Building community in a global village improves retention rates

KAREN DAVIDSON

KAREN DAVIDSON

Ever pick up an asparagus harvesting knife? Its razorsharp blade is best left in the dexterous hands of a pro like José Francisco Perez. He’s skilled at quickly spotting prime asparagus, then deftly slicing the spear free from its rhizome. His movements are spare, as he inches down the row on his customized, gasoline-powered harvesting cart. Perez is a highly valued temporary foreign worker (TFW) at Sandy Shore Farms Ltd., Port Burwell, Ontario. He’s worked at the farm for four years now, returning to his home in San Luis Potosi, Mexico every winter. A big part of what makes him feel at home here in Canada is the ability to chat in his Spanish mother tongue with Sandy Shore’s assistant human resources manager, Pancho Chanquin.

Originally from Guatemala, Chanquin offers another unique story. He came to the farm under the AgStream program in 2022 and then successfully applied for

permanent residency. Along with his Canadian-born wife, he now lives in a rental property, a short commute from the farm. Chanquin is often found in the field, deep into conversation with Jamaican Curtis Dixon, Sandy Shore’s harvest and labour manager. Dixon originally came to Canada under the Seasonal Agricultural Worker Program (SAWP) then switched to the AgStream program. With the support of Sandy Shore Farms, he gained permanent residency.

“Curtis plays a huge role in our operation,” says Amanda Doughty, human resources manager, surveying a work crew at full throttle. “He has up to 146 people reporting to him in the field.”

Doughty, formerly a Best Buy store manager, is now pursuing her dream in human resources.

“For the last three years, I’ve been responsible for ensuring that labour needs are met to support the operational and strategic goals of Sandy Shore Farms,” she says. “At first, I was looking after the process of Labour Market Impact Assessments (LMIAs), but that role

has expanded to not only submitting the LMIAs but truly understanding the AgStream and SAWP. I make sure that we have the right people at the right time in the right roles.”

She supports Curtis Dixon in his training and orientation role. He has created cue cards showing the five growth stages of asparagus. For a new cutter, it’s a daunting task to identify the differences, especially as the season progresses. But after visual training, it’s obvious which seedy heads should stay in the field.

“Quality is very important to us,” says Doughty. “Real productivity is picking only what can be marketable.”

The themes of quality and quantity are important to the farm’s success. “We have focussed on continuous improvement,” says Doughty. “People need to know their goal. We measure labour costs per pound of produce, graded, packed, and marketed.”

Continued on page 3

JUNE 2024 CELEBRATING 145 YEARS AS CANADA’S PREMIER HORTICULTURAL PUBLICATION THEGROWER.ORG RIGHT PEOPLE, RIGHT ROLES

Volume 74 Number 06 P.M. 40012319 $3.00 CDN @growernews BC Tree Fruits Cooperative in Oliver P6 8 Loblaw and its food court PG 15 Logistics and transport PG 18

Asparagus harvest is intense for six to eight weeks each season. The role of Amanda Doughty, human resources (HR) manager is to support the harvest and labour manager in his oversight of 200-plus workers who are cutting quality spears at Sandy Shore Farms Ltd., Port Burwell, Ontario. It’s the first of three crops that include bell peppers and onions. Her HR assistant, Pancho Chanquin, R, is a Guatemalan who is valued for his leadership qualities and ability to speak Spanish to field workers such as José Francisco Perez. Photos by Jeff Tribe.

AT PRESS TIME…

Loblaws to sign on to Grocery Code of Conduct with caveat

Canada’s largest grocery retailer, Loblaw Companies Ltd., has told its 1,300 suppliers that it will sign the Grocery Code of Conduct as long as hold-outs do too. That means Wal-Mart Canada and Costco.

In a May 16, 2024 news release, president and CEO Per Bank said, “We have worked intensively and collaboratively with industry groups so that the Code is clearly drafted and fair for all industry participants. We believe in the value of a code of conduct for the industry and are happy with the progress made. The Code now requires the participation of all major retailers and suppliers to help bring in a new era for Canada’s grocery industry, enhancing the relationship between retailers and suppliers, who both exist to best serve customers.”

The path to the Code was initiated by the federal-provincial and territorial ministers of agriculture as a volunteer, industry-led solution. For more than two years, organizations within the grocery industry –including retailers, processors and manufacturers – have been grappling with the details. time, A large focus was on developing a code that works for small suppliers, consumers and the industry.

“It is welcome news that Loblaw has agreed to participate in the Grocery Code of

Conduct,” said Michael Graydon, chair of the Interim Board for the Code of Conduct.

“Within a very complex food system, the vision for the Code has always been based on a fully inclusive, voluntary Code, developed by the grocery industry and managed by its stakeholders across the supply chain. We are one step closer to the implementation of the Code as we continue to work with all industry partners to ensure we have maximum participation by all stakeholders.”

Canada’s ag minister Lawrence MacAulay and Québec’s ag minister André Lamontagne, weighed in:

“The goal of the Grocery Sector Code of Conduct is to bring fairness, transparency, and predictability to our grocery sector and supply chain. We believe that uniting all supply chain partners around these principles will produce the best outcomes for the sector and all Canadians. With the news that Loblaw is signing on, we now call

on the remaining large retailers to do what is in the best interests of Canadians and follow suit.”

For its part, the Fruit and Vegetable Growers of Canada issued a statement:

“We believe this is a significant step forward in promoting fair and transparent practices within the grocery sector, which will benefit both growers and consumers. We understand there have been discussions around clarifying certain aspects of the Code to address concerns from various stakeholders.

Our focus remains on advocating for the interests of Canadian growers, and we are pleased to see progress in this direction.

We will continue to monitor developments and work closely with our representative on the Interim Board of Directors, Patrice Léger Bourgoin, and other stakeholders to support the implementation and adherence to the Grocery Code of Conduct.”

NEWSMAKERS

The Canadian Produce Marketing Association held its Fresh Week in Vancouver from April 23 to 25. Hearty congratulations to all the winners:

• Fresh Health Award – City Wide Produce

• Young Professional Award –Jessica Levac, Bellmont Powell

• CPMA Lifetime Achievement Award – Murray Driediger, BC Fresh Vegetables Inc. (BCfresh)

• The Packer’s Produce Person of the Year Award – David Karwacki, former CEO of The Star Group

• Best Island Booth Award –Mastronardi Produce, booth 1130

• Best Inline Booth Award – Sollum Technologies, booth 751

• Best First-Time Exhibitor Booth Award– Quik’s Farm, booth 1223

New Product Showcase Awards

• Best New Product Award –Steamed fresh vegetables by EarthFresh

• Best Snackable Product Award – Snack Packs by Taylor Farms

• Packaging Innovation Award – Mucci Farms

Three-time Olympian Cassie Campbell-Pascall was the motivational speaker who kicked off the CPMA conference and trade show in Vancouver. Her fame came as the longest serving captain of the Canadian Women’s Ice Hockey team and a former sports commentator with Hockey Night in Canada. She described the paradox of making the front page of Canadian newspapers as a demoralized, tear-stained loser in an epic Canada-U.S. series. But then realized the breakthrough of first-time, headline coverage of women’s hockey in national media.

Congratulations to Clean Works Inc, St. Catharines, ON and Genecis Bioindustries Inc, Toronto, ON. They are the winners of the Novel Technologies Streams for the Food Waste Reduction Challenge sponsored by Agriculture and Agri-Food Canada. Each will receive up to $1 million to accelerate their proprietary solutions. Clean Works Inc. developed a solution that uses hydrogen peroxide, ozone and UV to control mildew and micro-organism growth in pre-harvest (greenhouses, field crops, grapevines) fruit and vegetables. This solution allows the shelf life of produce to be increased by up to 20 per cent, which Clean Works estimates to prevent nearly 50 tonnes of food waste annually for grapes and spinach alone in Canada.

Genecis Bioindustries developed a specialized bacteria that transforms food waste into compostable bioplastics. Over the last three years, the company has diverted more than 2.1 tonnes of food waste from the landfill, allowing them to produce around 5,000 tonnes of environmentally-friendly bioplastic at their Toronto facility each year.

The Canadian Grapevine Certification Network held its annual general meeting on April 30. The 2024 chair is Hans Buchler (BC); vice chair Mélanie Gore (QC); treasurer Matthias Oppenlaender (ON); secretary Scott Savoy (NS). Directors include: Ross Wise (BC); Albrecht Seeger (ON); Louis Thomas (QC); Bill Armstrong (NS). The board of directors is appointed by respective provincial grape-growing associations: the British Columbia Wine Grape Council, the Grape Growers of Ontario, the Conseil des vins du Québec, and the Grape Growers’ Association of Nova Scotia.

THE GROWER

PAGE 2 –– JUNE 2024

Sponsors of the motivational speaker, the Ontario Greenhouse Vegetable Growers, were pictured with Cassie Campbell-Pascall. To her left, George Gilvesy, chair of the board, and to her right, Richard Lee, executive director.

Building community in a global village improves retention rates

Continued from page 1

While she doesn’t reveal proprietary data, Doughty does share that worker retention rates have improved markedly over the last two years, increasing from 60 to 73 per cent of the 207 annual workers currently at the farm. She attributes this success to building community amongst the workers who travel from Mexico, Jamaica, Barbados, and Trinidad and Tobago. Working alongside her Spanish-speaking HR colleague, she’s been able to respond to after-work needs such as blenders for salsa and dominoes in every bunkhouse.

The

El Salvador pilot

Coming off this track record, Sandy Shore Farms owners Ken Wall and his son Marc are confidently participating in a pilot with El Salvador in summer 2024.

“There are two elements that really excite me about participating with the El Salvador pilot,” says Ken Wall. “First, historically we have sourced workers from only two regions: the Caribbean and Mexico. We have found that over the years, and especially during COVID, there has been an increased administrative strain in both of these regions. By adding additional regions to source workers from, we are increasing the diversity of our community, and ensuring a sustainable workforce in years to come.”

“The second element I am extremely excited about is the level of engagement and hands-on support we are receiving from the El Salvadorian Government. They have created some incredible programs designed to support the workers both before and after their arrival here in Canada. The El Salvadorian Government is committed to make this pilot a success, and we are grateful for their support.”

Doughty visited El Salvador in March 2024 to learn more about the country and the government’s program. While there, she provided a slide show to the 10 selected workers on what to expect at Sandy Shores. They gave an enthusiastic thumbs-up to the annual Norfolk Soccer Tournament.

It’s pilots like these that encourage Bill George, chair of the labour section, Ontario Fruit & Vegetable Growers’ Association. Members have voiced their needs for more hands on deck as the horticultural sector grows.

“COVID gave us a wake-up call,” says George, “that our source countries might not send international workers. So we’re reaching out to embassies and consulates to gauge their interest. El Salvador has proven to be a good fit.”

In fact, El Salvador’s minister of labour visited leaders of the Ontario horticultural sector in summer 2023 and held on-farm meetings with prospective employers.

“We would like Ontario to become the leading destination for international workers,” said George, pointing to the labour committee’s efforts to share best HR practices.

For her part, Amanda Doughty is pioneering a new path on how to welcome and support temporary foreign workers. Out of that respect for diversity, she’s currently learning to speak Spanish with Pancho Chanquin as her coach. A Spanglish-speaking office? Buenos dias is how they start the day.

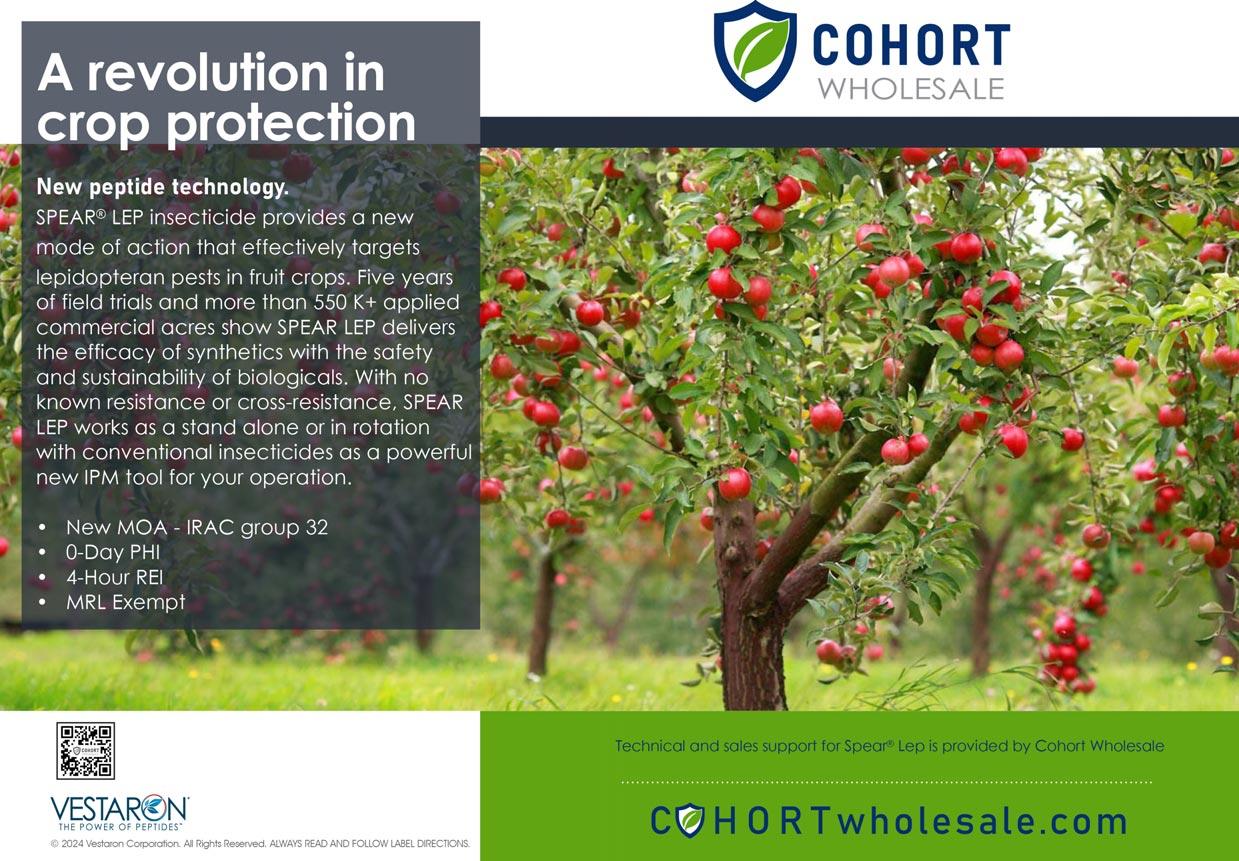

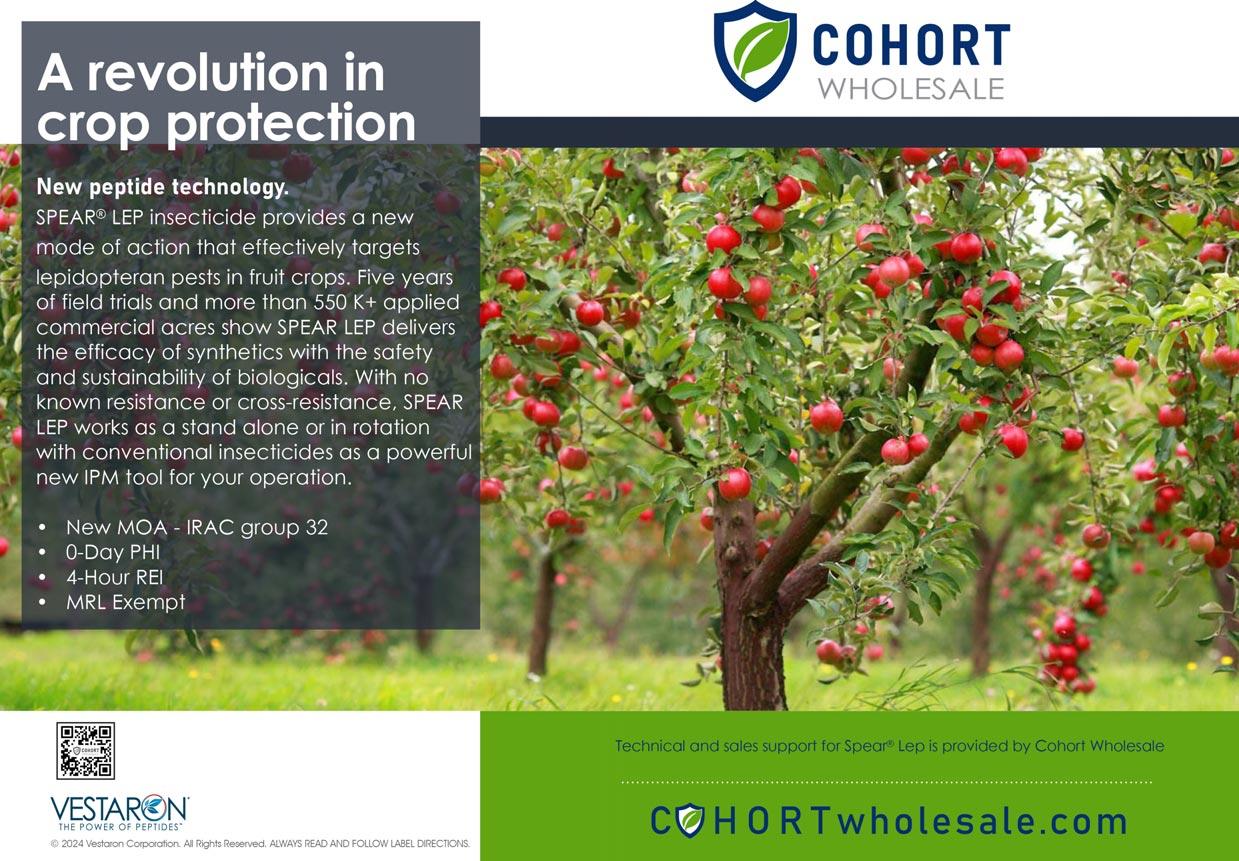

The Grower is “Digging Deeper” with Amanda Doughty, human resources manager at Sandy Shore Farms Ltd., Port Burwell, Ontario. She shares her experiences in training, supporting and retaining 200plus temporary foreign workers as they harvest asparagus, bell peppers and onions. This podcast is sponsored by Cohort Wholesale.

JUNE 2024–– PAGE 3 THE GROWER COVER STORY

Curtis Dixon, a Jamaican, is now a permanent resident and has the pivotal role of harvest and labour manager. He works closely with Amanda Doughty, centre, and Pancho Chanquin, far left.

Curtis Dixon developed this visual guide on asparagus stages – how to pick straight spears and firmly closed heads and to recognize the differences as the season progresses. The message to pickers? Leave the less desirable spears in the field.

Marc Wall, chief operating officer, Sandy Shores Farms Ltd., is confident in his management team to bring a quality product to customers across Canada and the U.S.

CROSS COUNTRY DIGEST

BRITISH COLUMBIA

BC cherry growers look for new insurance model to address extreme weather

meeting can be arranged, Bal would like to pitch a perennial crop resiliency program that would cover costs of retractable covers and wind machines. And for growers historically purchasing 80 per cent coverage, there would be an optional top-up to 90 per cent. The wellbriefed premier was aware of his ag ministry’s $70 million replant program, but Bal says that more needs to be done to prevent losses in real-time with technology. Rather than wait to “farm” the insurance program, Bal is advocating for a resiliency fund to anticipate and manage extreme weather events.

KAREN DAVIDSON

Kelowna, BC — Come the end of April, Sukhpaul Bal’s blooming cherry orchards should resemble a late spring snowfall. Instead, he finds himself scratching open a blossom to look for signs of life at the base of the pistil. Nope, no hope for this particular bloom.

“It’s the silent disaster,” he says of the -30°C temperatures last January 13 that destroyed the fruiting potential of his 85 acres at Kelowna. Although growers in the southern Okanagan valley,

BRITISH COLUMBIA

around Osoyoos and Oliver, fared better, forecasts are that British Columbia’s 6,500 acres of cherry orchards will yield less than 30 per cent of what’s normally expected.

As president of the BC Cherry Association, Bal is advocating today for the future viability of a $200 million/year sector that’s faced five consecutive years of extreme weather and its impacts. The provincial government has announced a $70 million disaster recovery program but as Bal explains those funds cover only plant materials and none of the

costs associated with orchard maintenance directed at extreme weather resiliency.

Most of the province’s cherry growers buy crop insurance for perils such as hail, too much rain, too much heat. But even at the highest levels of insurance, covering up to 80 per cent of losses, growers can’t stay in business just farming the government’s insurance program. Nor do they want to.

“We’re advocating that the provincial government’s insurance agents decide earlier in the crop season that the crop is

not viable, it’s a full write-off,” says Bal. “What we’ve learned in the past five years is that we should abandon the prospects of a crop earlier and move on. The crop insurance program was originally designed decades ago for a once-off bad year. There was no calculation for multiple extreme weather events. Over five years, the 20 per cent deductible becomes a big number.”

A bold encounter with BC premier David Eby at a press conference in Vancouver gives a glimmer of hope. If a follow-up

Almost all of Okanagan grape crop lost to deep freeze

KAREN DAVIDSON

Oliver, BC — Hopes for a 2024 grape crop in British Columbia’s Okanagan and Similkameen valleys have dimmed as buds have failed to show viable growth this spring.

BC agriculture officials say that up to 95 per cent of the crop is affected. The long-term damage

to vines is being assessed says Lindsay Hainstock, regional agrologist and grape specialist.

Hainstock explains that vines have three sets of buds.

“It’s a lot of those first and second buds that have been lost, and when we’re getting down to the tertiary buds, they can be a little later to come out, so we’re still in the assessment stage right now to see how extensive is the

damage out there,” she explained.

“But a lot of people are waiting to see if the vines can be salvaged. That is going to be the first choice for most people because it is quite costly to replant.”

Crop insurance officials are estimating up to 50 per cent of vines will need to be replanted, especially in the North

Okanagan. The situation is more mixed in the South Okanagan.

The BC Ministry of Agriculture and Food says that many grape growers are participating in the province’s crop renewal program with $2.3 million pledged towards removing unproductive vines and planting heartier varieties suited to the region’s climate conditions.

Approximately $27 million in

The coming weeks will be telling as the BC government weighs options. Will the national Agri-Recovery program be invoked? It’s a shared business risk program that requires provincial funding at the rate of 40 per cent.

“Extreme climate is the biggest threat to horticulture and food security,” says Bal. This simple truth with a not-so-simple story was delivered virtually during his invited address to the House of Commons Standing Committee on Agriculture and Food on May 2.

©The Grower

production insurance claims were paid out to growers in 2023, mostly stemming from that winter’s freeze event. It’s estimated that more than $500,000 in AgriStability payments will be paid to grape growers to help offset losses experienced in 2023.

Moving forward, the robust winery industry is looking south of the border for grapes to crush in the fall of 2024. To that end, the Washington Wine Growers is liaising with Washington State Department of Agriculture to see if their grapes can plug the gap.

Kristina Kelley, executive director for the Washington State Wine Commission confirmed that the proposal is for Washington fruit to be supplied in the August/September time frame so that BC wineries can process the fruit.

PAGE 4 –– JUNE 2024 THE GROWER

Sukhpaul Bal, president, BC Cherry Association, examines blossoms for signs of life after a deep freeze event in his Kelowna orchards on January 13, 2024.

On April 27, these grape buds were not showing life in a vineyard near Oliver, BC.

Little Potato Company opens packaging facility in Nisku

The Little Potato Company held the grand opening of its sustainable potato packaging facility in Nisku, Alberta on May 2.

Spanning 240,000 square feet, the new facility represents a $39.5 million investment and is strategically located in the Nisku Business Park. This location was chosen for its proximity to exceptional agricultural regions, dedicated family growers, efficient transportation networks, and a skilled workforce.

The new facility showcases technology that revolutionizes the way little potatoes

are washed, sorted and packaged, prioritizing eco-friendly processes. With a substantial reduction in carbon footprint and waste, The Little Potato Company is at the forefront of steering the industry toward a more sustainable future in food production. Notably, one-fourth of the facility’s energy is generated by 3,288 solar modules, marking the second largest privately funded rooftop microgenerator in Alberta. Additionally, a state-of-the-art water recycling system has been installed, allowing the facility to recycle water used in washing little potatoes. This ground-

breaking system significantly reduces water usage, lowers operational expenses, and boosts both the value and safety of its products.

With the capacity to process approximately 125 million pounds of little potatoes annually, the facility is poised to set new industry standards. Roughly 70 percent of this capacity will be used for export sales, primarily to the United States. The project received support from the Agri-Processing Investment Tax Credit program of the Government of Alberta, contributing $1.3 million. This initiative is designed to bolster local businesses, driving economic growth and diversification in the province.

Angela Santiago, CEO, and co-founder of The Little Potato Company, expressed

her heartfelt gratitude and enthusiasm about this milestone, stating, “Today is more than an opening; it’s a promise to our community and the planet. What started as a humble dream has blossomed into a global endeavor dedicated to sustainably nourishing and feeding the world better, one little potato at a time. Our innovative facility is built with future generations in mind. We are ensuring that we lead in eco-friendly production to meet growing demand for families wanting to serve delicious and nutritious whole food quickly.”

Source: Little Potato Company May 2, 2024 news release

ALBERTA JUNE 2024–– PAGE 5 THE GROWER CROSS COUNTRY DIGEST

GREENHOUSE GROWER

AgriScience Cluster research includes two greenhouse projects

The Canadian AgriScience Cluster for Horticulture (Cluster 4) is under way, with the first year of research activities starting in 2023. Spanning from 2023 to 2028, Cluster 4 represents 10 research activities. These activities are focused on the innovation, competitiveness, and sustainability of Canada’s fruit and vegetable industry.

Cluster 4 addresses key challenges in the Canadian horticulture industry for the production of apples, berries, field vegetables, greenhouse vegetables, and potatoes. Through the 10 research activities, researchers plan to discover improved operational efficiency and sustainability for growers. Various activities

target reduction of on-farm chemical use, improving soil health, and finding more sustainable fruit and vegetable varieties for growers across the country.

The Cluster is a collaborative effort between the Fruit and Vegetable Growers of Canada (FVGC) and Agriculture and Agri-Food Canada’s (AAFC) Sustainable Canadian Agriculture Partnership. The activities include researchers working at AAFC, universities, colleges, and private industry.

Over the next few years, researchers will share updates on their work through the FVGC website and its social media accounts. Research activity updates will include bi-annual knowledge translation

and transfer (KTT) reports, current updates, and early research findings. These updates are being compiled by the team at Burr Forest Group, an agricultural communications company with specialized knowledge of cluster activities.

The Cluster 4 research activities are:

• Reducing losses from apple pests with alternative control strategies

• Apple crop load management: enhancing thinning predictability and tree response through advancements in modeling, new precision thinning products and strategies, and technology

• Canadian Berry Trial Network

• Increasing field vegetable yield and resilience to abiotic and biotic stresses through soil microbial engineering

• Reduce risk strategies for cabbage maggot control

• Developing a systems approach to pest management on greenhouse vegetable crops: mirid predator selection

• Novel approaches for the management of tomato brown rugose fruit virus (ToBRFV)

• National potato variety evaluation for sustainability, resilience, and climate change

• Regenerative and sustainable agriculture for climate change adaptation and carbon sequestration: rebuilding soil health and increasing crop productivity of Canadian potato production systems

• Positioning Canada’s potato industry for improved sustainable production

Greenhouse growers, specifically, will be interested in two of the projects.

1) Developing a systems approach to pest management on greenhouse vegetable crops: mirid predator selection is led by Roselyne Labbé, a research scientist in greenhouse entomology with AAFC at the Harrow Research and Development Centre. The research team is working to find new integrated pest management strategies to protect greenhouse vegetable crops by studying three native North American mirid species: D. discrepans, D. famelicus, and Macrolophus tenuicornis. They are conducting trials to compare the biological characteristics of select strains of these mirid species and to rate their ability to manage greenhouse pests such as whitefly, spider mites and aphids.

2) Novel approaches for the management of tomato brown rugose fruit virus (ToBRFV) is led by Aiming Wang, research scientist with AAFC at the London Research and Development station. Tomatoes are the primary host of ToBRFV. The viral pathogen has been recently identified and spreads rapidly. Researchers are studying the infection process and working to develop novel genetic resistance to ToBRFV in greenhouse vegetable crops.

What does a booth say about your company? Marketing executives answer

Vancouver, BC - The Canadian Produce Marketing Association Conference & Trade Show is always an intense event. Start with the Innovation Zone. And then cruise the trade show floor for the most creative booths. The greenhouse sector is famous for its chef-inspired bits and bites.

Best Inline Booth Award -- Sollum Technologies

“We take great pride in presenting our innovative dynamic LED grow light solution, aiming to capture the authentic ambiance of a greenhouse. At CPMA, our booth provided a welcoming space for engaging with dedicated growers and influential industry figures, fostering meaningful interactions. This recognition of receiving the Best Inline Booth award is a testament to our commitment to excellence and the meticulous attention to detail we apply in all our endeavors.”

- Jenny Zammit, vice president marketing & communications

Best Island Booth Award – Mastronardi Produce

“We love to bring flavour to every show we attend, and this year’s CPMA was a special event for the Mastronardi Produce team,” said Paul Mastronardi, president and CEO of Mastronardi Produce. “As we approach our 70th anniversary as a company, we feel privileged to be part of an industry that is collectively pushing boundaries in Canada and beyond. It was an honor to wrap up the show with many positive connections and the award for Best Island Booth.”

- Paul Mastronardi, president and CEO, Mastronardi Produce

Organics

Award – Windset Farms

“These environmentally friendly, 100 percent recyclable packs not only contribute to our sustainability efforts but also offer excellent merchandising opportunities with exceptional product visibility,” said Ryan Cherry, director of sales, Windset Farms. “We’re excited to provide this pack option for our Organics line, a testament to our commitment to high quality, sustainably grown products.”

- Ryan Cherry, director of sales, Windset Farms

Packaging Innovation Award – Mucci Farms

Congratulations to our Packaging Development Team for another well deserved recognition for our Paper Bamboo Mesh Bag.

- Ajit Saxena, communications manager, Mucci Farms

PAGE 6 –– JUNE 2024

THE GROWER

D. discrepans female and D. famelicus female, two of the native mirid bug species under study. Photos by Carly Demers.

KAREN DAVIDSON

GREENHOUSE GROWER

Cucumber grower looks back on 45 years

“

We’ve been anchored in the industry for more than 45 years now.

~ SEAN ROBINSON

KAREN DAVIDSON

Abbotsford, BC – Big glass greenhouses, little cities unto themselves, now dot British Columbia’s landscape south of Vancouver and east into the Fraser Valley. But when the sector was in its infancy, Sean Robinson grew tomatoes, peppers and cucumbers under polyethylene plastic. Not always at the same time.

“We’ve been anchored in the industry for more than 45 years now,” says Robinson.

The energy crisis of 2000, with prices doubling and tripling, forced Robinson to reconsider his passion for tomatoes and peppers. To eliminate heating in the darkest months, he turned to cucumbers. Still, they required seeding in February to be ready for transplanting March 1. Those were the days before propagators took over this specialized component of greenhouse growing.

“Greenhouse cucumbers are a jungle plant,” explains Robinson. “They like refracted light, just like coffee trees in the understory of a forest.”

Under polyplastic, cucumbers thrive in the humid environment producing seven to 10 per cent higher yields per square meter than under glass. Along with his son Christopher and four local Punjabi workers, they aim to harvest 150 to 155

cucumbers/square meter based on two turns per year. Yes, higher yields can be produced under a high-wire system – up to 230 cucumbers/square meter without lights and up to 300 cucumber/square meter with lights. But cost of production also goes up with a high-wire system. It’s not a simple calculation depending on geography.

The Robinson’s are gratified with their “holistic” system that allows the family to manage the labour-intensive, one-hectare greenhouse. Their harvest is marketed by BC Hothouse/The Star Group.

Over the years, Christopher has gained confidence in biological controls, distributing sachets of beneficial insects that control insects such as aphids, thrips and whiteflies – the triple threats to greenhouse yields.

He’s been quite successful with thrips, in particular, doubling the density of sachet numbers at the correct time. Getting in early and ramping up sachet rates over the first six weeks of the season is critical.

“With biologicals, it’s important to understand the life cycle of insects and how they respond to light,” says Robinson. He explains that their management system is tuned to their location – amongst hundreds of acres of blueberries and subject to the winds off the Pacific ocean. These factors contribute to insect pressure.

“You must consider the history of your location,” he says. “and lean on your experience.”

At this stage of his career, Robinson has no romantic notions about farming. That’s a sentiment echoed by Christopher who’s been all-hands-on-deck for the last 10 years. After tending to a crop nine months

THE GROWER JUNE 2024–– PAGE 7

of the year, the rest is clean-up and readying the greenhouse for the next season. Robinson concludes: “You have to be dedicated and totally in.”

Christopher Robinson has been vigilant in thrips control, understanding that early timing and correct rates are key to success.

Sean Robinson and his son Christopher grow greenhouse cucumbers near Abbotsford, British Columbia.

BC Tree Fruits Cooperative resets in Oliver

KAREN DAVIDSON

Oliver, BC – The BC Tree Fruits Cooperative, with its 230 member families, is undergoing transformational change with a newly upgraded packing facility in Oliver, British Columbia. Thanks to MAF Roda AgroBotic, the France-based company installed a turn-key solution in January 2024. The plant is drawing on its apple storages throughout the Okanagan Valley to wash, sort and pack apples before the new harvest begins in August. While kinks are being sorted out, the promised benefits of the $60 million investment are near at hand says Craig Ogilvie, vice-president of supply chain. The revamped Oliver operation includes a building expansion and new apple and cherry lines.

The supervisor screen allows the grading technician to monitor the apples running down the line. The grading is constantly finetuned throughout the season to maximize grower returns and provide the customers with good quality product.

The automatic sorting Pregrade line sorts apples by grade and size. It allows BC Tree Fruits to know exactly what size and grade of apples are available throughout the season, allowing the cooperative to meet customer demand more effectively.

place apples into trays. The unique capability of this technology is that it can place apples colour-side up and have the stems facing in a specific orientation.

Tray Packing Line. Once the apples have been packed, they run through the Sinclair labelling system for domestic product. No labels are applied when producing for the export market. The apple trays then feed an automatic TOPs tray inserter and packs into half and full boxes.

The TOPs automatic robotic palletiser system stacks the boxes into full pallets.The robotics can be configured to a number of pallet orientations. It can palletize RPCs, half and full size boxes.

PAGE 8 –– JUNE 2024 THE GROWER NEW TECHNOLOGY

MAF Roda Automatic Line Pack. This new automation is the first of its kind in North America. The Line Pack uses robotic arms to

SEE YOU IN MONTREAL As of April 1, 2024 F ARMER’S FRESH MUSHROOMS PLATINUM GOLD CHAIRMAN’S CLUB #CPMA2024 www.convention.cpma.ca

Biodegradable rubber band tag launched in Canada

KAREN DAVIDSON

KAREN DAVIDSON

Vancouver, BC – Dampack, a family-owned company from the State of Mexico, attended the Canadian Produce Marketing Association’s conference and trade show with a mission: to launch their new MEGTag. This is a rubber band tag that is biodegradable in the printed tag part, and the band can be directed to recyclable waste once detached from it.

“About eight years ago, the company started discussing the possibilities of manufacturing sustainable rubber band

tags,” says Manuel Núñez Rodríguez, CEO. He refers to a tag made from biodegradable materials with a recyclable elastic band.

“We tested many paper specifications,” he continues. “It’s not easy to find paper that you can print on and apply the coating that allows you to maintain its physical and functional characteristics. Finally, we found the materials that enable us to offer this material that meets market requirements and can also be sustainable.”

Tests have been conducted in Mexico on packaging, with parsley, cilantro, asparagus, onions, potatoes, and watermelons. Depending on the volume ordered, the cost

ranges between $19 and $22 per thousand tags.

Dampack has been manufacturing alternative packaging for the agro-industry and retail sectors for more than 20 years. This innovation promises to eliminate hundreds of tons of polymers in future waste, while maintaining the reliable strength standards of their tags.

THE GROWER JUNE 2024–– PAGE 9 PACKAGING

Manuel Nunez Rodriguez, CEO, Dampack, is pictured in his company’s booth at the Canadian Produce Marketing Association Conference & Trade Show, in Vancouver.

INTERNATIONAL SUSTAINABILITY SUMMIT

Sustainability needs to be more than just a cost centre

KAREN DAVIDSON

KAREN DAVIDSON

Vancouver, BC – The angst of a grower in the audience at the International Sustainability Summit captured a common sentiment: “We feel these sustainability issues in a real way, but who pays? No one has offered me $2,500 to adjust my operational schedule in the middle of June to do your audit. And there are no promises that the retailer will buy my produce in the end. There’s a cost to doing that audit.”

Her fearless comment is at the heart of a current discussion about sustainability at all levels of the food supply chain. More companies are requesting metrics around sustainability, even all the way up the chain to finance. The Royal Bank of Canada recently established a director of sustainable finance. Graeme Blair works with mid-market clients ($300 million+ in revenues) who view sustainability and Environmental Social and Governance

(ESG) factors as essential parts of their corporate strategy and investment decisions.

Lofty ideals but back on the farm, it would seem there’s scarce commonality about how to define many sustainability issues, such as soil health and water use for example. In fact, another audience member voiced an opinion that “Reducing water is not necessarily good for the environment. We should have less prescription of practices and more agreement on the outcome: reducing the carbon footprint.”

The common sense here being that growers can’t reduce irrigation anywhere close to zero without adverse results.

“Everyone is having difficulty navigating this soup of sustainability,” said John Tesko, executive director, Potato Sustainability Alliance, an organization that’s just published its 2023 annual report with 420 growers representing almost 600,000 acres in Canada and the U.S. “My goal is how to harmonize what’s asked of growers. In agriculture, monitoring and measuring favours larger operations.”

A current bright spot in the push for improved supply chain sustainability is the example of an partnership between Sobeys and Verdant Technologies. Tom Pierce, national director of produce sourcing and supplier development, Sobeys shared results of grower trials using HarvestHold Fresh, a product of Verdant Technologies.

“Innovation is not just new tech,” added Matt Aronson, chief revenue officer, Verdant Technologies. “It’s how we partner and how the broader industry can benefit. Sustainability should be thought of as a pre-competitive concept. We all need to have competency in sustainability.”

Results from these trials illustrate the broad impact new tech can have on sustainability. A single sheet of HarvestHold, engineered to bind 1-MCP crystals that slowly vaporize, is placed in every box of fresh broccoli at

harvest. Gaseous 1-MCP curbs the ripening process, which in the real world means longer shelf life.

Environmentally, eliminating ice from vegetable shipping is a big plus for sustainability – think broccoli packed in ice being trucked from Arizona to Eastern Canada. Beyond carbon savings from no longer making ice and hauling its extra weight cross country, there’s also improved safety – no more water-soaked loading docks. Potentially, this is twice the bang for the buck, lowering costs while advancing sustainability.

Improving shelf life and sustainability on their own is winning enough. As Graeme Blair, Royal Bank of Canada commented, “In a time of high food inflation, we’re looking to better quality produce that lasts longer.”

The HarvestHold Fresh product is but one example of how ongoing research and improved practices can reduce strain on dwindling resources, ultimately providing benefits from farms right through to retailers’ shelves.

Innovation and new tech notwithstanding, every grower needs to approach sustainability initiatives on a case-by-case basis. Capturing the sentiment of many growers at the Vancouver conference, Richard Schouten, Freshfel Europe, summerized “We want to be at the table, but not on the menu.”

The Canadian Produce Marketing Association (CPMA), in partnership with the International Federation for Produce Standards (IFPS) and the Global Coalition of Fresh Produce, hosted the International Sustainability Summit on April 26 in Vancouver. The event attracted 100 participants from seven countries to discuss leading sustainability challenges, barriers and opportunities for the fresh produce industry.

Next steps, says Dan Duguay, CPMA sustainability specialist, is to draft a Fresh Produce Sustainability Charter in Q2 2024.

THE GROWER PAGE 10 –– JUNE 2024

L-R: Tom Pierce, Sobeys and Matt Aronson, Verdant Technologies.

THE GROWER JUNE 2024–– PAGE 11

Making it through agriculture jobs alive isn’t a given. But it should be.

KATHARINE REID

Farming is one of the most dangerous professions in Canada. It needs to get better—but how? Beyond proper safety protocols, involved supervisors and proper training, we need to instill a safety mind-set in our youth, otherwise, we’re doomed to repeat past mistakes.

Ryan Dick has shattered his forearm so severely that fragments of bone are in his spine. He nearly had his fingers ripped off. He almost inhaled fatal

fumes. And he’s had several close calls involving heavy equipment. Given the severity of Dick’s injuries, and the number of near-death experiences he’s suffered over the years, you might guess he’s a double agent or a stuntman. He’s actually a farmer who started young. He is applauding a new blog that encourages parents to talk safety with their kids.

“There’s a reason it’s one of the most dangerous professions in Canada,” says Dick. “We have one of the smallest workforces but some of the highest injury ratings.

And honestly, the numbers don’t even do it justice, because we typically don’t report illnesses in agriculture.”

Good supervisors and proper training are key to worker health and safety

When Ryan Dick was just 14, the tractor he was driving sunk into a washout. The tractor stalled suddenly, slamming the steering wheel into Ryan’s arm, shattering his forearm. With no cell phones, he travelled a painful quarter mile on foot, before

finding help and was rushed to the Children’s Hospital of Eastern Ontario.

The injury still affects him today. But it could have been so much worse. “If I had been standing, I would have been thrown off and probably killed flat out,” he says. “Oddly enough, I just sat down.”

His life, it turns out, had been spared by luck—not by the person who was supposed to keep him safe: his supervisor. Unbeknownst to him, a worker in the field had informed the farm supervisor several days prior that there was a

washout and that it needed to be marked. The supervisor did nothing.

Dick is still farming, but his day job is now focused on keeping farms, farm operators and their workers safe as a consultant at Workplace Safety & Prevention Services. He’s passionate about protecting farmers and the people who work for them, at any age. He understands the position of young workers. They may not have been properly trained on how to do their job safely and feel uncomfortable asking questions.

“Kids go into the workforce with a sense of invincibility,” he says. “They’re happy to have a few bucks in their pocket and a little independence. Safety is often the last thing on their mind.”

This is why parents are the focus of a new blog called First Job Safe Job. “We may not always feel it, but we are still pretty significant influencers in our kids’ lives. We can help prepare them by talking about workplace safety. And helping them understand their rights.”

As Ryan Dick changed jobs, his exposure to danger continued. As a young adult, he worked for a company that did custom agricultural extermination, involving the application of herbicides. Because he was unfamiliar with the product he was being asked to use, he checked in with his supervisor.

“I’ve never sprayed this crop before, and I’ve specifically never sprayed with this chemical before,” he recalls. “Is there anything I need to worry about?”

The supervisor gave him the all clear but he didn’t feel right about working with an unknown chemical so he checked for himself.

“I went out to the chemical storage, grabbed the safety data sheet and the product label. Right there, in large letters it said: fatal if inhaled.”

This is why, he explains, supervisors need to be aware of what chemicals are on their worksite and train their new workers accordingly. If he hadn’t taken the proper precautions himself, he could have died.

For more information, go to: engage.wsps.ca/first-job-safe-job

Katharine Reid is with Workplace Safety and Prevention Services.

THE GROWER PAGE 12 –– JUNE 2024 WORKER HEALTH

JUNE 2024–– PAGE 13 THE GROWER 1-866-267-6255 1-866-267-6255 CALL TO ACCESS FREE, CALL TO ACCESS FREE, UNLIMITED COUNSELLING UNLIMITED COUNSELLING Stress on the farm Family or relationships Financial pressure Anxiety or depression Managing your workload Substance use Loneliness or isolation Supporting loved ones Processing traumatic events FREE MENTAL HEALTH SUPPORT FOR ONTARIO FARMERS, FARM WORKERS AND THEIR FAMILIES FARMERWELLNESSINITIATIVE.CA SCAN THE BAR CODE TO ADD THE LINE TO YOUR CONTACTS

CHAIR’S PERSPECTIVE

Food production faces barriers, hurdles that hinder growth

A new growing season is underway, and while that’s normally a cause for optimism, there isn’t as much brightness on the horizon this year.

As an entire industry, agriculture is facing increasing barriers and hurdles that are hindering and in some cases stifling growth. This includes ongoing rising costs; high interest rates; increasing financial burdens from things such as the carbon tax and development charges; regulatory challenges at all levels of government related to fertilizer, plastics, stormwater management, labour and more; and ever-increasing pressure from the marketplace, activists and society in general.

Horticulture is even more heavily impacted by these challenges than other sectors of the agriculture industry because growers must deal with a wide range of provincial ministries, federal departments and municipal organizations that all touch on food in some way.

Provincially, this includes Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), Ministry of Labour, Ministry of Housing, Ministry of Transportation, and Ministry of Environment, Conservation and Parks. Federally, it’s Environment and Climate Change Canada; Environment and Social Development Canada; Health Canada; Agriculture and AgriFood Canada; and Immigration, Refugees and Citizenship Canada.

In addition, there are fire marshals, health units, building departments, CanadaGAP and retail auditors, the Canadian Food Inspection Agency, international liaison officers, source country partners and more – and there is little to no

coordination between these groups.

This results in inconsistencies, extra costs, and excessive regulatory burdens which lower productivity, profitability and competitiveness for farm businesses, for the sector, and for the Ontario economy as a whole.

One such example is municipal regulations and rapidly rising fees that hinder building of new on-farm worker housing. Another is three-phase power infrastructure that is essential to growth and greater sustainability but too expensive for farms to access.

There is often also a singular, insular approach to addressing issues that may help solve one problem, but create various new ones, such as the federal government’s focus on removing single-use plastics.

Most horticultural crops can’t be sold in bulk, but sustainable plastic alternatives don’t yet exist or aren’t practical or costeffective. Phasing out single-use plastics in the absence of work-

WEATHER VANE

able alternatives will increase food waste and greenhouse gas emissions as well as impact food security, food affordability and the economic viability of fruit and vegetable businesses.

In the short term, this hinders growth and competitiveness, but long term, it will lead to the permanent erosion of Ontario’s ability to feed our population. In some instances, it could mean the shifting of investment across the border to neighbouring states. In others, we could see growers transitioning to lower risk, easier to grow cash crops such as corn and soybeans.

Both outcomes reduce overall economic activity for the province and increase our reliance on imported fruits and vegetables to feed Ontarians – an increasingly risky gamble in an era where climate change is impacting production capacity around the world.

This is a complex web of challenges and greater collaboration to bring everyone to the table is absolutely essential to

finding solutions that are workable for everyone. As a sector, we know we have to work together, and we would like to see the various levels of government take the same approach – both with growers and with each other.

On-farm worker housing is an issue that involves not just OMAFRA, but also Ministry of Labour and Ministry of Housing.

Environmental Compliance Approvals for storm water and wash water management touch both OMAFRA and Ministry of Environment, Conservation and Parks.

Labour is a provincial issue, but for fruit and vegetable growers with international workers, it also involves three federal departments: Employment and Social Development Canada, Immigration, Refugees and Citizenship Canada, and Agriculture and Agri-Food Canada.

It would be great, for example, if different ministries and departments could collaborate with

each other when developing new legislation and policy instead of expecting growers and grower organizations to try to address problems with one or more organizations individually.

In an ideal world, there would be a collective focus, including prioritization and mandate by all levels of government, on food produced right here at home.

This would include greater provincial collaboration with municipalities, with clear, consistent and enabling local rules that support domestic food production, and greater nonpartisan collaboration with the federal government.

To put it simply, food is life. The changing climate is making growing environments more challenging around the world, so it’s never been more important to ensure we continue to have the ability to feed ourselves.

Shawn Brenn is chair, Ontario Fruit & Vegetable Growers’ Association

PAGE 14 –– JUNE 2024 THE GROWER

STAFF Publisher: Ontario Fruit and Vegetable Growers’ Association Editor: Karen Davidson, 416-557-6413, editor@thegrower.org Advertising: Carlie Melara 519-763-8728, advertising@thegrower.org The Grower reserves the right to refuse any advertising. Any errors that are the direct result of The Grower will be compensated at our discretion with a correction notice in the next issue. No compensation will be given after the first running of the ad. Client signature is required before insertion. The Ontario Fruit and Vegetable Growers’ Association is the sole owner of The Grower. All editorials and opinions expressed in The Grower are those of the newspaper’s editorial staff and/or contributor, and do not necessarily reflect the view of the association. All rights reserved. The contents of this publication may not be reproduced either whole or in part without the prior written consent of the publisher. OFFICE 355 Elmira Road North, Unit 105 Guelph, Ontario N1K 1S5 CANADA Tel. 519-763-8728 • Fax 519-763-6604 The Grower is printed 12 times a year and sent to all members of the Ontario Fruit and Vegetable Growers’ Association who have paid $30.00 (plus G.S.T.) per year for the paper through their commodity group or container fees. Others may subscribe as follows by writing to the office: $30.00 (+ HST) /year in Canada $40.00/year International Subscribers must submit a claim for missing issues within four months. If the issue is claimed within four months, but not available, The Grower will extend the subscription by one month. No refunds on subscriptions. P.M. 40012319 ONTARIO FRUIT AND VEGETABLE GROWERS’ ASSOCIATION BOARD OF DIRECTORS 2023 MANAGEMENT COMMITTEE Chair Shawn Brenn, Waterdown Vice-chair Mike Chromczak, Brownsville Grapes Matthias Oppenlaender, NOTL Fresh Veg Joann Chechalk, St Anns Small fruit/Berries Morris Gervais, Springwater BOARD OF DIRECTORS Apples Brian Rideout, Chatham-Kent Fresh Veg other Joann Chechalk, St Anns Tender Fruit Dave Enns, Niagara-on-the-Lake Asparagus Mike Chromczak, Brownsville Grape Matthias Oppenlaender Fresh Veg muck Quinton Woods, Cookstown Potato Shawn Brenn, Waterdown Small Fruit/Berries Morris Gervais, Springwater Ginseng Glen Gilvesy, Tillsonburg Greenhouse Jan VanderHout, Dundas Greenhouse George Gilvesy, Tillsonburg Processing Vegetables Tracy Gubbels, Mount Brydges OFVGA SECTION CHAIRS Crop Protection Brian Rideout Environment and Conservation Jan VanderHout Labour Bill George Safety Nets Mike Chromczak Energy, Property, Infrastructure and Food Safety Brian Gilroy

The high-density apple

Manitree Fruit Farms

buzzing

pollinators in early May. Also hard at work

a crew of temporary foreign workers. Here,

Jamaica

apples near Blenheim, Ontario.

Jeff Tribe.

orchards at

were

with

was

Vivian May from

prunes Ambrosia

Photo by

SHAWN BRENN

Grocery price cuts are in retailers’ food court

Other than the electric vehicle sector, you’d be hard pressed to find an industry as caught up in confusion and controversy right now as food retailing. Growers have mostly avoided the blame of price hikes. But when the public – and governments – are fingerpointing at who’s to blame for high food prices, then it’s time to raise your antennae.

Here’s why. Food retailers play a huge role in making quality food accessible to consumers. They are almost always the interface between producers and the public. So naturally, people consider them responsible for prices.

Prices have consumers on edge and Canadians have lined up at

food banks like never before.

The federal government called on the retail chain in the fall of 2021 to develop a Grocery Code of Conduct to govern their behaviour when negotiating with suppliers. The meetings have dragged on, until Loblaw president and CEO Per Bank announced on May 16 that the company would sign, provided that hold-outs would sign too. Over to you, Wal-Mart Canada.

The Standing Committee on Agriculture and Agri-Food has called on five of the country’s biggest grocers – Loblaw, Empire, Metro, Wal-Mart and Costco –to do something to stabilize food prices.

Sure, the grocers said. How about aggressive discounts, price freezes and price-matching campaigns?

Um, OK . . . but wait. Those measures already happen in grocery stores. This is a chronic, frustrating smokescreen. And with just a handful of retailers dominating 80 per cent of the market, there’s hardly anywhere in the mainstream for consumers to turn. Loblaw Companies, for example, own discount chain No Frills and Maxi.

The same thing is happening in the U.S. There, the Federal

Trade Commission has for now blocked the largest supermarket acquisition in history – that is, Kroger’s proposed $24.6 billion acquisition of another grocery giant, Albertsons.

The commission said what everyone believed: the deal is anti-competitive. The Biden government loathes monopolies; in the food sector, it’s seen terrible collusion and price manipulation between meat companies that took advantage of consumers over the pandemic and made obscene profits. Again, the shrinking ownership base and lack of competition were cited as the cause.

Excessive profits irk Canadian food shoppers too. While they were limping along through the pandemic, Loblaw was unapologetically posting huge profits. Most lately, Loblaw chief financial officer Richard Dufresne gushed that company earnings and sales will keep rising because it’s gaining market share in the discount segment. It will spend $2 billion in capital investments for stores such as No Frills and Maxi this year.

All this means that even when consumers turn to discounters, more and more they face the prospect of lining Loblaw’s

pockets or as one consumer said, “trading our loyalty points for higher prices.”

In May, some disgruntled shoppers said they had enough, and aimed their ire at Loblaw.

On the same day the company reported $13.58 billion in first quarter profit (a 4.5 per cent increase from a year earlier), a group on the social media platform Reddit said “Loblaws is out of control.” The group launched a 30-day boycott of Loblaw’s 2,450-plus stores and brands such as the Real Canadian Superstore, Zehrs, Your Independent Grocer (IGA), Valumart, Shoppers Drug Mart, Provigo and City Market.

The group said it was fighting what it called “greedflation” and wanted to see prices come down 15 per cent.

Loblaw chairman Galen Weston was unmoved. He responded by calling the group’s efforts misguided and said a steep price cut like that would sink his ship. He failed to gain much sympathy with the boycotters though: a week into the boycott, Loblaw share price hit an all-time high of $156.

If the boycott works or even gives the appearance of working, expect a trickle-down effect on

the farm. Imagine the opportunity this boycott gives retailers like Weston to say sure, we’ll charge consumers less, but farmers must sell to us for less, too.

What a field day: retailers finally getting the chance to chisel producers with consumers’ support. Farmers who failed to comply would look greedy, like retailers do now.

I’d like to think this wouldn’t happen, at least not in a year when net cash income is forecast to fall 14 per cent. Take another 15 per cent away? That’s when ships would truly sink.

The ball is in retailers’ court.

Owen Roberts is a past-president of the International Federation of Agricultural Journalists and a communications instructor at the University of Illinois

JUNE 2024–– PAGE 15 THE GROWER

COWBOY

URBAN

OWEN ROBERTS

Mental health made personal

Editor’s note: This message, dated May 8, 2024, from Melissa Tesche, general manager of the British Columbia Fruit Growers’ Association deserves to be shared across Canada.

It’s Mental Health Week. It’s okay to not be okay. Especially for growers.

Dear BCFGA Members,

I’ve just finished my second month as your new general manager at the British Columbia Fruit Growers’ Association (BCFGA) and I’ve felt very welcomed. Thank you! I am energized and I am dedicated to working on the many challenges our industry is facing.

I am also deeply concerned about you, the growers. You are

OFVGA at work

Members of the Ontario Fruit and Vegetable Growers’ Association (OFVGA) met with Ontario Minister Caroline Mulroney, president of the Treasury Board, about the state of the horticultural sector and the challenges growers are facing right now, the sector’s long standing ask to increase the funding available to the Risk Management Program (including Self-Directed Risk Management for fruit and vegetable growers) and Environmental Compliance Approvals.

the ones on the front lines of agriculture. I hear the stress in your voices and see the pain in your faces when you share your financial situations and you talk about the future of farming in the Okanagan.

I come from a family of farmers, and I’ve watched my own family members suffer in silence and self-medicate with alcohol and drugs. No one talked about mental health when I was growing up. Never. I have relatives diagnosed with depression, schizophrenia, and bipolar. I’ve had more than one episode of depression myself. I’ve lost a loved one to addiction and during the pandemic, I lost a loved one to suicide.

We need to change this, especially in these extremely

tough times. Please, don’t suffer alone and in silence. Let’s talk more. Listen more. Ask more.

Let’s break the stigma around mental heath in farming. Let’s come together as a community. We’ve got some divisions in the tree fruit sector, sure, but growers have a lot more in common with each other than they have differences. We’re stronger together. We’re healthier together. We will get through the next couple of years together.

I’ve listed and linked to some resources below if you or someone you know is struggling.

Take care of yourselves and each other, Melissa Tesche BCFGA general manager

COMING EVENTS 2024

June 1 Garlic Growers Association of Ontario Field Day, Van Raay Farms, Dashwood, ON

June 3-9 Local Food Week in Ontario

June 11-13 GreenTech Amsterdam, RAI Amsterdam, Netherlands

June 19 Ontario Potato Board Industry Social Golf Tournament, Hockley Valley Golf Resort, Mono, ON

June 22 Farm & Care Ontario Breakfast on the Farm, Blackrapids Farm, Ottawa, ON

June 23-26 12th World Potato Congress, Adelaide, Australia

July 9-11 Potato Sustainability Alliance Summer Symposium, Hoxton Chicago, Chicago, IL

July 10 Ontario Apple Growers’ Summer Orchard Tour

July 16-17 Federal-Provincial-Territorial Agriculture Ministers’ Meeting, Whitehorse, Yukon

Aug 3 Food Day Canada

Aug 7 Nova Scotia Fruit Growers’ Association Orchard Tour, Kentville, NS

Aug 15-16 U.S. Apple Outlook Conference, Ritz-Carlton Hotel, Chicago, IL

Aug 21 Ontario Potato Research Open House, Elora Research Station, Elora, ON

Aug 22 Ontario Potato Field Day, HJV Equipment, Alliston, ON

Sept 10-12 Canada’s Outdoor Farm Show, Woodstock, ON

Sept 19-21 Quebec Produce Marketing Association 77th Convention, Fairmont Tremblant, Tremblant, QC

Oct 1-5 International Plowing Match & Rural Expo, Lindsay, ON

Oct 8-10 Fruit Attraction, Madrid, Spain

Oct 9-10 Canadian Greenhouse Conference, Niagara Falls Convention Centre, Niagara Falls, ON

Nov 1-10 Royal Agricultural Winter Fair, Toronto, ON

Nov 19-21 Alberta Potato Conference and Trade Show, Grey Eagle Resort & Casino, Calgary, AB

Nov 27-Dec 1 Canada’s Outstanding Young Farmer National Event, Sandman Signature Lethbridge Lodge, Lethbridge, AB

THE GROWER PAGE 16 –– JUNE 2024 ON THE RECORD

ADVOCACY

L-R: Shawn Brenn, chair, OFVGA; Jody Mott, executive director, Holland Marsh Growers’ Association; Hon. Caroline Mulroney; Gordon Stock, senior policy and government relations advisor, OFVGA; Mike Chromczak, vice-chair, OFVGA.

RETAIL NAVIGATOR

Managing customer expectations as food inflation subsides

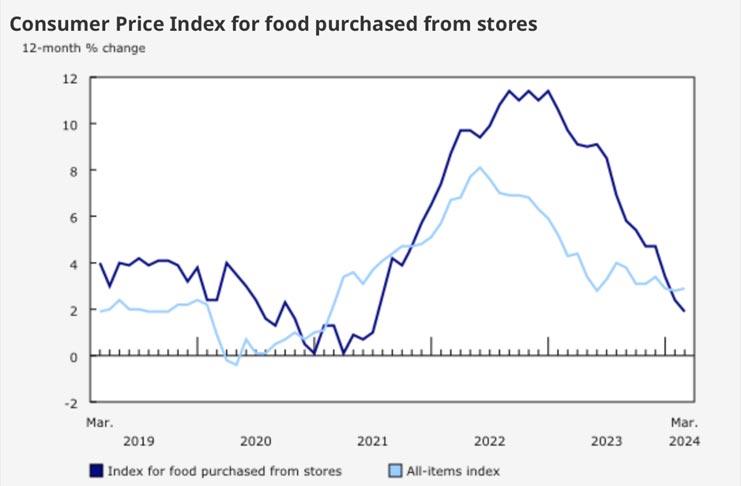

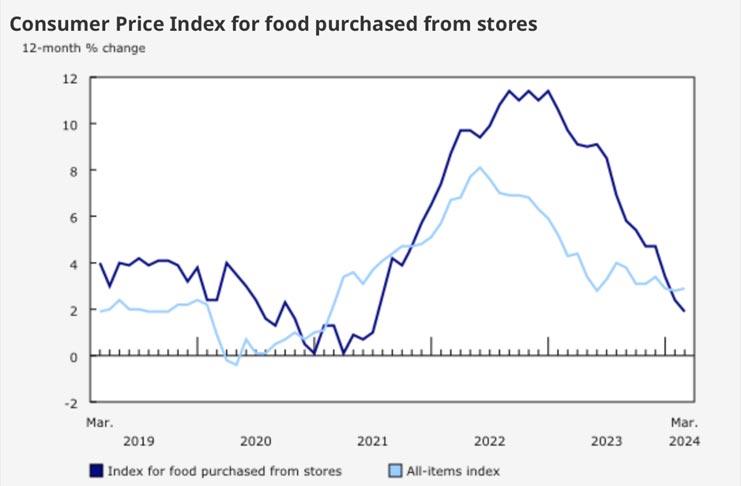

We have been operating in an environment where food inflation is in the news, impacting consumer’s grocery orders and challenging the relationships between producers and retailers. For the last two years, food inflation was considerably higher than the all-items index, as illustrated by the Statistics Canada chart.

As we enter 2024, Food price inflation has subsided and dropped below the all- items index. Consumers will be excited. Producers and processors will be operating in a different environment with customers. You will shift from trying to justify an increase, to maintaining the prices you are at.

Retailers will be looking for change

The last few years have been a challenge for your customers, as they have been blamed for high food prices. Politicians have pointed the finger at them and consumers have organized boycotts of Loblaw. Retailers who have invested millions in creating a price image have been accused of charging prices that are artificially high.

As the overall inflation rate for food purchased at stores is getting close to zero, your customers will be asking different questions. The conversation will shift from ‘why is it more?’ to ‘can it be lower?’ it will be more important than ever to know the facts and understand the cost components of your products.

Retailers will be looking at the inputs you might have talked about increasing in recent years. If they see them coming down, they will expect your cost of goods to decline.

Know the facts

You are selling to sophisticated customers. They will know the facts, so you need to bring your perspective. They might see ‘fertilizer has decreased’ but not understand the specific type you use is up five per cent year over year. Don’t be upset that they are challenging you -- it is their job. If you know the question is coming, be proactive. Be ready with the facts and help them understand the impact on your

products and your cost of goods. Retailers do not always understand cost components such as freight or logistics. In their business distribution is an expense that merchandising people really are not exposed to. Many have large, sophisticated networks but they do not understand the hard costs of something such as Less than a Load (LTL) freight. They will ask for more frequent deliveries but not comprehend the incremental cost per case of moving a few pallets at one time.

Consumers, regulators and retailers continue to demand changes to reduce the environmental impact of the food industry. Often these improvements cost more. Sustainable packaging is great and people are looking for it. But packaging can cost more in price per unit or plant efficiencies. If you are making these changes, share the impact with your customers.

Adjust your mindset to a new environment

Many producers and processors have been operating with several price increases in recent years. This does not mean it will just continue. Retailers have had to accept increases, because the reality is costs went up. These increases were justified.

The climate will change as they read about decreases in commodities and inputs. Food producers and processors will need to change their approach.

We also know food price inflation has impacted consumer buying patterns. They are shopping more in discount stores and trading down in categories. They are doing as much as they can to keep their grocery bill affordable. This can impact your volume. Your customer might buy less if they are losing sales in their format, such as conventional stores.

Consumers are buying more items with a temporary price reduction than ever. This can impact your pricing if you are selling more at promotional prices. Track your sales to ensure you can predict the cost to your business.

Do your part to keep prices in line

If overall inflation is beginning to subside, then you should also see some relief in the prices you are paying. Challenge your suppliers and do not just accept a two per cent increase. Your customers expect you to challenge your suppliers to keep pricing in line. If you are able to keep costs the same year over year or perhaps even get a decrease, let your customers know. They like their suppliers to be a champion of keeping costs in line. If you are able to get a decrease to offset an increase somewhere else that can be a win-win.

Source: https://www.statcan.gc.ca/en/topics-start/food-price

As we move into a new period for food pricing, the challenges will be different. The best strategy is to understand your business and focus on where your customers want to go. They will always be demanding. Perhaps they are even more demanding

right now because they have been pushed into a corner. Communicate as much as possible and do not assume they understand your business.

Peter Chapman is a retail consultant, professional speaker and the author of A la Cart-a suppliers’ guide to retailer’s priorities. Peter is based in Halifax, N.S. where he is the principal at SKUFood. Peter works with producers and processors to help them get their products on the shelf and into the shopping cart.

JUNE 2024–– PAGE 17 THE GROWER

PETER CHAPMAN

FOCUS: LOGISTICS AND TRANSPORT

Three experts on how to improve produce transport

The Canadian Produce Marketing Association hosted a Learning Lounge in Vancouver on April 25 titled: Produce Transportation – Elements of Success. L-R: Moderator Steve Bamford, Fresh Advancements Inc; Jaime Bustamente, director of trading assistance, DRC; Avio Paparisto, founder and CEO, Trans Globe; Stewart Lapage, executive director, supply chain and logistics, Oppy.

KAREN DAVIDSON

Vancouver, BC — For those who attended the CPMA’s Learning Lounges in Vancouver, it was a chance for unique access to the industry’s top experts. This was the case for learning about how to prevent and manage transportation-related disputes that arise from conveying perishable fruits and vegetables into and within North America.

Jaime Bustamente, director of trading assistance, Dispute Management Corporation

Q. What are the key elements for growers to keep in mind when shipping produce?

A.

• In a FOB transaction, if the driver encounters conflicting temperature reefer setting instructions on the Bill of Lading at shipping point and the receiver’s carrier instructions,

they should contact the receiver to confirm which temperature setting is required. The same applies to an LTL load, where the Bills of Lading show conflicting temperature reefer setting instructions.

• The reefer unit must always be set on continuous mode when transporting fresh fruits and vegetables.

• Temperature and commodity compatibility are very important when transporting more than one commodity.

• Reefer units are there to maintain temperatures, not to bring commodities’ temperatures down or up.

• Loading patterns are important. Loading pallets sideways or too close to the walls may prevent proper air circulation inside the trailer.

• Regarding temperature recorders, make sure they are placed properly, written down in the Bill of Lading, recovered at the destination, and their location is documented upon arrival.

• Both, a temperature recorder and a reefer unit, are temperature reporting instruments that help determine if there was a temperature issue during transit. What determines which one reflects a more accurate picture of what transpired temperature-wise inside the trailer can be decided by looking at all the other factors involved in the transaction, such as, product pulp temperatures at the shipping point, loading pattern, number of pallets, airchute condition, outside weather conditions, location of the temperature recorder, pulp temperatures upon arrival, the product’s condition upon arrival, among other factors.

Stewart Lapage, executive director, supply chain and logistics, Oppy

Q. What are the technical improvements in data loggers?

A. The ability to communicate data wirelessly without the need to physically have access to the unit has been a true game changer for data loggers. So many times in the past the recorders would be lost, misplaced or required specific technology to access the information. These new units can provide real-time updates, reporting and alerts not only for temperature but also other key information such as humidity and light levels (indicating a container or trailer has been opened etc.). Many of the new technology data loggers also provide the added benefit of providing real-time GPS tracking to pinpoint the physical location of a truck while in transit from shipper to consignee. This brings a tremendous amount of transparency and creates efficiencies for companies tracking their shipments in transit.

Reefer units are there to maintain temperatures, not to bring commodities’ temperatures down or up.

~

JAIME BUSTAMENTE “

Q. Why are data loggers better than those used five years ago?

A. All of the reasons mentioned above and the cost has continued to come down as more companies have competitive products and solutions available in the market.

Q. Can you mention your top three to five brands?

A. We have had a long-term relationship with Copeland (formally Emerson and before that formally LocusTraxx) and have fully integrated systems with them to provide us with benefits such as real-time, automatically generated notifications to our transport staff when a shipment in transit is flagged as running outside of the specified temperature range. There are however a number of other great solutions on the market from companies such as Sensitech, Xsense, DeltaTrak and many others that we use based on requests from our customers.

Q. How important are data loggers in risk business management? Explain an incident.

A. They are a tremendously valuable and cost-effective tool to protect everyone involved in the movement of fresh produce. They protect shippers, carriers and receivers by helping to determine which party is liable in the event of suspected temperature negligence in transit. As a company we have units added to every shipment over a certain dollar value or distance traveled. These loggers and the real-time data/notifications they provide Oppy help us to avoid hundreds of carrier claims or customer rejections annually by allowing us to proactivity address issues in transit where reefers may be malfunctioning or set incorrectly.

Avio Paparisto, founder and CEO, Trans Globe, Toronto, ON

Q. What are the biggest pain points that your company, Trans Globe, encounters with growers? What advice or solutions do you offer?

A. Communication Challenges: Miscommunication or lack of communication between growers and logistics can lead to misunderstandings, delays, or mistakes in crop management or delivery schedules. Solutions may include implementing clear communication channels, utilizing technology such as apps or software for real-time updates, and fostering strong relationships built on trust and transparency.

Quality Control Issues:

Maintaining consistent quality standards across different batches of produce can be a challenge, especially when dealing with factors like weather fluctuations or pest infestations. Providing growers with training and resources on best practices for crop management, implementing quality control measures at every stage of the supply chain, and offering incentives for meeting quality targets can help address this issue.

Supply Chain Management: Managing the logistics of t ransporting crops from growers to distribution centres or customers can be complex and prone to inefficiencies or delays. Investing in technology solutions like supply chain management software or blockchain-based tracking systems can improve visibility and traceability throughout the supply chain, enabling better planning and coordination.

Continued on page 19

THE GROWER PAGE 18 –– JUNE 2024

Three experts on how to improve produce transport

Continued from page 18

By addressing these pain points through effective communication, training, technology adoption, and support for sustainable practices, companies like Trans Globe can build stronger partnerships with growers and enhance the overall efficiency and resilience of their supply chains.

Q. What advice can you give to a grower to lower the cost? How best to prepare and present the load for pickup?

A. Supply Chain

Optimization: Streamline logistics and transportation processes to minimize handling and transportation costs. This might involve optimizing delivery routes, consolidating shipments, or leveraging technology for real-time tracking.

Equipment Maintenance and Upgrades: Regular maintenance of farm equipment can prevent costly breakdowns and prolong their lifespan. Additionally, investing in modern, more efficient machinery and technology can improve productivity and reduce labor costs in the long run.

Quality Assurance: Ensure that the produce meets quality standards and is properly sorted, graded, and packaged according to customer specifications.

Timeliness: Coordinate with the pickup schedule to have the load ready for pickup at the agreedupon time. This helps avoid delays and ensures timely delivery to customers.

Proper Packaging: Use appropriate packaging materials that protect the produce during transportation and storage. Labeling each package with necessary information such as product name, quantity, and expiration date can help streamline the pickup process.

Documentation: Prepare all necessary documentation, including invoices, packing slips, and certificates of origin, to accompany the load. This ensures smooth customs clearance and compliance with regulatory requirements.

Controlling temperatures throughout a refrigerated (reefer) trailer, especially in less-thantruckload (LTL) shipments with multiple commodities, requires careful planning and execution to ensure that each product maintains its required temperature range. Here are some strategies to control temperatures effectively:

Q. With LTL and several commodities, how do you control temperatures throughout the reefer?

A. Pre-cooling: Before loading any products, pre-cool the reefer trailer to the desired temperature range for the most temperaturesensitive commodity in the shipment. This ensures that the trailer’s temperature is stable before loading begins.

Temperature Zoning: Divide the reefer trailer into zones based on the temperature requirements of different commodities. Use insulated bulkheads, curtains, or airflow management systems to create separate temperature zones within the trailer. This allows you to maintain different temperature ranges for various products without compromising quality.

Proper Stacking and Loading:

Arrange the pallets or containers in the trailer in a way that promotes even airflow and temperature distribution. Ensure that there is adequate space between the products for air circulation and that temperaturesensitive items are not placed near the reefer unit’s airflow vents, which may cause temperature fluctuations.

Temperature Monitoring and Alarms: Install temperature

monitoring devices throughout the trailer to continuously monitor temperatures in each zone. Set up alarms to alert drivers or dispatchers if temperatures deviate from the specified range, allowing for immediate corrective action.

Airflow Management:

Optimize airflow within the trailer to maintain consistent temperatures throughout. Use fans or airflow baffles to ensure uniform distribution of cold air, especially in larger trailers or when transporting mixed loads with varying temperature requirements.

Insulation and Sealing: Ensure that the trailer is properly insulated and sealed to minimize heat transfer from the external environment. Check for any gaps,

leaks, or damaged insulation that could compromise temperature control.

Regulatory Compliance: