1 minute read

TANIOBIS

Based on our 60 years expertise in manufacturing and development of refractory metals, we have developed AMtrinsic® atomized tantalum and niobium spherical powders and their alloys for demanding additive manufacturing technologies. Our ability to adjust specific intrinsic material properties enables us to push the limits according to the requirements of your application.

AMtrinsic® spherical tantalum and niobium powders provide outstanding combinations of material properties customized for specific applications. Aligned with 3D-printing technology, AMtrinsic® powders can help overcome hurdles in various high-tech industries. The high temperature stability, excellent corrosion resistance and biocompatibility of AMtrinsic® Ta, Nb powders and their alloys deliver a perfect fit for biomedical (Ta, TNT and TNTZ), chemical (Ta, Nb, Ta-W) and aerospace (Ta-W, C103 and FS-85) applications. In addition, AMtrinsic® Nb with its prominent superconducting properties is ideal for the superconducting industry.

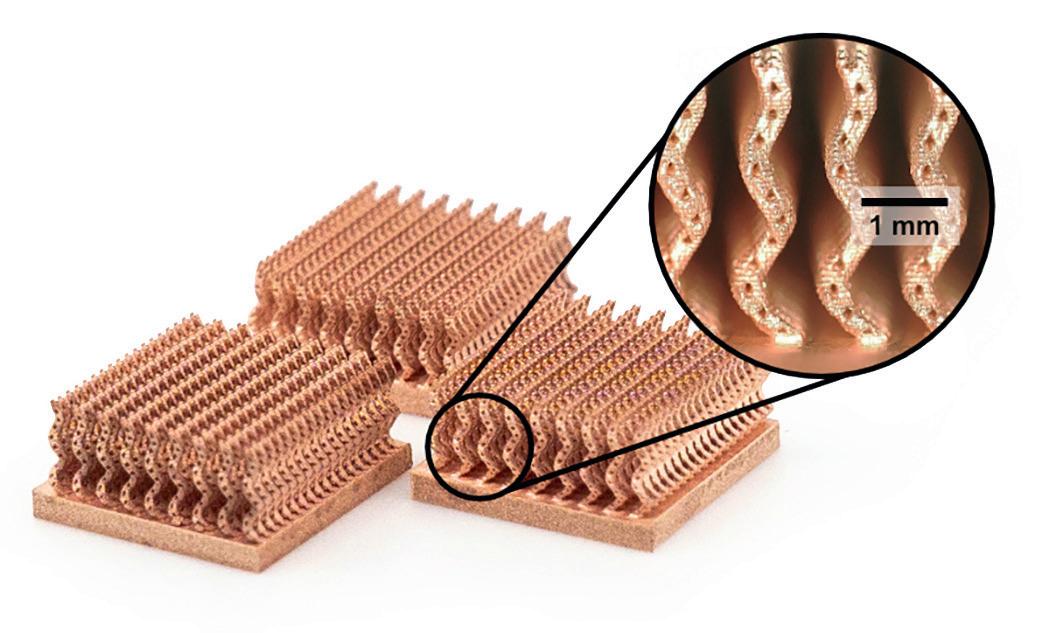

TANIOBIS has recently expanded its AMtrinsic® portfolio adding C103 (Nb-10Hf-1Ti) and FS-85 (Nb-28Ta10W- 1Zr) pre-alloyed powders. High-temperature strength, superior creep properties and their excellent workability with Additive Manufacturing make these alloys great candidates as structural material for various aerospace applications. AM offers design freedom enabling manufacturing of lightweight components with complex features e.g. rocket thruster with integrated cooling channels which is one of the applications of our AMtrinsic® C103 and FS-85 alloys.