration.”

Naughton adds: “Many logistics companies are an important resource because they are undergoing their own digital transformations, and businesses need to work with them to understand how their digital transformations can add value to their own organisation. Only through collaboration will we see such benefits coming through.

“But not only do organisations need to collaborate with logistics companies, the logistics companies also need to collaborate with one another.”

3PL collaboration ‘more important going forward’

Collaboration among logistics providers is an emerging area but it is one Naughton feels will become more prominent going forward, particularly regarding sharing capacity.

“A good example is the delivery of goods and services,” he says. “Traditionally, logistics will measure delivery ‘fill’ and yet it doesn't necessarily always measure and monitor its return fill. This is why, often, returning vehicles don’t contain any products. This is called empty running and

The 2022 global third-party logistics market is estimated to be worth over US$1tn and is projected to be worth $2,144tn by 2032, according to market research.

The report – The State of the ThirdParty Industry Report – says the rise of globalisation has contributed to the establishment of a global network of manufacturing activity, and that the demand for 3PL services is projected to rise in order to keep it running smoothly.

The 3PL market is expected to be driven by an increase in demand for shipping cost reduction and a focus on timely delivery management, as well as a reduction in company assets, the ability to focus on core business, and an advantage in managing seasonal variations. The report also said that manufacturers' lack of control over logistic services and delivery processes may have a negative impact on the sector “in the near future”.

it’s a big sustainability issue for the logistics industry.”

He adds: “So there is definitely an opportunity for logistics companies to consider sharing capacity to make the entire network more efficient.

“With the drive towards sustainability becoming more and more important, reducing the amount of inefficient transport moving around is definitely something logistics providers will seek to tackle.”

But for every logistics provider who has succeeded in digitally transforming its operations, there is another one that either hasn’t begun the process or has stalled. McKinsey research suggests that as many as 30% of all digital transformation programmes either fail or do not have the desired results. Putting people first is one of the keys to a successful transformation, “CHANGE IS A PEOPLE SPORT; PEOPLE CHANGE

according to Ben Godfrey, Raw Materials and Forming Procurement VP with Rolls Royce, who heads up the company’s civil procurement of raw material, castings and forgings.

People are the heart of supply chain transformation Speaking on the same panel as Naughton at Procurement & Supply Chain LIVE, Godfrey said: “I think change is a people sport; it's only ever people that change things, while capital and technology provide huge leverage.”

Godfrey feels that technology is now allowing logistics providers and others across the supply chain to “leverage ideas on a scale you've never been able to do before”.

He says: “You can reach anybody in the world effectively. The challenge is connecting those dots in an effective and efficient way for your enterprise.

WHILE

AND TECHNOLOGY

THE LEVERAGE”

“You've got a huge competing infrastructure on digitalisation, and as a manufacturer, it's quite challenging to pick the digital and technology providers that are going to be here for the long haul. Then you’re left wondering what the future standard is going to be, because there are a huge number of competing infrastructures, and not all of them are going to be successful. I can understand why there is nervousness.”

Although Naughton agrees people have to be at the heart of any transformation, he points out that skill and expertise are barriers to change.

“It’s something that firms really need to be focused on. This is especially true right now because of labour constraints in the supply chain network due to the Great Resignation.”

Another obstacle to the digital transformation of supply chains is developing a business case for it, Naughton notes. “Lots of businesses still tend to focus on the top- and bottom-line, which is understandable because that's how we're all measured. But, if organisations are to start moving things forward, they will have to migrate towards more of a valuedriven proposition.

Naughton says this is particularly true of those with limited investment capabilities, and also points out that different sectors face slightly different challenges, and that decisions need to be made between investment from both a financial perspective and a resource perspective, because “that will be needed to decide what you actually want to focus on within your supply chain.”

PRODUCED BY: MIKE SADR

PRODUCED BY: MIKE SADR

There’s an old saying which, in a world awash with ‘Big Data’, has taken on greater meaning: ‘All models are wrong; some models are useful.’

But forward-thinking companies are working on how to tame overwhelming amounts of data, with machine learning (ML) and artificial intelligence (AI) to speed up processes, save on spending and find new opportunities for business growth.

These industry leaders include Las Vegas, NV-headquartered Westfall Technik. The growth trajectory of Westfall Technik has proven to be compelling for customers and the markets alike. Accelerated by the significant platform built through the acquisition of 15-20 companies over an approximately 4-year timespan, the company has seen continued solid organic growth from their customers in their target markets of healthcare and consumer packaged goods and continues on their new customer acquisition journey.

Westfall’s corporate methodologies, backed by their “Stacked Integration Model”, certainly deliver as these relate to their value proposition supported by correlative moulding processes and effective Industry 4.0 concepts.

Westfall’s portfolio of healthcarerelated products features medical devices, pharmaceutical delivery systems, diagnostic tools, consumer health products, and

Westfall Technik’s David Schultz and Arkestro’s Edmund Zagorin explain how machine learning and game theory can benefit supply chains across industries

a range of services that also includes the moulding of plastic parts used in COVID-19 diagnostic rapid testing for both home and clinical use.

VP and Chief Supply Chain Executive David Schultz joined Westfall in February this year. He is responsible for the global supply chain across the entire enterprise, covering a broad range of critical responsibilities, including all areas of procurement and supply chain functions.

“Westfall is a company that's made over 15 acquisitions in the last four-and-a-half

years. This activity, along with significant organic growth, has resulted in explosive expansion, with hundreds of millions of dollars in revenue,” explains Schultz. “And, as all those companies were brought together, I was approached by Mark Gomulka, the CEO of the organisation, who said, ‘We need somebody to come in and put this all together, make this all work as a cohesive unit’. And that’s now my major goal: to bring all those operating units together and build teams of people who leverage use the right intelligence.”

Among Schultz’s early business decisions was the introduction of a Predictive Procurement Orchestration solution provided by San Franciscobased Arkestro for use across the entire Westfall enterprise.

“I first met David at a Chief Procurement Officer event, where he was chairing the conference and giving a talk about the state of the market and some of the changes that he was seeing,” says Arkestro Founder and CEO Edmund Zagorin. “I saw that we had alignment in terms of how we perceived the market landscape. One of those key points of alignment was that there's so much volatility and complexity that it can be really challenging to deliver business impact fast using any digital solution that requires widespread user adoption to be successful. That's something that we take really seriously, so David and I got to talking, ultimately finding that we had vision lock.”

Zagorin has a background in quantitative network analysis and strategic sourcing consulting. He and his team launched Arkestro to help large enterprise procurement teams solve tough supply chain problems, drive continuous process improvement, and – in his own words –be their supplier's best customer.

Westfall is also an Arkestro Corporate Alliance Partner and will advise on the functionality of new Arkestro products and capabilities. Westfall recently joined the Association of Plastic Recyclers’ Demand Champions Program and the Ellen MacArthur Foundation's Global Commitment for a New Plastics Economy.

The Arkestro platform embeds preferred outcomes into any organisation's system or process, which practically means

TITLE: CHIEF SUPPLY CHAIN EXECUTIVE COMPANY: WESTFALL TECHNIK

INDUSTRY: SUPPLY CHAIN

LOCATION: SOUTH CAROLINA, US

David is a senior management executive whose broad business experience and data-driven approach enables organisations to dramatically reduce costs in extremely competitive markets.

He is an imaginative dealmaker passionate about building trusting relationships and highly skilled at managing several billion dollars of spend resulting in significant dividends and speed-to-margin.

Prior to joining Westfall, David served as VP CSCO/Chief Procurement Officer for several public and privately held companies.

He thrives in organisations that promote and support the acquisition of new skills, technologies, and transformative thinking.

LOCATION: SAN FRANCISCO, US

Edmund Zagorin is a procurement thought leader obsessed with the power of recommendations to fix broken processes and supply chains. Prior to founding Arkestro, Edmund worked as a consultant focused on datadriven supplier negotiations for large healthcare providers, contract manufacturers and multi-campus retail brands.

Edmund is widely recognised as an expert on the emerging role of machine learning and artificial intelligence in procurement and has presented executive briefings on this topic to leadership teams.

pre-populating validated data about the supplier, the pricing and commercial terms of a transaction. It accomplishes this using an AI model that simulates a procurement cycle before it happens and then sends recommendations on quotes to the suppliers. Arkestro also routes more purchases to preferred suppliers (including suppliers that align more with ESG and risk objectives) and the price recommendation functionality saves significant time and resources.

Environmental, social and governance (ESG) criteria are vitally important, so Westfall Technik also leverages the Arkestro platform

to ensure they are working with suppliers that meet their environmental goals, while improving the effectiveness and productivity of the internal supply chain team.

"Westfall Technik's decision to work with Arkestro validates the value that we bring to managing supplier relationships, while also highlighting an important and innovative use case for us," says Zagorin.

Investing in technology means investing in people Schultz says he had a very specific challenge he wanted to address at Westfall and was initially drawn to the platform’s predictive

“Westfall Technik's decision to work with Arkestro validates the value that we bring to managing supplier relationship”

EDMUND ZAGORIN FOUNDER & CEO, ARKESTRO

DAVID SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK

DAVID SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK

pricing feature, which he felt was unique and well-suited to offer transparency and credibility with the supplier base. Once he took a closer look at the platform, he realised it was the most practical solution to provide the best value possible in the least amount of time.

“David came to me shortly after joining the organisation and suggested multiple options to accelerate the transformation to one operating system and mindset,” says Westfall Technik CEO Mark Gomulka. “It was vitally important that our supplier and customer partners fully understood the power of One Westfall and the competitive advantages for their respective businesses. The Arkestro platform has been a key part of our strategy to attain this vision on the supply side of the equation.”

Schultz found that the team of people

“It's not just technology, it's people, and the pedigree of Edmund’s background and experience, as well as his vision for the company, was very reassuring to us”

behind the platform were also eager to support his own business operations, as well as the vast ecosystem of suppliers he deals with on a daily basis.

“We invest in people,” explains Schultz. “It's not just technology, it's people, and the pedigree of Edmund’s background and experience as well as his vision for the company – this was all very reassuring to us. In particular, we need the suppliers to want to participate, cooperate, and know they have taken part in a fair process.

“We can never forget that, no matter how much technology can be an enabler, it all starts and ends with people,” says Schultz. “There’s certainly a tremendous amount of information out there about AI and ML, which is very important, but I often remind myself that it’s the intersection of artificial intelligence with human intelligence that really makes it all work.”

parts. This might include suppliers working with manual spreadsheets, having to copy and paste prices and pitches, dealing with procurement teams on a case-by-case basis, and a wealth of additional measures, each created from scratch by individual companies and teams.

percentage of companies that experienced more disruptions to their supply chain in 2021 than in previous years, according to the Hubs Supply Chain Resilience Report 2021

Arkestro is at the forefront of costmodelling by ML and behavioural science, says Zagorin, following the groundwork on dynamic pricing laid by Expedia and Uber.

“Predictive pricing is a concept that fundamentally simplifies a transaction,” says Zagorin. “It’s not necessarily better for one side or the other; the advantage is it's so much faster to settle the terms of the transaction, enabling both parties to move on to building great supplier relationships.

The Arkestro platform is designed to cut through the disparate collection of workflows and workarounds that a typical company has to deal with today in order to source pricing for everything from materials to spare

“And, in many cases when it comes to long-held supplier relationships, personal knowledge of the companies is important when making supplier decisions,” says Zagorin. “Traditionally, the entire process can take, conservatively speaking, weeks, but frequently, months and sometimes years depending on the complexity. When we looked at this, we knew that if we simulated the process at the start where requests are pre-filled with validated datadriven recommendations, Arkestro could make it so much easier and faster for suppliers to conduct business.”

“Data-driven solutions are the ultimate goal – we should all do our best to ignore any opinions masquerading as fact”

Arkestro’s data and behavioural economics research backs this up, demonstrating how the platform is better in financial terms for the procuring organisation, particularly for those companies looking to scale operations across more spend without necessarily having additional procurement headcount available.

“That's really Arkestro’s mission: to amplify the impact of procurement’s influence,” says Zagorin. “And that's where we see the power of embedding ML recommendations on price and supplier terms into processes wherever they are – be that email, spreadsheets or other systems the company might already be using.”

Westfall’s work with Arkestro has allowed Zagorin’s team to learn from a large company working with thousands of suppliers. Zagorin himself has said that David’s input has been something of an inspiration, particularly his drive to get teams working with data to see what benefits can be generated.

“David got his team to ‘kick the tyres’ and challenge us really early on when we came together,” says Zagorin. “I’m always a student of our clients, and David has a great ability to get people in a room to say, ‘We’re going to see how this works, so let’s analyse the

data and use it carefully and strategically to make the proper decisions’. David has referenced on several occasions that, in the business world, we all need to be cautious of ‘opinion masquerading as fact’. It's been really powerful and a big part of what's made the partnership so great.”

Schultz says that he and his team have been impressed with the Arkestro platform’s ability to bring order to traditional networks of suppliers, contacts and contracts, which inevitably produce a cascading flow of actionable data at every turn.

“It's been awesome to see what our extended team at Westfall has done with the platform,” says Schultz. “Most procurement and supply chain leaders

DAVID SCHULTZ CHIEF SUPPLY CHAIN EXECUTIVE, WESTFALL TECHNIK“It's the intersection of artificial intelligence with human intelligence that really makes it all work”

will tell you every industry's a little bit different, every category of spend is a little bit different, that there are unique dynamics with a supplier relationship based on how much money you spend with them. Or perhaps it’s a case of ‘Do we have a contract with them? How often is that potentially going to change? Is the contract being used as a kind of ad hoc purchase?’ All of these questions create a tremendous amount of complexity –and complexity can often mean more work. That’s why having model-driven recommendations can help cut through the noise.

“It’s that old expression,” he says. “‘All models are wrong; some models are

useful’ – we would say that all models are wrong, some models are useful, but the Arkestro model – used in partnership with our suppliers – is the best way to get a tangible business impact.”

The move away from wasteful and carbon-heavy linear supply chains to circular models is happening, albeit very slowly & with huge challenges ahead

Currently, just 8.6% of the world’s economy is circular, which means around 91 billion tonnes of material each year is being left to its fate in the natural environment. Research conducted by SAP alongside the World Economic Forum shows that 61% of the world's population (4.9 billion people) lacks access to infrastructure around waste management or recycling. The numbers around sustainability – or rather, those showing how far we still have to go – are mind-boggling.

Speaking at BizClik Media’s Sustainability

LIVE event in April this year, Stephen Jamieson – Global Head of Circular Economy Solutions at SAP – addressed the significant sustainability challenges that lie ahead.

“We're using more resources than the planet can sustainably provide, and half of total global emissions comes from the way we use materials,” he told his live and virtual audience. “Shifting to a circular economy means a change in how we design not only products and new materials to eliminate waste, but also new policies, infrastructure and business ecosystems.”

Circular supply chains are operationally vital Sustainability has never been higher on the agenda for businesses, both politically and operationally. In today’s world, organisations

Stephen Jamieson Global Head of Circular Economy Solutions at SAP

Stephen Jamieson Global Head of Circular Economy Solutions at SAP

The e2open connected supply chain platform provides the end-to-end visibility and collaboration you need to tackle unpredictability. Build trust and confidence with your channel, supply, logistics, and global trade partners. Take control of supply constraints through direct procurement and meet customer commitments in the face of disruptions and scarcity.

The connected supply chain. Moving as one™. www.e2open.com

E2open and the e2open logo are registered trademarks of e2open, LLC, or its affiliates.

STEPHEN JAMIESON GLOBAL HEAD OF CIRCULAR ECONOMY SOLUTIONS, SAP

must make net-zero practices an integral part of their strategic thinking.

This means sustainability must be embedded in end-to-end operations, from design to consumption. Only this way will we be able to escape the ‘take, make, use and dump’ linear supply chain model, relying instead on a circular model built on reuse and recyclability.