13 minute read

How Track-and-Trace Capabilities Solve Food Logistics Challenges

HOW TRACK-AND-TRACE CAPABILITIES

SOLVE FOOD LOGISTICS CHALLENGES

After a year of uncertainty and disarray, manufacturers, shippers and end customers are increasingly using advanced technology to improve predictability and consistency in food logistics. Players throughout the food supply chain are turning to artificial intelligence, Internet of Things (IoT), sensor improvements, telematics, GPS and a host of other options to increase visibility of shipments and communication with clients. That shift to digitalization is only expected to escalate during the next decade. One of the fastest-growing technology segments in food logistics is the use of track-and- trace technologies. Use of trackand-trace solutions is expected to grow by 10.5% through 2027, and is forecasted to become a $6.1 billion market, according to a Report Ocean analysis. The pace of adoption will quicken, experts say, as companies turn to digital solutions to track and trace shipments.

Improving shipment reliability

With track-and-trace technology, products and shipments can be located throughout the shipping journey with real-time updates. The ability to find shipments became critically important in 2020, when the pandemic created unexpected delays and shipping interruptions.

“The purpose of track-and-trace software is to help improve reliability by giving shippers advance warning of delays,” says Thomas Bagge, CEO and statutory director of Digital Container Shipping Association (DCSA).

When it comes to food shipments, those kinds of delays can be catastrophic.

“Increasing reliability has a positive impact on business performance, as the timely arrival of goods, particularly perishable goods, is vital to maintaining quality and supply levels,” he says.

To reduce waste, manage product recall and trace shipments in general, visibility is necessary. The time for calls and emails to various vendors and shipping partners is over, says Ryan Camacho, director of Axele.

“The trend is moving away from constant check-calls toward using technology to provide visibility to the end customer is growing every day,” Camacho says. “The carrier has had the ability to see where his trucks are for quite some time, but being able to share that information on demand to the customer is growing in popularity.”

The rise of IoT

The IoT is an Axele’s TMS connects to load boards, electronic logging devices, integral component market rates and accounting systems to automate mundane tasks and of track-and-trace reduce deadheads. technology. Not only does it help locate shipments, but it is also such as the temperature in the container, indispensable to quality control. remotely. Shippers could receive warnings

“Using digital standards, integrated about unsafe environmental conditions at IoT technology can stream high-quality, any point along the container journey via real-time data from connected devices, a smartphone or any connected device. providing end-to-end visibility into both the The problem could then be diagnosed and whereabouts of containers and the status mitigated via the same application. Being of their contents,” Bagge says. able to provide this level of data to cross-

Data generated by track-and-trace border authorities may also potentially systems can be used in the decision-making reduce the number of inspections and process throughout the supply chain, he resulting delay.” says. The IoT plays an important role in

“Applications can use this data to warn logistics as the number of shipments and if certain thresholds are violated at any deliveries increase, says Alistair Fulton, VP point along the container journey,” Bagge and general manager, wireless and sensing says. “Shippers would not only be able products group at Semtech. to make informed, data-driven decisions “Logistics companies are certainly about the status of their shipments, [but] experiencing a greater volume in shipments they [also] would also have the power to due to the number of people staying home adjust environmental and other controls, and buying online,” Fulton says. “And, it’s

With track-and-trace technology, products and shipments can be located throughout the

shipping journey in real-time.

not just your regular clothes or toy purchase. People are relying on delivery services for their groceries, medications and bigger price-tag items. Installing long-range, lowpower consumption IoT sensors to track packages is an affordable way for logistics companies to cover their bases, from loading items into the truck to dropping a package off at someone’s doorstep.”

Track and trace in trucking

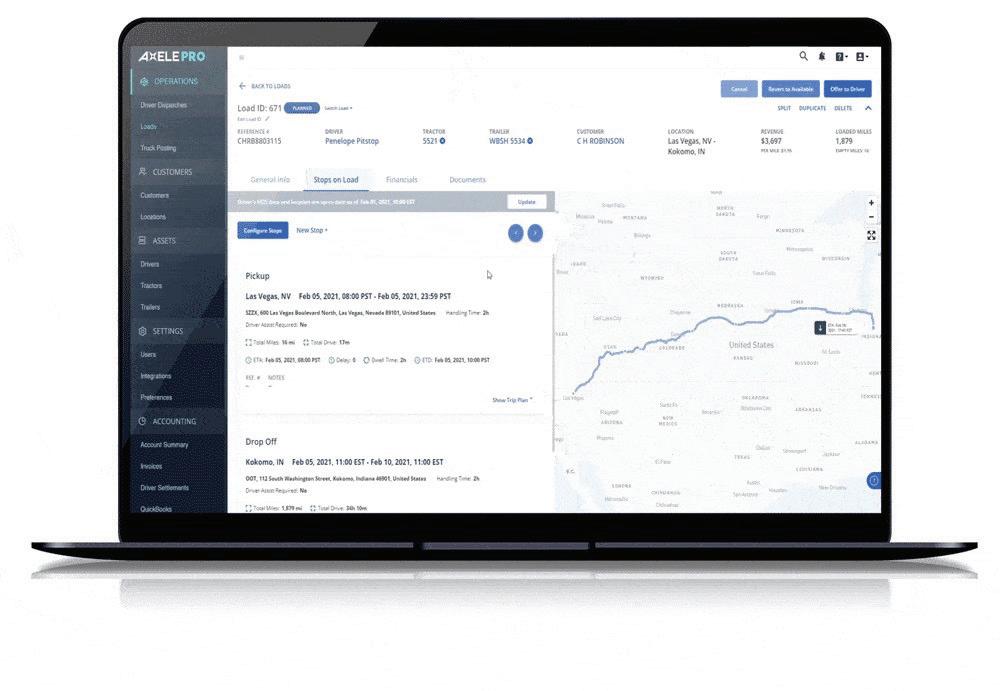

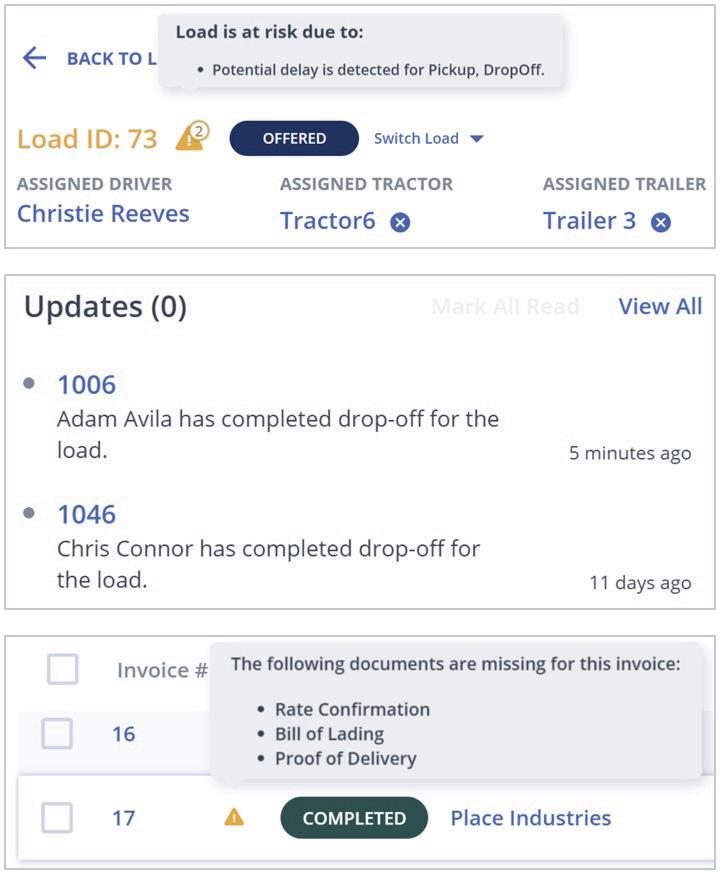

the obvious benefits of helping understand where your drivers, assets and loads are at all times,” Camacho says. “In addition, it helps carriers see the big picture of what the workload and driver schedule look like, so they can better understand where opportunities exist to take on new deliveries and reduce outof-route miles.” ELDs and telematics help create accurate estimated Effective track-and-trace strategies times of arrival (ETA). involve more than visibility, “Extending track-and-trace especially in trucking, Camacho visibility to your customer says. Axele’s transportation takes it to the next level and management system (TMS) is reduces the number of ‘where designed for truckload carriers. are you’ driver interruption Axele connects to load boards, calls, endless calls back and electronic logging devices (ELDs), market rates and accounting Axele forth between the carrier and customer, etc.,” he says. “With systems to automate mundane Track and trace allows users to identify route adaptations and today’s more advanced and tasks and reduce deadheads. opportunities. connected TMS solutions,

“Electronic logging devices and the carrier has the ability to telematics devices deliver GPS- receive feeds from third-party based tracking, but increasingly, we’re loading time, delays and more to provide ELD and telematics solutions, seeing solutions that also rely on location the most accurate ETAs. Just knowing plus the driver’s mobile app, to provide tracking using mobile applications running where the truck is does not accurately the most accurate ETAs possible, and on the driver’s phone or tablet,” he says. predict when it will arrive.” share that same information back with the “The best types of solutions are those that Not only can customers see where their customer via a live tracking link.” factor in both types of technologies and shipments are at all times, but track and also ‘see’ the driver’s trace also allows users to identify route schedule because adaptations and opportunities. they consider “For carriers, track and trace has

Navigating a pandemic

The effects of the Coronavirus disease (COVID-19) pandemic on logistics and shipping are many, including an increased demand for visibility. “The COVID pandemic has increased the sense of urgency and commitment from ocean carriers and other industry stakeholders to collaborate on solutions that will increase visibility of transport services across the end-to-end supply chain,” Camacho says. The standardization of data will help companies meet those needs going forward. “This includes digitalizing shipping data for track-and-trace purposes. But, digitalization alone isn’t enough,” Bagge says. “Creating end-to-end visibility requires a common data language and framework for processes and applications that allows high-quality data to be communicated in a way that is understandable and useable for everyone. For track and trace to provide its intended benefits to all stakeholders, digital standards must be in place to enable the interoperability that will allow any trackand-trace solution to offer end-to-end visibility.”

Once standardized data becomes available, carriers would need to provide a standard application programming interface (API) for users to access the data, Bagge says.

“The quality, consistency and interoperability of data across carriers is crucial to delivering useful information on, for example, the arrival time of cargo at port or changes to the temperature of the goods shipped,” he says. “If a smart reefer container from a carrier is loaded onto a ship of another carrier, it will not be able to communicate with the systems on the ship if the carriers do not have a standardized approach for data exchange.”

And, the reliance on digital tools will only increase as the technology improves.

“In some cases, the technologies that were rushed to market to accommodate the pandemic will get refined as the carriers who are benefiting from them come to rely on them as a way of doing business,” says Camacho.

The pandemic triggered an accelerated pace of digital transformation throughout the industry. But, the need for digitization will continue.

“We expect, over the coming five years, logistics providers that fast-track their track-and-trace digitalization efforts based on industry standards will gain significant competitive advantage over the digital laggards, similar to what’s happened in retail and other industries in their journeys to digitalization,” Bagge says. “By adopting standards, these companies will futureproof their platforms, enabling them to free up resources currently spent on maintaining legacy solutions to invest in innovation. This, in turn, will enable them to offer better cargo visibility, real-time responsiveness, and as a result, greater reliability and a better customer experience.”

At Syfan, our commitment to shippers remains

steadfast and true. The demands of COVID have created a shortage of carriers and tight capacity that have strained partnerships with some shippers – but not Syfan Logistics. Throughout the challenges of the past year, Syfan has not wavered from standing by its customers and continuing to provide drama-free service.

Because when we make a promise, we deliver.

A partnership of trust

SyfanLogistics.com | Gainesville, GA | 855.287.8485 | 770.287.8485

ORCHESTRATING SUCCESS

THROUGH COLD CHAIN MONITORING TECHNOLOGY ADVANCEMENTS

In collaborating with thought leaders throughout the foodservice and logistics industries, a paradox emerged, giving us pause. Collectively, the world produces enough food to feed the entire planet one and a half times over. Yet somehow, despite this excess, hunger still exists and our global food distribution network proves to be ineffi cient. This is perhaps the greatest motivator for more effi cient and interconnected supply chains. These solemn facts do not deter, but instead encourage the foodservice industry to collaborate and utilize “SMART” technology (self-monitoring, analysis and reporting technology) to break down the barriers to safely feed the planet.

Synchronizing the supply chain to fi ne-tune solutions

A few years ago, Golden State Foods (GSF) adopted the mantra, “Think Big... Start Small,” which led to GSF taking bold steps in its digital supply chain journey. We converged emerging technologies like Internet of Things (IoT) and artifi cial intelligence (AI) to maximize potential. By leveraging a data-rich environment, we created meaningful connections with suppliers, service providers and customers, and enabled the visibility of near real-time product movement, building trust in every transaction. Trust was built because transactions were captured and validated digitally, eliminating human intervention and the potential for error. We quickly compiled a backlog of additional use cases resulting from ideating with our supply chain partners. The melody from a single violin is unique, but when you combine it with other sounds from an orchestra, the result is a symphony. The violin’s melody is still audible, but it’s also synchronized with every other instrument. This delivers a sound that is far richer than a single violin could ever produce. This is analogous to what you can create when collaborators from across the supply chain come together and work off of the same sheet of music. Common goals promote a harmonious environment, while collaborating to monitor food and get it to where it is needed, at the right time and in the right quantity.

Golden State Foods Technology brings together new enti-

ties within the supply chain and enables them to listen and connect seamlessly. Orchestrating success beyond traditional reach

Digital technology advancements allow businesses to transcend beyond a brickand-mortar mentality and potentially create new operating models that connect every player regardless of their size and geography. In the future, businesses will continue to evolve their operating models into digitally connected business networks whose collaboration creates shared value.

The rapid advancement and accessibility of IoT solutions allows monitoring systems to act as accelerators. Companies are employing these

technologies to be increasingly attuned to their customers’ preferences, while reaping the benefi ts of increasing yield, extending product shelf life and optimizing resources. Fine-tuning and harmonizing solutions that also supports sustainability leads to greater growth and stability.

As GSF advanced on its journey to track, trace and monitor product freshness along its supply chain, it unmasked the benefi ts of utilizing IoT and monitoring devices to reduce process variability and ensure product freshness from the manufacturer to the kitchen table.

Monitoring temperature throughout the supply chain ensures product quality, effectively eliminating manual check points as product changes custody. Unintended inventory management benefi ts from tracking the product movement included increased visibility into shelf-life optimization, agility to pivot in response to consumer demand and improve effectiveness of production schedules, thus providing an opportunity to prevent waste in near real-time. Throughout the global food supply chain, the primary vision is to fi ne-tune the performance of every player to create a circular economy where everyone wins at reducing waste and optimizing resources. Making the in-demand amount of product, turning the inventory over faster and shipping it to the correct in-need location reduces the use of energy and power, thereby supporting sustainability. The power of this circular economy view is that we can avoid over-production, thereby reducing our carbon footprint and excess consumption of resources such as energy, water and materials.

Technology is bringing together new entities within the supply chain and enabling them to listen and connect seamlessly, so they can fully participate in an orchestra conducted by a digitally savvy consumer. Companies that prefer to work alone or to be siloed create new tunes that only increase the static in the world. However, if we leverage SMART technology to connect and synchronize, we can make music out of the noise. Only then can we build strength in our interconnectedness to reach the masses and serve an even greater purpose, providing sustainable supply chains to those who need them most.

When you think of SMART technology, think of an orchestra and a conductor. Technology is the instrument played by the many diverse, talented players in an ecosystem and conducted by the end consumer’s purchasing behavior.

Using advanced monitoring technology to fi ne-tune effi ciencies in production and match consumption trends will accelerate efforts to create more sustainable food systems and life-saving distribution networks.

ABOUT THE AUTHOR

GUILDA JAVAHERI

chief technology officer, Golden State Foods.

FES believes that food safety is not just about public health - it is also a good business investment. There is growing consumer demand for safe and nutritious foods globally. Food businesses throughout emerging economies are adapting to meet this demand, creating fertile market opportunities for cold chain logistics companies and investors.

With decades of experience in food supply chain logistics in Africa, Asia and Latin America - FES offers expertise and services for operating effectively and profitably in this space. By adopting food safety practices and technologies, businesses can:

• Expand market access • Improve product appeal • Increase efficiency

Contact FES President, Russ Webster, to learn more.

Partner with FES to expand your presence in emerging markets.