What a whirlwind two months it has been. We’re only just taking a moment to breathe, let it all sink in and reflect on what we’ve experienced.

In just this period alone, we’ve attended the FPLMA Conference in Melbourne, Printing United expo in Las Vegas, and Labelexpo Americas expo in Chicago –and that’s not including all the other recent and local awards and social gatherings.

My last Editor’s Letter to you before I went on leave was about Labelexpo Europe 2023, and it seems that life has come full circle with me now writing about Labelexpo Americas 2024 in my first issue back. What a year it has been!

It’s clear that the printing and packaging space has plenty going on – and it’s thriving! We got to feast our eyes on so

many new innovations and technologies, learnt about the latest trends and caught up with some of our international friends.

This issue of ProPack.pro brings you our in-depth review of Labelexpo Americas, which focused on flexible packaging, sustainability, RFID technology, and automation. The tradeshow showcased flexo, hybrid and digital press technology, along with a wide range of finishing technology, combining conventional and digital equipment and sustainable materials.

One of the local highlights of the event was Currie Group selling its first HP Indigo 200K digital press in A/NZ to Brisbane’s Ultra Labels & Flexpack.

And if reading the Labelexpo Americas review isn’t enough, scan the QR codes to watch videos of the latest machines in action.

This issue also features our coverage of the Flexible Packaging and Label Manufacturers Association’s (FPLMA) annual technical forum in Melbourne, which had around 100 delegates in attendance – the highest number of attendees in more than six years.

The conference provided two days of education sessions, panel discussions, networking, and business building, and concluded with the FPLMA’s annual Awards Dinner.

And if you’re keen on finding out more about what happened at the Printing United expo, have a read of ProPrint to benefit from the world of printing.

There’s plenty in this issue to keep you glued from cover to cover, so we hope you enjoy the read.

Action Labels & Nameplates transitions into Label Power P06

The move follows Label Power’s acquisition of Action Labels & Nameplates in 2020

Jet Technologies launches Jet iQ range in A/NZ P06

The new Jet iQ range of finishing solutions is for the label and packaging markets

Orora to sell OPS business to Veritiv for $1.775B P08

The completion of the sale is expected to occur in late 2024

Palmolive reaches sustainability milestone in Australia P08

It has made the switch to 100 per cent recycled plastic bottles for its ranges in A/NZ

VMA forms Labels and Packaging Coalition P10

The coalition will offer expert advice, drafted policies and potential legislative recommendations

Pakko acquires Boxes R Us P10

Pakko will expand its business capabilities with the acquisition

Detpak launches its new PBS packaging range P12

The range of more than 20 products aims to cut out single-use plastics

Networkpak installs Screen L350UV SAI S P12

Networkpak now meets a broader range of its clients’ label and packaging needs

Spicers Australia delivers on greener solutions P14-16

Spicers Australia has strengthened its commitment to the development of sustainable products and services, which help its customers and their clients achieve their sustainability goals

Navigating the new frontiers: FPLMA 2024 Technical Conference P18-22

The recent FPLMA 2024 Technical Conference in Melbourne provided two days of education sessions, panel discussions, and networking

Nekkorb Solutions boosts productivity for clients P24-25

Nekkorb Solutions provides relevant solutions for the printing and packaging industry

Labelexpo Americas 2024 ends on a high note P26-33

A total of 450 exhibitors from all over the world showcased the latest and greatest of their innovations at the event

2024 PIDA Award winners announced P34-35

The PIDAs recognised excellence and innovation in packaging

When sustainability becomes good business P36

Orora invests in initiatives to ensure the ‘future-proofing’ of glass packaging

Plastic recycling to sink or swim? P37

Pact Group’s view on how to take Australia’s recycling industry to the next level

Neuromarketing study reveals insight for gin label design P38-40

UPM Raflatac’s Ginnasium project blends science and art, using neuromarketing

A guide to the upcoming events locally and internationally

Victoria-based label convertor Action Labels & Nameplates has been rebranded as part of Label Power as of 1 October, bringing together the best of both companies and allowing the combined entity to offer enhanced customer service and support.

The move follows Label Power’s acquisition of Action Labels & Nameplates in 2020, during the peak of COVID. Action Labels & Nameplates was operating under its own brand name even after the acquisition – until now.

Label Power CEO James Malone told ProPack.pro that this was the plan all along for the business.

“Out of respect to the old owners, we didn’t want change Action Labels & Nameplates’ name straight away when it got acquired. Action Labels & Nameplates was founded in 1945 in Melbourne – it’s over 75 years old – so the plan was to first invest money in the business to give it much of the same capabilities that Label Power has before rebranding it,” Malone said.

As part of this investment, Label Power installed an Epson UV inkjet press and a

Jet Technologies has launched the new Jet iQ range of finishing solutions for the label and packaging markets.

Designed and built in partnership with Polly Automatics, the collaboration aims to bring together the intellectual property (IP) and expertise of both companies, positioning Jet Technologies to deliver a comprehensive suite of finishing solutions.

Jet Technologies said together with its range of digital presses by Screen GP, the Jet iQ range will provide Australian businesses with access to a fully integrated end-to-end solution, enhancing productivity and innovation in the digital print space.

“Jet Technologies has long been recognised for its leading digital print solutions, but until now, the company has been unable to offer a complete end-to-end process that includes finishing. The partnership with Polly Automatics changes this, allowing Jet Technologies to close the loop and offer a fully integrated solution,” the company said.

“The Jet iQ range covers everything from slitting, rewinding, and inspection to shrink

Mark Andy 2200 into Action Labels & Nameplates’ Melbourne facility in 2020. printIQ software was also installed so that both companies utilise the same cloudbased management workflow system.

“A lot of the machines at Action Labels & Nameplates were old – it had letterpress machines. So, the purchase of the Epson UV inkjet press was very good for the business because it’s UV resistant and durable with inks for durable labels,” Malone said.

“And as for the Mark Andy 2200, it gave Action Labels & Nameplates flexo capabilities in line with Label Power.”

Having both businesses well aligned, Malone added that clients will now get a much more seamless service and the ability to deal with just one business, as well as an

increased range of products and services.

“This merger will also allow businesses with access to a much wider range of label and tag stocks, materials as well as in-house label printing and cutting solutions. Our combined operations from Melbourne and Brisbane will ensure faster production and delivery.

“We are now a national company, so depending on where our clients are, we could dispatch either from Melbourne or from Brisbane. And we have stock of common dispatch labels and things in both locations so it’s quick for us to supply no matter where our clients are.

“The plans for Label Power are to continually grow the business and invest in more machinery. There’s plenty that the industry can expect from us in the near and far future.”

sleeve processing and digital finishing equipment.”

One of the standout innovations of the Jet iQ range is the optional inclusion of the Vesatex Print Bar by Xaar.

When integrated in a finishing solution, it enables clients to add substantial value to their print, utilising the Print Bar to add digital effects such as digital foil and a combination of gloss and high-build varnishes in a single pass. In the past, these were only possible via conventional print techniques.

“The results have been outstanding,” Jet Technologies director Jack Malki said. “To be able to print a high-build varnish of

around 100 microns directly onto uncoated wine stocks is an absolute game changer. No primer, no limitations and outstanding results on a wide range of locally supplied materials. Feedback from printers as well as brand owners has been extremely positive.”

The entire Jet iQ range will be available to A/NZ customers.

“The Australian market has been crying out for a well-supported alternative, and we are thrilled to be able to provide that with the Jet iQ range. Our focus is not just on delivering cutting-edge technology, but also on ensuring that our customers have the support they need to make the most of these innovations,” Malki said.

CO-LOCATED

Orora recently entered into a binding agreement to sell its Orora Packaging Solutions (OPS) business to Veritiv Corporation, an investee company of Clayton, Dubilier & Rice, for $1.775 billion on a cash and debt-free basis.

Veritiv, headquartered in Atlanta, Georgia, is a full-service provider of packaging, jan-san and hygiene products, services and solutions. Additionally, Veritiv provides print and publishing products. Serving customers in a wide range of industries in North America and globally, Veritiv has distribution centres throughout the US and Mexico.

The transaction is subject to customary conditions, including obtaining all necessary regulatory approvals from applicable governmental antitrust authorities. If all the conditions are met, the completion of the sale is expected to occur in late 2024.

The news follows Orora’s financial results announcement for the year ending 30 June 2024, where it revealed that the OPS business reported a loss of revenue by 10.8 per cent to US$1.954 billion (down 8.4 per cent to $2.981 billion on a reported basis) and that it intends to divest the unit.

Orora added that the loss was due to the flowthrough impact of price deflation and lower volumes from continued softness in the broader North American manufacturing industry.

“As announced at the company’s FY24 results, a strategic review of OPS was undertaken with the objective of unlocking

Palmolive Australia has recently made the switch to 100 per cent recycled plastic bottles for its ranges in Australia and New Zealand, embracing a circular packaging approach.

This has resulted in a sustainability milestone for the personal care brand, eliminating over 1,900 tonnes of virgin plastic.

Advancing the company’s commitment to a circular plastics economy and setting a clear standard for the industry in the region, the company said this transition underscores its dedication to reducing its environmental footprint and aligns with the Colgate-Palmolive Sustainability Goal to eliminate one-third of new (virgin) plastics and ensure all plastic packaging is recyclable, reusable, or compostable by 2025.

value for shareholders,” Orora said.

“Veritiv’s offer fully values OPS and implies approximately 9.9x FY24A cash EBITDA, a premium to Orora’s trading multiple and relevant comparable transactions. The Transaction is expected to result in net cash proceeds of approximately $1.687 billion after tax, transaction costs and purchase price adjustments.”

Orora also said it intends to bring forward $130 million of capital investment to further expand its Cans capacity in Rocklea, Queensland. The Rocklea expansion, in combination with recent and ongoing projects, is said to increase Cans capacity by more than 30 per cent.

The company added that it intends to distribute surplus proceeds from the transaction to shareholders over time in a tax efficient manner to deliver a balance sheet that is consistent with a global beverage packaging business. More information on this will be provided later.

“Today’s announcement marks a new era for Orora as well as the OPS business as it transitions to Veritiv ownership. Veritiv’s interest in acquiring OPS provided us with an opportunity to realise an attractive valuation for shareholders and accelerate our strategy of becoming a speciality value-added beverage packaging player,” Orora managing director and CEO Brian Lowe said.

“This leaves Orora with a strong balance sheet, allowing the company to grow our beverage packaging business, including further investment in high returning projects such as the expansion of our Rocklea Cans facility in Queensland.

“We are extremely proud of the way the OPS business has grown and the value it has delivered whilst being part of the Orora Group. Veritiv’s offer is an exciting opportunity for the OPS team to join an industry leader in the North American packaging distribution market, with differentiated capabilities.”

Palmolive is accelerating its commitment to a circular plastics economy by increasing the use of recycled materials in its packaging –it said around 15 per cent of its range already contain at least 30 per cent recycled content.

“At Palmolive, our world centres around nature. It’s big, meaningful projects like this

that really let us demonstrate our respect for nature,” Palmolive Australia senior representative Kate Johnson said.

“Implementing this project across our entire range helps us stay true to our brand purpose, and it’s this type of evolution that keeps our brand relevant.”

The Visual Media Association (VMA) has formed the Labels and Packaging Coalition, a new initiative to provide industry technical expertise into government policy, targets and regulations.

The Labels and Packaging Coalition will address industry feedback and offer expert advice drafted policies and potential legislative recommendations at both federal and state levels.

Comprising of members from various sectors of the labels and packaging industry, the coalition welcomes close collaboration with the Australian Packaging Covenant Organisation (APCO), Australian Institute of Packaging, brand owners, and key stakeholders.

Its mission is to provide technical expertise and scientific evidence from independent laboratory results to support the informed implementation of regulations affecting labels and packaging manufacturing in Australia.

Speaking at the recent FPLMA Conference, VMA CEO Kellie Northwood outlined the role industry must play as both educators and technical advisors to government, end-users and each level in between those two.

“The VMA and our members are committed to advancing sustainable labels and packaging solutions. However, some

Pakko has acquired Boxes R Us, formerly known as CraftPak, bringing in its key machinery and database to expand business capabilities.

Boxes R Us’ Kirsty and Scott Buckley have also joined the Pakko team.

Pakko founder Nina Nguyen said Boxes R Us was looking to close its doors, and wanted to ensure that the commitment of Boxes R Us continues within the Pakko family.

“The manufacturing industry in Australia has been undergoing significant transformations in recent years. The rise of digitalisation, economic fluctuations, and market consolidation have pushed many smaller businesses to either merge with larger entities or, unfortunately, close their doors,” she said.

“As a company deeply embedded in the Australian manufacturing sector, Pakko has witnessed these shifts firsthand, and we have committed ourselves to not only adapt to these changes but to thrive and support our industry partners along the way.

“One of the most recent and heartbreaking news in our sector was the closing

recent recommendations, such as the shift from water-based to soy-based inks, may be based on misconceptions that could have unintended negative environmental impacts,” she said.

“Improving recovery rates are terrific; however, we do not want to see repeats of recovered packaging sitting in warehouses with no recycling waste stream solution. We also need to understand the criteria for labels and packaging assessments, as the current

of Boxes R Us, formerly known as CraftPak. This company, led by Kirsty and Scott Buckley, has been a respected name in the industry for years.

“Its sudden closure is a reminder of the challenges that small businesses face in today’s volatile market. The impact of this

assessment tools for labels and packaging design does not always align with science.”

Northwood said industry leaders have lobbied to the VMA to unify the industry position and challenge the misrepresentation across the APCO PREP Tool which prioritises the kerbside recyclability of packaging which includes labels.

The Packaging Recyclability Evaluation Portal (PREP) tool is an online tool that assesses packaging specifications to determine how a piece of packaging will perform in the Australian and New Zealand resource recovery systems.

Currently, Northwood said the industry claims there are errors in the technical advisory across the PREP tool, and that the Labels & Packaging Coalition has committed to providing technical advice across all products, finishes and print manufacturing processes for APCO and the government.

“The generalisation of terms like ‘aqueous’ needs closer scrutiny. It is our responsibility as an industry association to offer precise technical advice to APCO and government departments. Our members have local and global expertise in these areas and it makes sense to include them in the decision-making process – thus the formation of the Labels and Packaging Coalition,” she said.

“Collaborating with APCO, government ministers, and key stakeholders is crucial to ensuring that policies and legislation are accurate and effective. We call on all members and non-members in this sector to join us in this important initiative.”

situation has been felt across the industry, particularly by those of us who have worked closely with them.

“As such, by joining forces, we aim to maintain the high Australian standards that both Pakko and Boxes R Us have been known for. We are excited about the future as we continue to provide top-quality packaging solutions to small, emerging, and growing businesses across Australia.

“This is not just a business acquisition; it is an integration of values, experience, and a shared commitment to delivering excellence in print and packaging.”

Nguyen added that while it is unfortunate to see a valued partner like Boxes R Us close its doors, Pakko is proud to carry forward its dedication and passion.

“Pakko’s commitment to innovation and quality remains unwavering, and we believe that by embracing these changes, we can contribute positively to the industry’s future,” she said.

“Pakko is not just a packaging manufacturer, we are a community of professionals who support each other through thick and thin.

As we move forward, we will continue to adapt, innovate, and lead by example, ensuring that the Australian manufacturing and packaging industry remains strong and vibrant for years to come.”

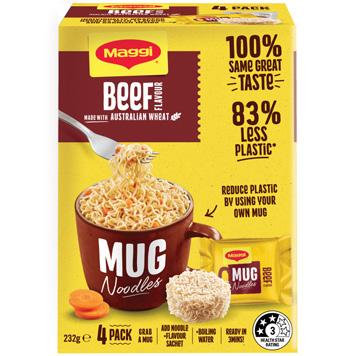

South Australian-based packaging solutions company Detpak has launched a range of more than 20 commercially compostable and recyclable PBS-lined cartons, trays, and lunchboxes, aligning with legislation to cut single-use plastics.

PBS – or polybutylene succinate – is a polymer which is made from both renewable plant sources and a fossil fuel-based component.

PBS linings are typically extruded onto material to create a barrier, which makes them ideal to be used for a variety of purposes including cartons, cups and other applications requiring a robust barrier performance.

The new PBS packaging range of more than 20 products is unique as it holds the ability to attain both kerbside recyclability and commercial composting accreditation to both Australian and European standards.

Single Use Problematic Plastics Legislation changes have been enacted in both South Australia and Western Australia to include plastic plates and bowls among other takeaway food packaging, with Detpak’s new PBS range providing alternatives to singleuse items being phased out of circulation.

In anticipation of these legislative changes, Detpak has been working closely with several of its key food service customers, including

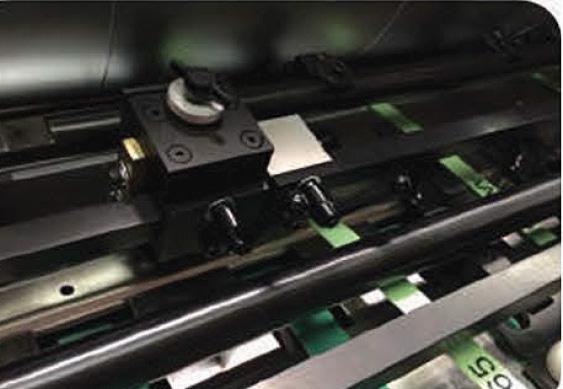

Victoria-based Networkpak, known for its high-quality printed folding cartons, has taken a significant step forward in expanding its service offerings with the install of a Screen L350UV SAI S.

In collaboration with Jet Technologies Australia, Networkpak installed the Screen digital printer, positioning itself to meet a broader range of its clients’ label and packaging needs.

This strategic investment is a bold move by Networkpak as it transitions the company from its traditional focus on folding cartons to include high-quality digital label printing. The new Screen L350UV SAI S press is expected to play a crucial role in this expansion, allowing Networkpak to fulfil the increasing demand for premium labels and packaging solutions.

Networkpak director Paul O’Sullivan said, “As a company with deep roots in printed folded cartons, we have earned the trust of leading Australian brands by consistently delivering top-tier products.

Nando’s, to develop and test PBS packaging over the past 18 months, for compliance in the South Australian and Western Australian market.

Detmold Group general manager of product and brand Keith Bishop said the range provided another option for businesses and consumers conscious of the environment.

“As sustainability becomes not just important, but essential, we’re working to reduce single-use plastics by increasing the number of recyclable and compostable packaging options for the takeaway food service market. The more sustainable choices we provide for businesses and consumers, the easier it will be to change

“The addition of the Screen L350UV SAI S to our lineup is a natural progression for us, enabling us to offer an even wider array of solutions to our clients. We can now meet their label and packaging needs with the same level of quality and reliability they’ve come to expect from our carton work.”

The Screen L350UV SAI S features vibrant colour reproduction, precision, and speed, and is particularly well-suited to the

habits within our wider community.

The more packaging we can re-use, recycle or compost, the more we can help protect the environment,” Bishop said.

The new range will include hot food boxes, pail packs, lunch boxes with windows and food trays, and contains no added PFAS.

Detpak’s PBS cartons are compliant with all Australian state-based plastic legislation. The range is certified to European standards EN 13432 for commercial composting, with certification pending as Industrially Compostable to Australian Standards (AS 4736). It is also recyclable, currently undergoing assessment by the ARL to be able to apply the Australian Kerbside Recyclable Logo (ARL).

demands of label printing. It offers Networkpak the flexibility to produce a wide variety of labels, from simple designs to complex, high-impact graphics, catering to the diverse needs of its clientele across various industries.

Jet Technologies Australia, a key partner in this project, has been instrumental in facilitating the installation and ensuring that Networkpak is fully equipped to leverage the capabilities of the new press.

“Since installation, we have been very impressed with the L350UV SAI S – it has done absolutely everything that we expected and has not skipped a beat. Jet Technologies have been outstanding with their service and support, ensuring that we have made a seamless transition into labels,” O’Sullivan added.

As Networkpak continues to grow, the integration of the Screen L350UV SAI S is expected to significantly boost the company’s production capabilities, reduce lead times, and open up new opportunities for creative packaging solutions.

Jet Technologies sales director David Reece said, “We are delighted to be working with Networkpak. Whilst they may be new in the label space, their team has significant experience in the market and their choice of the L350UV SAI S is a strong endorsement in the brand and our support”.

Spicers Australia has strengthened its commitment to the development of sustainable products and services, which help its customers and their clients achieve their sustainability goals

Spicers Australia is leading the way when it comes to integrating sustainability and sustainable practices into not only its own company, but also into the businesses of its customers and their clients.

As a leading wholesaler and distributor of commercial print, labelling, signage, and visual display solutions such as packaging, a key sustainability focus for Spicers Australia is to continually improve the supply chains for its operations.

“Our products are sourced with consideration of environmental factors. Measures to improve environmental impact, such as the use of certified forest fibres, alternative renewable energy sources, reducing chemical, energy and water usage and effluent, and manufacturing products that contain recycled content are discussed with key suppliers,” Spicers general manager of products and marketing Ken Booth said.

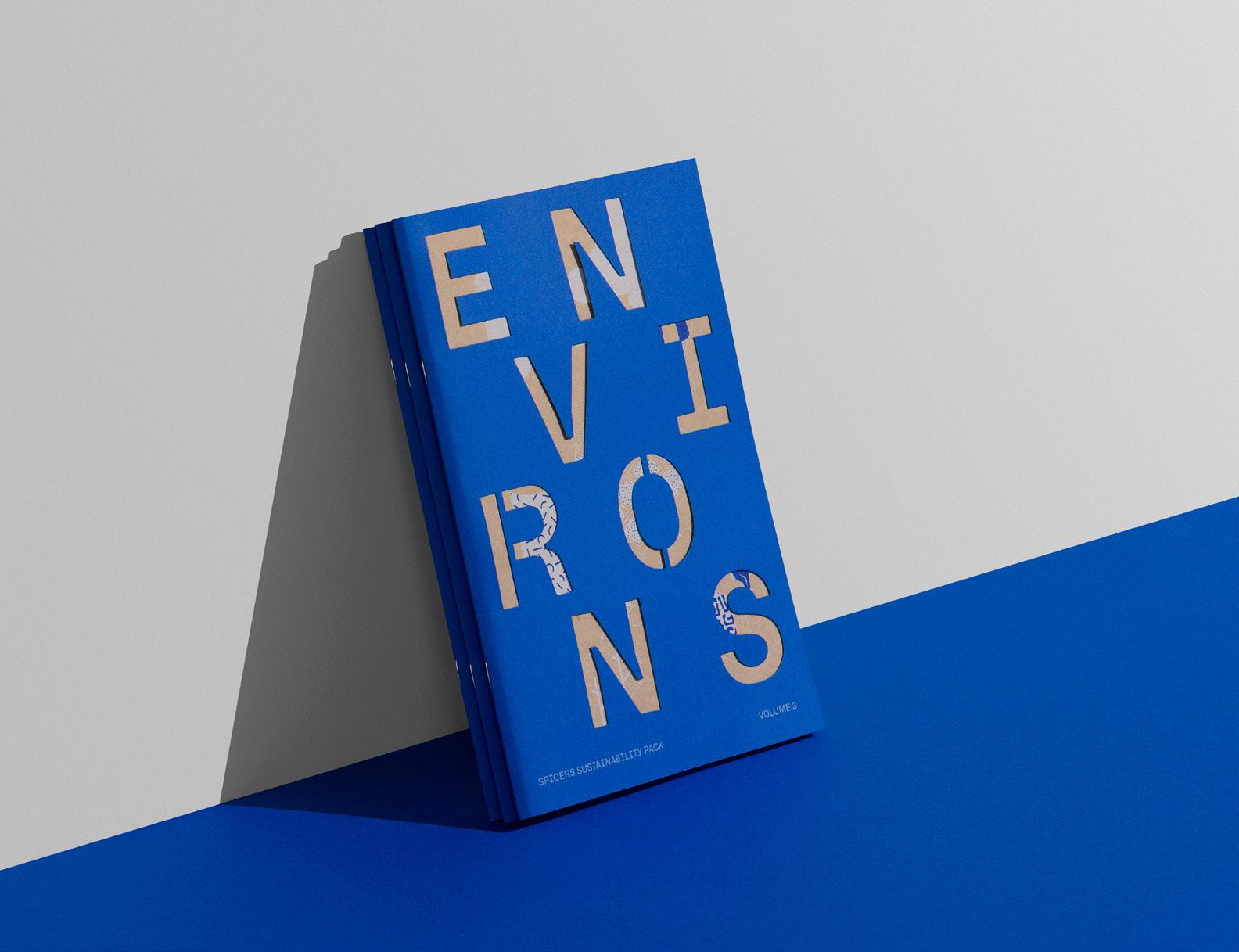

To spread the sustainability message to its customers and the end clients, Spicers Australia has released its Environs Volume 3 pack, which outlined some consumer insights about sustainable packaging, its 2023 Greenfleet impact summary, its sustainable targets and 2024 goals, and details of the sustainable choices it has on offer.

Environs Volume 3 focuses on its labels and packaging products, while Volume 1 and Volume 2 details Spicers Australia’s wide format products and commercial and digital products respectively.

“We promote sustainable business practices across the organisation, ensuring that we conduct ourselves responsibly and ethically, and are continually looking for opportunities to strengthen the sustainability of our supply chain. We make available the latest environmental and technical information on our products to customers, staff

and stakeholders through training and education,” Booth said.

“The ongoing development of sustainable products and services assist our customers and their clients to achieve their sustainability goals as well as their print and production requirements. By thinking and acting sustainably, we strive to deliver excellent customer service and position the company and industry for a strong future.”

Spicers’ focus on the packaging space was amplified following its acquisition of Direct Paper in 2020. The purchase added new dimensions to Spicers’ offering, with packaging board supply being one of the key reasons it found Direct Paper to be a natural fit.

Since then, the acquisition has supported Spicers’ business position, especially in packaging, and with food services products.

Spicers has gone on to further solidify its packaging portfolio with several acquisitions, the most recent being Signet Packaging, a supplier of packaging, protective papers, marking, and other business supplies.

“We have a strategy out to 2030 and this helps us on that journey. If you look at our history over the last three years, we have added a number of strategic brands. Within packaging, there are several ways we can broaden the portfolio and that will mean more to the customers,” Spicers Group CEO David Martin said.

“There is a high proportion of the Spicers business that is fibre-based – and not just within our local portfolio, but globally. We are a strong supplier of fibre-based products whether it is paper, board or rolls.”

Spicers Australia’s products are sourced from manufacturers and suppliers that are committed to smart and greener practices. It takes a minimalist, less is more approach to packaging design and emphases the simplicity of a product and how it can reduce material usage.

Ninety per cent of Spicers Australia’s featured packaging range is biodegradable and 90 per cent of its featured packaging range is fully kerbside recyclable. In addition, 58 per cent of its featured label range is EcoVadis Platinum rated, sourced from supplier Manter by Fedrigoni Self-Adhesives. Eighty per cent of the company’s print range contains recycled content, while 95 per cent of its print range is FSC and PEFC certified.

Within Environs Volume 3, Spicers Australia has identified consumer insights in response to sustainable packaging. It said these findings support elements to consider during the design process:

• 74 per cent of Australians think recycling on a regular basis is the most effective thing they can do for the environment, with product packaging being the most common source of recycling information.

• 63 per cent of consumers say they try to buy products packaged with renewable materials.

• In Australia, 72 per cent of paper packaging is recycled. Paper, along with aluminium, is the most recycled material.

• 79 per cent of consumers are looking for products in sustainable packaging, with 82 per cent willing to pay more for sustainable packaging (including lowincome earners).

• While higher prices affected consumer spending to some degree, 70 per cent of consumers chose not to swap sustainably packaged products for alternatives. As sustainable habits have become a normal part of many consumers’ lives and dictate their product choices, they continue to favour these types of goods and services, even during economic struggles.

• 86 per cent of consumers say they check product information before buying to make informed and sustainable choices. The FSC label is the most recognised, rigorous and trusted mark of sustainable forestry. Consumers know they are taking positive action when they choose FSC-certified products.

“By identifying the environmental impacts of a product, businesses can consider ways to reduce these impacts without compromising the product’s quality,” Booth said.

“Sustainable product design considers the environmental impacts of the entire product lifecycle – from conception to disposal. It’s focussed on ensuring that natural resources are only used at the same rate as they can be replenished.

“Sustainable product design means better environmental outcomes and can also reduce operating costs by lowering energy consumption.”

Another step that Spicers Australia has taken to contribute to a more sustainable future is its partnership with Greenfleet.

All Spicers warehouses, offices, and deliveries are now fully carbon-neutral, thanks to the company’s commitment to sustainability and its partnership with the leading not-for-profit environmental organisation. Since 2022, Spicers has worked closely with Greenfleet to offset the total carbon footprint of its operations, ensuring that every aspect, from footprint to delivery, contributes to a more sustainable future.

It does this by planting native biodiverse forests to capture carbon emissions and help fight the impacts of climate change.

Greenfleet’s remarkable efforts include the revegetation of land in Victoria, New South Wales, Queensland and New Zealand. The forests it plants will be protected beyond this century and are projected to remove nearly 513,887 tonnes of carbon as they grow. This initiative not only offsets Spicers’ emissions but also contributes to the long-term health and sustainability of the environment.

Greenfleet has restored 493 hectares of koala habitat in 2023, planted more than 550 native Australian forests and planted 10.8 million native trees.

Spicers Australia’s staff also participate in the Greenfleet tree planting days and in total, the company has contributed towards projects that have helped to remove more than 356,700 tonnes of CO2 emissions from the atmosphere – this is equivalent to removing more than 82,000 average cars from Australia’s roads for a whole year.

Spicers’ 2023 Greenfleet impact saw 1,962 tonnes of carbon offset, adding to its current lifetime impact of 4,042 tonnes of carbon offset since it partnered with Greenfleet in 2022.

“By partnering with Greenfleet, we are confident that our climate action provides genuine and lasting environmental benefits,” Martin said.

“We are proud of the impact we have made and that we will continue to make into the future. By offsetting our emissions with Greenfleet, we are taking practical action against climate change to help restore Australia’s forests, recreate crucial habitat for native wildlife and transform degraded land back to its natural state.

Spicers is prioritising sustainability and actively pursuing initiatives to reduce its

environmental footprint to a more sustainable size.

Eco-friendly products

Spicers Australia provides a wide range of products with strong sustainability and environmental credentials, particularly recycled paper products and alternative fibre products such as cotton, hemp or bamboo.

One of the most recent products from Spicers Australia within its packaging category is Allyking Cream – a coated carton board which has exceptional bulk, strength and printability. It ensures high performance in finishing and on packaging lines.

Made from PEFC-certified virgin fibres, Allyking Cream is ISEGA certified, OBA free and hard sized to resist water. Economically priced and ideal for a wide range of packaging applications, it is recyclable, compostable and biodegradable. It is also FDA approved for direct food contact.

Some applications that Allyking Cream is suitable for include: confectionery and bakery boxes, fragrance packaging, cosmetics packaging, pharmaceutical packaging, posters, swing tags, point-ofsale products and multimedia products.

Another of Spicers Australia’s go-to products is Carta Solida, a versatile packaging board that offers durability and sustainability. It is a fully coated bleached carton board with a smooth finish on the top side and a clean, white surface on the reverse.

Offering outstanding brightness, smoothness and stiffness, Carta Solida is PEFC certified, fully recyclable and home compostable. It is ideal for cosmetics, skincare, and fragrance packaging, delivering on high-end packaging, and is available in digital sheets.

A popular product within its packaging category is Zenith – a two-sided bleach board with a premium coated print surface and light-coated reverse side.

Zenith is ultra smooth, bright white and designed for any high-quality printing and packaging requirements. Economical and without compromising on quality, Zenith is crafted using PEFC certified virgin fibres to hit sustainability targets and is FDA approved. In addition, it is food safe, fully kerbside recyclable, biodegradable and compostable.

Zenith is suitable for a range of applications including graphical print for postcards, business cards, folders, book covers, pointof-sale, swing tags and posters, packaging for fragrance products, cosmetics, toiletries, confectionery and dry goods, and is suitable for all conventional printing methods.

Zenith

Other key products within Spicers Australia’s packaging range include (but not limited to) Eclipse Greyback, Customkote, Kraftpak and RC Kraft.

Within its labels category, Manter Tintoretto Gesso Recycled H+O Ultra has become one of the most popular products.

A 100 per cent pure ECF pulp recycled paper, it is felt-marked on both sides. It has a high opacity (H+O) treatment and is FSC certified.

Displaying a natural and elegant texture, this stock is specially designed for highend bottled products including wine and spirits, cosmetics and health care. It is suitable for flexo, UV, screen, foil and offset

The Spicers Packaging Series is a favourite collectable among specifiers, showcasing the best in innovative and sustainable packaging solutions

Spicers Packaging Series, crafted in collaboration with Contain Design Studio. This collection blends innovative design with functionality, elevating your packaging experience

Some applications that Allyking Cream is suitable for include confectionary and bakery boxes

printing. However, it is not suitable for very small radius applications.

Specially developed for neck labelling and the perfect match to Manter Tintoretto Gesso Recycled is Manter Tintoretto Gesso Neck Label H+O WS. This pure ECF pulp paper includes wet strength treatment and ensures a high opacity in wet conditions. It also is highly durable and is suited to small radius applications.

In addition, it has excellent water resistance with good stability even after immersion in ice and water.

Some other key products within Spicers Australia’s labels range are: Manter Cotone Bianco Ultra, and Verdure Harvest Ultra.

The recent FPLMA 2024 Technical Conference in Melbourne provided two days of education sessions, panel discussions, and networking

The Flexible Packaging and Label Manufacturers (FPLMA) Association recently held its annual technical forum in Melbourne, with more than 100 delegates in attendance – the highest number of attendees in more than six years.

In his opening address, outgoing FPLMA president Vince Sedunary said this year’s forum examines the emerging trends shaping the future of the flexible packaging and labels industries.

“We were deciding on what we were going to call the forum this year, ‘navigating the new frontiers’ came to the forefront,” Sedunary told attendees.

“There are many new frontiers we are facing as an industry. We are facing technology changes, industry changes, and regulation changes. There are a whole lot of new things happening in our industry.

“I think the number one thing that’s going on is the change in packaging substrates, whether it’s labels, films, papers, coatings or inks,” he said.

“We also have some tight regulations we have to meet with recycling sustainability. Another challenge that remains is bringing new people into the industry – how do we do that? How do we make it interesting? How do we get them into the industry?

“We are still and always will be a very relevant industry, and that was very evident during COVID. We all went through it, globally and at a local level, and the industry survived and moved forward into what we’re calling ‘the new frontiers’. It’s important to look back at history, but to always be moving forward.”

This year, more than 20 industry thought leaders took part in the event’s highly

technical speaker sessions and panel discussions. Topics discussed included sustainability, technology, and legislation.

Keynote speaker, Victorian head of the Australian Industry (AI) Group, Tim Piper, kicked off the forum with an extensive overview of the current state of the Australian market.

Piper told attendees the industry is grappling with three transformational challenges, referred to as the ‘three Ds’: decarbonisation, diversification, and digitalisation.

“Decarbonisation refers to the change of Australia’s economy and society as we transition towards net zero carbon and is impacting just about everything we do. Digitalisation is about changing your business models, and done right, can improve productivity, enable faster

decarbonisation, and support the development of diversified industries. Diversification reflects the need to build a broader economic base for national prosperity,” Piper said.

“The three Ds are what business leaders need to recognise.”

Sandra Dal Maso, head of packaging transformation at APCO, discussed the national packaging targets and how businesses can prepare for the incoming mandates. Dal Maso also provided practical advice on how to choose the best packaging for your product.

“You need to understand the role of your packaging. Understand the packaging value chain, and you need to assess your packaging against the sustainable packaging guidelines,” Dal Maso said.

Dal Maso added that the role of packaging is multi-faceted.

“[Packaging] is there to contain your product. It’s there for consumer safety. It needs to convey regulatory information and product information. It also needs to be machinable, cost effective, it needs to convey a brand, and it needs to be functional for the product you’re containing,” she mentioned.

According to Dal Maso, there are four key areas to consider when creating a package to meet circularity.

“Firstly, it needs to be designed to protect the product and maximise the recovery and functionality of the product. Secondly, there needs to be clear instructions with what to do with the packaging at the end of its life,” she said.

“Thirdly, it needs to be able to be collected and sorted. And finally, you need an end market to retain the value of the recyclable material.”

“Sustainable packaging design is nuanced. There’s no black and white. Everything is a guideline because it all depends on the package the product that you’re containing, and it depends on your application. Therefore, understand that protecting the product and keeping the consumer safe is the key function of your packaging. Also, understand that future mandates are coming, and you need to keep up with what you can do and what you can change in packaging so that you can meet these future mandates.”

Dal Maso’s presentation was followed by a sustainability panel discussion. Panellists included Louis Nottle, J&P Flexographics;

Stephanie Too, general manager –innovation and sustainability, PPG; Thai Q Nguyen, technical manager, RollsPack; as well international guests Sante Conselvan, president of European FTA, and Garrett Taylor, sales director, Soma US.

Panellists shared how their businesses are responding to sustainability opportunities and challenges.

“A lot of the time customers come to us with problems to solve, they don’t have a solution in mind,” said Stephanie Thoo, general manager of innovation and sustainability at PPG.

“There’s lot of jargon and greenwashing in the market. Therefore, what customers are asking us for is clarity. It’s now our job to try to help them figure out the best sustainable option for them, and the implications and environmental impacts that you have to

consider when choosing one application over another. For example, if you pick one sustainable solution, it might be more recyclable, but does it have a negative implication on carbon footprint? These are the types of conversations that we have been having with customers over the last six months,” she said.

Other day one speakers included Trevor Barr, Wilmar; Michael Kingsbury, ULLU; Trevor Crawley, Flint Group Digital; Pieter Mulder, X-rite; Scott Thompson, Esko; Alex Frenk, Windmoeller & Hoelscher; and Ricardo Camatta, Uteco.

Day two began with a presentation by Visual Media Association (VMA) CEO Kellie Northwood on the future of the packaging industry.

“We need to more collective and collaborative, not only in our uniting of the

industry but how we work with customers and brand owners,” Northwood said.

During her presentation, Northwood announced the formation of the Labels and Packaging Coalition, a new initiative to provide print industry technical expertise to inform government policy, targets, and regulations.

Another highlight of the conference for delegates was a joint presentation by FPLMA 2019 and 2021 Apprentice of the Year winners Demi Samaras from MCC and Matilda Milligan from BrandPack respectively, who shared learnings and insights from their trip to the US as part of their prize.

Other presenters included John Watters, AuSIP; Charles Watson, VMA; Yvonne Hackett, Visy; Wolf Viergever, Starward (New Whisky Distillery Company); David Robins, DIC Asia Pacific, Brenton King, Hybrid Software; Richard Smith, Amcor; and Dave O’Reilly, Maxcess.

The technical conference concluded with the FPLMA’s annual Awards Dinner, with more than 350 guests in attendance.

The FPLMA Print Awards represent a centre of excellence for the packaging industry in Australia. The awards highlight what can be achieved by dedicated and passionate people who take pride in their work, striving to achieve the highest print quality using a wide range of technologies.

“It’s important as an industry that we get together and congratulate each other, and more importantly, enjoy each other’s company,” outgoing FPLMA president, Vince Sedunary told guests.

Jon Murray from the Currie Group was awarded the 2024 FPLMA Merit Award, while RollsPack’s Phillip Rolls received the FPLMA’s Chairman’s Award.

Craig McCulloch from J&P Flexographics was announced the 2024 recipient of the prestigious FPLMA Hall of Fame Award.

The 2024 Apprentice of the Year was awarded to Nicholas Smith from Park Douglas Printing. The Apprentice of the Year is targeted at final-year college apprentices nominated by their tutors. Candidates must demonstrate they are competent to the standard they have been trained to, with high academic levels and a keen interest in printing processes.

As the 2024 winner, Smith will receive a trip to the US, including airfares and accommodation, attending the FFTA Forum and Print Awards on behalf of FPLMA while there.

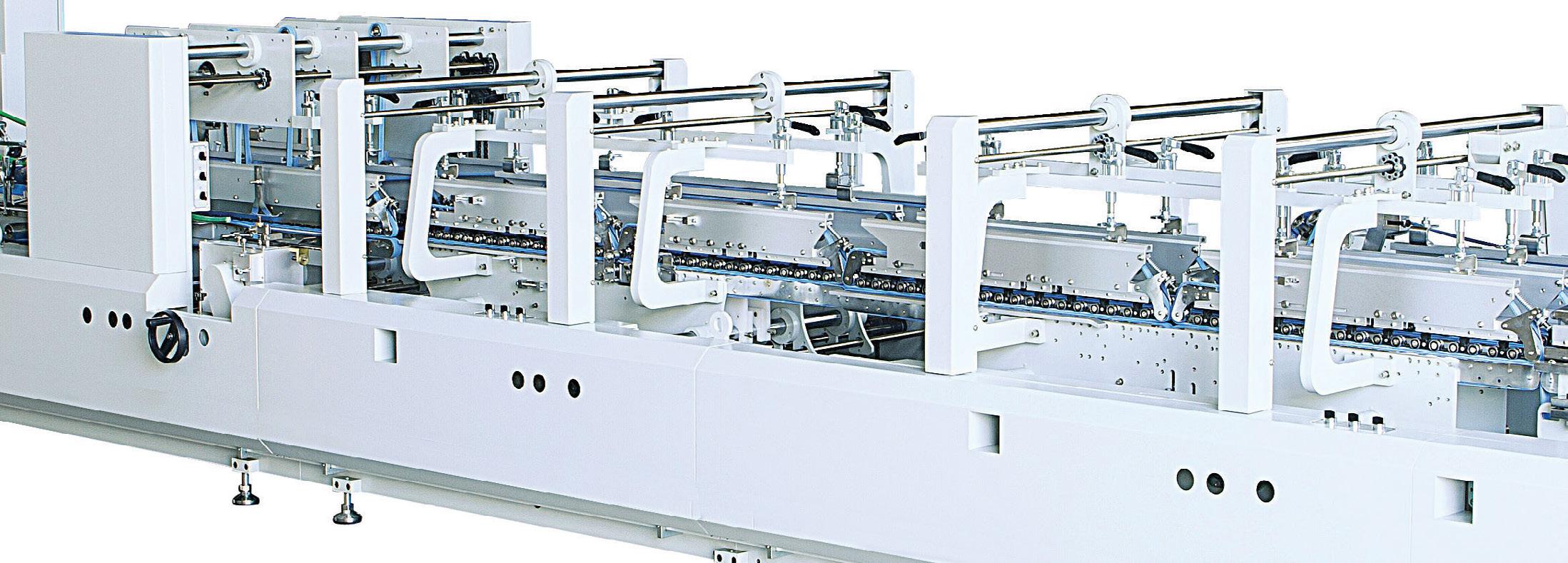

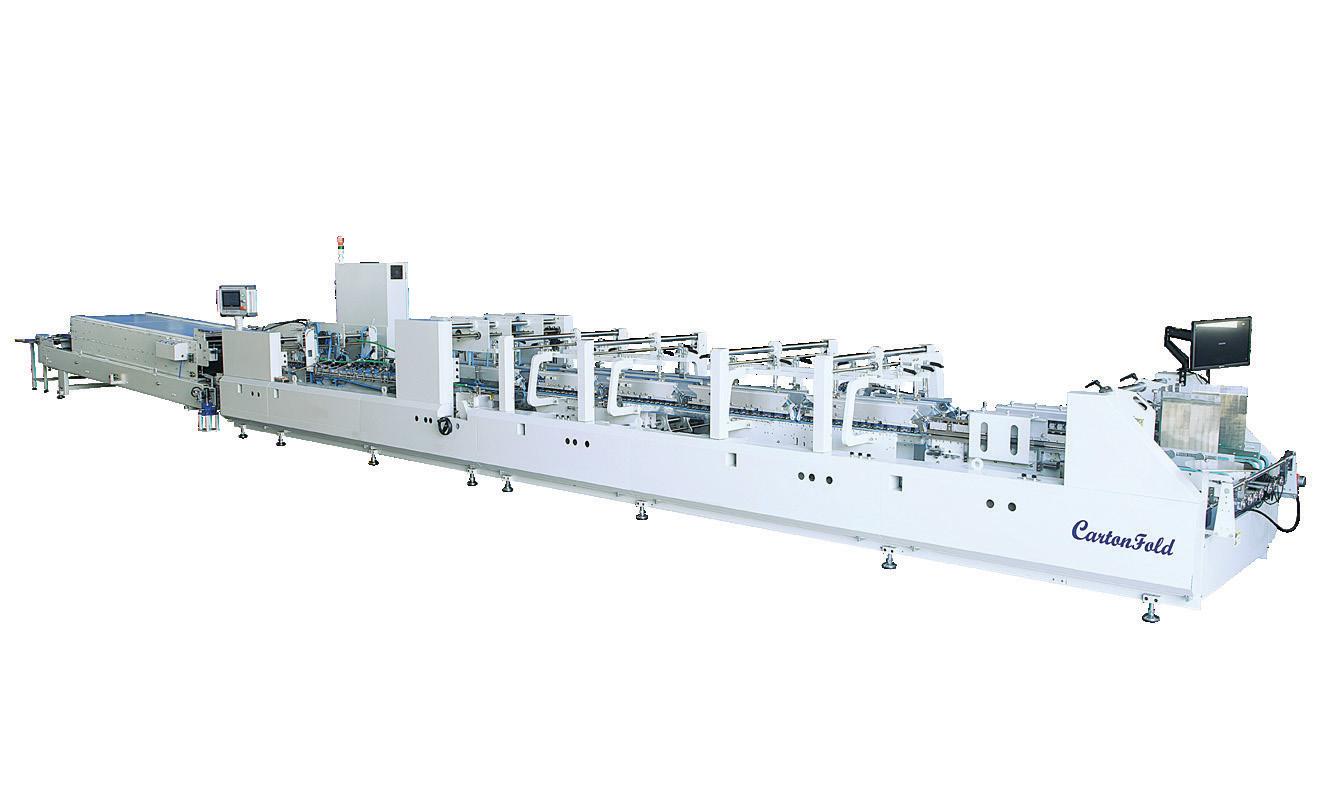

See our range of folding box gluers, board slitters, creasing machines, auto loaders, unloading cutting tables and more.

Guowei 52/68/78/92/115, and Datien 115/137/155/185/260/300 cm, available with handling equipment.

The FPLMA Print Awards recognised excellence in the packaging industry and showcased the outstanding work of several companies and individuals

The recent FPLMA Print Awards celebrated creativity, innovation, and technical skills. FPLMA Print Awards were given in a wide range of categories, including flexo, gravure, labels, and digital.

The 2024 Awards winners are:

Best in Show – Amcor

Best in Show (Offset Litho: Line Work)

– MultiColor Corporation

Best in Show (Offset Litho: Wine and Spirits)

– James Print

• Gold – Ultra Labels – Flexo – Labels Line and Tone – Repro: Independent Design and Graphics

• Gold – Fantastic Labels – Flexo – Labels Line and Process – Repro: Kirks

• Gold – James Print – Offset Folding Cartons Colour Process – Repro: James Print

• Gold – MultiColor Corporation – Offset – Labels Wine and Spirits – Repro: MultiColor Corporation

• Gold – Ultra Labels – Digital (All labels except wine and sprits) – Repro: Ultra Labels

• Gold – Ultra Labels – Digital

– Labels Wine and Spirits – Repro: Ultra Labels

• Gold – Ultra Labels – Digital

– All digital printed labels – Repro: Ultra Labels

• Gold – Label Avenue – Combination Labels

– Colour Process – Repro: Label Avenue

• Gold – Label Avenue – Combination Labels

– Wine and Spirits – Repro: Label Avenue

• Gold – RollsPack – Flexo Narrow Web

– Surface Print Paper – Repro: Kirks

• Gold – RollsPack – Flexo Wide Web

- Surface Print Film – Repro: Kirks

• Gold – RollsPack – Flexo Wide Web

– Reverse Print Film – Repro: Brandpack

• Gold – RollsPack – Gravure Wide Web

– Flexbile Packaging – Repro: RollsPack

• Gold – CCP Newcastle – Flexo Post Print

– Corrugated – Repro: Kirks

Innovation Award – Peacock Bros

Innovation Award – RollsPack

Best in Show – Labels – MultiColor Corporation – Repro: MultiColor Corporation

Best in Show – Digital – Ultra Labels – Repro: Ultra Labels

Best in Show – Flexo – RollsPack – Repro: BrandPack

Best in Show Asia Pacific – MultiFlex PolyBags India – Repro: Veepee Graphics India

Elite Label-i Automatic Inspection Slitter Rewinder BGM Elite Comflex Compact Digital Converting Finishing System

Nekkorb Solutions supplies Rutherford Graphic Products (RGP) and X-Rite in Australia and New Zealand

Acombination of RGP’s IntelliLoop system, which automates pressside colour setups and X-Rite’s IntelliTrax, a fully automatic scanning system, can reduce ink and paper costs on all print runs, said Nekkorb Solutions managing director Frank Brokken.

He pointed to the experience of awardwinning commercial print company Printwell. Based in Michigan, US, Printwell runs several of the IntelliLoop systems retrofitted to its Heidelberg presses. These systems adjust and maintain colour accuracy throughout the print process, quickly and easily.

RGP engineers and manufactures its colour console and closed-loop system as a straightforward, uncomplicated retrofit to most makes of offset printing machines, enabling them to achieve higher print standards, greater print consistency and increased profitability than in the past. The RGP colour console allows quick and easy adjustments. It ties into X-Rite and

Pantone systems and maintains colour accuracy throughout the printing process.

User friendly and engineered to reduce time, labour, paper and ink costs, it assists with colour management and improves colour accuracy, making it an excellent companion for every printer and print job.

In addition, IntelliLoop handles both standard press runs and the more sophisticated, high gamut presswork that requires light cyan and light magenta inks. The system easily manages spot colours, including metallic and white inks.

Printwell’s 15,000 square metre shop houses three Heidelberg full-web, six-colour heatset (with ribbon deck) presses; one Heidelberg Harris M-110, six-colour heatset web press; a six-unit Heidelberg non-heatset web press; as well as two, Heidelberg sheet-fed presses and digital equipment.

Because of the time, ink and paper required for web press colour setups, Printwell has tended to forego short print runs in the past. However, with the RGP and X-Rite retrofit solution, Printwell has reversed its short-run print strategy.

Printwell president Paul Borg said, “To be profitable with short run work on web presses, Printwell has to get colour right the first time, every time.

“The job control, colour accuracy and colour consistency using the Rutherford and X-Rite process is simple. Make a scan, feed the data to the press, and get consistent results. We enjoy not having to make constant press checks and the subsequent paper cost savings. It is fast and it is accurate. We’re happy, and, even better, our customers are happy. Our job opportunities have increased exponentially, especially in the once difficult short-run area. Rutherford Graphic Products and X-Rite has helped get us to this point.”

Brokken added, “Please contact us at Nekkorb Solutions to discuss how these advancements can help your business improve its profitability.”

New Zealand label and packaging manufacturers can now add Bar Graphics solutions to their armoury

Available from Nekkorb Solutions, Bar Graphics designs and manufactures a wide range of finishing solutions for the label and packaging sector. Nekkorb Solutions commercial manager Tash Brokken said, “With these solutions, you can enjoy highspec features commonly found on more expensive machines”

Their advantages include:

BGM Elite 410/450 iSR Label Inspection Slitter Rewinder

Boasting automatic unwind braking with an adjustable roll end stop, as well as reversible rewind and machine diagnostics, this machine lives up to its reputation as the most cost-effective, compact, robust and free-standing Label Inspection Slitter Rewinder on the market.

With running speeds of up to 300m/m, and requiring just a 230v/13amp supply, this is a highly efficient machine. Roll end wastage is as little as 1.2m. A colour HMI touch screen allows the operator to setup the machine quickly and efficiently. Plus, no operator intervention is needed with the automatic unwind and rewind tension control system once set, thus maximising productivity.

BGM Elite eDSRt Die Cut Slitter SemiAutomatic Turret Rewinder

With speeds of up to 250m/m, this is the fastest, free-standing, semi-automatic turret die-cutting machine on the market.

For loading, the weight of the die is supported by a bottom guide rail, meaning the operator can quickly and effortlessly load dies into the machine. This feature vastly improves operator setup and handling times, and it helps to reduce damage caused by incorrect loading (a common problem in conventional die stations).

The easy loading die station accommodates most styles of dies, utilising existing dies, and minimising any tooling costs. A twospindle semi-automatic rewinder enables you to pre-load cores on to one spindle, while the second spindle is rewinding. The turret also incorporates an automatic tail cut and applier.

With the aid of an integrated support attachment, it is possible to run 12.7mm cores. Users of this system have claimed an increased productivity output by as much as 60 per cent.

BGM Elite Label-i Automatic Inspection Slitter Rewinder

Cost-effective, compact, robust and free-standing, this machine enables you to inspect, slit and rewind unsupported and supported substrates as thin as 15 microns at speeds of up to 300m/m.

Simply key in the rewind shaft size and the machine will automatically adjust the acceleration and deceleration times. It offers automatic unwind braking with an adjustable roll end, reversible rewind and machine diagnostics. Plus 100 per cent inspection and defect detection of the printed web is possible when fitted with an Esko AVT Helios inspection camera system from Nekkorb Solutions.

Suitable for paper labels, transparent clear-on-clear and films, the Label-i Automatic Inspection Slitter Rewinder will increase your productivity.

Bring new life back into your old printing machine

Paper

Paper

your old printing machine

Save money

Energy

Ink

Save money

• Save money

Best in class colour consistency • Seamless integration with most rips

Ink

Paper

Ink

Paper

Save money

Energy • Best in class colour consistency

Paper

Energy

Energy

Paper

Best in class colour

• Seamless integration

Best in class colour consistency

Seamless integration with most rips This closed loop colour measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

production quicker than ever before.

measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

This closed loop colour measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

This closed loop colour measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

or considering the upgrade?

Ready or considering the upgrade? Contact us

Ready or considering the upgrade?

Rutherford

Ready or considering the upgrade?

closed loop colour measurement solution delivers fast make ready and gets the machine into production quicker than ever before.

Ready or considering the upgrade?

us now

Rutherford fr

Rutherford.

A total of 450 exhibitors spread across five halls showcased the latest and greatest of their innovations at the event, which took place in September

The recent Labelexpo Americas in Chicago was the place to be for all things labels and packaging. A total of 450 exhibitors took part at the event, with a key focus on flexible packaging and automation.

Many exhibitors took the opportunity to show off their latest and greatest machines, with organisers saying this year’s event had more technologies and live demonstrations than any previous show. These machines included new, wider flexo presses, conventional and hybrid technology as well as a range of digital label and package printing equipment.

Labelexpo Americas group director Tasha Ventimiglia said, “From networking to discovering new products, solutions and technologies in RFID, flexible packaging and automation, as well as a host of educational content, Labelexpo Americas 2024 presented a perfect

opportunity for the industry to come together all under one roof to see the latest innovations that are shaping the future of this dynamic industry”.

Here are some of the many technologies that made their way to the show:

ABG took to Labelexpo Americas to demonstrate its NSU Lite technology. NSU Lite is a new addition to its non-stop winding range. This new system was demonstrated in-line with ABG’s 4th generation converter platform and the recently launched Vectra AutoSet Turret Rewinder, displaying seamless integration and non-stop capabilities.

Non-stop production is achieved by automatically butt splicing the leading roll edge of a new roll to the trailing end of the current, running roll without any drop

in process speed. The machine is highly efficient and ensures as little roll material is wasted as possible during this process.

Additionally, ABG presented its flagship Digicon Series 3, including the ABG Connect workflow system. This system exemplifies ABG’s commitment to automation and streamlined processes, allowing users to experience significant improvements in operational efficiency.

Providing a comprehensive overview of ABG’s extensive product range, live demonstrations of several key solutions were also available. These include SRIs, a DigiLite, DigiLase and Shrink Sleeve solutions, each designed to address specific industry challenges and enhance production capabilities.

The SRI 3 was on display and Ralph Wirtz from ABG discussed the technology with ProPack.pro.

“The SRI 3 is a slitter/rewinder and this machine has been upgraded with some nice modules like die cutting and inkjet printing. It prints beautiful labels and delivers on wasteless print,” he said.

Currie Group is the technology partner of ABG in the supply of digital finishing solutions to the A/NZ label and packaging market.

Scan the code to see Mark Hyde from ABG demonstrating the NSU technology

BOBST set up shop at Labelexpo for visitors to experience live demonstrations of its Digital Master 340.

The Digital Master 340 showed BOBST’s all-in-one label production concept with printing, finishing, die-cutting and quality control in a single pass. As every machine in the Digital Master series, it features ACCUCHECK – BOBST’s proprietary inline inspection and calibration system.

It also comes with full digital automation on all print and finishing modules, controlled via a single user-friendly

interface that offers cloud-connectivity to BOBST Connect and third-party MIS integration.

Visitors also were educated about the new BOBST Connect and pre-press features. Combined with an extensive network of industry partners, it allows label converters to accelerate job preparation, with faster job completion, less dependent on operator skills, and with a more connected production floor.

At the event, Patrick Graber from BOBST said, “BOBST Connect connects end-toend production floors from brand owners to the end customer. This is part of the implementation of our industry vision, where we gather data from every single step of the process of the complete production line, which helps to improve, automate and optimise your production in future.”

BOBST’s label solutions are intended to address three major pain points: ease of use, workflow integration and colour consistency across all technologies. In this regard, BOBST experts also discussed oneECG (Extended Color Gamut) printing technology for inline flexo presses.

Scan the code to see Patrick Graber from BOBST discussing the Digital Master 340

Canon showcased its first water-based inkjet label press, the LabelStream LS2000. Based on innovative Canon technologies and designed for industrial-scale label printing, the LabelStream LS2000 was announced in October 2023.

The five-colour inkjet digital label press prints CMYK plus white on self-adhesive substrates, with a new ink set designed to comply with food safety standards.

It also prints on a variety of media types such as coated and uncoated paper, and synthetic PVE, PET and PPE.

The machine was designed to serve the surging demand for digital, high-quality label converting, and implements many newly developed Canon technologies, such as high-density aqueous ink, printhead, advanced fixing system and a variety of automation features designed to support efficient production.

“It is ideal for any type of labels for your specific needs,” Canon USA’s Jason Koyama said at the event.

Visitors to Canon’s booth at the tradeshow also saw live label production on paper and film media on the LabelStream LS2000.

Other highlights from the Canon booth included:

• The LX-P5510, LX-D5500, and LX-P1300 dye and pigment-based inkjet desktop printers to meet the needs of on demand in-house printed labels

• The Colorado M-series roll-fed printer, the modular 64-inch roll-to-roll printer with optional UVgel white ink

Scan the code to see Jason Koyama from Canon introducing the LabelStream LS2000

At Labelexpo Americas, CERM introduced its AI-support chatbot and had a lot of interest for its AI-based planning optimiser, CERM Scheduling Optimizer.

The cloud-based AI solution aims to transform the landscape of job scheduling in the labels and packaging printing industry. The technology is based on constraint optimisation and is tailored to a user’s unique production processes and printing methods.

The CERM MIS Software serves as the gateway to this innovation. It pushes

a dataset of all orders that are ready for production into the Scheduling Optimizer application. Using a set of customisable parameters, the AI-scheduling cloud application processes this data, returning an optimised schedule to the user’s CERM MIS.

One of the standout features of the CERM Scheduling Optimizer is its ability to prevent production bottlenecks. The AI-technology prioritises in-timeproduction and delivery, allowing scheduling operators to focus on efficiency parameters and to concentrate on the most critical aspect of production: costeffectiveness and profitability.

When comparing manual scheduling to AI-scheduling, the CERM MIS planning report reveals a slight edge in timely scheduled jobs. However, the real benefits of AI scheduling are more profound and less immediately visible.

The CERM AI-Scheduling Optimizer completes the scheduling of a user’s entire order list in about an hour, according to the company. CERM said it meticulously adheres to all predefined parameters, achieving a level of precision and consistency unattainable by human schedulers.

Scan the code to see CERM’s Jan Heyse discussing AI innovations

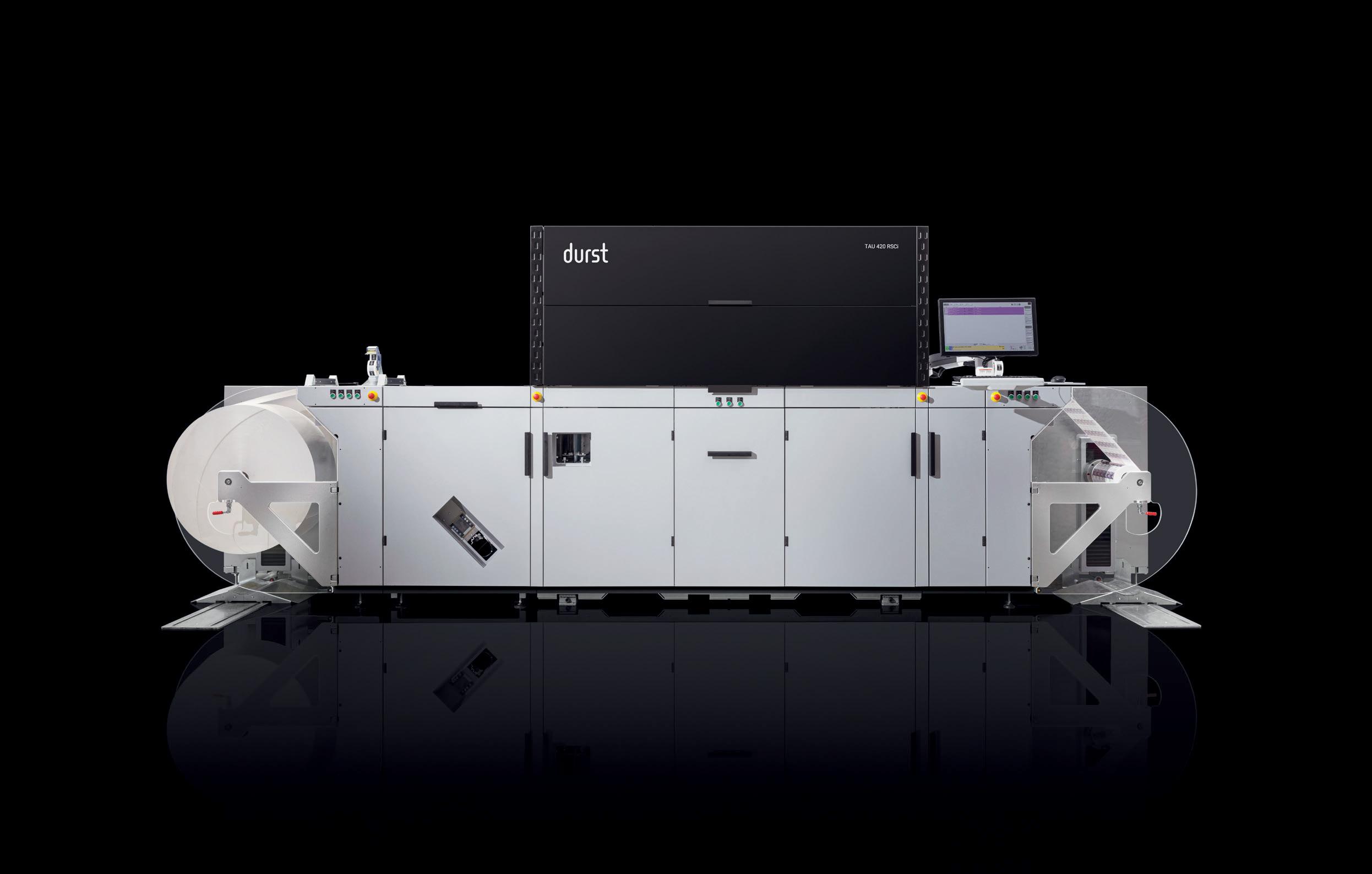

Durst showcased a captivating lineup of its products, including the new hybrid KJet. Making its American debut at the snow, the KJet is an end-to-end solution that combines OMET’s dual servo flexo printing units with Durst’s RSCi inkjet technology.

Modules for finishing and further processing (such as cold foil stamping or die-cutting units) can be integrated into the KJet, offering flexibility and an enormously broad application portfolio. In addition, the configuration of the KJet can be tailored to the specific requirements of each customer.

The launch of the KJet follows an announcement at Labelexpo in Brussels extending the hybrid development partnership between the two organisations beyond the XJet platform.

Durst labels and flexible packaging head of product management Martin Leitner was at Labelexpo Americas talking about the features of the machine.

“The KJet is a digital labels production machine that showcases the power of the Durst RSCi inkjet technology. It is available in a 420mm-wide configuration, as well as

durst-group.com/label

a 510mm-wide configuration, and can hold up to nine colours in digital – CMYK, orange, violet, green, and double white,” Leitner said.

Durst also had on display the Durst Tau RSCi. Designed for an industrial level of productivity, this printer offers high quality in an economical way. Available in printing widths of 330, 420 or 510mm, the printer is a productivity workhorse with printing speeds up to 100m/min.

The printer can be equipped with the double white feature, increasing productivity when printing with white ink at highest opacity to 80m/min.

Durst Software & Solutions rounded out the lineup. The software ecosystem ranges from web shops and online graphics editors to comprehensive workflow and analytics solutions, and ERP/MIS systems, all to help improve and simplify business.

“All strategic Esko applications – from ArtPro+, ArtiosCAD, and the award-winning Phoenix through to Cape Pack and Automation Engine – connect to the new platform, giving all stakeholders in the value chain 24/7 real-time access to live data and identical resources, wherever in the world they reside. Moreover, Esko S2 is an open platform supporting connectivity with partners.”

Existing customers will be able to seamlessly integrate their Esko on-premise applications with the S2 platform, for a new way of working.

As well as introducing its newest software platform, Esko also demonstrated its latest hardware innovations – its AVT varnish inspection solutions.

The new Varnish Inspection Module for the Esko AVT Helios system facilitates viewing and inspection of varnish and coating on various printed substrates simultaneously with print inspection. This unique and patented Varnish Inspection Module detects issues such as varnish misregister, partial and full starvation simultaneously with the existing print defect detection.

As an add-on to the Helios system, the Varnish Inspection Module enables the concurrent review and monitoring of varnish and coating on multiple printed materials, enabling labels converters to achieve maximum output while reducing waste in their print production process.

the code

Gallus, a subsidiary of Heidelberg, is aiming to transform the narrow-web print landscape with its latest research – Gallus MatteJet technology.

Announced at Labelexpo Americas 2024, the company said the innovation represents an important advancement in inkjet printing, unlocking a premium matte finish previously unachievable with digital inkjet, bringing the possibilities of inkjet technology to the wine label market for the very first time.

Exemplifying Heidelberg’s position as a total solution provider for all modern printing processes – offering the entire spectrum from toner to inkjet, offset printing to flexo and all controlled from a common Prinect workflow – MatteJet was developed in-house at Gallus’ innovation hub in St. Gallen, the Gallus Experience Center.

At Labelexpo Americas 2024, Gallus exhibited alongside Heidelberg, where it explained how this innovation addresses one of the key challenges that has historically restricted the growth of digital inkjet technology.

Importantly, visitors at the show also learnt how MatteJet transforms the market segment for wine and spirit labels and provided converters with the key to a profitable new area of business growth.

Visitors that attended Labelexpo Americas this year discovered the latest innovations in the Esko ecosystem that are helping brands and label converters to accelerate go-to-market of goods. These advancements include cloud technology, sophisticated estimating software, and inline inspection hardware.

“Representing a significant advancement in software architecture, the new Esko S2 platform is a multi-tenant cloud-native platform that delivers on a new technological reality based on cloud computing, data sharing, and artificial intelligence,” Esko director of marketing, industry relations and strategy Jan De Roeck said.

The glossy finish inherent to digital inkjet technology has been one of the foremost barriers to its widespread adoption across labels and packaging – specifically in premium segments such as wine and spirit labels where brands traditionally expect a sophisticated matte finish.

Until today, this was only achievable through conventional printing, or the addition of post-processing equipment to utilise matt varnishes, adding time, complexity and cost.

Now, Gallus MatteJet technology delivers fast, cost-effective, and high-quality matte finishing capabilities, integrated directly into the digital inkjet process.

This will allow converters to achieve a high-end matte finish at the touch of a button, without changing inks or adding overprint varnish, eliminating the need for external finishing processes or separate conventional machines.

MatteJet will also enable more converters and brands to enjoy the benefits of digital printing, such as more profitable short runs, personalisation, and on-demand printing.

Designed to integrate with Gallus’ Digital Printing Unit, the new MatteJet technology also represents further expansion of Gallus’ System to Compose concept. Under the System to Compose, converters can add, adjust and remove units to their Gallus One as their business needs evolve – now further expanded to comprise workflow and service options as well as equipment.

The latest iteration of the Gallus One also made its global tradeshow debut at this Labelexpo, in the newly expanded 430mm web width.

Visitors to the stand saw first-hand the possibilities achievable with its recently extended colour gamut, with the integration of orange and violet Saphira inks developed jointly in-house with Heidelberg.

Existing equipment can be effortlessly retrofitted or modified, and entirely new configurations can be customised by integrating all proven Gallus Labelmaster modules, up- and downstream, allowing print service providers to “compose your print masterpiece” with the Gallus One.

The Gallus one facilitates not just gamechanging levels of adaptability, but market-leading levels of speed and quality – boosting profitability, by design.

The fully hybrid solution also has the capability to not only print in four colours but also in orange and violet with the gamut extended.

“This hybrid solution allows us to combine our system to compose directly with all the

configurations. At the front of the system, we can add some flexo printing units from the Labelmaster. Downstream we can add other functionalities like embellishing and die-cutting,” Heidelberg head of sales Thomas Schweizer said.

“What’s also new is that with regular inkjet, labels are glossy. But now, we have new technology that allows matt labels to be printed. With just a push of a button, we can change the behaviour of the ink from glossy to matt. This is totally revolutionary.”

Global Graphics Software, a Hybrid Software company, has integrated its SmartDFE solution into more OEMs’ digital presses, naming Mark Andy and Dantex as its latest partners at Labelexpo Americas.

Hybrid Software has expanded its partnership with Mark Andy to integrate SmartDFE into the Mark Andy Digital Series HD press.

In addition, it has announced a strategic partnership with Dantex Group to integrate SmartDFE into Dantex’s Pico range of digital UV inkjet printers.

Hybrid Software CEO Mike Rottenborn said, “Here at Labelexpo Americas, we finally have closed the loop between our offering for OEMs – companies who make digital presses – and print providers –companies who buy them to print labels and packaging.

“The same products we use for professional pre-press tools are also integrated in front of many other digital front ends. We’ve made two major announcements at the show – our SmartDFE driving the Mark Andy Digital Series HD Press as well as the Dantex Pico range.”

SmartDFE is a full software stack for highspeed, single-pass, label and packaging inkjet presses. It includes everything from job creation and pre-press workflow through to printhead drive electronics. SmartDFE includes print intelligence, giving users quality and secure connectivity to power Industry 4.0 scenarios.

Mark Andy said the Digital Series HD already offers high-definition digital printing with the capability to handle complex and variable data jobs.

It added that the Mark Andy Digital Series HD has one of the most robust and durable

profiles in the hybrid inkjet printing space. Adding on SmartDFE to its digital front-end solution has enabled it with a toolkit that delivers complete workflow automation.

As for the Dantex Pico range, it offers highly productive, affordable label printing for short- to long-runs, no minimum run quantity, minimal waste, fast turnarounds and makes label production fast and easy.

PicoJet models are available as either reelto-reel or as a true hybrid press with inline finishing capabilities – modular station options include: flexo, die cut, cold foil, lamination, edge trim, back scoring and rotary or shear slitting. SmartDFE integration adds to a user-friendly experience.

Scan the code to see Hybrid Software’s Mike Rottenborn speaking at Labelexpo Americas

Currie Group sold its first HP Indigo 200K digital press in A/NZ to existing partner Ultra Labels & Flexpack in Brisbane.

The deal was made at Labelexpo Americas, where Currie Group A/NZ labels and packaging director Mark Daws made the announcement.

“I am absolutely thrilled to announce that we sold the very first HP Indigo 200K digital press in A/NZ to our dear friends and partners at Ultra Labels & Flexpack in Brisbane,” Mark Daws said.

“This press is the next iteration of a number of machines that they have – Series 3, Series 4 and this is the Series 5. It is very well suited to digital labels and flexible packaging – primarily flexible packaging which we see as a big growth opportunity.

“We are very excited to see how this cutting-edge technology will grow their production capabilities, delivering

unmatched quality and efficiency for labels and flexible packaging.

“Congratulations to Ross Fursey, Johnny Marusic, and the whole team at Ultra. We are proud to partner with you on your continued journey in digital labels and flexible packaging.”

Ultra Labels & Flexpack also owns eight HP S3 presses, a Series 4 press, and now the Series 5 press, all purchased from Currie Group.

At the show, HP exhibited the HP Indigo 200K Digital Press with an add-on slitter and the HP Indigo 6K Digital Press. This comprehensive portfolio, along with the HP Indigo V12 Digital Press, aims to offer customers a wide range of options, leading to above market growth of HP Indigo users. HP Indigo digital press fleet is part of an E2E approach including the Digital Pouch Factory, ABG Non-stop Winding and converting. The HP PrintOS software suite helps converters automate the entire production line and produce higher volumes thanks to its complete ecosystem across leading industry players.

In addition, adjoining stations such as PrintOS Spot Master showed how to reach spot colours within minutes and streamline the print process, or automated workflow solutions to demonstrate how Intelligent Automation can address key customer challenges such as labour shortages, waste reduction, mass customisation, and on-demand production.

facilitating rapid changes for standup pouches using Charter MDO PE Mono Material.

Karlville is available in A/NZ from Currie Group.

Kurz

Kurz presented the latest development from its subsidiary Steinemann DPE, the DM-Uniliner 3D, at Labelexpo Americas,

The DM-Uniliner 3D is a modular, standalone digital printing system for finishing labels with impressive 3D effects. The digital printing system for narrow web label printing enables almost flat as well as raised coating and metallisation effects.

With the machine, unusual design ideas for small to medium-sized product series and special editions in the narrow web sector can be implemented digitally and cost-effectively. At the heart of the system is Steinemann DPE’s inkjet technology with UV varnishing, combined with Kurz Digital Metal finishing technology.

functional protection over the digital metallisation, or simply as a design element.

Depending on the substrate and design, 3D print jobs can be finished at up to 100 m/min on the machine, with roll diameters of up to 800mm enabling time-optimised work without roll changes.

The industrial design with intuitive and easy-to-use operation provides fast job changes, and the system also impresses with its low varnish consumption, very short setup times and low maintenance requirements.

Karlville Converting and Karlville Swiss came together to display their post-print flexible packaging machinery for pouch production, lamination, and slitting, in collaboration with HP Indigo.

Karlville had on display its compact pouch machine, the KS-SUP-400-D, which is made for short- to medium-runs and caters to digital and conventional printing. Some of its features include offering minimal waste, low power consumption, as well as low maintenance costs and quick setup.

Karlville also had on show its Converting Compact Thermal Laminator, designed for surface print applications. It utilises a Protect-all MET PET in conjunction with Nobelus Soft Touch thermal laminate.

In addition, the Karlville Swiss Compact D Model pouch machine was on display,

Up to six different metallisation rolls can be processed in parallel on the DM-Uniliner 3D. The digital varnishing can be used as

Mark Andy

With a strong presence and focus on helping its customers perform and scale, Mark Andy exhibited five of its latest technologies as well as additional cuttingedge systems and products, highlighting the company’s commitment to driving progress in the narrow web industry.

Mark Andy CEO Duane Pekar said, “Our commitment to advancing print technology is exemplified by our ongoing partnerships with Domino and Konica Minolta, and our continued development of best-in-class products”.

Mark Andy’s exhibits included the: