1 minute read

ENABLING WAAM IN MANUFACTURING AIRCRAFT LANDING GEAR

Landing gear systems are one of the most critical components of an aircraft, providing principal support for the aeroplane when parked, taxiing, taking o or landing. To meet the stringent demands of bearing large loads in long-term service, 300M ultra-high strength steel (UHSS) is regarded as one of the most ideal materials for manufacturing aircraft landing gear, benefiting from its high strength, sound toughness and excellent fatigue performance. However, severe notch sensitivity and local stress concentration make 300M UHSS challenging to be processed into complex structures using conventional forging techniques. Moreover, a massive post-machining workload is required in the manufacturing process after forging, significantly increasing the Buy-To-Fly (BTF) ratio and prolonging the lead time. Currently, industry-wide, manufacturers across the world are seeking manufacturing processes, designs and methods with the purpose of reducing the cost of manufacture, lead times and supporting the race to net zero. Wire Arc Additive Manufacturing (WAAM) o ers an alternative approach with great promise for 300M UHSS landing gear due to high cost-e ectiveness, short lead time and design flexibility.

The Welding and Additive Manufacturing Centre at Cranfield University recently teamed up with Airbus to demonstrate the feasibility and reliability of using WAAM technology in depositing steel landing gear components. The project was funded by the Aerospace Technology Institute (ATI), the ‘Hybrid Direct Energy Deposition Sprint’ project, with partners including National Manufacturing Institute Scotland (NMIS), Cranfield University and the Northern Ireland Technology Centre (NITC) at Queen’s University Belfast, along with an industry steering group of more than ten companies.

To ensure that WAAM can produce aircraft landing gear that is free from defects and performs to the required standard, Cranfield conducted a comprehensive investigation of WAAM 300M UHSS. This involved feature deposition studies, interface studies, and post-heat treatment studies. In the feature deposition work, both gas metal arc (GMA) and plasma transferred arc (PTA)-based WAAM processes were applied to deposit various features under di erent shielding conditions. It was found that both GMA and PTA-based WAAM are feasible for the manufacture of defect-free 300M features. However, all the as deposited 300M features had lower strength but higher ductility compared with forged ones. To overcome this, a post-heat treatment investigation was done by austenisation using oil quenching, followed by low-temperature tempering with water cooling. These treatments refined primary austenite grains through recrystallization, dissolved the carbide precipitates, and eliminated residual stress, thereby obtaining good comprehensive performances. The results show that this heat treatment scheme could normalize the microstructure and mechanical performance evolution along the building direction and make the strength and fracture toughness of the WAAM 300M deposits meet the qualification. These fundamental studies provide su cient confidence to apply WAAM to produce aircraft landing gear.

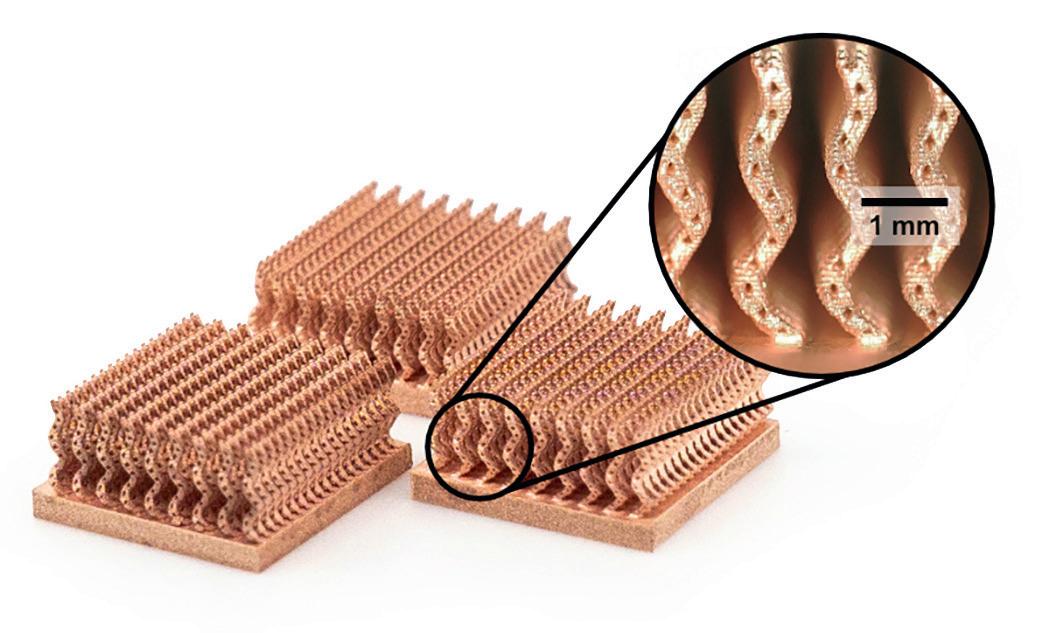

Subsequently, a 300M UHSS Landing gear demonstrator was deposited using the PTA-based WAAM method with optimized process parameters. The demonstrator with dimensions