catalogue FLEXIBLE PACKAGING 2024 Edition

03 B2B value proposal Culture and approach About usExperience - Capabilities - Segments - Products - Packaging with better environmental performance Certifications Contact 05 07 14 15

About us

We are a corporate group with a high commitment to excellence, responsibility and continuous improvement. We design, produce and market packaging that makes our clients win and ensures the growth of their businesses.

+53 YEARS OF EXPERIENCE

providing innovative solutions to all types of industries.

03

LEADERS IN FLEXIBLE PACKAGING IN CENTRAL AMERICA & SOUTHEAST ASIA, located in El Salvador and with operations in Asia through its plant in Vietnam.

WE ARE A CORPORATE GROUP with exponential growth in recent years reaching a population of more than 1,800 employees in 7 countries, distribution centers in Central America, Dominican Republic and Vietnam.

04

Focused culture

in customer service and continuous improvement

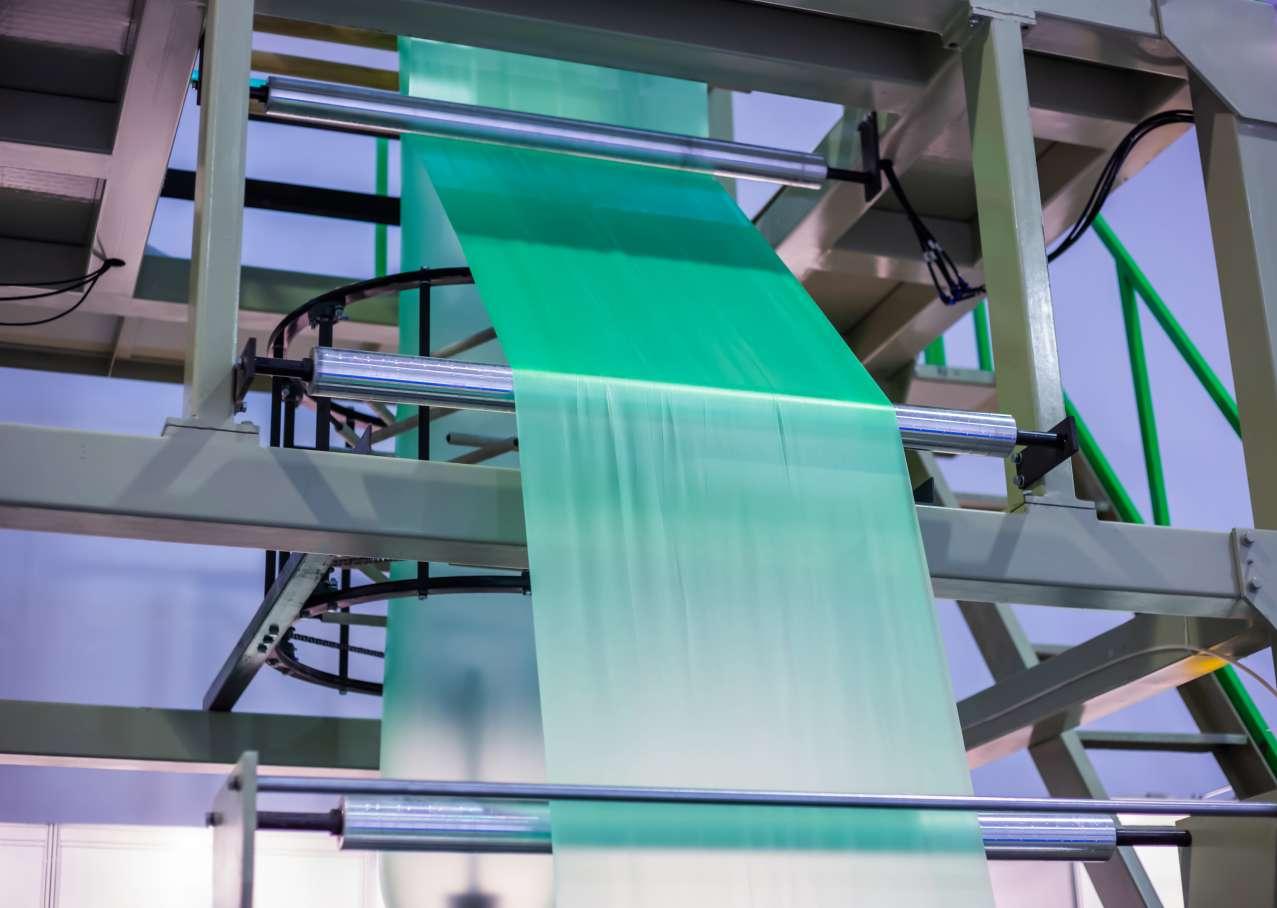

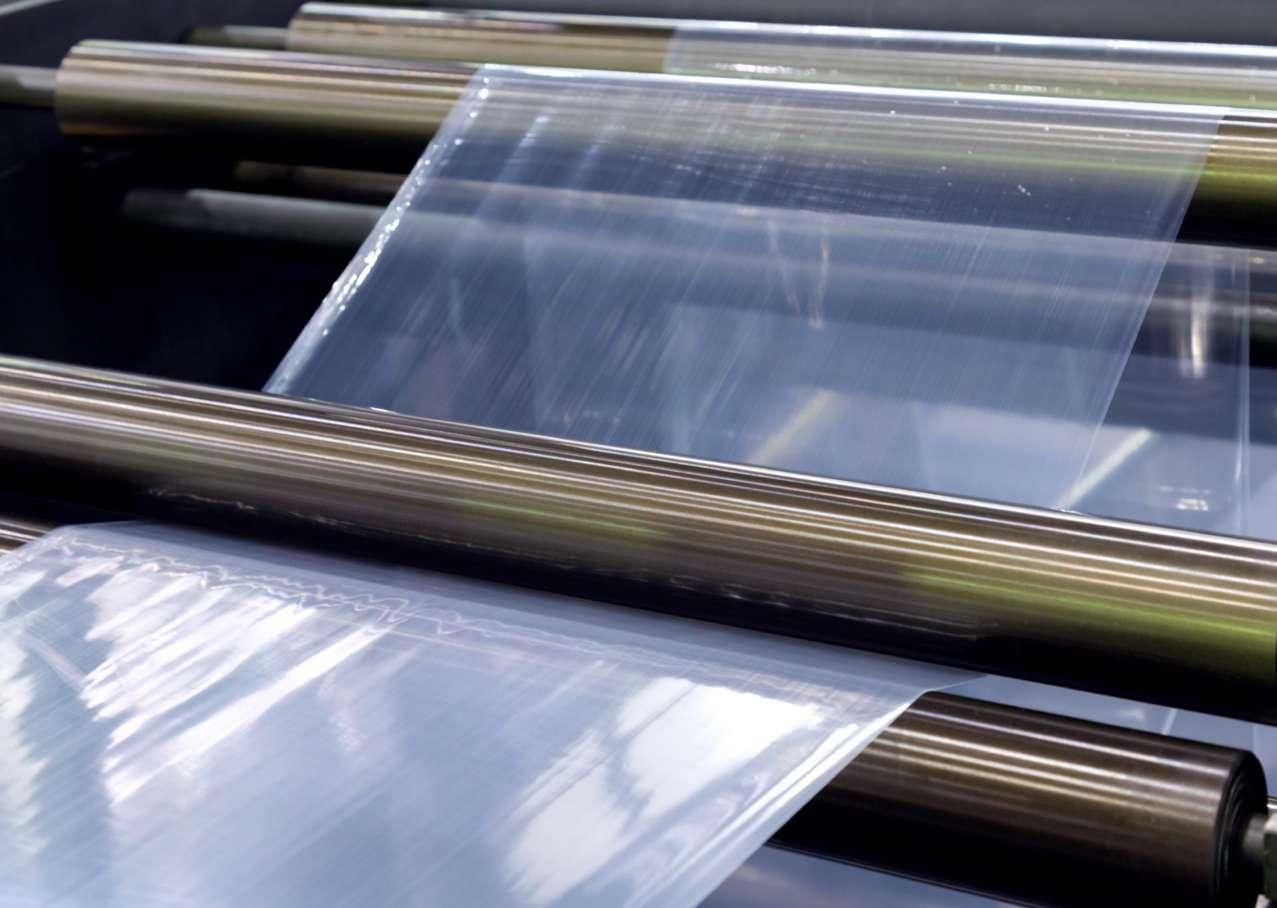

Ternova's production system incorporates cutting-edge technology, which positions us as an essential partner for companies that place their trust in us.

This advanced technology opens new opportunities and allows us to offer innovative solutions that exceed our customers' expectations.

Focus

To build strategic long-term relationships with our customers.

To generate value to their brand and products.

To create packaging solutions for each necessity in different market segments.

Business model

Winning culture

We act based on 3 pillars, continuous improvement, respect for people and sustainable development.

Business system

We seek the development of our clients, team and business in a sustainable way.

“ Rodrigo Tona

At Ternova, our vision goes beyond conventional limits. We are leading the way towards a sustainable future, driven by innovation and commitment to the environment.

With the largest recycling plant in the Central American region, certi ed by the Global Recycled Standard (GRS), we are proud to be Carbon Neutral thanks to the focus on inclusive recycling. We are committed to Ellen's vision MacArthur of a circular economy”, and that is what drives us to be pioneers in the transformation of the materials of the future ”

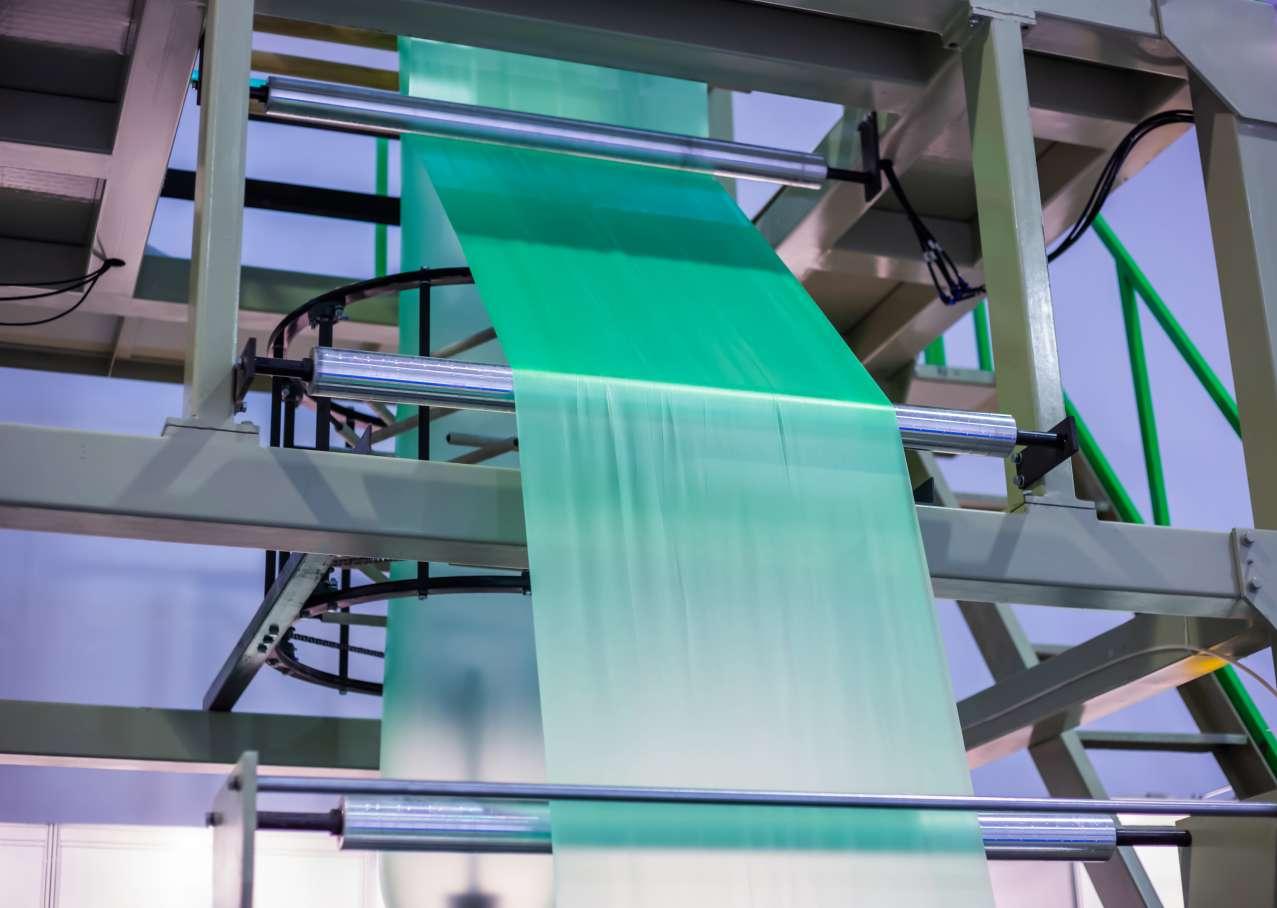

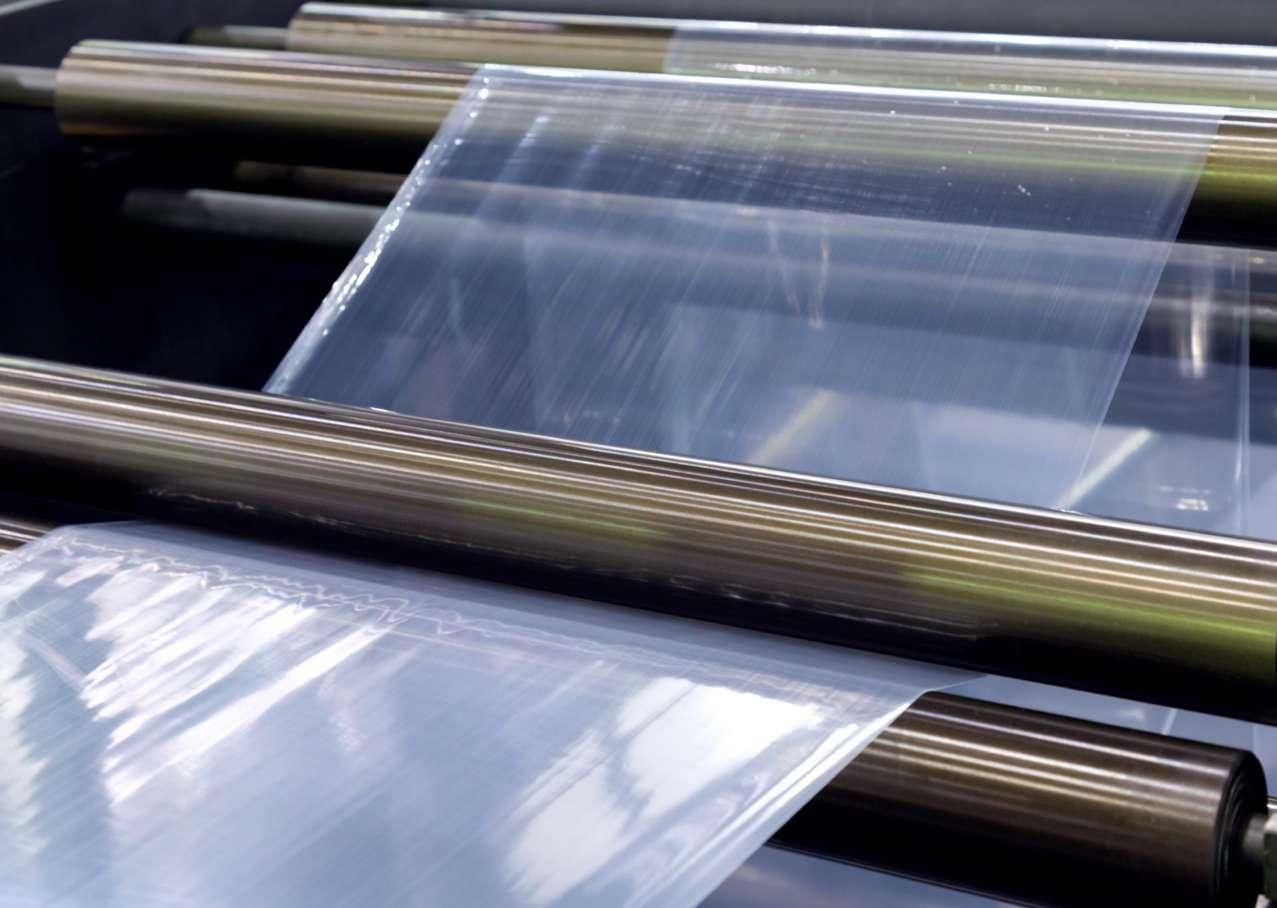

CAPABILITIES

Recycling

Recycling up to 18,000 MT/Year

Extrusion

Extrusion up to 3 layers

Print

-Flexographic up to 10 colors

-In-house processing of arts and production of flexographic plates

Lamination

Solventless lamination

Slitting

Seal Variety of bag and film finishing

3 months of coverage

raw material handling customer inventory

600 TM / MONTH (32 M BAGS / MONTH)

B2B

Quality assured

Our value proposal is possible thanks to our human talent, who are constantly trained and certified in different areasandprocesses.

They are the main engine of the company and promoters of continuous improvement in each production process and service, to guarantee that our products are manufactured with the greatest possible excellence.

Our cutting-edge technology allows us to offer a variety of products for flexible packaging

Food Home

Dehydrated

Frozen Fresh

Detergents

Soaps

Care of fabrics

Personal care

Feminine towels

Toilet paper

Institutional

Napkins

Textile

Womenswear

Underwear

Socks

T-shirts

Products +Materials and applications

LDPE CPP / BOPP LDPE / LDPE MDOPE / LDPE BOPP / HBBOPP / LDPE PET / LDPE PP met / LDPE PET / PA / LDPE Applications

Fresh Food

Frozen Food

Dehydrated powders

Oils

Bread

Soap

Powder detergent

Cloth softener

Apparel

Paper

Feminine towels

*Available

09

* * * * *

in PCR content *

+Lamination

Solventless

Bilaminations or trilaminations

+Types of bags

Custom packaging with die and accessories

Bag with side or bottom gusset

Bag with tape

Zipper bag

Doypack

+Print

Flexographic

Up to ten colors

Prepress Capabilities

10

BAG WITH ZIPPER DOYPACK

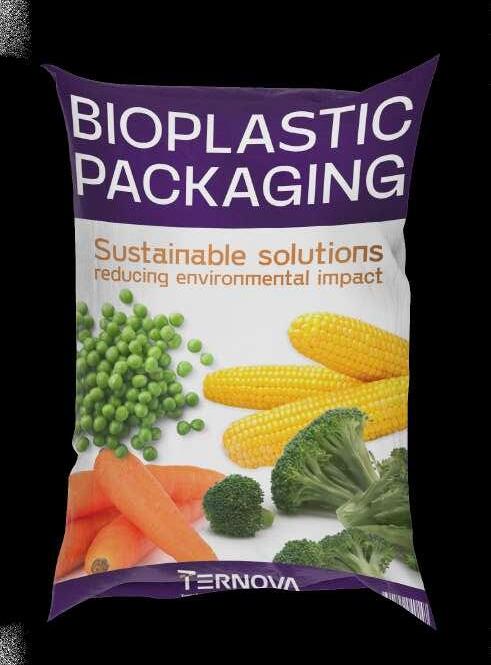

WITH BETTER ENVIRONMENTAL PERFORMANCE

in sustainability

We help brand owners co-create packaging with better environmental performance and thus reduce their carbon footprint without compromise performance.

RECYCLED CONTENT

RECYCLABLE BIODEGRADABLE BIOPLASTICS

The application of these solutions represents progress in the sustainability initiative and the brands' commitment to the environment.

STRUCTURE:

LDPE / PCR

APPLICATION:

Packaging for household products, detergent, personal care, textiles and heat-shrinkable packaging (Shrink film).

STRUCTURE:

Packaging created with up to 95% post-consumer material.

LDPE / LDPE

LDPE / OPP HB / CPP

Ready to recycle packaging with vapor and oxygen barrier. Switch to a recyclable plastic matrix and reduce your carbon footprint without compromising performance.

MDO PE / LDPE EVOH

APPLICATION:

Frozen foods, dry foods, form film seal films, among others.

For food contact

PE films and packaging (LDPE AND HDPE) with content of FDA-approved food contact PCR

STRUCTURE:

LDPE / PCR FOOD GRADE

Through the use of a sources, such as corn starch and other plants, the main use of this resin is to reduce plastic pollution.

APPLICATION:

Packaging for foods such as

APPLICATION:

Packaging for frozen foods, among others.

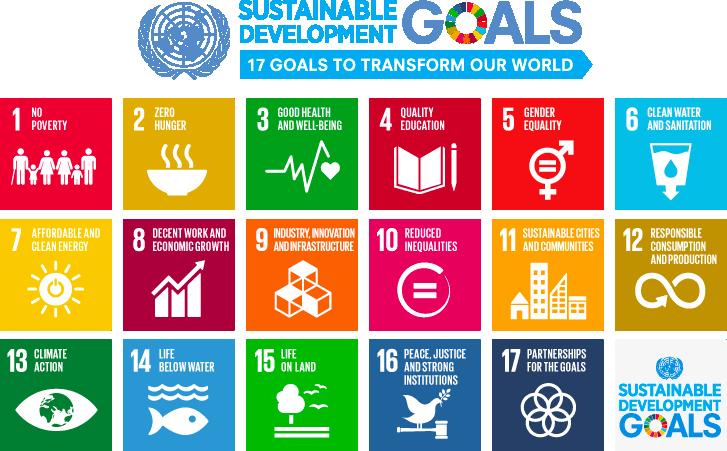

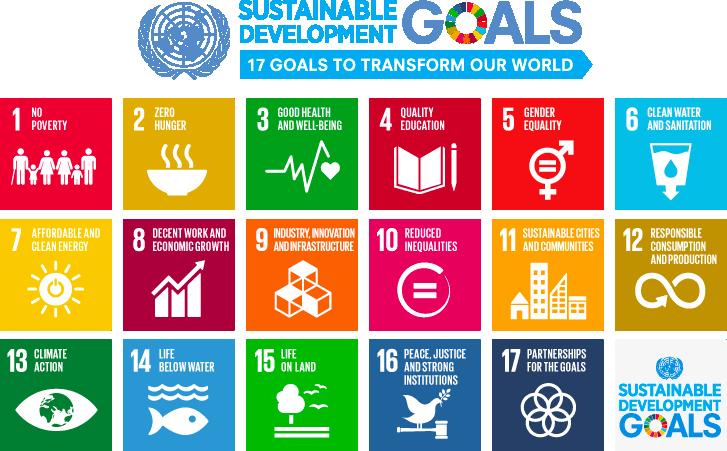

ESG STRATEGY

aligned with the UN Sustainable Development Goals

By 2040, Ternova's purpose is to become Latin America's most sustainable company

ISO 9001-2015 certification since: 06/24/2009

Graphic Measures International, Certified since 2018

CLASS TEAM

Food safety management system certification 22000 since: 08/16/2019

Global Recycled Standard Certified since: 06/17/2020

First company in our sector in Central America to obtain Carbon Neutral Certification, since 2018

SMETA: Labor, health and safety environmental performance and ethics.

Since 11/19/2014

El Salvador

(503) 2212 - 7377

(503) 2212 - 7300

Vietnam

(84) 932 - 290 - 885

USA

(1) 470- 301 - 9215

Marketing: drochez@ternova.group

New business: scea@ternova.group

Know more:

https://bit.ly/SomosTernovaPackaging

Website: https://ternova.group/

Ternova

Ternova

Ternova Group

Ternova Group