6 minute read

RAPID + TCT: FIRST LOOK

North America’s largest and most influential additive manufacturing event returns to Detroit on 17-19th May.

Following its 30-year anniversary in 2021, the additive manufacturing community will reconvene in-person at RAPID + TCT 2022 where more than 300 hands-on exhibits from the industry’s leading figures will take over Huntington Place, Detroit.

This year also marks SME’s 90th year of supporting and advancing manufacturing technologies throughout North America. For additive manufacturing technologies, RAPID + TCT continues to be a launch pad for the latest and greatest in innovation in the U.S. and this year is set to be no different as the show floor and packed conference line-up promise next-level solutions to real-world challenges.

"For more than 30 years, AM has experienced dynamic growth that continues to unlock unlimited potential for manufacturers," SME Executive Director and CEO Robert Willig said. "RAPID + TCT has defined and established a field that conceives, tests, improves and manufactures new products that are not only more cost-efficient, but are truly lifechanging. Combining decades of 3D technology insights and experiences with the latest evolving trends in AM, RAPID + TCT is the place to be for players of any size in the AM industry. We can feel the support and excitement within the AM community from far and wide, and we're looking forward to another successful event."

Whether it’s metal or polymer systems from Desktop Metal to Formlabs, software solutions by nTopology to Materialise, postprocessing technology from DyeMansion to PostProcess Technologies, materials from BASF to Covestro, 3D scanning solutions from FARO to Nikon, or services from Dinsmore to Xometry, the show floor will enable visitors to get a first-hand look at the entire AM ecosystem.

RAPID + TCT CONFERENCE This year, TCT has been working closely with the team at SME and its dedicated advisors to deliver a three-day conference program which will bring together over 150 speakers and seven themed tracks across three days. The agenda will once again focus on the three key stages of the AM adoption journey: Evaluation, Adoption and Optimization, with talks from leading users, researchers and technology developers sharing insights from across the curve.

“With high-level talks and discussions delivered by senior guest speakers, the conference promises to provide the AM community with an unmissable opportunity to learn and network in the ‘Automotive capital of the world’, Detroit, MI,” Lu Tikrity, TCT Conference Content Manager said. “The sessions are carefully tailored to meet your needs through our EAO stages of the adoption curve – Evaluation, Adoption and Optimization. Whether you are an experienced AM user or new to the industry, the agenda can be tailored to your requirements to offer you an insightful experience into the AM world.”

Attendees will have the opportunity to take in daily keynotes, thoughtleadership panels, interactive workshops and a diverse range of presentation topics. Each track will highlight applications in a variety of industries including automotive, healthcare, aerospace, heavy industry and more. Speakers will also delve into solutions to industry challenges such as IP and certification, sustainability and supply chain, while the latest AM research will be presented around emerging materials and processes.

TRACKS: AT A GLANCE

Industries: • Healthcare • Aerospace • Automotive • Defense • Metal Applications • Nonmetal Applications • Construction,

Energy & Power • Heavy Industry

Solutions: • IP & Security • Standards &

Repeatability • Supply Chain &

Sustainability • People & Culture

Ecosystem: • Justification & Economics • Materials & Processing • Metrology • DfAM • Post-Processing

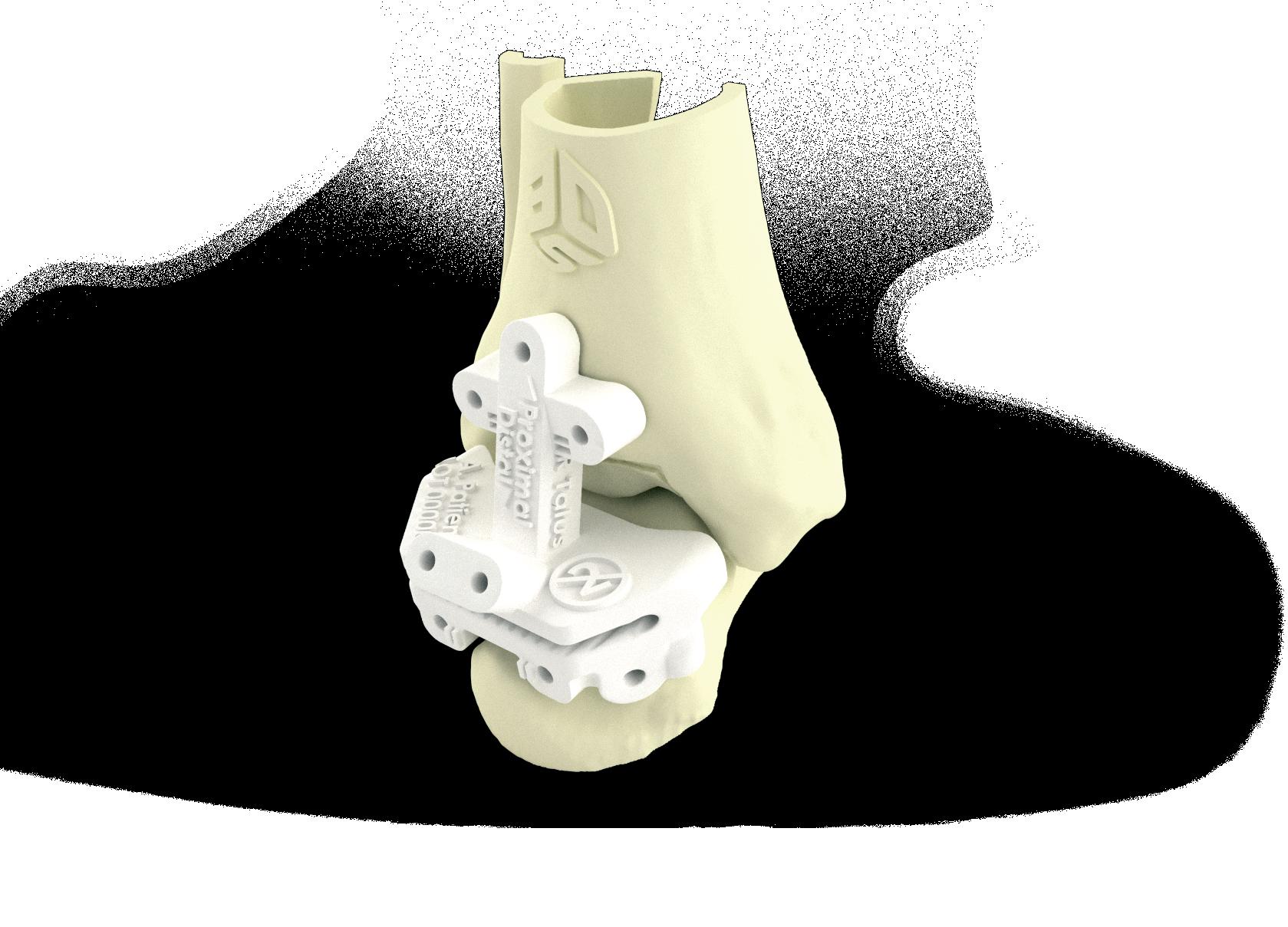

SHOWN:

SEE LATEST AM TECH IN-PERSON

R&D: • Materials • Hardware • Software

For those unable to attend the live event in-person, RAPID + TCT will also offer a Digital Experience where attendees can access exclusive digital content, livestreams and resources.

We’ll be unveiling more details on the full conference line-up and technology launches expected from the show floor in the next issue of TCT North America.

Registration is now open at rapid3devent.com

SHOWN:

MORE THAN 300 LIVE EXHIBITS

SHOWN:

HEAR FROM 150+ SPEAKERS

Tram front central fairing 3D printed, reinforced, installed, and qualified by Stratiforme Industries for ©ALSTOM. Custom vessel hardtop 3D printed and reinforced by Velum Nautica.

Massivit 5000

Look Ma! No Mold!

Tool-less FRP Manufacturing with Large-Scale AM

The holy grail for additive manufacturing is to provide manufacturers with a fast and feasible way to produce enduse parts. One manufacturing arena that is in dire need of digital transformation is the composite materials market. Composites fabricators across many industries spend copious time and costs producing a master and a mold for each desired FRP part.

Massivit 3D – a global provider of large-scale 3D printers – has introduced a new process for ultra-fast manufacturing of composites in short-to-medium runs. The process is based on the ability of the company’s Gel Dispensing Printing technology (GDP) to print large, thin, complex structures at high speed.

By coating the printed core structure with a layer of composite material using hand layup or vacuum bags, a composite part is formed with high strength and stiffness and low weight compared to other AM technologies. The printed core can be reinforced on either one or both sides.

Tool-less composite manufacturing is just one of many innovative applications facilitated by Massivit 3D’s large-scale 3D printers. Visitors to the upcoming AMUG Conference on April 3-7 will have the opportunity to see Gel Dispensing Printing technology at the Massivit 3D Booth P16, Salon D. Live demos of the colossal Massivit 5000 large-scale 3D printer – capable of printing a 6-foot part within a matter of hours – will be running throughout the show. Attendees will be able to see and handle 3D printed parts and find out how largescale AM is being leveraged for fast production of end-use parts, prototypes, and molds across industries such as rail, marine, automotive, scenic fabrication, and architecture.

The Massivit 5000 offers a long-awaited solution to AM market gaps in printing size and speed, providing a build volume of 57” x 44” x 70”. Advanced photo polymer materials, that cure instantly under UV light, enable a production speed up to 30 times that of other 3D printers.

Parts printed on the Massivit 5000 can serve as a geometric core for composite end parts. Laying the composite directly on the printed part eliminates the need for a mold altogether as the final form and geometry are digitally fabricated according to the desired CAD design. This has immense advantages over traditional composite manufacturing processes that demand extensive setup times for molds and tools as well as high tooling costs.

One sector that benefits from Gel Dispensing Printing technology is the rail manufacturing industry.

Railway manufacturers frequently require custom parts and spare parts on demand for a wide range of train and tram models. Conventional rail manufacturing requires a minimum three months just to produce a mold for a composite end-use part.

Stratiforme Industries – a renowned service bureau that serves leading rail manufacturers – 3D printed the front FRP cabin panels for the ALSTOM light rail vehicle pictured above and reinforced it without any need to produce an initial mold.

Likewise, the marine industry has long awaited a high-speed solution for manufacturing large, lightweight, composite parts that withstand harsh environmental conditions.

Velum Nautica, a leading provider of custom and spare marine parts, uses their Massivit 3D printer to produce on demand radar masts, dashboards, stern extensions, and interior fixtures at high speed.

At AMUG, Massivit 3D will also provide a sneak-peek of the award-winning Massivit

10000 AM tooling system

for composites. Due to be commercially launched in May 2022, it is designed to automate tooling for composite manufacturing by directly casting isotropic molds with high-performance materials.

Massivit 3D’s large-format additive manufacturing combined with the inherent benefits of composite materials present a match made in heaven for manufacturers at large.