2 minute read

Essentials of Pumping Technology

from BPMA Training Guide

by Michael Lane

INTENDED AUDIENCE

This course, is aimed at those who have a strong basic knowledge of Pumps, their differences and uses and with a good understanding of standard pumping systems. candidates who will find this challenging world-class course most beneficial will have a good engineering background and are likely to be involved with some aspects of managing including specifying, selling sourcing, installing, servicing and maintaining pump equipment.

Advertisement

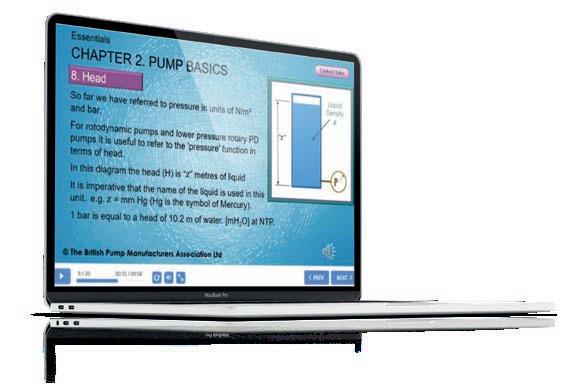

COURSE DESCRIPTION

Following the format of the Introduction to e-Learning course divided into chapters each with a short test at the end for students to monitor their progress and understanding. At the completion of the course is a final test, this is a selection of randomised questions that will give a final score and determines if the student has achieved a pass, credit or distinction which be shown on their certificate issued from the BPMA.

COURSE PROGRAMME

A pass rate of 60% must be obtained to gain NOCN certification.

Study in your own time and at your own pace. Working in this way you can gain a recognised qualification. f Pump Basics f Maths Refresher f Physics Refresher f Liquid Flow includes

Cavitation f Inlet Features f Outlet Features f Rotodynamic Pumps f Rotary PD Pumps f Reciprocating PD Pumps f Drives & Seals f Energy f Legal Issues f Pump Systems f Metals f Pump Selection f Statuary Requirements f Glossary & References f Useful Data

IN DETAIL ESSENTIALS OF PUMPING TECHNOLOGY

Aimed at delegates who, through experience and knowledge of the industry, feel able to undertake what we believe to be the most comprehensive pump training course available anywhere in the world.

Initially, each student will go through up to 50 pages of Maths and Physics tuition to ensure they will understand all of the information covered in this course.

The next three chapters cover all the main features you would expect to find when researching liquid flow, pump inlet and outlet conditions.

Chapters 8, 9, 10 & 11 form the bulk of the course and covers a wealth of information on Rotodynamic, PD, Rotary and Reciprocating Pumps with over 230 topics covered. As Pumps are one of the largest consumers of motive electricity, energy and energy reduction is covered extensively in the later chapters. Chapter 15 covers metallurgy, an area rarely touched upon in Pump training because of its complexity. Here you will investigate eight forms of corrosion and their effects.

Finally, the course concludes with pump selection and making sure the correct pump is used.

A final test is taken from the large pool of questions covered in the course content.