In 2022, the electronics manufacturing industry continued to be affected by the COVID-19 pandemic, which contained to cause disruptions in the global supply chain and affected the production of electronic components. Despite these challenges, the industry continued to grow and innovate, driven by advancements in technology and the increasing demand for electronic devices.

As we know, the electronics industry is an important sector of the global economy, contributing to the development and growth of a variety of industries, including consumer electronics, telecommunications, automotive, healthcare, and aerospace, and playing a critical role in enabling technological advancements and innovations, such as the development of smartphones, computers, wearables, smart homes, and IoT devices.

Our industry has faced several challenges, including the need to constantly innovate and keep up with rapidly evolving technology trends, manage complex supply chains, ensure product quality and reliability, and comply with increasingly stringent regulations and standards.

In 2023, it is expected that the electronics manufacturing industry will continue to experience growth, driven by several key trends. These include:

Internet of Things (IoT) - the proliferation of IoT devices is driving demand for electronics components, particularly sensors, processors, and wireless communication modules.

5G - the rollout of 5G networks is expected to drive demand for new devices and infrastructure, which will require a range of electronic components.

Artificial Intelligence (AI) - the integration of AI into electronics devices is creating new opportunities for manufacturers to develop more intelligent and responsive products.

Sustainability - there is an increasing focus on sustainability in the electronics manufacturing industry, with companies seeking to reduce their carbon footprint and improve their environmental impact.

Supply Chain Resilience - the disruptions caused by the COVID-19 pandemic have highlighted the need for greater supply chain resilience and diversification, with manufacturers seeking to reduce their dependence on a single supplier or region.

However, there may still be challenges related to geopolitical tensions, which could impact the industry’s growth and supply chain stability, as well as the threat of global recession and the cost of living crisis potentially dampening down demand for components for consumer electronic products.

This issue, please enjoy articles from Astute Electronics, Electronic Partner Srl, and Humiseal, as well as coverage from electronica 2022, ASYS Technology Days and IPC APEX Expo 2023.

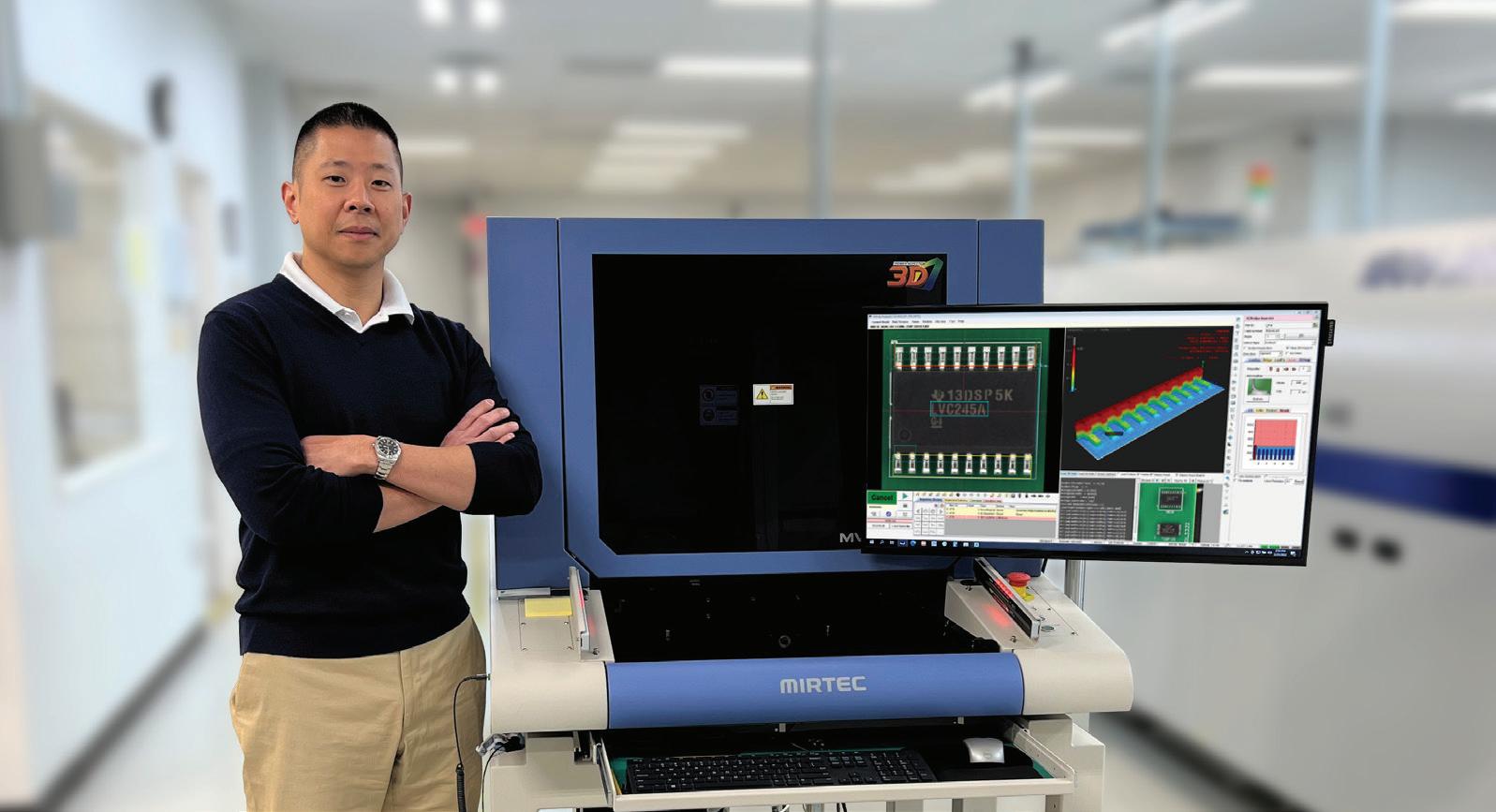

Kirsty Hazlewood Editor“Located in rapidly growing Houston, Texas, PPSI Manufacturing has been a trusted Electronics Manufacturing Services (EMS) provider since 1986. PPSI is committed to providing high-quality electronics assemblies and world class service to a wide range of customers in high-reliability markets, such as energy, transportation, and industrial control. As part of our ongoing commitment to continuous quality improvement, PPSI has partnered with MIRTEC to incorporate their state-of-the-art 3D AOI technology into our SMT inspection processes. MIRTEC’s MV-3 OMNI 3D AOI system is easy to program and delivers optimal defect detection as well as critical in-process feedback. With this capability, PPSI is able to meet the most stringent customer quality requirements in a consistent and cost-effective manner.”

– Jerry J. Huang, CEO

– Jerry J. Huang, CEO

Electronic components are now essential for the production of a very wide range of products. Independent distributors can be excellent allies for manufacturers of products with electronic components because they work hard to maintain lasting, trust-based relationships, both with their suppliers and with their customers.

Why is this so important? Current market reality. Exponentially growing demand for components makes them difficult to find (if they are not already obsolete due to their natural evolution). This shortage has triggered a wild expansion of the industry, especially in the parallel market (an area where the average independent distributor or broker operates), and it has resulted in the entry of many new players onto the market who, driven by the need for quick and easy profits, supply non-conforming –at best reconditioned, but often fake or counterfeit – components to desperate manufacturers. These new players try to win your business by offering you attractively priced, but often poor-quality, parts.

Choosing to work with a reputable and trustworthy independent distributor with proven experience and a good reputation – that you can confirm, for example, by contacting their regular customers directly – is the best way to avoid being scammed when buying products in such an inflated electronics market.

Even if you have an established screening procedure in your company, it is always wise to contact your hypothetical new supplier’s regular customers or references to confirm their experience. We know that this is not easy to do because it is our standard practice. As a distributor with 20 years of experience, Electronic Partner srl first determines whether the potential supplier has ever supplied non-compliant material and, if so, investigates how they handled the situation with the customer and whether refunds or reimbursements were granted.

Today, independent distributors are often accused of introducing counterfeit parts or poor-quality

components into the electronics supply chain. Why is this? Customers end up with the fake parts that were originally sold by counterfeiters to unscrupulous or careless distributors or brokers who, in turn, resold them on to other independent distributors or brokers.

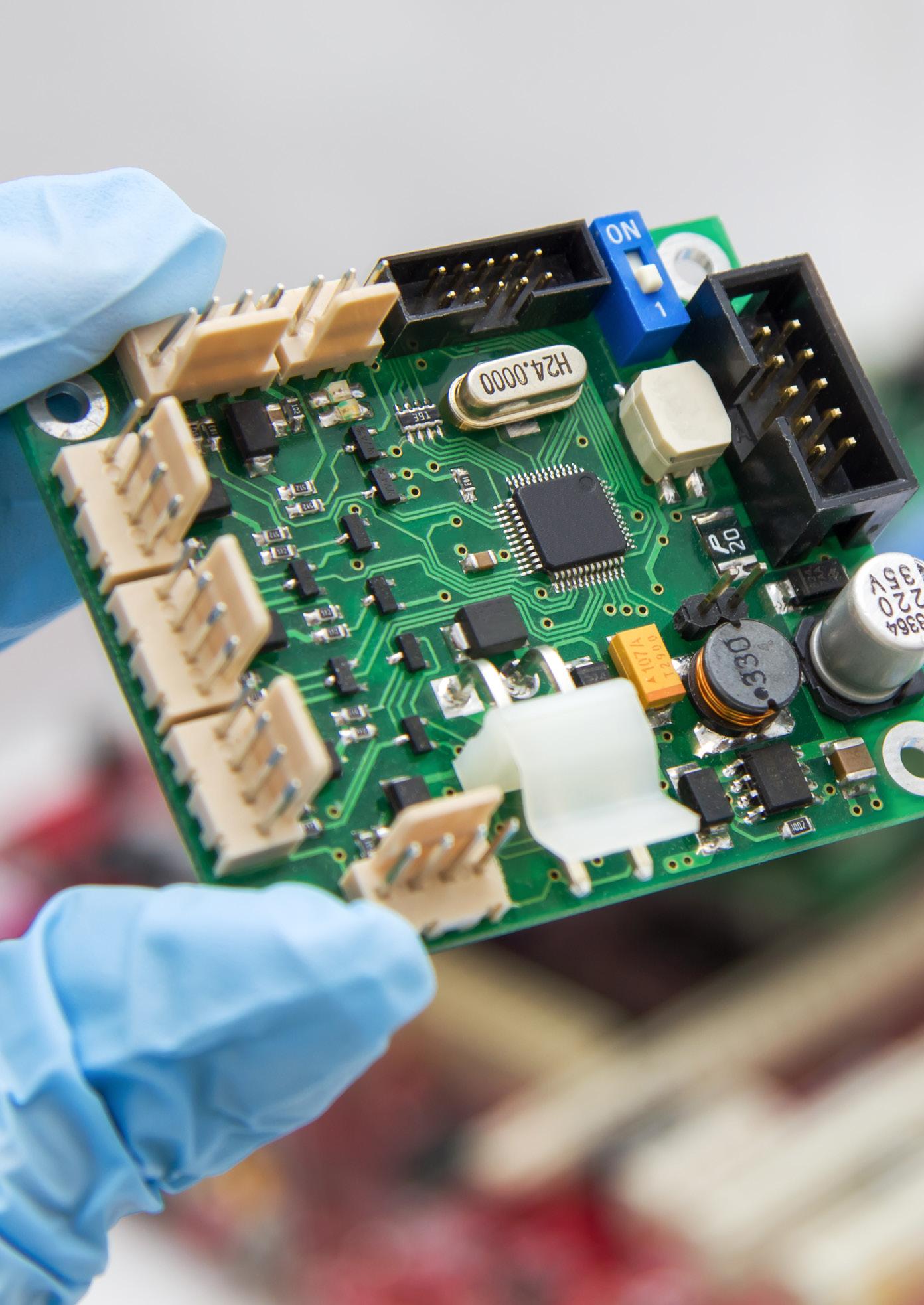

Fake or nonconforming parts can usually be detected by using a test house, or by inspecting them as they are mounted on a board. In the worst case, fake parts are only discovered when there is a problem with the final product, which may already be on the market – causing significant economic damage to the manufacturer and its reputation.

For this reason, a reliable independent distributor will typically use a test house (preferably an external one that performs unbiased and objective quality testing and inspection) to inspect random samples of parts before accepting potential suppliers’ offers.

The only way to completely guarantee the authenticity of components, according to electronics industry associations and several authorized distributors, is to purchase them directly from manufacturers or authorized distributors.

While we agree in principle, this is not always possible to do given the recent and ongoing changes in the global electronic component market, particularly for hard-to-find or obsolete items, or older models of components.

As a responsible independent distributor that seeks long-term win-win relationships with its customers, Electronic Partner srl knows that counterfeiting is a serious problem in the electronic component supply chain. For this reason, the company conducts rigorous internal and external screening, and testing procedures using completely unbiased external test houses whose only task is to identify non-conforming components (including production rejects or fakes). Electronic Partner also constantly monitors its network of suppliers to ensure that they always meet the quality standards demanded by the market.

For those companies tempted to take advantage of stock you find on the open market (and not only there!), the real challenge is to determine if that stock has reliable origins or not.

One way to protect yourself, in this case, is to rely on a carefully chosen independent distributor (using the factors mentioned above). This will help you avoid unpleasant surprises.

Generally, when buying directly from suppliers around the world, you are also directly responsible for ensuring that the stock is genuine, compliant, and free of quality issues (refurbished goods, not original items, counterfeits, etc.).

This means taking the following steps:

• Verifying any reviews or references left by other customers;

• Analysing the photos provided, starting with the packaging;

• Examining the labels on the packaging and the pictures of the goods;

• Requesting test reports (preferably from an external test house) and analysing these.

All of this ties up a lot of your and your team’s valuable time and resources, which could have been dedicated to other activities, especially profit generation, adding further risk to your business. And all of these aspects are becoming more and more complicated to analyse: the world of counterfeiting has been evolving twice as fast as the market over the past two years.

Partnering with a carefully chosen independent distributor can free you of all of these onerous tasks, allowing you to concentrate on your core business.

If you have decided to try a new supplier of electronic components, it is advisable to carefully consider your payment options – particularly in the beginning when mutual familiarity is not yet fully developed. Avoiding losing money to someone who might disappear after meeting you for the first time must be your top priority!

Your best protection here is to complete payment only after receiving proven confirmation of material shipment and part quality. In this situation, a trustworthy independent distributor would be able to provide you with other options to realize and safeguard the achievement of your objectives.

If you are struggling to source hard-to-find or obsolete components that you can trust, or simply want to put us to the test to ensure you are getting the best deal available on your electronic components, contact us today at: info@electronicpartnersrl.com or visit www.electronicpartnersrl.com.

Have you discovered your favorite independent broker or distributor? Have they offered you the opportunity to contact their references? In your opinion are independent distributors and brokers the same thing?

“Located in rapidly growing Houston, Texas, PPSI Manufacturing has been a trusted Electronics Manufacturing Services (EMS) provider since 1986. PPSI is committed to providing high-quality electronics assemblies and world class service to a wide range of customers in high-reliability markets, such as energy, transportation, and industrial control. As part of our ongoing commitment to continuous quality improvement, PPSI has partnered with MIRTEC to incorporate their state-of-the-art 3D AOI technology into our SMT inspection processes. MIRTEC’s MV-3 OMNI 3D AOI system is easy to program and delivers optimal defect detection as well as critical in-process feedback. With this capability, PPSI is able to meet the most stringent customer quality requirements in a consistent and cost-effective manner.” –

Jerry J. Huang, CEO

Jerry J. Huang, CEO

OMNI-VISION ® 12 Projection Digital 3D Moiré Technology

Exclusive 25 Mega Pixel CoaXPress Camera System

10 um Telecentric Compound Lens Design

Eight Phase C O L O R Lighting System

18 Meg Pixel SIDE-VIEWER ® Camera System

Programmable Z-Axis Multi-Focus System

INTELLI-PRO ® Automatic Programming Software

Multi-Functional AOI-SPI Fusion Technology

an eventful history and got an insight of what lies ahead for the future. In a live exhibition, the global technology leader showcased process and line solutions through to autonomous shopfloor solutions.

SERIO 6000

DIVISIO Gen 5000

Tech Tour Thomas Endler and the Smart Factory

30 Years and Beyond - Interview with Jürgen Ries

Technology Days 2022 - Day 1

Technology Days 2022End of Day 1

Technology Days 2022 - Welcome to Day 2

Technology Days 2022 - Day 2

Technology Days 2022End of Show

The market may not have worsened in the last quarter, but has it stabilised? Not yet. There are still shortages; supply and demand remain at odds. Regardless of the industry, it is impossible to navigate these stormy waters without a trusted partner.

In challenging times, the importance of trust, collaboration, and partnership become paramount, says Mark Shanley, Astute’s Director of Sales & Marketing. These values have established Astute as a leader in supply chain solutions, not only within the Aerospace and Defence (A&D) industry but across several key sectors: Medical, Electric Vehicles (EV), Renewables, Maritime, and Rail. The solution may be in plain view, right from the start.

“Demand for electronics is generally rising. There’s a technology aspect in virtually everything we do. All industries are under the same pressure. The problem is, when you can’t get hold of a critical $1 component your production may have to stop – for weeks or even months – until you come up with a solution.”

“Astute has made a large investment in electronics engineering,” says Mark. “We get involved at early stages to support product design, prototyping, and development. Our involvement mitigates the issues of scarcity, non-supply, counterfeit materials, component End of Life, and obsolescence.

“We can guarantee a surety of supply in some situations. For example, when a component becomes

scarce, we can do a forward-buy and store on-site in nitrogen cabinets until needed - 5, 10, even 15 years. Ultimately, our roots of success -- the Astute DNA – is adding value through the supply chain and providing support throughout the product life cycle.”

Adding value is not only adding service: new products and full solutions are integral to Astute’s future success.

“The A&D sector faces multiple challenges. We have urgent operational requirements to support, not only the Ukraine conflict but a general rise in geopolitical tensions. Extending military equipment service life is critically important. Inflation is adding further pressure – driving up costs of raw materials and components and interfering with demand forecasting, planning, and supply chain management,” Mark told WNIE.

“There is never only one challenge, and there is never just one solution -- only different approaches to mitigate risk. You have to innovate.”

Astute is no stranger to innovation. From their beginnings in 1989, when Geoff Hill founded the company to assist Tier 1 A&D customers like BAE and Thales to find obsolete components, the focus was squarely on how to solve problems.

Mark continues, “We take a consultative approach to our customers: analysing their supply chain, digging out the problems, and building solutions around them. For example, we devise ways to mitigate future problems by avoiding risk during the design and procurement stages.”

Part of this has been the acquisition of ISMOsys, a technology-driven enterprise that represents a range of components and systems manufacturers who can take a concept into production. The acquisition extends Astute’s capabilities for early-stage design, prototyping, and through-life support – ‘cradle to grave’ -- for A&D equipment.

Around the same time, Astute also launched SALUS, a ground-breaking asset tracking solution. Using RFID tags, this solution can accurately track the location of equipment or people to within two metres and report back their status and behaviours in real time. Since its wireless signals pass quickly and securely across great distances, there’s the possibility to track assets across different zones and buildings – across a military facility, for instance.

“With SALUS, Astute has identified and addressed a major gap in the provision of asset tracking solutions for the A&D sector. Historically, inefficient asset tracking, monitoring and recovery has resulted in billions of dollars of missing or lost equipment.”

“Medical has become an important sector for Astute. Since our involvement in the Covid-19 ventilator challenge, we’ve observed the similarities between the Defence and Medical sectors: supporting the supply chain for life-critical devices. That needs an agile dynamic partner to secure material,” says Mark.

“We’ve since expanded our involvement within the medical sector by investing and adapting, as with all of our customers. Covid accelerated the need for portable screening and early detection devices. There was an urgency to get the equipment mobile, especially for use outside hospitals in health centres, surgeries, and care homes.

“Meeting this challenge, we’ve formed a strategic alliance with medical pioneers, Level42 AI, to supply their contactless disease screening and health diagnostics equipment. Their AI-powered equipment provides early, accurate, and instantaneous detection

and monitoring of infection and non-communicable illness as well as continuous vital-sign monitoring.”

The AI platform learns to distinguish “Healthy” people from “Sick” people at an individual level and mass population scale. They work contactless, through-clothes to reveal signs of the user’s current and future health, along with actionable diagnostics.

“It’s a very exciting product, not only for screening against illness, but to enhance general well-being and productivity.”

“Electrification of transport is official government policy in the UK. Apparently, EV charge points are set to become the “next great British emblem” and will replace the iconic red telephone box!”

“As an organisation, we’re branching out into new industries to meet tomorrow’s needs. We’ve teamed up with Kayal to distribute their electric vehicle charging infrastructure across the country, in response to growing government-backed demand for EVs.

As part of the deal, Astute will offer all Kayal charging products across a range of sizes and power-grades for residential, commercial, and public use. Kayal offers a complete range of products for commercial and domestic EV charging station installations including AC, DC & portable EV charging stations,

energy storage cabinets, and a full accompaniment of photovoltaic products

“Partnering with Kayal during this period - an EV revolution - is a very exciting prospect for Astute. Customers will gain access to Kayal’s full EV infrastructure building expertise. All in all, we will provide extensive value-added services to our customers.”

Astute has recently become a franchised distributor of Bren-Tronics battery and charging systems. Using a combination of off-the-shelf technology, teamed with their innovative solutions, Bren-Tronics offer an extensive collection of rechargeable and nonrechargeable batteries, and their array of chargers ranging from high rate bulk chargers through to portable lightweight chargers.

“Renewable technology is one of the most exciting, innovative areas, and we’re thrilled to be representing a pioneer in this area - Solivus. If you’ve not heard of them - you will. Their approach is truly groundbreaking.

“Their thin-film solar solutions are fundamentally different to heavy, glass solar panels. They’re making it simpler for buildings and homeowners to decarbonise using these amazing, innovative materials.”

Astute is supplying their Solivus Arc solution for domestic, localised energy production. It uses a 3D design with greater surface area to capture more sun and produce more energy than flat panels, and generates more consistent energy throughout the day. And it’s a portable system, so you can take them with you when you move.

“The carbon footprint is phenomenal - payback as good as conventional systems, recyclable, no heavy metals, great life expectancy.”

For industrial use, the thin-film technology overcomes weight restrictions on buildings. It’s far more flexible; can stick to the side of a building; and offers a significant reduction in reflection.

Astute further supports the Renewables sector with a range of components, including Pulsiv semiconductors. These intelligent devices deliver a PFC AC input to a DC output that eliminates inrush currents and considerably increases the efficiency at low loads. Pulsiv offers configurable reference designs and flexible development systems.

“Whilst we serviced the defence industry, Naval/ Maritime became the core sector for Astute, having supported major builds including the Astute Class, Australian Hunter Class, and Dreadnought submarines, as well as Future Maritime Support Programme (FMSP) contract to name just a few,” Mark told WNIE.

“Forming a dedicated maritime division, focusing on all areas of Naval and Civil marine, was a natural progression. We’ve appointed a specialist, highly knowledgeable team with previous project experience of controls and instrumentation, emergency propulsion systems, comms upgrades, MSSP, towed arrays, and weapons and power.”

The team will focus on rapid response to service and repair – keeping ships out of dock as much as possible – electronics, service provisions, kitting and IT hardware, cable assemblies, consumables, hand tools, and obsolescence management including longterm storage.

Astute’s long standing supply chain services, global sourcing and counterfeit mitigation services can help maritime customers avoid the pitfalls of fraudulent parts and component obsolescence.

“It’s important that customers know we are RISQ certified. We’ve provided support on the TFL central line upgrade, signal upgrades for Great Western Railway, rolling stock upgrades and sensor systems for monitoring movement in tracks and sleepers.

“Like every industry, volatility and shortages have affected Rail, but we can mitigate by removing supply chain risk in design and procurement, especially with the longevity of equipment in the field.”

Logistical support & obsolescence management expertise is backed by technology teams with an array of world class manufacturers of electromechanical and power products.

Mark ends by pointing out that Astute’s global reach allows them to support multinational rail platforms and infrastructure projects.

Mike Bartley from Tessolve at Electronica 2022

Adam Chinery from CCL at Electronica 2022

Harald Eppinger from Koh Young Technology at Electronica 2022

Sailesh Chittipeddi from Renesas at Electronica 2022

Gerry Thurgood from Thermco at Electronica 2022

Harald Eppinger from Koh Young at Electronica 2022

Geoff Hill from Astute Electronics at Electronica 2022

Dr Denis Marcon from Innoscience at Electronica 2022

Gavin Hsu from Delta Electronics at Electronica 2022

Dr Giorgia Longobardi & Professor Florin Udrea from GaN Devices at Electronica 2022

Steve Antonacci and John Cronin from North Shore Components

Rachel Anderson & Harald Eppinger from IC Resources & Koh Young

Quentin Jones from Megatech at Electronica 2022

James Holava from Checksum at Electronica 2022

Duncan Milroy from Adaptsys at Electronica 2022

Andrew Smith from Integrations at Electronica 2022

Mike Bartley from Tessolve at Electronica 2022

Adam Chinery from CCL at Electronica 2022

Harald Eppinger from Koh Young Technology at Electronica 2022

Sailesh Chittipeddi from Renesas at Electronica 2022

Gerry Thurgood from Thermco at Electronica 2022

Harald Eppinger from Koh Young at Electronica 2022

Geoff Hill from Astute Electronics at Electronica 2022

Dr Denis Marcon from Innoscience at Electronica 2022

Gavin Hsu from Delta Electronics at Electronica 2022

Dr Giorgia Longobardi & Professor Florin Udrea from GaN Devices at Electronica 2022

Steve Antonacci and John Cronin from North Shore Components

Rachel Anderson & Harald Eppinger from IC Resources & Koh Young

Quentin Jones from Megatech at Electronica 2022

James Holava from Checksum at Electronica 2022

Duncan Milroy from Adaptsys at Electronica 2022

Andrew Smith from Integrations at Electronica 2022

UV conformal coatings have been gaining popularity since they were first introduced nearly twenty years ago. HumiSeal remains, at the cutting edge of developing and bringing these new types of materials to the market as replacements for water based and ultimately traditional solvent based coatings.

Though, as time moves on and technology evolves, conformal coating manufacturers must refine and develop new generations of these 100% solid materials to not only keep up with demand, but also anticipate future needs.

HumiSeal has recently announced the launch of its 3rd generation UV curing material line that meest these new industry demands, providing environmental protection to sensitive electronic assemblies.

Before we look at these innovative new products, let’s recap on what the drivers for change have been and how HUmiSeal materials have responded to these challenges.

HumiSeal’s first generation UV curing materials were UV40 and UV40 250; the latter being developed specifically for swirl coating applications. They were easy to use and apply, displayed high chemical resistance properties, were rated to IPC- CC830, Mil-I plus UL-V0 and are still widely used to this day. But why were they developed?

Water-based coatings offered a convenient solution to the European Unions Volatile Organic Compound Directive 1999, but suffered from the fact that they took longer to cure and performance did not match that of classic solvent based coatings.

HumiSeal’s UV40, offered a route to significantly improve the quality of the conformal coating protection, whilst largely eliminating VOC emissions and yet dramatically increasing the speed of curing.

HumiSeal found that customers using its UV40 were able to reduce the floor space requirements of a typical coating curing cell by at least 50 percent using UV cure against conventional thermal ovens.

Fast forward ten years and as technology evolved, a new generation of coating materials was needed. This included UV50, UV50LV, UV500 and UV500-2. But why move from a winning formula; what was the drive for improvement?

This product development was based on the requirements from the Automotive industry for extended T-Shock for coatings over lead free solder and up to 1000 hours of SIR testing.

The new products were built on the success of its highly successful and popular predecessors. They significantly increased performance to meet and exceed the stringent test requirements that were being introduced.

With the recent introduction of our third generation UV curing materials, HumiSeal continues to anticipate and address the needs of the electronics industry.

What is driving this shift in performance characteristics now?

The introduction by volume automotive manufactures of electric powered vehicles and associated charging stations. Continued miniaturisation of PCB assemblies with introduction into ever more harsh environments, has resulted in a new generation of materials.

HumiSeal’s UVA 300 LED cured conformal coating is uniquely designed to be cured through simple, single wavelength LED UV light. The use of LED curing allows for simpler and more consistent curing, much lower energy consumption, reduced equipment maintenance costs, and no hazardous ozone or UVC exposure. UVA 300 provides superior protection and value for medium and high-volume PCB manufacturing applications. UVA 300 allows for short cycle times and maximum production speeds as it cures in seconds upon exposure to appropriate UV light. Its unique, dual cure chemistry eliminates the need for solvents and thinners, while the secondary moisture cure provides assurance of cure in hard to reach or shadow areas. UVA 300 can be sprayed using traditional automated spray equipment and fluoresces under UV light to allow for easy inspection.

Properties of UVA 300 include:

• LED curing mechanism with secondary moisture cure

• Superior flexibility, excellent thermal and mechanical shock resistance

• 100% solids, no solvents or thinners required, minimal environmental impact.

• ROHS 2011/65/EC compliant

• Superb adhesion to a wide range of commonly used solder resists

• Excellent insulation resistance and moisture insulation resistance

• Resistant to a wide range of solvents

UV40 LED coating is a one-part, high solids, dual-cure acrylate polyurethane conformal coating possessing LED cure capability. HumiSeal® UV40 LED has been developed with the following characteristics:

• Tack free cure with LED UV light at 385nm or 395nm as well as microwave light

• Application possible at elevated temperatures to give increased process stability

• Secondary cure mechanism that will fully cure any unexposed areas of the coating within 7 days at ambient conditions

• Fluoresce under UV light to allow coating inspection

• Excellent chemical and moisture resistance.

The material is also compliant with IPC-CC-830 testing, RoHS Directive 2015/863/EU and China standard GB30981-2020.

This solvent free, UV curable elastomeric acrylate conformal coating displays higher flexibility compared to other UV curable conformal coatings. It was designed to withstand at least 1000 cycles of thermal shock in areas of high thickness between adjacent components. The SIR characteristics are stable for over 1000 hours. The material can be cured by LED or using an Arc or Microwave systems.

The product was specifically developed to have excellent flexibility with high moisture and electrical insulation properties. It also demonstrates high chemical resistance and is compliant with RoHS Directive EU 2015/863, China RoHS 2 and China Standard GB30981-2020.

To comply with the increasing environmental and technology trends, manufacturers must utilise new techniques and technologies. HumiSeal’s range of UV curing conformal coatings are easy to process, solvent-free and touch-dry in a matter of seconds. Full cure, in areas not exposed to UV radiation, will be achieved by reaction with moisture.

If you are considering the switch to a non-VOC conformal coating solution, align yourself with a supplier that not only understands the intricacies of chemical development but also understands perfectly how they align to electronic manufacturers’ needs.

It’s that time of year again: The SMTconnect will be opening its doors in the Nuremberg exhibition halls from May 9 – 11. The anticipation is already high as trade fairs visitors will once again have the opportunity to enjoy a varied expert program. In addition, there will be the opportunity to network intensively with experts and thus further advance technologies.

In a unique atmosphere, visitors can experience innovations and products up close along the entire value chain as well as gain valuable insights into the industry.

True to the motto: “Driving Manufacturing forward”, the SMTconnect 2023 offers, in addition to various opportunities for technical discussions and information exchange, special highlight topics at the trade fair. These include for example, sustainability, obsolescence management as well as AI in electronics manufacturing. The exhibitors at this year’s SMTconnect are already looking forward to interesting customer discussions and to presenting their solutions. On board are ASYS, Ersa, Essemtec, FUJI, JUKI, Panasonic, SMT Wertheim and Viscom, among many others.

A fixed component at the SMTconnect this year as well: the diverse and expert forum program with panel discussions, product presentations and company presentations. Special insights into top topics will be offered, among others:

• Tuesday 9 May 2023: The neglected KPI –potential for competitive advantage in electronics manufacturing (Juki Automation Systems GmbH).

• Wednesday 10 May 2023: AI in electronics manufacturing (Siemens AG) under the moderation of Dr Sandra Engle (VDMA)

This year, the “Future Packaging” production line of the Fraunhofer Institute for Reliability and Microintegration (IZM) is once again a proven and exclusive hotspot at the SMTconnect. It maps the entire assembly process with subsequent test procedures. The focus in 2023 will be on “Trust the Line” - Competitiveness through Trust, Sustainable Tool and Supply Chain. Visitors can take part in live

guided tours with commentary every day at 10 a,m., 1 p.m. or 3 p.m. In 45 minutes, technical know-how as well as insights into innovations and trends will be provided.

The EMS Park special display area also deals with the topic of supply chains. Here, visitors will meet partners from the Electronic Manufacturing Services sector. With impulse and best practice presentations, this special showcase demonstrates the advantages of close cooperation between EMS service providers and OEMs for both sides and creates space for personal exchange. Participating EMS companies include Assel, Elhurt and Coronex. Hot topics at the EMS Speakers Corner include Luminovo GmbH’s “Electronics made easy - What OEMs and EMS can learn from each other” by Sebastian Schaal and Elhurt EMS’s “The power of trust and dedicationElhurt EMS way of navigating through components shortage reality”.

In addition to the EMS Park, the special show area “PCB meets Components” presents exhibitors around the topic of PCBs, components and materials, e.g. Würth Elektronik, The German Electronics Design & Manufacture Association and Piciesse Elettronica Srl. Visitors have the opportunity to find tailor-made solutions as well as products for their questions and, thanks to the thematic concentration on the action area, the right contact persons in a short time.

This year, the hand soldering competition at the SMTconnect will once again bridge the gap between theory and practice. Organized by the IPC - Association Connecting Electronics Industries, soldering professionals and young professionals will put their expertise to the test. They will compete against each other in the hand soldering of complex printed circuit boards and will be judged primarily on speed and precision. Further information can be found at: ww.smtconnect.com.

We spoke to Jeanette Meyer (Above), Deputy Vice President at Mesago Messe Frankfurt GmbH

Why is it important for people to visit in-person industry events again now that the world has moved on from virtual events during the pandemic?

The feeling of meeting experts in a certain field and discussing current issues and challenges face-to-face over a cup of coffee or snack has never been so in demand as now. In the field of technology it is also essential to experience electronics production live. This year the Fraunhofer Institute for Reliability and Microintegration IZM, will once again be presenting their “Future packaging” production line – a real highlight that shouldn’t be missed!

What can people expect from the event and are there any new features for the SMTconnect 2023?

Our well-known and trusted highlights will be shown but adapted to deal with the challenges faced by the industry at present. As mentioned, the “Future Packaging“ Production Line focusing on the subject of

“Trust the line “ - Competitiveness through trust & Sustainable Tool & Supply Chain” by the Fraunhofer Institute for Reliability and Microintegration IZM will be demonstrated; the trade fair forum will showcase current topics such as KI in electronics manufacturing, sustainability, re-shoring and skills shortage.

We also have an interesting program at the EMS Speaker’s Corner with topics such as Luminovo GmbH’s “Electronics made easy - What OEMs and EMS can learn from each other” by Sebastian Schaal and Elhurt EMS’s “The power of trust and dedication - Elhurt EMS way of navigating through components shortage reality”.

A range of key players will also be presenting their latest technologies such as ASYS, Ersa, Essemtec, FUJI, JUKI, Panasonic, SMT Wertheim and Viscom.

With the rapid changes and challenges in the field of electronics manufacturing, it is essential for experts to come together this year and discuss the way forward.

Once again, the team is looking forward to talking with the community and there are many opportunities to do so. This year we would like to welcome people to our stand for a chat over coffee. We are, as ever, interested in hearing about the latest challenges faced – this is also a great place to network!

As well as attending the event, are there any other ways in which people can get involved in the SMTConnect?

Nick Walters from Robotas at IPC Expo 2023

Mike Gunderson from PBT Works at IPC Expo 2023

Anthony Ambrose from Data I:O at IPC Expo 2023

Chintan Sutaria from CalcuQuote

Andy Naisbitt from Gen3 Systems at IPC Expo 2023

Jonny Nichols from Hanwha

Bob Bouchard from BTU at IPC Expo 2023

Phil Kinner from Electrolube

Danny Lumbreras from Scienscope at IPC Expo 2023

Jason Norman from EVS International at IPC Expo 2023

Jayne Carthy from Absolute EMS at IPC Expo 2023

Mark Waterman from ECD

Steve Lowder from Mechnano at IPC Expo 2023

Chris Nash from Indium at IPC Expo 2023

Gadi Meik & Luisa Herrmann from Arch Systems

Gustavo Sepulveda from Panasonic

Nick Walters from Robotas at IPC Expo 2023

Mike Gunderson from PBT Works at IPC Expo 2023

Anthony Ambrose from Data I:O at IPC Expo 2023

Chintan Sutaria from CalcuQuote

Andy Naisbitt from Gen3 Systems at IPC Expo 2023

Jonny Nichols from Hanwha

Bob Bouchard from BTU at IPC Expo 2023

Phil Kinner from Electrolube

Danny Lumbreras from Scienscope at IPC Expo 2023

Jason Norman from EVS International at IPC Expo 2023

Jayne Carthy from Absolute EMS at IPC Expo 2023

Mark Waterman from ECD

Steve Lowder from Mechnano at IPC Expo 2023

Chris Nash from Indium at IPC Expo 2023

Gadi Meik & Luisa Herrmann from Arch Systems

Gustavo Sepulveda from Panasonic

Ciara McCarthy from EPS Global

David Bennett from Bentec

Ian Nichols from Spectrum SMT

Frank Hart from PVA

Torsten Vegelahn from ASYS

Jason Wahba from The JW Corporation

Ivan Romo from SmartSol

Alun Morgan from EIPC

Francois Erceau from Europlacer

Miles Moreau from KIC

Steven Wongsonvanee from Pemtron

Michael Ford from Aegis

Ciara McCarthy from EPS Global

David Bennett from Bentec

Ian Nichols from Spectrum SMT

Frank Hart from PVA

Torsten Vegelahn from ASYS

Jason Wahba from The JW Corporation

Ivan Romo from SmartSol

Alun Morgan from EIPC

Francois Erceau from Europlacer

Miles Moreau from KIC

Steven Wongsonvanee from Pemtron

Michael Ford from Aegis

Don Dennison from PIT Equipment

Jesper Lykke from Viscom

Michael W. Hinshaw Jr from Green Circuits

David Pickavance from KiwkTic

Harald Eppinger & Joel Scutchfield from Koh Young

Joe Garcia from Evolve

Steve Mango from Keysight

Darren Fill from Impossible Objects

Charlie Zhu from CyberOptics

Mike Slowik and Ryan Banfield from X2F

Don Dennison from PIT Equipment

Jesper Lykke from Viscom

Michael W. Hinshaw Jr from Green Circuits

David Pickavance from KiwkTic

Harald Eppinger & Joel Scutchfield from Koh Young

Joe Garcia from Evolve

Steve Mango from Keysight

Darren Fill from Impossible Objects

Charlie Zhu from CyberOptics

Mike Slowik and Ryan Banfield from X2F

MESA (Manufacturing Enterprise Solutions Association) International is a global nonprofit providing education, networking and best practice sharing around Smart Manufacturing and Industry 4.0. MESA’s community includes manufacturers, producers, industry leaders and solution providers who are focused on driving business results from manufacturing technology.

We spoke to Steven Hewitt, chairman of MESA UK, to find out more about MESA and its new event on energy and sustainability taking place later this year in Coventry, UK….

The Manufacturing Enterprise Solutions Association (MESA) is a not-for-profit association of manufacturers, technologists and academics whose aim is to share best practice around industrial digital transformation.

We are effectively the world’s only ‘Crowdsourced’ Impartial Advice Centre for smart manufacturing. We are probably unique in the industrial digital

transformation space in that there is no commercial undercurrent to what we do.

MESA UK is holding the Energy and Sustainability event to help British Industry to better understand how we can help reduce energy and waste.

Clearly this is in the forefront of everybody’s mind at the moment, because of the severe hike in energy prices, with no real prospect of this reducing in the medium term. However, it’s not just about energy. Its also about the bigger picture around overall sustainability. If industry doesn’t embrace sustainable business models this will eventually strangle us with essential resource scarcity or a planetary environment that disrupts economic operations (and the standard of living for our children and their children’s children).

However, people in charge of industrial operations are in a strong position to help alleviate the environmental burden that manufacturing places on

the world. People who understand how to achieve higher operational efficiencies through industrial digital transformation, can have a disproportionately beneficial effect on both their own company and our world in general.

We want to ensure that manufacturers, technologists and academics share best practice and help to bring this about.

The conference will be held at the Fanuc robotics factory in Coventry and will include a factory tour afterwards. It will be held on the 20th September 2023 and will run from 09:00 to 16:30.

This event is suitable for management and engineering and IT, from C-Level to production and engineering management, who are involved or affected by energy and sustainability concerns, and need to take actions that contribute to the continued success of operations.

Attendees will learn specific techniques and methods to discover energy saving opportunities, such as controlling of sleep states that may be possible within machines, detailing the conversations to be had with equipment vendors and solution providers.

The event will also explore the larger topic of sustainability, from both a business and environmental perspective, with specific take-aways aimed at helping businesses, using the MESA model and associated tools.

If you want to come along, please register using the link on the MESA website. Existing MESA Members can attend free of charge. As a not-for-profit there is small fee to non members to cover lunch, refreshments etc.

If you have important insights that you want to share with the group – ie conduct a presentation or lead a discussion session etc. then please contact Steve Hewitt Chairman MESA UK shewitt@ra.rockwell. com +447720807055

MESA continues to be the industry’s number one source of ‘crowd sourced’ impartial advice around Smart Manufacturing Digital Transformation and Industry 4.0. The ‘not for profit’ Manufacturing Enterprise Solutions Association (MESA) has a unique environment where impartiality means that there is no sales pitch, only the sharing of ideas and advice from Smart Manufacturing thought leaders from all major industries.

M.O.L.E.™ EV6 Delivers Factory Floor Handheld Thermal Profiling Control, Pairs Perfectly with OvenSENTINEL™ Reflow Monitoring.

April 25, 2023 – Following a highly-successful Americas launch earlier this year, ECD today announced that its revolutionary M.O.L.E.™ EV6 thermal profiler will be shown live in Europe for the first time during the upcoming SMTconnect 2023 event in Nuremberg, Germany. As the market’s only traveling thermal profiler with full color touchscreen control, M.O.L.E. EV6 frees personnel from the PC, as profile data can be viewed directly on the device. This time-saving solution complements ECD’s award-winning OvenSENTINEL™ reflow monitoring system, which will also be demonstrated at SMTconnect from booth #4-317.

As electronics manufacturers look to improve productivity and automate process insight, OvenSENTINEL has seen a doubling of installations year-on-year. When paired, M.O.L.E. EV6 and OvenSENTINEL deliver an unparalleled solution to setting, maintaining, and verifying reflow process parameters for advanced PCB assemblies.

Mike Hayward, ECD EMEA Director of Operations, notes that all ECD’s process control tools –especially M.O.L.E. EV6 and OvenSENTINEL –embody the theme of this year’s SMTconnect event: ‘Driving manufacturing forward’. “M.O.L.E. EV6 marks the most significant development in thermal profiler technology in ten years,” he explains. “Touchscreen control is long overdue in the profiling arena, and we are proud to be the first to bring it to market.

Now, users can view and interact with process calculation templates, view profiles, and see pass/fail analysis in the palm of their hand. This simplifies the profiling process, raises productivity, reduces errors, and allows on-the-fly decision-making. Likewise, OvenSENTINEL offers dynamic and customizable real-time monitoring of the reflow process, taking the burden off operators while delivering deep data-supported product traceability – all in an open communications protocol.”

Both M.O.L.E. EV6 and OvenSENTINEL will be displayed in booth #4-317 throughout the three-day SMTconnect exhibition, May 9 – 11. To learn more, visit www.ecd.com or email mike.hayward@ecd.com.

• Instrument status display with live temperature readings

• USB-C communications and charging

• Wireless capability via Bluetooth

• Compatible with multiple thermocouple types

• No PC downloads required; all data displayed on-screen, on the device

• Built-in calibration reminders for maintenance simplicity

• Seamlessly integrates with all RIDER verification tools: OvenRIDER, WaveRIDER, and SelectiveRIDER for a complete, multi-process, soldering machine verification system

• Dynamic measurement capabilities with customizable data extractions and sensor types

• Open architecture, Industry 4.0-enabling

• Interface supports multiple lanes, ovens, and factories

• Profile SnapShot™ one-button, ondemand profile confirmation of oven readiness and KPI alignment

• TrueProfile™ trusted traceability technology

This digital industry publication will offer a global perspective for the whole of the electronics and off board sectors. Complimenting our existing industry hub and weekly WNIE (What’s New in Electronics) platforms, we are confident that in this ever changing world these titles will offer companies a complete marketing solution.

CLAIRE SAUNDERS

Publisher

ROB SAUNDERS

Features Editor

KIRSTY HAZLEWOOD Editor in Chief

TERRY JEFFREYS Account Manager

IAIN HAZLEWOOD Designer

CLAIRE SAUNDERS

Publisher

ROB SAUNDERS

Features Editor

KIRSTY HAZLEWOOD Editor in Chief

TERRY JEFFREYS Account Manager

IAIN HAZLEWOOD Designer

Offering a magazine that’s targeted at the entire industry will add huge benefits for advertisers too. To maximise budgets, companies need to appeal to both designers and purchasers, without the additional cost of having to advertise across multiple publications. The pandemic has forced companies to drastically reduce their marketing spend, thus reducing their reach, but featuring in Global Industry Focus means there is no need to compromise, inclusion in Global Industry Focus allows enhanced visibility and access to the whole electronics industry, including multiple sectors and multiple job functions, all in one magazine at one cost.

Global Industry Focus will feature guest editors, regular updates, plus key content and opinion pieces from industry sector specialists.

We have packages to suit your requirements, either bespoke or ready-made and with an opportunity to advertise across both the Global Industry Focus (GIF) and the What’s New In Electronics (WNIE) industry hub and newsletter.

Global Industry Focus (GIF) is 100% digital, why did we choose a digital publication instead of print?

Digital issues offer:

• Larger circulations

• Reduced advertising costs over printed issues

• Direct delivery to readers in-boxes

Traceability offering peace of mind to advertisers

Digital offers more innovative ways for companies to market themselves such as embedded videos. Digital delivery of information is now the preferred choice for reading the industries latest news.

“After years of seeing so many magazines target either a specific industry sector or job function, we believe it is high time for something different - a magazine that targets the whole industry.”

claire@globalindustryfocus.com