4 minute read

CUSTOM CARE

WORDS: SAM davies

CUSTOM CARE

We didn’t have any choice,” Ewa Waliczek says frankly, in reference to a decision made back in 2016.

Having spent her entire career up until February of that year in software development, Waliczek had started to yearn for a vocation with more social impact. Harnessing that desire – and combining her software development expertise with the orthopaedic and craniomaxillofacial shape modeling proficiency of Paweł Skadłubowicz – she co-founded a medical device development company called Customy.

The mission of Customy is to make craniomaxillofacial procedures more precise and less complex in a more affordable way. And central to that objective is 3D printing technology.

“I think it’s the only way that we can do it,” Waliczek tells TCT. “Our models are patientspecific, so they’re different every time. We need to create every model, guide or implant for every patient, so there is no other way to do it.”

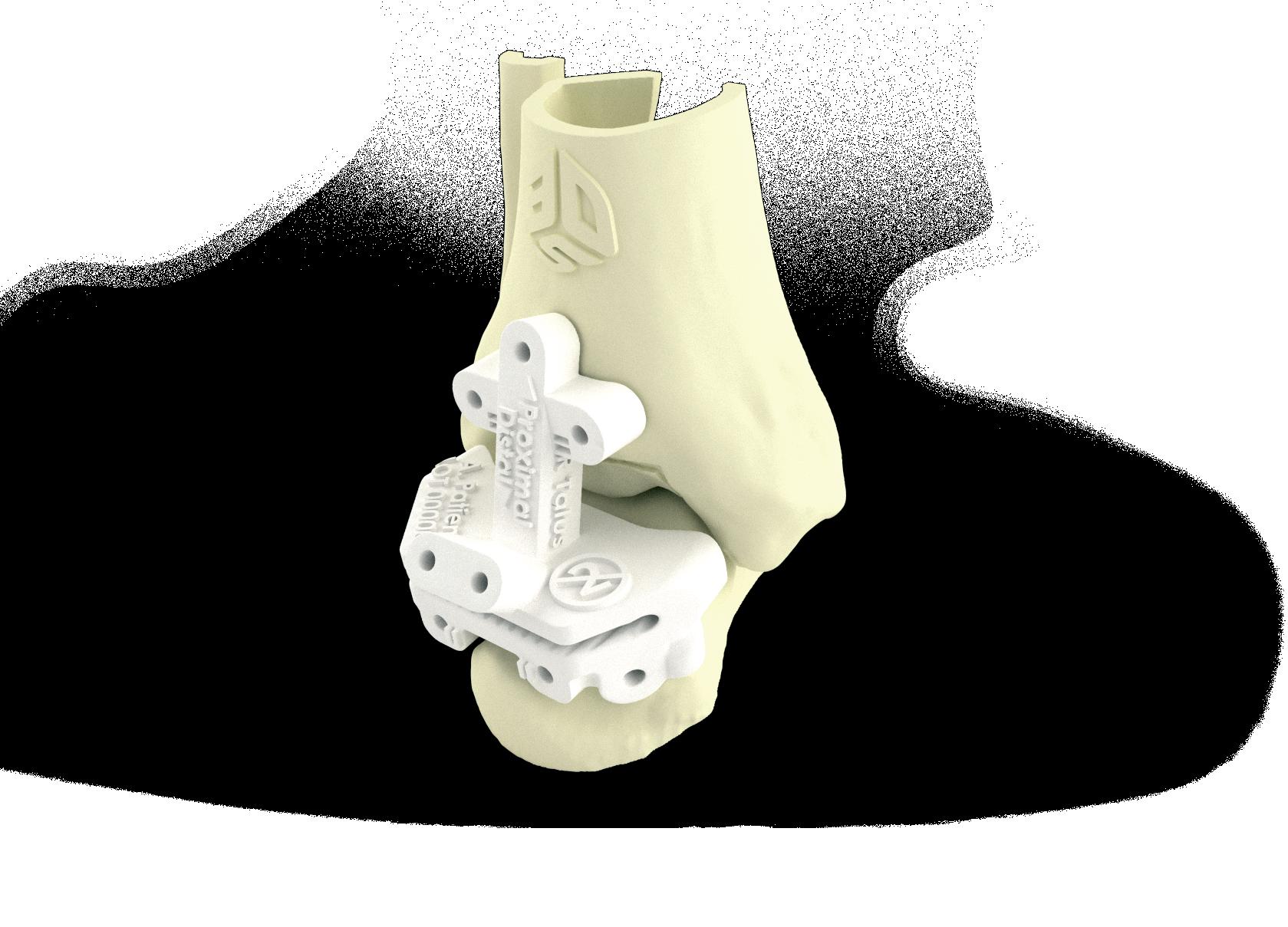

In the six years since Customy was founded, the company has provided many customized parts to surgeons and doctors, including models that help them prepare for surgery and implants that ensure better outcomes. One instance saw the reconstruction of 65% of a patient’s mandible from the right condyle to the left mandibular body after a young woman was diagnosed with a malignant jaw tumor. During a nine-hour surgery, the condyloma and soft tissues were removed and a patient-specific, 3D printed titanium implant was inserted without any complication. In another case, a 3D printed implant with an internal mesh structure (60-80% porosity) was produced in a shape that matched the patient’s anatomy perfectly – the patient, who had been diagnosed with a benign tumor, had previously experienced complications in an earlier procedure that used a standard implant. Manufactured with electronbeam melting in titanium, the porous implant facilitated full integration between bone and mesh, while also reducing the structure’s weight. This procedure was carried out without any complications.

It is for these reasons why Customy has bet big on patient-specific devices, and in turn 3D printing. For while standard implants are often enough, there are times when more personalized care is required.

“There are some cases that the standard implants may [bring] limitations for patients and postoperation complications regarding the size or the way that the implants were used,” Waliczek says. “Patient-specific implants are how you can design what you actually need, and you can reconstruct the bone structure [to] how it was before. You won’t achieve it by using the standard implants. We were focusing, at first, with printing maxillofacial reconstructions. There, every face is different and having a mandible tumor are really hard cases [to operate on] because most of the patients lose their bones. We wanted to give them the possibility to look the same after the surgery.”

Being able to deliver these benefits to patients and share these success stories with medical professionals is key for Customy. When the company first started out, Waliczek noted the surprise of some doctors that their offering was able to speed up surgery times. That surprise had its roots in an uncertainty and hesitancy that is being chipped away at with every Customy application.

While patient-specific implants are the obvious headline grabber, it is the customized surgical guides and anatomical models that are often underpinning those successful procedures. For Waliczek and her colleagues, there is a hope that parts like this will become standard in the healthcare sector. But the key to that, the company believes, is enabling medical professionals to bring the capability in-house.

Hence, Waliczek has overseen the development of Customy Vision, a 3D visualization software for the modeling of medical images, with design modules for surgical guides and implants to come. Boasting smart segmentation, advanced visualization, DICOM anonymization and surface modeling features, this platform has been designed for surgeons and bioengineers to create anatomical models in their labs. This is the next step of Customy’s mission, and it is one with a long-term vision. While 3D printing’s application in medical today is ‘making healthcare more patient oriented’, Waliczek believes there is even more value to be captured.

“We were wondering,” Waliczek says, “what will be the best way of propagating the use of anatomical models? Of course, we can do it inhouse and collaborate with hospitals, but we think the best way is when they have their own laboratory and they can do it on their own because then they could have the models within one day, right? And such models are also the entry point for later designing surgical guides or implants. We want to try to be independent [from surgeons]. We think it’s more scalable and it’s saving time and cost doing it in-house, so we are convincing them, educating them to do it by themselves.”

SHIPPING NOW

The Production System™ P-50 Now delivering AM 2.0 benefits with metal 3D printing at scale

—

The P-50 is the result of nearly $100 million of investment over four years, producing a sophisticated solution with exclusive technology for speed, cost, and reliability now proven on the P-1 worldwide

—

Patent-pending Single Pass Jetting™ technology binder jets parts with high speeds up to 100x faster than legacy 3D printing methods

—

P-50 delivers per-unit costs that compete with conventional manufacturing, while offering greater geometric flexibility and other AM 2.0 benefits

—

Wide range of part sizes and high throughput enabled by large build box of 490 x 380 x 260 mm (19.2 x 15.0 x 10.2 in)

—

Open material platform supports robust library of third-party MIM powders qualified to industry standards — stainless steels, tool steels, low alloys steels, nickel alloys, copper, and more

—

Controlled atmosphere system delivers consistent results and enables printing of reactive metals

www.desktopmetal.com/learnP50 Sign up to learn more about how the P-50 delivers Additive Manufacturing 2.0 benefits at scale