counting. It began with an idea of how to make this industry more appealing to a broader audience.

So, we decided to experiment by doing something different than how technical magazines used to be. We want to engage our readers with creative designs and light but informative content. We hope all our readers enjoy what we’re presenting here and wish to stay on course with this idea to hopefully spark new interests in this industry. And for anyone who wants to give advice or opinions to improve our work, we would love to hear from you.

CEOThe CHIEF

Hi, and welcome to July’s issue of THE CRUST!

This month marks the 10th issue of our beloved magazine since we started on September 2022. We have come a long way since we started; the magazine is read in over 30 countries around the world, with hundreds of readers each month and counting. It began with an idea of how to make this industry more appealing to a broader audience.

So, we decided to experiment by doing something different than how technical magazines used to be. We want to engage our readers with creative designs and light but informative content. We hope all our readers enjoy what we’re presenting here and wish to stay on course with this idea to hopefully spark new interests in this industry. And for anyone who wants to give advice or opinions to improve our work, we would love to hear from you.

EDITOR OVERVIEW

As shown on the cover, last month, we just had our annual meeting called the Shrimp Aquaculture Conference (SAC) in Bali. It was a chance for shrimp industry players to meet and learn from one another. We learned, laughed, and hopefully left with a renewed spirit to continue working in this industry. And for that, we want to thank the attendees especially. Those who flew from far away to attend the event. It was always an honor to welcome and host such enthusiastic and amazing people. And thank you to all of the sponsors who made this event possible. Additionally, we appreciate the honest feedback you gave us to improve. We’ve taken it to heart and will use it to improve next year’s SAC.

Nowadays, we’ve been hearing a lot about bearish shrimp prices. Many events are discussing this; processors and producers are concerned about it, yet no solutions have come out. This situation is undoubtedly complicated and caused by various global factors. We’re sure this struggle is felt in the whole supply chain, from feed mills all the way to the last downstream. We believe that efficiency plays a big role right now and is vital to survival. Some ways to do this are by saving costs and increasing production performance. For now, the industry’s current failure rate of at least 30% is unsustainable. All in all, hopefully, the whole industry will come out of this situation better than before. As the saying goes, innovations usually come from necessity.

Rizky Darmawan Chief Editor

CEO

As annual ference dustry learned, spirit we want flew an honor amazing who ate the taken SAC. Nowadays, shrimp cessors solutions ly complicated

come saying ciency plays a big role right now and is vital to sur

We’re from believe is vital costs the industry’s sustainable.

2 Issue 10 | July -2023

THE CRUST - RIZKY

Photo source : The CRUST

ICLEArt

ONE DSM AQUA SEMINAR 2023:

it can help increase our production,” explained Mrs. Chiow.

Immunity is the fundamental of health that protects the animals from harmful pathogens, reduces the impact of stressors, and facilitates the animals’ overall physical, hormonal, and cellular function. So, immunity is the fundamental building block of shrimp farming.

Shrimp Industry Challenges in Asia

Disease outbreaks are a major challenge in the competitiveness of the shrimp farming industry in Asia. It directly affects the higher production costs and crop failure, especially for small-scale farmers. Dr. Putth Songsangjinda, a Shrimp Farming Expert from Thailand, said that the shrimp industry in Asia could adopt Ecuador’s strategy to increase production.

“It is time for Asia’s shrimp industry to change and show its existence by using shrimp genetics suitable to the culture environment, lowering stocking density to meet the pond carrying capacity, improving feeding efficiency to increase productivity and reduction of cost, using probiotics in shrimp farming for reduction of disease outbreak and enhance shrimp health, and implementing the use of green energy to reduce energy cost and reduce the emission of CO2,” Dr. Putth explained.

Toxins in Shrimp Farming

Toxins are mainly divided into two types based on their source: exotoxins and endotoxins. Exotoxins are found in Grampositive and Gram-negative bacteria and

PROICLE

polypeptides. Meanwhile, Endotoxins are primarily found in Gram-Negative bacteria and lipopolysaccharide complexes.

According to Ngoc Diem Nguyen, Aqua Technical Expert, APAC at DSM-Firmenich, exotoxins are more dangerous for animals, including shrimp, compared to endotoxins. A small concentration of exotoxins can be lethal. Meanwhile, endotoxins are only lethal when in a large concentration. That is why smaller shrimps are more sensitive to toxins in some cases, like EMS. “Since toxins affect the shrimp industry, we must be aware, and it’s better to spend our investment in prevention than on treatment,” she advised.

Shrimp Feed Management

Given the current condition of outdoor pond culture, there is no fixed daily nutrient requirement for shrimp. When shrimp needs more nutrients, it will automatically eat more. Dr. Dean Akiyama, Aquaculture Consultant, said that a proper mix in feed composition is critical. Shrimp requires a water-stable feed. Moreover, feed mix homogeneity is crucial. For example, a 20g shrimp will only eat 0.35g feed per day. The amount of feed quantity given should provide the daily essential nutrients required.

As we cannot control shrimps’ daily nutrient intake, the feeds given should be nutrient balanced, highly palatable, and digestible. Maintaining lower levels of total nitrogen and phosphorous is also essential to better preserve the pond water quality. Theoretically, lower nutrient-dense feeds will have higher FCR (feed conversion ratio)

if properly managed.

“It is more difficult and expensive to make a lower protein feed with the same amount of available EAA (essential amino acid) and available phosphorous compared to a higher protein feed with higher total phosphorous. Lower protein and phosphorous feeds are better for water quality stability,” Dr. Dean explained.

Feed Efficiency

The last speaker, Rutchanee Chotikachinda of Aqua Technical Expert Manager, APAC at DSM-Fermenich, discussed about feed efficiency. She said that a standard measure of the efficiency level is shown in the feed conversion ratio; a lower value signifies a higher efficiency. Factors affecting the improvement in feed efficiency are feed composition that matches the nutritional needs of shrimp, the digestibility of feed, feed additives, feeding practices, farming system, farm management, environment, and genetic improvement by selective breeding.

to better preserve the pond ity. Theoretically, lower feeds will have higher FCR (feed

“It is more difficult and make a lower protein feed amount of available EAA (essential able

compared to a higher protein higher total phosphorous. and phosphorous feeds are better quality stability,” Dr. Dean explained.

The last speaker, Rutchanee achinda of Aqua Technical Expert APAC at DSM-Fermenich, discussed feed efficiency. She said that measure of the efficiency level the feed conversion ratio; a lower nifies a higher efficiency. Factors the improvement in feed efficiency composition that matches

Rizky Darmawan

Ngoc Diem Nguyen

Dr. Dean Akiyama

Rutchanee Chotikachinda

Rajeev Murthy

Dr. Putth Songsangjinda

Chiow Yen Liew

Rizky Darmawan

Ngoc Diem Nguyen

Dr. Dean Akiyama

Rutchanee Chotikachinda

Rajeev Murthy

Dr. Putth Songsangjinda

Chiow Yen Liew

SCHOOLFish

In The Lab

The TBC (Total Bacterial Count) and TVC (Total Vibrio Count) are lab tests to measure the health of the bacterial population inside the pond system. Vibrio is a naturally occurring bacteria in bodies of saltwater that has several detrimental effects on aquatic animals and humans. It is also strongly credited to the occurrence of various diseases in aquaculture, such as vibriosis and AHPND (Acute Hepatopancreatic Necrosis Disease). Hence, farmers often use probiotics to suppress vibrio in their culture pond. The presence of vibrio is especially high in waters with high TOM (Total Organic Matter) or in the later stage of the cultivation period where nutrient buildup is already high.

The TBC and TVC tests both focus on counting bacterial colonies and are done similarly using agar plates and an incubator. The difference, however, came in the media each test used:

• TBC test uses TSA (Trypticase Soy Agar) as its media and counts the total bacteria population in the system regardless of species.

• TVC test, on the other hand, uses either the TCBS (Thiosulfate–citrate–bile salts–sucrose) agar or the Chromagar. The difference is that the TCBS can differentiate two types of colonies, while Chromagar can test for three types. Tests using TCBS will yield colonies with either yellow or green color, and tests using Chrom agar will produce purple, blue, and white colonies of bacteria.

It is crucial to make sure all of the equipment is clean and sterile to avoid contaminations that will render the result unusable. Both tests take around 24 hours due to their incubation period. When done correctly, colonies of bacteria should be clearly seen on the plates and can be counted using a particular method. After the count, the TVC result should be compared with TBC to measure pond health:

TVC = % TBC

Previously, farmers were content as long as TVC didn’t dominate the TBC. But recent problems with diseases force a shift to a new standard. Nowadays, the best practice is to have TVC/TBC be much less than 5% to minimize disease risk.

Additionally, any trace of green vibrio in the TCBS test should be taken seriously because of its higher toxicity compared to the yellow colonies; this often signals that a disease outbreak might come soon.

5 Issue 10 | July -2023 THE CRUST - DELTA MARINE INDONESIA

TBC vs TVC Photo source : Cdc, Jaron Nix, drew hays

SURVIVING TURBULENCES

The Shrimp Aquaculture Conference (SAC) 2023 was held by the Indonesian Young Farmers Association (Petambak Muda Indonesia/PMI) in Bali over three days (June 20-22). This year, SAC raised the theme “Surviving Turbulences” as a response to the inevitable threats in the shrimp aquaculture industry.

At the opening of the event, Rizky Darmawan, the President of PMI, said the shrimp industry is experiencing turbulence amidst the continuous disease occurrence, the environmental effect of climate change, the global recession taking place, and the sustainability issues of the business. To tackle these problems, we should learn from another industry that is more careful in managing its risks: the airline industry. “Before flying an airplane, a pilot must go through elaborate checklists, verify nothing is left behind to ensure we will have a smooth flight. This should be done when we start our journey as we prepare for our cultivation cycle. In addition, what we need to learn from the airplane industry is how they strive to provide the best service to customers. We too must produce the best products that consumers can enjoy to gain a competitive advantage and attract customer attention,” he stated.

Haris Muhtadi, the Chairman of Shrimp

Club Indonesia (SCI), concurred. According to him, the shrimp industry in Indonesia is not in good condition. So far, we have only emphasized the production aspect. But marketing is also important to be able to compete in the international market. “Although it’s late, it’s good to keep trying. I want PMI to focus more on the marketing aspect because only focusing on production is not enough,” he explained.

The Seminars

The 2023 SAC offered top industry leaders and professionals the opportunity to engage with peers from the aquaculture industry and to learn from experts and each other to achieve success. The seminars presented speakers from various fields, such as marketing, experts in shrimp management, nutritionists, and startups that focus on aquaculture, curated from around the world to bring the best that the industry has to offer.

On the first day, one of the topics discussed was technology and its effect on shrimp farming, delivered by Andrew Campbell of AQ1 Systems. According to him, the shrimp farming world has changed. Shrimp farmers are moving from an art to a science, moving commercial aquaculture from the traditional experience-based to a

knowledge-based production regime. This can only be achieved through increased use of emerging technologies and automated systems, for example, in the feeding system. “Most shrimp production costs can be reduced by effective feeding. Overfeeding leads to feed waste - high FCR, toxicity, unstable water quality, affects shrimp health, and increases feed costs. Whereas underfeeding leads to low ADG - longer cycles, shrimp entering muddy fields for feed, affecting shrimp health, and increasing energy maintenance costs,” he said. Other speakers presented on the first day were Alexander H. Farthing from DELOS, Abung M. Simanjuntak from dsm-firmenich, Régis Bador from Innove’Aquaculture, Budi Tanaka from BioCycle Indonesia, Dr. Melony Sellars from Genics, and Dr. Dean Akiyama as Aquaculture Consultant, each presenting various topics within their expertise.

Meanwhile, on the second day, the presenting speakers were Dr. Chalor Limsuwan from Kasetsart University, Martha Aulia Mamora from Adisseo, and Rubiyanto Widodo Halim from CP Prima. Then there were the “Business Classes” that focus on shrimp farming outside its technical aspects, such as the presentation brought by Wan Nadhri Wan Fauzi and Anuar Sani from Blue Archipelago Berhad about managing

7 Issue 10 | July -2023

ICLEArt SAC 2023:

Haris Muhtadi

Dr. Melony Sellars

Dr. Dean Akiyama

Budi Tanaka Benedict Tan

Dr. Chalor Limsuwan

ICLE

and improving big shrimp farm Inc, sustainable production and branding using the Vietnam approach by Huynh Le Dinh from Vietnam Sustainable Shrimp Alliance, and attracting investments for growth by Benedict Tan from Hatch.

The seminars and business classes were fascinating, with speakers sharing the latest developments in their perspectives. Participants also enjoyed and shared their experiences in the Q&A session. Apart from the seminar schedules, there were also mini-exhibitions organized by some companies that supported the SAC, such as DELOS, dsm-firmenich, Haida, Thai Union, and CP Prima.

The 2023 SAC ended with a visit to Kona Bay Indonesia’s shrimp broodstock center facility in Tejakula. The broodstock center is a joint company formed by Japfa Comfeed Indonesia’s aquaculture arm, Suri Tani Pemuka (STP), and animal breeding company Hendrix Genetics to guarantee the supply of quality shrimp broodstock in the SEA region.

The Resounding Success

This year, the event reached a much more significant number of participants

than last year. “Previous year, we had around 120 participants. Whereas this year, we counted approximately 300 participants, both local and foreign. This shows the excitement this community has to engage and collaborate in building a better shrimp industry going forward,” said Mr Rizky. He added that what’s unique about the event is that this is the first year we rebranded our annual event from the previous PMI conference. This event will use the name Shrimp Aquaculture Conference (SAC) starting this year.

In closing, Mr. Rizky thanked everyone who stayed until the end. He conveyed how he would like to thank the sponsors who have helped make this event possible. And to thank the participants for their enthusiasm and the support that’s been given in this event. “I am so happy seeing you smiling, meeting new people, and listening to all the presentations. That’s why we made this event. We gathered all of you, the industry leaders, and friends to meet in one room to hopefully solve any problems that we might face in this industry. Hopefully, this will not be the last time we meet. We are going to do this every year. I hope you can come to next year’s SAC,” he concluded.

SUR 8 Issue 10 | July -2023

Photo source : The CRUST

THE CRUST - DEE, RIZKY

Rizky Darmawan

Andrew Campbell Anuar Sani

Wan Nadhri Wan Fauzi

Rubiyanto Widodo Halim

Régis Bador

Martha Aulia Mamora Huynh Le Dinh

Abung M. Simanjuntak Alexander H. Farthing

MARKETWet

There has long been talk about the diversification of markets for Indonesian shrimp. In the 1980’s & 1990’s, Indonesia had but one option for shrimp export, Japan. The best price for the best quality. What happened to shrimp that did not meet the cut though? In the 1990’s when Indonesian farmed Vannamei began to get into stride, the European market started importing and Indonesia got a slice of the pie. Finally here was a market that was not so picky about the quality.

The catch was though, labelling & different specifications. You’d have a container with 10-15 different product forms, packing, labelling in 5-6 different languages. Absolute pain in the arse.

The US market came next & it was the processors wet dream. All sizes, one spec, the most common being EZP or PND. No glaze, one type of packaging. And US importers had the market volume. So they were able to place multiple loads worth of orders at once. Boomtown Charlie. The trouble with a market like that, is that everyone else wants a piece of the action. India lifted the vannamei farming ban in 2010. And now, they are at 1,000,000MT of

produce a year. Where does all that shrimp go to?

Ecuador has long been trumpeting their superior HOSO shrimp. Due to their extensive farming, they’ve been able to come up with a product that holds the head very well. The natural market for this product has been Asia where we like our shrimp whole. Naturally the biggest market in Asia is China. When China shut down in 2020 however, Ecuadorians were left in a bind. Where should their shrimp go? The natural answer is of course, the US.

The USA is a natural market for Ecuador, it’s 2 weeks away. Indonesian & Indian shrimp take 4-6 weeks to get there. Ecuadorian takes half the time. Much less risk for the importer. The trouble with Ecuador is the labour cost. However, one cannot discount the effect that technological advances will have. We already have high quality peeling & grading machines. This will go a long way towards solving the labour crunch there. In the next 2-3 years we can expect Ecuador to focus more on the US market.

THE CRUST - MIDA

Where does that leave Indonesia? In the next few articles, we will explore alternative markets in detail & try to understand how the industry can diversify.

9 Issue 10 | July -2023

Photo source : marcos paulo prado, ian taylor, mika baumeister, pesce huang

1 Decomposing the remaining organic matter of the feed into free nitrogen for growing feed for shrimp 2 excess of the shrimp digestive system 3 4 are more resistant to digestive infections 5 Bactericidal effects (AMPs) 1 Maintain a healthy digestive system 2 Amino acids for boost the immune system 3 Good for absorption of calcium, hormone production and enzymes, and growth 4 Increase the rate of shrimp survival 5 Lauric Acid as natural antimicrobials 1 43.13% Lauric Acid 2 Stimulant effect (easily penetrates mitochondria bacteria) 3 Easily absorbed and oxidized to energy 4 Suppress growth bacteria Vibrio spp. Harm 5 www biocycleindo com + 62 813 8851 2771 info@biocycleindo.com DISTIBUTOR: PT. PANJUNJUNG ALAM LESTARI OFFICE PARK 2, JL. BUKIT DARMO BOULEVARD NO.18, PRADAHKALIKENDAL, SURABAYA, KOTA SBY, JAWA TIMUR 60226 CONTACT NUMBER : +62 822-8206-6429 PT. SARANA ALAM SUBUR JL. TEUKU UMAR NO.62B, KOTA TINGGI, KEC. PEKANBARU KOTA KOTA PEKANBARU, RIAU 28155 CONTACT NUMBER : +62 812-8528-8918

ICLEArt

EMBRACING UV AND OZONE AS ECO-FRIENDLY ALTERNATIVES FOR SHRIMP WATER MANAGEMENT

In the vibrant world of aquaculture, shrimp farming stands as one of the most lucrative and vital industries, providing a delectable seafood delicacy enjoyed by millions around the globe. However, like any thriving business, it comes with its own set of challenges, one of which is water quality management is a critical concern for sustainable production.

Currently, shrimp farmers have heavily relied on chlorine, commonly in the form of calcium hypochlorite (chlorine), to maintain water quality and curb bacterial growth. While effective in the short term, the use of chlorine raises environmental concerns due to its potentially harmful byproducts and adverse effects on aquatic ecosystems.

But fear not, as the tides are turning towards a greener horizon. Enter UV (Ultraviolet) and ozone treatment technologies - the eco-friendly power duo that offers a promising alternative for managing water quality in shrimp ponds. These innovative approaches leverage the power of nature to ensure a clean, safe, and sustainable environment for both the shrimp and the surrounding ecosystem.

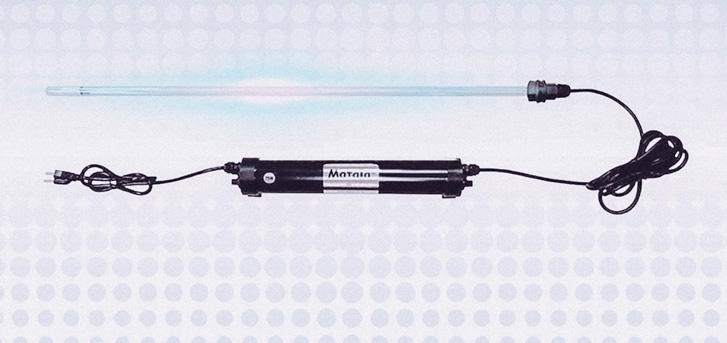

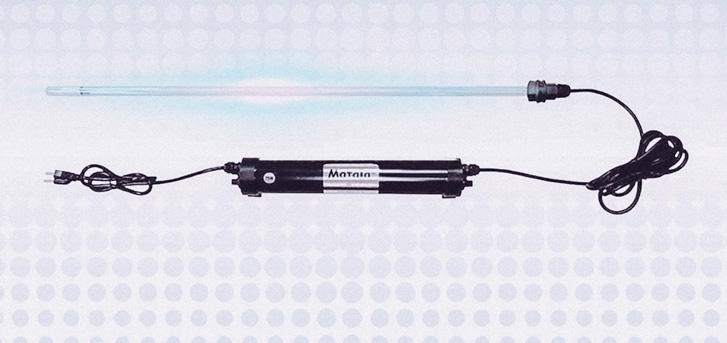

UV Technology

Successfully applied at the hatcheries, UV technology is now making its way into grow-out shrimp ponds. CEO of PT Tequisa Indonesia, Darjono highlights the similar

principles behind UV usage in hatcheries and grow-out farms. The primary purpose of UV is to eliminate bromine residues that adversely affect shrimp PL. However, in the grow-out ponds, a higher dose of approximately 190 J/L of water is used. “This high dosage has proven to eliminate Vibrio bacteria by over 4 log scales effectively,” he tells THE CRUST.

His product, UV-C 256 Wavelength, offers an environmentally friendly sterilization method that not only benefits the ecosystem but also streamlines production costs, reducing variable expenses like chlorine. However, Darjono recommends allowing the water to settle before UV treatment, as UV treatment works best when the water is relatively clear. With a close UV exposure and sufficient duration, water sterilization can be effectively achieved.

On the other hand, YUKI, a distributor of UV technology for aquaculture, offers a different perspective. According to them , water quality management is one of the most significant factors in successful shrimp cultivation. The survival rate of shrimp in aquaculture only ranges from 20-70% due to limitations in water treatment expertise and access to suitable water treatment technology. With nearly 40 years of experience in water treatment, YUKI, along with renowned water treatment equipment manufacturers, is here to contribute to this sector by lowering mortality rates and increasing efficiency by using proper tech-

nology.

Although UV is just one of the water treatments, YUKI suggests that the appropriate use of UV has consistently reduced mortality rates to below 10%. Achieving this is possible through correct system sizing, which involves analyzing water conditions and conducting additional water testing.

According to YUKI, UV treatment saves time as it instantaneously disinfects and effectively deactivates pathogens by up to 99.99%. Moreover, it is safe for shrimp, as it does not involve the use of chemicals that could risk overdosing or causing stress to the shrimp. YUKI state that “Unlike chlorine, which generates potentially harmful that can stress and endanger shrimp, UV treatment promotes healthier shrimp. This also resulted in a better Feed Conversion Ratio (FCR) due to increased shrimp feeding and reduced uneaten feed in shrimp farms.”

While UV technology holds significant potential, its major challenge lies in the need for extensive education among shrimp farmers. Currently, sales and promotion to farmers are handled directly by agents with a limited understanding of aquaculture, resulting in suboptimal assistance and the impact of UV usage. YUKI say that this is evident in inconsistent shrimp production. On the other hand, some products are manufactured with inadequate components, such as non-corrosion-resistant materials, the absence of UV sensors, and the lack of automatic quartz sleeve cleaning technology.

To overcome these challenges, it is es-

11 Issue 10 | July -2023

Kanigya Kadiso & Vivi Kadiso

ICLE

sential to properly educate shrimp farmers on UV technology. This includes appropriately sizing UV systems based on flow rate and water conditions, ensuring correct UV system installation, and implementing effective after-sales support to ensure optimal UV performance.

Echoing the sentiments of Darjono and YUKI, Tiptopp Aquaculture representatives , Vivi Kadiso, and Kanigya Kadiso, emphasize that UV usage can enhance aquaculture success by reducing Vibrio and pathogen presence, preventing pathogen carriers such as fish and shellfish eggs from entering the ponds, and minimizing chemical contamination during sterilization processes.

Ozone Technology

In principle, an ozone generator produces ozone gas and injects it into the seawater for disinfection purposes. Like an UV technology, ozone has also been used in hatcheries for a long time. The main difference in utilization between hatcheries and ponds lies in the ozone dosage for effective disinfection. Due to the significantly higher water flow rate in grow-out farms, a larger ozone dosage is needed. Therefore, the ozone generator’s capacity used in ponds is much larger than that used in hatcheries.

Herman Susanto, the Director of PT Triotirta Karsa Abadi (distributor of BWT products), who has been involved in ozone generator applications for hatcheries, firmly believes that ozone can also be successfully used for shrimp farm disinfection. Besides its powerful and rapid disinfection capabi-

lities, which outperform other methods like chlorine, ozone’s impact on the environment is more natural as it does not introduce additional chemicals. Ozone naturally decomposes and reverts to oxygen.

Impressive results were obtained by Herman during a 10-month trial in shrimp ponds in 2020. He says that tests for Vibrio (TCBS and CHROMagar) consistently yielded negative results (0). Another positive aspect of using ozone is the more efficient water usage, shorter disinfection time, minimal environmental impact, and superior Deozonisation compared to the dechlorination process, which requires chemicals (H2O2), mechanical equipment, and a much longer time. “This shows that the disinfection process is working well and has been successful,” he adds.

Unlike UV treatment, which requires pre-treatment, ozone generally does not demand specific water conditions. It dissolves in water and exhibits a “residual effect,” allowing the disinfection process to continue as long as there is residual ozone in the water. The disinfection process time can be adjusted to obtain the best results based on the water conditions. It’s different from UV which occurs briefly within the UV chamber and is influenced by water clarity and UV transmission factors.

“While it’s worth noting that ozone usage requires a significant initial investment (capex), its operational costs are minimal, primarily comprising electricity expenses without the need for regular consumable components or materials (opex),” Herman concludes.

ECO 12 Issue 10 | July -2023

THE CRUST - AB, DENNY

Mr. Darjono (center) and Tequisa team

Photo source : YUKI, PT Tequisa Indonesia, PT Triotirta Karsa Abadi

Herman Susanto

UVC Immersion

Ozone instalation at hatchery

TIMEBreak RIDING THE WAVES

Surfing is more than just a sport; it’s a way of life that combines adrenaline-pumping excitement with a profound connection to the vast and untamed ocean. Originating in ancient Polynesia and evolving into a global phenomenon, surfing has transcended its humble beginnings to become a symbol of freedom, adventure, and harmony with nature.

At its core, surfing is the art of riding ocean waves using a specially designed board. Surfers, donning wetsuits or rash guards, paddle out to meet the swells, patiently awaiting the perfect wave. Once the moment arrives, surfers swiftly leap to their feet, balancing their bodies with grace and skill. The wave becomes their canvas, and the surfer, a dancer, as they carve elegant lines across the face of the water.

Beyond the exhilarating rush, surfing offers an unmatched communion with nature. In those fleeting seconds atop a wave, surfers harmonize with the ocean’s raw power, feeling its energy surge beneath their feet. The sound of crashing waves, the salty sea breeze, and the sun’s warm embrace all contribute to an immersive experience that invigorates the senses and calms the mind.

Surfing culture is a unique and vibrant community that spans continents. Surfers share a mutual respect for the ocean and its unpredictable nature, forming a bond that transcends language barriers and cultural differences. The surf tribe embodies values of camaraderie, environmental stewardship, and the pursuit of personal growth.

Despite its allure, surfing demands dedication and perseverance. Learning to surf is a journey in itself, requiring countless hours of practice and facing the frustration of tumbling into the waves. Not to mention the danger a surfer might face while partaking in this strenuous activity, yet, it is precisely this challenge that makes the eventual triumph so rewarding. The journey is a testament to the surfer’s determination and passion, traits that extend beyond the surfboard and into everyday life.

Surfing also plays a crucial role in environmental awareness. Surfers are on the front lines of witnessing the impact of pollution, climate change, and plastic debris on the oceans they hold dear. This firsthand experience has spurred numerous initiatives and organizations dedicated to preserving our marine ecosystems and inspiring the global community to take action.

For many, surfing is a spiritual experience—a means to escape the fast-paced world, unplug from technology and reconnect with nature. Surfers often find themselves embracing the Zen of the sea, finding solace and meditation in the rhythmic ebb and flow of the waves.

To sum up, surfing is more than just a pastime; it’s a celebration of life, freedom, and the immense power of nature. With its roots tracing back centuries, surfing remains an eternal dance between humans and the vast ocean, harmonizing athleticism, artistry, and a profound sense of belonging. Whether a novice or a seasoned pro, the call of the waves beckons, inviting all to join this remarkable journey of surfers worldwide—riding the waves towards a profound connection with the sea and themselves.

13 Issue 10 | July -2023

THE CRUST - RIZKY

Photo source : freepik.com

Protect your profits

Mitigate risk through mycotoxin deactivation

In addition to rising feed costs, mycotoxins further impact profitability by impairing growth performance and health status. The risk is never zero. Mycotoxin risk management is the insurance policy to secure feed quality and safety, whilst optimizing productivity.

Reduced risk

Increased productivity and efficiency

Sustainable production

If not us, who? If not now, when? WE MAKE IT POSSIBLE Follow

us on:

www.dsm.com/anh

always an honor to enthusiastic and amazing the sponsors who Additionally, we appre gave us to improve. use it to improve hearing a lot about events are discuss producers are concerned come out. This sit complicated and caused by this struggle is from feed mills all We believe that now and is vital to are by saving costs performance. For now, of at least 30% hopefully, the whole in situation better than innovations usually

TACTCon

Shrimp is love Shrimp is life

The more I know, the more I realize how little I understand. So stay humble and keep on learning.

I probably be up in the sky, deep in the sea, exploring the unknown, or building a shrimp farm

My secret to joy in life is in finding balance. Balance in family, sweating, and making decisions.

one another. We learned, laughed, and hopefully

to Cover art by Al - Ad

efficiency plays a big role right now and is vital

Rizky Darmawan

Cynthia Darmawan Gemilang Lim

Denny Leonardo

IN CRUST WE TRUST admin@pmindo.com Contact Us Rosebay Unit A101, Graha Famili, Blok W, Pradahkalikendal, Kec. Dukuhpakis Kota Surabaya, Jawa Timur 60227, Indonesia

Rizky Darmawan

Ngoc Diem Nguyen

Dr. Dean Akiyama

Rutchanee Chotikachinda

Rajeev Murthy

Dr. Putth Songsangjinda

Chiow Yen Liew

Rizky Darmawan

Ngoc Diem Nguyen

Dr. Dean Akiyama

Rutchanee Chotikachinda

Rajeev Murthy

Dr. Putth Songsangjinda

Chiow Yen Liew