The market for automotive software and for electrical and electronic components is expected to grow strongly in the next decade, with the market for automotive software and for electrical and electronic components (E/E), projected to grow to $469 billion, from $238 billion, between 2020 and 2030.

Today, an ever-increasing amount of electronics are found in today’s vehicles, and alongside this an everincreasing amount of challenges for manufacturers.

In this edition of Global Industry Focus, we hear from companies addressing real world issues concerning the e-mobility sector and how they are finding solutions.

Indium Corporation discusses its Rel-ion suite of products, which have been used in EV manufacturing for more than a decade, while Samsung ElectroMechanics’ introduces its high voltage Auto MLCC, promising to guarantee reliability in high voltage applications.

With 25 years’ experience in obsolescence management and a broad spectrum of members, the International Institute of Obsolescence Management (IIOM) sets out in its article how it can help industry to tackle today’s supply chain hurdles using good obsolescence management processes.

We also feature articles from Scienscope regarding the installation of their incoming materials technology to automotive electronics manufacturer, Varroc Lighting Systems, based in Romania, as well as Astute Electronics, who have a wide range of resources and articles on their website for anyone looking to strengthen their knowledge of the automotive markets.

Finally, on pages 26-29, Adaptix details how to speed up your suspected counterfeit component testing, and how its solutions can transform the economics of test.

We hope you enjoy this issue, to get in touch please email kirsty@globalindustryfocus.com

Kirsty Hazlewood Editor

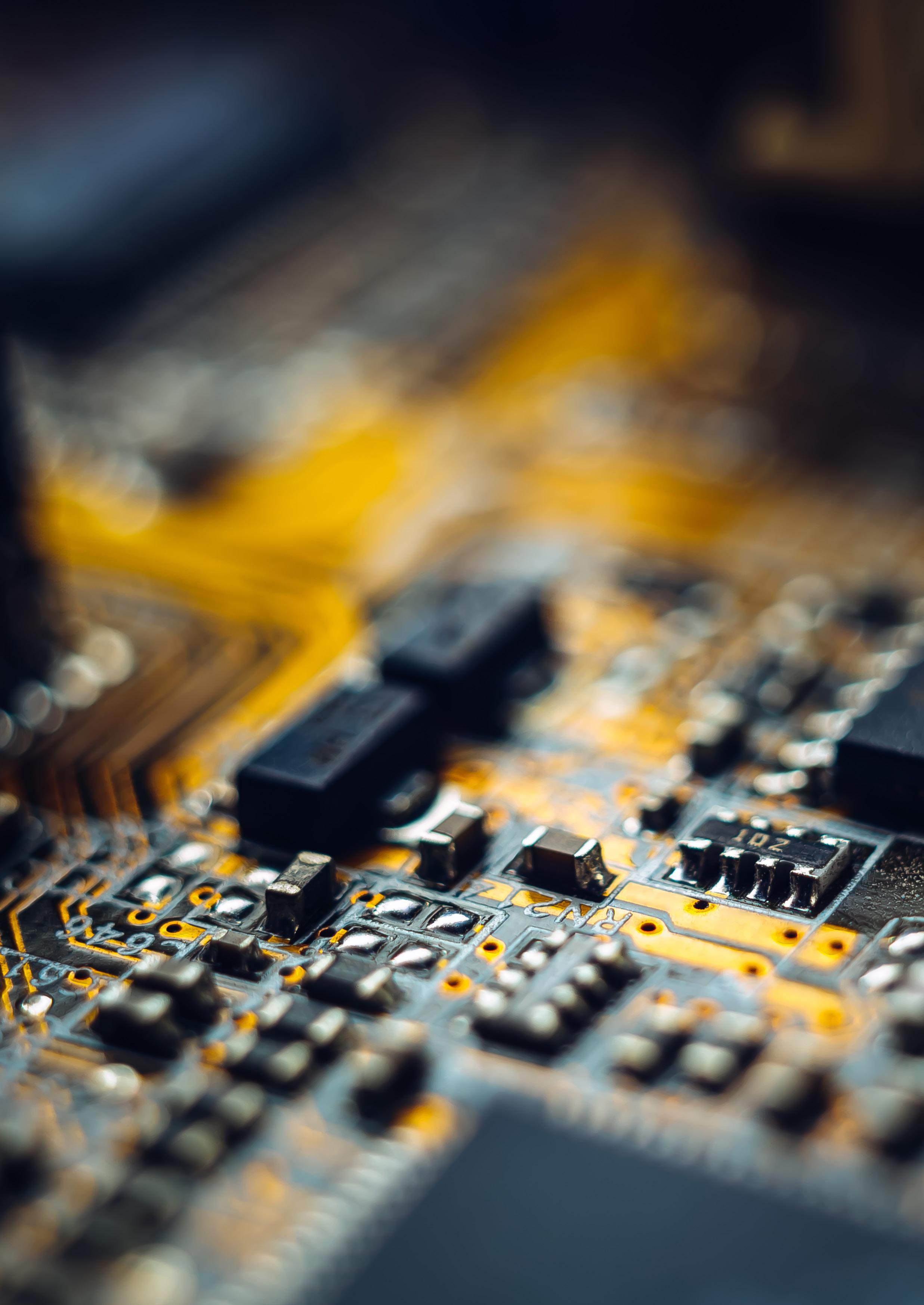

The e-Mobility industry is evolving before our eyes as lower barriers to entry, climate change, and governmental policy have created a demand to launch new electric vehicles (EVs) that didn’t exist within the legacy original equipment manufacturer (OEM) marketplace. EVs are mostly driven by electronics, and OEMs—who have worked primarily with mechanical assemblies—have had to alter the way they interact with their supply chains, often by going directly to PCBA manufacturers.

With change comes pain points, and the stakes are high as consumers require far more reliability from their vehicles than their consumer electronics. As has happened in at least one well-known case, a dendritic growth in a display panel has the potential to immobilize an EV in the middle of a crowded highway.

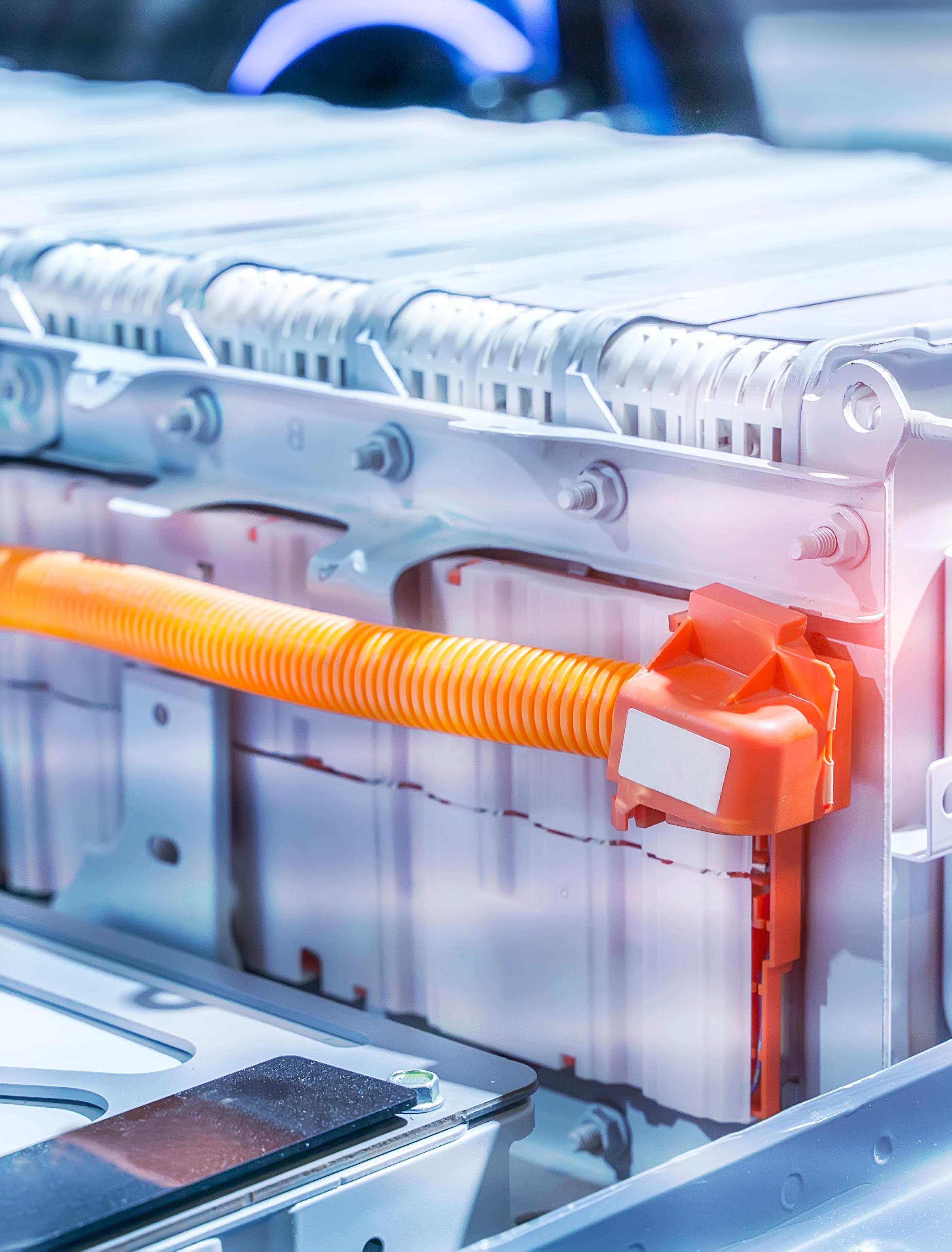

What started as an EV discussion has grown into a much larger e-Mobility evaluation incorporating batteries, charging stations, and the public utility

infrastructure required to support it. This requires massive cooperation across the public and private sectors. Within this new and sometimes confusing paradigm, Indium Corporation® has emerged as a trusted source of expertise and industry leadership.

Electrical, mechanical, and thermal stresses can negatively impact the performance of the final product and, with electric vehicles, the challenge is even greater. Requirements are more demanding for high-power electric engines which run almost nonstop between charging and driving cycles, along with myriad connected electronics within the car.

Indium Corporation is more than a materials provider—they work with customers to optimize and customize their procedures. Below are common

challenges within EV electronics assembly and how Indium Corporation’s Rel-ion™ suite of awardwinning products can effectively eliminate or reduce defects such as dendritic growth, voiding, head-inpillow, and more.

Electrical

Dendrites and Corrosion – Meets stricter surface insulation resistance (SIR) with rework solutions to pass SIR unheated

Electrical Continuity – Eliminates non-wet opens and head-in-pillow defects

Leakage Current – Contains low alpha particle solution for >650-volt GaN dies

Mechanical

Solder Delamination – Provides precision bondline control, increased creep resistance, and increased fatigue resistance

Longer Mission Profiles – Shows increased operating temperatures and longer thermal and power cycles

Thermal

Hot Spots – Reduces voiding, increases CPU/GPU thermal requirements, and provides materials for power modules, IGBT, and DSC modules

The industry is looking for solutions that can help bring products to market faster and without recalls. Along with the development of industry standards, the use of proven products backed by expert knowledge and experience is a key component to success. Over three million electric vehicles are currently on the road with Indium Corporation’s Rel-ion™ suite of products because they are specially engineered to meet three vital criteria.

First—they’re reliable. They are designed with higher quality standards that meet the evolving demands of automotive electrification. Second—they’re scalable. They are readily available and capable of meeting supply chain expectations. Third—they’re proven. Most Rel-ion™ products have been used in EV manufacturing for more than a decade.

Rel-ion™ materials deliver reliability to EV modules, components, and systems, such as:

ADAS

Autopilot

Battery Cells

Battery Management Systems

DC-DC Converters

DC Fast Charging (DCFC)

Energy Storage

IGBT

Infotainment

Inverters

Battery Chargers

Power MOSFET

Telematics (TCU)

To learn more about Indium Corporation’s suite of proven products for EV and other automotive applications, visit indium.com/relion.

If you are looking for expert insight on the rapidly evolving EV market, Indium Corporation is proud to offer two free channels shedding light on both the technical challenges facing the industry, as well as the business side of e-Mobility.

For expert technical insight on the challenges present in the rapidly evolving electric vehicle market, including how to ensure electrical, mechanical, and thermal reliability, check out Driving e-Mobility: Rel-ion™ Technical Webinars. These unique sessions, offered as part of Indium Corporation’s popular InSIDER Series of webinars, are led by global industry technical experts in advanced materials and the automotive market. Register for upcoming webinars or access the on-demand archive at no cost at https://www.indium.com/corporate/media-center/ webinars/rel-ion.php.

EV InSIDER Live, driven by Indium Corporation, is a webcast series co-hosted by Brian O’Leary and Loren McDonald. Conducted in an approachable, conversational format suitable for business executives, casual observers, and seasoned engineers alike, EV Insider Live sheds light on the most pressing business issues facing the e-Mobility industry. O’Leary and McDonald are joined by a different high-profile guest from the EV industry on each episode. Register for upcoming webcasts or access the on-demand archive at no cost at https://www.indium. com/corporate/media-center/webinars/ ev-insider.php

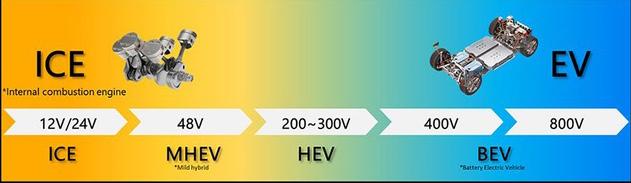

The global car market is going through a massive transition to electric vehicles. So far, internal combustion engine (ICE) vehicles have improved powertrains to cope with emission regulations. Emission regulations, convenience technologies and self-driving have driven electrification increases with automobiles. As the number of electronic units increased, the amount of power consumption for a vehicle increased. Battery voltages have changed to deal with increased power consumption requirements, and they are associated with efficient power systems. Within this article we will discuss electric vehicle technology using high voltage applications and introduce Samsung Electro-Mechanics’ high voltage Auto MLCC.

The battery voltage increase of the car is related to the trend of electrification. In order to understand the electrification trend, we must first look back on how the voltage of a car battery has changed. Before the mid-1950s, a vehicles operating voltage was 6V. Since then, the engine displacements increased and required a large electric starter motor. The 12V system became standardized in the need of more electronic devices. Historically, early cars only needed a small battery to crank engine and turn on the radio.

However, as the number of in vehicle electronic devices has increased over time, so has the need for more power. To resolve this problem, discussions took place to increase the voltage from 12V to a higher voltage system capable of dealing with the additional power demand. In the 1990s, the 42V system was proposed, and in 2011, German carmakers made 48V the standard. Since then, hybrid cars and electric vehicles have begun to use higher voltages. Power (Watt) is voltage (V)*current (A). When increasing power, it is more efficient to raise the voltage rather than the current. When current is

increased, thicker cables are required and connector pins must also be changed. Both have an impact on the hardware cost. So, battery voltages increased instead of current.

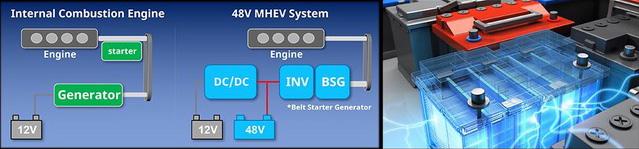

The main reason why the 48V system emerged in the 2010s was due to emission regulation. Automakers producing internal combustion engines had to achieve their emission goals and increase fuel efficiency by improving powertrains. Mild Hybrid (MHEV) is said to be a simple inexpensive hybrid system. The reason why car manufacturers preferred MHEV is because it was easy to manufacture. The MHEV system can be manufactured by adding a 48V system to the existing internal combustion engine powertrain , emission reduction can be achieved at a lower cost than full-hybrid. But the question remains; why was 48V selected in particular? The reason is that, in many countries, 60V is regarded as a low voltage and not dangerous to the human body. In addition to the above, telephone lines have used 48V power systems for the last 100 years, which further proves the safety aspect of 48V systems in vehicles.

The basic powertrain configuration of electric vehicles consists of high voltage battery, inverter, and electric motor. EV powertrains use high voltage . The efficiency of an EV is linked to the efficiency of the DC/DC converter . Electric cars have various power conversion applications such as LDC, OBC, and Inverter. Various DC/DC Converter Topologies are being applied to integrate similar applications. For example, OBC (On Board Charger) and LDC (Low-Voltage DC/DC Converter) are under development for the system integration which have an advantage of reducing components and saving spaces.

400V 800V AC

Charging System

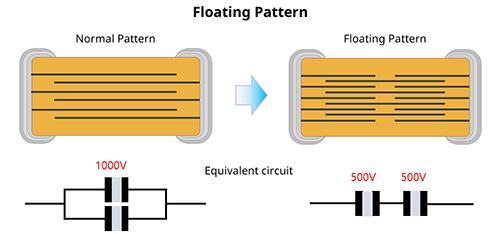

How is the structure of high voltage MLCC different from that of general MLCC? Reliability should be guaranteed in high voltage environments. MLCC applied for high voltage applications are exposed to the risk of Arc-over and a short-circuit can occur inside of the MLCC. Under high voltage, a strong electric field is formed around the MLCC, which ionizes the surrounding air. Particularly, a strong electric field is concentrated on both terminals of the MLCC. If it exceeds the inception voltage of the ionized air, electrical arcs occurs, ultimately leading to a short-circuit inside the MLCC. The structure that prevents this phenomenon is a shield pattern inside MLCC.

Floating design is a design that lowers the short-circuit risk when MLCC crack occurs, but it is also useful for high-voltage products. The floating structure distributes voltage so the voltage inside the MLCC is only half of the voltage applied to the end terminals. For example, when 1000V is applied to both ends of the MLCC, if the floating design is used only 500V is applied to the MLCC dielectric layer, which is half of 1000V. It’s definitely an advantage from the perspective of reliability because the electric field applied between dielectric layers decreases. Voltage along with temperature are key factors to determine MLCC lifetime.

Samsung Electro-Mechanics’ High Voltage MLCC guarantees reliability in high voltage applications. Additional information and details about the company’s line-up can be found on the website, or if there are any questions, readers can simply click (here) to send a message.

EV Powertrain

DC/DC Invert er Motor

OBC HV Battery

EV Powertrain

DC/DC Invert er Motor

OBC HV Battery

Carlton Industries Corporation (CIC) is the single source for manufacturing circuit boards, electronic assemblies, and cables to meet the critical requirements for fast turnaround, high-reliability and exceptional quality. The company excels at satisfying customers in challenging markets like industrial, commercial, aerospace, medical, and defense. “Our customers don’t compromise on the level of electronics manufacturing services they expect,” said Ken Maduri, VP Sales & Marketing.

Since 1994, CIC has offered complete electronics manufacturing services backed by cutting-edge equipment and a team of professionals unmatched in skill, experience and dedication to the customer. CIC’s workmanship follows IPC A-610 guidelines and customer requirements to meet all expectations. CIC is an expert at tailoring manufacturing services to create an end-to-end process that correctly fits each customer’s unique functional, performance, cost, and time-to-market requirements.

From documented best practices to state-of-the-art optical inspection, to complete electrical, mechanical, functional test and failure analysis, CIC places quality first. This is why it continually invests in the most up-to-date equipment, conducts ongoing training and continually outperforms in critical markets like industrial, medical and defense. The company is certified to the latest revision standards of both ISO 13485 and ISO 9001. It also is RoHS and REACH compliant. CIC offers a high-quality product at a competitive price, exceptional customer service and manufacturing support through responsiveness and flexibility to satisfy customers’ needs.

In order to continue to meet these expectations, CIC provides only the most up to date, innovative equipment from companies whose quality standards are on par with CIC’s. MIRTEC is one such partner.

According to Maduri, CIC has worked with MIRTEC for nearly two decades. The company first purchased

one of MIRTEC’s MV-2HTL Desktop AOI Systems in 2005 adding a total of three machines in the years to follow.

“To stay competitive, CIC continually invests in state-of-the-art equipment and training. Earlier this year, the decision was made to upgrade our current three MIRTEC automated optical inspection (AOI) machines to the latest MV-3 OMNI Desktop 3D AOI Machines,” Maduri added. “Our employees find the system easy to program and operate. By adding this

to our already updated surface mount line, we have higher quality and can take on more capacity for our existing and future customers. Not only can we run faster with even better quality, but we also can keep cost to our customers in check during these trying times.”

MIRTEC’s Award-Winning MV-3 OMNI Desktop 3D AOI machines feature the company’s exclusive OMNI-VISION® 3D Inspection Technology which combines a 15 Megapixel CoaXPress Camera with MIRTEC’s patented 12 Projection Digital Blue DLP Technology in a cost-effective Desktop platform.

MIRTEC’s 15 Megapixel CoaXPress vision system is a proprietary camera system designed and manufactured for use with its complete product range of 3D inspection systems. MIRTEC’s 12 projection Blue DLP Moiré Technology provides true 3D inspection to yield precise height measurement

data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured, the MIRTEC MV-3 OMNI machines feature four 10 Megapixel sideview cameras in addition to the 15 Megapixel top-down camera as well as multifunction AOI/SPI inspection capability. “Without question, the MV-3 OMNI is the most Technologically Advanced Desktop 3D AOI Machine on the market,” stated Brian D’Amico, President of MIRTEC’s North American Sales and Service Division. “We are proud to have worked with CIC for many years and are pleased to provide them with an upgrade path to MIRTEC’s State-of-the Art 3D Inspection Technology allowing CIC to continue to offer their customers the advanced solutions they have come to rely upon.”

CIC provides a range of services including automated optical inspection (AOI), printed circuit board assemblies, consignment assembly services, plated through-hole assembly, robotic conformal coating, supply chain management, SMT, box build, cable assembly, testing and programming. These services are provided to a diverse set of markets with a common set of needs when it comes to selecting

the right manufacturing partner for their circuit boards, electronic assemblies and cable assemblies. Its customers typically are manufacturers of higher-end products that contain significant electronics content. Markets served include aerospace, communications, emerging technologies, healthcare/medical, industrial controls, military/defense, scientific instruments, and security.

Companies in these markets succeed by providing clear performance advantages to sophisticated buyers who leverage rapidly advancing technology

to serve critical needs. They require fast turnaround, best industry manufacturing practices, and the ability to work collaboratively with designers to turn innovative ideas into manufacturable prototypes that ultimately can be produced in higher yields at competitive costs. CIC prides itself on meeting – and exceeding – these expectations daily with the help of its dedicated team of employees.

CIC is comprised of 50 employees with an average longevity within the company of more than 13 years. They excel at satisfying customers in challenging market segments including aerospace, military and defense, medical, robotic, industrial, and instrumentation.

CIC’s long-standing reputation is proven through its customer longevity, which averages more than 12 years. The company believes in having a long-term partnership with all of its customers, much like MIRTEC, and being the essential part in reaching customers’ specific business goals.

Maduri added that MIRTEC has been an ideal partner for the past 17 years and that CIC appreciates the outstanding service and responsive technical support. “MIRTEC’s AOI equipment is always at the cutting-edge of technology,” he concluded. “With the way MIRTEC is keeping up with state-of-theart technology, CIC expects to keep our long-term partnership going. MIRTEC is considered a valuable partner and an extension of our company.”

For more information about Carlton Industries Corporation, contact the company at 33 Rossotto Dr., Hamden, CT 06514; 203-288-5605; E-mail: kmaduri@cicems.com; Web site: www.cicems.com To find out more about MIRTEC’s Award-Winning 3D Inspection Technology, visit www.mirtecusa.com.

With 25 years’ experience in obsolescence management and a broad spectrum of members, the International Institute of Obsolescence Management (IIOM) is the right choice for helping to tackle today’s supply chain hurdles.

IIOM is 25 years old this year. Having started in the UK as the Component Obsolescence Group (COG) in 1997 to bring together asset owners and operators, manufacturers, public bodies and obsolescence solution providers, it now boasts a global membership and a professional recognition scheme, and has four active chapters - in France, Germany, UK, and USA.

We all love the buzz of getting the latest technology but how often does it not work as planned with integrated systems or require other support? The modern world is a whirlwind of technological

creativity and advancement. However, there are many applications for which newer, smarter, and faster means an existing system or product no longer works and is pushed towards a premature end-ofservice or obsolescence.

Electronic systems such as air traffic control, aviation flight computers, railway signalling, nuclear powerplant controls, medical scanners, and communication infrastructure have always been susceptible to being overtaken by new technology, but could we have foretold a situation where today’s electronic component supply chain would be so badly affected by long lead-times shortages and where even the most common parts would be hard to find, and then liable to being declared obsolete? For equipment with long development and service lifecycles, the original design requirement remains unchanged, sometimes for several decades, meaning

that proactive obsolescence management has become a necessity to ensure delivery to the customer in a cost effective and timely manner.

Organisations with good obsolescence management processes have been less affected by current supply chain issues, and companies in sectors such as automotive that were previously immune to obsolescence are employing engineers with obsolescence skills to develop their supply chain resilience.

In the International Standard IEC62402:2019, developed with a major contribution from IIOM members, obsolescence is defined as the nonavailability of parts that were previously available, but it is about much more than electronic components. For example, non-availability of materials, processes, skills, and software can occur at all stages of an equipment’s life cycle, such as development, design, production and in service. Using obsolescence management as a tool in an organisation creates an understanding of why this may happen and to plan and mitigate for these instances in the future. It is also now recognised as a vital part of support and through-life strategy by many progressive companies.

IIOM is the professional body for those involved in obsolescence management. The Institute is for professionals worldwide who wish to further their knowledge and understanding of the obsolescence management discipline, obtain professional recognition and network with like-minded individuals.

The organisation welcomes corporate and individual members and has obsolescence solution providers among its corporate membership, as well as manufacturers and operators. These solution providers offer various obsolescence management services, including component monitoring; counterfeit avoidance; reverse engineering; sustainable solutions for obsolete designs; stocks of obsolete and end-oflife components; and training.

Formal obsolescence management training is available from IIOM endorsed trainers that offer online and in-person training at the introductory level, enabling successful trainees to become AIIOM (Associate) level. Experienced practitioners may opt to apply for MIIOM (Member) or FIIOM (Fellow) level accreditation if they have the appropriate experience. Regular meetings in each chapter country provide a mix of formal presentations and informal events at which obsolescence engineers, buyers and solution providers can exchange ideas—not just on obsolescence but also on key issues such as REACH, conflict minerals and counterfeiting. Meetings also provide access to suppliers of the latest tools and systems developed to support obsolescence monitoring and management.

After a successful conference in Munich in May 2022, IIOM’s next international conference will be held in London in October 2023 and the call for papers will be issued soon.

Obsolescence is here to stay but you can manage the risk to your business. The good news is that with 25 years’ experience and a diverse membership, IIOM is here to help wherever you are. To join your local chapter, or to participate at the international conference, please contact the support team at admin@theiiom.org

You can follow IIOM on LinkedIn, subscribe to IIOM channel on YouTube and go to the website www.theiiom.org

Right: Stuart Broadbent - IIom UK Chapter Chairman

arroc Lighting Systems Electronics Romania (Varroc) was initially founded in 2019 as a joint venture between Varroc Lighting Systems (70%) and ELBA (30%). In December 2020, Varroc purchased ELBA’s 30%, and the company became a new electronic business unit of VLS. Since then, the company has grown from one to three SMT/BEs. Varroc is based in Targu Mures, Romania, focused on manufacturing electronics for the automotive industry. Varroc Lighting Systems is a global automotive supplier providing custom design solutions and innovative product development for exterior vehicle lighting systems.

Varroc places customer care and innovation at the top of its success list. “Our people are the key drivers for our success,” said Cristian Szpisjak, a .net developer. “We ensure sustainable economic growth and a constant contribution to our customer’s success through innovative and high-quality products.” To actively support the development of products from concept to manufacturing, the team strives to continuously improve its performance and anticipate and drive change to be one step ahead of the competition.

So, when the company was working to automatically receive and process materials, including the option to validate the process data at the end, it turned to Scienscope. Varroc began discussing this process in 2021, and while researching potential suppliers, the company came across Scienscope and realized it had a facility in the same city as Varroc. Once it was ready to move forward, the company purchased the Reel Smart Lite (Incoming Material System-100 (IMS-100) equipment to improve its reception of materials process. Before the IMS-100, Varroc had to conduct reception, including printing the labels manually, and the information gathered from the process was not validated. Now, with the help of automatic validation done by the Scienscope system, the company knows the information will be accurate, which is a significant time and cost-benefit.

Szpisjak continued, “In addition to being local, Scienscope provided a service tailored to our unique needs by adjusting how the software on the equipment works to support our business needs. Since implementation, we’ve noticed a marked reduction in time for receiving materials/automatic validation and significantly fewer errors generated

by manual reception.” He added that because Scienscope is local, Varroc was able to implement the system quickly.

The integration and management of components are critical when trying to achieve a “smart factory.” Scienscope’s IMS system integrates from start to finish with accurate and complete data of all material processes and procedures. Packed components are received with labels from manufacturers’ barcodes, a distributor’s barcode, a forwarder’s barcode, the customers’ barcode, etc. When received, it can be difficult for the person scanning to pick the correct barcode to scan. Any incorrect reading can lead to an inventory and manufacturing process nightmare.

The IMS-100 high-resolution barcode camera system has an image-based algorithm that reads any barcode, even with defects. It reads and stores the information of four 7” reels simultaneously. As one reel is removed, a unique identification number label is printed, archiving reliable data that can be easily and conveniently traced. Additionally, the IMS-100 allows for EMS/ERP integration in seconds. It captures multicodes quickly and without errors, enabling seamless

integration of any material. Additionally, it helps automate the incoming goods process and boosts productivity dramatically.

Szpisjak added that he was impressed with the level of engagement from Scienscope. “This was one of the contributing factors when we chose the supplier, and the same level of engagement was shown throughout the course of the implementation. Additionally, technical assistance has been comprehensive, and everyone we’ve come into contact with at Scienscope has been knowledgeable and friendly.”

Because the IMS-100 has been received so well, Varroc is considering purchasing the Reel Smart Pro (IMS-200) system as the company grows and continues strategizing for plant automation.

“We aim to be the best electronics provider for intelligent vehicle lighting,” said Szpisjak. “Scienscope’s Reel Smart Lite technology helps us accomplish our goal. We enjoy partnering with companies like Scienscope that are reliable and flexible enough to provide a tailored service to fit our specific needs.”

Varroc Lighting Systems is a premier developer and manufacturer of next-generation external lighting systems and vehicle control electronics for the automotive and two-wheeler industries.

Focused on safety, mobility, and style, Varroc Lighting Systems brings leading-edge technology to the mainstream automotive market with high-quality and cost-competitive solutions. Headquartered in Plymouth, Michigan, U.S., the company has more than 8,000 employees worldwide with operations in 17 countries and capabilities on every continent where vehicles are produced. Varroc Lighting Systems is a vital member of the Varroc Group family of automotive components businesses.

Scienscope was founded in 1994 to meet the growing need for reliable and affordable generalpurpose optical and video inspection solutions for the electronics and PCB industries. The company began with essential stereo zoom microscopes used for SMT inspection and reworking circuit

boards and electromechanical assemblies with a commitment to quality, value, and support. Over the past 28 years, Scienscope has evolved to become a complete inspection solution provider, offering offline and inline X-ray systems, Video coordinate measurement systems, video inspection systems, and microscopes to meet a wide variety of applications and manufacturing quality requirements. It also offers the X-Scope 1800 X-ray inspection system, AXC-800 III Component Counter, and Smart Storage Rack.

To find out more about Varroc Lighting Systems Electronics Romania, contact the company at +40 265262.870, office@zass.ro,

For more information about Scienscope International Corp. and its range of technologies, contact the company at 5751 Schaefer Ave., Chino, CA 91710; 909-5907273; E-mail: Info@scienscope.com; Web site: www. scienscope.com.

The use of electronics has become standard place, not just in the automotive sector but across products and industries where such things were unimaginable in the past. However, whilst continuing reduction in device sizes and available real estate drives increasing technology break throughs, there are requirements that stay constant Assemblies and their components are expected to hold up to extensive vibration and thermal cycling over long time periods.

Two new product innovations help to address these requirements:

UV20GEL - Designed to Provide Protection Against Vibration & Mechanical Shock in Electronic Devices

UV20GEL is a recent innovation f rom the polymer scientists at HumiSeal. It provides additional durability and ruggedisation for printed circuit boards in demanding applications including

high adhesion gel is used for staking taller or sensitive components to provide resistance to vibration and mechanical shock conditions.

Reductions in component sizes and distances make applying conformal coatings and avoiding “keep out” areas more challenging. This is where our UV curable masking Gel excels. It is a soft, one part, UV curable masking material in the form of a thixotropic paste. It can and is 100% cured by exposure to UV to provide a temporary barrier to prevent ingress of coatings into keep out areas. The material demonstrates excellent solvent resistance that provides selective release f rom conformal coating. It also boasts the ability to survive intermittent exposure to temperatures up to 150°C and is REACH and RoHS compliant

Subscribe today for useful “How To” videos and industry insights and much more!

Astute Electronics is an international leader in global sourcing, with excellent credentials and a track record of helping companies to avoid supply-chain disruptions and future risk.

Regarding the EV sector, Astute is anticipating shortages of microchips, ICs, power management modules, microcontrollers, and other vital components into 2023, and beyond. Geopolitics, scarcity, and Covid stoppages will further disrupt supply.

If you are involved in EV production, eMobility, mechatronics, vehicle electronics, or electrified or electronic engineering, Astute Electronics can advise on all aspects of global sourcing as well as how to avoid counterfeit components and untrustworthy sources.

The Astute Electronics website hosts a wealth of pertinent articles regarding the automotive industry which are available to read online for free, including the following recent articles: https://www.astutegroup.com/resources/ si-automotive-semiconductor-shortage-willcontinue-until-2023/ https://www.astutegroup.com/resources/moodyswait-until-some-time-in-2023-for-chip-lead-timesto-normalise/ https://www.astutegroup.com/resources/supplychain-automotive-mcu-mpu-demand-remainsstrong/

https://www.astutegroup.com/resources/autofirms-launching-record-number-of-new-modelsamid-continuing-supply-chain-concerns/

https://www.astutegroup.com/resources/chip-

shortage-not-about-to-end-for-automotiveindustry/

https://www.astutegroup.com/resources/gmexpects-chip-shortage-will-go-into-2023/ https://www.astutegroup.com/resources/pricesup-sales-down-automotive-supply-chain-woespassed-on-to-consumer/

https://www.astutegroup.com/resources/ shortages-finally-catch-up-with-tesla/

These are some of the ways in which Astute Electronics can help you streamline your supply chain:

- Source components in short supply from trusted suppliers

- Avoid counterfeit components

- Bring in material to locations that avoid tariffs

- Undertake BOM analysis

- Connect with local suppliers closer to your manufacturing

T he car you drive, and more so the self-driving vehicle that will drive you; the pacemaker we hope you will never need; and the missiles on which our armed forces depend all have electronics at their heart. What if ~15% of the electronics were counterfeit? Well, they are. Counterfeits affect sectors from military to medical; approximately 1 in 7 electronic parts in the US Military were estimated to be counterfeit (according to the US Senate in 2011) and 1 in 12 medical devices being counterfeit (according to the World Health Organization in 2010). As a result, standards such as ISO9000, AS9100, SAE AS5553, and IEC 62239-1 all state supply chain companies must have anti-counterfeit measures and management plans.

A post-pandemic surge in demand for electronic components has caused lead times often to exceed 52 weeks, and corporate buyers are now scouring parts of the supply chain that they would not have previously trusted. Counterfeiters have seized the chance to monetise the opportunity and have become much more sophisticated in doing so given the massive values at stake. The combination of these factors results in a scale and significance of problem that many privately acknowledge but will not publicly speak of.

The counterfeiters ‘pepper’ good batches with around 10% non-authentic components to drive their yield and avoid detection, which works not least

as the batch may be bought and sold several times. Existing inspection protocols are not stopping the ingress, and buyers are accepting downstream product failure as a cost of doing business. Understandable if it is a non-safety critical device, but problematic in a car, pacemaker, plane or missile guidance system.

AdaptixNDE sees a way to change the balance of power in the war on counterfeit. Initially this is about transforming the economics of testing: accelerating inspection workflow; increasing the productivity of skilled inspectors and improving the sensitivity and diagnostic certainty with respect to counterfeit. This is achieved by bringing the external test house to the warehouse through putting affordable and deployable 3D imaging on the test bench to deliver 3D clarity in 60 seconds.

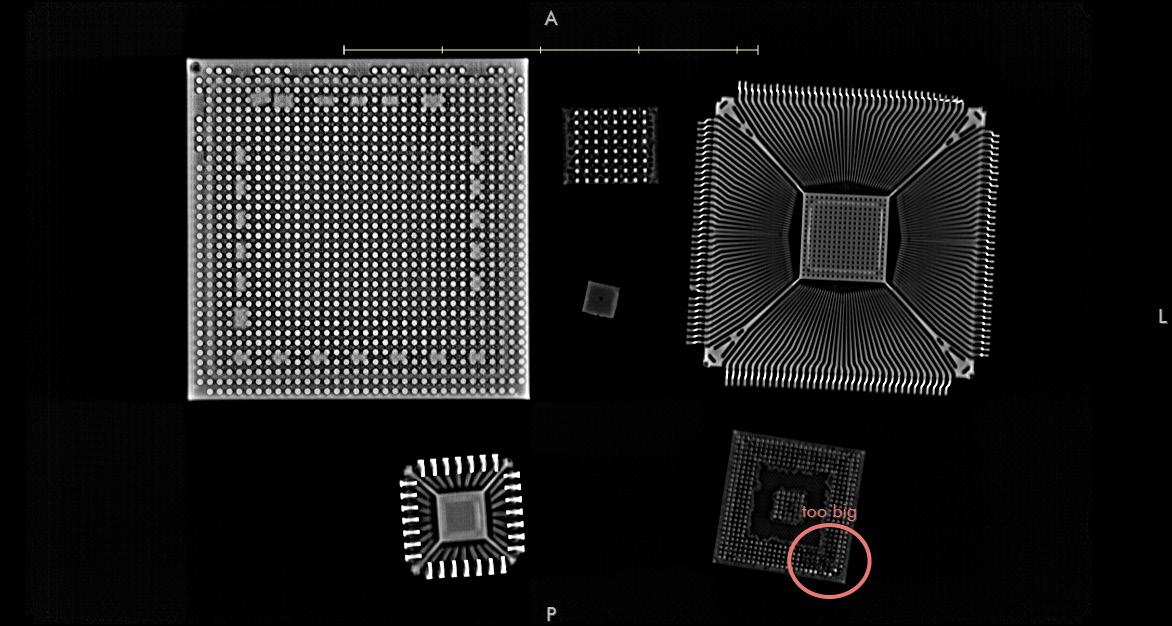

Conventionally 3D X-ray (typically via Computed Tomography) has been beyond the reach of many organisations because of the infrastructure (leadlined radiation room), cost (hundreds of thousands), weight (the same as two Nissan Micras) and (crucially) the full workflow time it takes to acquire an image. Fast, affordable, fully shielded 3D is now available for in-house routine use via Adaptix, and it weighs just 85kg. This ‘benchtop’ 3D allows a rapid test for coplanarity, while also visualising deformities (such as twisted chips or bent pins); uneven BGAs; missing or variants in dye; and seeing broken wires.

All while in the box, allowing focussed selection of components for inspection.

Capability is important, but in order to ‘move the needle’ it is the economics that are important, specifically on-site inspection reduces component handling and transit, allows faster stock-turns to reduce working capital and stock-holding risk, and increases the throughput capacity for a test, storage or warehouse facility allowing the following advantages:

In-house testing allows compression of the inspection cycle from 6 weeks to 60 seconds Allows for lower inventory holding periods due to not needing to wait for test results Faster time to cash receipt from customers

Allows for reduced risk from price fluctuations on price-volatile components Allows for reduced economic exposure when placing components in to long-term storage

Allows for reduced external test costs Reduced handling, transit and administration costs Removes capital cost of test equipment purchases

More productive use of in-demand skilled inspectors to improve efficiency and effectiveness

Potential to increase sample size with same resource or give equal assurance at lower cost Better data to refute false return claims

AdaptixNDE is delivering this value on a ‘per-scan’ basis with a small up-front and monthly fee to reduce the perceived risk of adoption and ensure that incentives are aligned. Just as in healthcare, from where the technology emanates, the key is ‘quality up, cost down’. Again, as in healthcare, the technology is not standing still and the Company has a product roadmap that will further accelerate inspection and enhance assurance as the war against counterfeit will never be won. The pipeline of further innovations includes:

- automated quantification - automated comparison with external data sets - multi-modal and multi-spectral inspection - automated oxidation detection - comparison with large data sets of known-good and know-bad

The future of counter-counterfeit is a strategy built on data and leveraging the lessons of antivirus i.e. the aggregation and dissemination of threat information to the benefit of all benign market participants by provide ever more certain characterization and evaluation of components and devices. Adaptix’s solution will extend to a complete solution that evolves as the threat develops to support reputable companies in their anticounterfeiting management plan in line with ISO, AS, SAE and IEC requirements. Today AdaptixNDE can transform the economics of test, tomorrow we aim to equip manufacturers and brokers in the war against the counterfeiters.

Committee on Armed Services US Senate 112th Congress: Investigation into Counterfeit Electronic Parts in the DOD Supply Chain (2011) [- THE COMMITTEE’S INVESTIGATION INTO COUNTERFEIT ELECTRONIC PARTS IN THE DEPARTMENT OF DEFENSE SUPPLY CHAIN (govinfo.gov)]

NS Medical Devices Publication, reporting a World Health Organisation Report of 2010 [MMI046 (zmags.com)]

Top Left: Artemis Desk Top system

Top Right: Unsatisfactory ball alignment (rectangular coloured dots

Bottom Left:

and solder ball

Bottom Right:

This digital industry publication will offer a global perspective for the whole of the electronics and off board sectors. Complimenting our existing industry hub and weekly WNIE (What’s New in Electronics) platforms, we are confident that in this ever changing world these titles will offer companies a complete marketing solution.

Offering a magazine that’s targeted at the entire industry will add huge benefits for advertisers too. To maximise budgets, companies need to appeal to both designers and purchasers, without the additional cost of having to advertise across multiple publications. The pandemic has forced companies to drastically reduce their marketing spend, thus reducing their reach, but featuring in Global Industry Focus means there is no need to compromise, inclusion in Global Industry Focus allows enhanced visibility and access to the whole electronics industry, including multiple sectors and multiple job functions, all in one magazine at one cost.

Global Industry Focus will feature guest editors, regular updates, plus key content and opinion pieces from industry sector specialists.

We have packages to suit your requirements, either bespoke or ready-made and with an opportunity to advertise across both the Global Industry Focus (GIF) and the What’s New In Electronics (WNIE) industry hub and newsletter.

Global Industry Focus (GIF) is 100% digital, why did we choose a digital publication instead of print?

• Larger circulations

• Reduced advertising costs over printed issues

• Direct delivery to readers in-boxes

Traceability offering peace of mind to advertisers

Digital offers more innovative ways for companies to market themselves such as embedded videos. Digital delivery of information is now the preferred choice for reading the industries latest news.

At the heart of the electronics industry

years of seeing so many

target either a specific industry sector

we believe it is high time for something different - a

that targets the whole