BRUSSELS EXPO 11 - 14 SEPTEMBER 2023 HALL 7 | STAND #7C45 LABEL OPEN HOUSE DURST HQ, BRIXEN, ITALY SATURDAY 9 & FRIDAY 15 SEPTEMBER 2023 www.propack.pro August 2023 People Technology Business A FOCUS ON: ALSO INSIDE... ‘Outside of the box’ design Pride in Print NZ awards industry Labels and packaging companies were put in the spotlight at the recent awards ceremony Labelexpo Europe 2023 preview Some of the innovations that will be on display at the upcoming show Building on Label Line’s success Label Line builds on its momentum with the hire of Jason Brown

My client and I both sayYOU’RE A LEGEND !!!

The cards arrived this morning -which was perfect timing as they are being used today. Thank you so very much.

Phil

I really appreciate how quickly the books arrived and loved your notification system. The quality is gorgeous.

:)

Marie

Just wanted to say a big thank you to you for rushing the booklet job through and dropping off to the client.

I know it was a huge ask and again you did not let me down.

Angela

Client has received their 8pp A5 brochure this morning, way earlier than expected (thank you!!!), and they are delighted.

Mel

The books have arrived and are amazing! You do a fantastic job.

I am so happy to be working with you because I can trust we are in good hands and it will be a quality result.

Luke

We received the business cardsthey look great! Everyone was surprised at the quick turnaround.

Xheantelle

OF OUR NEW CLIENTS ARE REFERRALS

SEE WHY... AUSTRALIA’S BEST TRADE PRINTER

YOU CAN

Gearing up for the biggest labels event

The excitement around the first Labelexpo show in Europe since 2019 is building, and with the tradeshow just a few weeks away, the industry is getting more eager to find out about the new technologies and innovations that will be on display.

Labelexpo Europe will take place on 11 to 14 September at Brussels Expo in Belgium, promising demonstrations of the latest printing and converting equipment, masterclasses and special events focused on automation and flexible packaging.

In addition to the new product launches and live demonstrations, the show will also feature themed areas highlighting fast-growing areas of the industry.

The show will span across nine halls, showcasing cutting-edge technology launches – including everything from prepress to materials, and digital and conventional print and converting

technology. Key technology themes are already emerging from the snippets of previews that we are now getting from manufacturers.

Tarsus Group, organiser of the Labelexpo Global Series, said diversification across labels and flexible packaging technologies, digital embellishment, workflow and machine automation, real-time data collection over the Cloud and sustainability across multiple fronts from LED-UV to more new materials and adhesives choices are just some of the trends making headway.

With converters and brand owners facing growing legislative pressure to demonstrate the sustainability of the labels industry, the key theme of ‘sustainability’ is also expected to go mainstream at Labelexpo Europe.

With hundreds of product launches planned for the event, this issue of

Hafizah Osman

ProPack.pro keeps you up-to-date with some of the latest and greatest innovations that are planned for the event. There’s plenty to learn and takeaway from this issue, so I hope you enjoy the read.

The ProPack.pro team aims to bring you all the information about the latest launches from Labelexpo Europe as they come so keep an eye on the website for the news. We’ll also publish a detailed review from the show in the next issue of the magazine, in October.

On a side note, this will be my last ProPack.pro editor’s note to you for this year – fret not, I’ll be back next year following a few months of leave. The very capable ProPack team will continue to support you and their details are as below.

Hafizah Osman | Editor hosman@intermedia.com.au

Ph: +61 431 466 140

ProPack Industry Supporters

Editor: Hafizah Osman News Editor: Piotr Wnuk

Sales Manager: Carmen Ciappara

Production Manager: Jacqui Cooper

Pre-Press Manager: Tony Willson

Design: Sarah Vella

DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2023 — Charted Media Group Pty Ltd

EDITOR’S LETTER Stay informed… visit www.propack.pro and subscribe to receive the latest packaging industry news and views

www.propack.pro 4 ProPack.pro August 2023 ProPack.pro is published by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication.

Managing Director & Publisher: James Wells

Printed by: Hero Print, Alexandria, NSW 2015

Mailed by: D&D Mailing Services

IN THIS ISSUE...

Unimax upgrades to Screen

Truepress Jet L350UV SAI S P6

Jet Technologies and Fujifilm NZ partner with Unimax for New Zealand’s first Screen Truepress Jet L350UV SAI S digital label press

Orora Beverage brings digital can decoration to the region P8

Orora Beverage has launched Helio by Orora, a “transformative packaging decoration and first-to-market high-speed digital printing technology” for can design and decoration

From the brink of closure to getting NZ$70M in investment P9

New Zealand’s Whakatāne Paper Mill has secured private investment of over NZ$70 million for further factory expansion

Labels and packaging shine at Pride in Print

P10-11

Labels and packaging companies were put in the spotlight at the recent Pride in Print Awards in New Zealand

Innovation to shine at Labelexpo Europe 2023 in Brussels

P12-18

An exciting range of new conventional, digital and hybrid press technology will be on display at the upcoming Labelexpo Europe event in Belgium

Setting the foundations for Label Line’s success P20

Label Line’s new managing director Jason Brown explains how he intends to build on the company’s momentum moving forward

Key considerations to take note of for label print quality

P22-23

Mediapoint reviews the elements of label print quality using its new equipment to help you understand, compare and evaluate options

Refining packaging by thinking ‘outside

of the box’

P24-27

‘Outside of the box’ thinking is one of the vital strategies to creating designs that stand out from the crowd

THIS ISSUE SUPPORTED BY

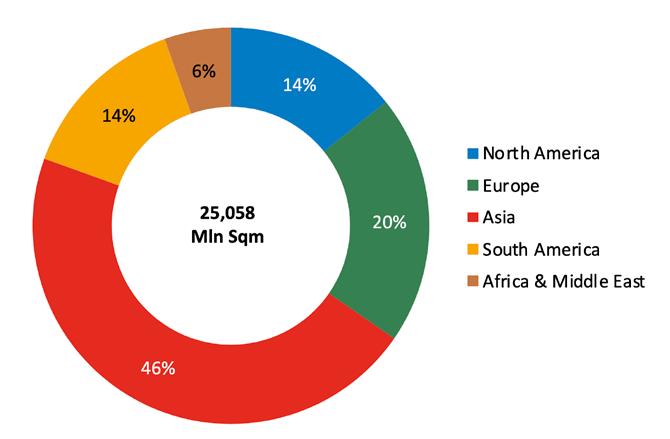

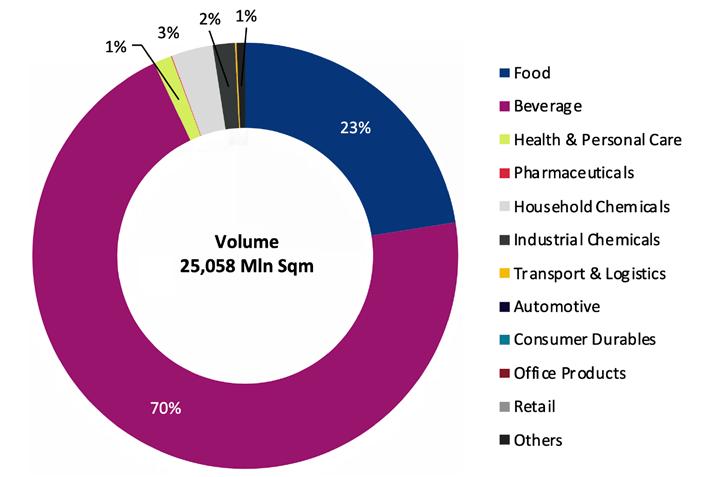

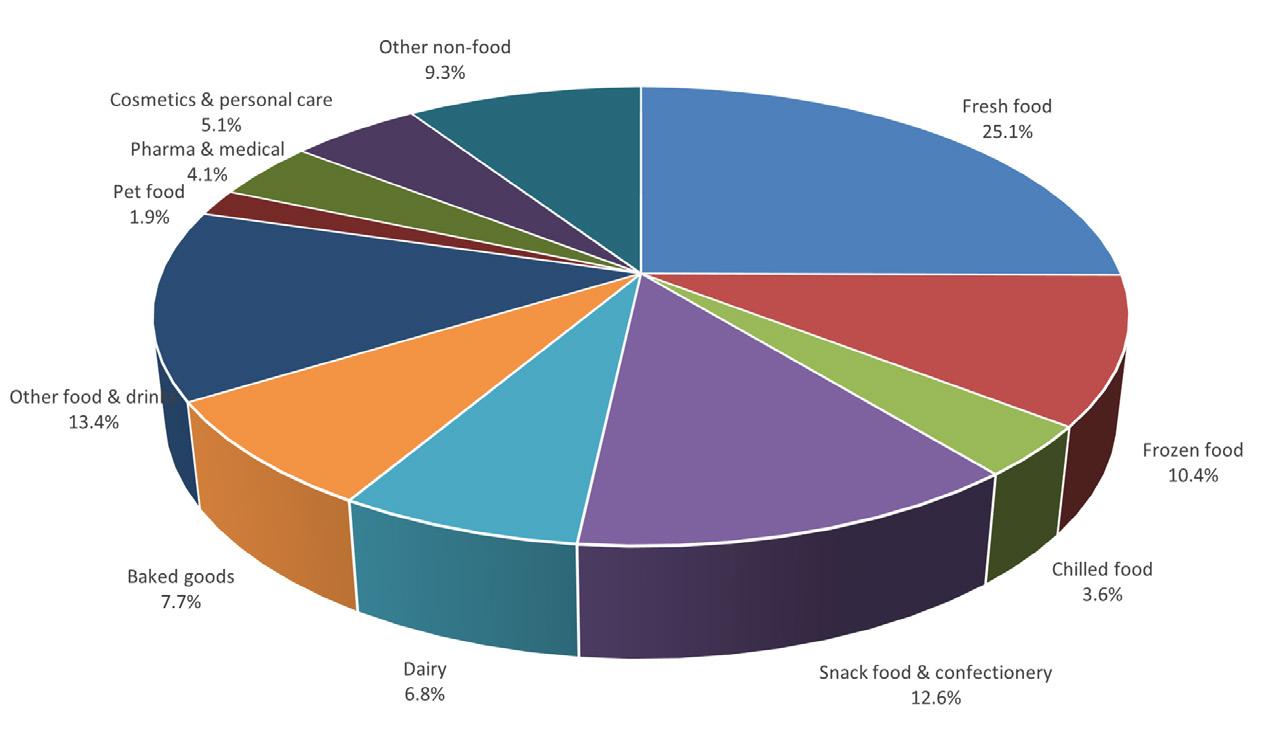

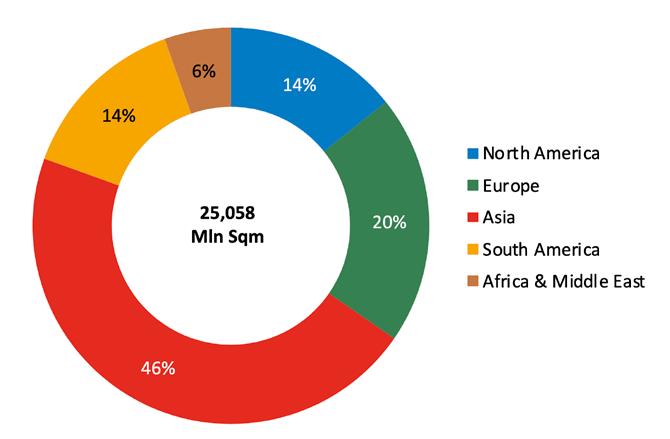

Flexible mono-material plastic packaging segment growth

A new Smithers report tracks growth segments for the mono-material flexible plastic packaging films market

The future of paper vs plastic packaging markets to 2028

In the next few years, brands will focus on developing smart designs and packaging solutions that improve packaging performance while minimising environmental impact

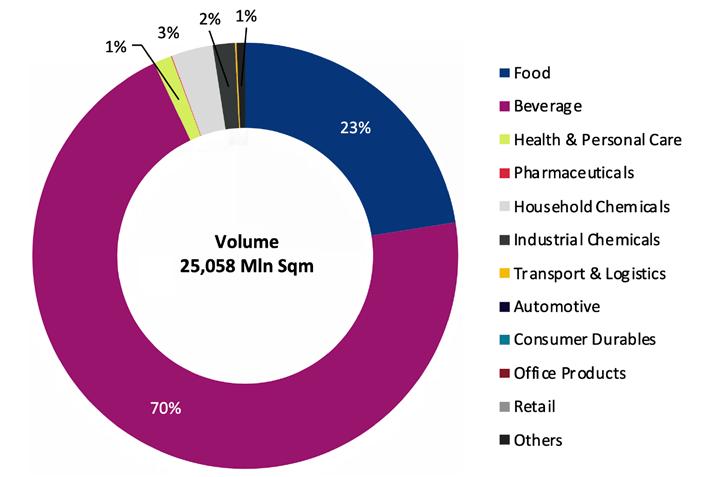

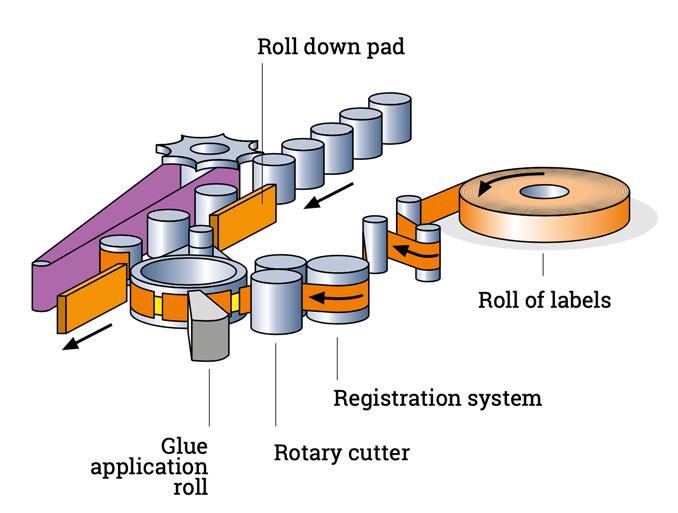

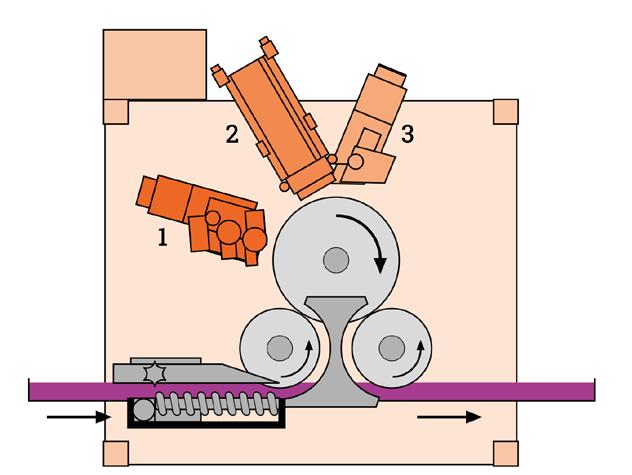

Sustainability trends boost wet glue label appeal

P28

P29

P30-32

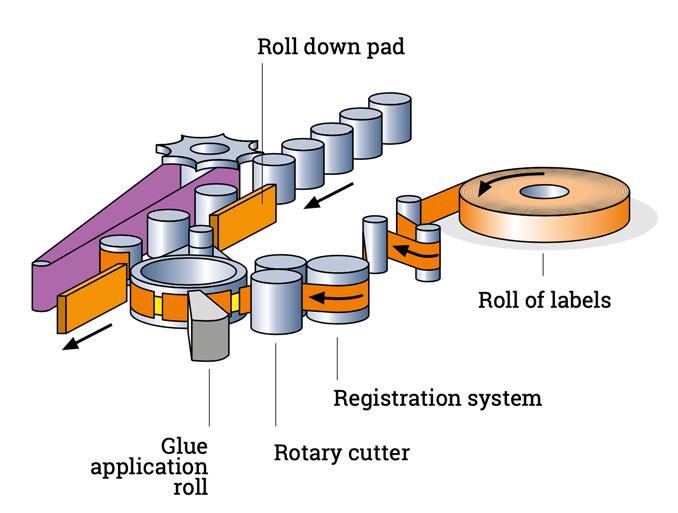

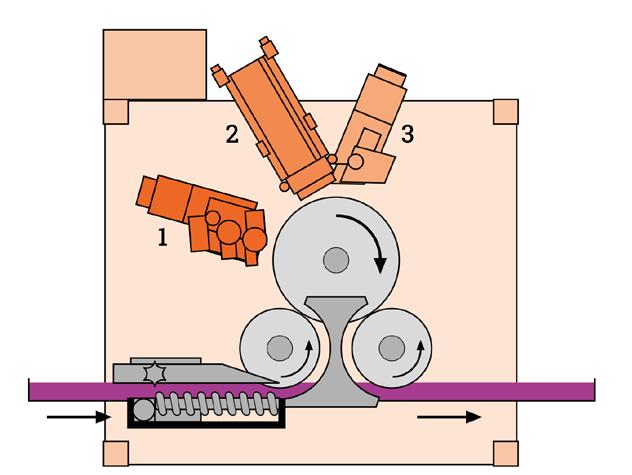

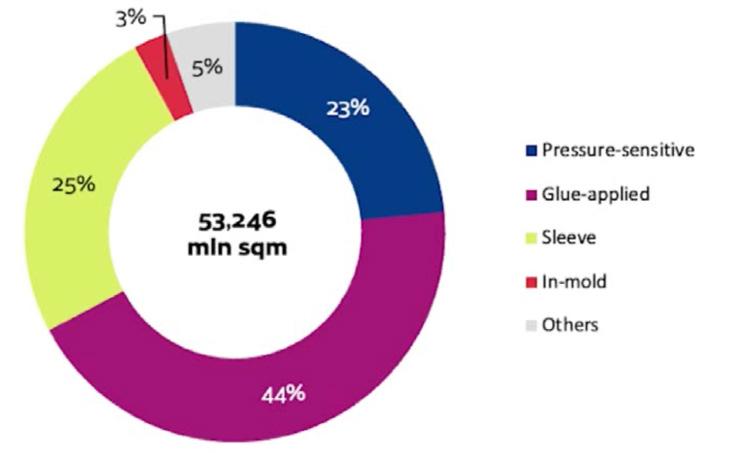

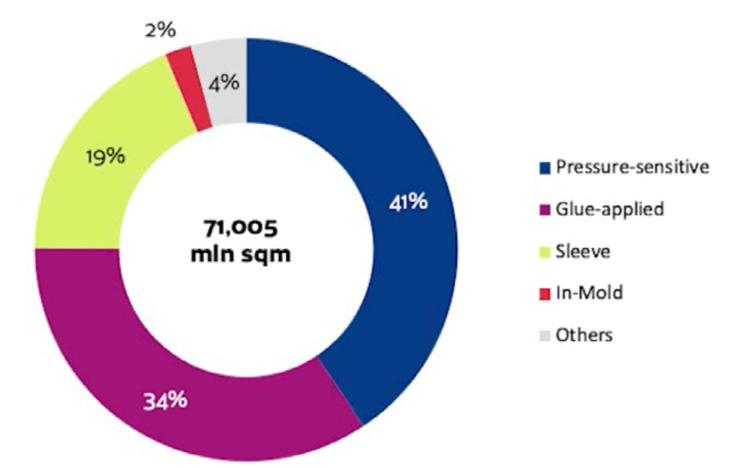

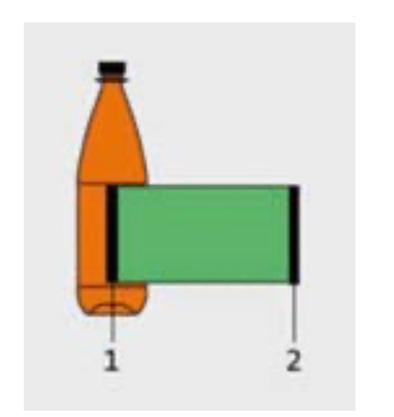

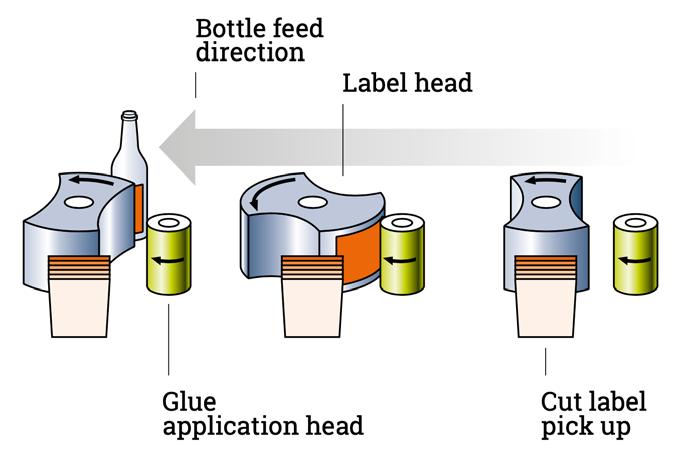

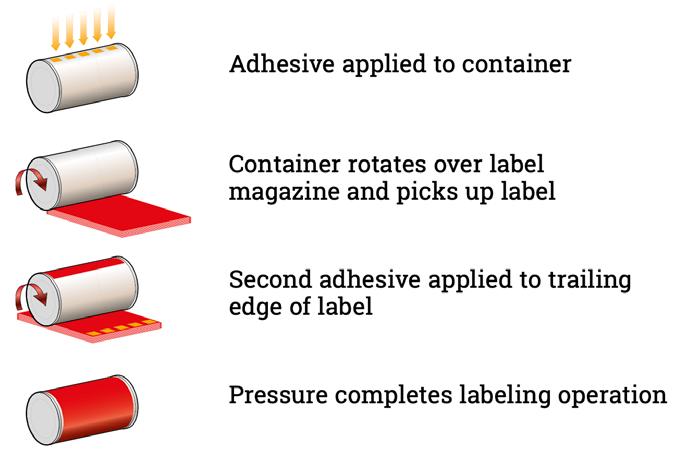

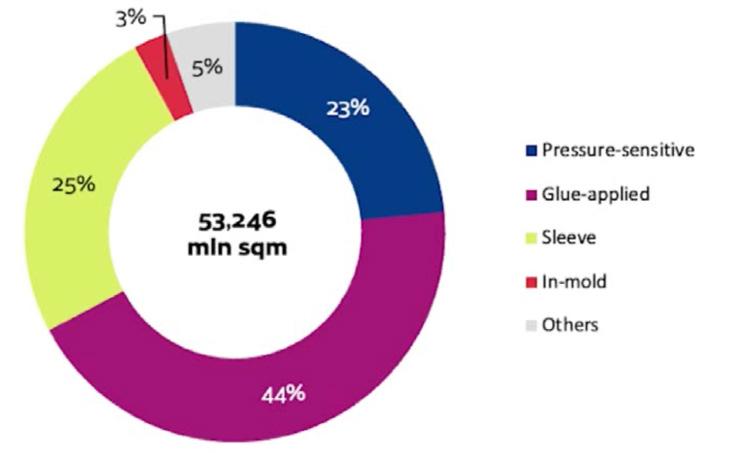

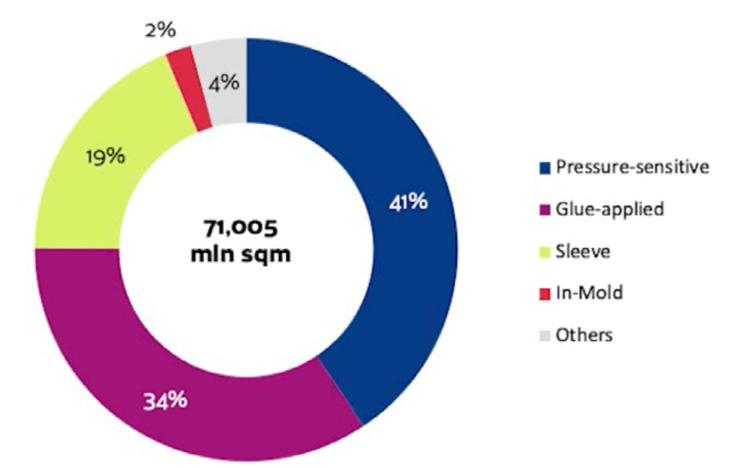

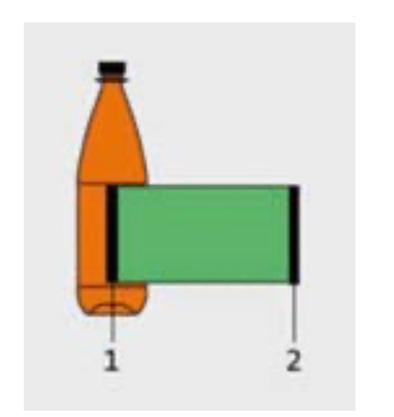

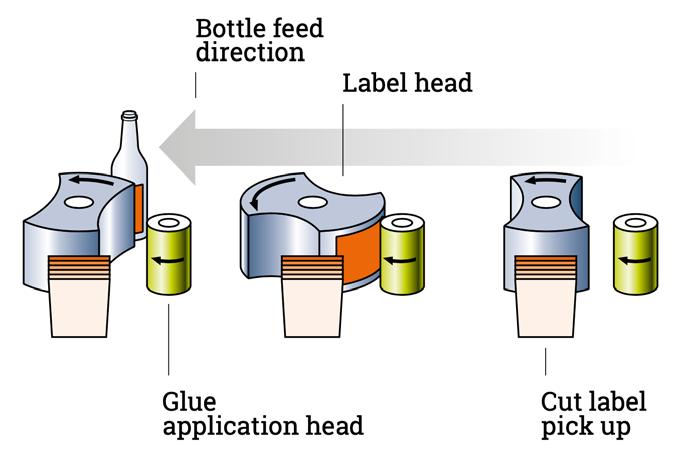

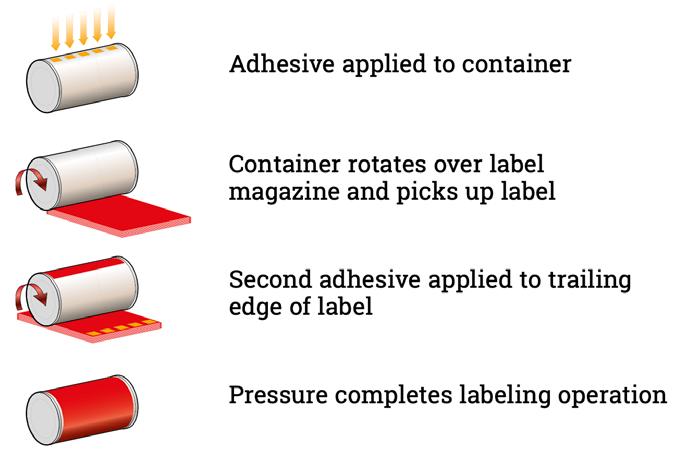

Labels & Labeling report: Glue-applied labels remain the dominant form of prime product labelling, providing key volume, sustainability and print quality benefits for end users

Pack diary

A guide to the upcoming events globally

P34

CONTENTS

P8

www.propack.pro August 2023 ProPack.pro 5

P24-27

P12-18

Unimax upgrades to Screen Truepress Jet L350UV SAI S

Jet Technologies and Fujifilm New Zealand partner with Unimax for New Zealand’s first Screen Truepress Jet L350UV SAI S digital label press

we receive from both Fujifilm New Zealand and Jet Technologies”.

The range of substrates available to Unimax has increased substantially with the new model, enabling the company to print on thinner synthetic stocks, as well as a thicker range of paper and hybrid products.

From its base in Avondale, Auckland, labels and packaging printer Unimax works with a diverse group of clients across the agriculture, transportation, health, food, and beverage sectors.

Recently, Unimax installed Screen’s most productive label inkjet press – the L350UV SAI S digital label press, supplied and supported by Jet Technologies and Fujifilm New Zealand. With an eye to the future, Unimax looked for a solution to support its growth and competitiveness with the capability to provide a broader variety of printing options for its customers.

Unimax director Dinesh Kumar said, “We were looking for a digital printing press that offered the highest quality print product and consistency. The solution we chose has those two qualities and was the most cost-effective of the options we considered.

“We feel particularly pleased to bring the first L350UV SAI S into the country. We have always been huge fans of inkjet and what it can do. In fact, we were the first to bring the L350UV into New Zealand and can proudly say that we are now the first with the new SAI model.”

Increasingly, industry sectors such as liquor, cosmetics, food, and beverage employ UV inkjet-based digital printing as a substitute for silk-screen printing. Digital printing provides these industry customers with several benefits, including shorter turnaround times, lower costs and reduced environmental impact. Demand for quality label and packaging printing continues to grow. Unimax recognised this trend five

years ago when it invested in its first Screen Truepress, which helped take the business “from letterpress to the digital age”.

Kumar said, “Our original press was extremely reliable over its five years with us. It helped us to diversify our client base and grow our business in higher-value markets. Upgrading to the L350UV SAI S was an easy decision, especially with the service

Kumar added, “Productivity has increased on all jobs and particularly for the work containing Screen’s high opacity white. The Screen Truepress Jet L350UV SAI S digital label press has impressed everyone, and we are thrilled with the results, which are next level in quality and productivity. Another benefit is the addition of orange and blue, which has increased the colour gamut.”

Fujifilm New Zealand director Stephen Hodson mentioned, “We are proud to partner with Screen and Jet Technologies to deliver this solution to Unimax and we look forward to continuing our support.”

New press broadens the options for label production

Introduced in 2020, the Screen Truepress Jet L350UV SAI S digital label press builds on the success of the popular Plus (+) range, as a high-productivity, highquality and versatile UV inkjet label press.

Screen developed the SAI series to help printers produce a wider range of spot colours to meet brand owners’ challenging demands. The machine prints on media widths of up to 350mm wide, with a print speed of up to 60 metres per minute. Using white ink, it can still achieve 50 metres per minute.

As a compact and configurable platform, the SAI series can accommodate the full range of label printing requirements. For example, the four-colour CMYK standard ink set and can easily upgrade to seven colours, as Unimax has done. to include white, orange, and a vivid blue.

Another option for the Truepress Jet L350UV SAI S digital label press is the recently introduced high opacity white mode. When used with clear film or similar labels, this new printing mode provides more opaque white, preventing the colour of bottles or package contents, from showing through. This helps to maintain rich colour saturation, ensuring high-quality labels with eye-catching visual appeal, even when applied to translucent base materials.

The printer has already taken out the EDP (European Digital Press) Best Label Printer Award for its “its ease-of-use, thanks to its advanced software, as well as for its improved colour quality and increased speed”. It is the third time Screen’s digital inkjet label press technology has an EDP award for its digital inkjet technology.

LABELS & PACKAGING www.propack.pro 6 ProPack.pro August 2023

(l-r) Stephen Hodson (Fujifilm New Zealand), Dinesh Kumar (Unimax) and Jason Jones (Jet Technologies) with the Screen Truepress Jet L350UV SAI S digital label press

Versatile Printing. Consistent Quality.

Expand your service offering with high quality short-run digital labels of exceptional quality and improve your bottom line. SurePress is easy to operate, offering consistent colour reproduction and precise colour matching.

• Extra wide colour gamut including Orange, Green & Opaque white inks

• Improved turn-around times

• Proven Epson technology

• Non-contact Epson micro-piezo printhead array delivers high quality results even on textured and uncoated materials

THE NEW SUREPRESS DIGITAL LABEL PRESS

Learn more, visit

NEW MODEL SurePress L-4733AW *Product shown includes Epson SureSpectro AS-4000 option

www.epson.com.au/surepress

Orora Beverage brings digital can decoration to the region

Orora Beverage has launched Helio by Orora, a “transformative packaging decoration and first-to-market high-speed digital printing technology” for can design and decoration

Orora has partnered with Velox Digital, an Israel-based global developer and manufacturer of industrial-grade direct-to-shape digital decoration solutions, to install the first digital printer in Oceania at the company’s can production facility in Dandenong, Victoria.

Orora said the name Helio, derived from the ancient Greek god of sunlight and colour Helios, symbolises the brand owners’ ability to realise their colour, texture and finish imagination and inspiration to engage consumers through a means currently unavailable.

“With Helio, the can becomes the canvas for leading marketing communication, innovation and infinitely unique promotional execution,” Orora said.

By adding the new advanced digital printing technology, the company, which currently decorates cans with traditional high-speed offset processes, is aiming to provide its customers with a quick turnaround by eliminating with the lead time required for the development of printing plates.

Moreover, the Velox Digital technology is expected to provide greater operational flexibility, catering to smaller minimum quantities and reduced inventory overproduction as well as complement

and capitalise on the new multi-size can line investment at Dandenong.

Orora beverage can general manager Chris Smith said, “We have been assessing the development of direct-to-shape digital decoration technology for cans for some time – we’re thrilled about our new technology choice and the introduction of Helio enabled by new high-speed digital decoration capability.

“Our role in primary packaging is to help our brand owners engage the shopper at the point of purchase. Helio and the Velox solution will transform our ability to do this for our customer’s brands.

“Once commissioned, what this means for our customers is that wait time will be significantly reduced in delivering a specific can size or label design for activities such as promotions, new products and limited-edition retail events.

“With no label set-up required and nearimmediate supply, shorter, faster minimum runs can be accommodated, providing greater flexibility in product and campaign planning.”

Expansion into the can market

Orora also mentioned that the introduction of Helio adds to the company’s significant investment

in cans capacity expansion, uniquely positioning it to meet the strong outlook for growth in the cans market.

In June, construction of the company’s new $80 million multi-size can line at Dandenong was completed to plan, increasing production capacity by 10 per cent and allowing for varying can sizes and formats.

A $30 million project to expand can ends capacity at Ballarat was completed in March, and a new $85 million can line at Revesby, NSW, is underway and expected to come online by Q1 2025.

Smith added, “We are seeing the demand for aluminium cans continue to grow, with particularly exciting developments across a number of categories including craft beer, soft drinks, RTDs and seltzers.

“Cans are a terrific sustainable, packaging option, convenient for many occasions and most importantly, produced from aluminium containing recycled content, with the can itself being infinitely recyclable.

“We know that can graphic design and decoration is a critical tool for engaging consumers – with strong in-house can decoration capability, the Helio solution enabled by high-speed, direct-to-shape digital printing, adds even greater value to Orora’s service offering for its customers.”

LATEST NEWS www.propack.pro 8 ProPack.pro August 2023

Helio by Orora introduces digital printing technology in the can decoration sector

Orora’s multi-size can line Dandenong

From the brink of closure to getting NZ$70M in investment

New Zealand’s Whakatāne Paper Mill, which was on a brink of closure in early 2021, has secured private investment of over NZ$70 million for further factory expansion

Additionally, WML will eliminate plastic consumption by transitioning from plastic to paper wrap for packaging of its finished products.

Construction commenced in the last week of June and will continue until mid-late August with full production expected to be achieved by November.

Whakatāne Paper Mill (WML) is New Zealand’s only paperboard mill located on the North Island, where since 1939 it has been a big part and one of the significant employers in the Bay of Plenty. The mill employs approximately 210 personnel, the vast majority from the local Whakatāne area.

The company started the production of paper over 80 years ago to turn the nearby Central North Island Pine forests into export paperboard for New Zealand’s growing economy. Since then, the company has been owned by NZ Forest Products in the early days, Carter Holt Harvey and Rank Group and more recently SIG Combibloc.

However, its Swiss owner SIG announced plans to close the facility in February 2021, attributing the move to the loss of its biggest customer that resulted in its operations becoming uneconomical.

Under the closure proposal, all staff at the mill were to be made redundant, the plant decommissioned and the site remediated.

The situation then changed a few months later, when the Irish paper and packaging tycoon Dermot Smurfit and New Zealand private equity chief Ross George expressed their interest in the mill.

They struck a deal in May 2021, when SIG Combibloc agreed to sell it to a consortium of investors led by Smurfit who, together with other European consortium members,

have extensive experience in owning and operating paper packaging businesses. They also brought a number of New Zealand investors alongside them.

The company most recently announced securing a substantial private investment of over NZ$70 million from its shareholders, signalling its robust health and promising future.

This investment marks the most significant capital expenditure for WML since 2004 and the infusion of funds will facilitate a major upgrade, elevating it to industry-leading standards.

The upgrade will deliver an additional 50,000 tonnes of premium folding box boards, increasing WML’s production from 150,000 to 200,000 tonnes. Customers will enjoy the advantages of higher quality board, while the production process will be more environmentallyfriendly, utilising less raw materials and operating with improved energy efficiency.

The upgrade is paving the way for WML to potentially produce up to 300,000 tonnes of premium folding box board in the future.

The upgrade will also present significant sustainability improvements. Per tonne of board, the energy efficiency will be approximately 30 per cent better, gas consumption will be reduced by more than 30 per cent, and WML’s water consumption from the local river will also see a significant decrease.

The equipment for the upgrade has been sourced from highly specialised manufacturers in Europe. The core equipment for the board machine, specifically the water removal/drying section, has been imported from Germany, while the fully automated paper wrap line originates from Finland, and the crucial heat recovery system has been acquired from Italy.

Fifty contracting companies from across the Bay of Plenty are involved in the upgrade with over 400 contractors on site to install approximately 45km of cable and 5.5km of piping.

WML executive chairman Ian Halliday expressed his pride in this achievement, not only for the WML’s workforce but also for their commercial partners, customers and the local community.

“As the largest private employer in Whakatāne, with an 80-year history of exporting, this moment is a significant step towards a bright, positive, and sustainable future for WML,” Halliday said.

As the sole folding box board producer in Australasia, WML’s advancements offer main brand owners such as DB Breweries, McDonalds, and Griffins the chance to reduce their carbon footprint and avoid importing packaging from countries like Finland, Korea, China, and Chile.

Whakatāne Mill was on a brink of closure in February 2021

LATEST NEWS www.propack.pro August 2023 ProPack.pro 9

WML executive chairman Ian Halliday

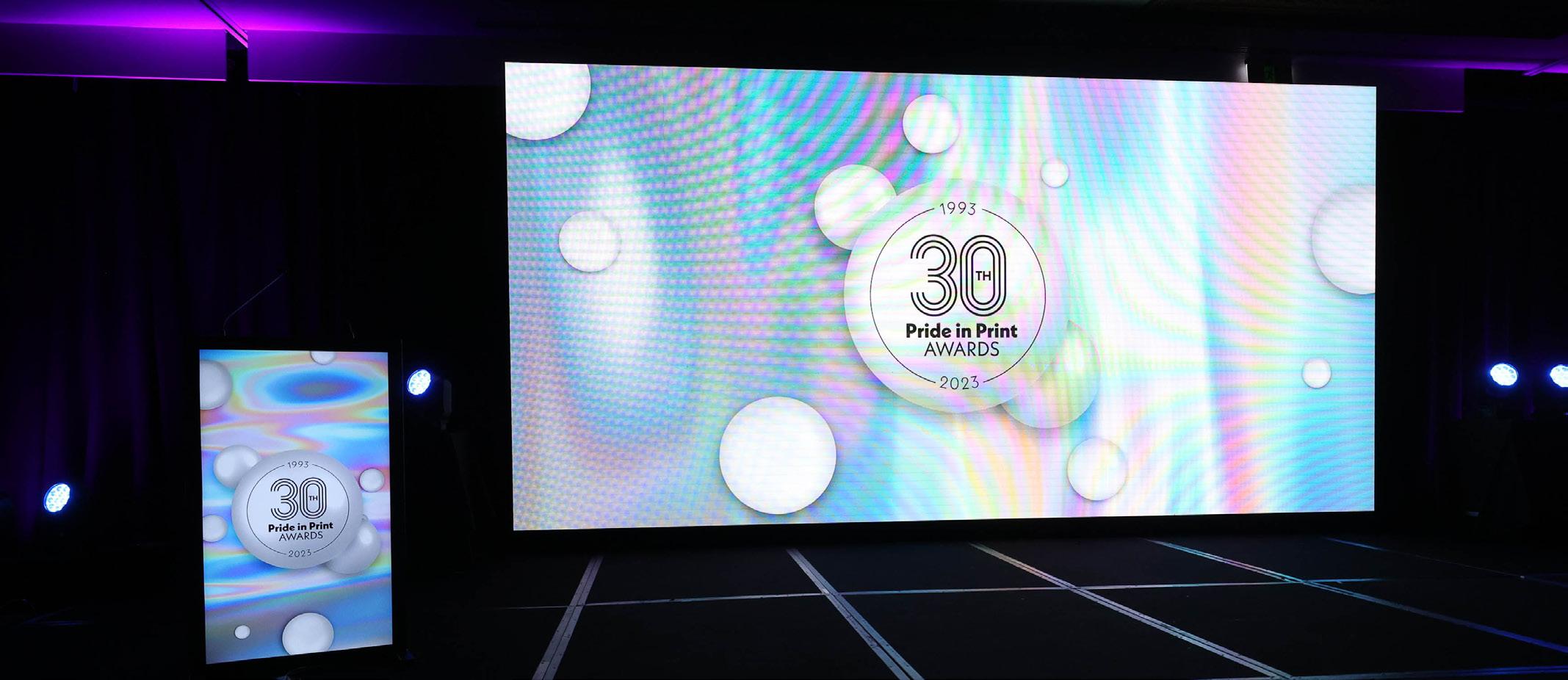

Labels and packaging shine at Pride in Print in New Zealand

Labels and packaging companies were put in the spotlight at the recent Pride in Print Awards in New Zealand, as they won several gongs in their categories

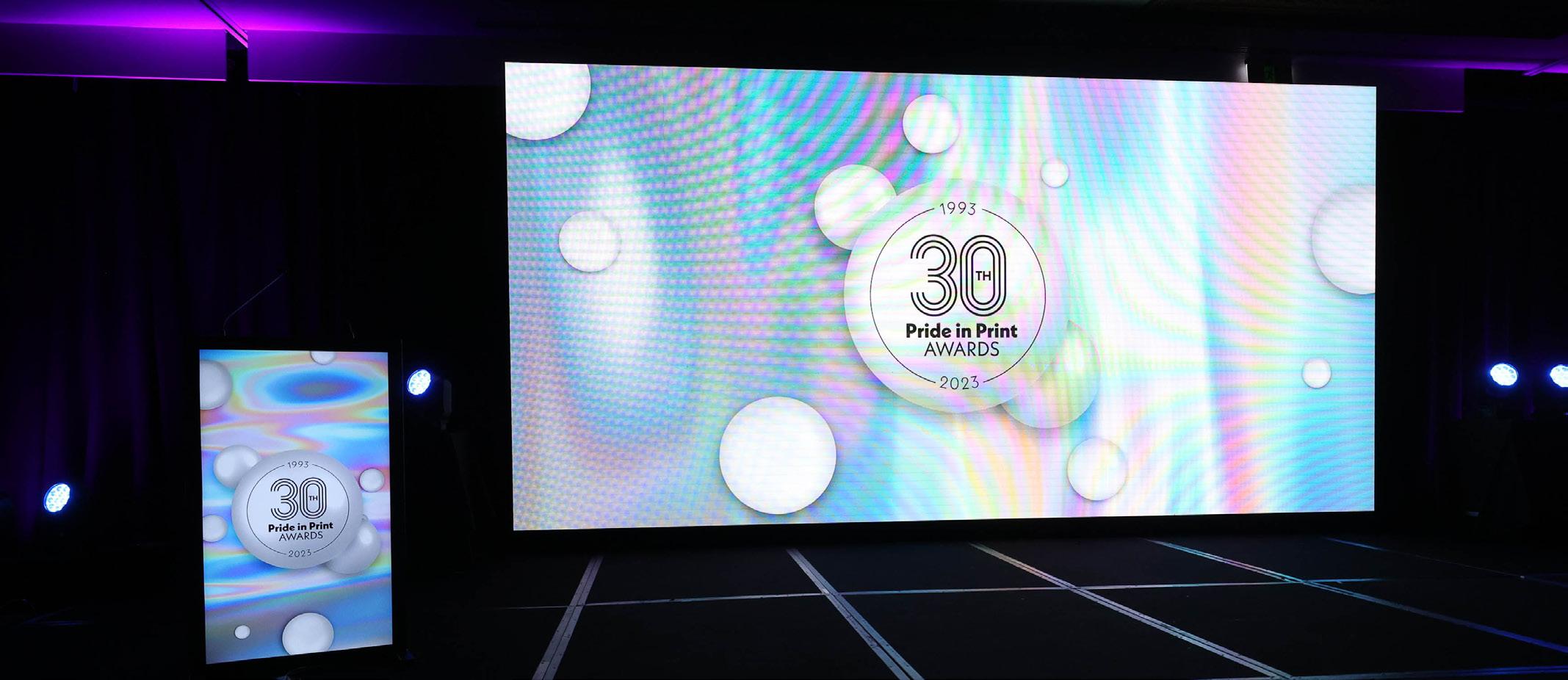

The 30th annual Pride in Print Awards recently took place in Auckland, New Zealand, recognising the best in visual print communication products produced in the country.

Labels and packaging winners shared the spotlight with their print counterparts as they took home some of the most coveted awards within their categories.

Here are some of the labels and packaging winners from the evening:

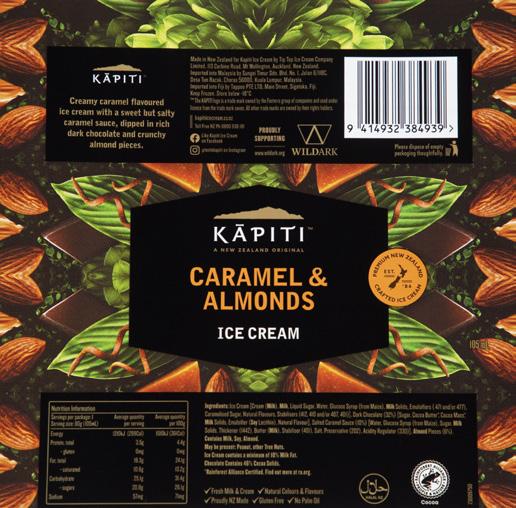

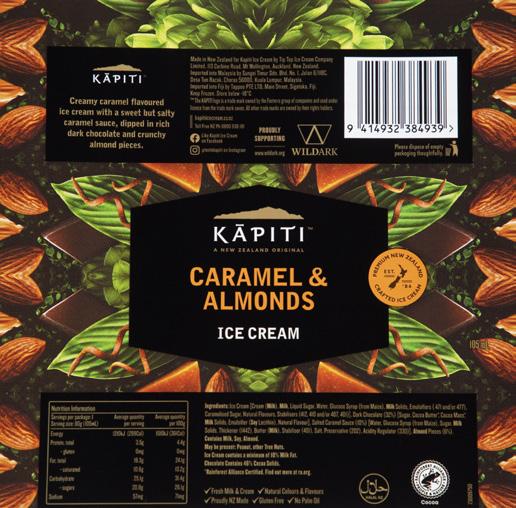

Amcor Flexibles bags two awards for flexible packaging job

Judges appreciated this work as a great demonstration of achievable quality

in the flexible packaging category.

Judges appreciated this work as a great demonstration of the quality achievable when all the correct technical attributes are utilised to produce work as good as any other printed media.

The same job has been also recognised with the award in the flexographic process.

According to the judges Kāpiti Caramel and Almonds flexible packaging is an outstanding example of technical excellence from a demanding print process.

Innovative Taco Truck brings recognition to APC Innovate

Judges described this work as a standout example of excellence in point of sale

Auckland-based brand display and packaging solutions business, APC Innovate has been praised by Pride In Print judges for producing a “standout example of excellence in point of sale” in taking out this year’s Structural Design Packaging Category award.

Judges awarded this work, which “won out in a closely contested category, for its job features functionality, good

New Zealand Original Kāpiti Caramel and Almonds ice cream packaging produced by Amcor Flexibles Christchurch won

PRIDE IN

www.propack.pro 10 ProPack.pro August 2023

PRINT

Amcor’s printing manager Brent Watson with the Flexible Packaging category award

The Pride in Print Awards recognise the best of the best in New Zealand’s visual communications industry

attention to detail, good print work and robustness, executed at large size.

“Instead of resorting to the ‘same old, same old’, it is obvious they’ve had a hard think about the modular design structure – the shelving is well made, everything fits as it should, and all components are removable to assist transportation to stores around the country. Additionally, they’ve demonstrated significant attention to detail – for example, printing inside the taco element. It’s all there.”

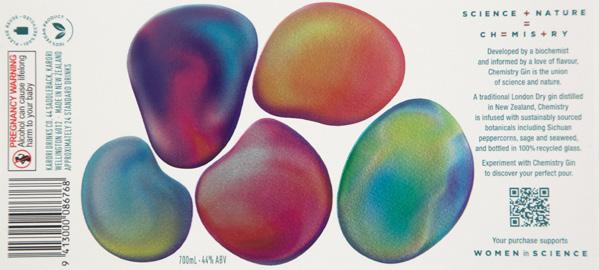

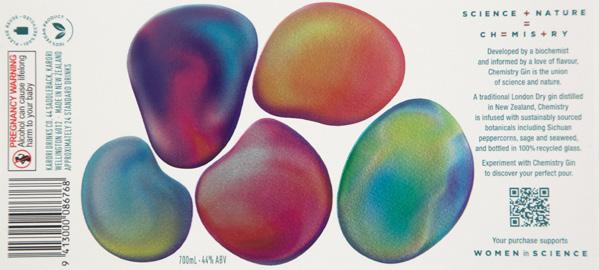

Multi-Color wins label category by adding chemistry to gin

Chemistry is a modern London-Dry gin infused with Sichuan peppercorns, sage and seaweed. Born from a love of science and nature, the company explored botanicals at a molecular level to bring out the best of each flavour for a perfectly balanced New Zealand gin.

Judges thought it was a great example of a creative concept combined with high-quality digital print and finishing.

“This label has expertly drawn together a silver foil, high-build varnish and beautiful colours to deliver an amazing effect,” said the judging panel.

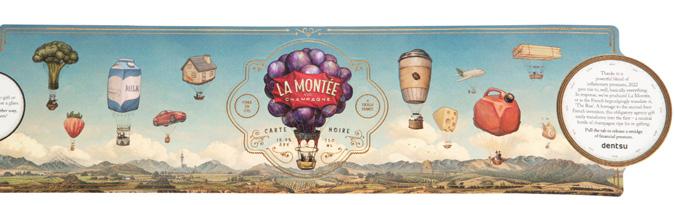

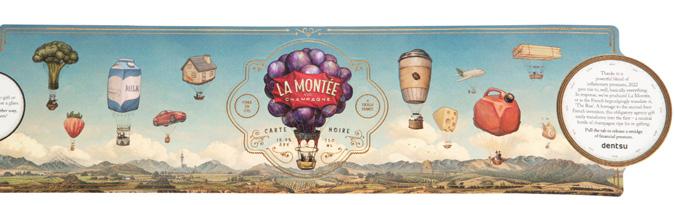

Rapid Labels cheers double category win

PRIDE IN PRINT

Judges commented, “As well as being a beautifully printed job, featuring fantastic foiling and other enhancements, this double-acting label has been innovatively devised to enable the printer’s customers to seamlessly regift their bottles of wine, if so desired.”

The second entry by Rapid Labels, Rapid Remix, has also grabbed the award in the Print Industry Promotion category with its concept utilising a mini turntable with “playable” sleeved records demonstrating a wide range of print processes.

Rapid Remix was appreciated by the judges as an amazing concept utilising a mini turntable with “playable” sleeved records to demonstrate a wide range of printing processes and techniques has delivered an outstanding piece of selfpromotion for the printer.

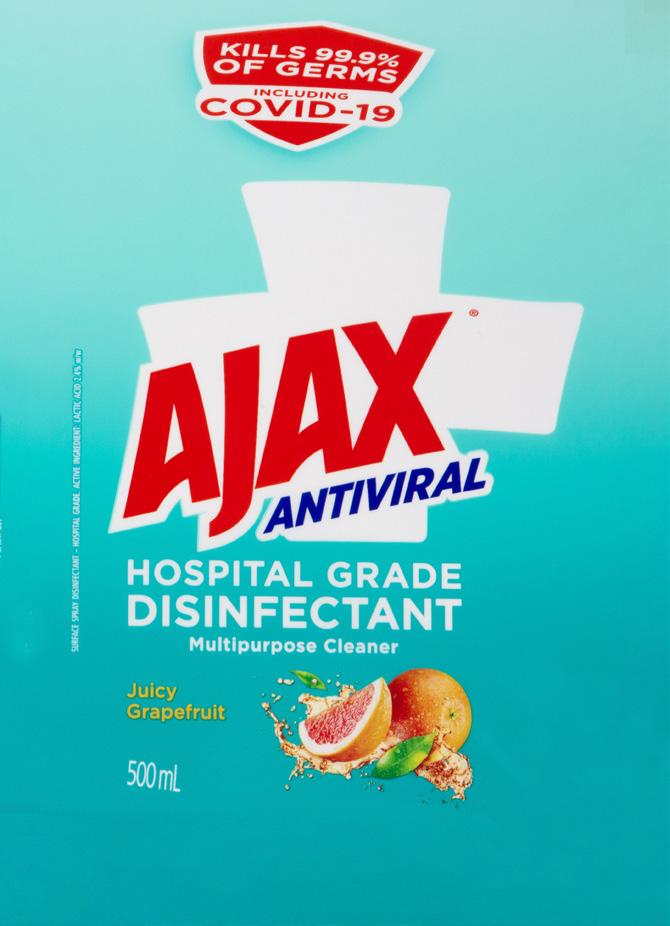

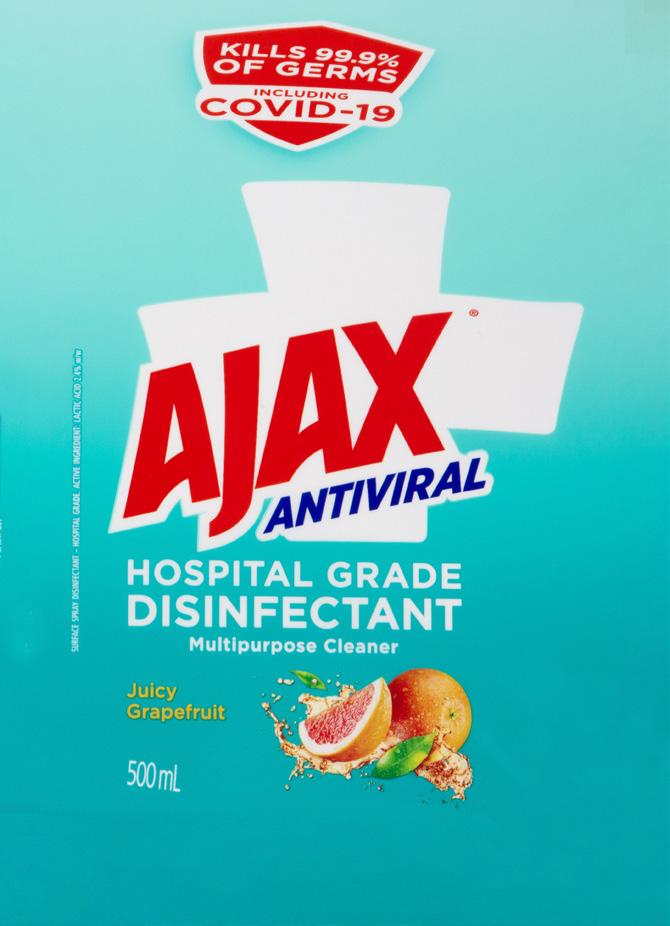

Gravure Packaging scores with Ajax Hospital Disinfectant

Gravure Packaging, a privately owned flexible packaging and shrink sleeve manufacturer, headquartered in Wellington, scored gold in the Gravure category with its Ajax Hospital Disinfectant job.

Gravure Packaging technical director Grant Amelung enthuses that being bestowed with the Pride In Print Gravure Process award “enshrines the competitiveness and relevancy of rotogravure”.

Judges commented, “This job has been very well printed with crisp and vibrant graphic elements. The background vignette is very clean and effective. There has also been clever use of software to distort the image to ensure perfect reproduction when applied to the final product. A very welldesigned and well-executed example of gravure print work.”

Multi-embellished, colourful Chemistry Gin label brought a win for the East Tāmaki-based Multi-Color New Zealand in the label category.

La Montée Champagne label and packaging printed by Rapid Labels has been names the winner of the Industry Development and Creativity category.

Designed to be re-gifted, La Montée Champagne, which translates as “The Rise” is a beautifully designed comment on the soaring cost of living and a little something to help ease the pain.

Judges were impressed with the well-executed example of gravure print

www.propack.pro August 2023 ProPack.pro 11

APC Innovate’s creative manager Zane Barclay collected the award

Rapid Labels entered the competition with a concept utilising a mini turntable with playable sleeved records

Alex Straight, technical director and Dale Bamford, general manager of Rapid Labels collected the awards at the Gala Dinner

MCC’s senior account manager Phoebe Rudge collected the award on the night

The winning label drew together silver foil, high-build varnish and beautiful colours

Innovation to shine at Labelexpo Europe 2023 in Brussels

An exciting range of new conventional, digital and hybrid press technology will be on display at the upcoming Labelexpo Europe event in Brussels

Labelexpo Europe 2023 is expected to be a landmark event, unleashing four years of pent-up technology development for visitors to the Brussels Expo. The event, which will soon take place from 11 to 14 September, will focus on the key themes of automation, sustainability and diversification.

Over 600 confirmed exhibitors will be taking part in Labelexpo Europe 2023, including ABG, Avery Dennison, Bobst, Canon, Domino, Durst, Epson, Fujifilm, Gallus, HP, Kocher & Beck, Konica Minolta, Lombardi, Mark Andy, Nilpeter, OMET, RotoMetrics, and Xeikon.

Between them, they will be demonstrating their latest innovations and technology including: digital and conventional printing presses; high tech label and packaging materials; finishing and converting systems; inspection, overprinting and label application equipment; inks and coatings; RFID and security solutions; as well as software and interactive technology.

With just a few weeks to go until the event, many manufacturers have already announced what they will be showing

at the tradeshow. Here is a round-up of some of them:

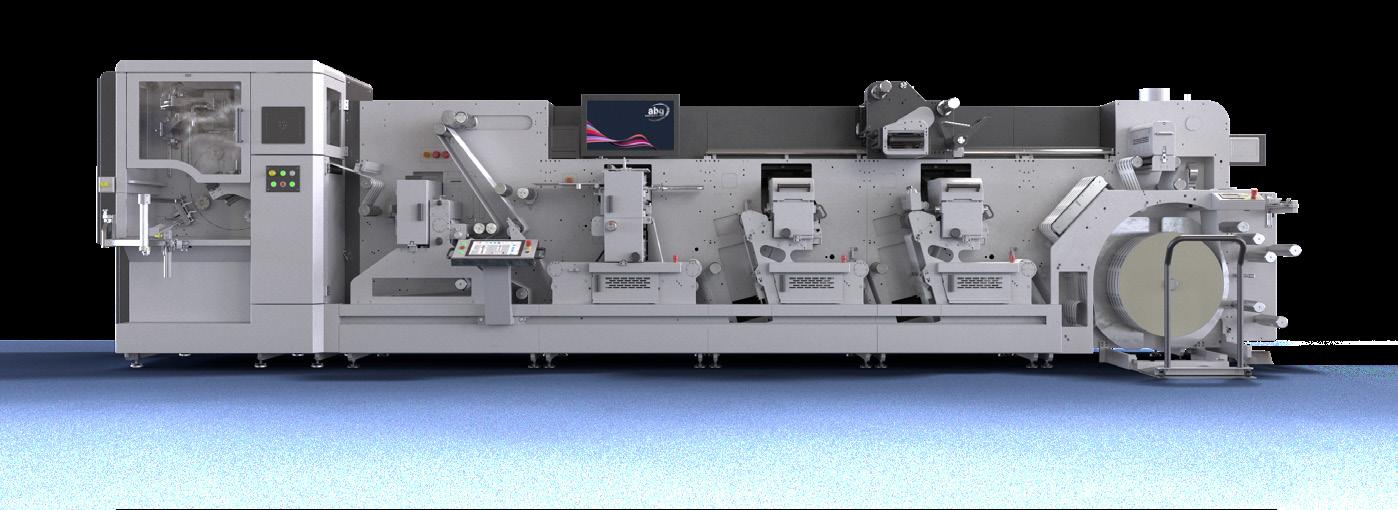

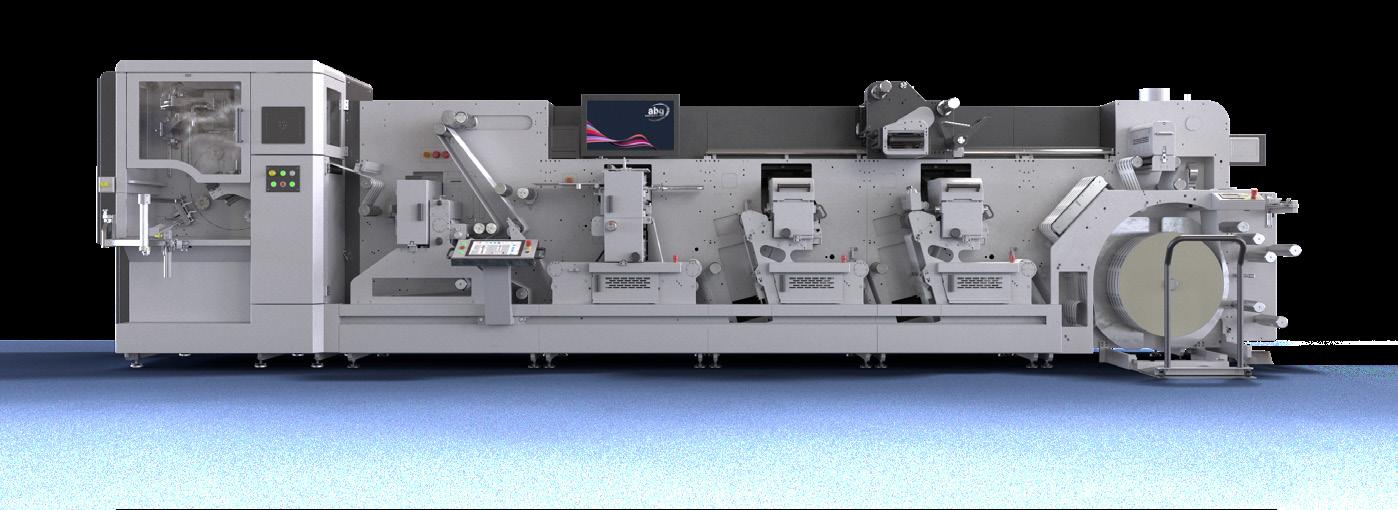

A B Graphic International (ABG)

ABG is preparing for its biggest presence yet at this year’s Labelexpo Europe event, where it will unveil its automation technology and showcase its latest product innovations. The company said its primary focus will be unveiling its new automation technology – ABG Connect – and showcasing its latest product innovations.

ABG Connect is an automated workflow solution that streamlines the print and finishing process by connecting all stages into one automated workflow.

ABG will also showcase its latest new product innovations, which will include advancements in non-stop winding technology and the new turret rewinder model. It will introduce the Converter – a new fully modular converting line that boasts higher speeds, new flexo technology and a smaller footprint.

Other products include a Digicon with screen and Ecoleaf unit for sustainable foiling, DigiLase 4.0, DigiJet 330, DigiLite, SRI3 430 with monochrome inkjet, shrink sleeve seaming, doctoring solutions and an entry-level SRI. ABG’s stand will also feature a booklet module and its partner Maan Engineering’s module for laminate and linerless label solutions.

LABELEXPO EUROPE PREVIEW www.propack.pro 12 ProPack.pro August 2023

Labelexpo Europe will be a showcase of the latest innovations and technologies

ABG’s primary focus will be unveiling its new automation technology, ABG Connect

To complete its extensive showcase, ABG will also collaborate with HP to demonstrate its non-stop unwind and rewind system, seamlessly integrated into the HP Indigo V12 line.

Asahi Photoproducts

At Labelexpo Europe, visitors to the Asahi Photoproducts stand will be able to learn how switching from solvent-wash to waterwash plates can not only make their operations more sustainable, but also reduce waste, improve print quality, and speed time to market.

The company has developed a specific roadmap towards a Solvent ZERO solution that will help platemaking operations not only be more sustainable, but create a safer, more enjoyable work environment for their employees as they migrate to a Solvent ZERO operation.

At Labelexpo Europe, the company will be unveiling this roadmap and helping visitors understand their best pathway to a Solvent ZERO future.

At Labelexpo Europe 2023, Asahi Photoproducts will also be introducing its updated AWP wastewater recycling unit for use with AWP plate processing systems.

The Asahi Photoproducts water-washable AWP-DEW CleanPrint flexographic plates have been certified Carbon Neutral by the Carbon Trust.

In addition, to increase sustainability of its platemaking solutions even more, Asahi has developed this innovative water recycling system for AWP plate processing equipment. The unit features proprietary filtering technology developed by Asahi Kasei –Asahi Photoproducts’ parent company –that reduces wastewater by 75 per cent, and detergent usage by 40 per cent.

Bobst

Under the motto “Simplifying label production”, Bobst will be demonstrating its innovation in labels and flexible packaging production with two main production lines in focus.

The company said it is spearheading digitalisation, automation, connectivity and sustainability in packaging production with a portfolio that includes flexo, digital and all-in-one presses for the widest variety of applications.

The Bobst Digital Master 340 All-in-One modular and upgradable label press, equipped with the latest UV inkjet technology, will be running live at 100 m/min.

Visitors will be able to see how Bobst’s AccuCheck system, which comes as standard on this machine, performs 100 per cent inline at full speed. The full configuration will also include flexo modules and a highly automated diecutting unit to showcase true end-toend label production.

As converters face manpower shortages and demands for more sustainable solutions, Bobst said it will highlight unique automation features that can alleviate these issues.

The high-end Bobst Master M6 flexo press will demonstrate how oneECG technology for extended colour gamut printing and V-Flower printing units enable fast, automatic changeovers of the printing cylinders without stopping the press and with only very minimal waste.

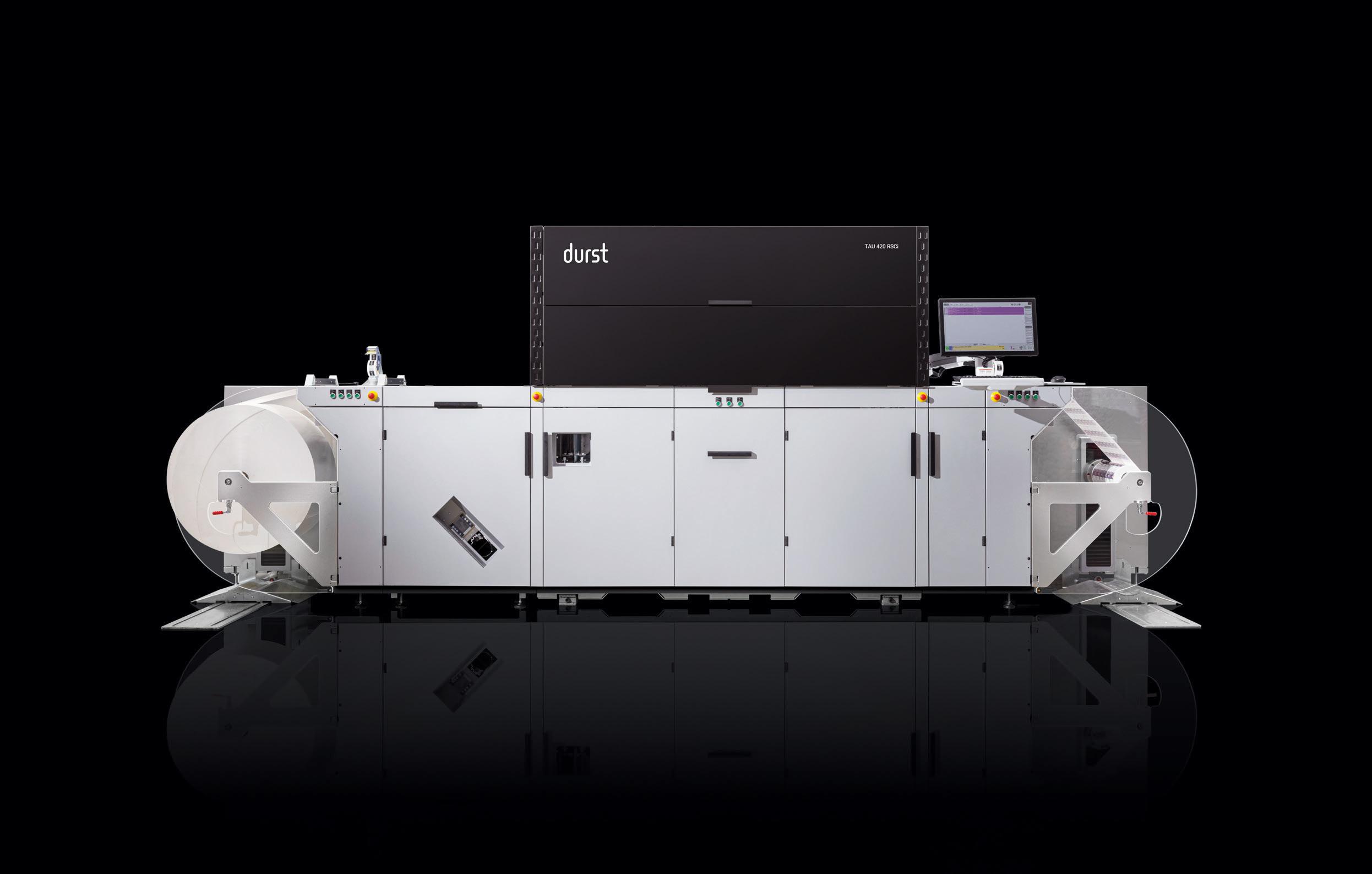

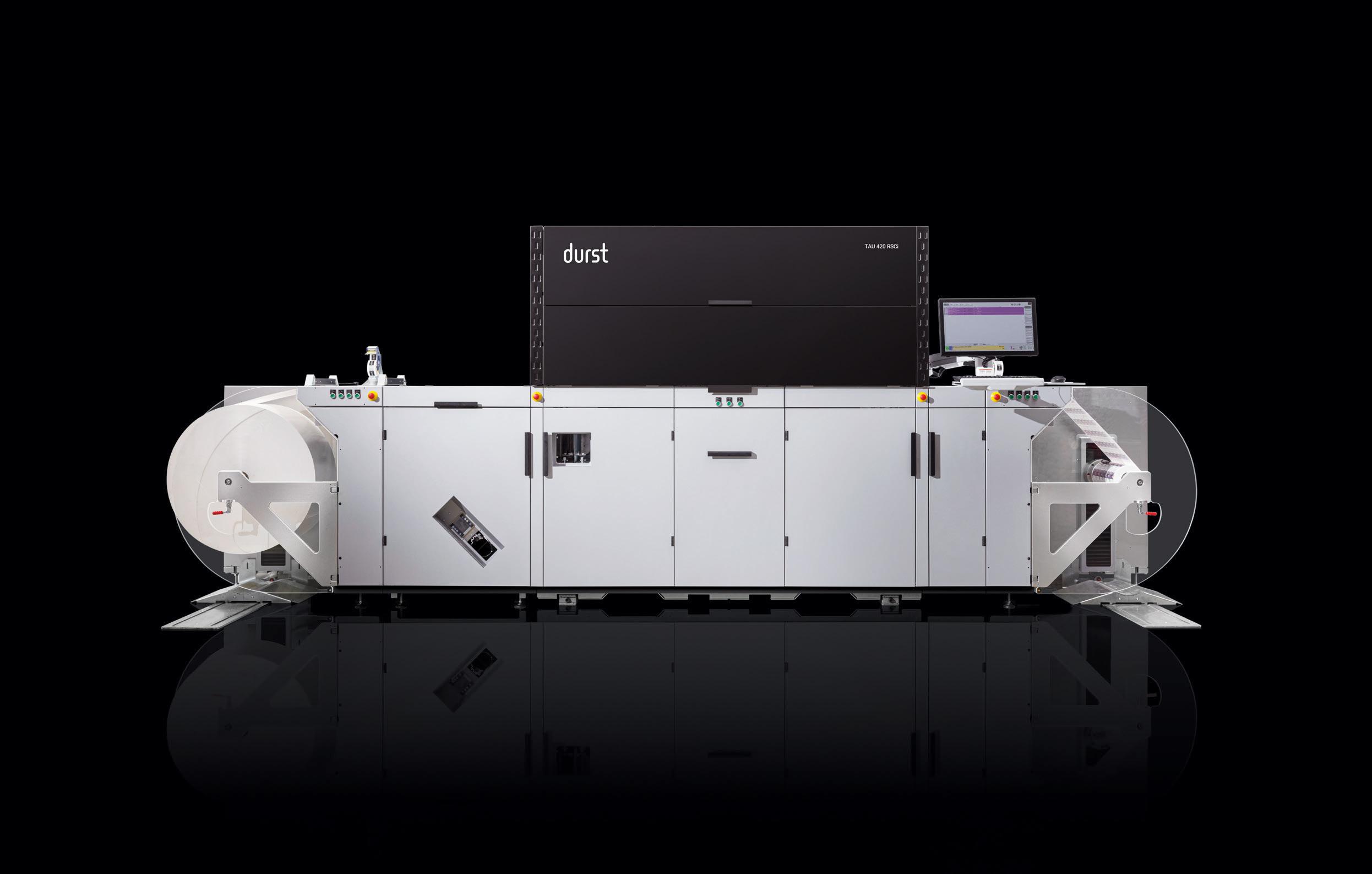

Durst

The spotlight on the Durst booth will be on three primary themes – more applications, more automation and less waste.

At Labelexpo Europe, Durst Group will again be setting the benchmark in digital printing with the introduction of its Durst Hawk Eye technology. This innovative technology utilises camera vision systems with the aim of automating print quality, resulting in significantly reduced waste and overall improved print quality. The Durst Hawk Eye is not only an inspection system – it goes one step further as it is correcting print mistakes, such as missing nozzles, inline and in real-time, without any setup needed and without any operator intervention. Additionally, it aims to significantly reduce setup time and waste, resulting in enhanced efficiency and an even more competitive total cost of ownership for the Tau RSC platform printers.

“The Durst Hawk Eye is revolutionary for the digital printing industry. This technology will greatly increase productivity and efficiency, but more importantly, it will reduce waste and the carbon footprint of our customers. We are thrilled to introduce this innovative solution to the market and provide exclusive information during Labelexpo,”

LABELEXPO EUROPE PREVIEW www.propack.pro August 2023 ProPack.pro 13

Asahi’s new water recycling unit for the plate processor

The Bobst Digital Master 340 All-in-One modular and upgradable label press

Durst’s Tau RSCi range is designed to take over mid-to long-run jobs

Durst Group product manager Martin Leitner said.

Durst Group will also unveil the next generation of the Tau RSC UV ink set at Labelexpo. This new ink set, available in the colours CMYK OVG and white, will meet the latest regulatory requirements and expands the converters’ application range even further.

On the showfloor, alongside a new digital printing press, the successful Tau 510 RSCi will be showcased. This press will demonstrate its capabilities in real-time, printing at a remarkable speed of 80m/min at a printing width of 510mm, leading to productivity of over 3000 square metres per hour. The Tau 510 RSCi brings powerful advantages to production: material and application versatility and excellent print quality even at highest productivity and extremely aggressive TCO. These are a few reasons why label converters are using the Tau 510 RSCi to switch their flexo production to digital.

Durst has equipped the Tau 510 RSCi with new automation features, making the life of the operator easier and increasing the overall high efficiency of the machine. The press on the showfloor will be equipped with the new, powerful double white feature, as well as inline flexo stations, adding an extra option for customers that need just a little bit more for challenging applications. Visit the Durst booth to see these technologies and for other surprises.

Esko

Esko and X-Rite Pantone will join forces at Labelexpo Europe to spotlight one connected workflow across the label and packaging supply chain.

Visitors will see first-hand how a connected Esko and X-Rite Pantone ecosystem of automated workflow, colour management, flexo platemaking, digital printing and print inspection tools can deliver consistent performance and accelerate business growth. The companies will lead a deep dive into all facets of labelling and packaging.

“Visitors to our combined booth will discover how Esko and X-Rite Pantone

are helping the packaging industry achieve consistent performance from concept to market,” Esko director of marketing, industry relations and strategy Jan De Roeck said.

“Using demonstrations of the latest technology, displays and expert discussions, we will highlight how an end-to-end ecosystem of new colour management software and measurement solutions supports digital workflows to increase efficiency, enhance sustainability and drive growth opportunities.”

Esko and X-Rite Pantone will showcase their entire range of digital workflow solutions – from design through production. Highlights include:

• Phoenix, Esko’s AI-based tool that unlocks planning and imposition productivity improvements, with a seamless interface between prepress data and production data in Esko applications.

• The award-winning CDI Crystal XPS 4835, utilising UV main and back exposure to produce highly consistent digital flexo plates while minimising waste.

• AVT Helios System, which automatically inspects printed labels or packages for defects and imperfections, delivering exceptional quality results and eliminating customer rejections.

• The latest Esko Software version, which delivers a combination of prepress editing and cloud-based workflow automation solutions, now more integrated and connected throughout the entire pre-press workflow.

• X-Rite eXact 2, a connected and easyto-use handheld spectrophotometer that can measure colour across various substrates – including flexible film and paper – in a single device, while also verifying customer standards.

• X-Rite ColorCert Suite, which works with Esko WebCenter, AVT’s Spectralab, and eXact 2 to provide printers an overall view of print quality and colour performance in a single number score to confirm compliance with brand specifications.

• PantoneLIVE digital colour libraries for the creation and sharing of accurate brand colour standards that are achievable across printing technology and substrates.

“Error and waste reduction has a direct impact on the environmental footprint of a packaging businesses,” De Roeck said.

“As we are all looking to protect the environment in which we live and to safeguard it for future generations, we must reduce the impact of our operations

on the environment. With sustainability and digitalisation fundamentally altering how the industry operates, it is imperative that today’s label and packaging companies invest in digital workflow technology that enables them to boost efficiency, reduce costs and improve their overall productivity.”

Gallus

At Labelexpo Europe, Gallus, a subsidiary of Heidelberg, will celebrate its 100 years in business as well as the opening of its landmark facility, the Gallus Experience Center.

It will showcase unique digital solutions developed with parent company Heidelberg, to support increased automation of the entire eco system. The objective of these solutions is to facilitate ‘Smart, Connected, Printing’ to support skilled labour shortages, increase productivity and reduce waste.

In line with this theme, the company will be showcasing its Gallus One digital label press. Launched in August 2022, it was specifically designed to remove the Total Cost of Ownership (TCO) barrier for the adoption of reel-to-reel digital labels with the highest level of automation and cloud-based technologies. In doing so, Gallus One provides brands, for the first time, with access to cost effective and sustainable, high quality digital labels.

Built on the Gallus Labelmaster press platform, Gallus One is a 340mm wide rollto-roll UV inkjet digital inline labels press. It utilises a host of impressive features to achieve high levels of automation and press efficiency, with unrivalled UV inkjet print quality and stand-out print speeds of up to 70 metres per minute.

HP Indigo

HP Indigo will be showcasing end-to-end digital production at Labelexpo. With the first presentation in Europe, both the HP Indigo V12 Digital Press and the recently launched HP Indigo 200K Digital Press will be on the show floor, demonstrating digital efficiency, sustainability, and profitability for the labels and packaging industry.

www.propack.pro 14 ProPack.pro August 2023 LABELEXPO EUROPE

PREVIEW

Built on the Gallus Labelmaster press platform is the Gallus One

Esko will demonstrate its latest technology at Labelexpo Europe

REACH & SVHC COMPLIANT HEAVY METAL FREE VOC FREE BS5609 SECTION 3 COMPLIANT For more information, please visit durst-group.com/label Industrial scalability 330 / 420 / 510 m m print width Jumbo winders Flexo-like productivity Competitive ink pricing Low ink consumption Print quality 1200 x 1200 dpi @ 2 pl Up to 95 % P antone coverage BEST IN CLASS COMPETITIVE EDGE SCALABILITY TAU RSCi INNOVATES YOUR BUSINESS

LABELEXPO EUROPE PREVIEW

narrow web market will showcase its latest space-saving technology at the upcoming Brussels trade fair in September.

On working display will be two of its most popular machines in the narrow web sector, an MBS automatic unwind butt splicer and an LRD transfer rewinder.

The company said creative use of the vertical festoon on the butt splicer and a proprietary roll unloading feature at the rewind saves users nearly one metre of overall space in the running direction.

Alongside the popular HP Indigo 6K Digital Press, converters will be able to learn how Indigo’s LEP and LEPX technologies can help them grow their business.

The HP Indigo V12 Digital Press ensures non-stop production and earning power. A narrow-web label press, it prints at 120 linear metres per min with all the capabilities of HP Indigo’s technology for label production. HP said it is a versatile digital press with offset- and gravurematching print quality for commercial and labels and packaging jobs.

The HP Indigo 200K Digital Press delivers a 30 per cent improvement in speed and 45 per cent increase in productivity, opening the door to more flexible packaging converters who want to enter the digital market. It provides an entire production line in a small footprint and prints up to 56 metres a minute.

As for the HP Indigo 6K, it is a versatile, narrow-web printing solution for digital labels and packaging production, delivering high productivity, wide versatility and intelligent colour automation.

The Digital Pouch Factory, featuring the HP Indigo 200K Digital Press, will also be demonstrated at the booth with pre-press and finishing equipment. An elaborate application showcase will invite visitors to examine samples of unique and sustainable labels, shrink sleeves and flexible packages.

and packaging production by igniting creativity on its stand at Labelexpo Europe.

Seeing the potential by stepping into a world of digital label production will be a major theme on the stand where Konica Minolta will demonstrate its unwavering commitment to customers and growing importance within industrial printing markets.

As well as its toner-based AccurioLabel 400 digital press, Konica Minolta will demonstrate its entry-level AccurioLabel 230 configured with a DC 330 Mini finisher with an integrated inkjet module supplied by Industrial Inkjet Ltd (IIJ). This unit can be used for a wide range of applications from white, to security inks and digital varnishes.

Konica Minolta will also be sharing the booth with partner MGI Digital Technology, to showcase the latest trends and the full label production cycle as well as packaging solutions.

The company said pooling both their knowledge and know-how, they will show how customers can increase profitability, as well as benefit from comprehensive software and global service capabilities delivered locally.

Martin Automatic

Furthermore, these machines can be installed directly against walls at either end of the press and still allow access for the maintenance and roll loading and unloading, without the use of carts.

In addition to the innovative machinery on display, Martin Automatic said it looks forward to welcoming visitors to its newly designed stand and serving up some true American hospitality with its renowned hotdogs.

Martin Automatic vice-president of sales and marketing Gavin Rittmeyer said, “After a four-year break, we are looking forward to meeting friends old and new, and continuing our commitment to in-person working relationships with our longstanding sales team”.

OKI

Konica Minolta has pledged to show firsthand how converters and brands can rethink end-to-end sustainable digital label

OKI Europe has announced a key strategic partnership with Graphtec Europe to provide solutions that address the varying applications for creating ‘ready to use’ labels and packaging in the market. Labelexpo Europe will showcase this partnership.

As part of OKI’s continued expansion in the provision of solutions for printing labels in-house, it will be using Labelexpo Europe as a platform to highlight the increased demand for specialist finishing requirements.

As customers want to make the most of media flexibility, the OKI Pro 10xx range of roll-to-roll label printers and the OKI Pro 9xx range of sheetfed package/label printers will be on display.

www.propack.pro 16 ProPack.pro August 2023

Konica Minolta

Martin Automatic, a supplier of non-stop unwind and rewind technology for the

The Martin Automatic MBS butt splicer with stacked festoon

The HP Indigo V12 Digital Press

Konica Minolta’s AccurioLabel 230

The OKI Pro 10xx roll-to-roll label printer

www.hp.com/indigo www.curriegroup.com.au

LABELEXPO EUROPE PREVIEW

Their key features include being able to run blank media, which OKI said provides the freedom to create labels of constantly changing size, shape and durability.

As for the Graphtec range of cutting devices, they enable customers with flexibility to cut, perf, slit and rewind a variety of substrate types.

Being able to perform these functions on a separate device means customers can print the next job at full production speeds whilst finishing others at the same time.

“One minute, you can print silver paper labels and at the same time you can be cutting synthetic white labels, so regardless of whether your business is in beauty or beer, cosmetics or coffee, a joint print and finish solution from OKI and Graphtec gives your business a whole host more flexibility to print a huge range of labels in-house and on-demand,” OKI said.

OMET

OMET will be running live demonstrations of its new KFlex flexo printing machine at its stand.

The KFlex flexo printing machine is a modular platform press that can handle substrates from 12 microns up to aluminium lidding and light carton board. It comes in two web widths – 16-inch and 20-inch – and boasts a maximum print speed of 200m/min.

The machine is targeted at end-use applications in markets including food and beverage, industrial, household, healthcare, cosmetics and wine and spirits. The press is also designed to handle a range of jobs – from wraparound, shrink sleeve labels to lids, self-adhesive labels to wet glue and multi-layer.

With 60 years on the market and proudly serving market leaders across 100 countries, OMET said it will also take to Labelexpo Europe to demonstrate its ability to provide optimised solutions in the areas of flexo, digital, offset and gravure printing technologies with the capability to provide all these printing technologies in single pass combination printing solutions.

In addition, OMET will present its proven capability to print from 12 microns mono films such as PET, PVC/PET shrink, BOPP, IML and foils to 600 microns paper-based packaging such as cartons, paper cups and liquid packaging, covering the widest gamut of packaging materials on the market.

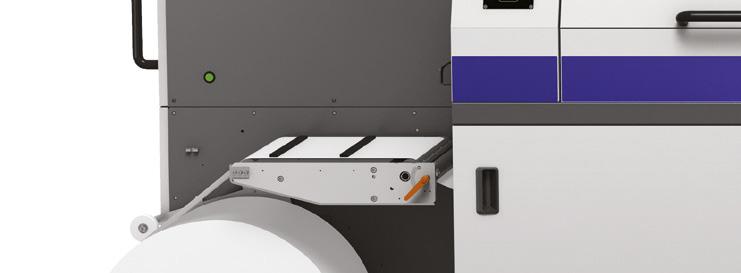

Screen

At Labelexpo Europe, Screen and Nilpeter will present an innovative printing press for the digital hybrid printing segment. The collaboration showcases a third generation press that combines Screen’s SAI inkjet digital printing technology with Nilpeter’s FA-Line flexo platform, delivering stable and high-quality combination printing.

This end-to-end solution is said to enable efficient production of value-added labels with expanded gamut printing and white imprinting capabilities.

Additionally, Screen will be introducing an In-Line Digital Primer prototype for the Truepress L350UV SAI Label Digital Printing Press. The company said this feature addresses the challenge of poor ink adhesion on various substrates by incorporating a digital primer directly into the press.

In addition, it said this solution could deliver superior ink adhesion and better printing quality. Visitors at LabelExpo 2023 can witness this technology firsthand and experience its transformative impact on label printing.

Finally, Screen will also showcase the Truepress PAC520P Inkjet Digital Printing Press for paper packaging, responding to the growing trend of replacing plastic packaging with environmentally friendly paper alternatives.

This high-speed, water-based inkjet press offers label converters seamless entry into the profitable flexible packaging market. With its compact footprint, low environmental impact, and compliance with food-safety regulations, the Truepress PAC520P aims to provide a competitive edge and increased profitability.

A host of solutions will be on show when Xeikon sets up its stall at the 2023 edition of Labelexpo Europe. Xeikon will unveil important new advancements at Labelexpo Europe, taking its Cheetah technology to new heights with the introduction of Cheetah 3.0.

Leveraging the success of the Cheetah Series of toner presses, this latest iteration represents a leap forward in sustainable production. Cheetah 3.0 is poised to revolutionise the manufacturing of labels and packaging, playing a pivotal role in minimising the industry’s carbon footprint. Upgrades include:

• A new Xeikon ECO toner that is formulated with over 60 per cent highgrade recycled PET. ECO toner will be available for the high-end presses in the Cheetah Series – the Xeikon CX300 and Xeikon CX500.

• Xeikon has developed the Quality Measurement Module (QMM) which can be fitted on all Cheetah 3.0 CX Series presses as an option. The QMM will be responsible for the quality assurance of the printed output, closely monitoring the density and registration throughout the print run.

Xeikon will also use Labelexpo 2023 as the European premiere for its new TITON toner technology, which has been developed to meet market demands for paper-based flexible packaging applications, such as stand-up pouches and sachets.

The first press presented with TITON technology will be the Xeikon TX-500 which prints in up to five colours at 30m/min in a resolution of 1200dpi. The 520mm-wide press will be instrumental in opening new market opportunities in paper-based labels and flexible packaging, helping converters to future-proof their businesses and respond to consumers’ concern for the environment.

As the next step in digitalising label production, Xeikon will be showing the Xeikon TX-500 press running live in-line with a digital embellishment module from Kurz.

www.propack.pro 18 ProPack.pro August 2023

Xeikon

The Screen Truepress L350UV SAI Label Digital Printing Press

The Xeikon CX500

OMET’s new KFlex flexo printing machine

www.gd90.de

Setting up the strong foundations for Label Line’s success

Label Line’s new managing director Jason Brown explains how he intends to build on

printing, we cater for just about every need possible.

We operate in several sectors as we’re supplying our products to a broad base of trade printers throughout Australia –we’re across various verticals including food and beverage and chemical.

Holistically, we want to broaden our service offer further. At the moment, we offer one of the best turnaround times in the market for blank die-cut labels, and the most options. We intend to broaden this service, while continuing to deliver the best turnaround times in the market. We also intend to attract more clients.

Jason Brown has been at the helm of Label Line, having taken on the newly-created role of managing director about three months ago. He speaks to ProPack.pro about the company’s forward-looking plans and how he intends to lead them.

Q: You’ve recently taken on the role of managing director at Label Line. Tell us more about your appointment.

Jason Brown (JB): Label Line is gearing up for future growth and to support its plans, the company created a new managing director role at the business. I took on that role three months ago. This has resulted in the creation of a strong executive team that will bolster our plans and take the business forward, with my appointment being part of this strategy.

As the managing director, I have the responsibility for all of the operations within business, sales, finance and marketing. Linda Scott will continue in her role as general manager, running the day-to-day of the business.

Q: You were with ePac Flexible Packaging Australia as its managing director before taking on this role. How has your experience equipped you with the necessary skills at Label Line?

JB: ePac was moving its business in a different direction. The opportunity at

Label Line presented itself and I found that to be one that is very exciting. ePac was just establishing itself in Australia, so it was operating in a way that start-ups do. And, as everyone who has ever been involved in a start-up knows, that requires a significant amount of hustling and setting up of things like infrastructure, processes, workforce and even brand awareness.

Having gone through all of that has equipped me well with skills across all sorts of functionalities in the business, which is great, as it is not something I always experienced in my previous roles. It has made me a more well-rounded manager, which makes me better equipped to handle my current role.

Q: What do Label Line’s plans include and how do you intend to achieve them?

JB: Label Line has been in the market for 24 years. It is a trade supplier of pre die-cut labels, predominantly for the flat sheet offset and digital markets. In the last five years, it has added to its offerings roll-toroll printed colour labels as a trade printer, offering a range of trade label services to the print market.

We’ve had healthy growth patterns every year, servicing Australian and New Zealand-based customers. With over 21,000 options available in both an offset range (with optional side grip) and a fully centred range designed for digital

In the colour roll-to-roll side of the business, we want to expand our offering into new technologies. Currently, we use Konica Minolta’s roll-to-roll technology and have flexo and letterpress machines. We intend to build on them further but at this stage, we’re still exploring and investigating what new technologies are available.

Q: What else can the industry expect from Label Line moving forward?

JB: The industry has already been receiving amazing service from Label Line for 24 years. They can only expect enhancements on the services that they’ve received in the past.

Our team works hard in its commitment to excellent service by employing three simple principles:

• Saving customers time and money by offering an extensive range of label shapes, sizes and stocks on hand –without any waiting for stock or extra die costs.

• Offering fast turnarounds due to an efficient team. We are proud to offer quick processing of orders. Customers can email or log into our website to place their order in the morning and we endeavour to despatch it on the same day.

• Saving customers money by buying at the right price. We keep the prices low without sacrificing quality, and customers can take advantage of even lower prices when bulk purchasing.

Q&A LABEL LINE www.propack.pro 20 ProPack.pro August 2023

the company’s momentum moving forward

Label Line managing director Jason Brown

APR SOLUTIONS – Compact folder gluers for digital and offset, hot foil stamping machines, e commerce folder gluers and taping machinery.

BMATIC – Paper counting, tab inserters, friction feeders, batching machinery.

BOXWAY – The main products are on demand box making machinery for just in time packaging solutions, different box designs can be realised in seconds.

BUSCH – Pile turners, wate conveyors, table banding machinery, ink mixers and automatic punching machines.

COL-TEC – Flatbed collating systems, inline finishing, fold-stitch-trim.

COMPACT FOILERS – Our modules transform and bring a new dimension to your printing capabilities. They are suitable for both the application of cold foil and the creation of special 3D effects (cast & cure) using UV varnish on all makes of conventional and UV press.

INSIGNIA – The Insignia Series is a new class of sheet-fed rotary die cutter capable of diecutting, kiss-cutting, embossing, perforating, scoring, and cut-scoring a range of papers, plastics, magnetic material, PVC, styrene and polypropylenes. It is the only machine in its class capable of die cutting up to 30 pt. in thickness.

KOHMANN – Manufacturer of carton converting machinery and window patching machinery.

OSAKO – Established 1916, Osako is one of the world's most professional manufacturers of saddle stitching machinery, 3 knife trimmers, compensating stackers, section gatherers new and factory certified refurbished options.

ROLLEM – The leader in offset and digital print conversion for over 50 years, the most respected name for slitting, scoring, creasing, cutting, numbering, die cutting, inline with digital press finishing solutions.

THERMOTYPE – Digital finishing equipment – hot foil stampers, business card slitters from desktop to full industrial as well as the world's most flexible finishing machine the TSL2 which can die cut, kiss cut, perforate, score in cross directions, emboss, guillotine, drill holes, delivering endless capabilities.

TRANKSPAK – Manufacturer of strapping machines for the print media markets, inline and office solutions.

WINSHINE – Is a paper container making machine manufacturer with years of vast experience and expertise. Paper box-making machines we provide have a wide range such as paper lunch box machine, paper bowl making machine, and more.

WINPACK – Window patching machinery, easy nick grinders for removal of die cut waste.

Engineering, Maintenance & Rubber Rollers Services

We provide a national footprint of service and support for our products. Our trusted and reputable partners are TRS, Merhone, Grafika Links, JTS Engineering, Print Repairs and NewTech Graphics. We offer machinery and factory moves, preventative maintenance, breakdown and repair services, engineering and fabrication. Our rubber roller service offers a swap-out rubber roller service for products under our supplier banners as well as new roller sales and services, additionally, we supply the best rubber rejuvenator, rubber cleaners and washes.

TRS – Trim removal systems and bailers, conveyers, engineering solutions. MERHONE – Engineering services, mechanical, electrical, service & maintenance of all press & bindery equipment relocations and installations.

D.W.RENZMANN GROUP – RENZMANN’s core competency is the removal of stubborn residues and the handling of the flammable organic solvents or aggressive alkaline washing agents used for this purpose. The market is making higher and more diverse demands than ever on the cleaning of ink-carrying components that are removed from the press after a job change. And because print runs are becoming shorter, necessitating frequent job changes, there are also more parts that need to be washed. That is why the efficient cleaning of anilox rollers, impression cylinders and press parts is becoming an increasingly important part of the process chain in print shops, paint and ink manufacturing and similar. We offer a powerful and robust systems for all cleaning tasks, washing machines for all cleaning requirements in the paint and ink producing industry, together with energy-efficient solvent distillation units.

Laminating & Spot UV & UV Varnishing

AUTOBOND – World leaders in thermal and waterbased laminators, multi-purpose machiney, UV and spot UV.

D&K EUROPE – High quality thermal laminating equipment.

Laminating Film Supplies

Wide range of laminating films for offset and digital, high quality high tack bopp and PET films, glueable, stampable, printable.

72 Grady Crescent, Erskine Park, NSW, 2759 Call us toll free: 1300 885 550 | www.graph-pak.com.au We offer a diverse selection of pre-owned equipment that is available for purchase. We also buy used equipment. Supplier Profile Specialising in capital equipment sales, service, engineering solutions and consumables

Post Press – Bindery

Ltd Environmental

YOSHINO – Perfect binders, PUR systems, 3 way trimmers and gathering machines. Compact

Foilers

Key considerations to take note of for label print quality

Mediapoint reviews the elements of label print quality using its new equipment to help you understand, compare and evaluate options

By Mediapoint’s Jamie Xuereb

By Mediapoint’s Jamie Xuereb

Mediapoint assesses the quality of print using its Durst Tau 330 RSC E

The quality of label printing significantly influences the overall appeal and effectiveness of the product.

For ourselves and our print resellers, it also has an effect on reputation and customer satisfaction. As such, label print quality should never be an afterthought. Producing high quality stickers and labels, for whatever application a customer requires, can be a real boon for business.

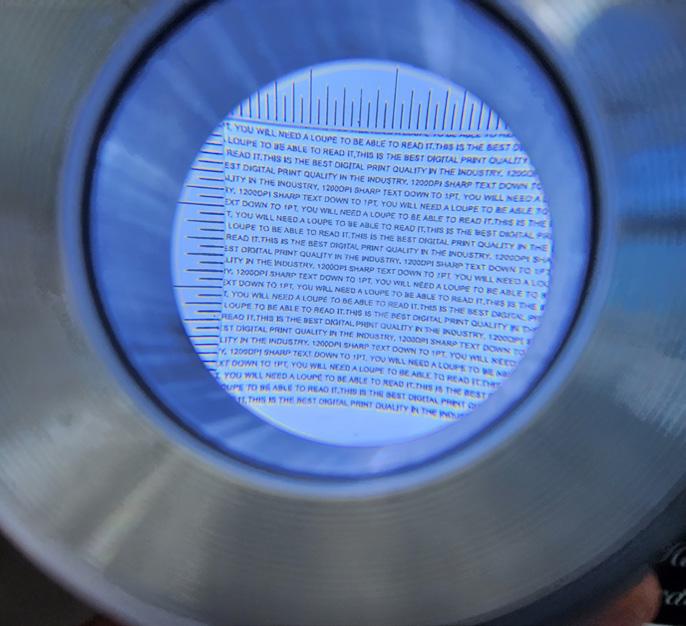

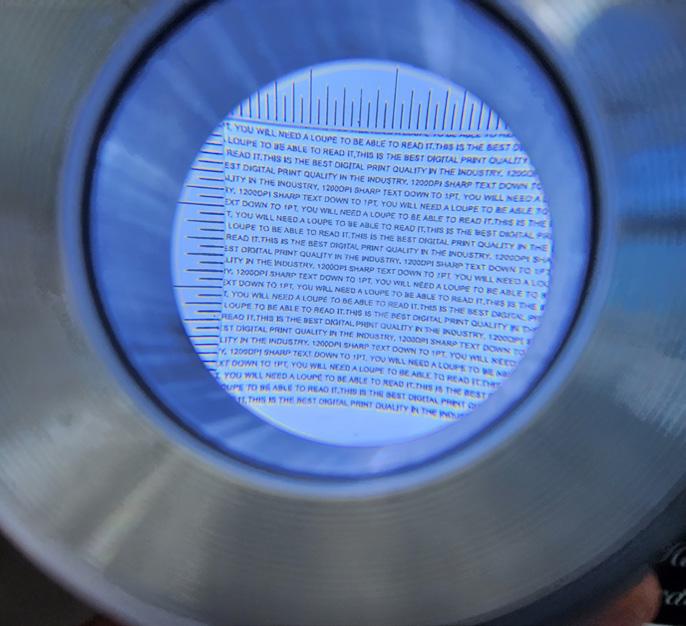

When considering print quality for labels and stickers, several factors come to play. We’ve addressed some key considerations in a sample print run on our new addition, the Durst Tau 330 RSC E to highlight these for you. So, let’s get into it…

Resolution: The foundation of label print quality

Perhaps the biggest consideration of any print job is resolution. Stickers and labels are no exception. Getting sharp imagery and legible text means using the right equipment and technology for the application.

When it comes to labels, you generally want a high dpi (dots per inch) count and small drop size. The higher the dpi the more nuance you can give designs, and the smaller drop size the less dot gain occurs – leading to crisp print details.

The Durst Tau 330 RSC E boasts a resolution of 1200dpi and a two-picoliter drop size.

That combination results in a marketleading label print quality. Just check out the quality sheet below. It’s an A4 paper showcasing ‘worst case’ scenarios, pushing a machine to its least effective print mode. Design details still pop and the varying elements don’t bleed into each other.

Legibility of small text

Small text has always been a tricky element to print clearly. On par with colour richness and image resolution, text issues are the most noticeable label print quality defects.

Naturally, a majority of label and sticker printing jobs require small text. You don’t want packaging and branding details

FOCUS LABELS www.propack.pro 22 ProPack.pro August 2023

being missed – especially in applications that fall under strict regulations.

The smaller you can print text, the more you can play around with text on a design. Plus, the more peace-of-mind you’ll have of information being accessible to the end audience.

Taking this to the extreme, we’ve been able to print text on the Durst at one-point size. That’s text that requires a loupe to read. This text is illegible to the naked eye, but the legibility under magnification is a testament to the printer’s precision.

Even better, italicised text also comes out beautifully. Even ‘reversed out’ printing still yields good results. See the images below from our test outcomes:

options, these elements really open up the range of applications.

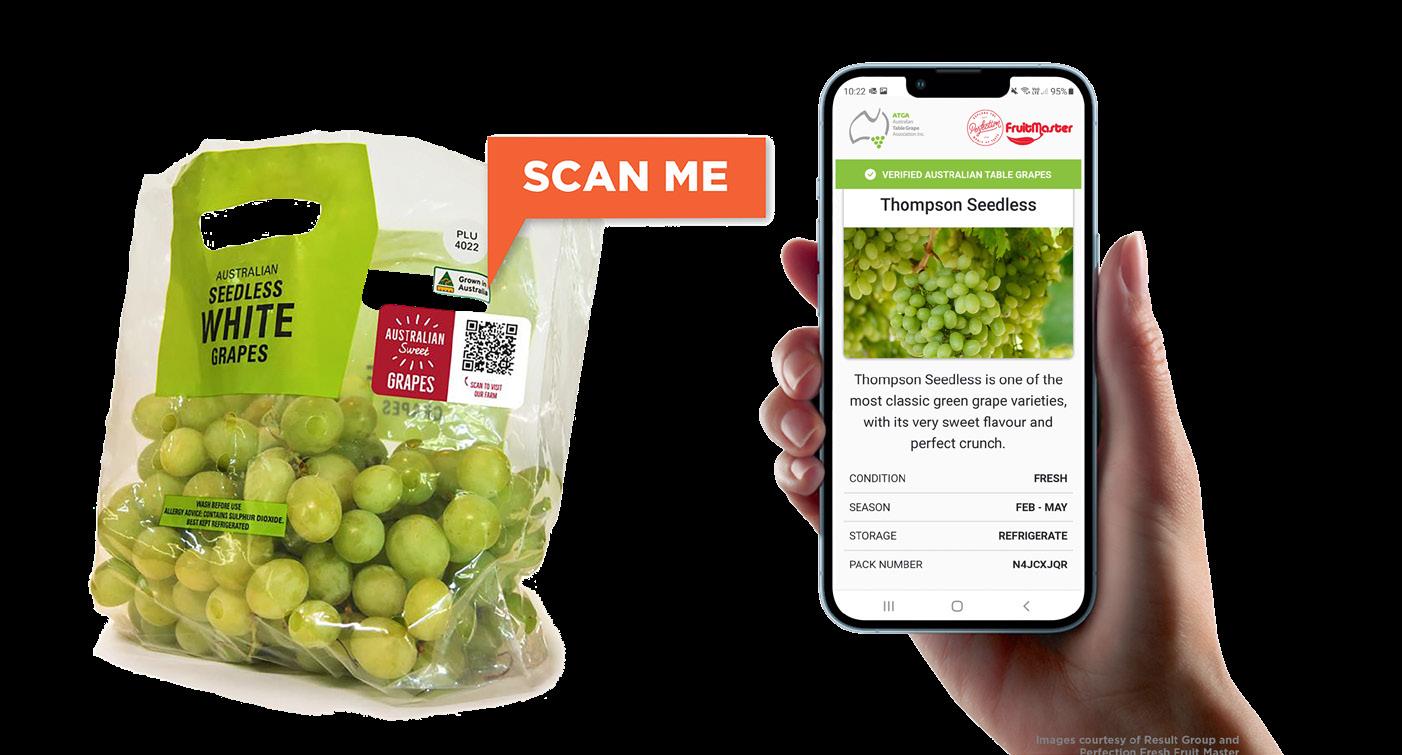

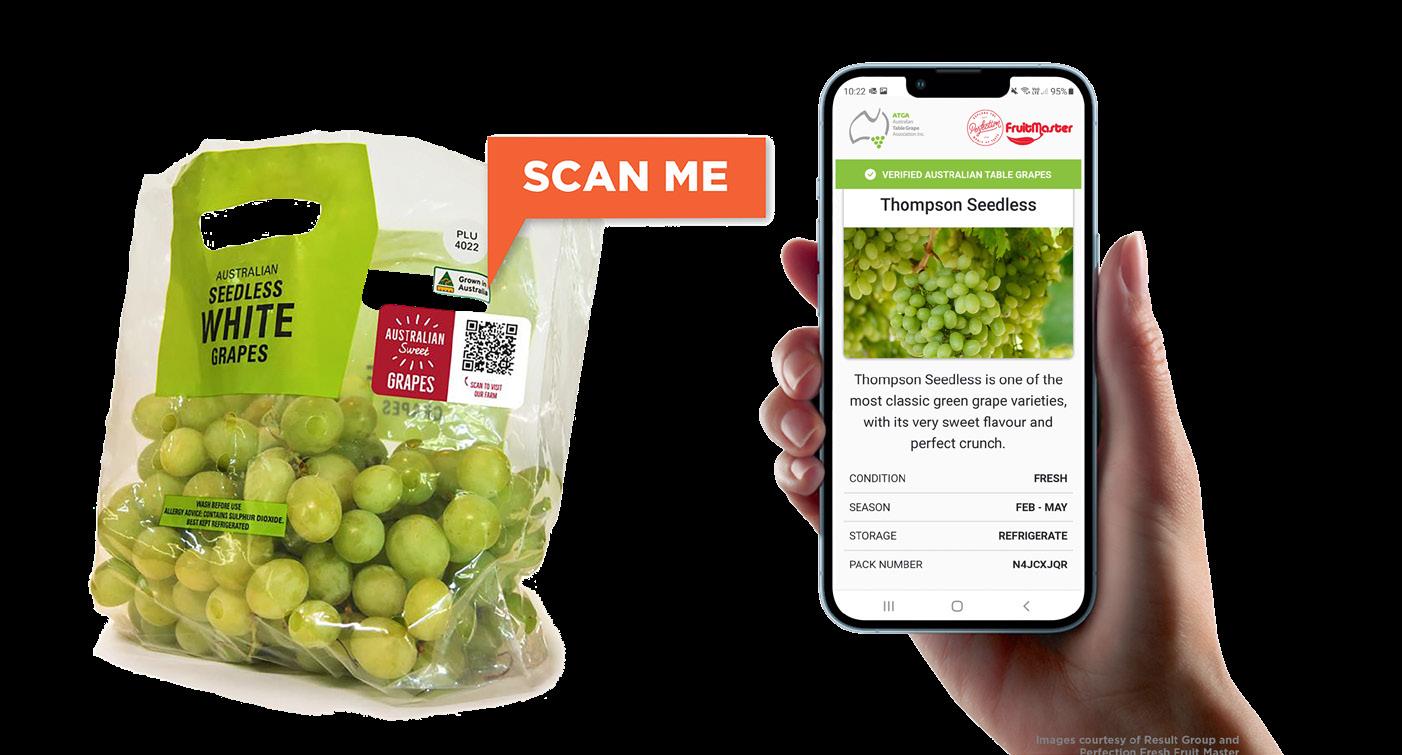

Scannability of QR codes and barcodes

The ability to produce legible, scannable QR codes is of great concern to printers. It’s in high demand from the customers of print resellers post-2020. That’s thanks to the take-up of QR code functionality and how they can be used in packaging or marketing applications.

Again, when it comes to labels, these generally need to be printed at small sizes. The clarity of the code print influences its scannability – you can’t have lines bleeding into each other.

With the Durst Tau 330 RSC E, we can print barcodes in any direction. That gives our customers the confidence to submit label and sticker designs knowing codes will scan perfectly.

Rich solid colours

Colour richness is another instantly obvious aspect of label print quality that can significantly enhance overall appeal. It’s a factor influenced by the printer’s colour reproduction capabilities, ink quality, and the interaction between the ink and the printing medium.

The Durst Tau 330 RSC E, leveraging the advanced inkjet tech we mentioned before, excels in this regard. Colours are both rich and vibrant, giving printed labels a high-end, premium look and feel.

Durability and useful life

Many of the applications of stickers and labels require the product to maintain quality label printing over a long-term. Furthermore, the products are usually regularly handled, exposed to light, and outdoor conditions.

This is the smallest size QR code that we have seen scan through any of our presses. Whilst not all applications will require such small sizing, it’s a testament to what’s possible using leading-edge tech. It opens up many options too for our print resellers and their customers.

Barcodes in any direction

This leads us to a quick note on something often overlooked – directionality of barcodes. Due to the setup of generic label printers, printing barcodes often requires a change in orientation to ensure scannability. That means compromising on design and often extra work for designers. This can lead to lower customer satisfaction and longer lead times.

So printing equipment that utilises ink sets specifically for these purposes, in combination with durable stock, can greatly affect useful life. Our stickers and labels are printed with UV resistant ink sets that don’t require lamination and withstand outdoor conditions for up to two years. This, of course, isn’t necessary for every use case but it provides peaceof-mind to the end user.

It also unlocks a wide range of applications in combination with custom size options (stickers of up to 1m in length), a large die library, and the aforementioned label print quality.

Our aim for label print quality

As you can see there are some clear pillars of label print quality when it comes to stickers and labels. Taking these into consideration when selecting a print partner for jobs can save you money and frustration.

At Mediapoint we’re not just addressing these concerns but pushing the boundaries of what’s possible in digital label and sticker printing. Whether it’s resolution, colour richness, readability of small text, scannability of QR codes and barcodes, or length of useful life. Our label and sticker solutions provide peace-of-mind and quality customers will love (at prices you’ll love). We’re not just improving the quality of our customer’s labels; we’re enabling them to elevate their brand and offer an enhanced experience and wider range to customers.

FOCUS LABELS www.propack.pro August 2023 ProPack.pro 23

When designing sticker and label printing or evaluating your printer

The smaller you can print text, the more you can play around with text on a design

As shown in this picture, italicised text come out beautifully

‘Reversed out’ printing yields good results

In the above example you can see that under a loupe, the clarity of a 5mm QR code remains impeccable

Barcodes printed on different directions on the Durst Tau 330 RSC E

Refining packaging by thinking ‘outside of the box’

A mix of creativity and boldness is required to create the best ‘out of the box’ solutions

Packaging is no longer just your usual square (or rectangular) box made of cardboard and held together by glue or tape. It is now a visually appealing package that performs based on form and function, in addition to being sturdy, having sustainable properties and having a purpose.

Box design ideas now inspire and excite, with some solving real-world problems even if they’re minimal. Many packaging companies are ‘thinking outside of the box’ when it comes to developing designs and aim to create unique, interactive experiences for customers.

We’ve rounded up some examples of how some companies have thought differently and found uncommon solutions to complex problems using packaging:

Close the Loop Group

Close the Loop Group was awarded a high commendation for Lousy Ink within the Outside of the Box Design of the Year category of the 2022 Australasian Packaging Innovation & Design Awards (PIDAs), organised by the Australian Institute of Packaging (AIP).

Since 2000, Close the Loop has been involved in the reclaiming and recycling of hard-recycled print consumables –mostly ink and toner cartridges. Lousy Ink is made from ink sourced from discarded inkjet printer cartridges which have been sent to Close the Loop.

The brainchild of Oliver Ruskidd and Mike Eleven from Lousy Ink, the two Australian artists turned discarded printer ink into

sustainable art supplies, claiming it is the world’s first 100 per cent recycled ink for artists.

FOCUS ‘OUTSIDE OF THE BOX’ DESIGN www.propack.pro 24 ProPack.pro August 2023

‘Out of the box’ thinking is one of the vital strategies to creating designs that stand out from the crowd, and is a necessary tool for today’s packaging companies

Lousy Ink is made from ink sourced from discarded inkjet printer cartridges

Before the partnership with Close the Loop came about, the ink would have been either collected and stored in 80,000L containers or burnt for energy, but after finding out about the massive amounts in storage Ruskidd and Eleven decided to see if it could be put to better use.

The end result was a high-quality ink made from recycled materials, and while each bottle can vary slightly in tone and consistency it provides artists with a truly unique medium to work with.

“It’s a great story as Lousy Ink was able to save over 85,000L of ink in 2022 itself. It’s a good circular story and a great initiative that shows that these products can be in use for as long as possible,” Close the Loop Group marketing manager Jessica Ansell said.

This product was also produced in conjunction with Cartridges 4 Planet Ark.

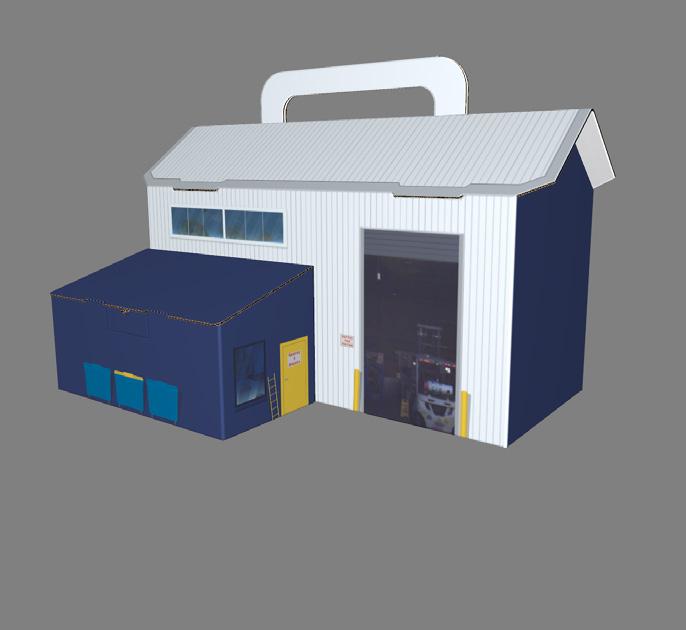

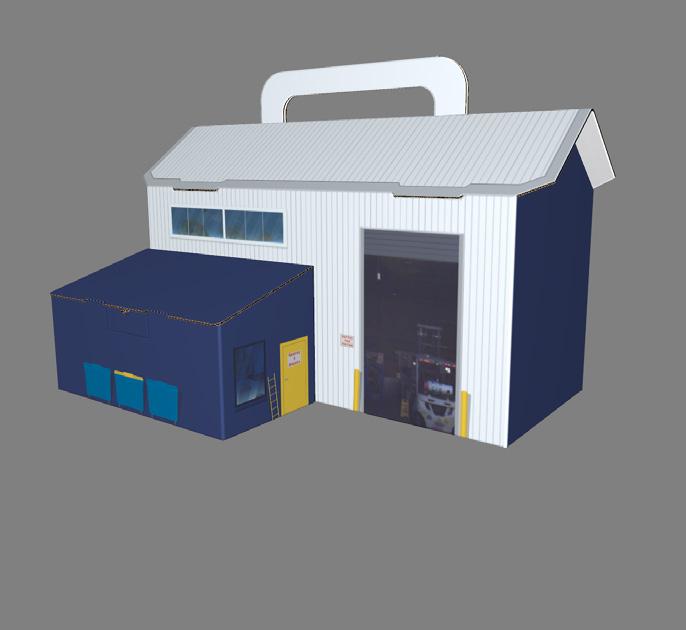

closure and windows etched into the chipboard using a debossing technique.

The packaging not only demonstrates a commitment to creativity – it also considers the environmental impact. All materials used in the production are sustainably sourced with no plastics, no lamination (no celloglaze) and printed using soy-based inks.

For the manufacture of this product, sheets were printed using a Heidelberg five-colour offset printing machine. They were die cut before going through the debossing machine, automatic rigid box making machine and gluing machine, all of which were best suited to produce high quality, premium packaging with a variety of special finishes.

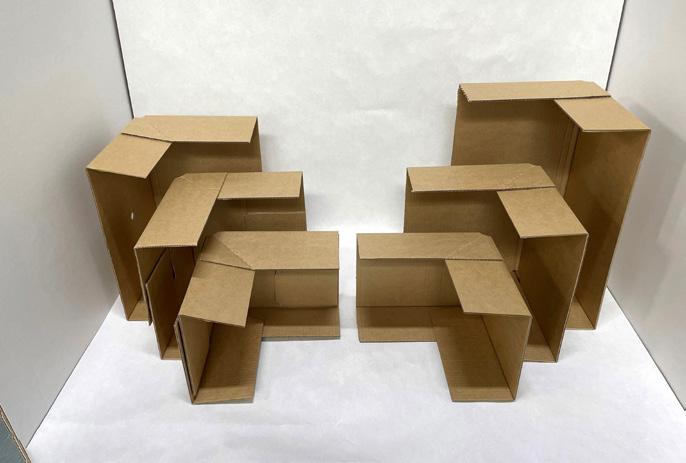

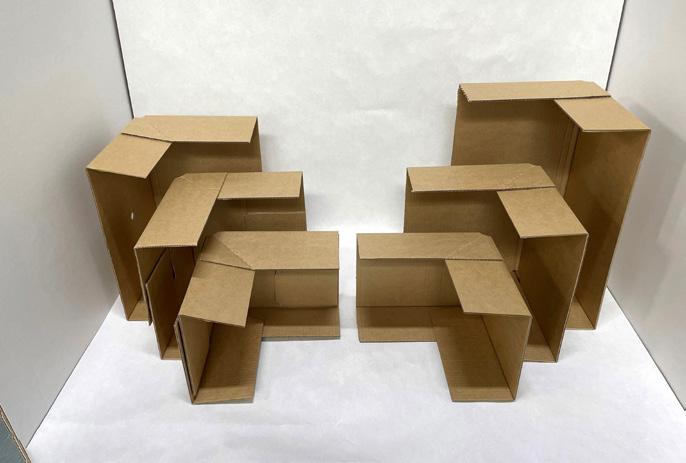

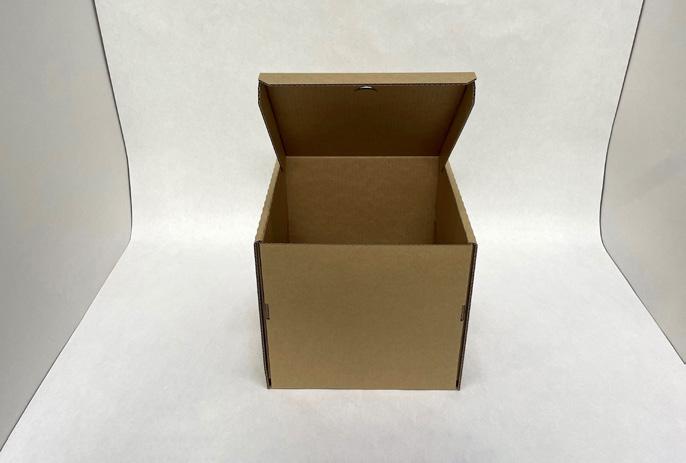

Packaging Design of the Year category at the 2023 Australasian PIDAs. Its Coola Box won the gold award, while its Snell Packaging – Mattress Corner Protector and Future Ecology – EmGuard solutions won the silver and bronze awards respectively.

The gold-winning Coola Box has an innovative design that allows for cool air to be contained inside the box, typically used for e-commerce deliveries. The structure of the box was designed to feature a snug fit with overlapping walls to help in better frozen and chilled ingredient arrangements that are packed with ice packs and required headspace.

According to the company, the design successfully achieves the requirement of temperature control needed for all delivery cycles.

This smart, sturdy box also achieves better space utilisation as more items can be safely packed within the area, resulting in lesser transit damages.

The box is also made from 100 per cent New Zealand recyclable corrugated board, meaning that the end user can easily dispose of the packaging with other recyclable items in their collection bins.

As for its silver-winning Snell Packaging –Mattress Corner Protector solution, its four corners were glued with trays snapped in half to make the perfect corner to protect a mattress.

The 2022 New Directions Australia Advent Calendar box is more than just a box. The skincare manufacturer and wholesale supplier of essential/vegetable oils, cosmetic ingredients and skincare cosmetic bases wanted to showcase its product and service offering in a unique way which truly embodied the essence of its company.

Operating in the industry for over 30 years and proudly Australian-owned and run, the company wanted to create an advent calendar and partnered with its specialty packaging division, New Directions Packaging, on a solution which needed to be both functional and fun. The advent calendar housed various skincare products whilst being visually striking with the incorporation of an exquisite illustration of its almost 100-year-old building by talented artist Aaron Favaloro.

The end result packaging is truly an experience – it allows the end user to open the ‘doors’ of the package in the same way that they are welcomed into the iconic art-deco style building.

The front and sides of the box simulate the actual front and sides of the building, including front doors recreated in the box design through the use of a magnetic flap

“Four sizes were required, and we developed one design that work for all. The slit in the design allows it to be adjustable, so the customer no longer needs to hold all the SKUs,” Oji Fibre Solutions NZ said.

Its bronze-winning Future Ecology –EmGuard solution is a robust product and proven solution to plastic debris entering waterways from plantings on or near riparian margins and waterways.

“In the past, green plastic corflute triangle guards were imported from overseas. We worked with our customer to create a more sustainable product that would break down after the tree is mature enough to thrive on its own,” Oji Fibre Solutions NZ added.

Omni Group

The Omni Group was the silver award winner for the Outside of the Box Design of the Year category at the 2021 Australasian PIDAs for its VentX Unico solution.

Omni Group said for several years, it had a focus to reduce the volume of plastic waste from discarded stretch film, which led the company to create the concept and eventual invention and rollout of VentX Unico.

Oji Fibre Solutions NZ

Oji Fibre Solutions NZ wiped out all the awards within the Outside of the Box

New Directions Packaging

www.propack.pro August 2023 ProPack.pro 25

FOCUS ‘OUTSIDE OF THE BOX’ DESIGN

The 2022 New Directions Australia Advent Calendar box

Oji Fibre Solutions NZ’s gold-winning Coola Box

Oji Fibre Solutions NZ’s silver-winning Snell Packaging – Mattress Corner Protector solution

Oji Fibre Solutions NZ’s bronze-winning Future Ecology – EmGuard solution

The company said the product is the world’s most innovative, effective, and sustainable ventilated pallet wrapping solution. The innovation guarantees optimum ventilation and superior load containment while halving stretch film usage.

“End-of-line packaging plays a vital role in protecting and prolonging our farmer’s and supermarket’s perishable foods,” the company said.