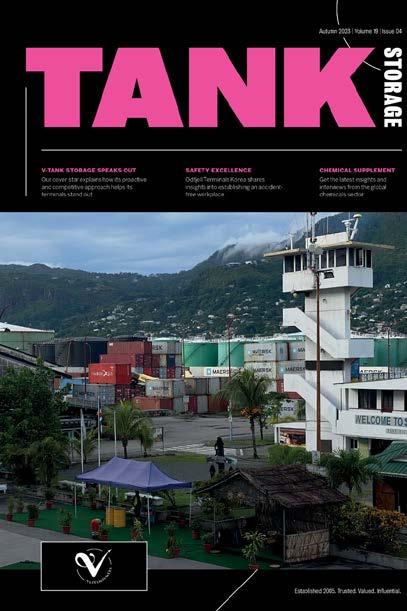

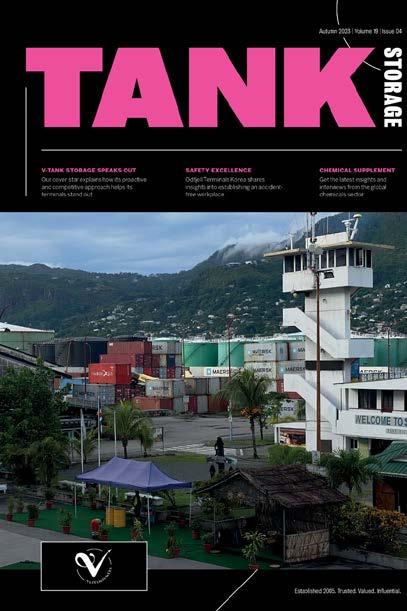

V-TANK STORAGE SPEAKS OUT

Our cover star explains how its proactive and competitive approach helps its terminals stand out

SAFETY EXCELLENCE

Odfjell Terminals Korea shares insights into establishing an accidentfree workplace

CHEMICAL SUPPLEMENT

Get the latest insights and interviews from the global chemicals sector

Autumn 2023 | Volume 19 | Issue 04

Established 2005. Trusted. Valued. Influential.

EXCLUSIVE INTERVIEWS 38 36 40 43 34 Following dreams; making choices Tank Storage Magazine sits down with Agnes Kiss, sales representative at Walter Tosto to discuss what route led her to tank storage 36 Proactive, competitive and always on the go Tank Storage Magazine speaks to this edition’s front cover sponsor, V-Tank Storage SA, about its global sites 38 Prioritising safety for customers and employees Having won gold in Safety Excellence at the Global Tank Storage Awards, Odfjell Terminals Korea shares insights into establishing an accident-free workplace 40 Operating in the Middle East Star Energy Advario CEO and VP of Advario Middle East, Andrew Drayton, tells Tank Storage Magazine about the Dubai terminal 43 Expanding terminals to supply future fuels Alexander Fokker, managing director at Vopak, explains the development of its sustainable feedstock storage in Rotterdam CHEMICAL STORAGE SUPPLEMENT INSIDE GLOBAL NEWS UPDATE 10 Editor’s Picks 12 Energy Transition 16 Product Launches 17 LNG 18 Digitalisation 21 Asia 25 Incident Report 34 Tank Terminal Update 30 Global Project Update UP FRONT 04 Contributors 06 Advertiser index 06 Social Storage 08 Editor’s Note 37 What’s Online? CONTENTS Autumn 2023 | Volume 19 | Issue 04 UP FRONT CONTENTS PAGE 01

MARKET ANALYSIS

44 In transition: energy security & digitalisation

FETSA’s executive director Ravi Bhatiani discusses the links between geopolitics, future fuels and the digital transformation for the energy industry

45 Asia’s outlook for LNG

President of Chevron Global Gas, Freeman Shaheen explains Chevron’s role in Asia’s LNG market

46 Energy security, transition & emissions

Andy Brooks, director of new ventures at the North Sea Transition Authority, explains the UK’s new licenses for CCS

48 What path lies ahead for hydrogen?

Insights from Argus’ latest webinar on the progress across different areas of policy, demand and project advancement and the outlook for the hydrogen sector

TECHNICAL FEATURES

51 Making inspections faster and easier

The experts at Skygauge explain why drone inspections are the future

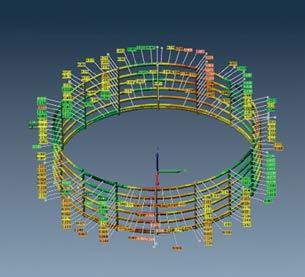

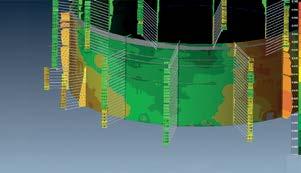

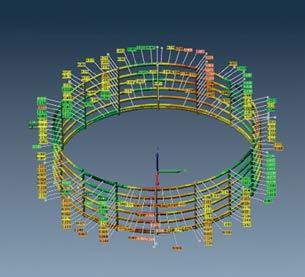

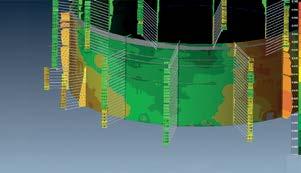

52 How mapping assets is key to maintenance

Cyann Fielding talks to industry experts about how tank mapping with lasers can improve the efficiency and longevity of assets

56 Modern foam for safer fire suppression

David Garris, firefighting foam agent & hardware product manager, at Johnson Controls explains how its new non-fluorinated foam has proven effective for large tank fire suppression

58 The key to success for data integrity

Cesar Espinoza and Veronica Dominguez at Rosen USA break down the essentials for ensuring smooth and effective data management and integrity

60 Avoiding reputational damage and injuries

Aidan Doherty, managing director of Re-Gen Robotics, discusses how no-man tank cleaning can impact safety, costs and reputation

61 Protecting critical infrastructure

Molly Cooper investigates how tank terminal operators can protect their staff and assets from terrorism and security threats

EVENTS

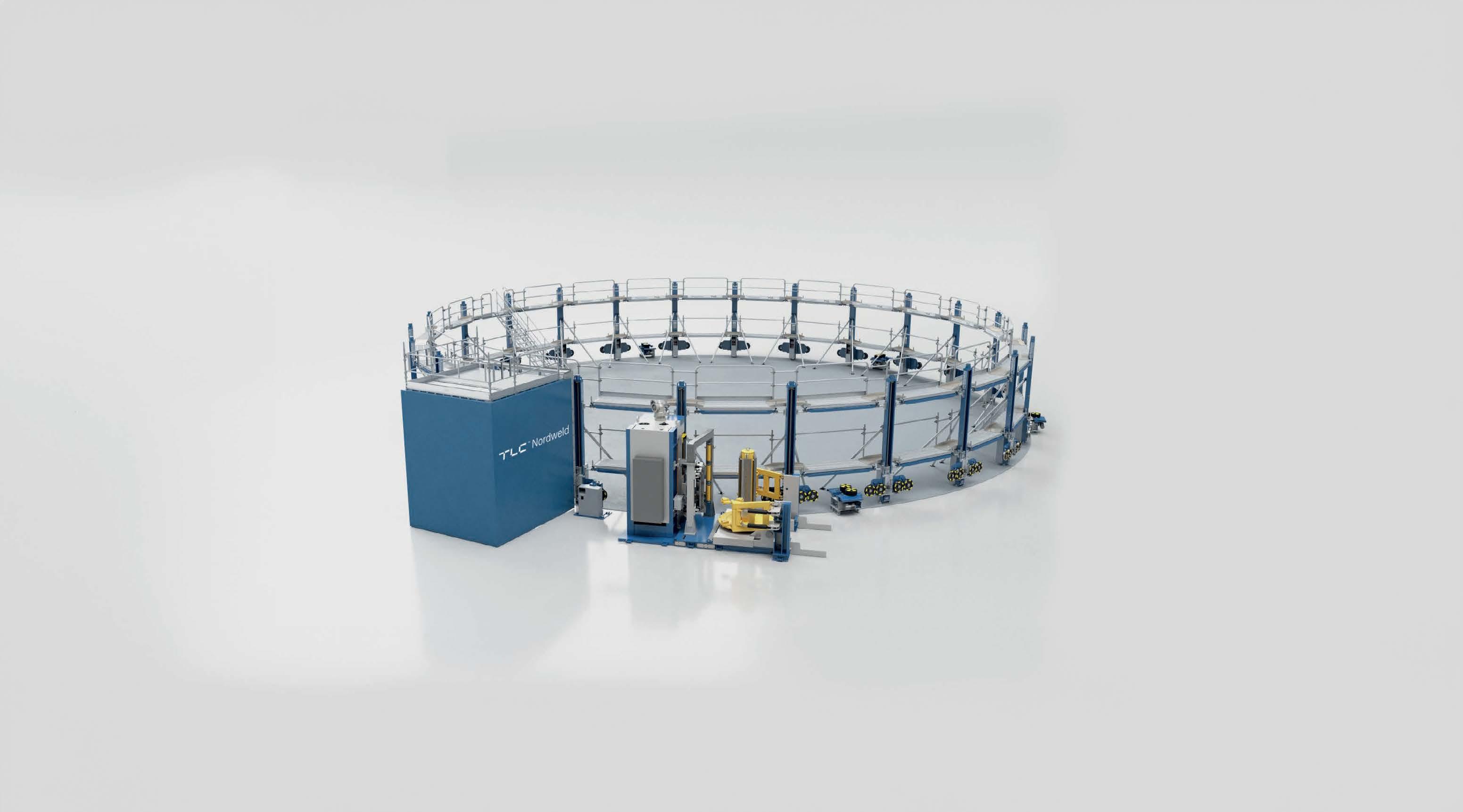

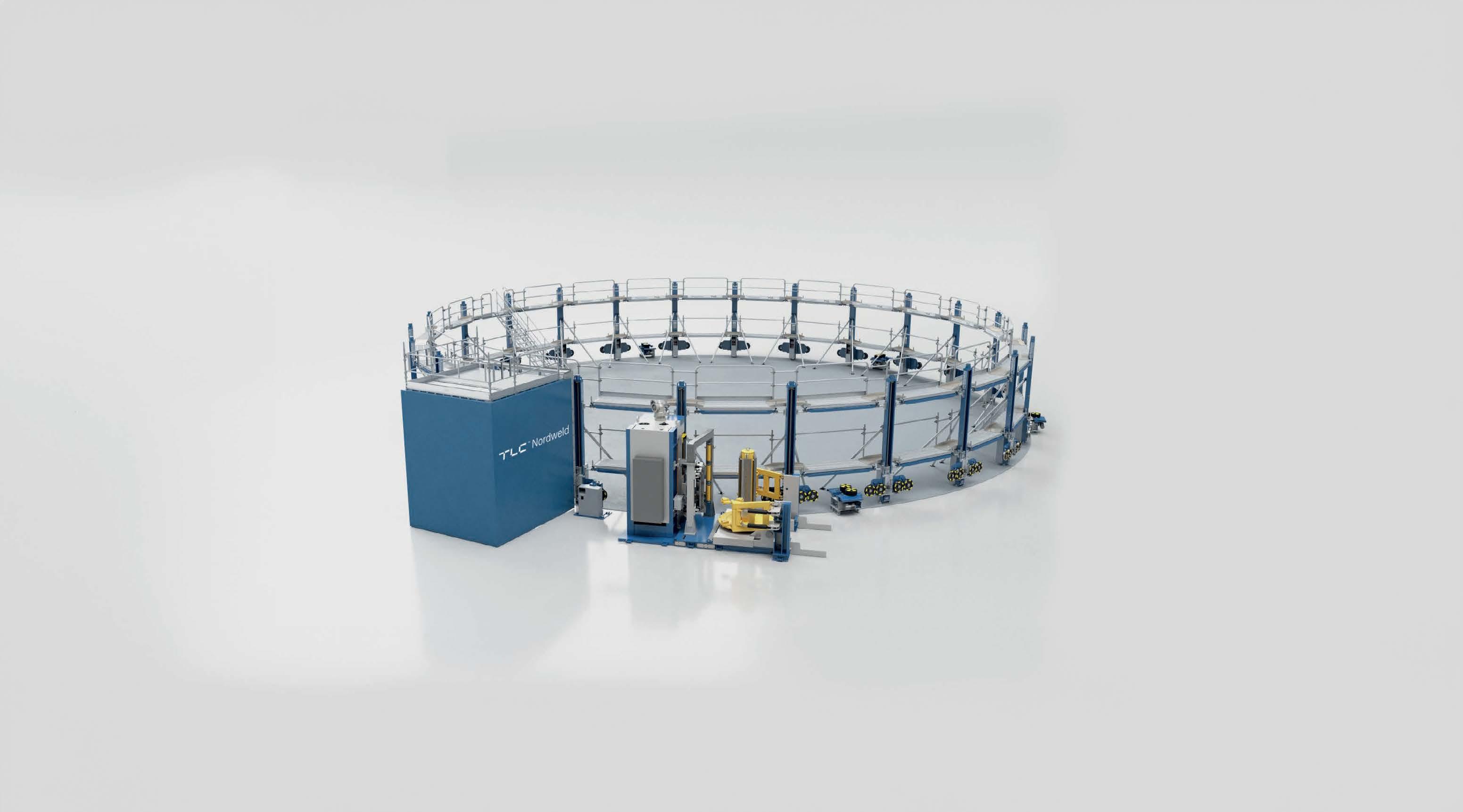

64 Taking the tank world by storm, one build at a time

Niklas Nordin, CEO and project manager at Nordweld, talks to Tank Storage Magazine about the company’s recent win at the Global Tank Storage Awards

68 Revolutionising tank maintenance & inspection processes

Cyann Fielding speaks to iSensPro about its gold win for Emerging Technology at the Global Tank Storage Awards 2023

71 Entering a new phase

Aquarius Energy CFO, Nicholas Gohl tells Tank Storage Magazine about winning the Outstanding Achievement award

75 Opportunities for tank storage in the hydrogen economy

Nick Waple, senior engineer at Wood Plc, gives Tank Storage Magazine an exclusive preview of his talk at the Hydrogen Technology Expo and how this relates to tank storage professionals

AT THE BACK

77 Events 2023

44

UP FRONT CONTENTS PAGE 02

51 56 60 71 64

Proven Performance. Powerful Protection.

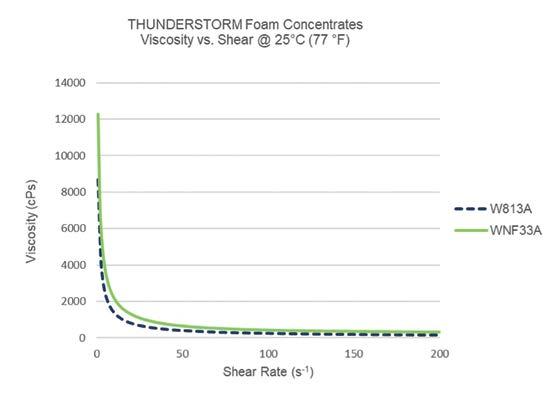

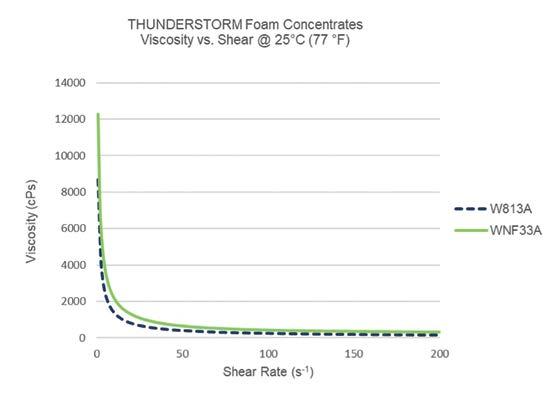

Non-Fluorinated THUNDERSTORM® WNF33A 3x3 AR-SFFF Concentrate

The new, no-compromise firefighting solution to today’s most challenging oil, gas and chemical fires:

• Demonstrated effective on fuel in-depth tank fires.

• High-quality foam blanket produced with most conventional response equipment.

• UL 162 listed.

Backed by 70 years of WILLIAMS FIRE & HAZARD CONTROL® fire protection expertise, THUNDERSTORM® WNF33A foam is the proven, no-compromise solution for large tank fires.

For more information, contact your regional WILLIAMS FIRE & HAZARD CONTROL® product representative or visit www.williamsfire.com.

EDITORIAL

ANAMIKA TALWARIA

Anamika is the editor for Tank Storage Magazine. She curates all the fantastic content in every edition and online.

MOLLY COOPER

Molly is a journalist for Tank Storage Magazine and looks after the news section. On page 38, she speaks to Star Energy Advario about their terminal.

CONTACT

T +44 (0)20 3196 4300

F +44 (0)20 8892 1929 anamika@tankstoragemag.com www.tankstorage.com

Easyfairs

2nd Floor, Regal House 70 London Road Twickenham TW1 3QS United Kingdom

ISSN 1750-841X

CYANN FIELDING

Cyann is a journalist for Tank Storage Magazine. She’s covering our Women in Tanks series this issue, speaking to Johnson Matthey’s Hande Cote inside the Chemical Storage Supplement.

SALES & MARKETING

PORTFOLIO DIRECTOR

Margaret Dunn +44 (0)20 3551 5721, margaret@tankstoragemag.com

HEAD OF SALES

Sophie McKimm +44 (0)20 3196 4356, sophie.mckimm@easyfairs.com

INTERNATIONAL SALES MANAGER

David Kelly

+44 (0)20 3196 4401, david@tankstoragemag.com

SALES MANAGER

Josh Lyle +44 (0)20 3196 4364, josh.lyle@easyfairs.com

KEY ACCOUNT MANAGER

Gary Kakoullis

+44 (0)20 3196 4248, gary.kakoullis@easyfairs.com

MARKETING MANAGER

Ream Demnati

+44 (0)20 3196 4282, ream.demnati@easyfairs.com

HEAD OF DATA

Beth Welcomme beth.welcomme@easyfairs.com

CEO EASYFAIRS UK & GLOBAL

Matt Benyon

matt.benyon@easyfairs.com

Anne Lafère anne.lafere@easyfairs.com

Autumn 2023 Volume 19 Issue 04 Our cover star explains how its proactive and competitive approach helps its terminals stand out Odfjell Terminals Korea shares insights into establishing an accidentfree workplace Get the latest insights and interviews from the global chemicals sector Established 2005. Trusted. Valued. Influential. Aug Sep 2019 AN INTERNATIONAL CONCEPT IN A CAPTIVE MARKET Oiltanking matola explains how it is introducing the independent storage model in sub-saharan africa. AN INTERNATIONAL CONCEPT IN A CAPTIVE MARKET Oiltanking matola explains how it is introducing the independent storage model in sub-saharan africa. SPEARHEADING THE UAE’S NEW GAS CHAPTER The sharjah national oil corporation is ensuring greater energy security as it explores gas storage.

WITH US

Storage Magazine

Storage Magazine UP FRONT CONTRIBUTORS PAGE 04

CONTRIBUTORS CONNECT

@tankstorageinfo Tank

Tank

Expanding horizons

Driving change to meet the energy transition

At Exolum we see the energy transition as an opportunity to expand our horizons. A chance to diversify our business and meet the challenges of climate change and our customers’ businesses. We have adopted Sustainable Development Goals (SDGs) to touch every aspect of our business and made a commitment to minimising our impact on the environment by striving to use energy resources and raw materials e ciently.

Europe’s leading bulk liquid logistics provider

To find out more visit exolum.com

taken the final investment decision to expand the terminal in Antwerp, Belgium and has started the construction of 28 tanks, collectively providing a significant storage capacity of 80,000 m³. #tankstorage #storagetank #portterminal #terminalport #storageterminal #terminalstorage #petrochemicals #oilandgas #futurefuels #energytransition #bulkliquid #tankterminal #tankport

Mabanaft expands storage footprint into Denmark by acquiring 100% of Oiltanking’s terminal in the capital, Copenhagen: https://bit.ly/46vDci5 #tankstoragemagazine #tankstorage #oil #gas #tankterminals #bulkliquids #storagetanks #storageterminals #liquids #news

Vault selects Chart Industries, Inc. to supply integrated liquid hydrogen storage and fuel delivery system. The system will be for a green hydrogen long-duration energy storage system (BH-ESS) used in conjunction with a utility-scale battery to provide back-up power to the city of Calistoga, California, USA.

https://lnkd.in/dGH_x7bg

#tankstorage #storagetank #tankterminal #storageterminal #terminalstorage #futurefuels #oilandgas #petrochemical #energytransition #hydrogen

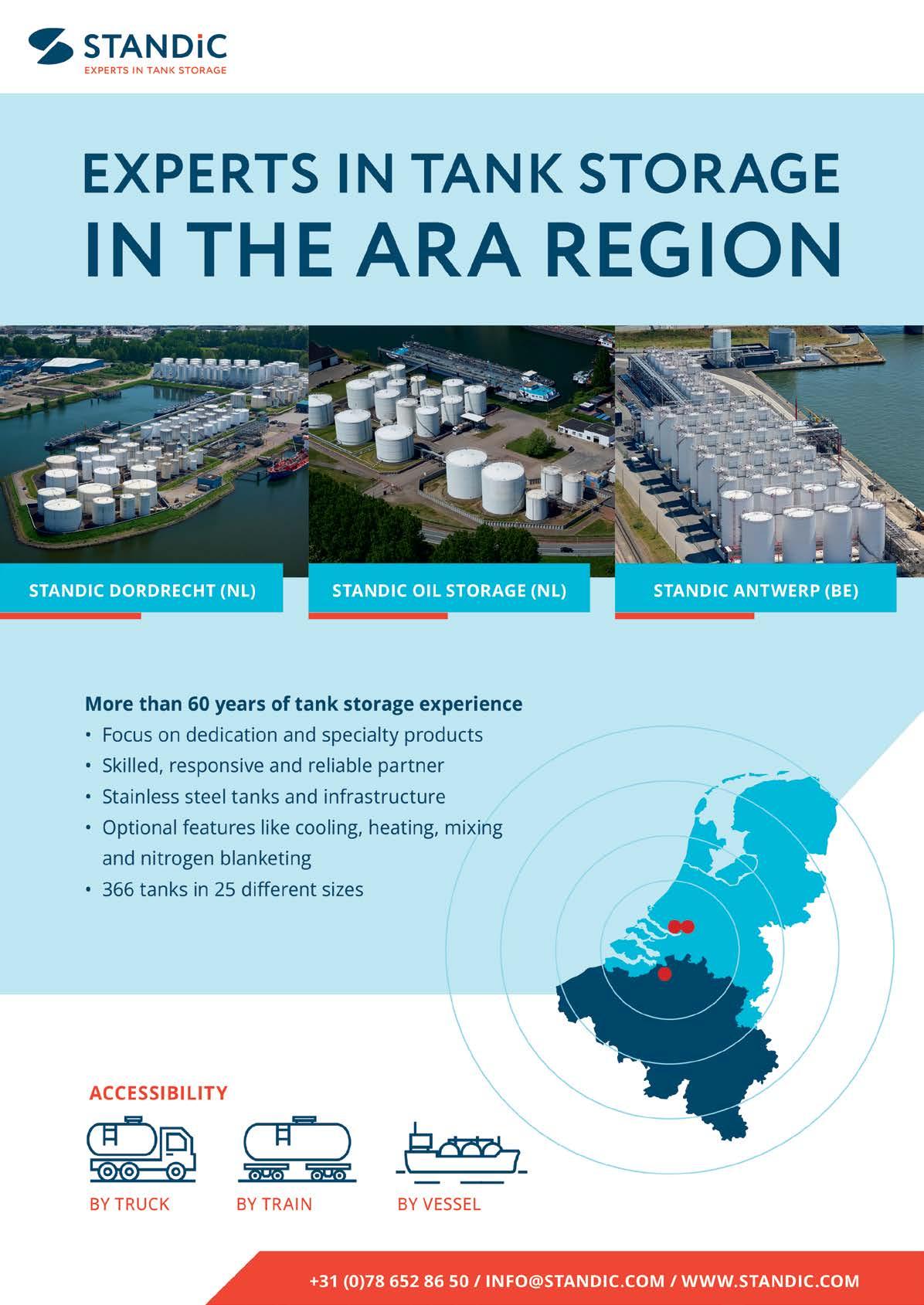

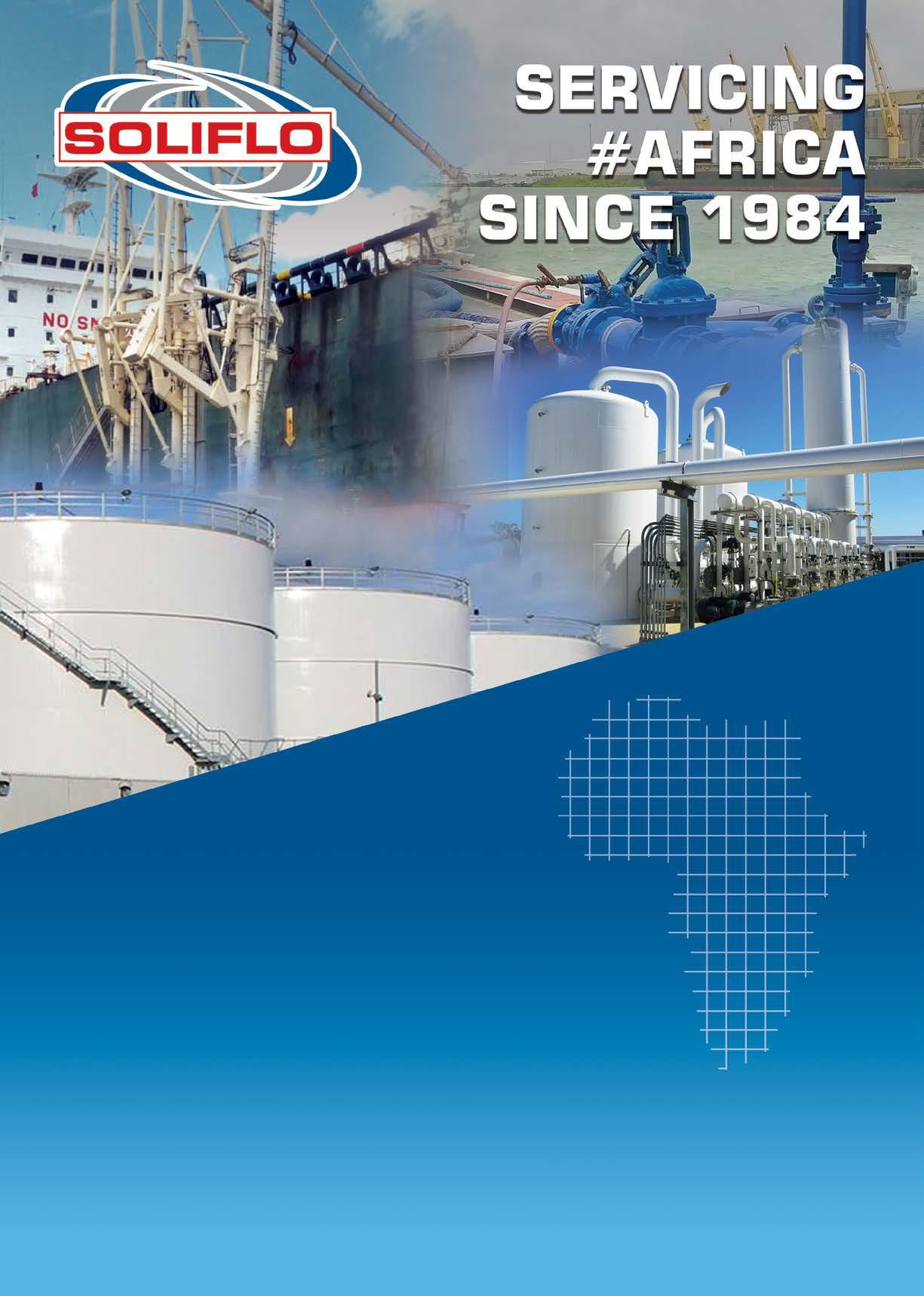

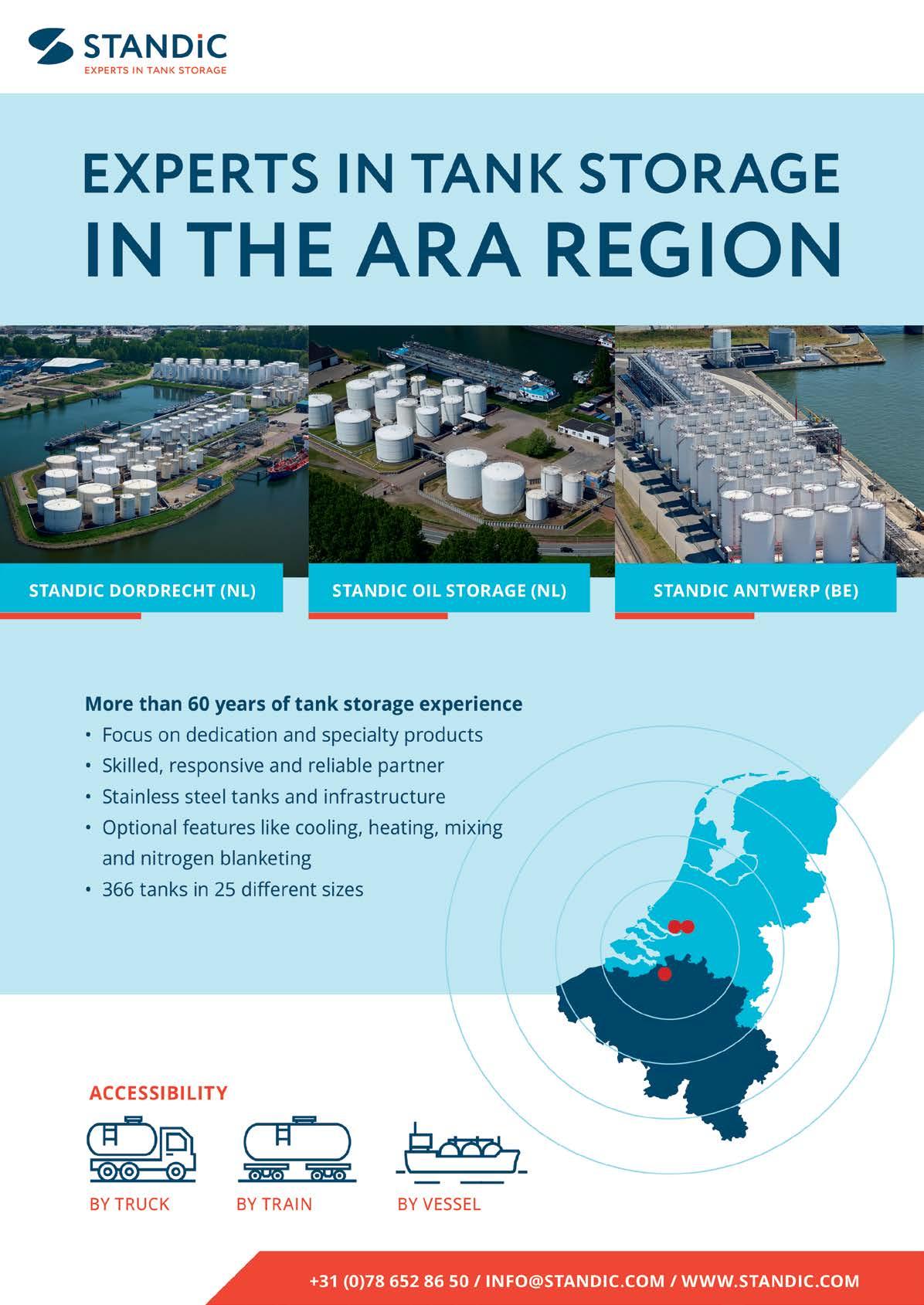

ADVERTISERS INDEX SOCIAL STORAGE Most liked posts this summer: UP FRONT ADVERTISERS INDEX & SOCIAL STORAGE PAGE 06 V-Tank Front Cover Standic Inside Front Cover JCI Williams 3 Exolum 5 Rosen Group 7 Rubis-Tepsa 9 Gerotto 11 EEMUA 13 Auma 15 Suma 17 EEMUA 19 E2G 20 Protego 21 Soliflo 22 Koerting 23 Dantec 24 StocExpo 26 Walter Tosto 29 SGB 33 FETSA 44 TSA Conference 47 EPCA 49 Merrett Surveys 55 Re-Gen Robotics 60 Nordweld 65 iSensPro 69 AntwerpXL 70 World Hydrogen Week 73 API Conference 74 ADIPEC 76 Rotary Engineering Back Cover CHEMICAL STORAGE SUPPLEMENT Port of Tarragona Front Cover Hazard 33 5 VII Med Hub Day Back Cover Tank Storage Magazine, (ISSN 1750-841X) is published five times a year by Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. A one-year, 5-issue membership costs €299. The US annual subscription price is $243. Airfreight and mailing in the USA by agent named WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Periodicals postage paid at Jamaica NY 11431. US Postmaster: Send address changes to Tank Storage Magazine, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Subscription records are maintained at Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. Tank Storage Magazine 12,845 followers 1mo • Edited Tank Storage Magazine 12,845 followers 2mo • Edited Tank Storage Magazine 12,845 followers 2mo • Edited LBC Tank Terminals expands Antwerp terminal: https://lnkd.in/eA5aN-zu LBC Tank Terminals has

Energy

LBC Tank Terminals expands Antwerp terminal Mabanaft Acquires Oiltanking Terminal in Copenhagen Energy Vault Selects Chart Hydrogen technology 116 • 2 comments • 6 reposts 2,624 engagements 164 • 3 comments • 14 reposts 6,054 engagements 74 • 2 comments • 1 repost 3,183 engagements Like Like Like Comment Comment Comment

The syntheses of non-destructive testing and integrity allows for the comprehensive understanding of an asset’s safety, lifetime, and performance. By bringing together technology, expertise, and consultancy, we become your partner in reliable decision-making. | Always a leading innovator, we deliver solutions that give operators confidence in their assets, ensuring safety and compliance with accurate diagnostic data and dedicated integrity services to protect and manage plants & terminals.

Comprehensive Asset Management

www.rosen-group.com

EDITOR’S NOTE

A WARM welcome back to you all. It’s been a while since the last print edition landed on your desk, so let me remind you of the high quality content you can enjoy. This issue has our annual Chemical Storage supplement, which you can find on page 50. Inside is an exclusive interview with Stolthaven Singapore, centring on the facility’s Dow SEA S4TAR Award win.

There’s also updates from the Chemical Business Association about creating a safe and sustainable supply chain, plus Cepsa Quimica offers insight into its range of sustainable chemical products.

Throughout the rest of the magazine, you’ll find an exclusive interview with one of 2023’s Global Tank Storage Award winners Odfjell Terminals Korea (page 36), key insights into how LNG and hydrogen fit into the tank storage industry, and the role of carbon capture and storage. Our editorial team has also been working hard to produce some exciting and original articles on laser mapping for inspections (page 52) and on security at the terminal (page 61).

So whether you’re reading this on release day in early September, or at one of the many events this edition is available at throughout the Autumn months, I hope you enjoy the content we’ve packed in.

A lot has changed for TankStorage Magazine over the summer.

We launched a brand new website and membership model, with the aim of bringing you lots more exclusive content, without needing to wait for the quarterly editions of each magazine. So look out for interviews with high-level professionals in the tank storage industry, original editorials about the topics that matter most to you, and our event previews (and reviews).

Make sure you become a member to avoid missing out – and please tell us what you think! We’ve set up our Google Business Account, but it doesn’t mean much without the input of our valued readers and members. Plus, if you follow us on LinkedIn, you’ll have your chance to give us your input by telling us what you want to read about! So give us a follow.

We’ve also onboarded some new staff members – sales manager Josh, and marketing intern, Lily. They’ll both have a huge role to play in the success of our magazine and I can’t wait to help immerse them in our industry.

A final word from myself and the editorial team: thank you! We all joined this world a year ago, and the community that we’ve managed to forge within the tank storage community has been inspirational. It’s partly why we’ve create the new membership model – to help build a community and share knowledge between everyone in the industry.

I look forward to connecting with you all at the various events over the next few months, but don’t hesitate to get in touch with our team in the meantime.

Best wishes,

PAGE 08 UP FRONT EDITOR’S NOTE

Anamika 01

01 The Tank Storage Portfolio team enjoying lunch in the sunshine this summer

Sustainable storage solutions for everyday life. We connect industries with people through safe storage solutions. We preserve essential products in sustainable ways. www.rubis-terminal.com FRANCE – SPAIN – NETHERLANDS – BELGIUM

GLOBAL NEWS UPDATE

Stay informed with our round-up of all the news hitting the tank storage sector

ESSAR OIL PARTNERS WITH OIKOS STORAGE

Essar Oil can now transport and distribute middle distillate fuels at the Oikos Storage Canvey Island facility, in the UK, to serve the Thames and surrounding regions. This enhances Oikos’ connectivity to the United Kingdom Oil Pipeline (“UKOP”) system, strengthening both supply and resilience to the Essar terminals in Northampton and Midlands region.

Larry Khanna, head of business development at Essar Oil UK, says: ‘We are delighted to have expanded our rack offering with Oikos and to be able to serve the largest market in the country. Supply resilience and security of supply are paramount for our customers, and we pleased to be able to offer this as we leverage our strong fuel expertise to serve existing and new customers and markets across London and the South East. It has been great to welcome long-standing customers to our new facility at Oikos and we look forward to meeting customers old and new at the site.’

Arunan Sriskanda, managing director at Oikos, says: ‘Oikos is delighted to support Essar with their rack commissioning as part of the long-term contract. There are great synergies between our operations, where we hope to support on both Essar’s midstream and downstream strategic aspirations. The new Essar rack offering will improve the UK’s fuel connectivity and supply chain resilience, as well as develop our site’s capability as we look to play an important role for future fuel trends.’

EXOLUM PARTNERS WITH VOPAK FOR HYDROGEN LOGISTICS

Exolum and Vopak Ventures have invested in the French start-up HSL Technologies, a company focused on the development and industrialisation

of simple, efficient, innovative, and cost-effective methods to safely transport and store hydrogen.

HSL Technologies’ is developing a unique process to introduce hydrogen molecules into a silica-based liquid carrier, where the hydrogen can be released on demand. Initial tests have shown that this carrier is stable and can be safely transported and stored in existing infrastructures at ambient pressure and temperature.

Martijn Schouten, of Vopak Ventures says: ‘This investment very well fits into Vopak Ventures’ New Energies, Feedstocks & Sustainability fund, in which we focus on funding ventures facilitating new sustainable solutions in areas such as zero emission fuels, green feedstocks, recycling solutions and flow batteries. We are very much looking forward to give our support in further developing this promising technology.’

Europe

BAKER HUGHES TO DEVELOP LOW-CARBON AIRPORT SOLUTIONS

Energy technology company Baker Hughes has announced a memorandum of understanding (MoU) with airport management and operations company Avports to develop, implement and operate onsite microgrid solutions for the airport industry. The collaboration addresses emissions reduction and zero-emission buildings, horizontal airport infrastructure, vehicles and aircraft systems.

‘Providing a technical and economic roadmap to airports to meet their energy needs of the future is key as an airport management and operations company,’

says Jorge Roberts, CEO of Avports. ‘Our partnership with Baker Hughes brings world-class technology and know-how together with our ability to support airport customers to realize these solutions at their facility.’

Together, Avports and Baker Hughes are committed to a more sustainable industry.

EUROPEAN COMMISSION APPROVES DUTCH SCHEME FOR RENEWABLE HYDROGEN

The European Commission has approved a €246 million Dutch scheme to support the production of renewable hydrogen.

The measure aims to contribute to the development of renewable hydrogen in line with the objectives of the EU Hydrogen Strategy and the European Green Deal. The scheme will also contribute to the objectives of the REPowerEU Plan to end dependence on Russian fossil fuels and fast forward the green transition.

The Netherlands notified the European Commission of its intention to introduce a €246 million scheme to support the production of renewable hydrogen in order to increase the country’s electrolysis capacity.

Margrethe Vestager, executive vicepresident in charge of competition policy, says: ‘This €246 million Dutch scheme is another example of how we work towards securing Europe’s decarbonised future. It will help ramping up the production of renewable hydrogen and facilitate the greening of sectors that are otherwise

Europe Europe

PAGE 10 NEWS UPDATE EDITOR’S PICKS GLOBAL NEWS UPDATE

United Kingdom

difficult to decarbonise. The aid will support the most cost-effective projects. And this while minimising possible distortions of competition.’

The tender will be open to all companies established in the European Economic Area and operating, or wishing to build and operate, a hydrogen production unit in the Netherlands.

WSG SELLS WELL INTERVENTION DIVISION FOR NEW ENERGY SERVICES

WSG has sold its Well Intervention division and will use the funds raised to lay the foundations for a period of international expansion for the rebranded WSG Energy Services (WSGES).

In a major reorganisation, WSGES has divested its traditional Well Intervention offering – including coil tubing and slickline services – and will now focus on growing its market share in process, pipeline and industrial services (PPIS). There are no redundancies aspects to the deal.

The Netherlands-headquartered business retains its global footprint with a strong presence in the UK, mainland Europe, Asia and Australia, and its next objective is to establish a permanent presence in North America to capitalise on recent project successes.

Proceeds of the Well Intervention division sale to Excellence Logging (Exlog), a leading provider of oilfield services and launched by Bluewater in 2015, will be used to fund further acquisitions and to maintain R&D for refining the company’s emissions management processes and technologies, which are in demand from energy companies looking to reduce emissions on the route to net-zero.

Founder Geert Prins will remain an integral part of WSGES’ C-suite as chairman, while Andrew Burrell continues in the role of CEO leading the growth of WSG Energy Services globally.

STOLTHAVEN NEW ZEALAND SENDS TWO TANKS OUT TO SEA

Stolthaven Terminals sparked the interest of onlookers and local media in New Zealand when it floated two

225 tonne tanks down the coast of the North Island to its storage terminal at Mount Manganui.

The empty tanks – measuring 25 m in diameter and 16 m in height – were hard to miss. Built by Culham Engineering in Whangarei, in the far north-east of the North Island, they completed their 290-nautical-mile, five-day sea voyage south earlier this month. Fortunately, for such hefty cargo, it was plain sailing despite a 48-hour stopover along the way due to the threat of bad weather.

‘Obviously, we needed stable weather conditions for the barge journey and for the unloading as well, so we had to take precautions,’ says Brent Metson, general manager of Stolthaven Mount Maunganui.

‘That included conducting the land transportation and heavy lifting operations overnight because we had to close roads. I’m pleased to say, it all went very smoothly, and the tanks are now safely on site. This new tankage will take up most of our remaining land and significantly increase our operating income.’

Stolthaven Terminals commissioned the new tanks, which each have a capacity of 8,100m3, to store very low sulphur fuel oil (VLSFO) for one of its customers. The VLSFO stored at the terminal will be used to replace heavy fuel oil for ships at the nearby Port of Tauranga.

Netherlands

New Zealand

PAGE 11 NEWS UPDATE EDITOR’S PICKS

MITSUBISHI LAUNCHES OPERATIONS AT NAGASAKI CARBON NEUTRAL PARK

Japan’s Mitsubishi Heavy Industries (MHI) has started operations at Nagasaki Carbon Neutral Park, a centre dedicated to the development of MHI Group’s energy decarbonisation technologies.

The new base is expected to progressively expand over the coming years. According to MHI, of its main capabilities will be fuel production, combustion and carbon capture technologies.

By applying the thermal energy system design and manufacturing capabilities developed at Nagasaki Shipyard & Machinery Works’ Nagasaki and Koyagi plants, the park will accelerate research and development toward product commercialisation and business viability.

Regarding hydrogen production, the facility will focus on next-generation technologies such as advanced water electrolysers that operate by solid oxide electrolysis cells (SOEC).

Key technologies developed at Nagasaki Carbon Neutral Park will be demonstrated at Takasago Hydrogen Park in Hyogo prefecture, along with a demonstration of a hydrogen turbine generating power.

The development will target the commercialisation of synthetic fuel production facilities, such as biomass. This is to include sustainable aviation fuels (SAF) produced by biomass gasification integrated Fischer-Tropsch synthesis.

Ammonia combustion testing will be performed using an actual-size burner of a large-scale combustion test furnace located within the Nagasaki district. The plans will call for co-firing with at least 50% ammonia demonstration testing at a power plant in FY2024 or soon thereafter.

STANLOW TERMINALS AND ENI UK SIGN MOU

Independent bulk liquid storage provider, Stanlow Terminals has signed a memorandum of understanding (MoU) with the UK subsidiary of global energy company, Eni UK to explore the development of CO2 collection, shipping and storage. Collection, shipping and storage would occur at the Stanlow Terminal location in the UK, with delivery into Eni UK’s carbon transport and storage infrastructures currently being developed in the north west region of the UK.

Stanlow Terminals and Eni UK will evaluate opportunities to establish an open-access CO 2 transport and storage terminal which will be capable of receiving, gathering and storing CO 2 from industrial emitters and other sources via shipping.

The objective is to ultimately connect multiple emitters with Eni UK’s licenced storage location through an open-access system, facilitating the sequestration of substantial volumes of CO 2 in the future.

This will play a significant role in the expansion of CCS infrastructure, by offering feasible and flexible routes between sources and storage sites.

The agreement follows Stanlow Terminal’s announcement of plans to also develop open access green ammonia facilities on the River Mersey.

BUREAU VERITAS BECOMES CERTIFICATION BODY FOR CERTIFHY HYDROGEN SCHEME

Bureau Veritas has announced it has become certification body for CertifHy hydrogen scheme. The CertifHy non-governmental certification scheme offers certified proof of origin for hydrogen throughout Europe.

CertifHy aims to facilitate and advance the production, procurement, and use of non-renewable, renewable, and low-carbon hydrogen. It has developed the CertifHy non-governmental certification (NGC) scheme in Europe to support the growth of the hydrogen market by providing a reliable tool for consumers to track hydrogen’s origin and environmental credentials.

The methodology underpinning this scheme focuses on two aspects: the origin of the energy used, and the carbon footprint of the hydrogen produced. These non-governmental certificates facilitate the trade of renewable and low-carbon hydrogen throughout Europe. With this new accreditation, its auditors can now perform CertifHy audits of hydrogen production facilities to ensure that the energy produced meets the CertifHy NGC Scheme requirements.

Europe

Japan

PAGE 12 NEWS UPDATE ENERGY TRANSITION

United Kingdom

CARBON CATALYST AND PERENCO UK AWARDED CARBON STORAGE LICENCES

Independent UK company, Carbon Catalyst and independent hydrocarbon producer Perenco UK (PUK) has announced it has been the awarded of two carbon storage licences by the North Sea Transition Authority (NSTA) to progress the Orion carbon storage project in the Southern North Sea sector of the UK Continental Shelf.

The two carbon storage licenses cover the PUK-operated and decommissioned Amethyst and depleted West Sole gas fields.

These high-quality geological stores represent the most geographically proximal offshore storage sites to Humberside, the UK’s largest industrial cluster, and are directly connected by pipeline to the PUK-operated onshore Dimlington Gas Terminal.

Orion will play a crucial role in providing additional, cost-effective CO 2 transport and storage services to various industrial and power generation emitters across the broader Humberside area.

The project is planned to be operational by 2031, with initial CO 2 injection rates of 1 MTPA.

PORTHOS WELCOMES COUNCIL OF STATE’S GREEN LIGHT FOR CO2 STORAGE

The Port of Rotterdam has announced that the first major project for CO 2 transport and storage in the Netherlands can go ahead, now that the Council of State has given a positive opinion on the ecological assessment of the Porthos project. The Council of State concluded today that the ecological research has shown that the nitrogen deposition of Porthos has no significant effects on nearby nature reserves.

It is expected that 2.5 million tonnes of CO 2 per year will soon be captured and permanently stored by Porthos.

The final investment decision is now being prepared by Porthos. The aim is to start construction in early 2024. The construction of the Porthos system takes about two years. Porthos is expected to be operational from 2026.

Specialist Training for the Storage Tank Industry

Classroom, live online, blended, in-house, and e-learning

Gain or renew up to 5-year Certificates of Competence*

Courses based on EEMUA 159 English, Dutch, German and French language options

Select from courses throughout each year:

TankAssessor courses*

2-5 October 2023 – in French –classroom – Près de Lyon, FR

9-12 October 2023 – in Dutch –classroom – Rotterdam, NL

6-9 November 2023 – in German –live online

13-16 November 2023 – in English –near Manchester, UK

TankInspector courses*

16-18 October 2023 – in English –live online

TankBasics courses

25 September - 3 November 2023 –in English – blended (live online and e-learning)

Storage Tanks e-learning

On-demand – in English or Dutch

In-house courses*

By arrangement – to suit your time, location, language

Also...

*** Storage Tanks Seminar ***

30 November 2023 – Rotterdam, NL

More choices, information and registration at www.eemua.org

Above ground flat bottomed storage tanks A guide to inspection, maintenance and repair Pub icat on 159 Edition 5

. . . .

. United Kingdom Netherlands PAGE 13 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE ENERGY TRANSITION

WOOD TO DESIGN FUTURE GRID WITH NATIONAL GAS

Consulting and engineering company, Wood, is working with independent gas supplier, National Gas to ensurethe secutity and sustainability of Britain’s gas transmission system.

National Gas currently operates the entire gas transmission system in Great Britain and has appointed Wood to digitally upgrade 7,600 km of essential pipelines, compressor stations and terminal infrastructure as part of their commitment to energy transition.

Over five years, Wood will apply digital solutions to transform National Gas infrastructure to modern, cyber-secure technology across their entire network of critical assets across Britain.

Wood is also delivering specialist hydrogen studies to National Gas on its National Transmission System (NTS) to support its target of achieving net zero by 2050. Wood Virtuoso, a digital twin solution, will analyse the characteristics of blended hydrogen and natural gas and advise on the level of investment required to repurpose the NTS infrastructure.

Azad Hessamodini, Wood’s executive president of consulting, says: ‘This work demonstrates the intrinsic link between digitalisation and decarbonisation and Wood’s expertise to deliver tangible solutions that drive towards the industry’s net zero goals…Through our ability to combine hydrogen and digital expertise, we are also providing a path for NGT to transition to low-carbon fuels through hydrogen blending, further supporting the UK’s net zero ambitions.’

UNIPER LAUNCHES RESEARCH FOR HYDROGEN PROJECT

Uniper’s HyStorage research project aims to investigate the influence of hydrogen on porous rock formations in order to determine the feasibility and integrity of pore storage facilities for the storage of hydrogen. A specialised gas-technical unit for the storage test has been set up on a designated drilling site at Uniper Energy Storage’s Bierwang site.

Commissioning is currently in progress and the first hydrogen will be injected from September onwards.

The storage test intends to inject different methane-hydrogen gas mixtures with a 5%, 10 % and 25 % hydrogen content into a smaller former natural gas reservoir in three operating phases. The gas will be withdrawn again after a standstill period of about three months. The storage horizon is independent of the existing Bierwang natural gas storage facility. Individual investigation of each site is needed to store hydrogen in porous rock reservoirs.

The collected data will be analysed and evaluated. Reliable technical assessments for the storage potential can be expected as early as 2024.

WÄRTSILÄ AND AGL COMPLETE CONSTRUCTION OF AUSTRALIA ENERGY STORAGE FACILITY

Technology group Wärtsilä has completed construction at the Torren Islands Grid Scale battery energy storage system (ESS) with AGL Energy Limited, one of Australia’s leading integrated energy companies.

The 250-megawatt (MW) / 250 megawatt-hour (MWh) ESS installed at Torrens Island in South Australia is the second-largest operational battery in the country.

The project delivers a major step towards Australia’s renewable energy future, supporting the nation’s decarbonisation goals. The flexible capacity provided by Wärtsilä’s advanced ESS balances the supply of energy from renewable sources, maintaining the stability and reliability of the grid.

The ESS will provide enough electricity to power approximately 75,000 South Australian homes for one hour, with the potential to extend the duration to four hours in the future.

The Torrens Island system will operate in grid-following mode, transitioning to grid-forming mode (virtual synchronous generation – VSG) later. This groundbreaking feature makes it the largest energy storage solution capable of operating in VSG mode, enabling fast response times and futureproofing operations for the Torrens Island facility. The solution is supported by Wärtsilä’s advanced GEMS Power Plant Controller.

TOTALENERGIES ACQUIRES 40% INTEREST IN CARBON STORAGE EXPLORATION LICENSE

TotalEnergies has signed an agreement with CapeOmega Carbon Storage AS, a wholly owned subsidiary of CapeOmega AS, to acquire the 40% participating interest held by CapeOmega in the CO 2 storage exploration license ExL004 (the ‘Luna’ project).

Located 120 km offshore Bergen, Norway, in 200 m water depth, ExL004 covers an area of 453 km². It is adjacent to the license where the Northern Lights CO 2 storage project (TotalEnergies, 33%) is under development, with a first phase due to start in 2024.

ExL004 is operated by Wintershall DEA Norge AS with a 60% participating interest. ‘This transaction is an important milestone to grow our CO 2 storage offering: subject to a successful exploration, this area could enable the storage of several hundred million tons of CO 2 from hard-to-abate industries in Europe,’ says Arnaud Le Foll, senior vice-president new business – carbon neutrality at TotalEnergies.

He adds: ‘With the Northern Lights start-up in 2024 and other projects under development in the Netherlands, Denmark and the UK, TotalEnergies is building a world-class carbon storage portfolio across the North Sea. Norway will play a leading role in this portfolio thanks to its large geological storages and supportive government policies.’

STOLTHAVEN TERMINALS DAGENHAM ACHIEVES ISCC

Stolthaven Terminals has announced that its terminal in Dagenham, UK has achieved the ISCC – International Sustainability and Carbon Certification, an internationally recognised standard in the biofuels and energy industry that demonstrates the fuel, biobased feedstocks and renewables stored on site meet defined sustainability criteria.

Gary St Pier, Stolthaven Dagenham’s operations excellence manager says: ‘This certification confirms our biofuels credentials, which are increasingly

Australia

United Kingdom

United Kingdom

PAGE 14 NEWS UPDATE ENERGY TRANSITION

Norway Germany

valuable to our customers as more of them require storage for bio-based products. The ISCC also reinforces our own commitment, both here in Dagenham and as a global business, to operating as sustainably as possible.’

Stolthaven Terminals is committed to continuously enhancing the sustainability of our operations and reducing our environmental impact.

UM GROUP UNVEILS SOLAR PANEL PROJECTS IN HUNGARY AND BELGIUM

Molasses marketing and trading, UM Group has announced that two companies with the group have taken steps towards becoming more sustainable.

UM Argos Feed in Hungary and UM Tameco in Belgium have installed solar panel arrays at their respective facilities. The solar panel projects form an important part of UM Group’s sustainability strategy which was launched earlier this year.

The 44 kWp solar power plant at the UM Argos Feed site in Hungary includes 80 solar panels with the possibility of adding more in the future. The plant is expected to produce 49,616 kWh a year, feeding 9,625 kWh back into the country’s national grid during the summer months.

The UM Tameco site in Belgium has a capacity of 29 kWp for 64 panels, the maximum on the flat roofs available. Expected production is 26,000 kWh with the company potentially using over 90% of the power generated itself.

UM Group will be monitoring the success of the two solar panel projects with a view to installing similar systems at other sites operated by the business.

AUMA CORALINK Discover our digital ecosystem SAVE RESOURCES AUMA SERVICE coralink.auma.com E x p e r t c are fo r yo ur ac tua to r s CO R A LI N K

PAGE 15 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE ENERGY TRANSITION

Belgium

INOXPA LAUNCHES DINAMIX SMX SIDEENTRY AGITATOR

INOXPA has announced the launch of the Dinamix SMX side-entry agitator range. It offers an adaptable system using standard components to produce many different configurations, avoiding the need to manufacture made-to-measure agitators.

The concept’s success is based on adaptability, responsiveness and efficiency. Products are configured using a system of modules, interfaces and structural rules. The range is configured with different standardised supports and flanges, and power ranging from 0.18 kW to 22 kW.

Side-entry agitators are a cost-effective solution for process and storage tanks in the food, pharmaceutical and cosmetic industries. The agitator features: stainless steel lantern, gear drive with hollow shaft and more robust fitting, optional hygienic design, standardised EN 1092-1 type 01 PN 10 flange, ATEX certification, shut-off system, mechanical seal with hidden springs and a T16 Gamma propeller.

SHERWIN WILLIAMS ANNOUNCES HEATFLEX CUI COATINGS

Sherwin-Williams Protective and Marine has announced its new line of Heat-Flex CUI-mitigation coatings to help mitigate the dangerous condition of corrosion under insulation (CUI).

The line includes Heat-Flex ACE (advanced CUI epoxy), which is an ultra-high-solids epoxy novolac developed with a functional chemical enhancement for CUI mitigation. In addition, three coatings featuring a high concentration of micaceous iron oxide (MIO) pigment round out the lineup, including Heat-Flex 750, Heat-Flex 1200 Plus and Heat-Flex 650.

Mark Rubio, energy business manager at Sherwin-Williams says: ‘The battle against CUI is never-ending, as coated steel encapsulated in insulation will inevitably corrode over time. Our goal is to mitigate that corrosion process for as long as possible, and we’ve developed some high-performance coatings that enable just that. For example, Heat-Flex ACE is the best product we’ve tested for long-term CUI mitigation. We anticipate it becoming a preferred specification

solution as the industry gains experience with this enhanced CUI-mitigation system. We have also boosted the market’s CUI-mitigation capabilities for existing specifications with the three MIOenhanced Heat-Flex coatings.’

PORT OF ANTWERPBRUGES LAUNCHES DRONE NETWORK

The Port of Antwerp-Bruges has partnered with DroneMatrix, SkeyDrone and Proximus to create a network of six autonomous drones. The D-Hive drone-in-a-box network is a world-first that makes an important contribution to the overall security of the complex port environment. The drones will perform daily flights in the Antwerp port area, Belgium, covering an area of more than 120 km².

The network will act as additional eyes to help coordinate smooth, safe and sustainable operations in this complex environment. The drones will offer a perspective from the air and enable port authorities to manage, inspect and supervise a large area, quickly and effectively. The port will use the drones for a range of functions including berth management, monitoring, infrastructure inspections, oil spill and floating waste detection, and to support security partners during incidents.

The 18 daily BVLOS (Beyond Visual Line of Sight) drone flights will be remotely controlled from a command-and-control centre in the heart of the port. The

operational permit was built around a new BVLOS framework (known as preUspace airspace), built by Skeydrone and approved by the BCAA (Belgian Civil Aviation Authority) and EASA (European Union Aviation Safety Agency), as an appropriate and safe framework for BVLOS drone flights.

SECURING ENERGY FOR EUROPE SIGNS FOURYEAR CONTRACT WITH OMAN LNG

Under the agreement, Securing Energy for Europe (SEFE) will receive 0.4 MTPA from Oman LNG. The agreement is based on a 4-year contract, starting in 2026.

The signing of agreement between SEFE and Oman LNG marks a milestone as SEFE becomes the first German firm to receive Omani LNG in the partnership between Oman LNG and international energy firms.

Mahmoud Al-Baloushi, CCO of Oman LNG says: ‘The term-sheet signing with SEFE marks another milestone, where the Omani LNG will be accessing new market through Germany, and beyond. Going further, the agreement leverages our constant efforts to add value to Oman’s economy through growth and

Port of Antwerp-Bruges

Inoxpa

Oman

PAGE 16 NEWS UPDATE PRODUCT LAUNCHES NEWS UPDATE LNG

Sherwin-Williams

collaborations, especially as we see Oman tapping further on Germany’s technologies and market, more broadly, thus creating a win-win for both.’

‘As pioneers among German companies to embark on this partnership, SEFE is proud to lead the way towards enhanced collaboration. The partnership with Oman LNG diversifies SEFE’s portfolio and reinforces our efforts to continue to reliably supply our customers with energy,’ adds Egbert Laege, CEO of SEFE.

EL MUSEL LNG TERMINAL RECEIVES ITS FIRST COMMERCIAL SHIP

Enagas LNG terminal, El Musel, Gijón, Spain has announced it has received the its first commercial ship, Gaslog Warsaw, after successfully completing the unloading of the first two LNG gas tankers required for the commissioning of the terminal.

The commissioning of El Musel is a milestone for the start of commercial operations of the terminal, which is part of the Government’s More Energy Security Plan, and will strengthen the security of energy supply in Europe.

Jarmo Stoopman, managing director at Gate Terminal, says: ‘Now that all elements are in place, we are happy that today we can start with the construction of this important expansion. We look forward to working with our contractors and ensuring safe and timely construction of this 4th tank.’

LEDWOOD AWARDED £13 MILLION CONTRACT FOR GRAIN LNG

Pembroke Dock-based Ledwood Mechanical Engineering has begun work on a £13 million (€15.1 million) contract to expand the capacity of the largest LNG terminal in Europe located on the Isle of Grain, UK.

Working on behalf of a VINCI Joint Venture (EVT), Ledwood will fabricate 300 tonnes of steel and 280 linear metres of pipework before installation and testing on-site. The contract will create and safeguard up to 65 jobs.

SUMA

This project will create a 190,000 m³ liquified natural gas reservoir as part of the programme to expand the capacity of Europe’s largest LNG terminal. The new full containment tank will consist of a 9% nickel steel inner tank with a prestressed concrete outer shell.

Liam Revell, commercial director for Ledwood, says: ‘Having been instrumental in the construction of the UK’s first three LNG import terminals: South Hook, Dragon and Isle of Grain we provide project management, manufacture and installation of pipework, tanks and mechanical engineering for the LNG sector.’

Netherlands

GATE TERMINAL STARTS CONSTRUCTION OF 4TH LNG TANK AT PORT OF ROTTERDAM

Gate Terminal and its shareholders Gasunie and Vopak, have announced that the final investment decision has been taken to expand Gate Terminal’s storage and regasification capacity in the Port of Rotterdam, the Netherlands.

The €350 million expansion consists of a new LNG storage tank of 180,000 m³ and an additional regasification capacity of 4 BCM per year. The new capacity is already rented out under long-term commercial agreements and is expected to be ready for operation by the second half of 2026.

The Gijón terminal could contribute up to 8 billion m3 of LNG capacity per year to Europe’s security of energy supply. SUMA

The new tank will be constructed alongside the three existing LNG tanks, next to the waterside. Once all envisaged projects at Gate Terminal have been

E-Mail:

SUMA

BRASUMA

■

■

■ Long-term reliability

■ High operational safety

PAGE 17 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE LNG

Rührtechnik GmbH

Str. 21 | 87477 Sulzberg/Germany

Martinszeller

info@suma.de | www.suma.de/en

America Inc. (USA)

| www.gosuma.com

Ltda. (Brasil)

for longterm digester efficiency?

| www.brasuma.com Looking

65 years of experience in mixing of various substrates

Tailored solutions

■ User friendly application , the leading innovator in advancing mixing technology.

United Kingdom

completed, the terminal will have a total regas capacity of 20 billion m³ per year.

Spain

HONEYWELL TO ACQUIRE SCADAFENCE

Honeywell has announced it has agreed to acquire SCADAfence, a leading provider of operational technology (OT) and Internet of Things (IoT) cybersecurity solutions for monitoring large-scale networks. SCADAfence provides asset discovery, threat detection and security governance which are key to industrial and buildings management cybersecurity programs.

Kevin Dehoff, president and chief executive officer, Honeywell Connected Enterprise says: ‘A simple breach in the OT environment has the potential to create safety and business continuity risk for organisations of all sizes. OT assets are inherently different than those in the IT environment as they are domain specific…Adding SCADAfence’s product portfolio will strengthen our capabilities and help our customers defend themselves against cyber security risks which are progressively increasing.’

‘We are thrilled to join Honeywell as we work towards fulfilling our mission of empowering industrial organisations to operate securely, reliably and efficiently… With this acquisition, we are poised to deliver some of the most advanced OT security technology to Honeywell’s broad customer base…’ adds Elad Ben Meir, chief executive officer, SCADAfence.

SCADAfence is headquartered in Tel Aviv, Israel and will expand Honeywell’s Cybersecurity Center of Excellence in Tel Aviv.

The transaction is expected to close in the second half of 2023.

NOVA TRANSPORTADORA DO SUDESTE APPOINTS ATMOS FOR PIPELINE SIMULATION

Nova Transportadora do Sudeste (NTS) has become the latest Latin American pipeline company to select Atmos for its natural gas transmission network.

The NTS network is made up of more than 2,000 km of pipeline and has the highest capacity of all pipelines in Brazil, with a transport contractual capacity of 158.2 million m3 of gas per day. NTS transports natural gas through a pipeline system that crosses Brazil’s most industrialized region and has links to the states of Rio de Janeiro, Minas Gerais and São Paolo.

NTS transports gas to areas that are responsible for around 50% of gas consumption in Brazil. NTS selected Atmos’ Simulation Suite (SIM) to help better understand the pipeline’s behaviour, improve operations and maximise efficiency.

The software is in operation in over 20 countries, supporting approximately 45,000 km of pipelines globally.

NORDIC STORAGE TRIALS NEW OMS

Nordic Storage is implementing a new and improved operating management system (OMS).

André Svensson, one of the company’s HSEC coordinators, explains the benefits: ‘The new OMS is a better and more effective way to ensure the safe, reliable, and responsible operations throughout our business. The aim of the OMS is to achieve quality at all levels and ensure the safety of our company, our customers, and our employees. The OMS describes how we conduct our business, why we do it and evaluates so that we can continuously improve our operations. This enables us to act in accordance with best practice. Everything we do must be anchored in a controlled system that everyone knows about.’

Last year, Nordic Storage attended the Aquarius Energy International HSEC Summit in Fujairah. For the first time the HSEC departments from the entire Aquarius Energy group gathered to share best practice and participate in safety seminars and on-site visits. Svensson shares the key takeaways: ‘We are stronger together than if we function as individual units in the group. By having the summit, the connection within the group becomes stronger and we can share experiences, which benefits everyone in the future.’

Australia

NSW PORTS ANNOUNCES SMARTFLOW DIGITAL SOLUTION IS LIVE

NSW Ports, Australia, has announced its selected comprehensive solutions provider, Platform8 and partners Smartflow digital solution for shipto-shore ISGOTT processes – are now live.

This solution is streamlining NSW Ports’ operations, boosting safety, and ensuring compliance within the maritime industry. The improved visibility and collaboration drives cost and carbon savings.

Josh Davidson, head of technology at NSW Ports says: ‘Working with Platform8 and Smartflow has been a seamless experience. Their solutions have proven to be efficient and reliable. We are impressed with the ease of implementation and the value they bring to our operations. We are excited to explore more of their solutions across our platform.’

NORTHWEST TANK JOINS TANKNOLOGY

Tanknology has announced the acquisition of Northwest Tank and Environmental Services (Northwest Tank), a Washington-based (USA) provider of underground storage tank (UST) compliance services and metre calibrations across various states including Washington, Oregon, Idaho, Montana and more. Allen Porter Tankology president and CEO, says: ‘The transaction is expected to provide significant benefits to both

USA

Europe Israel Brazil PAGE 18 NEWS UPDATE DIGITALISATION

companies’ customer base by adding highly skilled employees, expanding geographic capacity and offering additional proprietary testing and inspection services. Northwest Tank shares in our commitment to a customercentric culture and delivery of the highest quality of service.’

He continues: ‘Our objective has always been to meet the compliance needs of our customers and international partners. The integration of Northwest Tank’s expertise, services, and processes, further expands this mission and positions Tanknology toward many years of growth and industry leadership.’

RIGHTSHIP EXPANDS ACCESS TO DATA PLATFORM

ESG-focused digital maritime platform, RightShip, has launched RightSTORE, a self-service e-commerce platform providing access to RightShip data for accessible products.

As part of RightShip’s commitment to democratising data for the maritime industry, RightSTORE will also host a range of other zero-harm products from trusted partners.

Developed and delivered from RightShip’s technology hub in Singapore, RightSTORE is the key to the proverbial engine room, providing unprecedented levels of access to RightShip’s existing data and information, without the need for a traditional subscription. This new point of entry provides an alternative and cost-effective route to information beyond the traditional subscription model, breaking down data silos and empowering opportunities for innovation beyond the maritime sector.

Steen Lund, CEO, RightShip says: ‘RightShip has always been steadfast in our belief that no single person or entity is responsible for harm reduction; instead, it is the responsibility of everyone at all levels and in all businesses to be a proponent for zero-harm…Through RightSTORE, everyone from students, researchers and educators, through to tech start-ups, consultancies and regulators, will have access at the touch of a button – it’s a powerful opportunity and I’m excited to see where the industry takes it.’

Training to prevent loss of hazardous substances…

EEMUA's MIPC® course helps practitioner-level engineers to be on-site and on top of the latest industry developments and good practice in the primary containment of hazardous substances.

Blending live, online classes, 1-1 sessions with expert tutors, and e-learning, all enhanced by a Mentor’s support and guidance throughout, EEMUA’s Mechanical Integrity Practitioner Certificate course delivers in-depth training to engineers where they work – giving professionals flexibility to learn on-site or on-call, for industry-reconised, 5-year certification.

2-hour Induction adapts the MIPC course to the engineering needs of each Learner and their site/s. Only two MIPC courses run each year...

Next MIPC course of 2023: Learning starts October 2023. Induction to fit work diaries from September 2023.

Registration open now.

For details please contact EEMUA online-learning@eemua.org +44 (0)20 7488 0801 www.eemua.org

TERMINAL NEWS AFRICA & THE MIDDLE EAST

Singapore

MIPC® shortlisted for the Best E-learning/ Online Education Initiative memcom membership excellence awards 2020 and 2022

PAGE 19 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE DIGITALISATION

FITNESS-FOR-SERVICE (FFS)

E²G | The Equity Engineering Group, Inc. provides world-class engineering support for storage tank owners & operators. Our team of experts leverages design, inspection, and advanced analysis experience to solve problems both big and small.

SAFETY. RELIABILITY. INTEGRITY.

WE SOLVE PROBLEMS

⊲ Shell Distortions

⊲ Foundation Settlement

⊲ Structural Concerns

⊲ Overpressure & Overfill

⊲ Cracking & Brittle Fracture

VISIT CONTACT OUR TEAM www.E2G.com Sales@E2G.com ANSWERS FOR TODAY. INSIGHTS FOR TOMORROW. P: +1.216.283.9519 © 2023 E²G | The Equity Engineering Group, Inc.

E 2 G SOFTWARE

We help you ensure safety, manage risk, and maintain profitability throughout your tank’s lifecycle. DAMAGE MECHANISMS ASSESSMENTS

s )

RISK-BASED INSPECTION (RBI)

EQUITY ENGINEERING PRACTICES (EEP

⊲ Corrosion & Metal Loss

IMPROVE STORAGE TANK RELIABILITY

PRODUCTION RESTARTS AT NESTE’S SINGAPORE REFINERY AFTER SHUTDOWN

The production of renewable diesel at Neste’s Singapore refinery expansion restarted in early August 2023.

The production line at the expanded part of the refinery was shut down in June 2023 for unexpected equipment repairs.

The ramp-up of the production at the expanded part of the refinery continues and is planned to be completed by the end of the year.

Sustainable aviation fuel (SAF) production in Singapore is scheduled to start during the third quarter as communicated in Neste’s half-year report in July 2023.

The Singapore refinery expansion doubles Neste’s production capacity in Singapore. With the growth projects in Singapore and Martinez, the company targets to increase its total nameplate capacity of renewable products to 5.5 million tonnes in early 2024.

INEOS AND SINOPEC COMPLETE PETROCHEMICALS DEAL

Global chemical business, INEOS has completed the formation of a 50/50 joint venture with oil and gas business, SINOPEC for the Tianjin Nangang Ethylene Project, China announced in December 2022, which is currently under construction by SINOPEC and expected to be onstream by April 2024.

The petrochemical complex includes a 1.2 MTPA cracker, a new 500ktpa HighDensity Polyethylene plant to produce INEOS pipe grade under license and 11 other derivative units.

The completion of the agreement marks the continued progression of the significant petrochemical deals announced by the parties last year, and highlights the close relationship and growing collaboration between SINOPEC and INEOS.

STOLTHAVEN SINGAPORE WINS DOW SEA S4TAR AWARD

Stolthaven Terminals’ Singapore facility has won the Dow SEA S4TAR award for terminals for the third year in a row.

Dow Chemicals established the S4TAR SEA (South East Asia) programme to enhance collaboration with its logistics services partners in the region and recognise strong performance in safety, service, sustainability and social responsibility.

Stolthaven Singapore underwent a thorough assessment by Dow and scored highly in all four areas. General manager Chek Chai Foo says: ‘Dow rated our service as consistently good and reliable and this was further enhanced through our electronic data interchange project with them. We also scored much higher on sustainability than the three runners-up. This is due to our many local sustainability initiatives, including green terminal transportation.’

China PAGE 21 TERMINAL NEWS AFRICA & THE MIDDLE EAST NEWS UPDATE ASIA

Singapore Singapore

SANTOS BAYU-UNDAN JOINT VENTURE AND TIMOR GAP SIGN MOU FOR CCS

Australian oil and gas exploration and production company, Santos and its Bayu-Undan joint venture partners have signed a memorandum of understanding (MOU) with national oil company, Timor Gap. This is to explore partnership opportunities for the proposed BayuUndan carbon capture and storage (CCS) project offshore Timor-Leste, Asia.

The MoU follows four non-binding MOUs for CO 2 supply to Bayu-Undan CCS that indicate demand for CO 2 storage at BayuUndan CCS could be more than 10 MTPA.

The MOU with Timor Gap includes sharing information about Bayu-Undan CCS and exploring potential partnership opportunities, including equity participation for Timor Gap in the BayuUndan CCS project.

ENI ACQUIRES CHEVRON’S ASSETS IN INDONESIA

Eni has announced the acquisition of Chevron interests, including operatorship, in the Indonesian blocks Ganal PSC (Chevron 62%), Rapak PSC (Chevron 62%) and Makassar Straits PSC (Chevron 72%), in the Kutei Basin, offshore East Kalimantan.

Eni already has a 20% interest as nonoperator in the Ganal and Rapak blocks. The acquisition of Chevron’s assets in Indonesia will allow Eni to fast-track the development of the IDD project, leveraging its strong presence in the East Kalimantan area as well as the synergies with Eni-operated Jangkrik infrastructures, the existing Bontang LNG facility, and the domestic gas market. This acquisition is also in line with Eni’s energy transition strategy to increase the share of natural gas production to 60% by 2030, in conjunction with global demand for accessible, low-carbon and affordable energy. This operation comes shortly after the announcement of Eni’s agreement to acquire Neptune Energy, holding – among others – a significant presence in Indonesia and an excellent fit with Eni operations in East Kalimantan.

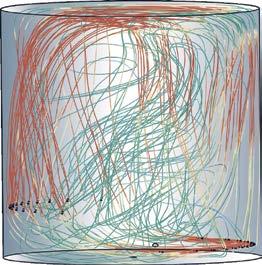

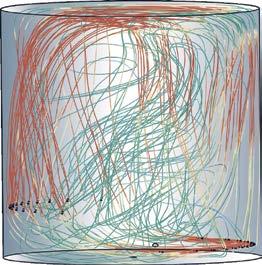

Customised tank mixing solutions

Essential

advantages with Körting tank mixing systems:

• low energy input

• no sealing problems

• low investment costs

• no unmixed dead zones

• wear-resistant operation

• no maintenance in the tank

• complete mixing of tank content

• optimisation with (CFD) Computational Fluid Dynamics

+49 511 2129-221 | sales@koerting.de | koerting.de Asia

NEWS UPDATE ASIA

Indonesia

EXPLORE OUR SOLUTIONS IN UPCOMING EVENTS: TANK STORAGE CONFERENCE & EXHIBITION, 21ST SEPTEMBER 2023 STOCEXPO,12-13TH MARCH 2024 WORLD LEADERS IN COMPOSITE HOSE TECHNOLOGY www.dantec.com sales@dantec.com +44 (0)151 678 2222 • OIL & CHEMICAL TRANSFER HOSES • HOSES FOR LIQUIFIED GASES SUCH AS LPG, AMMONIA AND LCO2 • IN PLANT TRANSFER HOSES

Incident Report: A summary of the recent explosions, fires and leaks in the tank storage industry

31 August 2023

USA

Leak at Calumet hydrogen plant to impact throughput

A leak detected in the steam recovery system at Calumet Specialty Products Partners’ Montana renewable hydrogen plant is limiting throughput until repaired. The company, which manufactures and produces specialty products and renewable fuels, said the leak was detected earlier this month and the repair is expected to be completed in late September.

The Montana plant’s redundant hydrogen systems allow it to continue to run at reduced rates.

The plant expects 8,000 to 8,500 barrels per day of renewable product sales for the third quarter, and the facility is currently processing all untreated feed, according to Calumet.

18

August 2023

SRI LANKA

Fire engulfs Sri Lanka chemical storage facility

A fire broke out in a chemical storage facility in the Homagama Industrial Zone (Katuwana, Sri Lanka) on 17 August.

Seven fire trucks attended the scene, in an attempt to douse the flames at the chemical factory.

A special team of Sri Lanka army personnel was also called to assist with managing the blaze.

The Disaster Management Centre has advised the residents of Homagama to wear face masks to avoid smoke inhalation. Inhaling harmful smoke can inflame lungs and airways, causing them to swell and block oxygen.

No casualties have been reported in the incident.

27 July 2023

UKRAINE

Russia attacks Ukraine port infrastructure

In an overnight missile attack, Russian forces hit port infrastructure in Ukraine’s Odesa region.

The regions governor says a security guard was killed in the attack and there has been damaged to the cargo terminal.

In the previous nine days it has been recorded that Russian air strikes had caused damage to 26 port infrastructure facilities in Ukraine.

10 July 2023

IRAN

Fire at Iran Bandar Abbas Oil Refinery under control

On 10 July, a large fire broke out at Aftab’s Bandar Abbas refinery in southern Iran. It is the second largest refinery in Iran.

As the blaze developed, two of the five neighbouring tanks exploded and eight firefighters sustained superficial injuries. The fire was completely extinguished within three hours.

Unsafe operation of a truck transporting crude oil materials during a period of excessive traffic in the operational area of the refinery led to the fire, which subsequently spread to the manufacturing plant’s storage tanks, Aftab said in a release. Aftab did not reveal whether the fire damaged any processing or production units at the refinery.

PAGE 25 TERMINAL NEWS XXXXXXXXX

INCIDENT REPORT

Save

12 & 13 March 2024

the date.

TANK TERMINAL UPDATE

GREENOCK OCEAN TERMINAL

Products: Port services

Construction/expansion/acquisition: UK port operator, Peel Ports Group, has appointed Turner & Townsend to provide project and cost management for the regeneration of its Greenock Ocean Terminal at Clydeport, Scotland, UK.

As part of improvement works to the Greenock Ocean Terminal, Turner & Townsend project and cost management teams across Scotland will support Clydeport Operations with the replacement of two ship-to-store (STS) cranes, together with upgrading of associated infrastructure.

Comment: James McSporran, Clydeport port director, says: ‘At Clydeport, we are dedicated to providing quality services and effective solutions to our customers. Our partnership with Turner & Townsend on this rejuvenation project highlights our commitment.’

VOPAK EUROTANK

Capacity: 263 x 400m 3

Construction/expansion/acquisition: Vopak Eurotank Antwerp has announced that it has increased its draft to a full 14 m. The Vopak Terminal Eurotank, Antwerp, has 116 tanks and a capacity of 263,400m 3

Comment: The increase to the draft means that Vopak Eurotank Antwerp can now offer customers an enhanced service.

DURA VERMEER

Construction/expansion/acquisition: Construction and infrastructure services group, Dura Vermeer is responsible for part of the dismantling of the Rotterdam company Aluchemie on the Oude Maasweg.

Comment: The work is expected to start in October 2023. The operation should be completed by mid-2025. A small team of Aluchemie employees will continue to work to manage the dismantling in collaboration with Dura Vermeer.

ADNOC GAS

Products: Gas

Construction/expansion/acquisition: ADNOC Gas, the world-class integrated gas processing company, has announced a $3.6 billion (€3.3 billion) contract to the joint venture between National Petroleum Construction Company and Tecnicas Reunidas to expand its gas processing infrastructure in the UAE.

FLUOR

Construction/Expansion/Acquisition: Fluor Corporation has announced that it was awarded an engineering, procurement and construction (EPC) contract by Mitsubishi Chemical Group for its SoarnoL ethylene vinyl alcohol copolymer (EVOH) facility in Saltend Chemicals Park, Hull, UK.

VTTI

Products: Bio-energy

Construction/expansion/acquisition: Energy storage infrastructure companies, VTTI has begun construction on its first bio-energy production plant in the UK. When complete the plant will produce 60 gigawatt hours (GWh) of renewable natural gas per year in Lincolnshire, UK. This is enough clean energy to heat over 5,000 homes annually.

Comment: The facility will be part of VTTI’s growing portfolio of bio-energy facilities in Europe. Commercial operations at the facility are due to begin in the second half of 2024.

Comment: Over 70% of the award value will flow back into the UAE’s economy under ADNOC’s successful In-Country Value (ICV) program, supporting local economic growth and diversification.

Comment: When complete and operational in 2025, the Saltend Chemicals Park EVOH facility will be Mitsubishi Chemical Group’s second largest SoarnoL site in the world.

PAGE 27 TANK TERMINAL UPDATE

United Kingdom

Antwerp

UAE

Rotterdam

United Kingdom

United Kingdom

TANK TERMINAL UPDATE

Belgium

LBC TANK TERMINALS

Capacity: 80,000 m³

Construction/expansion/acquisition: LBC Tank Terminals has taken the final investment decision to expand the terminal in Antwerp, Belgium and has started the construction of 28 tanks, collectively providing a significant storage capacity of 80,000 m³.

Comment: ‘With high energy prices, chemicals production in northwestern Europe is under increasing competitive pressure, while Middle Eastern and USbased producers have an advantage with access to lower priced feedstock,’ says Erik Kleine, general manager Europe.

PROJECT SPOTLIGHT: Odisha, India

INDIAN OIL CORPORATION

Estimated budget: €67.7 million

Contract value: €33.1 million

Main contractor: Artson Engineering Limited

Location: Odisha, India

Expected completion date: Q2 2024

INDIAN OIL (IOCL) plans to construct 10 new tanks Paradip Refinery. The tanks will be built along with allied facilities at the refinery. The new assets would comprise of feed tanks for diesel hydrotreater (DHDT), naphtha hydrotreating (NHT), vacuum gas oil (VGO), catalytic hydrotreating (HDT) and product tanks for MS, liquid sulphur, alkylate, and PCK.

In November 2020, Artson Engineering Limited (AEL) was awarded the EPC contract for the project. The contract scope includes the design, supply, fabrication, testing, and commissioning of storage tanks, including associated works. Construction work on the project then began in February 2021.

QUANTEM

Cost: $56 million (€33.8 million)

Construction/expansion/acquisition:

Provider of bulk liquid storage terminals across Australia and New Zealand, Quantem has announced a project to more than double the diesel storage capacity at its Pelican Point terminal in Adelaide, South Australia.

Comment: Quantem managing director and CEO Nick Moen says: ‘This project is a critical component of enhancing Australia’s domestic fuel security and safeguarding future supplies for the country’s transport sector and industrial supply chains which are vital to Australia’s infrastructure requirements.’

The additional tanks will increase the ullage and help sustain the refinery’s crude throughput during the outage of any secondary processing unit.

THE PROJECT SO FAR

The intital plan and budget was developed in November 2018. By December 2019, IOCL had issued an Engineering, Procurement, and Construction (EPC) tender for the storage tanks on a Lump Sum Turnkey (LSTK) basis for the project.

In mid-2021, SOPAN was awarded a contract for the composite works, and by the end of the year, the overall progress of the project had reached 60% completion.

A year later, in December 2022, the piping, structural fabrication, and erection works began.

The diesel hydrotreater (DHDT) tank’s hydro test was completed in June 2023, while internal blasting and painting of the bottom and the external painting of the shell began to progress. The overall physical progress of the project has reached 86.1%, and it is scheduled for completion by April 2024.

MABANAFT

Capacity: 461,652 m 3

Construction/expansion/acquisition: Mabanaft has expanded its storage footprint into Denmark by acquiring 100% of Oiltanking’s terminal in the capital, Copenhagen. Under Mabanaft’s ownership, the terminal will continue to handle liquid fuels for road transport and the marine and aviation industries.

Comment: ‘This terminal adds another key location to our network and will enable us to expand our footprint in Europe and help us provide high-quality liquid fuel products to our customers in the region, while maintaining the highest safety and environmental standards,’ says Mabanaft CEO, Jon Perkins.

PAGE 28

Australia Copenhagen

GLOBAL PROJECT UPDATE

A round-up of key terminal projects worldwide, powered by DMS Global

Quezon, Philippines

PETRONAS - BINTULU ADDITIONAL GAS SALES FACILITIES 2 (BAGSF-2)

Sectors: Gas

Facility: Storage Tanks, Liquefied

Natural Gas (LNG)

Budget: € 184,000,000

Status: Construction

Project date: 2021-Q4 – 2025-Q4

Ulsan, South Korea

KNOC - ULSAN OIL STORAGE HUB

Sectors: Onshore

Facility: Offsite & Storage Tanks

Budget: € 1,380,000,000

Status: Construction

Project date: 2009-Q1 – 2026-Q1

ENERGY WORLD - PAGBILAO (QUEZON) LNG TERMINAL

Sectors: Gas

Facility: LNG Terminal, LNG Regassification, Storage Tanks, Liquefied Natural Gas (LNG)

Budget: € 460,000,000

Status: Construction

Project date: 2006-Q2 – 2024-Q4

Jurong, Singapore

GOLAR LNG - FLOATING LIQUEFIED NATURAL GAS VESSEL CONVERSION PROJECT

Sectors: Gas

Facility: Storage Tanks, Liquefied Natural Gas (LNG)

Budget: € 1,196,000,000

Status: Engineering & Procurement

Project date: 2012-Q4 – 2023-Q4

KOGAS - MUI KE GA LNG REGASIFICATION TERMINAL

Sectors: Gas

Facility: LNG Terminal, LNG

Regassification, Storage Tanks, Liquefied

Natural Gas (LNG)

Budget: € 1,380,000,000

Status: Feasibility Study

Project date: 2019-Q3 – 2025-Q4

SAUDI ARAMCO - GAS STORAGE FACILITIES

Sectors: Gas

Facility: Storage Tanks

Budget: € 920,000,000

Status: Project Announced

Project date: 2019-Q4 – 2025-Q4

Ras Markaz, Oman

VTTI - ATT TANJUNG BIN (ATB) OIL TERMINAL

Sectors: Onshore

Facility: Offsite & Storage Tanks

Budget: € 552,000,000

Status: Construction

Project date: 2009-Q3 – 2024-Q2

Hail, Saudi Arabia

SAUDI ARAMCO - HAIL BULK PLANT

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 276,000,000

Status: On Hold

Project date: 2013-Q2 – 2021-Q4

Jamnagar , India

GSFC - SIKKA FERTILIZERS COMPLEX EXPANSION

Sectors: Chemicals

Facility: Diammonium Phosphate (DAP), Phosphoric Acid, Offsite & Storage Tanks, Fertilizer, Ammonia

Budget: € 157,320,000

Status: On Hold

Project date: 2012-Q4 – 2023-Q4

Doha, Qatar

QATARENERGY - HAMAD

INTERNATIONAL AIRPORT JET A1 FUEL STORAGE TANKS

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

OTTCO - RAS MARKAZ CRUDE OIL PARK - PHASE 2 - CRUDE OIL TANKS AND ASSOCIATED INFRASTRUCTURE

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 851,000,000

Status: Project Announced

Project date: 2012-Q4 – 2025-Q4

Ras Markaz, Oman

OTTCO - RAS MARKAZ CRUDE OIL PARK - PHASES 3, 4, AND 5 - CRUDE OIL TANKS AND ASSOCIATED INFRASTRUCTURE

Sectors: Exploration & Upstream

Production

SAUDI ARAMCO - STORAGE TANKS

Sectors: Exploration & Upstream

Production, Gas, Infrastructure

Facility: Storage Tanks

Budget: € 230,000,000

Status: Engineering & Procurement

Project date: 2020-Q2 – 2022-Q4

Budget: € 368,000,000

Status: Construction

Project date: 2018-Q4 – 2022-Q3

Facility: Offsite & Storage Tanks

Budget: € 193,200,003

Status: Project Announced

Project date: 2012-Q4 – 2027-Q4

PAGE 30

Tanjung Bin, Johor, Malaysia

Bintulu, Sarawak Malaysia

Saudi Arabia

Binh Thuan, Vietnam

TANK TERMINAL UPDATE

Saudi Arabia

PTT - LPG STORAGE TERMINAL

Sectors: Gas

Facility: Liquefied Petroleum Gas (LPG), Storage Tanks

Budget: € 460,000,000

Status: On Hold

Project date: 2013-Q1 – 2022-Q4

GULF PETROCHEM - FUJAIRAH OIL STORAGE TERMINAL FACILITYPHASE 2 - EXPANSION

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 276,000,000

Status: On Hold

Project date: 2014-Q1 – 2025-Q1

VTTI - IL&FS PRIME TERMINALS

FZC (IPTF) - PHASE 2 - EXPANSION

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 138,000,000

Status: EPC ITB

Project date: 2016-Q1 – 2024-Q1

BPGIC - FUJAIRAH OIL TERMINALOVERVIEW

Sectors: Exploration & Upstream

Production, Onshore

Facility: Offsite & Storage Tanks

Budget: € 516,120,000

Status: FEED

Project date: 2013-Q1 – 2025-Q2

ZAHARA GROUP - AL HAMRIYAH STORAGE TERMINAL

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 184,000,000

Status: On Hold

Project date: 2014-Q1 – 2024-Q2

QATARENERGY - OIL STORAGE TANKS OVERHAUL WORKS

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 55,200,000

Status: Construction

Project date: 2016-Q3 – 2024-Q1

SKA ENERGY - KAFZA TANK

TERMINAL - PHASE 3 - OIL

STORAGE TANK

Sectors: Gas

Facility: Storage Tanks

Budget: € 230,000,000

Status: On Hold

Project date: 2013-Q1 – 2024-Q4

ADNOC - EMARAT - FUJAIRAH

TERMINAL - PHASE 3 - EXPANSION

Sectors: Exploration & Upstream

Production

Facility: Offsite & Storage Tanks

Budget: € 36,800,000

Status: On Hold

Project date: 2014-Q3 – 2024-Q4

SAUDI ARAMCO - BULK PLANT

TERMINAL

Sectors: Onshore

Facility: Offsite & Storage Tanks

Budget: € 368,000,000

Status: On Hold

Project date: 2016-Q4 – 2020-Q1

KOC - WARA PRESSURE

MAINTENANCE PROJECT - TRAIN 3

Sectors: Exploration & Upstream

Production, Onshore

Facility: Development Drilling & Production, Oil Field, Offsite & Storage

Tanks

Budget: € 172,040,000

Status: Construction

Project date: 2013-Q2 – 2023-Q2

SAUDI ARAMCO - STORAGE TANKS AND ASSOCIATED EQUIPMENT

Sectors: Gas

Facility: Storage Tanks

Budget: € 368,000,000

Status: Construction

Project date: 2015-Q1 – 2022-Q2

IL&FS PRIME TERMINALS FZCFUJAIRAH OIL TERMINALS - PHASE 2 - OIL TERMINAL FARM

Sectors: Exploration & Upstream

Production, Onshore

Facility: Offsite & Storage Tanks

Budget: € 73,600,000

Status: On Hold

Project date: 2017-Q1 – 2023-Q2

GTI FUJAIRAH FZC - FUJAIRAH OIL STORAGE TERMINAL - PHASE 3PETROLEUM TANK FARM

Sectors: Exploration & Upstream

Production, Gas

Facility: Offsite & Storage Tanks

Budget: € 92,000,000

Status: On Hold

Project date: 2010-Q1 – 2023-Q4

SAUDI ARAMCO - STORAGE TANKS AND ASSOCIATED EQUIPMENT

Sectors: Gas

Facility: Storage Tanks

Budget: € 184,000,000

Status: Construction

Project date: 2016-Q1 – 2022-Q4

TOTALENERGIES - PAVILION ENERGY - LNG BUNKER VESSEL

Sectors: Gas

Facility: Storage Tanks, Liquefied Natural Gas (LNG)

Budget: € 27,600,000

Status: Construction

Project date: 2017-Q2 – 2023-Q1

PAGE 31

Fujairah, UAE

Thilawa , Myanmar

Fujairah, UAE

Fujairah, UAE

Fujairah, UAE

Southeast Kuwait, Kuwait

Sharjah, UAE

Halul Island, Qatar

Basra, Iraq

Fujairah, UAE

Duba, Saudi Arabia

Yanbu , Saudi Arabia

Eastern Indonesia, Indonesia

Fujairah, UAE

Jurong, Singapore

TANK TERMINAL UPDATE

SATORP - AMIRAL PETROCHEMICAL COMPLEX - PACKAGE 5A - TANK FARM

Sectors: Petrochemicals, Plastics, Onshore

Facility: Offsite & Storage Tanks

Budget: € 552,000,000

Status: Engineering & Procurement

Project date: 2017-Q3 – 2025-Q4

MITSUI OSK LINES - BRASSAVOLA LNG BUNKER VESSEL

Sectors: Gas

Facility: Storage Tanks, Liquefied Natural Gas (LNG)

Budget: € 161,000,000

Status: Commissioning

Project date: 2019-Q1 – 2023-Q3

ADNOC ONSHORE - WEST TO EAST PIPELINE (WEP)

Sectors: Pipeline, Onshore

Facility: Pumping Station, Offsite & Storage Tanks, Oil

Budget: € 736,000,000

Status: FEED

Project date: 2019-Q3 – 2025-Q4

IOCL - KANDLA LPG IMPORT TERMINAL AUGMENTATION

Sectors: Gas

Facility: Liquefied Petroleum Gas (LPG), Storage Tanks

Budget: € 84,272,000

Status: Construction

Project date: 2018-Q1 – 2023-Q3