7 minute read

From Everett to Livermore Paging Dr. O

Kip Hanson

TOlga Ivanova has 3D-printed plenty of interesting parts during her time in manufacturing.

Rocket nozzles. Turbine blades and impellers. Neonatal tracheostomy tubes. There are more, which we’ll get to in a moment, but to Star Wars fans, it’s the Static Dissipative Yoda that’s most intriguing.

yler LeBrun’s LinkedIn page describes his work at Sandia National Laboratories as “all things additive manufacturing (AM) all the time.” It’s a fitting motto, although LeBrun could just as easily have said “all things aerospace,” or even “all things materials.” That’s because this graduate of Berkeley and Southern California universities has worked for some of the leading aerospace firms in the world—namely, Boeing, Blue Origin, and Aerojet Rocketdyne—and somewhere in between, earned his doctorate in materials engineering from Osaka University in Japan.

“We printed a bunch of Yoda and Groot (Guardians of the Galaxy) figurines for high school students who visited our facility recently,” said Ivanova, director of technology at Mechnano, an additive manufacturing materials developer near Phoenix. “It’s our way of getting young people interested in additive manufacturing.”

Padawan Learning

LeBrun is also involved in numerous standards organizations, among them the ASTM Committee F42 on Additive Manufacturing Technologies, the International Organization for Standardization Technical Committee (ISO/TC)-261 on Additive Manufacturing, SAE International’s Aerospace Materials Specification group, and SME’s Additive Manufacturing Technical Community. Given his passion and 15 years of wide-ranging industry experience, he has brought significant value to each of these companies and groups.

She’s quick to point out that those educational giveaways were made of a gray-colored base resin, not the more expensive static dissipative material (which is black) that she spends much of each day working with—and yes, which she occasionally uses to print Yodas that are just as resistant to electrical charge as they are to the Dark Side of the Force.

All Things Additive

“I guess you could say that standards are my shtick,” said LeBrun. “Years ago, the FAA (Federal Aviation Administration) chartered the Society of Automotive Engineers to write standards for additive manufacturing. That’s where I first got involved in this area, because we used those documents most prevalently at Rocketdyne and Blue Origin. I’ve since spent considerable time volunteering with various committees, and am the document sponsor for a handful of industry standards that support binder jetting and laser powder bed fusion (LPBF) in aerospace.” that follows that same path, moving beyond pure research into using additive as a tool for production.”

Securing a Peaceful World

May 17 19 in Detroit, is proof positive as to how far AM has

This last part brings up another of LeBrun’s favorite topics: binder jet. Although he’s a big fan of LPBF, directed energy deposition (DED), and any other technology that produces metal or polymer parts one layer at a time, it’s binder jet that has a special place in his analytical heart. “Binder jetting is a great tool for producing a lot of the types of parts that we consider good candidates for additive, but at the same time, it’s also very cost effective,” he said. “I’m confident that we’re going to see the automotive industry pick it up because of its productivity advantage over laser powder bed, so it’s something that we don’t want to be caught flat-footed on for standards. And from my side, it fits a sweet spot for much of the work we do here.”

The AM community took center stage throughout the show. This includes the passing of the baton in two key leadership positions. John Barnes assumed the chair of the Additive Manufacturing Technical Community Leadership Committee, succeeding Christopher Williams; and Sarah Rimini now chairs the Medical AM Advisory Committee, succeeding Amy Alexander. I’d like to thank Christopher and Amy, who provided exemplary leadership and vision during their tenures, and welcome their replacements.

That work includes quite a bit of fundamental research and development within the AM space. “For instance, we have a number of scientists working on things like material characterization, process monitoring, and investigating different technologies across the entire AM spectrum,” said LeBrun.

3D-printing services. At RAPID + TCT, she moderated a panel discussion on 3D printing for point-of-care medical applica tions. The panel was one of several during a special town hall hosted by the Medical AM Advisory Team.

He’s in good company. Sandia has a 70-year history as an applied science and technology hub for the United States. Its multidisciplinary research activities include everything from advanced computing systems and biomass conversion to “keeping the U.S. nuclear stockpile safe, secure, and effective.” The government-funded agency boasts an operating budget of $3.9 billion, more than 900 buildings across five locations, and a workforce of 14,500, most of whom are fulltime employees.

LeBrun has been part of this team since late 2020. Aside from the tasks described earlier, he’s actively involved in defining qualification strategies and methods for the parts, materials, and processes that may support one of the many end-use applications Sandia delivers.

Other highlights included the winners of the 2022 SME Additive Manufacturing Community Awards: Slade Gard ner, founder of Big Metal Additive (Industry Achievement); VELO3D and IMI Critical Engineering (Aubin AM Case Study); and Virginia Tech students Daniel Chirvasuta, Nathanael High, Matthew Martin, Benjamin Nguyen, Omkar Shinde, and Nicolas Tomanelli (Digital Manufacturing Challenge).

To help foster the next generation of innovators, the SME Education Foundation’s Bright Minds Program welcomed nearly 1,000 middle and high school students to RAPID + TCT. There also was a special networking lunch for young professionals and a Career Forum Panel. The initiative is led by Ellen Lee and Jennifer Coyne, who are both advisors on the Additive Manufacturing Technical Community Leadership Committee.

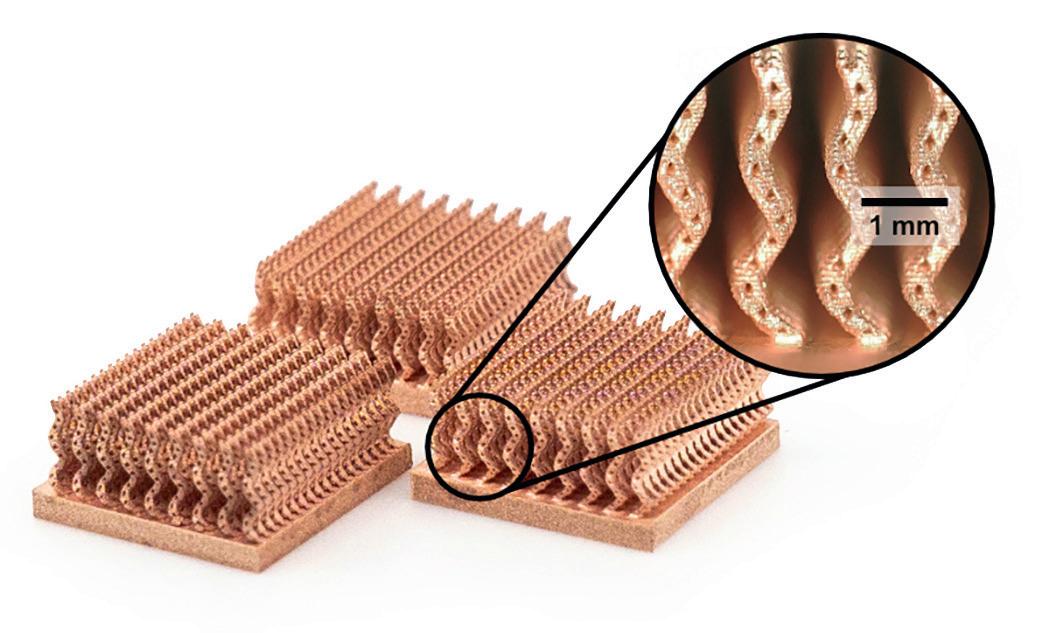

One example of these applications was when Sandia geoscientists used 3D-printed rocks to understand how fracking and carbon dioxide sequestration can lead to earthquakes. Technicians there have also used AM to print electrical circuits in High Operational Tempo (HOT) Shot rockets, eliminating the need for cables. Molds for wind turbine blades, mounts for quantum sensing devices, a lightweight, low-cost telescope—these are just a few of the research projects the Sandia additive team has worked on in recent years, many of them during LeBrun’s tenure.

John, who heads The Barnes Global Advisors and Metal Powder Works, has been involved in metal additive manufacturing throughout a distinguished career. He’s led teams that qualified the aerospace industry’s first series production metal AM parts, and developed a pilot metal production facility.

As an AM lead at Sandia’s facility in Livermore, California, it’s his job to support these efforts and help create strategies for deploying 3D printing equipment in the most productive and cost-effective manner possible. Much of his time is spent transitioning the lab’s decades of research and knowledge of AM into production-ready tools and processes, a large percentage of which has been focused on LPBF; as he sees it, this is where he’s able to add the greatest value to the national labs.

As senior manager of Ricoh’s Healthcare Center of Excellence, Sarah is developing a curriculum for the company’s Learning Institute that focuses on medical managed

Said LeBrun, “My background has largely been in aerospace, and I have more than a decade’s worth of hands-on experience in leveraging additive manufacturing to produce hardware specifically for space propulsion. That means leveraging the technology to make actual parts, inspect and qualify them, prove that they work, and then use them in the field. So I’m here to try and help create a standard approach

Rising Waters

SME Media also interviewed dozens of AM leaders during RAPID + TCT as part of its Voices AMplified initiative that showcases the people behind the technology. This month’s Voices AMplified report profiles two such visionaries: Olga Ivanova and Carl Dekker. Known as “Dr. O,” Olga has worked on innovative projects for the medical and defense industries, and is a tireless crusader for advancing AM.

Carl puts the emphasis on people. He leads a talented team at Met-L-Flo, which produces a wide range of 3D-printed products. He also chairs the Direct Digital Manufacturing Advisory Team and moderated a panel at RAPID + TCT.

The work extends beyond the purely scientific. It also helps the additive community in some very tangible ways. LeBrun explained that much of the research and development at Sandia centers around technologies that are either cost prohibitive or don’t have the guaranteed payoff that industry stakeholders might want to invest in. These high-risk, high-reward activities are often less attractive to organizations that are fiscally conservative, but in the end, produce a rising technological tide that lifts all boats equally.

Carl and Olga represent the spirit behind Voices AMplified. I hope you enjoy their stories.

“Within the next couple of years, we are planning to open a facility that will expand our footprint in research and development into AM,” LeBrun said. “Our goal is to double down on additive and, more broadly, advanced manufacturing, investing the resources and human capital needed to push that frontier even further.” trades, master-of-none approach to machine development, and while there’s some merit to specialization, it does make general-purpose adoption more difficult.

Sandia and LeBrun’s team also work with other research organizations, including Lawrence Livermore, Los Alamos, and Ames National Laboratories. In December, LeBrun hosted an AM alloy development workshop. Staff members from each of these institutions came together to share notes and compare what they were working on, collaborating on ways to straddle the academic and industrial worlds and hopefully make AM easier for both.

Although their movie counterparts possess awesome superpowers, the 3D-printed Baby Yodas (at left) and Groots (right) that Olga Ivanova gave to visiting high school students are unable to do so much as dissipate electrical charge--but they’re still very popular with the kids.

Keep it in America

“I attended an America Makes meeting recently that touched on some of these challenges,” LeBrun said. “The level of engineering skills, the learning curve, and the financial resources needed to develop robust AM capabilities can be prohibitive, which is why there needs to be some coalescence around industry standards and standard operating procedures and ways to make the technology more turnkey for these smaller consumers. You shouldn’t need a PhD to 3D print quality parts. That’s just not sustainable.”

It’s the AM integrators, equipment manufacturers, and aerospace OEMs that will need to drive the industry forward, he suggested, although the government has a role to play as well. As an example, he pointed to the Biden administration’s AM Forward initiative, which the White House website describes as a voluntary compact among large manufacturers, supported through several current and proposed federal initiatives, designed to help smaller U.S.based suppliers increase their use of AM.