3 minute read

SPACE BOUND

Oli Johnson speaks to Dr. Luis Fernando Velásquez-Garcia, a Principal Research Scientist at MIT about a project involving 3D printed sensors for satellites.

In August 2022, Massachusetts Institute of Technology (MIT) published research from a team that created completely digitally manufactured plasma sensors for satellites such as CubeSats, known as retarding potential analyzers (RPAs). The research team said that the 3D printed and laser-cut hardware performed just as well as state-of-the-art semiconductor plasma sensors that are manufactured in a cleanroom. CubeSats are a type of research spacecraft that typically weigh less than 1.33 kg (3lbs).

So what exactly is an RPA? An RPA is a type of sensor used in satellites to detect energy in ions in the ionosphere, and have been used in space missions since 1959. The ionosphere is made of plasma, which is a state of matter that occurs when gas is heated, and stretches roughly 50 to 400 miles above Earth’s surface, right at the edge of space. Along with the neutral upper atmosphere, the ionosphere forms the boundary between Earth’s lower atmosphere, and the vacuum of space. A lot of the issues surrounding global warming are influenced by what happens in this region.

Dr. Luis Fernando Velásquez-Garcia, Principal Research Scientist at MIT’s Microsystems Technology Laboratories (MTL) and senior author of the study,

told TCT: “The truth is, we don’t know enough about the ionosphere. So we really need better instruments and better data to be able to develop better models and to be able to face the global warming phenomenon. The second issue that an RPA can help you with is a mass spectrometer. Mass spectrometers are the gold standard for chemical analysis. If you want to know the composition of a sample, then you use mass spectrometry. They are based on using electromagnetic fields to sort out the ionized sample.”

Dr. Velásquez-Garcia said that having more information and better information on the ionosphere will allow for better predictions on weather conditions, and give a better understanding of things like the water cycle and how water is lost and replenished, which he says will be very useful.

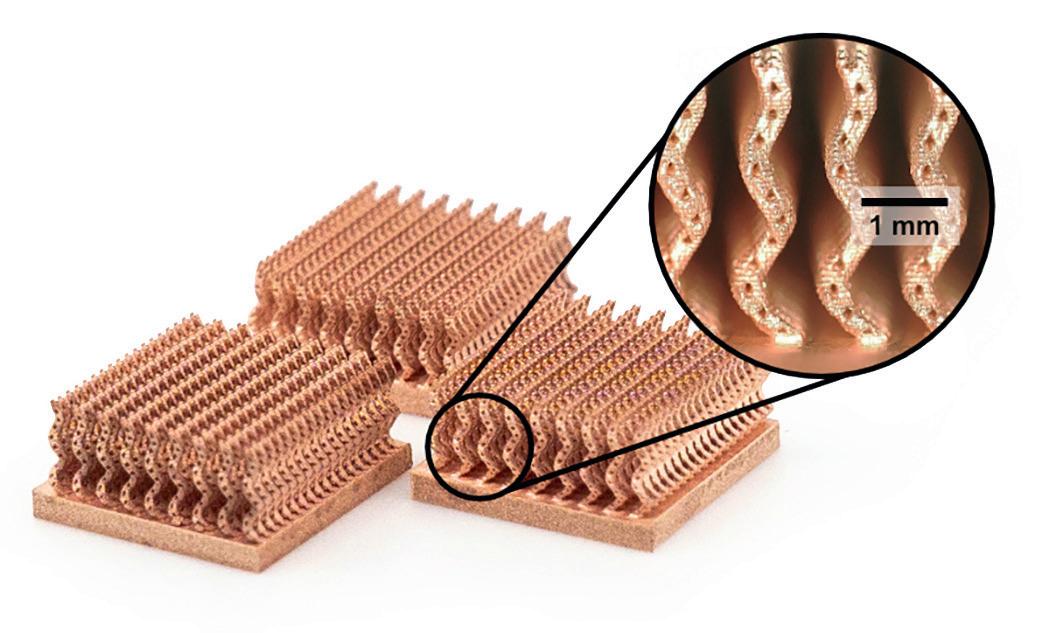

RPA’s include a dielectric, also known as an insulator. The team led by Dr. Velásquez-Garcia manufactured this part using VAT photopolymerization for this project, and printed it in a glass ceramic material.

Dr. Velásquez-Garcia added: “The process is fairly safe and fairly robust, but it has been mainly used to make polymeric parts. There are new advances in the technology and that’s how we can make the parts out of this ceramic. This is very important because the traditional way to make ceramics with additive manufacturing is using powders and a laser, and at the end you get this part that is coarse and there is porosity, so it’s not something that’s really meant to be used in space.”

The team that worked on this project are also working on other kinds of hardware for CubeSats, such as propulsion systems, mass spectrometers and Langmuir probes. Speaking about this, and how AM is being used in this area, Dr. Velásquez-Garcia said: “We are taking this vision of how to make better hardware via multi-material 3D printing. In some cases, the technology is not quite there, so what you need to do is create new printing capabilities, and that’s some of the work that we have done. For example, we have harnessed micro plasmas, which are plasmas that you can strike atmospheric pressure and with that you can create high-quality materials.”

Speaking further about the potential for multi-material 3D printing in aerospace, Dr. Velásquez-Garcia added: “In my view, multi-material additive manufacturing has a tremendous role for space, and in particular CubeSats. I feel that CubeSats are like an unfulfilled promise, by that I mean we can make them better and more capable, and in many cases, take over the traditional satellite. Traditional satellites are made with something that is called a death spiral. This is an issue because failure is very expensive, there is a redundancy in the systems and you end up having very big, very expensive pieces of hardware. I think the idea to make these compact satellites is an amazing idea, but it hasn’t been fulfilled because we really need to apply all our ingenuity to make the very best hardware we can, and at a very low cost. With that, I think we can break this cycle and be able to make the technology accessible to many people. Space does not need to be something that is only accessible to a few countries, I think the big issue is the barrier in the cost.”