O c tob e r 2016

w w w.suppl ycha indig it a l.com

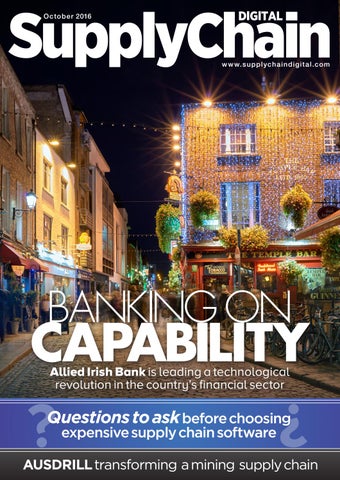

BANKING ON

CAPABILITY Allied Irish Bank is leading a technological revolution in the country’s financial sector

?

?

Questions to ask before choosing expensive supply chain software

AUSDRILL transforming a mining supply chain